2004年,一种异于传统合金设计理念的多组元中/高熵合金被提出,并迅速引起了金属结构与功能材料研究领域的广泛关注[1~6]。与传统合金相比,中/高熵合金的突出效应主要体现在4个方面:高配置熵、严重晶格畸变、迟滞扩散与鸡尾酒效应[3,7~9]。早期发现的具有单相fcc晶体结构的中/高熵合金体系主要包括FeMnCoCrNi[2,10]、CoNiCr[11,12]和CoNiFeCr[13]。2019年,Sohn等[14]报道了力学性能更为优异的单相fcc中熵合金CoNiV。随后,Park等[15]发现具有细晶组织(平均晶粒尺寸约为657 nm)的CoNiV合金屈服强度可达1.5 GPa,同时仍具有高达26.6%的断裂延伸率。CoNiV合金具有高屈服强度主要与以下2个因素有关:(1) V元素导致强的晶格畸变[16,17];(2) 在CoNiV合金中易于形成V-(Co, Ni)化学短程有序,其与位错交互作用可提升力学性能[18]。此外,CoNiV合金还具有良好的低温力学性能[19]、抗氢脆、耐腐蚀性能[20]与超塑性[21]等。例如,在-196℃低温下CoNiV合金屈服强度可达1.2 GPa,延伸率为42.1%[19]。上述优异性能的发现使得CoNiV合金成为多组元中/高熵合金领域的研究热点。

研究者通过元素掺杂的方式将Al[22~24]和Ta[25]等元素引入到合金中,期望进一步提高CoNiV合金的综合力学性能。Jang等[22]在Al掺杂的CoNiVAl0.2合金中利用剪切带诱导纳米尺寸的半共格沉淀L21相弥散析出,使合金抗拉强度从1.1 GPa提升至1.6 GPa,并仍有26.7%的断裂延伸率。Nutor等[23]通过Al合金化获得了具有fcc与B2双相结构的Al5(CoNiV)95合金,在室温和450℃都具有1.1 GPa的屈服强度。Tian等[24]在Al掺杂的Al7(CoNiV)93合金中实现了1.3 GPa的屈服强度和22.7%的断裂延伸率。但是双相合金中不同相之间的氧化还原电位差异以及存在大量耐蚀性差的相界面,致使Al掺杂往往恶化CoNiV合金的耐腐蚀性能,从而不利于其实际应用[26]。因此,开发新的能够提升CoNiV合金综合力学性能的合金化策略具有重要的理论和实际应用价值。

B元素微合金化,因其倾向于使B以硼化物或者游离态形式存在于界面位置从而实现晶界强化效果而被广泛应用于材料设计中[27~34]。此外,固溶于基体中的B可显著增加基体的局部晶格畸变,进而提升固溶强化效果。另外,与Al掺杂不同,微量B掺杂不会改变CoNiV单相fcc结构且有助于捕获晶界H原子,因而对耐腐蚀性能无恶化作用[32,35]。目前,关于B元素合金化在CoNiV合金中的研究还未见报道。基于此,本工作系统研究了B元素微合金化对CoNiV合金微观组织和力学性能的影响。研究发现,微量B掺杂(0.2%,原子分数)能够同时提升CoNiV合金的强度(增大约10%)和塑性(增大约30%),是一种有效的改善CoNiV力学性能的合金化策略。B微合金化致使强度和塑性同时提升主要归因于B的晶界强化。

1 实验方法

采用纯度为99.9%的Co、Ni、V与高纯CoB作为原料在高纯Ar保护气氛下进行电弧熔炼,分别制备了CoNiV、(CoNiV)99.9B0.1和(CoNiV)99.8B0.2 (原子分数,%) 3种合金。在900℃下,将合金铸锭保温10 min后进行多道次热轧,总压下量为50%,然后立即水冷。将热轧态合金样品在1200℃的Ar保护气氛中进行2 h均匀化处理,然后立即水冷。随后,将固溶态合金进行总压下量为70%的多道次冷轧,再将冷轧态合金在900℃下进行盐浴退火,保温3 min后进行水冷淬火处理(完全再结晶态)。利用电火花线切割方法加工狗骨头状拉伸试样,其平行段长度为13 mm、宽度为3 mm、厚度为1 mm。利用AG-XPLUS100KN万能力学试验机进行拉伸力学性能测试,拉伸方向沿着轧制方向,应变速率为1 × 10-3 s-1。为了使结果可重复,所有拉伸实验至少重复3次。

采用Smartlab X射线衍射仪(XRD)对样品进行晶体结构检测,X射线源为CuKα1 (波长λ = 0.154056 nm),扫描角度2θ为20°~100°,扫描速率为4°/min。利用配备了symmetry电子背散射衍射(EBSD)探头的FIB-Crossbeam 550扫描电镜(SEM)进行合金退火态样品的微观组织表征。采用电解抛光工艺制备EBSD样品,抛光液为10%HClO4和90%C2H5OH (体积分数)的混合溶液,抛光参数为电压20 V,时间15 s,温度-20℃。采用JEM-2100F透射电镜(TEM)对合金的变形态样品微观组织进行表征。TEM样品通过电解双喷减薄制备,电解双喷液为10%HClO4和90%C2H5OH (体积分数)的混合溶液,电解双喷参数为电压25 V,温度-25℃。采用Triboindenter原位纳米力学测试系统对样品侧轧面(RD-ND平面,其中,RD和ND分别代表轧向和轧面法线方向)进行了纳米显微硬度测试,测试载荷为2.5 mN,每隔3 μm进行一次压痕实验,每个测试区域选取5个不同位置的硬度并取其平均值。利用EBSD技术对纳米压痕实验区域进行晶体学取向分析,针对晶内、大角度晶界(最小取向差角> 10°)和Σ3孪晶界区域分别进行硬度统计分析。

