The key characteristics of the permanent magnet thruster for underwater vehicle

1

2020

... 磁力传动联轴器由内磁体、外磁体和隔离套组成,通过磁力耦合推拉效应将动密封转化为静密封,实现零泄漏[1~3].由于磁力驱动的设计原理,始终避免不了涡流损耗问题.研究[2]表明,采用高电阻率材料可降低隔离套上的涡流损耗.隔离套在服役过程中需要承受外界载荷,同时要求具有较高的电阻率来提高传动效率,因此,结构功能一体化是金属隔离套材料追求的目标.相比于钢、铝、铜等金属材料,α + β两相钛合金的比强度高、耐腐蚀性能好、电阻率较高[4,5],近年来已经被用来制备磁力驱动装置中的隔离套部件,其力学性能和导电性能(与电阻率相关)的优化匹配是材料设计优化的关键.α + β两相钛合金具有优良的综合性能,其力学性能受到微观组织和织构的强烈影响,显微组织和织构又取决于合金成分以及热处理工艺参数[6~8],所以有必要深入分析热处理调控α + β两相钛合金板材力学性能和导电性能的内在机理. ...

水下机器人永磁推进器关键特性

1

2020

... 磁力传动联轴器由内磁体、外磁体和隔离套组成,通过磁力耦合推拉效应将动密封转化为静密封,实现零泄漏[1~3].由于磁力驱动的设计原理,始终避免不了涡流损耗问题.研究[2]表明,采用高电阻率材料可降低隔离套上的涡流损耗.隔离套在服役过程中需要承受外界载荷,同时要求具有较高的电阻率来提高传动效率,因此,结构功能一体化是金属隔离套材料追求的目标.相比于钢、铝、铜等金属材料,α + β两相钛合金的比强度高、耐腐蚀性能好、电阻率较高[4,5],近年来已经被用来制备磁力驱动装置中的隔离套部件,其力学性能和导电性能(与电阻率相关)的优化匹配是材料设计优化的关键.α + β两相钛合金具有优良的综合性能,其力学性能受到微观组织和织构的强烈影响,显微组织和织构又取决于合金成分以及热处理工艺参数[6~8],所以有必要深入分析热处理调控α + β两相钛合金板材力学性能和导电性能的内在机理. ...

Calculation of eddy losses power of magnetic transmission isolation sleeve

1

2018

... 磁力传动联轴器由内磁体、外磁体和隔离套组成,通过磁力耦合推拉效应将动密封转化为静密封,实现零泄漏[1~3].由于磁力驱动的设计原理,始终避免不了涡流损耗问题.研究[2]表明,采用高电阻率材料可降低隔离套上的涡流损耗.隔离套在服役过程中需要承受外界载荷,同时要求具有较高的电阻率来提高传动效率,因此,结构功能一体化是金属隔离套材料追求的目标.相比于钢、铝、铜等金属材料,α + β两相钛合金的比强度高、耐腐蚀性能好、电阻率较高[4,5],近年来已经被用来制备磁力驱动装置中的隔离套部件,其力学性能和导电性能(与电阻率相关)的优化匹配是材料设计优化的关键.α + β两相钛合金具有优良的综合性能,其力学性能受到微观组织和织构的强烈影响,显微组织和织构又取决于合金成分以及热处理工艺参数[6~8],所以有必要深入分析热处理调控α + β两相钛合金板材力学性能和导电性能的内在机理. ...

磁力传动隔离套涡流损失功率计算

1

2018

... 磁力传动联轴器由内磁体、外磁体和隔离套组成,通过磁力耦合推拉效应将动密封转化为静密封,实现零泄漏[1~3].由于磁力驱动的设计原理,始终避免不了涡流损耗问题.研究[2]表明,采用高电阻率材料可降低隔离套上的涡流损耗.隔离套在服役过程中需要承受外界载荷,同时要求具有较高的电阻率来提高传动效率,因此,结构功能一体化是金属隔离套材料追求的目标.相比于钢、铝、铜等金属材料,α + β两相钛合金的比强度高、耐腐蚀性能好、电阻率较高[4,5],近年来已经被用来制备磁力驱动装置中的隔离套部件,其力学性能和导电性能(与电阻率相关)的优化匹配是材料设计优化的关键.α + β两相钛合金具有优良的综合性能,其力学性能受到微观组织和织构的强烈影响,显微组织和织构又取决于合金成分以及热处理工艺参数[6~8],所以有必要深入分析热处理调控α + β两相钛合金板材力学性能和导电性能的内在机理. ...

Eddy current loss of containment shell of high-speed magnetic driving pump

1

2012

... 磁力传动联轴器由内磁体、外磁体和隔离套组成,通过磁力耦合推拉效应将动密封转化为静密封,实现零泄漏[1~3].由于磁力驱动的设计原理,始终避免不了涡流损耗问题.研究[2]表明,采用高电阻率材料可降低隔离套上的涡流损耗.隔离套在服役过程中需要承受外界载荷,同时要求具有较高的电阻率来提高传动效率,因此,结构功能一体化是金属隔离套材料追求的目标.相比于钢、铝、铜等金属材料,α + β两相钛合金的比强度高、耐腐蚀性能好、电阻率较高[4,5],近年来已经被用来制备磁力驱动装置中的隔离套部件,其力学性能和导电性能(与电阻率相关)的优化匹配是材料设计优化的关键.α + β两相钛合金具有优良的综合性能,其力学性能受到微观组织和织构的强烈影响,显微组织和织构又取决于合金成分以及热处理工艺参数[6~8],所以有必要深入分析热处理调控α + β两相钛合金板材力学性能和导电性能的内在机理. ...

高速磁力泵隔离套的磁涡流损失

1

2012

... 磁力传动联轴器由内磁体、外磁体和隔离套组成,通过磁力耦合推拉效应将动密封转化为静密封,实现零泄漏[1~3].由于磁力驱动的设计原理,始终避免不了涡流损耗问题.研究[2]表明,采用高电阻率材料可降低隔离套上的涡流损耗.隔离套在服役过程中需要承受外界载荷,同时要求具有较高的电阻率来提高传动效率,因此,结构功能一体化是金属隔离套材料追求的目标.相比于钢、铝、铜等金属材料,α + β两相钛合金的比强度高、耐腐蚀性能好、电阻率较高[4,5],近年来已经被用来制备磁力驱动装置中的隔离套部件,其力学性能和导电性能(与电阻率相关)的优化匹配是材料设计优化的关键.α + β两相钛合金具有优良的综合性能,其力学性能受到微观组织和织构的强烈影响,显微组织和织构又取决于合金成分以及热处理工艺参数[6~8],所以有必要深入分析热处理调控α + β两相钛合金板材力学性能和导电性能的内在机理. ...

A review on heat treatment efficiency in metastable β titanium alloys: The role of treatment process and parameters

1

2020

... 磁力传动联轴器由内磁体、外磁体和隔离套组成,通过磁力耦合推拉效应将动密封转化为静密封,实现零泄漏[1~3].由于磁力驱动的设计原理,始终避免不了涡流损耗问题.研究[2]表明,采用高电阻率材料可降低隔离套上的涡流损耗.隔离套在服役过程中需要承受外界载荷,同时要求具有较高的电阻率来提高传动效率,因此,结构功能一体化是金属隔离套材料追求的目标.相比于钢、铝、铜等金属材料,α + β两相钛合金的比强度高、耐腐蚀性能好、电阻率较高[4,5],近年来已经被用来制备磁力驱动装置中的隔离套部件,其力学性能和导电性能(与电阻率相关)的优化匹配是材料设计优化的关键.α + β两相钛合金具有优良的综合性能,其力学性能受到微观组织和织构的强烈影响,显微组织和织构又取决于合金成分以及热处理工艺参数[6~8],所以有必要深入分析热处理调控α + β两相钛合金板材力学性能和导电性能的内在机理. ...

Toughening high strength titanium alloys through fine tuning phase composition and refining microstructure

1

2021

... 磁力传动联轴器由内磁体、外磁体和隔离套组成,通过磁力耦合推拉效应将动密封转化为静密封,实现零泄漏[1~3].由于磁力驱动的设计原理,始终避免不了涡流损耗问题.研究[2]表明,采用高电阻率材料可降低隔离套上的涡流损耗.隔离套在服役过程中需要承受外界载荷,同时要求具有较高的电阻率来提高传动效率,因此,结构功能一体化是金属隔离套材料追求的目标.相比于钢、铝、铜等金属材料,α + β两相钛合金的比强度高、耐腐蚀性能好、电阻率较高[4,5],近年来已经被用来制备磁力驱动装置中的隔离套部件,其力学性能和导电性能(与电阻率相关)的优化匹配是材料设计优化的关键.α + β两相钛合金具有优良的综合性能,其力学性能受到微观组织和织构的强烈影响,显微组织和织构又取决于合金成分以及热处理工艺参数[6~8],所以有必要深入分析热处理调控α + β两相钛合金板材力学性能和导电性能的内在机理. ...

高强韧钛合金组成相成分和形态的精细调控

1

2021

... 磁力传动联轴器由内磁体、外磁体和隔离套组成,通过磁力耦合推拉效应将动密封转化为静密封,实现零泄漏[1~3].由于磁力驱动的设计原理,始终避免不了涡流损耗问题.研究[2]表明,采用高电阻率材料可降低隔离套上的涡流损耗.隔离套在服役过程中需要承受外界载荷,同时要求具有较高的电阻率来提高传动效率,因此,结构功能一体化是金属隔离套材料追求的目标.相比于钢、铝、铜等金属材料,α + β两相钛合金的比强度高、耐腐蚀性能好、电阻率较高[4,5],近年来已经被用来制备磁力驱动装置中的隔离套部件,其力学性能和导电性能(与电阻率相关)的优化匹配是材料设计优化的关键.α + β两相钛合金具有优良的综合性能,其力学性能受到微观组织和织构的强烈影响,显微组织和织构又取决于合金成分以及热处理工艺参数[6~8],所以有必要深入分析热处理调控α + β两相钛合金板材力学性能和导电性能的内在机理. ...

Effects of heat treatment on microstructure, texture and tensile properties of Ti65 alloy

2

2019

... 磁力传动联轴器由内磁体、外磁体和隔离套组成,通过磁力耦合推拉效应将动密封转化为静密封,实现零泄漏[1~3].由于磁力驱动的设计原理,始终避免不了涡流损耗问题.研究[2]表明,采用高电阻率材料可降低隔离套上的涡流损耗.隔离套在服役过程中需要承受外界载荷,同时要求具有较高的电阻率来提高传动效率,因此,结构功能一体化是金属隔离套材料追求的目标.相比于钢、铝、铜等金属材料,α + β两相钛合金的比强度高、耐腐蚀性能好、电阻率较高[4,5],近年来已经被用来制备磁力驱动装置中的隔离套部件,其力学性能和导电性能(与电阻率相关)的优化匹配是材料设计优化的关键.α + β两相钛合金具有优良的综合性能,其力学性能受到微观组织和织构的强烈影响,显微组织和织构又取决于合金成分以及热处理工艺参数[6~8],所以有必要深入分析热处理调控α + β两相钛合金板材力学性能和导电性能的内在机理. ...

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

热处理对Ti65钛合金板材的显微组织、织构及拉伸性能的影响

2

2019

... 磁力传动联轴器由内磁体、外磁体和隔离套组成,通过磁力耦合推拉效应将动密封转化为静密封,实现零泄漏[1~3].由于磁力驱动的设计原理,始终避免不了涡流损耗问题.研究[2]表明,采用高电阻率材料可降低隔离套上的涡流损耗.隔离套在服役过程中需要承受外界载荷,同时要求具有较高的电阻率来提高传动效率,因此,结构功能一体化是金属隔离套材料追求的目标.相比于钢、铝、铜等金属材料,α + β两相钛合金的比强度高、耐腐蚀性能好、电阻率较高[4,5],近年来已经被用来制备磁力驱动装置中的隔离套部件,其力学性能和导电性能(与电阻率相关)的优化匹配是材料设计优化的关键.α + β两相钛合金具有优良的综合性能,其力学性能受到微观组织和织构的强烈影响,显微组织和织构又取决于合金成分以及热处理工艺参数[6~8],所以有必要深入分析热处理调控α + β两相钛合金板材力学性能和导电性能的内在机理. ...

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

Effect of heat treatment on microstructure and mechanical properties of a new β high strength titanium alloy

0

2014

Effect of solution treatment and aging on microstructure, tensile properties and creep behavior of a hot-rolled β high strength titanium alloy with a composition of Ti-3.5Al-5Mo-6V-3Cr-2Sn-0.5Fe-0.1B-0.1C

1

2021

... 磁力传动联轴器由内磁体、外磁体和隔离套组成,通过磁力耦合推拉效应将动密封转化为静密封,实现零泄漏[1~3].由于磁力驱动的设计原理,始终避免不了涡流损耗问题.研究[2]表明,采用高电阻率材料可降低隔离套上的涡流损耗.隔离套在服役过程中需要承受外界载荷,同时要求具有较高的电阻率来提高传动效率,因此,结构功能一体化是金属隔离套材料追求的目标.相比于钢、铝、铜等金属材料,α + β两相钛合金的比强度高、耐腐蚀性能好、电阻率较高[4,5],近年来已经被用来制备磁力驱动装置中的隔离套部件,其力学性能和导电性能(与电阻率相关)的优化匹配是材料设计优化的关键.α + β两相钛合金具有优良的综合性能,其力学性能受到微观组织和织构的强烈影响,显微组织和织构又取决于合金成分以及热处理工艺参数[6~8],所以有必要深入分析热处理调控α + β两相钛合金板材力学性能和导电性能的内在机理. ...

