镍基高温合金因其优异的高温强度和抗蠕变性能已被广泛应用于燃气轮机、航空航天等领域。定向凝固技术使得晶体沿着特定的方向生长,消除了大部分甚至全部的横向晶界,获得镍基柱状高温合金和镍基单晶高温合金,极大提高了材料的高温力学性能[1]。研究表明,在镍基高温合金制造过程中,添加元素Al、Cr、Ta等元素可以显著提高固相线温度,增强γ和γ'相的热稳定性,并降低层错能,促进其蠕变性能的提高[2,3];同时也可以稳定γ和γ'的共格界面,调整γ和γ'相的晶格错配度及γ'相的体积分数,获得更加优异的综合力学性能[4]。然而,合金元素的大量添加,尤其是Mo、Ta、W及Re等,会导致定向凝固微观偏析的加剧[5],使合金中共晶组织、碳化物、拓扑密堆(TCP)相等第二相析出增多,使枝晶干与枝晶间γ和γ'相的成分与共格界面稳定性受到影响,严重影响合金的综合性能[6,7]。改善合金定向凝固组织,如细化一次枝晶间距,减小共晶组织,改善γ'相尺寸和形状,调整晶界碳化物的含量、形状和分布等,是提高镍基单晶高温合金综合力学性能的重要手段[8]。目前改善镍基高温合金微观组织的常用方法是采用先进的定向凝固技术,如液态金属冷却(LMC)[9]、区域熔化液态金属冷却(ZMLMC)[10]、向下定向凝固(DWDS)[11]等,来提高定向凝固过程中铸件凝固界面前沿的温度梯度。然而,目前定向凝固技术的发展已达到现有科技水平的极限。

近些年,超导强磁体技术的发展使得利用磁场调控定向凝固合金组织成为可能。强磁场是一种非接触性的物理场,可以在无接触物质的情况下,在宏观、介观以及微观多尺度上改变物质的热力学和动力学行为,是调控高温合金定向凝固微观组织的一种新型有效手段[12]。研究[13,14]发现,静磁场不仅能抑制熔体流动,而且在一定条件下能产生热电磁力(糊状区内温度梯度引发热电流,并与磁场发生作用),该电磁力作用于糊状区液相,促使液相产生新的流动,即热电磁对流。热电磁对流现象的产生能细化一次枝晶间距,降低微观偏析程度[15,16]。同时,磁场的施加还可以显著减小γ'相的尺寸,降低碳化物与γ/γ'共晶的含量[17,18]。此外,研究[19,20]发现,在较低的抽拉速率下,强磁场的施加会破坏枝晶生长,促使柱状晶向等轴晶转变(columnar to equiaxed transition,CET),且临界转变磁场强度与抽拉速率呈正比,与温度梯度呈反比。然而,Ren等[21]研究表明,虽然磁场会在一定程度上破坏镍基单晶高温合金枝晶的完整性,但由磁场带来的成分偏析程度的降低仍使合金的高温蠕变性能显著提升。He等[22~24]以二元Al-Cu合金为研究对象,明确了稳恒磁场下凝固过程中磁场的多种效应对微观偏析的作用机制,获得了可用于磁场下微观偏析预测的数学模型。但目前,磁场细化一次枝晶间距的机理仍存在争议,且磁场对枝晶尺度内元素的分配系数的影响鲜有研究。

DD98M是在DD98合金的基础上通过调整Al、Ti等含量而设计的一种无Re第二代单晶高温合金,具有高强度、低成本和良好的高温力学性能等特点,已广泛应用于航空发动机、高压涡轮叶片等制造业领域[25,26]。目前关于DD98M合金的研究仅局限于无磁场下的微观组织和力学性能的探究,而磁场作用下DD98M的定向凝固组织以及元素的微观偏析还未见报道。因此,本工作以DD98M合金为研究对象,首先探究定向凝固过程中纵向静磁场对DD98M合金定向凝固组织(如一次枝晶间距、共晶组织以及γ'相)的影响规律,并在现有理论基础上进一步揭示其作用机理;接着通过多种成分采集方式全方位剖析磁场对微观偏析的影响,通过引入凝固曲线和有效分配系数阐释磁场对微观偏析的影响机制,为利用强磁场提升DD98M镍基单晶高温合金性能的技术方案提供理论依据。

1 实验方法

实验所使用的DD98M合金的化学成分(质量分数,%)为:Al 5.14,Cr 7.67,Co 7.32,Ta 5.32,Ti 1.02,Mo 2.31,W 6.76,Ni余量。DD98M母合金为直径100 mm、高度350 mm的棒状铸锭。用线切割技术在铸锭上截取直径10 mm、高度120 mm的圆柱试样作为定向凝固的初始试样。初始试样经砂纸表面打磨和丙酮清洗后装入内径为10 mm、厚度为3 mm的双通刚玉管(作为坩埚)中。采用高温胶将刚玉坩埚组件与316L不锈钢材质的凸台粘结,并装入定向凝固炉中。