2 实验结果与讨论

2.1 静态拉伸力学性能

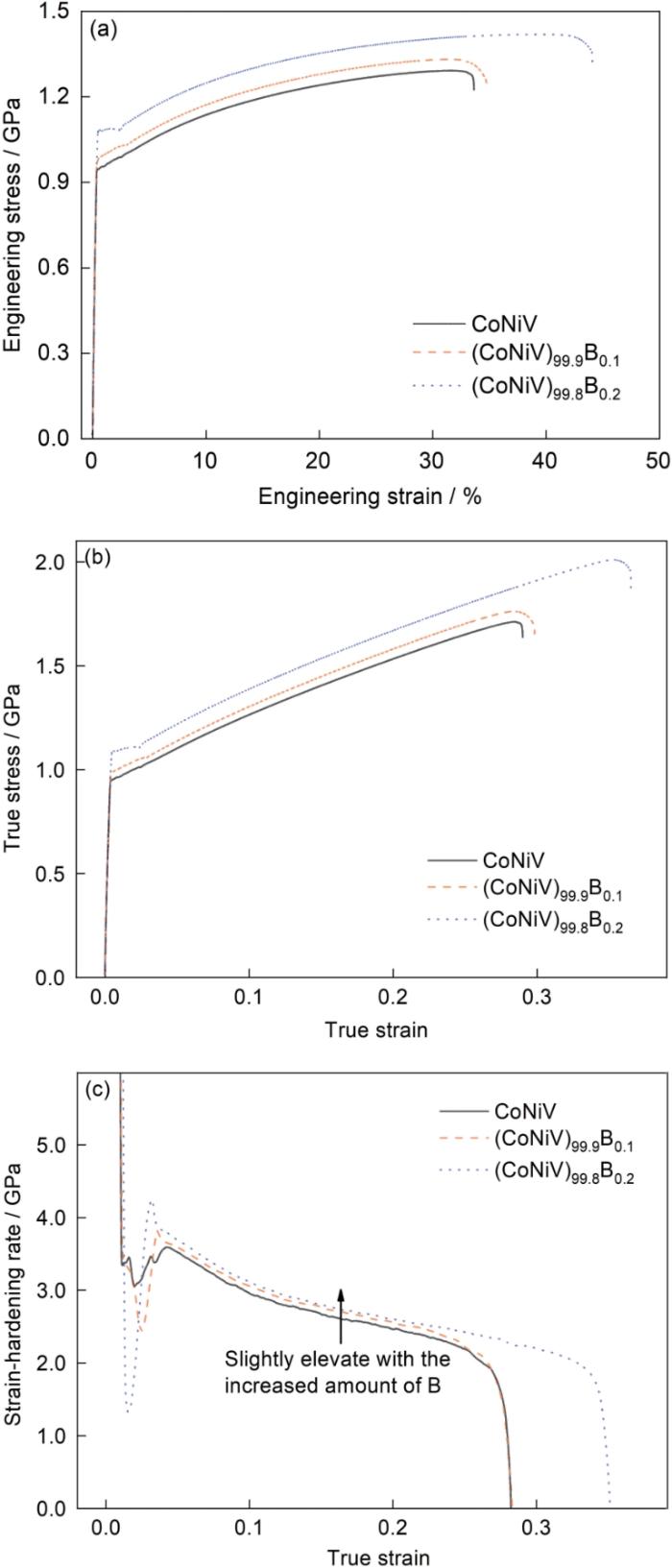

图1a为CoNiV、(CoNiV)99.9B0.1和(CoNiV)99.8B0.2合金的室温静态拉伸工程应力-应变曲线。CoNiV、(CoNiV)99.9B0.1和(CoNiV)99.8B0.2合金的屈服强度、极限抗拉强度与断裂延伸率见表1。可见,随着掺杂B含量的增加,(CoNiV)100 - x B x 合金的屈服强度、极限抗拉强度和断裂延伸率均呈现出单调递增的趋势。CoNiV合金的屈服强度、极限抗拉强度和断裂延伸率分别为968.7 MPa、1291.7 MPa和33.6%。添加0.2%B (原子分数)后,(CoNiV)99.8B0.2合金的屈服强度、极限抗拉强度和断裂延伸率分别提升至1087.4 MPa、1419.3 MPa和44.1%;相比于未掺杂B的CoNiV合金,屈服强度、极限抗拉强度和断裂伸长率分别增加了118.7 MPa、127.6 MPa和10.5%,其提升幅度分别达12%、10%和30%。上述结果表明,掺杂微量的B元素可以同时显著提升CoNiV合金的强度和塑性。另外,由图1a可知,随着B含量的增加,工程应力-工程应变曲线的屈服平台越来越明显。这是由于B原子掺杂促进了Cottrell气团[36]的形成,Cottrell气团对位错运动有钉扎作用从而导致了屈服平台的产生。

图1

图1

CoNiV、(CoNiV)99.9B0.1和(CoNiV)99.8B0.2合金的室温静态拉伸力学性能

Fig.1

Static tensile mechanical properties of CoNiV, (CoNiV)99.9B0.1, and (CoNiV)99.8B0.2 alloys at room temperature

(a) engineering stress-strain curves

(b) true stress-true strain curves

(c) strain-hardening rate curves

表1 CoNiV、(CoNiV)99.9B0.1和(CoNiV)99.8B0.2合金的屈服强度、抗拉强度和断裂延伸率

Table 1

| Alloy | Yield strength / MPa | Ultimate tensile strength / MPa | Fracture elongation / % |

|---|---|---|---|

| CoNiV | 968.7 | 1291.7 | 33.6 |

| (CoNiV)99.9B0.1 | 1030.1 | 1331.6 | 34.7 |

| (CoNiV)99.8B0.2 | 1087.4 | 1419.3 | 44.1 |

图1b和c分别给出了CoNiV、(CoNiV)99.9B0.1和(CoNiV)99.8B0.2合金的真应力-真应变曲线和加工硬化率曲线。可见,B掺杂并未显著改变CoNiV合金加工硬化率曲线特征。在变形初始,加工硬化率出现剧烈波动,这对应着合金发生了形变屈服。过了屈服阶段之后,加工硬化率随着应变的增加逐渐降低直至发生断裂。在整个形变过程中,未观察到加工硬化率显著增大现象,即所谓“驼峰”现象[37]。另外,随着掺杂B元素含量的提高,(CoNiV)100 - x B x 合金加工硬化率逐渐变大,表明B掺杂能够从一定程度上提升CoNiV合金的加工硬化能力。高的加工硬化率有利于延迟颈缩现象的发生[19],这与B掺杂的(CoNiV)99.8B0.2合金具有更高的抗拉强度和更大的断裂延伸率现象一致(图1a)。