Effect of annealing temperature and cooling rate on microstructure and properties of TC4 titanium alloy

2

2016

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

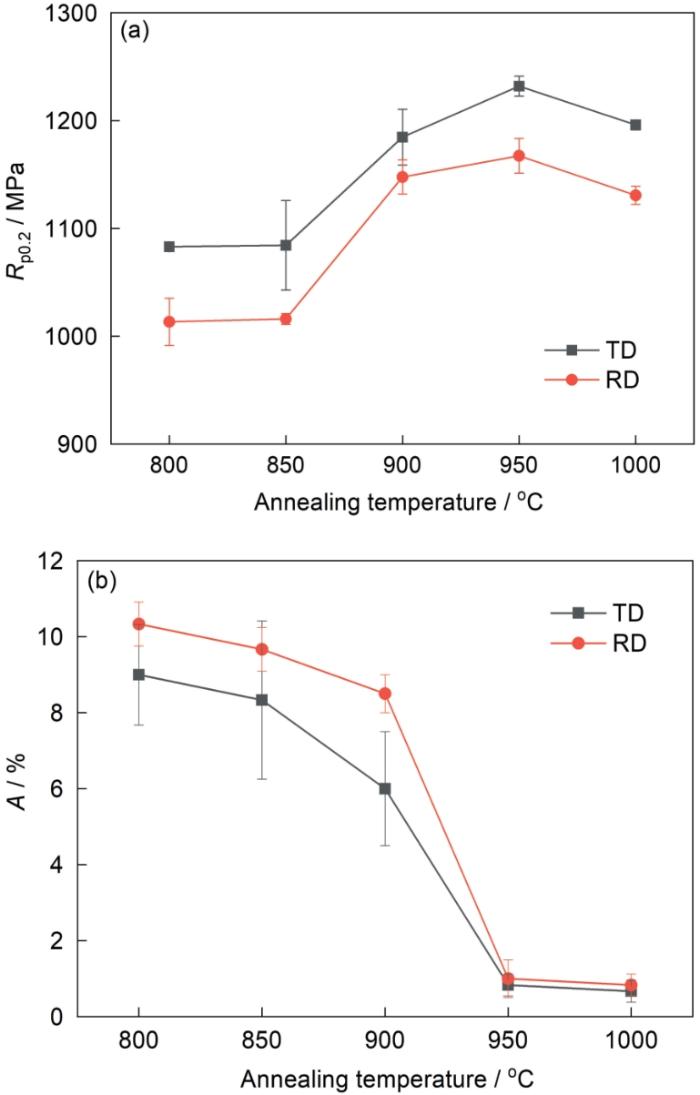

... 图10给出了退火处理前后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材的室温拉伸性能.由图可知,在两相区退火,随退火温度升高,板材的屈服强度呈上升趋势,延伸率呈下降趋势;而在单相区退火后,板材的屈服强度较900℃退火先升高后降低,延伸率则急剧下降.值得注意的是,800℃退火处理后板材的屈服强度和延伸率与原始轧制板材的屈服强度和延伸率(RD:屈服强度Rp0.2 = 995 MPa,延伸率A = 8%;TD:Rp0.2 = 1088 MPa,A = 10%)基本一致,900℃退火后,板材屈服强度的上升趋势更加明显.此外,在950℃退火时,板材的屈服强度最高,但其延伸率下降到1.0%.结合图10的分析结果和图4中板材显微组织随退火温度的变化,退火温度对板材拉伸性能的影响主要分为3个阶段.第1阶段是在800℃退火,板材组织由拉长的α相、等轴α相和β相组成,同时仍可观察到大量的条带状组织.这说明在800℃退火时合金组织内部仅发生回复,部分应变能释放,与未经退火处理的板材组织特征类似,因此其屈服强度和延伸率与退火前相比变化不大.第2阶段是在850~900℃区间内退火,αs相从部分析出到完全析出,αp相的体积分数从36%下降到12%,板材的屈服强度升高,延伸率降低,退火温度主要通过改变αs相的析出行为和αp相的体积分数来影响板材的拉伸性能.850℃退火后析出的αs相可以起到强化基体的作用,并且这种强化作用随退火温度的升高而加强.一方面,由于细小αs相的强度高于等轴αp相,随着αs相含量的增加,板材的屈服强度也升高[10,46];另一方面,αs相的析出增加了组织中α/β相界面.拉伸变形过程中,相界对位错的阻碍作用使得界面强化效应显著,界面增多提高了板材的屈服强度[9].这2方面的综合作用使得细小αs相的析出强化效应显著,导致板材强度升高.板材延伸率的降低主要与αp相的体积分数有关.板材试样进行拉伸变形时,塑性变形首先在少数αp晶粒中以滑移形式进行,当晶粒内的变形进行到一定程度后,最先开始变形的晶粒及其相邻晶粒发生转动,使得自身滑移系处于不利取向,而相邻晶粒处于有利取向,变形转移到相邻晶粒后逐渐占据越来越多的αp晶粒,降低了晶界处的位错塞积,从而不会在个别晶粒中引起应力集中而开裂[11].此外,αp相还可以限制原始β晶粒的长大,有利于改善钛合金板材的塑性.因此,随退火温度升高,αp相的体积分数下降,降低了合金组织的协调变形能力,板材的延伸率降低.第3阶段是在950~1000℃区间内退火后,提高了板材的屈服强度,但是却牺牲了板材的延伸率.950℃退火后获得了全片层组织,α/β相界面增多,αs相的体积分数也增加,这使得950℃退火处理后板材屈服强度最高.但是,将退火温度升高到1000℃后,αs相开始长大粗化,α/β相界面减少,导致板材强度降低.此外,板材单相区退火后,等轴αp相消失,形成了全片层组织,由于集束取向一致以及连续αGB相的存在,裂纹容易沿集束截面及晶界发生长距离扩展,导致板材延伸率大幅下降. ...

退火温度和冷却速率对TC4钛合金组织和性能的影响

2

2016

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

... 图10给出了退火处理前后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材的室温拉伸性能.由图可知,在两相区退火,随退火温度升高,板材的屈服强度呈上升趋势,延伸率呈下降趋势;而在单相区退火后,板材的屈服强度较900℃退火先升高后降低,延伸率则急剧下降.值得注意的是,800℃退火处理后板材的屈服强度和延伸率与原始轧制板材的屈服强度和延伸率(RD:屈服强度Rp0.2 = 995 MPa,延伸率A = 8%;TD:Rp0.2 = 1088 MPa,A = 10%)基本一致,900℃退火后,板材屈服强度的上升趋势更加明显.此外,在950℃退火时,板材的屈服强度最高,但其延伸率下降到1.0%.结合图10的分析结果和图4中板材显微组织随退火温度的变化,退火温度对板材拉伸性能的影响主要分为3个阶段.第1阶段是在800℃退火,板材组织由拉长的α相、等轴α相和β相组成,同时仍可观察到大量的条带状组织.这说明在800℃退火时合金组织内部仅发生回复,部分应变能释放,与未经退火处理的板材组织特征类似,因此其屈服强度和延伸率与退火前相比变化不大.第2阶段是在850~900℃区间内退火,αs相从部分析出到完全析出,αp相的体积分数从36%下降到12%,板材的屈服强度升高,延伸率降低,退火温度主要通过改变αs相的析出行为和αp相的体积分数来影响板材的拉伸性能.850℃退火后析出的αs相可以起到强化基体的作用,并且这种强化作用随退火温度的升高而加强.一方面,由于细小αs相的强度高于等轴αp相,随着αs相含量的增加,板材的屈服强度也升高[10,46];另一方面,αs相的析出增加了组织中α/β相界面.拉伸变形过程中,相界对位错的阻碍作用使得界面强化效应显著,界面增多提高了板材的屈服强度[9].这2方面的综合作用使得细小αs相的析出强化效应显著,导致板材强度升高.板材延伸率的降低主要与αp相的体积分数有关.板材试样进行拉伸变形时,塑性变形首先在少数αp晶粒中以滑移形式进行,当晶粒内的变形进行到一定程度后,最先开始变形的晶粒及其相邻晶粒发生转动,使得自身滑移系处于不利取向,而相邻晶粒处于有利取向,变形转移到相邻晶粒后逐渐占据越来越多的αp晶粒,降低了晶界处的位错塞积,从而不会在个别晶粒中引起应力集中而开裂[11].此外,αp相还可以限制原始β晶粒的长大,有利于改善钛合金板材的塑性.因此,随退火温度升高,αp相的体积分数下降,降低了合金组织的协调变形能力,板材的延伸率降低.第3阶段是在950~1000℃区间内退火后,提高了板材的屈服强度,但是却牺牲了板材的延伸率.950℃退火后获得了全片层组织,α/β相界面增多,αs相的体积分数也增加,这使得950℃退火处理后板材屈服强度最高.但是,将退火温度升高到1000℃后,αs相开始长大粗化,α/β相界面减少,导致板材强度降低.此外,板材单相区退火后,等轴αp相消失,形成了全片层组织,由于集束取向一致以及连续αGB相的存在,裂纹容易沿集束截面及晶界发生长距离扩展,导致板材延伸率大幅下降. ...

Influence of solution treatment on microstructure and mechanical properties of a near β titanium alloy Ti-7333

2

2015

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

... 图10给出了退火处理前后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材的室温拉伸性能.由图可知,在两相区退火,随退火温度升高,板材的屈服强度呈上升趋势,延伸率呈下降趋势;而在单相区退火后,板材的屈服强度较900℃退火先升高后降低,延伸率则急剧下降.值得注意的是,800℃退火处理后板材的屈服强度和延伸率与原始轧制板材的屈服强度和延伸率(RD:屈服强度Rp0.2 = 995 MPa,延伸率A = 8%;TD:Rp0.2 = 1088 MPa,A = 10%)基本一致,900℃退火后,板材屈服强度的上升趋势更加明显.此外,在950℃退火时,板材的屈服强度最高,但其延伸率下降到1.0%.结合图10的分析结果和图4中板材显微组织随退火温度的变化,退火温度对板材拉伸性能的影响主要分为3个阶段.第1阶段是在800℃退火,板材组织由拉长的α相、等轴α相和β相组成,同时仍可观察到大量的条带状组织.这说明在800℃退火时合金组织内部仅发生回复,部分应变能释放,与未经退火处理的板材组织特征类似,因此其屈服强度和延伸率与退火前相比变化不大.第2阶段是在850~900℃区间内退火,αs相从部分析出到完全析出,αp相的体积分数从36%下降到12%,板材的屈服强度升高,延伸率降低,退火温度主要通过改变αs相的析出行为和αp相的体积分数来影响板材的拉伸性能.850℃退火后析出的αs相可以起到强化基体的作用,并且这种强化作用随退火温度的升高而加强.一方面,由于细小αs相的强度高于等轴αp相,随着αs相含量的增加,板材的屈服强度也升高[10,46];另一方面,αs相的析出增加了组织中α/β相界面.拉伸变形过程中,相界对位错的阻碍作用使得界面强化效应显著,界面增多提高了板材的屈服强度[9].这2方面的综合作用使得细小αs相的析出强化效应显著,导致板材强度升高.板材延伸率的降低主要与αp相的体积分数有关.板材试样进行拉伸变形时,塑性变形首先在少数αp晶粒中以滑移形式进行,当晶粒内的变形进行到一定程度后,最先开始变形的晶粒及其相邻晶粒发生转动,使得自身滑移系处于不利取向,而相邻晶粒处于有利取向,变形转移到相邻晶粒后逐渐占据越来越多的αp晶粒,降低了晶界处的位错塞积,从而不会在个别晶粒中引起应力集中而开裂[11].此外,αp相还可以限制原始β晶粒的长大,有利于改善钛合金板材的塑性.因此,随退火温度升高,αp相的体积分数下降,降低了合金组织的协调变形能力,板材的延伸率降低.第3阶段是在950~1000℃区间内退火后,提高了板材的屈服强度,但是却牺牲了板材的延伸率.950℃退火后获得了全片层组织,α/β相界面增多,αs相的体积分数也增加,这使得950℃退火处理后板材屈服强度最高.但是,将退火温度升高到1000℃后,αs相开始长大粗化,α/β相界面减少,导致板材强度降低.此外,板材单相区退火后,等轴αp相消失,形成了全片层组织,由于集束取向一致以及连续αGB相的存在,裂纹容易沿集束截面及晶界发生长距离扩展,导致板材延伸率大幅下降. ...

Effect of heat treatment on microstructures and properties of Ti90 alloy

4

2021

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

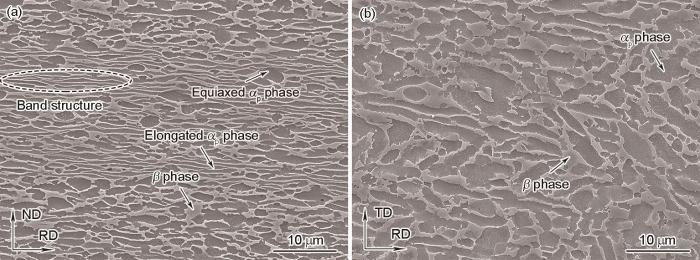

... Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材退火处理后显微组织的SEM像如图4所示.800℃退火处理后的板材组织(图4a和a1)与图2a轧制态板材组织类似,由拉长的α相、等轴α相和β相组成,仍可观察到明显的条带状组织,但组织中的α相含量减少,部分转变成β相.钛合金轧制变形后,组织中的位错密度快速增加,同时获得了足够高的应变能,这些能量可用来完成后续的回复及再结晶.由于800℃退火时,板材组织仅发生回复,部分存储应变能释放,热激活作用促进了原子扩散,位错密度降低,但不发生大角晶界的迁移,所以晶粒形状与轧制态组织类似,仍有许多畸变晶粒被保留下来[11].经850~920℃退火处理后,板材组织中的αp相均匀分布,αs相从β基体中析出后不断长大,最后与β基体相互交错排列,形成了β转变组织(βt相) (图4b~d1).随着退火温度的升高,原子扩散加剧,应变能进一步释放,在畸变度大的区域以多边化形成的亚晶为基础产生新的无畸变晶粒的核心,然后通过消耗周围的变形基体而长大,原来的畸变晶粒逐渐转变成无畸变的等轴新晶粒,条带状组织逐渐消失[32].而经950~1000℃退火后,板材组织中的αp相消失,β晶粒快速长大粗化,在随后冷却的过程中,αs相从β晶粒内部析出,相同取向的αs相平行排列成α集束,在β晶界处还有晶界α相(αGB相)析出(图4e~f1),最终形成由αs相和β相组成的全片层组织[22]. ...

... 值得注意的是,800℃退火组织中并没有析出αs相,850℃退火后部分β相开始析出αs相,进一步升高退火温度,αs相析出更加充分.由此可见,退火温度会影响αs相的析出行为.αs相的析出主要与β相的稳定性及冷却速率有关[33,34].由于α相转变为β相是一种扩散型相变,相变过程中存在合金元素再分配效应.黄森森等[35]发现,提高固溶温度,发生α→β转变,TC4合金中的β稳定元素沿化学势降低的方向扩散,V元素由αp相中心及相邻β相向αp相边缘扩散,β相中的V含量降低,β稳定性降低,导致TC4合金固溶空冷后析出αs相.因此,升高退火温度,合金元素再分配使得β相中的β稳定元素含量降低,β稳定性随之降低,有利于αs相的析出.另一方面,退火温度越高,在相同冷却速率条件下,需要的冷却时间也越长,也有利于αs相的析出[11]. ...