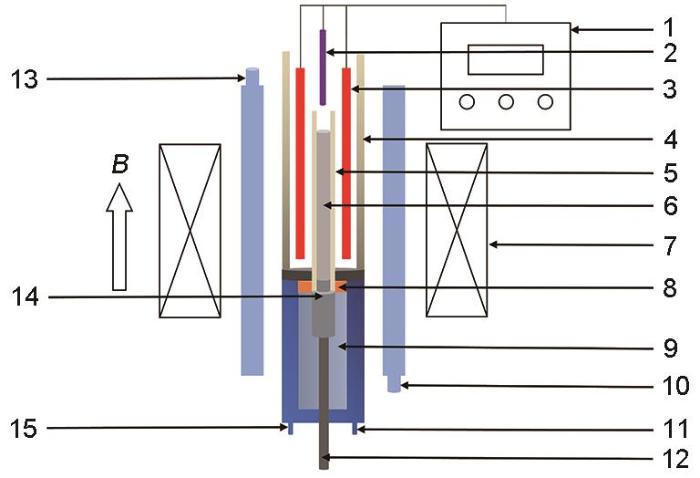

本工作所采用的定向凝固炉为自制立式配有强纵向磁场发生装置的LMC定向凝固炉,如图1所示。强磁场由超导磁体提供,最大磁场强度可达14 T。定向凝固采取Bridgman法,抽拉速率可在0.5~10000 µm/s范围内调节。加热元件为石墨碳管,用719P高精度PID温控仪与B型热电偶控制加热炉内温度,精确度为±1℃。采用液态Ga-In-Sn作为金属冷却介质,并通过在金属液池壁周围安装冷却水和在加热区与液态金属之间放置钢玉片和耐火石棉来维持工作过程中液态金属温度的稳定。每个样品首先被逐步升温至1500℃,并在该温度下保持30 min以保证合金完全融化,然后分别在0、0.5、2和4 T磁场强度(B)下以100 μm/s的速率将凸台与刚玉管坩埚组件一并向下拉出并浸入液态金属液中,完成定向凝固。

图1

图1

强磁场液态金属冷却(LMC) Bridgman定向凝固装置示意图

Fig.1

Schematic of liquid metal cooling (LMC) Bridgman directional solidification apparatus with a high static magnetic field (1—temperature control system; 2—thermocouples; 3—heating element; 4—heating element protection cover; 5—double pass corundum tube; 6—alloy; 7—superconductor magnet; 8—LMC seal; 9—Ga-In-Sn liquid metal; 10—water cooling protection cover water outlet; 11—LMC water outlet; 12—drawbar; 13—water cooling protection cover water inlet; 14—bumper; 15—LMC water inlet)

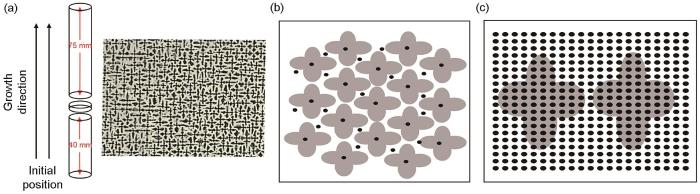

实验结束后,在已制备的合金试样40 mm高度处截取横截面,用于微观组织与成分偏析分析,如图2a所示。蚀刻剂由CuSO4 (4 g)、HCl (20 mL)、H2SO4 (12 mL)和H2O (25 mL)组成。采用DM6000金相显微镜(OM)观察凝固组织。一次枝晶间距(λ)采用面积计数法测量,即λ = (A / N)0.5,其中A为所选横截面区域的面积,N为所选横截面区域中初级枝晶的平均数量。使用Quanta 450型扫描电镜(SEM)观察腐蚀后的枝晶间与枝晶干的强化相γ'的形貌。γ'相的尺寸(L)使用公式L = (ST / M)0.5进行计算,其中ST为显微视野中γ'相的累积总面积,M为该视野下γ'相的总数量。

图2

图2

金相分析取样示意图以及不同模式EDS取点示意图

Fig.2

Schematic of the sampling location (a), EDS analysis of spot scanning in interdendritic and dendritic areas (b), and EDS analysis of matrix pattern (c)

采用SEM上附带的EDAX-Octance plus能谱仪(EDS)进行微观成分分析。采用2种数据采集模式对微观偏析规律进行分析:第1种是枝晶干/枝晶间固定取点模式,如图2b所示,在合适倍数下对每个试样选取5个不同位置的视场,并保证每个视场中完整枝晶的数量超过20个,然后分别计算枝晶干和枝晶间的元素浓度(CS)的平均值,2者之比即为元素的偏析系数;第2种为随机取样模式,即矩阵扫描法,在试样中心位置,对含2个完整枝晶的视场按矩阵分布采集20 × 20个位置点的元素浓度数据,如图2c所示。基于此数据,若某元素的浓度按对应的原始空间位置显示可以获得该元素的空间分布规律,对该数据进行一定方式的处理则可近似获得枝晶尺度上各溶质元素的分布曲线。获取元素分布曲线的处理方式如下:首先计算各位置点的溶质元素的相对浓度(CS / C0,C0为元素初始浓度),并选取某个代表性元素(偏析显著的元素)为基准,根据该元素相对浓度的大小对各位置点进行升序或降序排列;再从前至后依次为每一个位置点分配一个对应的序号i (区间1~N,N为位置点总数,N = 400),并对该序号进行归一化处理得[27]:

其中,fs (i)代表i点的固相率,序号1为凝固起点(fs ≈ 0),序号N为凝固终点(fs ≈ 1)。按此方式,i点某元素的CS / C0与其fs一一对应,即获得了该元素在凝固过程中的浓度分布曲线。

2 结果与讨论

2.1 磁场对微观组织的影响

式中,Bmax为临界磁场强度。

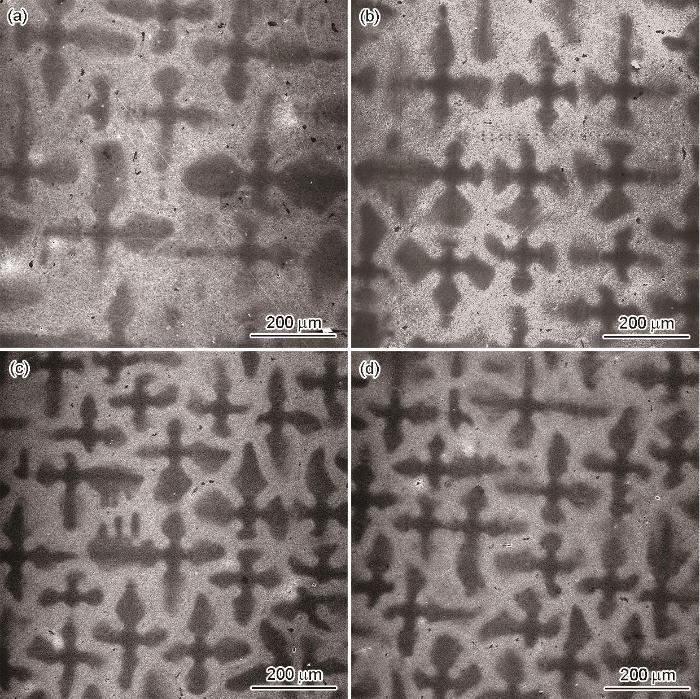

图3

图3

磁场对定向凝固DD98M合金枝晶组织的影响

Fig.3

SEM images showing the dendritic morphologies of transverse sections of directionally solidified DD98M alloy under magnetic field intensities of B = 0 T (a), B = 0.5 T (b), B = 2 T (c), and B = 4 T (d)

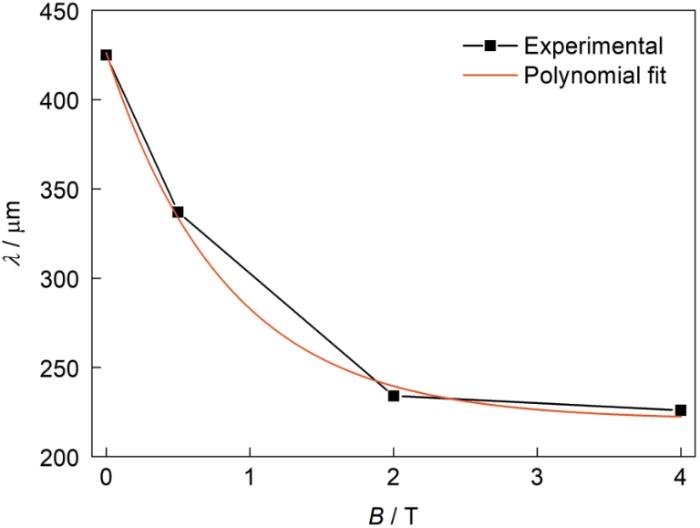

图4

图4

抽拉速率100 μm/s时磁场强度(B)对一次枝晶间距(λ)的影响

Fig.4

Effect of B on the primary dendrite arm spacing (λ) under withdraw rate 100 μm/s

Whitesell等[28]研究表明,在相同温度梯度和冷却速率的情况下,熔体对流是影响定向凝固组织一次枝晶间距的主要因素。本工作中保温温度和抽拉速率相同,磁场是唯一的变量,因此,一次枝晶间距的降低归因于磁场对熔体流动的影响。