2.2 微观组织

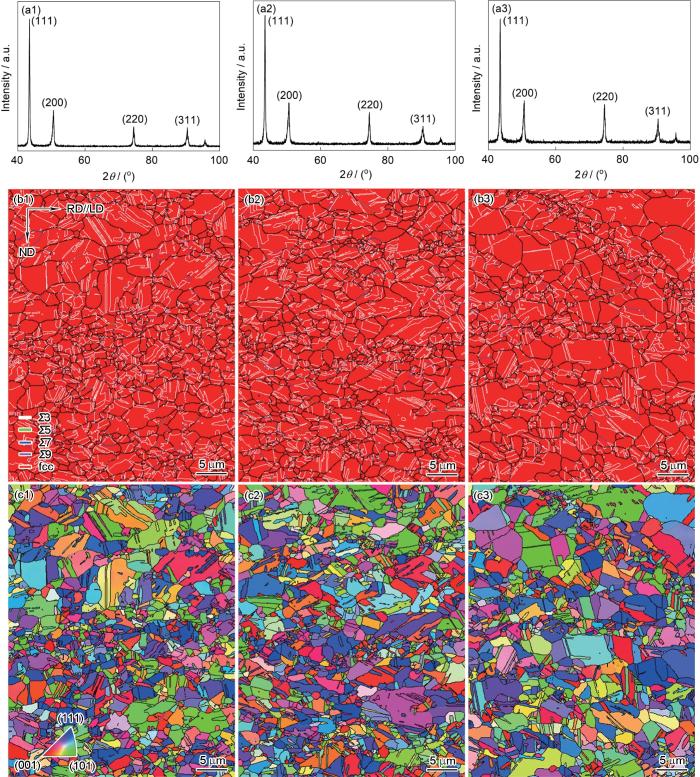

为了揭示B掺杂显著提升CoNiV合金力学性能的机制,对(CoNiV)100 - x B x 合金的晶体结构与微观组织特征进行了系统表征。图2a1~a3分别给出了CoNiV、(CoNiV)99.9B0.1和(CoNiV)99.8B0.2合金的室温XRD谱。可见,所有衍射峰均可被fcc结构完全标定且未观察到析出相衍射峰,表明(CoNiV)99.9B0.1和(CoNiV)99.8B0.2合金室温下仍旧为单相fcc结构。图2b1~ b3和图2c1~c3分别给出了CoNiV、(CoNiV)99.9B0.1和(CoNiV)99.8B0.2合金SEM/EBSD相分布与晶体学取向分布图。为了证实无bcc和hcp相的存在,除了fcc结构之外,在EBSD数据采集过程中bcc和hcp结构也被用来进行相的标定。从图2b1~b3可见,3种合金均为单相fcc结构,与XRD谱结果一致。从图2c1~c3可见,3种合金晶粒尺寸分布均匀,且无明显晶体学择优取向。

图2

图2

CoNiV、(CoNiV)99.9B0.1和(CoNiV)99.8B0.2合金的XRD谱、相分布图与晶体学取向分布图

Fig.2

XRD spectra (a1-a3), phase distribution maps (fcc phase colored in red) overlapped with Σ3 (white), Σ5 (green), Σ7 (blue), and Σ9 (purple) coincidence site lattice (CSL) boundaries (b1-b3), and orientation maps represented by inverse pole figures (IPFs) (c1-c3) for CoNiV (a1-c1), (CoNiV)99.9B0.1 (a2-c2), and (CoNiV)99.8B0.2 (a3-c3) alloys (RD—rolling direction, ND—normal direction, LD—loading direction)

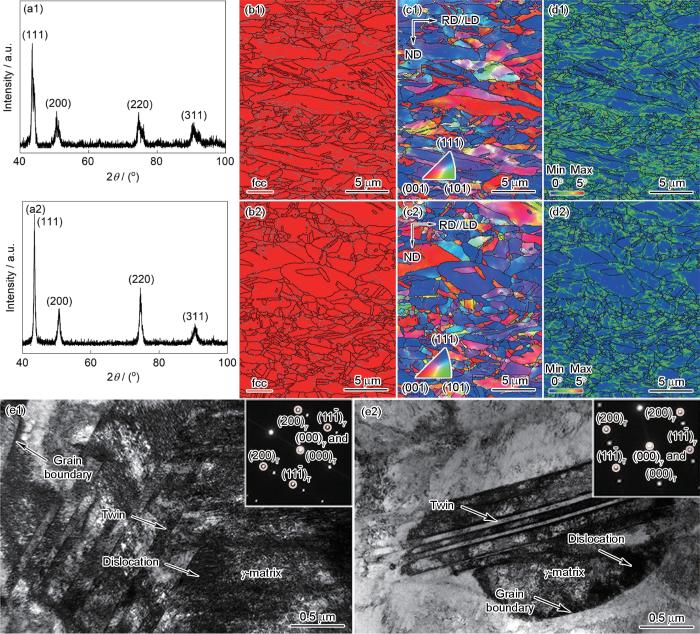

图3a为CoNiV、(CoNiV)99.9B0.1和(CoNiV)99.8B0.2合金平均晶粒尺寸(dm)随掺杂B含量的变化。为了全面反应晶粒尺寸特征,采用2种统计方法(即是否将重位点阵(CSL)视为晶界)进行dm计算,并分别探讨了其随B含量的演变规律。由图3a可知,对于2种统计方式而言,(CoNiV)100 - x B x 合金的dm随着B含量的掺杂均未发生显著变化。根据美国材料实验协会标准(即不将CSL视为晶界)[38],CoNiV、(CoNiV)99.9B0.1和(CoNiV)99.8B0.2合金的dm分别为4.11、3.53和4.55 μm。最近,Seol等[28]在B掺杂Fe20Mn20Cr20Co20Ni20B x 合金的研究中发现,当晶粒尺寸较小时(约3.5 μm),B元素掺杂对晶粒尺寸的影响很小,该研究结果与本研究的发现一致。

图3

图3

CoNiV、(CoNiV)99.9B0.1和(CoNiV)99.8B0.2合金微观组织定量特征

Fig.3

Quantitative characteristics of the CoNiV, (CoNiV)99.9B0.1, and (CoNiV)99.8B0.2 alloys

(a) relation between mean grain size (dm) and the content of doped B

(b) grain size (d) distributions

(c) length fractions of Σ3, Σ5, Σ7, and Σ9 CSL boundaries against the total length of all large angle grain boundaries

图3b为CoNiV、(CoNiV)99.9B0.1和(CoNiV)99.8B0.2合金晶粒尺寸分布。由图3b可知,不同含量B掺杂样品的晶粒尺寸分布均呈现出典型的正态分布特征,表明B掺杂并未显著改变CoNiV合金晶粒尺寸分布特征。图3c给出了CoNiV、(CoNiV)99.9B0.1和(CoNiV)99.8B0.2合金特殊CSL界面含量分布。由图3c可知,CSL特殊界面均是以Σ3型退火孪晶界为主,其含量高达约60%。其次,还包含约5%的Σ9型界面,Σ5和Σ7型界面的含量均很低。对比不同含量B掺杂合金的CSL特殊界面含量可知,B掺杂对CSL特殊界面含量也无显著影响。综合上述图2和3结果可知,B掺杂对CoNiV合金的晶体结构、晶体学取向及晶粒尺寸并未产生显著影响,因此这些因素均不是B掺杂同时提高合金强度和塑性的原因。