... 图10给出了退火处理前后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材的室温拉伸性能.由图可知,在两相区退火,随退火温度升高,板材的屈服强度呈上升趋势,延伸率呈下降趋势;而在单相区退火后,板材的屈服强度较900℃退火先升高后降低,延伸率则急剧下降.值得注意的是,800℃退火处理后板材的屈服强度和延伸率与原始轧制板材的屈服强度和延伸率(RD:屈服强度Rp0.2 = 995 MPa,延伸率A = 8%;TD:Rp0.2 = 1088 MPa,A = 10%)基本一致,900℃退火后,板材屈服强度的上升趋势更加明显.此外,在950℃退火时,板材的屈服强度最高,但其延伸率下降到1.0%.结合图10的分析结果和图4中板材显微组织随退火温度的变化,退火温度对板材拉伸性能的影响主要分为3个阶段.第1阶段是在800℃退火,板材组织由拉长的α相、等轴α相和β相组成,同时仍可观察到大量的条带状组织.这说明在800℃退火时合金组织内部仅发生回复,部分应变能释放,与未经退火处理的板材组织特征类似,因此其屈服强度和延伸率与退火前相比变化不大.第2阶段是在850~900℃区间内退火,αs相从部分析出到完全析出,αp相的体积分数从36%下降到12%,板材的屈服强度升高,延伸率降低,退火温度主要通过改变αs相的析出行为和αp相的体积分数来影响板材的拉伸性能.850℃退火后析出的αs相可以起到强化基体的作用,并且这种强化作用随退火温度的升高而加强.一方面,由于细小αs相的强度高于等轴αp相,随着αs相含量的增加,板材的屈服强度也升高[10,46];另一方面,αs相的析出增加了组织中α/β相界面.拉伸变形过程中,相界对位错的阻碍作用使得界面强化效应显著,界面增多提高了板材的屈服强度[9].这2方面的综合作用使得细小αs相的析出强化效应显著,导致板材强度升高.板材延伸率的降低主要与αp相的体积分数有关.板材试样进行拉伸变形时,塑性变形首先在少数αp晶粒中以滑移形式进行,当晶粒内的变形进行到一定程度后,最先开始变形的晶粒及其相邻晶粒发生转动,使得自身滑移系处于不利取向,而相邻晶粒处于有利取向,变形转移到相邻晶粒后逐渐占据越来越多的αp晶粒,降低了晶界处的位错塞积,从而不会在个别晶粒中引起应力集中而开裂[11].此外,αp相还可以限制原始β晶粒的长大,有利于改善钛合金板材的塑性.因此,随退火温度升高,αp相的体积分数下降,降低了合金组织的协调变形能力,板材的延伸率降低.第3阶段是在950~1000℃区间内退火后,提高了板材的屈服强度,但是却牺牲了板材的延伸率.950℃退火后获得了全片层组织,α/β相界面增多,αs相的体积分数也增加,这使得950℃退火处理后板材屈服强度最高.但是,将退火温度升高到1000℃后,αs相开始长大粗化,α/β相界面减少,导致板材强度降低.此外,板材单相区退火后,等轴αp相消失,形成了全片层组织,由于集束取向一致以及连续αGB相的存在,裂纹容易沿集束截面及晶界发生长距离扩展,导致板材延伸率大幅下降. ...

热处理对Ti90钛合金显微组织及性能的影响

4

2021

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

... Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材退火处理后显微组织的SEM像如图4所示.800℃退火处理后的板材组织(图4a和a1)与图2a轧制态板材组织类似,由拉长的α相、等轴α相和β相组成,仍可观察到明显的条带状组织,但组织中的α相含量减少,部分转变成β相.钛合金轧制变形后,组织中的位错密度快速增加,同时获得了足够高的应变能,这些能量可用来完成后续的回复及再结晶.由于800℃退火时,板材组织仅发生回复,部分存储应变能释放,热激活作用促进了原子扩散,位错密度降低,但不发生大角晶界的迁移,所以晶粒形状与轧制态组织类似,仍有许多畸变晶粒被保留下来[11].经850~920℃退火处理后,板材组织中的αp相均匀分布,αs相从β基体中析出后不断长大,最后与β基体相互交错排列,形成了β转变组织(βt相) (图4b~d1).随着退火温度的升高,原子扩散加剧,应变能进一步释放,在畸变度大的区域以多边化形成的亚晶为基础产生新的无畸变晶粒的核心,然后通过消耗周围的变形基体而长大,原来的畸变晶粒逐渐转变成无畸变的等轴新晶粒,条带状组织逐渐消失[32].而经950~1000℃退火后,板材组织中的αp相消失,β晶粒快速长大粗化,在随后冷却的过程中,αs相从β晶粒内部析出,相同取向的αs相平行排列成α集束,在β晶界处还有晶界α相(αGB相)析出(图4e~f1),最终形成由αs相和β相组成的全片层组织[22]. ...

... 值得注意的是,800℃退火组织中并没有析出αs相,850℃退火后部分β相开始析出αs相,进一步升高退火温度,αs相析出更加充分.由此可见,退火温度会影响αs相的析出行为.αs相的析出主要与β相的稳定性及冷却速率有关[33,34].由于α相转变为β相是一种扩散型相变,相变过程中存在合金元素再分配效应.黄森森等[35]发现,提高固溶温度,发生α→β转变,TC4合金中的β稳定元素沿化学势降低的方向扩散,V元素由αp相中心及相邻β相向αp相边缘扩散,β相中的V含量降低,β稳定性降低,导致TC4合金固溶空冷后析出αs相.因此,升高退火温度,合金元素再分配使得β相中的β稳定元素含量降低,β稳定性随之降低,有利于αs相的析出.另一方面,退火温度越高,在相同冷却速率条件下,需要的冷却时间也越长,也有利于αs相的析出[11]. ...

... 图10给出了退火处理前后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材的室温拉伸性能.由图可知,在两相区退火,随退火温度升高,板材的屈服强度呈上升趋势,延伸率呈下降趋势;而在单相区退火后,板材的屈服强度较900℃退火先升高后降低,延伸率则急剧下降.值得注意的是,800℃退火处理后板材的屈服强度和延伸率与原始轧制板材的屈服强度和延伸率(RD:屈服强度Rp0.2 = 995 MPa,延伸率A = 8%;TD:Rp0.2 = 1088 MPa,A = 10%)基本一致,900℃退火后,板材屈服强度的上升趋势更加明显.此外,在950℃退火时,板材的屈服强度最高,但其延伸率下降到1.0%.结合图10的分析结果和图4中板材显微组织随退火温度的变化,退火温度对板材拉伸性能的影响主要分为3个阶段.第1阶段是在800℃退火,板材组织由拉长的α相、等轴α相和β相组成,同时仍可观察到大量的条带状组织.这说明在800℃退火时合金组织内部仅发生回复,部分应变能释放,与未经退火处理的板材组织特征类似,因此其屈服强度和延伸率与退火前相比变化不大.第2阶段是在850~900℃区间内退火,αs相从部分析出到完全析出,αp相的体积分数从36%下降到12%,板材的屈服强度升高,延伸率降低,退火温度主要通过改变αs相的析出行为和αp相的体积分数来影响板材的拉伸性能.850℃退火后析出的αs相可以起到强化基体的作用,并且这种强化作用随退火温度的升高而加强.一方面,由于细小αs相的强度高于等轴αp相,随着αs相含量的增加,板材的屈服强度也升高[10,46];另一方面,αs相的析出增加了组织中α/β相界面.拉伸变形过程中,相界对位错的阻碍作用使得界面强化效应显著,界面增多提高了板材的屈服强度[9].这2方面的综合作用使得细小αs相的析出强化效应显著,导致板材强度升高.板材延伸率的降低主要与αp相的体积分数有关.板材试样进行拉伸变形时,塑性变形首先在少数αp晶粒中以滑移形式进行,当晶粒内的变形进行到一定程度后,最先开始变形的晶粒及其相邻晶粒发生转动,使得自身滑移系处于不利取向,而相邻晶粒处于有利取向,变形转移到相邻晶粒后逐渐占据越来越多的αp晶粒,降低了晶界处的位错塞积,从而不会在个别晶粒中引起应力集中而开裂[11].此外,αp相还可以限制原始β晶粒的长大,有利于改善钛合金板材的塑性.因此,随退火温度升高,αp相的体积分数下降,降低了合金组织的协调变形能力,板材的延伸率降低.第3阶段是在950~1000℃区间内退火后,提高了板材的屈服强度,但是却牺牲了板材的延伸率.950℃退火后获得了全片层组织,α/β相界面增多,αs相的体积分数也增加,这使得950℃退火处理后板材屈服强度最高.但是,将退火温度升高到1000℃后,αs相开始长大粗化,α/β相界面减少,导致板材强度降低.此外,板材单相区退火后,等轴αp相消失,形成了全片层组织,由于集束取向一致以及连续αGB相的存在,裂纹容易沿集束截面及晶界发生长距离扩展,导致板材延伸率大幅下降. ...

Effect of microstructure and texture on room temperature strength of Ti60 Ti-alloy plate

5

2018

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

... ,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

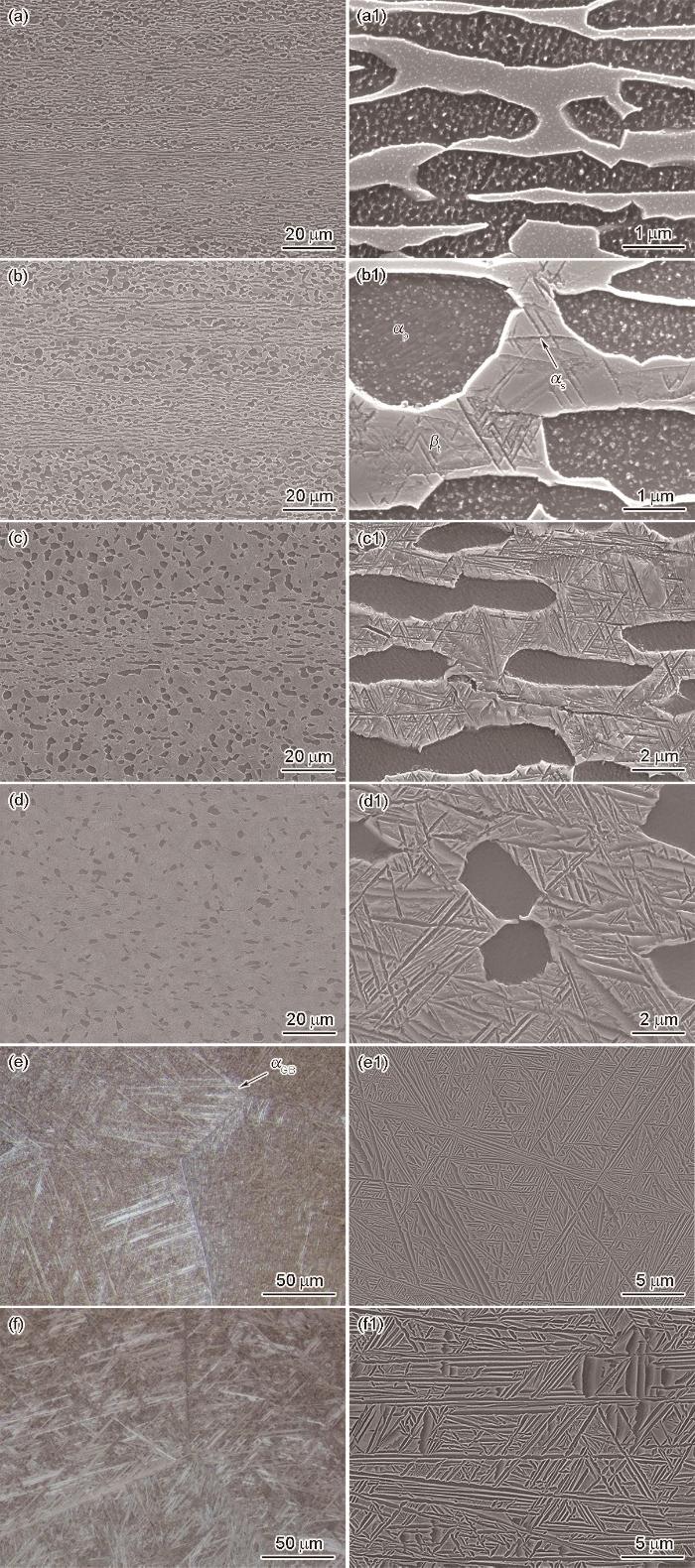

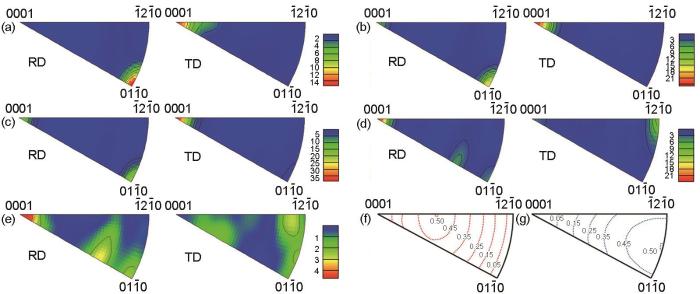

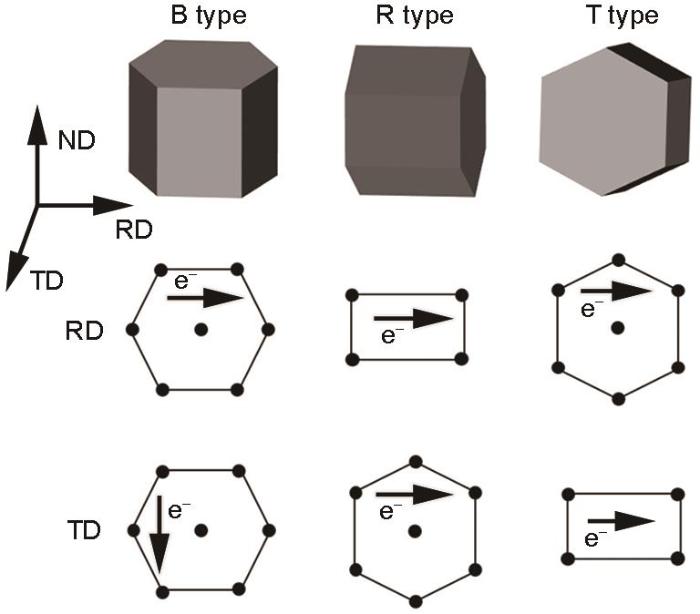

... 图6和7分别为利用XRD和EBSD测得的热处理态Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr板材α相极图.由图可知,通过XRD获得的宏观织构信息与微观织构信息符合较好.经800~850℃退火处理后,与原始态织构相比,板材织构类型未发生明显变化,依然呈T型织构,最大极密度值为4.5~6.0.当退火温度升高到900~920℃时,板材中除了存在T型织构外,还出现了α相c轴方向与RD平行的织构组分,简单地称之为R型织构[12,13].由图4及6可知,板材织构特征与其显微组织有一定的对应关系.在αs相析出之前,退火态板材中的αp相仅发生回复,其体积分数、形貌和尺寸与图2a中的αp相类似,所以板材织构类型保持不变.进一步升高退火温度,发生α→β→α相变,部分αp相转化为β相,αp相的体积分数逐渐降低(图5a),同时αp晶粒再结晶后长大粗化(图5b),β基体析出大量细小的αs相(图4d),织构类型发生明显的变化.因此,不同类型织构强度的变化可能与α晶粒粗化以及相转变有关. ...