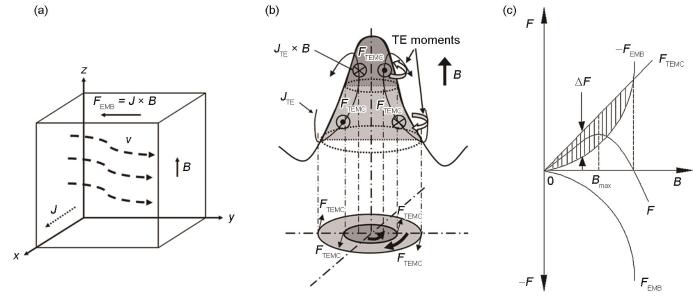

定向凝固过程中磁场对熔体流动的影响主要体现在2个方面:其一是流动的导电熔体在磁场作用下感生电流,并与磁场相互作用产生Lorentz力,该电磁力抑制熔体运动,产生电磁制动(EMB)[29,30],并对熔体产生作用力,为磁阻尼力(FEMB),如图5a所示;其二是凝固界面处枝晶与周围熔体因Seebeck系数不同以及纵向温度梯度的存在产生了热电效应。因此,枝晶周围的熔体在磁场下受到Lorentz力,从而引发热电磁对流(TEMC)[31],TEMC对熔体产生的力为热电磁力(FTEMC),如图5b[32]所示。FEMB是关于B2的函数,而FTEMC与B成正比。若促使熔体流动的力为正值,抑制流动的力为负值,则FTEMC和FEMB的共同作用产生的合力(ΔF)与磁场强度的关系如图5c[33]所示。熔体流速(或ΔF)先随磁场强度的增大而增大,此阶段热电磁效应占据主导;当达到某一临界磁场强度后流速随磁场强度的增大而降低,此阶段磁阻尼效应占据主导;当磁场强度达到临界值时,TEMC与EMB平衡,流速达到最大。根据Li等[32]的研究,Bmax表示如下:

式中,ρ为合金液体的密度,SL和SS分别为液体和固体的Seebeck系数,l为枝晶尺寸,σ为液体电导率,G为温度梯度。当B = Bmax时,ΔF达到最大,界面的湍流和不稳定性也达到最大。本课题组前期工作[34]估算了镍基单晶高温合金在LMC定向凝固过程中保温温度为1500℃时Bmax = 5.4 T。本工作采用的最高磁场为4 T,小于镍基高温合金的Bmax,因此本工作DD98M合金定向凝固过程主要受热电磁力影响。

图5

图5

磁阻尼力(FEMB)和热电磁力(FTEMC)的产生机制示意图以及2者与磁场强度的函数关系[32,33]

Fig.5

Sketches of generation mechanism of magnetic damping force (FEMB) (a) and thermoelectric-magnetic force(FTEMC)[32] (b); and variations of FEMB and FTEMC as a function of B[33] (c) (v—liquid velocity field, J—induced current, JTE—induced currents from the thermoelectric (TE) effect, F = FEMB + FTEMC, ΔF—difference between FEMB and FTEMC, Bmax—critical magnetic field intensity)

Curreri等[35]研究表明,一次枝晶间距与定向凝固过程中枝晶间熔体的过冷密切相关,增加熔体的流动(如超重引起的强自然对流)会增大枝晶间熔体的过冷度,降低一次枝晶间距。因此,本工作所施加的磁场在枝晶周围产生的热电磁对流有利于增加枝晶间的溶质向外运输,减小枝晶间熔体的溶质富集,从而增大枝晶间熔体的过冷度,进而减小一次枝晶间距。此外,根据Kurz-Fisher高速生长范围模型(经计算,LMC法制备镍基高温合金时,模型中临界固/液界面移动速率

结合

因此,根据上述分析,磁场细化一次枝晶间距的根本原因是枝晶间产生了热电磁对流。但热电磁对流引起的一次枝晶间距变化的直接原因尚无定论,可能是由于热电磁对流引起的枝晶间熔体过冷度的增加,也可能是由于G的升高或ΔT'的降低。

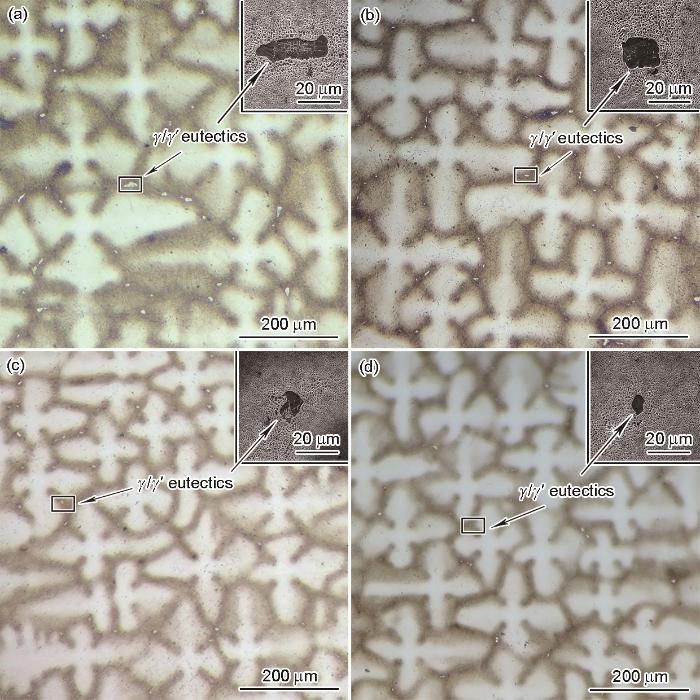

根据传统凝固理论,随着凝固的进行,溶质元素由固相向液相排出(溶质分配系数k < 1),导致后凝固的枝晶间区域产生不同元素的富集,从而易形成共晶组织。图6为不同磁场强度下DD98M合金中共晶组织的OM像和SEM像。可见,随着磁场强度的增加,共晶组织平均尺寸减小,但磁场对共晶组织的形貌无明显影响。上述现象的产生归因于磁场作用下枝晶间距的细化缩短了固相溶质逆扩散路径长度,降低了合金均匀化的时间,再加上细化组织的微观偏析程度更低,共晶组织的含量与平均尺寸进一步降低。