2.3 变形机制

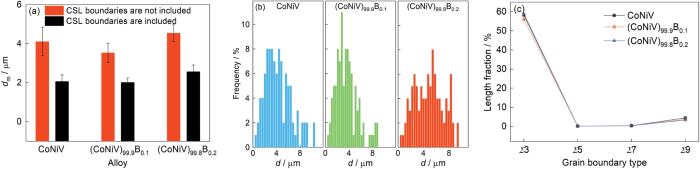

为了揭示B掺杂对CoNiV合金变形机制的影响,分别在CoNiV和(CoNiV)99.8B0.2合金拉伸试样断口附近(离断口约1.5 mm)切取合金样品,对其晶体结构与微观组织特征进行了对比研究。图4给出了CoNiV和(CoNiV)99.8B0.2合金拉伸后样品的XRD谱、SEM/EBSD相分布图、晶体学取向分布图、内核平均取向差(kernel average misorientation,KAM)分布图和TEM像。由图4a1、b1、a2、b2可知,CoNiV和(CoNiV)99.8B0.2合金形变之后仍旧为单相fcc结构,表明这2个合金在室温拉伸过程中未发生应力诱发马氏体相变,即相变诱导塑性(transformation induced plasticity,TRIP)[39~43]现象。

图4

图4

CoNiV和(CoNiV)99.8B0.2合金拉伸后样品的晶体结构与微观组织表征

Fig.4

Crystal structures and microstructure characterizations of the deformed CoNiV (a1-e1) and (CoNiV)99.8B0.2 (a2-e2) alloys

(a1, a2) XRD spectra

(b1, b2) phase distribution maps (fcc phase colored in red)

(c1, c2) orientation maps represented by IPFs

(d1, d2) kernel average misorientation (KAM) maps

(e1, e2) TEM images of the dislocation plugging at the interface (Insets show the selected area electron diffraction patterns. The subscripts γ and T denote γ matrix and twin, respectively)

另外,结合EBSD和TEM分析可知,在形变后样品中未观察到形变孪晶的出现,表明在这2个合金的拉伸过程中也不存在应力诱发机械孪生现象,因此不存在孪生诱导塑性(twinning induced plasticity,TWIP)[41,44,45]现象。上述结果与这2个样品加工硬化率曲线中不存在“驼峰”现象(图1c)一致。由图4d1、e1、d2、e2可知,形变后CoNiV和(CoNiV)99.8B0.2合金内均存在大量位错,且位错在孪晶界和晶界附近显著塞积。对比图4d1和d2可知,尽管(CoNiV)99.8B0.2合金具有较大断裂延伸率,但是其几何必需位错密度仍旧较低,并且位错在晶界处聚集的程度也低于未掺杂CoNiV合金。对比图4e1和e2可知,B掺杂并未改变CoNiV合金的变形机制,CoNiV和(CoNiV)99.8B0.2合金在静态拉伸变形条件下形变机制仍旧为位错滑移,该结果也与这2个样品加工硬化率曲线呈现相似特征相一致。

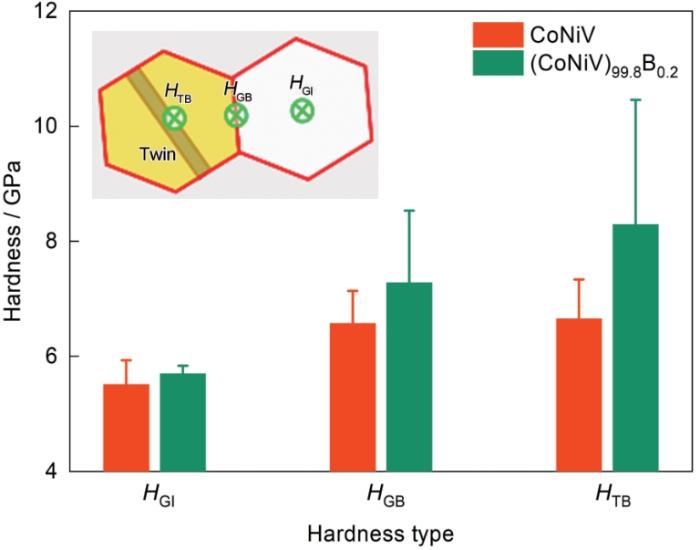

2.4 强韧化机制

众所周知,B是一种典型的晶界强化元素,由于其较小的原子尺寸以及与金属元素差异较大的电子结构特征[46],其更容易偏聚在晶界处从而增强晶界,即硼效应[27]。大量研究[28,29,31,47,48]表明,在金属材料中添加微量B往往可显著提升晶界强度,因此推测B微合金化导致的CoNiV合金强度和塑性的同时提升也可能与B导致的晶界强化有关。本工作采用纳米压痕测试方法分别对CoNiV和(CoNiV)99.8B0.2合金晶粒内部、大角度晶界(最小取向差角大于10°)和Σ3孪晶界位置区域(如图5中插图所示)的硬度进行了测试,结果如图5所示。可见,CoNiV和(CoNiV)99.8B0.2合金晶粒内部硬度(HGI)相差不大。(CoNiV)99.8B0.2合金晶界区域硬度(HGB)和孪晶界附近硬度(HTB)显著高于CoNiV样品。该结果表明,B掺杂能够显著提升晶界和孪晶界附近区域硬度,而对于晶粒内部硬度影响不大。为了进一步阐明B掺杂带来的晶内和晶界区域硬度提升的差异,对比了CoNiV和(CoNiV)99.8B0.2合金晶界区域与晶内区域硬度比值(HGB / HGI)以及孪晶界区域与晶内区域硬度比值(HTB / HGI),结果如表2所示。可见,随着B的掺杂,HGB / HGI和HTB / HGI均增加,进一步证实了B掺杂使晶界/孪晶界区域硬度增加幅度大于晶内。另外,由表2可知,在CoNiV和(CoNiV)99.8B0.2样品中HTB / HGI均大于HGB / HGI。该现象可能是由于CoNiV和(CoNiV)99.8B0.2合金中退火孪晶的尺寸往往都较小(数十至数百纳米),致使采用纳米压痕测试孪晶界硬度时(压痕宽度为数百纳米至1 μm)往往跨越2个孪晶界,而检测晶界硬度时只跨越单个晶界所致。

图5

图5

CoNiV和(CoNiV)99.8B0.2合金晶粒内部、晶界位置和孪晶界附近硬度

Fig.5

Hardnesses of grain interior (HGI), grain boundaries (HGB), and twin boundaries (HTB) (Inset shows the schematic of nanoindentation test)