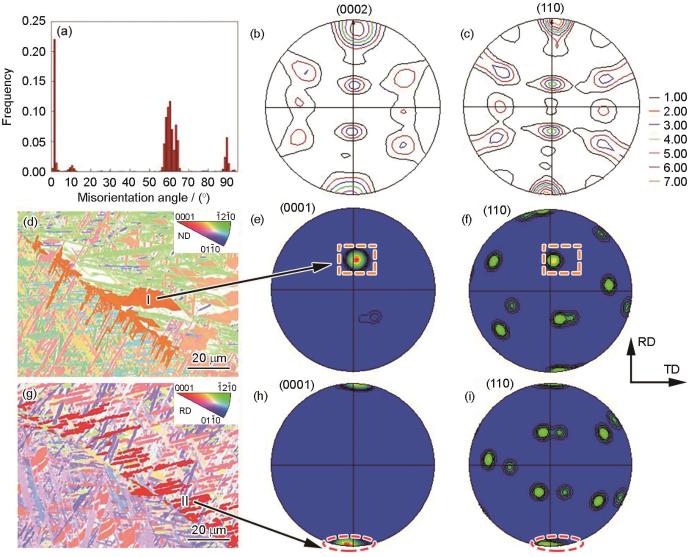

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... [12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

Ti60合金板材的室温强度与其显微组织和织构的关系

5

2018

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

... ,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

... 图6和7分别为利用XRD和EBSD测得的热处理态Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr板材α相极图.由图可知,通过XRD获得的宏观织构信息与微观织构信息符合较好.经800~850℃退火处理后,与原始态织构相比,板材织构类型未发生明显变化,依然呈T型织构,最大极密度值为4.5~6.0.当退火温度升高到900~920℃时,板材中除了存在T型织构外,还出现了α相c轴方向与RD平行的织构组分,简单地称之为R型织构[12,13].由图4及6可知,板材织构特征与其显微组织有一定的对应关系.在αs相析出之前,退火态板材中的αp相仅发生回复,其体积分数、形貌和尺寸与图2a中的αp相类似,所以板材织构类型保持不变.进一步升高退火温度,发生α→β→α相变,部分αp相转化为β相,αp相的体积分数逐渐降低(图5a),同时αp晶粒再结晶后长大粗化(图5b),β基体析出大量细小的αs相(图4d),织构类型发生明显的变化.因此,不同类型织构强度的变化可能与α晶粒粗化以及相转变有关. ...

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... [12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

Effect of annealing temperature on microstructure, texture and tensile properties of TA32 sheet

6

2021

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

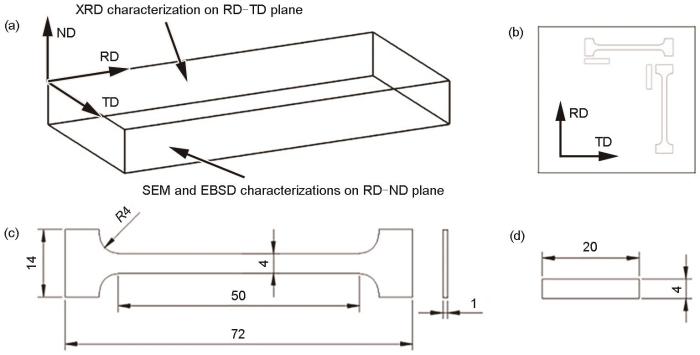

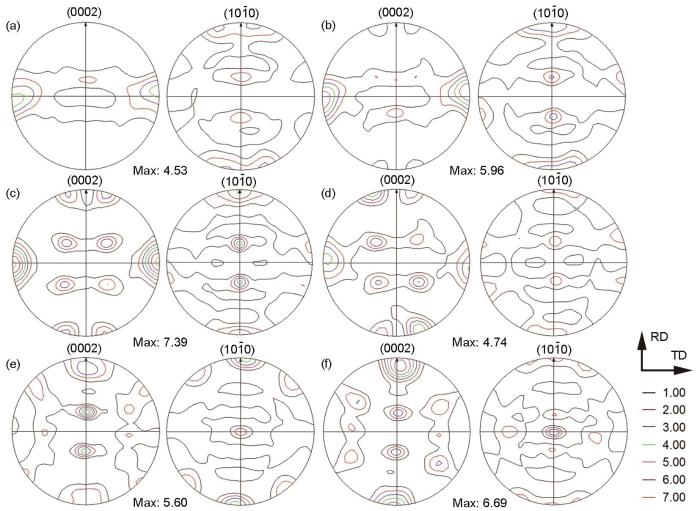

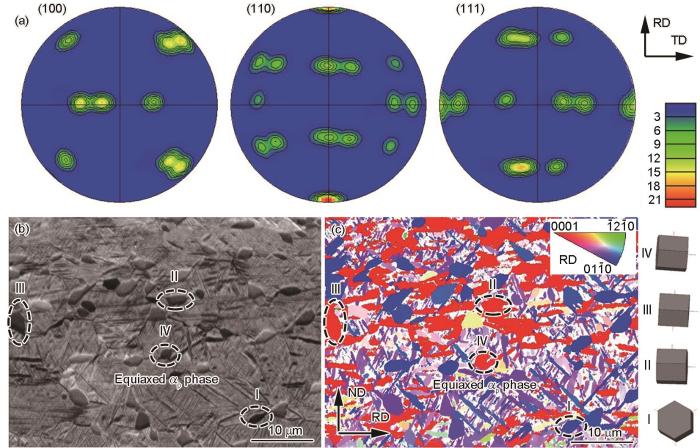

... 图2为Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材原始显微组织的SEM像.板材组织由拉长的α相、等轴α相和β相组成,α相的体积分数为61.85%,β相体积分数为38.15%.不同观察面上的显微组织形貌存在显著差异,RD-ND观察面有2种组织形态:一种是与RD平行的长条状α相为主的组织;另外一种是α等轴组织.αp相和β相在轧制过程中经历剧烈塑性变形后被压扁呈长条状,这些长条状α相和β相排列在一起,形成沿板材RD排列的条带状组织.而RD-TD观察面组织中的部分αp相接近等轴状,晶粒尺寸较大,一部分β相发生扭曲变形,没有观察到明显的条带状组织.这是因为板材组织中的αp相在轧制过程中受到沿板厚方向的挤压,αp相沿法向(ND)被压扁成长条状,而在RD和TD上延展.图3a给出了板材RD-ND面α晶粒的取向成像图,板材α相<0001>//TD取向的含量最高,α晶粒的晶体学c轴趋向于集中指向TD.同时图3b中的(0002)极图显示α相c轴平行于TD,这符合T型织构的特征[28,29].轧制时的应力状态可近似看成板材RD受到拉应力,板材ND受到压应力,结果使得各晶粒的某一晶面和晶向分别趋于与轧面和轧向平行.一般认为,轧制过程中α相的滑移变形机制会影响最终的织构取向[13,30,31],T型织构归因于柱面滑移系{100}<110>作为主要的滑移机制.图3c则显示板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19]. ...

... 图6和7分别为利用XRD和EBSD测得的热处理态Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr板材α相极图.由图可知,通过XRD获得的宏观织构信息与微观织构信息符合较好.经800~850℃退火处理后,与原始态织构相比,板材织构类型未发生明显变化,依然呈T型织构,最大极密度值为4.5~6.0.当退火温度升高到900~920℃时,板材中除了存在T型织构外,还出现了α相c轴方向与RD平行的织构组分,简单地称之为R型织构[12,13].由图4及6可知,板材织构特征与其显微组织有一定的对应关系.在αs相析出之前,退火态板材中的αp相仅发生回复,其体积分数、形貌和尺寸与图2a中的αp相类似,所以板材织构类型保持不变.进一步升高退火温度,发生α→β→α相变,部分αp相转化为β相,αp相的体积分数逐渐降低(图5a),同时αp晶粒再结晶后长大粗化(图5b),β基体析出大量细小的αs相(图4d),织构类型发生明显的变化.因此,不同类型织构强度的变化可能与α晶粒粗化以及相转变有关. ...

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... ,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... [13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

The influence of rolling temperature on texture evolution and variant selection during α→β→α phase transformation in Ti-6Al-4V

5

2012

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

... 图2为Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材原始显微组织的SEM像.板材组织由拉长的α相、等轴α相和β相组成,α相的体积分数为61.85%,β相体积分数为38.15%.不同观察面上的显微组织形貌存在显著差异,RD-ND观察面有2种组织形态:一种是与RD平行的长条状α相为主的组织;另外一种是α等轴组织.αp相和β相在轧制过程中经历剧烈塑性变形后被压扁呈长条状,这些长条状α相和β相排列在一起,形成沿板材RD排列的条带状组织.而RD-TD观察面组织中的部分αp相接近等轴状,晶粒尺寸较大,一部分β相发生扭曲变形,没有观察到明显的条带状组织.这是因为板材组织中的αp相在轧制过程中受到沿板厚方向的挤压,αp相沿法向(ND)被压扁成长条状,而在RD和TD上延展.图3a给出了板材RD-ND面α晶粒的取向成像图,板材α相<0001>//TD取向的含量最高,α晶粒的晶体学c轴趋向于集中指向TD.同时图3b中的(0002)极图显示α相c轴平行于TD,这符合T型织构的特征[28,29].轧制时的应力状态可近似看成板材RD受到拉应力,板材ND受到压应力,结果使得各晶粒的某一晶面和晶向分别趋于与轧面和轧向平行.一般认为,轧制过程中α相的滑移变形机制会影响最终的织构取向[13,30,31],T型织构归因于柱面滑移系{100}<110>作为主要的滑移机制.图3c则显示板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19]. ...

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... [14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... 在β单相区退火后,钛合金板材中的αp相完全消失,获得了全片层组织,板材中的T型织构消失,同时形成了R型织构和近B型织构(图6e和f).理论上,在α→β→α相变过程中,将生成6种不同取向的β变体,每个β晶粒内部可生成12种不同取向的αs变体[15,18,40,41],最终α相织构强度将大大降低.然而,实际上Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材经β单相区退火后α相织构依然明显,说明α→β→α转变时存在变体选择.Yang等[42]从热力学角度出发,认为变体选择的实质是形成某一αs变体时系统能量降低更多,从而表现为α相的局部择优取向生长.图9给出了1000℃退火处理后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材α相和β相的织构分析.由于Burgers关系,β晶粒内的αs变体之间满足5类取向差[43,44],即10°/<0001>、60°/<110>、60.83°/<1.377 2.377 0.359>、63.26°/<10 5 5 >和90°/<1 2.38 1.38 0>.与本工作观察到的现象相符,见图9a.此外,α相和β相保持良好的Burgers取向关系(图9b和c),可以观察到β相的<110>晶向在RD以及沿ND向RD偏转20°~30°处存在集中取向.这种在单相区退火后形成的β织构(RD//<110>)在TC4合金中也有报道,分析认为β晶粒可以通过Burgers取向关系继承α相的取向[18,20,21,39,45],还可能是β再结晶形成了新织构[14,19].另有研究[15,40]表明,当β相存在较强的<110>织构时,相邻β晶粒共有<110>方向的概率增大,β晶界的界面能较低,c轴平行于<110>方向的α相变体在β晶界两侧择优析出.随机选取了2类αGB相的子集(图9d和g),并给出了相应αGB相的(0001)极图(图9e和h)和β相的(110)极图(图9f和i).可以看到,αGB相的<0001>晶向在板材ND向RD偏转20°~30°以及RD处存在集中取向,这与图9b相符.由于板材在单相区退火后β相存在多种织构取向,这意味着板材组织中存在许多共有<110>晶向的β晶粒对,因而在冷却的过程中,αs相首先在这些β晶粒对的界面处形核,随后向界面两侧生长,由于这些αs相取向相近,在单相区退火后α相织构依然明显. ...

Crystallographic variant selection in Ti-6Al-4V

4

2004

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... 在β单相区退火后,钛合金板材中的αp相完全消失,获得了全片层组织,板材中的T型织构消失,同时形成了R型织构和近B型织构(图6e和f).理论上,在α→β→α相变过程中,将生成6种不同取向的β变体,每个β晶粒内部可生成12种不同取向的αs变体[15,18,40,41],最终α相织构强度将大大降低.然而,实际上Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材经β单相区退火后α相织构依然明显,说明α→β→α转变时存在变体选择.Yang等[42]从热力学角度出发,认为变体选择的实质是形成某一αs变体时系统能量降低更多,从而表现为α相的局部择优取向生长.图9给出了1000℃退火处理后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材α相和β相的织构分析.由于Burgers关系,β晶粒内的αs变体之间满足5类取向差[43,44],即10°/<0001>、60°/<110>、60.83°/<1.377 2.377 0.359>、63.26°/<10 5 5 >和90°/<1 2.38 1.38 0>.与本工作观察到的现象相符,见图9a.此外,α相和β相保持良好的Burgers取向关系(图9b和c),可以观察到β相的<110>晶向在RD以及沿ND向RD偏转20°~30°处存在集中取向.这种在单相区退火后形成的β织构(RD//<110>)在TC4合金中也有报道,分析认为β晶粒可以通过Burgers取向关系继承α相的取向[18,20,21,39,45],还可能是β再结晶形成了新织构[14,19].另有研究[15,40]表明,当β相存在较强的<110>织构时,相邻β晶粒共有<110>方向的概率增大,β晶界的界面能较低,c轴平行于<110>方向的α相变体在β晶界两侧择优析出.随机选取了2类αGB相的子集(图9d和g),并给出了相应αGB相的(0001)极图(图9e和h)和β相的(110)极图(图9f和i).可以看到,αGB相的<0001>晶向在板材ND向RD偏转20°~30°以及RD处存在集中取向,这与图9b相符.由于板材在单相区退火后β相存在多种织构取向,这意味着板材组织中存在许多共有<110>晶向的β晶粒对,因而在冷却的过程中,αs相首先在这些β晶粒对的界面处形核,随后向界面两侧生长,由于这些αs相取向相近,在单相区退火后α相织构依然明显. ...