图6

图6

不同磁场强度下定向凝固DD98M合金横截面共晶组织的OM像和SEM像

Fig.6

OM images showing the γ/γ' eutectic in transverse sections of directionally solidified DD98M alloy under B = 0 T (a), B = 0.5 T (b), B = 2 T (c), and B = 4 T (d) (Insets show the locally enlarged SEM images)

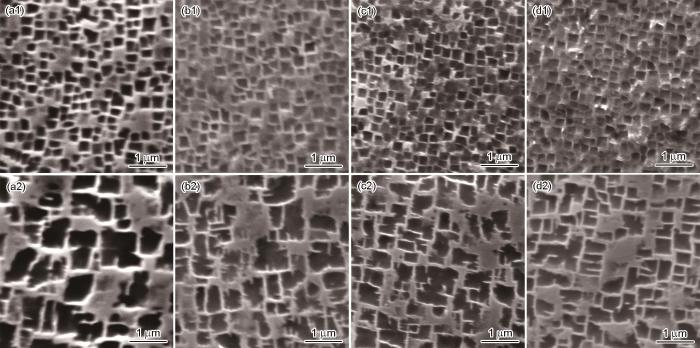

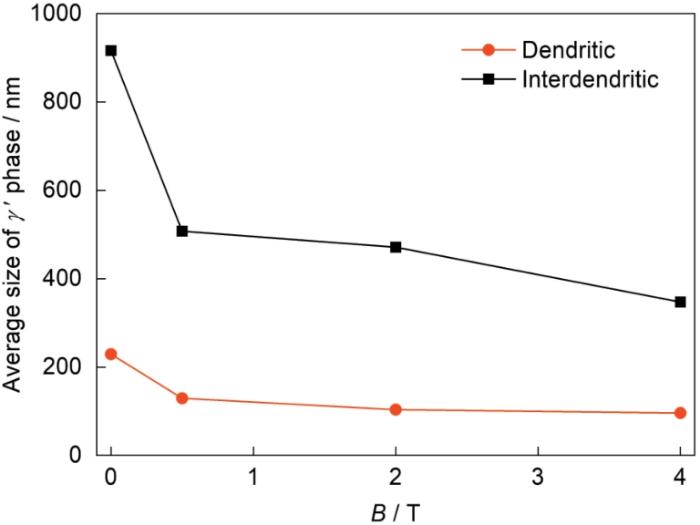

图7

图7

不同磁场强度下定向凝固DD98M合金横截面枝晶干与枝晶间γ'相组织的SEM像

Fig.7

SEM images of γ' phase dendritic areas (a1-d1) and interdendritic areas (a2-d2) in transverse sections of directionally solidified DD98M alloy under B = 0 T (a1, a2), B = 0.5 T (b1, b2), B = 2 T (c1, c2), and B = 4 T (d1, d2)