表2 CoNiV和(CoNiV)99.8B0.2合金的硬度比值

Table 2

| Alloy | HGB / HGI | HTB / HGI |

|---|---|---|

| CoNiV | 1.19 | 1.21 |

| (CoNiV)99.8B0.2 | 1.28 | 1.46 |

CoNiV合金中B元素的晶界强化作用主要与下述2个因素有关[27,49,50]。(1) 晶界固溶强化。B与金属元素Co、Ni、V等的原子尺寸存在明显差异,因此B偏聚将会增强晶界区域原子排列的畸变程度,导致晶界固溶强化。TEM观察结果表明,CoNiV合金基体和退火孪晶内部变形后均存在高的位错密度(图4e1),表明未掺杂B的CoNiV合金退火孪晶界对位错运动的阻碍作用较弱,因此位错可以大量地从基体穿过孪晶界运动至孪晶内部;与之相反,B掺杂的(CoNiV)99.8B0.2合金基体内位错密度显著高于退火孪晶内部(图4e2)。该结果表明B掺杂导致的退火孪晶界强度的提升能够显著增强其对位错运动的阻碍作用。(2) 增强内聚力。B为非金属元素,与Co、Ni、V等过渡族金属元素的化学性质(电负性等)存在显著差异,因此偏聚在CoNiV合金晶界处的B不可避免地将与Co、Ni、V等过渡族金属元素形成离子或共价键[27,51],从而增强晶界区域原子内聚力。综上可知,B掺杂可通过晶界固溶强化和增强内聚力等方式提升CoNiV合金的晶界强度,从而增加位错开动的临界剪切应力进而阻碍位错运动,提升材料的力学强度。关于B合金化导致CoNiV合金塑性提升的原因可能为,B掺杂合金中位错开动的临界剪切应力较高,这使得即便在较大断裂延伸率下位错在晶界处聚集的程度低于拉断后的未掺杂合金(图4d1和d2),(CoNiV)99.8B0.2合金中较低的位错密度为位错运动提供了空间。另外,B在晶界处的偏聚引起晶界强度提升,材料的流变应力增大导致硬取向晶粒中更多的滑移系被开动[52],从而增强了材料整体发生均匀塑性变形的能力。此外,B掺杂合金较高的晶界强度可提升微裂纹在晶界处萌生以及扩展的阻力[53,54],这有助于延迟颈缩和断裂的发生。

3 结论

(1) 微量B元素掺杂可同时有效提升CoNiV合金的强度和塑性。0.2%B掺杂可导致CoNiV合金屈服强度、极限抗拉强度和断裂伸长率分别达到1087.4 MPa、1419.3 MPa和44.1%,提升幅度分别达12%、10%和30%。

(2) 微量B元素掺杂对CoNiV合金微观组织和形变机制影响较小。与CoNiV合金类似,(CoNiV)99.8B0.2合金室温下为单相fcc晶体结构,晶粒尺寸分布均匀呈正态分布;CoNiV和(CoNiV)99.8B0.2合金的平均晶粒尺寸相差不大,分别为4.11和4.55 μm;静态拉伸过程中,(CoNiV)99.8B0.2合金塑性变形机制为位错滑移,无应力诱发马氏体相变和形变孪晶现象存在。

(3) 微量B元素掺杂能够显著提升CoNiV合金晶界/孪晶界强度。晶界/孪晶界强度的提升,一方面可增加其对位错运动的阻碍作用,另一方面能够增加其阻碍裂纹扩展能力,这是B掺杂导致CoNiV强度和塑性同时提升的根源。另外,固溶到基体中的B元素对位错移动起到一定钉扎作用,这也有利于合金强度的提升。

参考文献

Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes

[J].

Microstructural development in equiatomic multicomponent alloys

[J].

Orientation-dependent mechanical responses and plastic deformation mechanisms of FeMnCoCrNi high-entropy alloy: A molecular dynamics study

[J].

Hierarchical crack buffering triples ductility in eutectic herringbone high-entropy alloys

[J].In human-made malleable materials, microdamage such as cracking usually limits material lifetime. Some biological composites, such as bone, have hierarchical microstructures that tolerate cracks but cannot withstand high elongation. We demonstrate a directionally solidified eutectic high-entropy alloy (EHEA) that successfully reconciles crack tolerance and high elongation. The solidified alloy has a hierarchically organized herringbone structure that enables bionic-inspired hierarchical crack buffering. This effect guides stable, persistent crystallographic nucleation and growth of multiple microcracks in abundant poor-deformability microstructures. Hierarchical buffering by adjacent dynamic strain-hardened features helps the cracks to avoid catastrophic growth and percolation. Our self-buffering herringbone material yields an ultrahigh uniform tensile elongation (~50%), three times that of conventional nonbuffering EHEAs, without sacrificing strength.Copyright © 2021 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

High stress twinning in a compositionally complex steel of very high stacking fault energy

[J].Deformation twinning is rarely found in bulk face-centered cubic (FCC) alloys with very high stacking fault energy (SFE) under standard loading conditions. Here, based on results from bulk quasi-static tensile experiments, we report deformation twinning in a micrometer grain-sized compositionally complex steel (CCS) with a very high SFE of ~79 mJ/m, far above the SFE regime for twinning (<~50 mJ/m) reported for FCC steels. The dual-nanoprecipitation, enabled by the compositional degrees of freedom, contributes to an ultrahigh true tensile stress up to 1.9 GPa in our CCS. The strengthening effect enhances the flow stress to reach the high critical value for the onset of mechanical twinning. The formation of nanotwins in turn enables further strain hardening and toughening mechanisms that enhance the mechanical performance. The high stress twinning effect introduces a so far untapped strengthening and toughening mechanism, for enabling the design of high SFEs alloys with improved mechanical properties.© 2022. The Author(s).

High throughput screening driven discovery of Mn5Co10Fe30Ni55O x as electrocatalyst for water oxidation and electrospinning synthesis

[J].