... [15,40]表明,当β相存在较强的<110>织构时,相邻β晶粒共有<110>方向的概率增大,β晶界的界面能较低,c轴平行于<110>方向的α相变体在β晶界两侧择优析出.随机选取了2类αGB相的子集(图9d和g),并给出了相应αGB相的(0001)极图(图9e和h)和β相的(110)极图(图9f和i).可以看到,αGB相的<0001>晶向在板材ND向RD偏转20°~30°以及RD处存在集中取向,这与图9b相符.由于板材在单相区退火后β相存在多种织构取向,这意味着板材组织中存在许多共有<110>晶向的β晶粒对,因而在冷却的过程中,αs相首先在这些β晶粒对的界面处形核,随后向界面两侧生长,由于这些αs相取向相近,在单相区退火后α相织构依然明显. ...

Effect of heat treatment on the crystallographic orientation evolution in a near-α titanium alloy Ti60

4

2017

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... ,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... ,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

Analysis of sharp microtexture heterogeneities in a bimodal IMI 834 billet

1

2005

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

Variant selection during titanium alloy BCC?HCP phase transformation and its effect on crystal orientation

4

2019

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... 在β单相区退火后,钛合金板材中的αp相完全消失,获得了全片层组织,板材中的T型织构消失,同时形成了R型织构和近B型织构(图6e和f).理论上,在α→β→α相变过程中,将生成6种不同取向的β变体,每个β晶粒内部可生成12种不同取向的αs变体[15,18,40,41],最终α相织构强度将大大降低.然而,实际上Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材经β单相区退火后α相织构依然明显,说明α→β→α转变时存在变体选择.Yang等[42]从热力学角度出发,认为变体选择的实质是形成某一αs变体时系统能量降低更多,从而表现为α相的局部择优取向生长.图9给出了1000℃退火处理后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材α相和β相的织构分析.由于Burgers关系,β晶粒内的αs变体之间满足5类取向差[43,44],即10°/<0001>、60°/<110>、60.83°/<1.377 2.377 0.359>、63.26°/<10 5 5 >和90°/<1 2.38 1.38 0>.与本工作观察到的现象相符,见图9a.此外,α相和β相保持良好的Burgers取向关系(图9b和c),可以观察到β相的<110>晶向在RD以及沿ND向RD偏转20°~30°处存在集中取向.这种在单相区退火后形成的β织构(RD//<110>)在TC4合金中也有报道,分析认为β晶粒可以通过Burgers取向关系继承α相的取向[18,20,21,39,45],还可能是β再结晶形成了新织构[14,19].另有研究[15,40]表明,当β相存在较强的<110>织构时,相邻β晶粒共有<110>方向的概率增大,β晶界的界面能较低,c轴平行于<110>方向的α相变体在β晶界两侧择优析出.随机选取了2类αGB相的子集(图9d和g),并给出了相应αGB相的(0001)极图(图9e和h)和β相的(110)极图(图9f和i).可以看到,αGB相的<0001>晶向在板材ND向RD偏转20°~30°以及RD处存在集中取向,这与图9b相符.由于板材在单相区退火后β相存在多种织构取向,这意味着板材组织中存在许多共有<110>晶向的β晶粒对,因而在冷却的过程中,αs相首先在这些β晶粒对的界面处形核,随后向界面两侧生长,由于这些αs相取向相近,在单相区退火后α相织构依然明显. ...

... [18,20,21,39,45],还可能是β再结晶形成了新织构[14,19].另有研究[15,40]表明,当β相存在较强的<110>织构时,相邻β晶粒共有<110>方向的概率增大,β晶界的界面能较低,c轴平行于<110>方向的α相变体在β晶界两侧择优析出.随机选取了2类αGB相的子集(图9d和g),并给出了相应αGB相的(0001)极图(图9e和h)和β相的(110)极图(图9f和i).可以看到,αGB相的<0001>晶向在板材ND向RD偏转20°~30°以及RD处存在集中取向,这与图9b相符.由于板材在单相区退火后β相存在多种织构取向,这意味着板材组织中存在许多共有<110>晶向的β晶粒对,因而在冷却的过程中,αs相首先在这些β晶粒对的界面处形核,随后向界面两侧生长,由于这些αs相取向相近,在单相区退火后α相织构依然明显. ...

钛合金BCC?HCP相变的变体选择及其对晶体取向的影响

4

2019

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... 在β单相区退火后,钛合金板材中的αp相完全消失,获得了全片层组织,板材中的T型织构消失,同时形成了R型织构和近B型织构(图6e和f).理论上,在α→β→α相变过程中,将生成6种不同取向的β变体,每个β晶粒内部可生成12种不同取向的αs变体[15,18,40,41],最终α相织构强度将大大降低.然而,实际上Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材经β单相区退火后α相织构依然明显,说明α→β→α转变时存在变体选择.Yang等[42]从热力学角度出发,认为变体选择的实质是形成某一αs变体时系统能量降低更多,从而表现为α相的局部择优取向生长.图9给出了1000℃退火处理后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材α相和β相的织构分析.由于Burgers关系,β晶粒内的αs变体之间满足5类取向差[43,44],即10°/<0001>、60°/<110>、60.83°/<1.377 2.377 0.359>、63.26°/<10 5 5 >和90°/<1 2.38 1.38 0>.与本工作观察到的现象相符,见图9a.此外,α相和β相保持良好的Burgers取向关系(图9b和c),可以观察到β相的<110>晶向在RD以及沿ND向RD偏转20°~30°处存在集中取向.这种在单相区退火后形成的β织构(RD//<110>)在TC4合金中也有报道,分析认为β晶粒可以通过Burgers取向关系继承α相的取向[18,20,21,39,45],还可能是β再结晶形成了新织构[14,19].另有研究[15,40]表明,当β相存在较强的<110>织构时,相邻β晶粒共有<110>方向的概率增大,β晶界的界面能较低,c轴平行于<110>方向的α相变体在β晶界两侧择优析出.随机选取了2类αGB相的子集(图9d和g),并给出了相应αGB相的(0001)极图(图9e和h)和β相的(110)极图(图9f和i).可以看到,αGB相的<0001>晶向在板材ND向RD偏转20°~30°以及RD处存在集中取向,这与图9b相符.由于板材在单相区退火后β相存在多种织构取向,这意味着板材组织中存在许多共有<110>晶向的β晶粒对,因而在冷却的过程中,αs相首先在这些β晶粒对的界面处形核,随后向界面两侧生长,由于这些αs相取向相近,在单相区退火后α相织构依然明显. ...

... [18,20,21,39,45],还可能是β再结晶形成了新织构[14,19].另有研究[15,40]表明,当β相存在较强的<110>织构时,相邻β晶粒共有<110>方向的概率增大,β晶界的界面能较低,c轴平行于<110>方向的α相变体在β晶界两侧择优析出.随机选取了2类αGB相的子集(图9d和g),并给出了相应αGB相的(0001)极图(图9e和h)和β相的(110)极图(图9f和i).可以看到,αGB相的<0001>晶向在板材ND向RD偏转20°~30°以及RD处存在集中取向,这与图9b相符.由于板材在单相区退火后β相存在多种织构取向,这意味着板材组织中存在许多共有<110>晶向的β晶粒对,因而在冷却的过程中,αs相首先在这些β晶粒对的界面处形核,随后向界面两侧生长,由于这些αs相取向相近,在单相区退火后α相织构依然明显. ...

Effect of β grain growth on variant selection and texture memory effect during α→β→α phase transformation in Ti-6Al-4V

4

2012

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

... 图2为Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材原始显微组织的SEM像.板材组织由拉长的α相、等轴α相和β相组成,α相的体积分数为61.85%,β相体积分数为38.15%.不同观察面上的显微组织形貌存在显著差异,RD-ND观察面有2种组织形态:一种是与RD平行的长条状α相为主的组织;另外一种是α等轴组织.αp相和β相在轧制过程中经历剧烈塑性变形后被压扁呈长条状,这些长条状α相和β相排列在一起,形成沿板材RD排列的条带状组织.而RD-TD观察面组织中的部分αp相接近等轴状,晶粒尺寸较大,一部分β相发生扭曲变形,没有观察到明显的条带状组织.这是因为板材组织中的αp相在轧制过程中受到沿板厚方向的挤压,αp相沿法向(ND)被压扁成长条状,而在RD和TD上延展.图3a给出了板材RD-ND面α晶粒的取向成像图,板材α相<0001>//TD取向的含量最高,α晶粒的晶体学c轴趋向于集中指向TD.同时图3b中的(0002)极图显示α相c轴平行于TD,这符合T型织构的特征[28,29].轧制时的应力状态可近似看成板材RD受到拉应力,板材ND受到压应力,结果使得各晶粒的某一晶面和晶向分别趋于与轧面和轧向平行.一般认为,轧制过程中α相的滑移变形机制会影响最终的织构取向[13,30,31],T型织构归因于柱面滑移系{100}<110>作为主要的滑移机制.图3c则显示板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19]. ...

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... 在β单相区退火后,钛合金板材中的αp相完全消失,获得了全片层组织,板材中的T型织构消失,同时形成了R型织构和近B型织构(图6e和f).理论上,在α→β→α相变过程中,将生成6种不同取向的β变体,每个β晶粒内部可生成12种不同取向的αs变体[15,18,40,41],最终α相织构强度将大大降低.然而,实际上Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材经β单相区退火后α相织构依然明显,说明α→β→α转变时存在变体选择.Yang等[42]从热力学角度出发,认为变体选择的实质是形成某一αs变体时系统能量降低更多,从而表现为α相的局部择优取向生长.图9给出了1000℃退火处理后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材α相和β相的织构分析.由于Burgers关系,β晶粒内的αs变体之间满足5类取向差[43,44],即10°/<0001>、60°/<110>、60.83°/<1.377 2.377 0.359>、63.26°/<10 5 5 >和90°/<1 2.38 1.38 0>.与本工作观察到的现象相符,见图9a.此外,α相和β相保持良好的Burgers取向关系(图9b和c),可以观察到β相的<110>晶向在RD以及沿ND向RD偏转20°~30°处存在集中取向.这种在单相区退火后形成的β织构(RD//<110>)在TC4合金中也有报道,分析认为β晶粒可以通过Burgers取向关系继承α相的取向[18,20,21,39,45],还可能是β再结晶形成了新织构[14,19].另有研究[15,40]表明,当β相存在较强的<110>织构时,相邻β晶粒共有<110>方向的概率增大,β晶界的界面能较低,c轴平行于<110>方向的α相变体在β晶界两侧择优析出.随机选取了2类αGB相的子集(图9d和g),并给出了相应αGB相的(0001)极图(图9e和h)和β相的(110)极图(图9f和i).可以看到,αGB相的<0001>晶向在板材ND向RD偏转20°~30°以及RD处存在集中取向,这与图9b相符.由于板材在单相区退火后β相存在多种织构取向,这意味着板材组织中存在许多共有<110>晶向的β晶粒对,因而在冷却的过程中,αs相首先在这些β晶粒对的界面处形核,随后向界面两侧生长,由于这些αs相取向相近,在单相区退火后α相织构依然明显. ...

Characterization of the variant selection occurring during the α→β→α phase transformations of a cold rolled titanium sheet

2

2002

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

... 在β单相区退火后,钛合金板材中的αp相完全消失,获得了全片层组织,板材中的T型织构消失,同时形成了R型织构和近B型织构(图6e和f).理论上,在α→β→α相变过程中,将生成6种不同取向的β变体,每个β晶粒内部可生成12种不同取向的αs变体[15,18,40,41],最终α相织构强度将大大降低.然而,实际上Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材经β单相区退火后α相织构依然明显,说明α→β→α转变时存在变体选择.Yang等[42]从热力学角度出发,认为变体选择的实质是形成某一αs变体时系统能量降低更多,从而表现为α相的局部择优取向生长.图9给出了1000℃退火处理后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材α相和β相的织构分析.由于Burgers关系,β晶粒内的αs变体之间满足5类取向差[43,44],即10°/<0001>、60°/<110>、60.83°/<1.377 2.377 0.359>、63.26°/<10 5 5 >和90°/<1 2.38 1.38 0>.与本工作观察到的现象相符,见图9a.此外,α相和β相保持良好的Burgers取向关系(图9b和c),可以观察到β相的<110>晶向在RD以及沿ND向RD偏转20°~30°处存在集中取向.这种在单相区退火后形成的β织构(RD//<110>)在TC4合金中也有报道,分析认为β晶粒可以通过Burgers取向关系继承α相的取向[18,20,21,39,45],还可能是β再结晶形成了新织构[14,19].另有研究[15,40]表明,当β相存在较强的<110>织构时,相邻β晶粒共有<110>方向的概率增大,β晶界的界面能较低,c轴平行于<110>方向的α相变体在β晶界两侧择优析出.随机选取了2类αGB相的子集(图9d和g),并给出了相应αGB相的(0001)极图(图9e和h)和β相的(110)极图(图9f和i).可以看到,αGB相的<0001>晶向在板材ND向RD偏转20°~30°以及RD处存在集中取向,这与图9b相符.由于板材在单相区退火后β相存在多种织构取向,这意味着板材组织中存在许多共有<110>晶向的β晶粒对,因而在冷却的过程中,αs相首先在这些β晶粒对的界面处形核,随后向界面两侧生长,由于这些αs相取向相近,在单相区退火后α相织构依然明显. ...