图8

2.2 磁场对微观偏析的影响

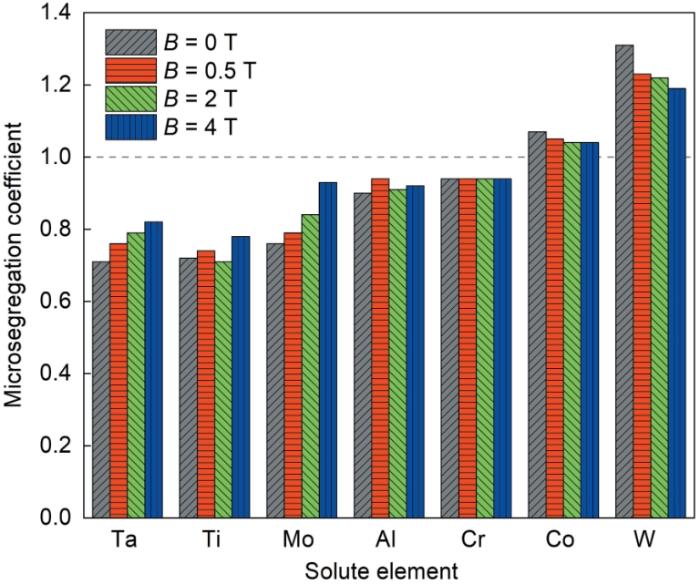

图9

图9

不同磁场强度下各溶质元素的微观偏析系数

Fig.9

Microsegregation coefficients of each alloying element under different B

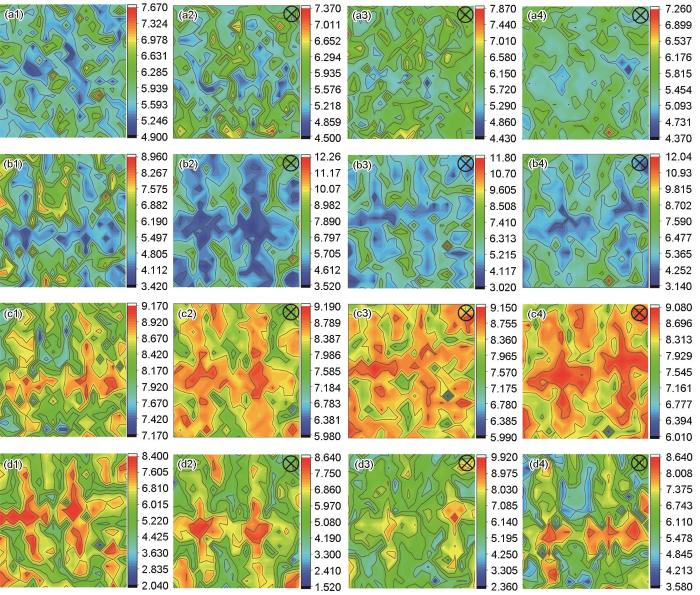

图10

图10

不同磁场强度下定向凝固DD98M合金横截面Al、Ta、Co、W元素分布的等高线图

Fig.10

Isoconcentration contour maps of Al (a1-a4), Ta (b1-b4), Co (c1-c4), and W (d1-d4) in the transverse section of directionally solidified DD98M alloy under B = 0 T (a1-d1), B = 0.5 T (a2-d2), B = 2 T (a3-d3), and B = 4 T (a4-d4) (Color bars in Figs.10a1-a4, b1-b4, c1-c4, and d1-d4 indicate the mass fractions of Al, Ta, Co, and W, respectively)

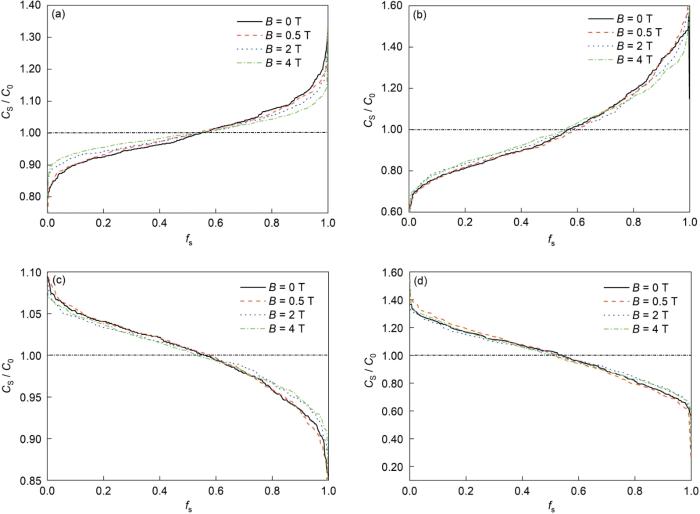

图11

图11

枝晶尺度上不同磁场强度下定向凝固DD98M合金中Al、Ta、Co、W元素的溶质浓度分布曲线

Fig.11

Concentration profiles of Al (a), Ta (b), Co (c), and W (d) of directionally solidified DD98M alloy under different B on dendritic scale (CS—solid composition, C0—original composition, CS / C0—relative solute concentration, fs—solid fraction)

凝固过程是由枝晶干核心逐步向枝晶间发展的,元素分布曲线反应了凝固各阶段元素的偏析规律。Shell方程[41]描述了CS / C0与k0以及fs之间的关系,方程如下:

实际凝固过程往往是一个非平衡凝固过程,通常采用有效分配系数(ke)来描述界面上溶质再分配规律。ke能够反映流动、液相扩散和生长速率等对微观偏析的影响[42]。使用ke代替k0,并两边同时取对数,

图12

图12

不同磁场强度下各溶质元素ln(CS / C0)与ln(1 - fs)关系图

(a) Al (b) Ta (c) Co (d) W

Fig.12

Relationships between ln(CS / C0) and ln(1 - fs) under different B ( fcritical—critical solid fraction ratio)