The effect of Co and Cr substitutions for Ni on mechanical properties and plastic deformation mechanism of FeMnCoCrNi high entropy alloys

[J].The elastic constants, ideal tensile strength (ITS), stacking fault energy (SFE), lattice constant and magnetic moment of FeMnCoCrNi high entropy alloys with varying Co and Cr contents at 0 and 300 K were systematically investigated by first-principle calculations. For the alloys with Co substitution for Ni, at both temperatures the elastic stability of the face-centered cubic (fcc) phase, bulk elastic modulus (B), Young's modulus (E), shear modulus (G) and ITS increase monotonically with increasing Co content. However, the Cauchy pressure (CP), Pugh ratio (B/G), Poisson ratio (v), Zener anisotropy ratio (AZ) and elastic anisotropy ratio (AVR) decrease monotonically. The SFE also decreases with the increase of Co, resulting in the change of plastic deformation mechanism from dislocation slip to mechanical twinning, and then to hcp-martensitic transformation. This elucidates the underlying mechanism of the effect of Co addition on the strength and micromechanical behavior of FeMnCoCrNi alloys. Compared with Co, the Cr substitution for Ni leads to the more complex change of elastic constants and ITS. The increase of Cr shows the similar effect on SFE and deformation mechanism as that of Co. The variation of valence electron concentration and magnetism affect the SFE. The increase of either Co or Cr leads to the reduced magnetic moments of Fe and Mn. This could be responsible for the monotonic decrease of both lattice constant and SFE as the Co content increases. However, for the Cr addition case, multiple factors may affect the evolution of lattice constant and SFE. These findings shed light on the deformation mechanism of the alloys with different compositions.

Joint contribution of transformation and twinning to the high strength-ductility combination of a FeMnCoCr high entropy alloy at cryogenic temperatures

[J].

A novel bulk eutectic high-entropy alloy with outstanding as-cast specific yield strengths at elevated temperatures

[J].

Molecular dynamic simulations of deformation mechanisms for FeMnCoCrNi high-entropy alloy bicrystal micropillars

[J].High-entropy alloys (HEAs) have attracted considerable research attention in the material field because of their outstanding mechanical properties. For metallic materials, grain boundary plays a crucial role in the mechanical behavior and plastic deformation mechanisms. To show the effect of grain boundary on deformation mechanisms in HEAs, the mechanical behavior and evolution of deformation systems in the equiatomic FeMnCoCrNi HEA bicrystals with various orientation combinations during uniaxial tension are investigated using molecular dynamic simulations, and the effect of the orientation relationship between the grain boundary and tensile direction on mechanical behavior is demonstrated. The findings reveal that for all models studied, dislocations nucleate preferentially at the grain boundary and slip into the grains on both sides. Grain boundaries are widened and curved during deformation. Necking tends to occur at the grain boundary when the grain boundary is perpendicular to the tensile direction, which decreases flow stress with increasing loading. For the model with a grain boundary parallel to the deformation direction, the model's flow stress remains at a level above 1 GPa during the whole plastic deformation. The bicrystal with a combination of [111] and [110] orientations shows the most significant fluctuation of flow stress and the highest work hardening ability compared with other models. The decrease in stress with deformation is due to the slip of numerous dislocations, while the high strain hardening ability is caused by the formation of ε-martensite, stacking faults, and twins. Furthermore, the deformation behavior of FeMnCoCrNi, FeCuCoCrNi HEAs, and pure Cu are compared. Compared with Cu, the larger lattice distortion in FeMnCoCrNi and FeCuCoCrNi HEAs makes the grain boundaries coarser, which makes dislocations easy to nucleate under loading, and the formation of ε-martensite is the most outstanding in FeMnCoCrNi HEA with a lower stacking fault energy. The results of this study can guide the design of microstructures and orientations in high-performance HEAs with micron- and nanoscaled grains.

FeMnCoCrNi高熵合金双晶微柱变形机制的分子动力学模拟

[J].为了揭示高熵合金中晶界对塑性变形机制的影响,利用分子动力学模拟方法研究了具有不同初始取向组合的等主元FeMnCoCrNi高熵合金双晶在单轴拉伸变形中的力学性能与变形系统演化,并揭示了晶界与拉伸方向的位向关系对高熵合金力学行为的影响。结果表明,对研究的所有双晶模型而言,位错优先在晶界处形核并向两侧的晶粒内滑移。在变形过程中,晶界发生了不同程度的宽化和弯曲。当晶界与拉伸方向垂直时,颈缩易于在晶界处发生,这导致双晶的流变应力随外加载荷增大而降低。而当晶界平行于拉伸方向时,在整个塑性变形过程中模型保持1 GPa以上的流变应力。相对于其他双晶而言,[111]与[110]取向组合的双晶流变应力波动幅度最大,同时呈现出最强的加工硬化能力。其中应力的下降归因于大量的位错发生了滑移,而高的硬化能力则是由较多的ε-马氏体、层错以及孪晶形成所致。此外,还对比了FeMnCoCrNi、FeCuCoCrNi和纯Cu 3种材料的变形行为。与Cu相比,FeMnCoCrNi和FeCuCoCrNi高熵合金中的晶格畸变使晶界更加粗糙,这使得外加载荷作用下位错易于形核,且层错能较低的FeMnCoCrNi中形成的ε-马氏体最多。

Heterogeneous precipitation behavior and stacking-fault-mediated deformation in a CoCrNi-based medium-entropy alloy

[J].

Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures

[J].High-entropy alloys are an intriguing new class of metallic materials that derive their properties from being multi-element systems that can crystallize as a single phase, despite containing high concentrations of five or more elements with different crystal structures. Here we examine an equiatomic medium-entropy alloy containing only three elements, CrCoNi, as a single-phase face-centred cubic solid solution, which displays strength-toughness properties that exceed those of all high-entropy alloys and most multi-phase alloys. At room temperature, the alloy shows tensile strengths of almost 1 GPa, failure strains of similar to 70% and K-JIc fracture-toughness values above 200 MPa m(1/2); at cryogenic temperatures strength, ductility and toughness of the CrCoNi alloy improve to strength levels above 1.3 GPa, failure strains up to 90% and K-JIc values of 275 MPa m(1/2). Such properties appear to result from continuous steady strain hardening, which acts to suppress plastic instability, resulting from pronounced dislocation activity and deformation-induced nano-twinning.

A precipitation-hardened high-entropy alloy with outstanding tensile properties

[J].

Ultrastrong medium-entropy single-phase alloys designed via severe lattice distortion

[J].

Ultra-strong and strain-hardenable ultrafine-grained medium-entropy alloy via enhanced grain-boundary strengthening

[J].

Vanadium is an optimal element for strengthening in both fcc and bcc high-entropy alloys

[J].

Alloy design strategies and future trends in high-entropy alloys

[J].

Direct observation of chemical short-range order in a medium-entropy alloy

[J].