Variant selection and its effect on phase transformation textures in cold rolled titanium sheet

2

2000

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

... 在β单相区退火后,钛合金板材中的αp相完全消失,获得了全片层组织,板材中的T型织构消失,同时形成了R型织构和近B型织构(图6e和f).理论上,在α→β→α相变过程中,将生成6种不同取向的β变体,每个β晶粒内部可生成12种不同取向的αs变体[15,18,40,41],最终α相织构强度将大大降低.然而,实际上Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材经β单相区退火后α相织构依然明显,说明α→β→α转变时存在变体选择.Yang等[42]从热力学角度出发,认为变体选择的实质是形成某一αs变体时系统能量降低更多,从而表现为α相的局部择优取向生长.图9给出了1000℃退火处理后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材α相和β相的织构分析.由于Burgers关系,β晶粒内的αs变体之间满足5类取向差[43,44],即10°/<0001>、60°/<110>、60.83°/<1.377 2.377 0.359>、63.26°/<10 5 5 >和90°/<1 2.38 1.38 0>.与本工作观察到的现象相符,见图9a.此外,α相和β相保持良好的Burgers取向关系(图9b和c),可以观察到β相的<110>晶向在RD以及沿ND向RD偏转20°~30°处存在集中取向.这种在单相区退火后形成的β织构(RD//<110>)在TC4合金中也有报道,分析认为β晶粒可以通过Burgers取向关系继承α相的取向[18,20,21,39,45],还可能是β再结晶形成了新织构[14,19].另有研究[15,40]表明,当β相存在较强的<110>织构时,相邻β晶粒共有<110>方向的概率增大,β晶界的界面能较低,c轴平行于<110>方向的α相变体在β晶界两侧择优析出.随机选取了2类αGB相的子集(图9d和g),并给出了相应αGB相的(0001)极图(图9e和h)和β相的(110)极图(图9f和i).可以看到,αGB相的<0001>晶向在板材ND向RD偏转20°~30°以及RD处存在集中取向,这与图9b相符.由于板材在单相区退火后β相存在多种织构取向,这意味着板材组织中存在许多共有<110>晶向的β晶粒对,因而在冷却的过程中,αs相首先在这些β晶粒对的界面处形核,随后向界面两侧生长,由于这些αs相取向相近,在单相区退火后α相织构依然明显. ...

2

2007

... 合金显微组织决定了其性能,而热处理则是控制合金组织的有效手段.通过热处理调控可以获得具有各种优异性能的钛合金,实现对材料力学性能的优化.徐戊矫等[9]发现,β转变相中α片层的尺寸增大,滑动距离增加,最终导致Ti-6Al-4V (TC4)合金的屈服强度降低.Fan等[10]指出,固溶过程中初生α相减少以及β晶粒长大使得Ti-7333合金强度降低.王可等[11]认为,Ti90合金在单相区退火后,初生α相消失,形成了原始β晶粒粗大的片层组织,易出现微区变形不均匀,使得延伸率下降.此外,热处理过程中还存在α织构的演化,这将对合金最终的力学性能产生影响.李文渊等[12]对Ti60合金板材进行了退火处理,结果表明在两相区退火没有α新织构出现.而Cheng等[13]认为β织构以及初生α织构的存在使得TA32合金板材在两相区退火后形成了新的α织构组分.有研究[14,15]指出,退火态TC4板材中的β织构通常与原始态板材有关,而β织构的存在使得β/β界面处发生变体选择的概率增大,析出的次生α相(αs相)呈择优取向.而且初生α相(αp相)和β相满足Burgers关系时,新生成的αs相与αp相的c轴方向相近[16~18].Obasi等[19]研究了TC4合金的织构“记忆”效应,发现随β晶粒长大,相邻β晶粒共有同一<110>晶向的概率增大,α{90°, 30°, 0°}变体择优析出.针对冷轧钛板的研究[20,21]表明,β晶粒通过α→β相变继承了α相的织构,在随后β→α相变过程中发生变体选择使得α相表现出强织构.室温下,α相可开动的滑移系较少,织构的存在使得钛合金力学性能表现出各向异性.以钛合金板材中的T型织构为例,板材横向(TD)具有更高的屈服强度[6,12,22].这说明显微组织及织构对钛合金力学性能有重要的影响,在钛合金实际应用过程中应予以重视. ...

... Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材退火处理后显微组织的SEM像如图4所示.800℃退火处理后的板材组织(图4a和a1)与图2a轧制态板材组织类似,由拉长的α相、等轴α相和β相组成,仍可观察到明显的条带状组织,但组织中的α相含量减少,部分转变成β相.钛合金轧制变形后,组织中的位错密度快速增加,同时获得了足够高的应变能,这些能量可用来完成后续的回复及再结晶.由于800℃退火时,板材组织仅发生回复,部分存储应变能释放,热激活作用促进了原子扩散,位错密度降低,但不发生大角晶界的迁移,所以晶粒形状与轧制态组织类似,仍有许多畸变晶粒被保留下来[11].经850~920℃退火处理后,板材组织中的αp相均匀分布,αs相从β基体中析出后不断长大,最后与β基体相互交错排列,形成了β转变组织(βt相) (图4b~d1).随着退火温度的升高,原子扩散加剧,应变能进一步释放,在畸变度大的区域以多边化形成的亚晶为基础产生新的无畸变晶粒的核心,然后通过消耗周围的变形基体而长大,原来的畸变晶粒逐渐转变成无畸变的等轴新晶粒,条带状组织逐渐消失[32].而经950~1000℃退火后,板材组织中的αp相消失,β晶粒快速长大粗化,在随后冷却的过程中,αs相从β晶粒内部析出,相同取向的αs相平行排列成α集束,在β晶界处还有晶界α相(αGB相)析出(图4e~f1),最终形成由αs相和β相组成的全片层组织[22]. ...

Nano-scale precipitates: The key to high strength and high conductivity in Al alloy wire

1

2017

... 热处理也能通过改变显微组织和织构影响合金的导电性能.铝合金及铜合金时效热处理后,合金中的溶质原子多以第二相的形式析出,晶格畸变程度减弱,提高了导电率(电阻率降低),这同时也起到了析出强化的作用,有利于改善强度和导电率的制约关系[23~25].对于钛合金而言,一般不强调强度和导电率的制约关系,不同组织类型的差别主要体现在组成相的体积分数、尺寸、分布以及形貌,这些因素在调节强塑性关系时发挥了至关重要的作用,但是它们对导电性能的影响还有待研究.此外,热处理过程中钛合金板材的织构演化对导电性能的影响不可忽略.织构的存在使得材料力学性能的各向异性显著.类似地,当α晶粒存在集中取向时,由于不同晶面的密排程度不同,hcp结构金属的电阻率同样存在各向异性[26,27].以钛合金板材中的T型织构为例,当电流方向平行于板材TD时,电子沿柱面传输,电流方向平行于板材轧向(RD)时,电子沿基面传输,由于电子在不同晶面传输时被原子核散射的几率不同,可以推测板材不同方向的电阻率存在差异,然而目前关于织构对钛合金电阻率的影响机制还不清楚. ...

Breaking the trade-off relation between strength and electrical conductivity: Heterogeneous grain design

0

2022

突破强度-导电率制约关系: 晶粒异构设计

0

2022

Microstructure, resistivity, and hardness of aged Ag-7wt.%Cu alloy

1

2017

... 热处理也能通过改变显微组织和织构影响合金的导电性能.铝合金及铜合金时效热处理后,合金中的溶质原子多以第二相的形式析出,晶格畸变程度减弱,提高了导电率(电阻率降低),这同时也起到了析出强化的作用,有利于改善强度和导电率的制约关系[23~25].对于钛合金而言,一般不强调强度和导电率的制约关系,不同组织类型的差别主要体现在组成相的体积分数、尺寸、分布以及形貌,这些因素在调节强塑性关系时发挥了至关重要的作用,但是它们对导电性能的影响还有待研究.此外,热处理过程中钛合金板材的织构演化对导电性能的影响不可忽略.织构的存在使得材料力学性能的各向异性显著.类似地,当α晶粒存在集中取向时,由于不同晶面的密排程度不同,hcp结构金属的电阻率同样存在各向异性[26,27].以钛合金板材中的T型织构为例,当电流方向平行于板材TD时,电子沿柱面传输,电流方向平行于板材轧向(RD)时,电子沿基面传输,由于电子在不同晶面传输时被原子核散射的几率不同,可以推测板材不同方向的电阻率存在差异,然而目前关于织构对钛合金电阻率的影响机制还不清楚. ...

时效Ag-7wt.%Cu合金的微观组织、电阻率和硬度

1

2017

... 热处理也能通过改变显微组织和织构影响合金的导电性能.铝合金及铜合金时效热处理后,合金中的溶质原子多以第二相的形式析出,晶格畸变程度减弱,提高了导电率(电阻率降低),这同时也起到了析出强化的作用,有利于改善强度和导电率的制约关系[23~25].对于钛合金而言,一般不强调强度和导电率的制约关系,不同组织类型的差别主要体现在组成相的体积分数、尺寸、分布以及形貌,这些因素在调节强塑性关系时发挥了至关重要的作用,但是它们对导电性能的影响还有待研究.此外,热处理过程中钛合金板材的织构演化对导电性能的影响不可忽略.织构的存在使得材料力学性能的各向异性显著.类似地,当α晶粒存在集中取向时,由于不同晶面的密排程度不同,hcp结构金属的电阻率同样存在各向异性[26,27].以钛合金板材中的T型织构为例,当电流方向平行于板材TD时,电子沿柱面传输,电流方向平行于板材轧向(RD)时,电子沿基面传输,由于电子在不同晶面传输时被原子核散射的几率不同,可以推测板材不同方向的电阻率存在差异,然而目前关于织构对钛合金电阻率的影响机制还不清楚. ...

Thermal conductivity of as-cast and as-extruded binary Mg-Al alloys

2

2014

... 热处理也能通过改变显微组织和织构影响合金的导电性能.铝合金及铜合金时效热处理后,合金中的溶质原子多以第二相的形式析出,晶格畸变程度减弱,提高了导电率(电阻率降低),这同时也起到了析出强化的作用,有利于改善强度和导电率的制约关系[23~25].对于钛合金而言,一般不强调强度和导电率的制约关系,不同组织类型的差别主要体现在组成相的体积分数、尺寸、分布以及形貌,这些因素在调节强塑性关系时发挥了至关重要的作用,但是它们对导电性能的影响还有待研究.此外,热处理过程中钛合金板材的织构演化对导电性能的影响不可忽略.织构的存在使得材料力学性能的各向异性显著.类似地,当α晶粒存在集中取向时,由于不同晶面的密排程度不同,hcp结构金属的电阻率同样存在各向异性[26,27].以钛合金板材中的T型织构为例,当电流方向平行于板材TD时,电子沿柱面传输,电流方向平行于板材轧向(RD)时,电子沿基面传输,由于电子在不同晶面传输时被原子核散射的几率不同,可以推测板材不同方向的电阻率存在差异,然而目前关于织构对钛合金电阻率的影响机制还不清楚. ...

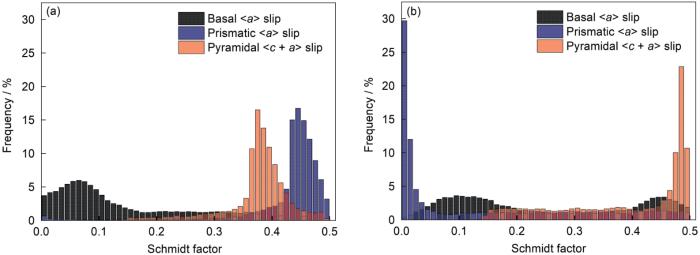

... 图13a为不同温度退火后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材RD和TD的电阻率.轧制态板材RD和TD的电阻率分别为1.81和1.73 μΩ·m,表现出一定的各向异性.随退火温度升高,板材RD和TD的电阻率呈现出截然不同的变化趋势,即板材TD的电阻率逐渐升高,板材RD的电阻率逐渐降低.已知合金元素、显微组织以及织构对合金电阻率有着重要影响[26,27].在本工作中,合金成分是固定的,因此可以排除成分对钛合金电阻率的影响.随退火温度升高,板材组织发生回复再结晶,条带状组织消失.而在板材显微组织变化的同时,α织构也在改变.由图13b可知,两相区退火时,随退火温度升高,T型织构和R型织构体积分数增加;单相区退火时,随退火温度升高,T型织构体积分数急剧减少,主要形成R型织构和B型织构.可以认为,条带状组织及T型织构的存在,使板材表现出一定的电阻率各向异性,条带状组织消失及R型织构体积分数增加,使电阻率各向异性减弱.因此,板材电阻率的变化主要与显微组织和α织构有关. ...

Anisotropy of thermal conductivity and mechanical properties in Mg-5Zn-1Mn alloy

2

2012

... 热处理也能通过改变显微组织和织构影响合金的导电性能.铝合金及铜合金时效热处理后,合金中的溶质原子多以第二相的形式析出,晶格畸变程度减弱,提高了导电率(电阻率降低),这同时也起到了析出强化的作用,有利于改善强度和导电率的制约关系[23~25].对于钛合金而言,一般不强调强度和导电率的制约关系,不同组织类型的差别主要体现在组成相的体积分数、尺寸、分布以及形貌,这些因素在调节强塑性关系时发挥了至关重要的作用,但是它们对导电性能的影响还有待研究.此外,热处理过程中钛合金板材的织构演化对导电性能的影响不可忽略.织构的存在使得材料力学性能的各向异性显著.类似地,当α晶粒存在集中取向时,由于不同晶面的密排程度不同,hcp结构金属的电阻率同样存在各向异性[26,27].以钛合金板材中的T型织构为例,当电流方向平行于板材TD时,电子沿柱面传输,电流方向平行于板材轧向(RD)时,电子沿基面传输,由于电子在不同晶面传输时被原子核散射的几率不同,可以推测板材不同方向的电阻率存在差异,然而目前关于织构对钛合金电阻率的影响机制还不清楚. ...

... 图13a为不同温度退火后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材RD和TD的电阻率.轧制态板材RD和TD的电阻率分别为1.81和1.73 μΩ·m,表现出一定的各向异性.随退火温度升高,板材RD和TD的电阻率呈现出截然不同的变化趋势,即板材TD的电阻率逐渐升高,板材RD的电阻率逐渐降低.已知合金元素、显微组织以及织构对合金电阻率有着重要影响[26,27].在本工作中,合金成分是固定的,因此可以排除成分对钛合金电阻率的影响.随退火温度升高,板材组织发生回复再结晶,条带状组织消失.而在板材显微组织变化的同时,α织构也在改变.由图13b可知,两相区退火时,随退火温度升高,T型织构和R型织构体积分数增加;单相区退火时,随退火温度升高,T型织构体积分数急剧减少,主要形成R型织构和B型织构.可以认为,条带状组织及T型织构的存在,使板材表现出一定的电阻率各向异性,条带状组织消失及R型织构体积分数增加,使电阻率各向异性减弱.因此,板材电阻率的变化主要与显微组织和α织构有关. ...