表1 不同磁场强度下枝晶干边界临界固相率统计

Table 1

| B / T | Mall | Mdendritic | fcritical / % |

|---|---|---|---|

| 0 | 400 | 146 | 0.365 |

| 0.5 | 400 | 135 | 0.338 |

| 2 | 400 | 150 | 0.375 |

| 4 | 400 | 139 | 0.348 |

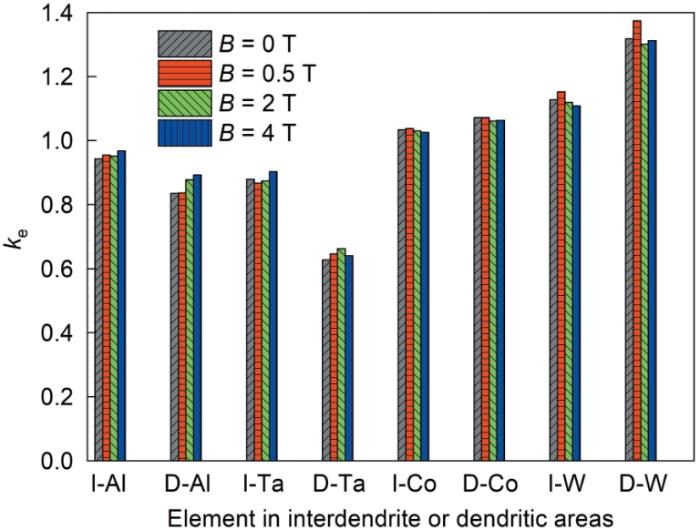

根据枝晶干边界临界固相率,在元素分配曲线上划分了枝晶干凝固阶段和枝晶间凝固阶段,如图12所示。由图可知,凝固过程中随着固相率的增加,元素的ke更加趋于1,且枝晶间的ke变化较为平缓,而枝晶干的ke变化则相对较大。这是由于在凝固前期,即枝晶干区域,凝固速率相对较慢但凝固速率变化较快,因此凝固更接近平衡凝固,ke整体更接近k0 (即更远离1),且变化率较大。而凝固后期枝晶间区域熔体温度较低,凝固速率加快,ke整体更接近于1。图13统计了不同磁场下不同溶质元素在枝晶间与枝晶干的平均ke。图12和13都表明了随着磁场强度的增加,凝固各阶段的ke都更趋于1。因此,磁场改善溶质元素偏析的本质就是磁场使元素的ke更接近于1。

图13

图13

磁场强度对枝晶间与枝晶干各溶质元素的平均有效分配系数的影响

Fig.13

Effects of B on the average effective partition coefficients (ke) of solute elements in interdendritic (I) and dendritic (D) areas

3 结论

(1) 纵向静磁场使DD98M合金定向凝固组织一次枝晶间距显著降低,共晶组织平均尺寸减小,此现象产生的原因为热电磁力作用于枝晶间熔体,产生了热电磁对流,加剧了熔体的流动,引起ΔT' / G的降低或枝晶间熔体过冷度的增大。

(2) 磁场使枝晶间与枝晶干γ'相的尺寸减小,促进枝晶间的γ'相逐渐规则化,其主要原因是磁场作用下γ'相磁自由能差的引入,降低了γ'相的形核激活能。

(3) 磁场能显著降低合金元素的微观偏析,其本质是磁场使枝晶间与枝晶干的平均有效分配系数更趋近于1。

参考文献

Recent progress in research and development of nickel-based single crystal superalloys

[J].

镍基单晶高温合金的研发进展

[J].

The microstructure and hardness of Ni-Co-Al-Ti-Cr quinary alloys

[J].

The coarsening behavior of γ′ phases in Ni-Al binary model single crystal superalloy at 1000oC

[J].

Optimal precipitate shapes in nickel-base γ-γ′ alloys

[J].

Segregation of elements in high refractory content single crystal nickel based superalloys

[A].

The relative effects of chromium, molybdenum, tungsten, and tantalum on the occurrence of σ phase in cast Ni-Co-Cr alloys

[J].

Interdendritic Mo homogenization and sub-solidus melting during solution treatment in the Mo-strengthening single crystal superalloys

[J].

Formation mechanism of stray grain of nickel-based single-crystal superalloy under a high magnetic field during directional solidification

[J].

Structure refinement by a liquid metal cooling solidification process for single-crystal nickel-base superalloys

[J].

Microstructure and stress rupture properties of single crystal superalloy CMSX-2 under high thermal gradient directional solidification

[J].

Effect of local cooling rates on the microstructures of single crystal CMSX-6 superalloy: A comparative assessment of the Bridgman and the downward directional solidification processes

[J].

New study and development on electromagnetic field technology in metallurgical processes

[J].Electromagnetic metallurgy technology is an essential method of high quality steel production. This article reviews the development of electromagnetic metallurgy technology in recent years, focusing on the whole process of continuous casting, including electromagnetic purification of steel in tundish, nozzle flow control, mould electromagnetic stirring and electromagnetic brake, flow field control via magnetic field, electromagnetic soft contact electromagnetic continuous casting, electromagnetic field regulation of solidification structure, solid phase transformation and microstructure control under electromagnetic field, the mechanism of electromagnetic field action is explained, the principle and characteristics of electromagnetic field technology are analyzed, and the concept of multi-mode magnetic field is proposed in the field of flow field control by using electromagnetic field to meet the requirements of complex states in high quality steel continuous casting. In the field of static magnetic field control solidification structure, a new principle of applying high thermal electromagnetic force is proposed, and it is presented that the development of electromagnetic metallurgy technology needs to combine the artificial intelligence of big data to play a better role.