Effects of cryogenic temperature on tensile and impact properties in a medium-entropy VCoNi alloy

[J].Multi-principal element alloys usually exhibit outstanding strength and toughness at cryogenic temperatures, especially in CrMnFeCoNi and CrCoNi alloys. These remarkable cryogenic properties are attributed to the occurrence of deformation twins, and it is envisaged that a reduced stacking fault energy (SFE) transforms the deformation mechanisms into advantageous properties at cryogenic temperatures. A recently reported high-strength VCoNi alloy is expected to exhibit further notable cryogenic properties. However, no attempt has been made to investigate the cryogenic properties in detail as well as the underlying deformation mechanisms. Here, the effects of cryogenic temperature on the tensile and impact properties are investigated, and the underlying mechanisms determining those properties are revealed in terms of the temperature dependence of the yield strength and deformation mechanism. Both the strength and ductility were enhanced at 77 K compared to 298 K, while the Charpy impact toughness gradually decreased with temperature. The planar dislocation glides remained unchanged at 77 K in contrast to the CrMnFeCoNi and CrCoNi alloys resulting in a relatively constant and slightly increasing SFE as the temperature decreased, which is confirmed via ab initio simulations. However, the deformation localization near the grain boundaries at 298 K changed into a homogeneous distribution throughout the whole grains at 77 K, leading to a highly sustained strain hardening rate. The reduced impact toughness is directly related to the decreased plastic zone size, which is due to the reduced dislocation width and significant temperature dependence of the yield strength.

A strong and ductile medium-entropy alloy resists hydrogen embrittlement and corrosion

[J].Strong and ductile materials that have high resistance to corrosion and hydrogen embrittlement are rare and yet essential for realizing safety-critical energy infrastructures, hydrogen-based industries, and transportation solutions. Here we report how we reconcile these constraints in the form of a strong and ductile CoNiV medium-entropy alloy with face-centered cubic structure. It shows high resistance to hydrogen embrittlement at ambient temperature at a strain rate of 10 s, due to its low hydrogen diffusivity and the deformation twinning that impedes crack propagation. Moreover, a dense oxide film formed on the alloy's surface reduces the hydrogen uptake rate, and provides high corrosion resistance in dilute sulfuric acid with a corrosion current density below 7 μA cm. The combination of load carrying capacity and resistance to harsh environmental conditions may qualify this multi-component alloy as a potential candidate material for sustainable and safe infrastructures and devices.

High-rate superplasticity in an equiatomic medium-entropy VCoNi alloy enabled through dynamic recrystallization of a duplex microstructure of ordered phases

[J].

Shear band-driven precipitate dispersion for ultrastrong ductile medium-entropy alloys

[J].Precipitation strengthening has been the basis of physical metallurgy since more than 100 years owing to its excellent strengthening effects. This approach generally employs coherent and nano-sized precipitates, as incoherent precipitates energetically become coarse due to their incompatibility with matrix and provide a negligible strengthening effect or even cause brittleness. Here we propose a shear band-driven dispersion of nano-sized and semicoherent precipitates, which show significant strengthening effects. We add aluminum to a model CoNiV medium-entropy alloy with a face-centered cubic structure to form the L2 Heusler phase with an ordered body-centered cubic structure, as predicted by ab initio calculations. Micro-shear bands act as heterogeneous nucleation sites and generate finely dispersed intragranular precipitates with a semicoherent interface, which leads to a remarkable strength-ductility balance. This work suggests that the structurally dissimilar precipitates, which are generally avoided in conventional alloys, can be a useful design concept in developing high-strength ductile structural materials.© 2021. The Author(s).

A dual-phase alloy with ultrahigh strength-ductility synergy over a wide temperature range

[J].

Effects of Al alloying on microstructure and mechanical properties of VCoNi medium entropy alloy

[J].

Effect of Ta content on stacking fault energy and microstructure characteristics of (VCoNi)100 - X Ta X (X = 0, 0.05, 0.5 and 1) medium entropy alloy

[J].

Effect of Al addition on the corrosion behavior of the VCoNi medium-entropy alloys

[J].

On the effect of boron on grain boundary character in a new polycrystalline superalloy

[J].

Boron doped ultrastrong and ductile high-entropy alloys

[J].

Short-range order strengthening in boron-doped high-entropy alloys for cryogenic applications

[J].Boron doping with an adequate concentration is highly desirable for alloy development because it profoundly improves the material's interface cohesion via interfacial segregation. However, scientific and applicable potentials of soluble boron that resides at the alloy internal grains are generally overlooked. Here we report a strategy for overcoming the typically low strengths of face-centered cubic high-entropy alloys (HEAs) through exploiting soluble boron instead of the interfacial boron. We find that soluble boron increases stress strain field at the recrystallized HEA grain structure, leading to the generation of short-range order (SRO) in those deformation structure under load at 77 K. The highly increased degree of SRO at planar dislocation slip band that forms during straining, proved by electron microscopy and synchrotron X-ray diffraction, strengthens a typical non-equimolar Fe40Mn40Co10Cr10 (at%) HEA, particularly increasing yield strengths by similar to 32%, to similar to 1.1 GPa compared to those of boron-free reference materials with similar grain sizes. The advent of deformation-induced SRO domains causes severe lattice distortion (specifically, contraction), leading to the increased cryogenic yield strength of similar to 210 MPa, but generating micro-voids at grain boundaries. This study on deformation-induced SRO via boron advances the fundamental understanding of SRO impacts on HEA grains and mechanical properties at cryogenic temperatures, which may pave a general pathway for developing a wide range of ultrastrong alloys for cryogenic applications. (C) 2020 Acta Materialia Inc. Published by Elsevier Ltd.

Effects of boron on microstructure and properties of microwave sintered FeCoNi1.5CuY0.2 high-entropy alloy

[J].

Effect of boron addition on the microstructure and mechanical properties of refractory Al0.1CrNbVMo high-entropy alloy

[J].

Ultrahigh cyclability of a large elastocaloric effect in multiferroic phase-transforming materials

[J].Multiferroic phase-transforming alloys demonstrate intriguing multicaloric effects, but they are intrinsically brittle and their elastocaloric effect shows poor cyclability, which remains a major challenge for exploiting more efficient multicaloric refrigeration. Here, by employing a novel strategy of strengthening grain boundary, the cyclability of elastocaloric effect in the prototype Ni-Mn-based multiferroic phase-transforming alloys is strikingly enhanced by two orders of magnitude. Ultrahigh cyclability of a large elastocaloric effect is achieved. This not only paves the way for exploiting multicaloric effects for more efficient cooling, but also provides a strategy for overcoming the cyclability issues in the ubiquitous brittle intermetallic phase-transforming materials. [GRAPHICS]IMPACT STATEMENT The cyclability of elastocaloric effect in the prototype Ni-Mn-based multiferroic phase-transforming alloys has been strikingly enhanced by two orders of magnitude through employing the strategy of strengthening grain boundary.