1

2003

... 图2为Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材原始显微组织的SEM像.板材组织由拉长的α相、等轴α相和β相组成,α相的体积分数为61.85%,β相体积分数为38.15%.不同观察面上的显微组织形貌存在显著差异,RD-ND观察面有2种组织形态:一种是与RD平行的长条状α相为主的组织;另外一种是α等轴组织.αp相和β相在轧制过程中经历剧烈塑性变形后被压扁呈长条状,这些长条状α相和β相排列在一起,形成沿板材RD排列的条带状组织.而RD-TD观察面组织中的部分αp相接近等轴状,晶粒尺寸较大,一部分β相发生扭曲变形,没有观察到明显的条带状组织.这是因为板材组织中的αp相在轧制过程中受到沿板厚方向的挤压,αp相沿法向(ND)被压扁成长条状,而在RD和TD上延展.图3a给出了板材RD-ND面α晶粒的取向成像图,板材α相<0001>//TD取向的含量最高,α晶粒的晶体学c轴趋向于集中指向TD.同时图3b中的(0002)极图显示α相c轴平行于TD,这符合T型织构的特征[28,29].轧制时的应力状态可近似看成板材RD受到拉应力,板材ND受到压应力,结果使得各晶粒的某一晶面和晶向分别趋于与轧面和轧向平行.一般认为,轧制过程中α相的滑移变形机制会影响最终的织构取向[13,30,31],T型织构归因于柱面滑移系{100}<110>作为主要的滑移机制.图3c则显示板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19]. ...

Research situation on the effect of manufacturing process and heat treatment on the titanium alloy sheet texture

1

2015

... 图2为Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材原始显微组织的SEM像.板材组织由拉长的α相、等轴α相和β相组成,α相的体积分数为61.85%,β相体积分数为38.15%.不同观察面上的显微组织形貌存在显著差异,RD-ND观察面有2种组织形态:一种是与RD平行的长条状α相为主的组织;另外一种是α等轴组织.αp相和β相在轧制过程中经历剧烈塑性变形后被压扁呈长条状,这些长条状α相和β相排列在一起,形成沿板材RD排列的条带状组织.而RD-TD观察面组织中的部分αp相接近等轴状,晶粒尺寸较大,一部分β相发生扭曲变形,没有观察到明显的条带状组织.这是因为板材组织中的αp相在轧制过程中受到沿板厚方向的挤压,αp相沿法向(ND)被压扁成长条状,而在RD和TD上延展.图3a给出了板材RD-ND面α晶粒的取向成像图,板材α相<0001>//TD取向的含量最高,α晶粒的晶体学c轴趋向于集中指向TD.同时图3b中的(0002)极图显示α相c轴平行于TD,这符合T型织构的特征[28,29].轧制时的应力状态可近似看成板材RD受到拉应力,板材ND受到压应力,结果使得各晶粒的某一晶面和晶向分别趋于与轧面和轧向平行.一般认为,轧制过程中α相的滑移变形机制会影响最终的织构取向[13,30,31],T型织构归因于柱面滑移系{100}<110>作为主要的滑移机制.图3c则显示板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19]. ...

加工工艺及热处理对钛合金板材织构影响的研究现状

1

2015

... 图2为Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材原始显微组织的SEM像.板材组织由拉长的α相、等轴α相和β相组成,α相的体积分数为61.85%,β相体积分数为38.15%.不同观察面上的显微组织形貌存在显著差异,RD-ND观察面有2种组织形态:一种是与RD平行的长条状α相为主的组织;另外一种是α等轴组织.αp相和β相在轧制过程中经历剧烈塑性变形后被压扁呈长条状,这些长条状α相和β相排列在一起,形成沿板材RD排列的条带状组织.而RD-TD观察面组织中的部分αp相接近等轴状,晶粒尺寸较大,一部分β相发生扭曲变形,没有观察到明显的条带状组织.这是因为板材组织中的αp相在轧制过程中受到沿板厚方向的挤压,αp相沿法向(ND)被压扁成长条状,而在RD和TD上延展.图3a给出了板材RD-ND面α晶粒的取向成像图,板材α相<0001>//TD取向的含量最高,α晶粒的晶体学c轴趋向于集中指向TD.同时图3b中的(0002)极图显示α相c轴平行于TD,这符合T型织构的特征[28,29].轧制时的应力状态可近似看成板材RD受到拉应力,板材ND受到压应力,结果使得各晶粒的某一晶面和晶向分别趋于与轧面和轧向平行.一般认为,轧制过程中α相的滑移变形机制会影响最终的织构取向[13,30,31],T型织构归因于柱面滑移系{100}<110>作为主要的滑移机制.图3c则显示板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19]. ...

Rolling texture and its effect on tensile property of a near-α titanium alloy Ti60 plate

1

2019

... 图2为Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材原始显微组织的SEM像.板材组织由拉长的α相、等轴α相和β相组成,α相的体积分数为61.85%,β相体积分数为38.15%.不同观察面上的显微组织形貌存在显著差异,RD-ND观察面有2种组织形态:一种是与RD平行的长条状α相为主的组织;另外一种是α等轴组织.αp相和β相在轧制过程中经历剧烈塑性变形后被压扁呈长条状,这些长条状α相和β相排列在一起,形成沿板材RD排列的条带状组织.而RD-TD观察面组织中的部分αp相接近等轴状,晶粒尺寸较大,一部分β相发生扭曲变形,没有观察到明显的条带状组织.这是因为板材组织中的αp相在轧制过程中受到沿板厚方向的挤压,αp相沿法向(ND)被压扁成长条状,而在RD和TD上延展.图3a给出了板材RD-ND面α晶粒的取向成像图,板材α相<0001>//TD取向的含量最高,α晶粒的晶体学c轴趋向于集中指向TD.同时图3b中的(0002)极图显示α相c轴平行于TD,这符合T型织构的特征[28,29].轧制时的应力状态可近似看成板材RD受到拉应力,板材ND受到压应力,结果使得各晶粒的某一晶面和晶向分别趋于与轧面和轧向平行.一般认为,轧制过程中α相的滑移变形机制会影响最终的织构取向[13,30,31],T型织构归因于柱面滑移系{100}<110>作为主要的滑移机制.图3c则显示板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19]. ...

Texture of Ti60 alloy precision bars and its effect on tensile properties

1

2015

... 图2为Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材原始显微组织的SEM像.板材组织由拉长的α相、等轴α相和β相组成,α相的体积分数为61.85%,β相体积分数为38.15%.不同观察面上的显微组织形貌存在显著差异,RD-ND观察面有2种组织形态:一种是与RD平行的长条状α相为主的组织;另外一种是α等轴组织.αp相和β相在轧制过程中经历剧烈塑性变形后被压扁呈长条状,这些长条状α相和β相排列在一起,形成沿板材RD排列的条带状组织.而RD-TD观察面组织中的部分αp相接近等轴状,晶粒尺寸较大,一部分β相发生扭曲变形,没有观察到明显的条带状组织.这是因为板材组织中的αp相在轧制过程中受到沿板厚方向的挤压,αp相沿法向(ND)被压扁成长条状,而在RD和TD上延展.图3a给出了板材RD-ND面α晶粒的取向成像图,板材α相<0001>//TD取向的含量最高,α晶粒的晶体学c轴趋向于集中指向TD.同时图3b中的(0002)极图显示α相c轴平行于TD,这符合T型织构的特征[28,29].轧制时的应力状态可近似看成板材RD受到拉应力,板材ND受到压应力,结果使得各晶粒的某一晶面和晶向分别趋于与轧面和轧向平行.一般认为,轧制过程中α相的滑移变形机制会影响最终的织构取向[13,30,31],T型织构归因于柱面滑移系{100}<110>作为主要的滑移机制.图3c则显示板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19]. ...

Ti60合金棒材中的织构及其对拉伸性能的影响

1

2015

... 图2为Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材原始显微组织的SEM像.板材组织由拉长的α相、等轴α相和β相组成,α相的体积分数为61.85%,β相体积分数为38.15%.不同观察面上的显微组织形貌存在显著差异,RD-ND观察面有2种组织形态:一种是与RD平行的长条状α相为主的组织;另外一种是α等轴组织.αp相和β相在轧制过程中经历剧烈塑性变形后被压扁呈长条状,这些长条状α相和β相排列在一起,形成沿板材RD排列的条带状组织.而RD-TD观察面组织中的部分αp相接近等轴状,晶粒尺寸较大,一部分β相发生扭曲变形,没有观察到明显的条带状组织.这是因为板材组织中的αp相在轧制过程中受到沿板厚方向的挤压,αp相沿法向(ND)被压扁成长条状,而在RD和TD上延展.图3a给出了板材RD-ND面α晶粒的取向成像图,板材α相<0001>//TD取向的含量最高,α晶粒的晶体学c轴趋向于集中指向TD.同时图3b中的(0002)极图显示α相c轴平行于TD,这符合T型织构的特征[28,29].轧制时的应力状态可近似看成板材RD受到拉应力,板材ND受到压应力,结果使得各晶粒的某一晶面和晶向分别趋于与轧面和轧向平行.一般认为,轧制过程中α相的滑移变形机制会影响最终的织构取向[13,30,31],T型织构归因于柱面滑移系{100}<110>作为主要的滑移机制.图3c则显示板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19]. ...

1

2010

... Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材退火处理后显微组织的SEM像如图4所示.800℃退火处理后的板材组织(图4a和a1)与图2a轧制态板材组织类似,由拉长的α相、等轴α相和β相组成,仍可观察到明显的条带状组织,但组织中的α相含量减少,部分转变成β相.钛合金轧制变形后,组织中的位错密度快速增加,同时获得了足够高的应变能,这些能量可用来完成后续的回复及再结晶.由于800℃退火时,板材组织仅发生回复,部分存储应变能释放,热激活作用促进了原子扩散,位错密度降低,但不发生大角晶界的迁移,所以晶粒形状与轧制态组织类似,仍有许多畸变晶粒被保留下来[11].经850~920℃退火处理后,板材组织中的αp相均匀分布,αs相从β基体中析出后不断长大,最后与β基体相互交错排列,形成了β转变组织(βt相) (图4b~d1).随着退火温度的升高,原子扩散加剧,应变能进一步释放,在畸变度大的区域以多边化形成的亚晶为基础产生新的无畸变晶粒的核心,然后通过消耗周围的变形基体而长大,原来的畸变晶粒逐渐转变成无畸变的等轴新晶粒,条带状组织逐渐消失[32].而经950~1000℃退火后,板材组织中的αp相消失,β晶粒快速长大粗化,在随后冷却的过程中,αs相从β晶粒内部析出,相同取向的αs相平行排列成α集束,在β晶界处还有晶界α相(αGB相)析出(图4e~f1),最终形成由αs相和β相组成的全片层组织[22]. ...

1

2010

... Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材退火处理后显微组织的SEM像如图4所示.800℃退火处理后的板材组织(图4a和a1)与图2a轧制态板材组织类似,由拉长的α相、等轴α相和β相组成,仍可观察到明显的条带状组织,但组织中的α相含量减少,部分转变成β相.钛合金轧制变形后,组织中的位错密度快速增加,同时获得了足够高的应变能,这些能量可用来完成后续的回复及再结晶.由于800℃退火时,板材组织仅发生回复,部分存储应变能释放,热激活作用促进了原子扩散,位错密度降低,但不发生大角晶界的迁移,所以晶粒形状与轧制态组织类似,仍有许多畸变晶粒被保留下来[11].经850~920℃退火处理后,板材组织中的αp相均匀分布,αs相从β基体中析出后不断长大,最后与β基体相互交错排列,形成了β转变组织(βt相) (图4b~d1).随着退火温度的升高,原子扩散加剧,应变能进一步释放,在畸变度大的区域以多边化形成的亚晶为基础产生新的无畸变晶粒的核心,然后通过消耗周围的变形基体而长大,原来的畸变晶粒逐渐转变成无畸变的等轴新晶粒,条带状组织逐渐消失[32].而经950~1000℃退火后,板材组织中的αp相消失,β晶粒快速长大粗化,在随后冷却的过程中,αs相从β晶粒内部析出,相同取向的αs相平行排列成α集束,在β晶界处还有晶界α相(αGB相)析出(图4e~f1),最终形成由αs相和β相组成的全片层组织[22]. ...

Evolution of microstructure and phase composition of Ti-3Al-5Mo-4.5V alloy with varied β phase stability

1

2018

... 值得注意的是,800℃退火组织中并没有析出αs相,850℃退火后部分β相开始析出αs相,进一步升高退火温度,αs相析出更加充分.由此可见,退火温度会影响αs相的析出行为.αs相的析出主要与β相的稳定性及冷却速率有关[33,34].由于α相转变为β相是一种扩散型相变,相变过程中存在合金元素再分配效应.黄森森等[35]发现,提高固溶温度,发生α→β转变,TC4合金中的β稳定元素沿化学势降低的方向扩散,V元素由αp相中心及相邻β相向αp相边缘扩散,β相中的V含量降低,β稳定性降低,导致TC4合金固溶空冷后析出αs相.因此,升高退火温度,合金元素再分配使得β相中的β稳定元素含量降低,β稳定性随之降低,有利于αs相的析出.另一方面,退火温度越高,在相同冷却速率条件下,需要的冷却时间也越长,也有利于αs相的析出[11]. ...

Influence of thermal treatment on element partitioning in α + β titanium alloy

1

2019

... 值得注意的是,800℃退火组织中并没有析出αs相,850℃退火后部分β相开始析出αs相,进一步升高退火温度,αs相析出更加充分.由此可见,退火温度会影响αs相的析出行为.αs相的析出主要与β相的稳定性及冷却速率有关[33,34].由于α相转变为β相是一种扩散型相变,相变过程中存在合金元素再分配效应.黄森森等[35]发现,提高固溶温度,发生α→β转变,TC4合金中的β稳定元素沿化学势降低的方向扩散,V元素由αp相中心及相邻β相向αp相边缘扩散,β相中的V含量降低,β稳定性降低,导致TC4合金固溶空冷后析出αs相.因此,升高退火温度,合金元素再分配使得β相中的β稳定元素含量降低,β稳定性随之降低,有利于αs相的析出.另一方面,退火温度越高,在相同冷却速率条件下,需要的冷却时间也越长,也有利于αs相的析出[11]. ...