Impact of B alloying on ductility and phase transition in the Ni-Mn-based magnetic shape memory alloys: Insights from first-principles calculation

[J].

A multielement alloying strategy to improve elastocaloric and mechanical properties in Ni-Mn-based alloys via copper and boron

[J].

Studies on the effect of B and B + Ce additions on the electrochemical corrosion behaviour of 9Cr-1Mo using electrochemical noise (EN) technique

[J].

Non-crystallographic shear banding in crystal plasticity FEM simulations: Example of texture evolution in α-brass

[J].

Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off

[J].

A TRIP-assisted dual-phase high-entropy alloy: Grain size and phase fraction effects on deformation behavior

[J].

Hierarchical microstructure design to tune the mechanical behavior of an interstitial TRIP-TWIP high-entropy alloy

[J].

Microstructure and mechanical properties of a FeMnCoCr high-entropy alloy with heterogeneous structure

[J].Growing attention has been placed on high-entropy alloys (HEAs) owing to their promising mechanical properties. Particularly, HEAs in which the main crystal structure is fcc are attracting significant attention. Although such alloys exhibit a good combination of strength and ductility, they cannot meet the increasing demands of applications because of limited yield strengths. In recent years, researchers have tried to improve yield strengths of HEAs by refining grains and introducing interstitial atoms. However, the processing cost is high and is often accompanied by the significant loss of ductility. In this study, we propose a simple processing route incorporating cold rolling at medium thickness reductions and short-time annealing at medium temperatures to obtain a heterogeneous structure in Fe-Mn based HEAs consisting of deformed grains with an average diameter of several tens of microns and recrystallized ultrafine grains. By simultaneously introducing multiple strengthening mechanisms, including the strengthening contributed by the microstructural characteristics of dense dislocations, grain refinement, precipitates, ε-martensite, α-martensite, and recovery twins, as well as the strengthening induced by deformation twinning and ε-martensite phase transition that occurs continuously during deformation, the yield strength of the alloy significantly increases compared with that of the fully recrystallized material and reaches 825 MPa. Simultaneously, due to the activation of significant deformation twinning and deformation-induced martensitic transformation, the uniform elongation of the alloy is about 28.6%. The proposed material fabrication method is simple, cost-effective, and can effectively improve the mechanical properties of Fe-Mn based HEAs, providing new insight into optimizing the mechanical properties of low stacking fault energy alloys of the fcc structure.

非均匀组织FeMnCoCr高熵合金的微观结构和力学性能

[J].提出了一种简单的高熵合金加工工艺,即对Fe-Mn系高熵合金采用中等形变量冷轧和中温短时退火相结合的方法,获得了由晶粒尺寸为数十微米的形变晶粒和超细尺度再结晶晶粒组成的非均匀结构。通过向合金中同时引入由高密度位错、晶粒细化、析出相、ε-马氏体、α-马氏体和回复孪晶等微观结构特征及变形过程中持续发生的形变孪生、ε-马氏体相变引起的多种强化机制,使屈服强度较充分再结晶态显著提升并达到825 MPa。同时,在塑性变形过程中由于发生了显著的形变孪生和一定的由形变诱发的奥氏体向ε-马氏体转变,合金仍具有约28.6%的均匀延伸率,合金的综合力学性能得到有效提升。该工艺为优化以fcc结构为主的低层错能合金的力学性能提供了新思路。

Microstructure evolution and deformation behavior of high manganese TRIP/TWIP symbiotic effect steels under high-speed deformation

[J].

高锰TRIP/TWIP效应共生钢高速变形过程中的组织演变及变形行为

[J].对18Mn-3Al-3Si和21Mn-3Al-3Si高锰TRIP/TWIP效应共生钢动态变形过程中的变形行为, 应变硬化速率、真应力和应变硬化指数随真应变的变化, 以及应变硬化和基体软化间的相互作用等进行了研究, 采用OM, SEM, TEM和XRD等方法对变形前后的组织进行了分析. 结果表明, 高应变速率下, TRIP/TWIP效应共生钢应变诱发相变途径为γ→ε→α; 高速变形对滑移的抑制、奥氏体向马氏体的相变和形变孪晶对奥氏体晶粒的细化是应变硬化的主要因素; 造成基体软化的原因是绝热温升效应、ε→γ的逆相变和孪晶的动态再结晶.

Design of a twinning-induced plasticity high entropy alloy

[J].

Effects of water quenching process on the microstructure and mechanical properties of TWIP steel

[J].

水淬工艺对TWIP钢显微组织和力学性能的影响

[J].研究了一种用于汽车车体的高强、高塑性中C-高Mn系孪晶诱发塑性(TWIP)钢, 有助于达到汽车减排、节能和安全的目的. 通过单向拉伸实验和OM观察, 分析研究了水淬工艺对TWIP钢的力学性能和微观组织的影响规律, 采用SEM和TEM对不同变形程度TWIP钢的精 细结构进行了分析. 结果表明, 随着水淬温度的提高, 退火孪晶体积分数和晶粒尺寸增大, 塑性、加工硬化性提高, 而试件的强度和屈强比降低, 可以获得抗拉强度960 MPa, 延伸率60.5%, 具有优异的综合力学性能(强塑积最高达6.096×10<sup>4</sup> MPa?%)的试件; 具有大量退火孪晶的奥氏体在变形过程中产生大量的形变孪晶, 提高了TWIP钢的强度和塑性.

Effect of dopants on grain boundary decohesion of Ni: A first-principles study

[J].

Transverse creep of nickel-base superalloy bicrystals

[J].

Investigation of creep deformation mechanisms at intermediate temperatures in René 88 DT

[J].

Grain boundary segregation engineering in metallic alloys: A pathway to the design of interfaces

[J].

First principles determination of the effects of phosphorus and boron on iron grain boundary cohesion

[J].Toward an electronic level understanding of intergranular embrittlement and its control in steels, the effects of phosphorus and boron impurities on the energy and electronic properties of both an iron grain boundary and its corresponding intergranular fracture surface are investigated by the local density full potential augmented plane wave method. When structural relaxations are taken into account, the calculated energy difference of phosphorus in the two environments is consistent with its measured embrittlement potency. In contrast to the nonhybridized interaction of iron and phosphorus, iron-boron hybridization permits covalent bonding normal to the boundary contributing to cohesion enhancement. Insights into bonding behavior offer the potential for new directions in alloy composition for improvement of grain boundary-sensitive properties.

The role of chemical bonding in grain boundary embrittlement

[J].

Segregation-driven exceptional twin-boundary strengthening in lean Mg-Zn-Ca alloys

[J].

A statistical investigation of the effects of grain boundary properties on transgranular fracture

[J].