Influence of alloying elements partitioning behaviors on the microstructure and mechanical properties in α + β titanium alloy

1

2019

... 值得注意的是,800℃退火组织中并没有析出αs相,850℃退火后部分β相开始析出αs相,进一步升高退火温度,αs相析出更加充分.由此可见,退火温度会影响αs相的析出行为.αs相的析出主要与β相的稳定性及冷却速率有关[33,34].由于α相转变为β相是一种扩散型相变,相变过程中存在合金元素再分配效应.黄森森等[35]发现,提高固溶温度,发生α→β转变,TC4合金中的β稳定元素沿化学势降低的方向扩散,V元素由αp相中心及相邻β相向αp相边缘扩散,β相中的V含量降低,β稳定性降低,导致TC4合金固溶空冷后析出αs相.因此,升高退火温度,合金元素再分配使得β相中的β稳定元素含量降低,β稳定性随之降低,有利于αs相的析出.另一方面,退火温度越高,在相同冷却速率条件下,需要的冷却时间也越长,也有利于αs相的析出[11]. ...

α + β两相钛合金元素再分配行为及其对显微组织和力学性能的影响

1

2019

... 值得注意的是,800℃退火组织中并没有析出αs相,850℃退火后部分β相开始析出αs相,进一步升高退火温度,αs相析出更加充分.由此可见,退火温度会影响αs相的析出行为.αs相的析出主要与β相的稳定性及冷却速率有关[33,34].由于α相转变为β相是一种扩散型相变,相变过程中存在合金元素再分配效应.黄森森等[35]发现,提高固溶温度,发生α→β转变,TC4合金中的β稳定元素沿化学势降低的方向扩散,V元素由αp相中心及相邻β相向αp相边缘扩散,β相中的V含量降低,β稳定性降低,导致TC4合金固溶空冷后析出αs相.因此,升高退火温度,合金元素再分配使得β相中的β稳定元素含量降低,β稳定性随之降低,有利于αs相的析出.另一方面,退火温度越高,在相同冷却速率条件下,需要的冷却时间也越长,也有利于αs相的析出[11]. ...

Texture heterogeneities induced by subtransus processing of near α titanium alloys

2

2008

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... ,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

Texture and microtexture variations in a near-α titanium forged disk of bimodal microstructure

1

2012

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

Effect of special primary α grain on variant selection of secondary α phase in a near-α titanium alloy

1

2020

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

In situ neutron diffraction study of texture evolution and variant selection during the α→β→α phase transformation in Ti-6Al-4V

2

2012

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... 在β单相区退火后,钛合金板材中的αp相完全消失,获得了全片层组织,板材中的T型织构消失,同时形成了R型织构和近B型织构(图6e和f).理论上,在α→β→α相变过程中,将生成6种不同取向的β变体,每个β晶粒内部可生成12种不同取向的αs变体[15,18,40,41],最终α相织构强度将大大降低.然而,实际上Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材经β单相区退火后α相织构依然明显,说明α→β→α转变时存在变体选择.Yang等[42]从热力学角度出发,认为变体选择的实质是形成某一αs变体时系统能量降低更多,从而表现为α相的局部择优取向生长.图9给出了1000℃退火处理后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材α相和β相的织构分析.由于Burgers关系,β晶粒内的αs变体之间满足5类取向差[43,44],即10°/<0001>、60°/<110>、60.83°/<1.377 2.377 0.359>、63.26°/<10 5 5 >和90°/<1 2.38 1.38 0>.与本工作观察到的现象相符,见图9a.此外,α相和β相保持良好的Burgers取向关系(图9b和c),可以观察到β相的<110>晶向在RD以及沿ND向RD偏转20°~30°处存在集中取向.这种在单相区退火后形成的β织构(RD//<110>)在TC4合金中也有报道,分析认为β晶粒可以通过Burgers取向关系继承α相的取向[18,20,21,39,45],还可能是β再结晶形成了新织构[14,19].另有研究[15,40]表明,当β相存在较强的<110>织构时,相邻β晶粒共有<110>方向的概率增大,β晶界的界面能较低,c轴平行于<110>方向的α相变体在β晶界两侧择优析出.随机选取了2类αGB相的子集(图9d和g),并给出了相应αGB相的(0001)极图(图9e和h)和β相的(110)极图(图9f和i).可以看到,αGB相的<0001>晶向在板材ND向RD偏转20°~30°以及RD处存在集中取向,这与图9b相符.由于板材在单相区退火后β相存在多种织构取向,这意味着板材组织中存在许多共有<110>晶向的β晶粒对,因而在冷却的过程中,αs相首先在这些β晶粒对的界面处形核,随后向界面两侧生长,由于这些αs相取向相近,在单相区退火后α相织构依然明显. ...

The role of crystallographic and geometrical relationships between α and β phases in an α/β titanium alloy

3

2003

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... 在β单相区退火后,钛合金板材中的αp相完全消失,获得了全片层组织,板材中的T型织构消失,同时形成了R型织构和近B型织构(图6e和f).理论上,在α→β→α相变过程中,将生成6种不同取向的β变体,每个β晶粒内部可生成12种不同取向的αs变体[15,18,40,41],最终α相织构强度将大大降低.然而,实际上Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材经β单相区退火后α相织构依然明显,说明α→β→α转变时存在变体选择.Yang等[42]从热力学角度出发,认为变体选择的实质是形成某一αs变体时系统能量降低更多,从而表现为α相的局部择优取向生长.图9给出了1000℃退火处理后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材α相和β相的织构分析.由于Burgers关系,β晶粒内的αs变体之间满足5类取向差[43,44],即10°/<0001>、60°/<110>、60.83°/<1.377 2.377 0.359>、63.26°/<10 5 5 >和90°/<1 2.38 1.38 0>.与本工作观察到的现象相符,见图9a.此外,α相和β相保持良好的Burgers取向关系(图9b和c),可以观察到β相的<110>晶向在RD以及沿ND向RD偏转20°~30°处存在集中取向.这种在单相区退火后形成的β织构(RD//<110>)在TC4合金中也有报道,分析认为β晶粒可以通过Burgers取向关系继承α相的取向[18,20,21,39,45],还可能是β再结晶形成了新织构[14,19].另有研究[15,40]表明,当β相存在较强的<110>织构时,相邻β晶粒共有<110>方向的概率增大,β晶界的界面能较低,c轴平行于<110>方向的α相变体在β晶界两侧择优析出.随机选取了2类αGB相的子集(图9d和g),并给出了相应αGB相的(0001)极图(图9e和h)和β相的(110)极图(图9f和i).可以看到,αGB相的<0001>晶向在板材ND向RD偏转20°~30°以及RD处存在集中取向,这与图9b相符.由于板材在单相区退火后β相存在多种织构取向,这意味着板材组织中存在许多共有<110>晶向的β晶粒对,因而在冷却的过程中,αs相首先在这些β晶粒对的界面处形核,随后向界面两侧生长,由于这些αs相取向相近,在单相区退火后α相织构依然明显. ...

... ,40]表明,当β相存在较强的<110>织构时,相邻β晶粒共有<110>方向的概率增大,β晶界的界面能较低,c轴平行于<110>方向的α相变体在β晶界两侧择优析出.随机选取了2类αGB相的子集(图9d和g),并给出了相应αGB相的(0001)极图(图9e和h)和β相的(110)极图(图9f和i).可以看到,αGB相的<0001>晶向在板材ND向RD偏转20°~30°以及RD处存在集中取向,这与图9b相符.由于板材在单相区退火后β相存在多种织构取向,这意味着板材组织中存在许多共有<110>晶向的β晶粒对,因而在冷却的过程中,αs相首先在这些β晶粒对的界面处形核,随后向界面两侧生长,由于这些αs相取向相近,在单相区退火后α相织构依然明显. ...

Effect of β (110) texture intensity on α-variant selection and microstructure morphology during β→α phase transformation in near α titanium alloy

2

2017

... 在α + β两相区热处理,随退火温度升高,αp相体积分数降低,而析出的αs相增多.此时,T型织构仍是主要的织构类型,但同时也形成了R型织构.由此可知,新织构的出现与呈多种取向的αs相有关.理论上,在β基体中应该随机析出αs相变体,但相邻β晶粒的<110>取向比较接近时,αs相将从β晶界择优析出[12,13].此外,Zhao等[16]发现β相被大量αp相包围后,冷却过程中β→α相变形成的αs相与周围的αp相有相近的取向.Germain等[17,36]和Gey等[37]在IMI 834合金中还观察到一些“宏区”内部αp相与αs相的(0001)面互相平行,这说明αp相可以为αs相提供形核位置,降低形核的能量.即R型织构的出现与β织构和αp相的取向有关[12,13,16,36~38].为了明确热处理过程中R型织构的形成机制,对920℃退火处理的板材进行了EBSD分析,如图8所示.由图3c可知,原始态板材β相存在{100}<110>织构,这与TC4合金中观察到的β变形织构类似[14,19,39].在热处理过程中,新生成的β相优先在原有β相处形核长大[14],所以在920℃退火后,退火态板材β织构与原始态板材的β织构相似(图8a).当板材存在较强的<110>//RD织构时,相邻β晶粒共有<110>晶向的概率增大,β/β界面处发生变体选择的概率增大,易析出<0001>//RD取向的αs相,形成R型织构[15,18,40,41].图8b和c分别为EBSD观察区域的前置背散射探头(fore scatter diodes,FSD)成像图以及α相的取向成像图.由图可见,920℃退火板材中取向为<0001>//TD的αp相(图8c中的取向Ⅰ)占据主导,但还存在<0001>//RD的αp相(图8c中的取向Ⅱ、Ⅲ及Ⅳ).当αp相和β相满足Burgers关系时(图7d、图8a),β晶粒的<110>晶向与周围αp相的c轴方向相近,在α/β相边界成核的αs相的c轴方向将接近相邻αp相的c轴方向以减小形核能[13,16].取向为<0001>//RD的αp相附近将择优析出<0001>//RD的αs相.由此可见,β相织构和αp相的取向是α + β两相区热处理后形成R型织构不可忽略的因素. ...

... 在β单相区退火后,钛合金板材中的αp相完全消失,获得了全片层组织,板材中的T型织构消失,同时形成了R型织构和近B型织构(图6e和f).理论上,在α→β→α相变过程中,将生成6种不同取向的β变体,每个β晶粒内部可生成12种不同取向的αs变体[15,18,40,41],最终α相织构强度将大大降低.然而,实际上Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材经β单相区退火后α相织构依然明显,说明α→β→α转变时存在变体选择.Yang等[42]从热力学角度出发,认为变体选择的实质是形成某一αs变体时系统能量降低更多,从而表现为α相的局部择优取向生长.图9给出了1000℃退火处理后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材α相和β相的织构分析.由于Burgers关系,β晶粒内的αs变体之间满足5类取向差[43,44],即10°/<0001>、60°/<110>、60.83°/<1.377 2.377 0.359>、63.26°/<10 5 5 >和90°/<1 2.38 1.38 0>.与本工作观察到的现象相符,见图9a.此外,α相和β相保持良好的Burgers取向关系(图9b和c),可以观察到β相的<110>晶向在RD以及沿ND向RD偏转20°~30°处存在集中取向.这种在单相区退火后形成的β织构(RD//<110>)在TC4合金中也有报道,分析认为β晶粒可以通过Burgers取向关系继承α相的取向[18,20,21,39,45],还可能是β再结晶形成了新织构[14,19].另有研究[15,40]表明,当β相存在较强的<110>织构时,相邻β晶粒共有<110>方向的概率增大,β晶界的界面能较低,c轴平行于<110>方向的α相变体在β晶界两侧择优析出.随机选取了2类αGB相的子集(图9d和g),并给出了相应αGB相的(0001)极图(图9e和h)和β相的(110)极图(图9f和i).可以看到,αGB相的<0001>晶向在板材ND向RD偏转20°~30°以及RD处存在集中取向,这与图9b相符.由于板材在单相区退火后β相存在多种织构取向,这意味着板材组织中存在许多共有<110>晶向的β晶粒对,因而在冷却的过程中,αs相首先在这些β晶粒对的界面处形核,随后向界面两侧生长,由于这些αs相取向相近,在单相区退火后α相织构依然明显. ...

Variant selection of β→α phase transformation in titanium alloys

1

2014

... 在β单相区退火后,钛合金板材中的αp相完全消失,获得了全片层组织,板材中的T型织构消失,同时形成了R型织构和近B型织构(图6e和f).理论上,在α→β→α相变过程中,将生成6种不同取向的β变体,每个β晶粒内部可生成12种不同取向的αs变体[15,18,40,41],最终α相织构强度将大大降低.然而,实际上Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材经β单相区退火后α相织构依然明显,说明α→β→α转变时存在变体选择.Yang等[42]从热力学角度出发,认为变体选择的实质是形成某一αs变体时系统能量降低更多,从而表现为α相的局部择优取向生长.图9给出了1000℃退火处理后Ti-6Al-3Mo-2V-1Cr-2Sn-2Zr合金板材α相和β相的织构分析.由于Burgers关系,β晶粒内的αs变体之间满足5类取向差[43,44],即10°/<0001>、60°/<110>、60.83°/<1.377 2.377 0.359>、63.26°/<10 5 5 >和90°/<1 2.38 1.38 0>.与本工作观察到的现象相符,见图9a.此外,α相和β相保持良好的Burgers取向关系(图9b和c),可以观察到β相的<110>晶向在RD以及沿ND向RD偏转20°~30°处存在集中取向.这种在单相区退火后形成的β织构(RD//<110>)在TC4合金中也有报道,分析认为β晶粒可以通过Burgers取向关系继承α相的取向[18,20,21,39,45],还可能是β再结晶形成了新织构[14,19].另有研究[15,40]表明,当β相存在较强的<110>织构时,相邻β晶粒共有<110>方向的概率增大,β晶界的界面能较低,c轴平行于<110>方向的α相变体在β晶界两侧择优析出.随机选取了2类αGB相的子集(图9d和g),并给出了相应αGB相的(0001)极图(图9e和h)和β相的(110)极图(图9f和i).可以看到,αGB相的<0001>晶向在板材ND向RD偏转20°~30°以及RD处存在集中取向,这与图9b相符.由于板材在单相区退火后β相存在多种织构取向,这意味着板材组织中存在许多共有<110>晶向的β晶粒对,因而在冷却的过程中,αs相首先在这些β晶粒对的界面处形核,随后向界面两侧生长,由于这些αs相取向相近,在单相区退火后α相织构依然明显. ...

Variant selection and intervariant crystallographic planes distribution in martensite in a Ti-6Al-4V alloy

1

2014