电磁冶金技术研究新进展

[J].电磁冶金技术是高品质钢生产的必备手段。本文综述了近年来电磁冶金技术的发展,围绕连铸的全流程,包括中间包电磁净化钢液、水口控流、结晶器内电磁搅拌和电磁制动等磁场控制流场、电磁软接触结晶器连铸、电磁场调控凝固组织、电磁场下固态相变及组织控制在内各方面,阐述了电磁场作用的机理,分析了应用电磁场技术的原理和特点,在电磁场控制流场领域提出了多模式定制磁场的概念,以满足高品质钢连铸中复杂状态的要求。在静磁场控制凝固组织领域提出应用强磁场热电磁力的新原理,并指出电磁冶金技术的发展需结合大数据的人工智能以更好发挥作用。

Effect of a high static magnetic field on microsegregation of directionally solidified Al-4.5Cu alloy

[J].<p>Microsegregation is the unbalanced distribution of alloying element between solid and liquid phases in dendritic scale during solidification. The solute redistribution usually leads to the formation of brittle secondary phase, which is harmful to the workability and final mechanical properties of casting component. It has been accepted that fluid flow plays a critical role in mass transfer during solidification and thus altering the microsegregation pattern. High static magnetic field has been considered as an effective way to control the convection in solidification. In this work, the impact of the high static magnetic field on the microsegregation was investigated. Al-4.5Cu (mass fraction, %) alloy was directionally solidified from <001> seed crystal under various magnetic fields with a constant pulling rate of 50 μm/s and temperature gradient of 101 K/cm. OM and BSE were applied to characterize the microstructure of the solidified samples. The fraction of Al<sub>2</sub>Cu second phase was obtained by software analysis from the transverse and longitudinal sections. The results show that the Al-4.5Cu alloy solidifies in dendritic morphology. The formation of second phase is significantly affected by the magnetic field. Without magnetic field, the continuous network of second phase is observed at grain boundaries. In the presence of the magnetic field, the second phase is disconnected in the grain boundaries and dispersed in grains. The fraction of the second phase is reduced with the increase of the magnetic field. EDS area scan was carried out to measure the concentration of Cu solute in dendritic scale. Isoconcentration contour maps of Cu in the plane perpendicular to the primary dendrite trunk were drawn. The concentration profiles of Cu were plotted from the measured data and the effective partition coefficient <i>k</i><sub>e </sub>was calculated. It is found that the redistribution of Cu solute in interdendritic region is greatly altered by the magnetic field. When the intensity of the magnetic field increases, the concentration profile and the <i>k</i><sub>e </sub>decrease. The disturbance of the Cu solute in the plane perpendicular to the primary trunk suggests the existence of fluid flow in the interdendritic region. The above phenomena could be attributed to the dendritic scale thermoelectric magnetic convection (TEMC) as well as the second flow driven by the TEMC. The azimuthal TEMC and meridional second flow will bring about stirring in mushy zone and lead to the modification of solute transport during solidification process.</p>

强磁场对定向凝固Al-4.5Cu合金微观偏析的影响

[J].

Effect of a high magnetic field on microstructures of Ni-based superalloy during directional solidification

[J].

Effect of horizontal magnetic field on the microstructure of directionally solidified Ni-based superally

[J].

横向磁场对镍基高温合金定向凝固组织的影响

[J].研究了横向磁场对镍基高温合金DZ417G定向凝固显微组织的影响. 在较低生长速率条件下, 磁场显著影响合金的枝晶生长和宏观偏析. 施加磁场后一次枝晶间距减小并在沿磁场方向试样的左侧出现了“斑状”偏析. 随着生长速率的增加, 磁场的影响减弱. 从磁场在合金熔体中诱发热电磁对流, 并影响枝晶生长的角度对实验结果进行了分析.

Effect of longitudinal magnetic field on the microstructure of directionally solidified superalloy DZ417G with different sizes

[J].

纵向磁场对不同尺寸定向凝固高温合金DZ417G组织的影响

[J].进行了外加纵向静磁场下高温合金DZ417G的定向凝固实验, 考察了纵向磁场对不同尺寸试样凝固组织形貌的影响. 结果显示, 在温度梯度为70℃/cm, 抽拉速率为5 μm/s时, 施加磁场后一次枝晶间距减小, 并在试样边缘出现等轴晶组织; 随着试样尺寸的增大, 在试样边缘和中心的柱状枝晶组织遭到破坏, 形成等轴晶组织, 且出现“斑状”偏析. 这些现象可归结为磁场在固/液界面前沿合金熔体中诱发的热电磁对流(TEMC)所致.

Effect of a high magnetic field on γ′ phase for Ni-based single crystal superalloy during directional solidification

[J].

The effect of magnetic field on precipitation phases of single-crystal nickel-base superalloy during directional solidification

[J].

Effect of high magnetic field on the microstructure in directionally solidified Co-Al-W alloy

[J].Recently, a new Co-Al-W-based alloy with ordered L12 structure has been attracted much attention of researchers, these alloys have higher melting point than Ni-base superalloys with morphologically identical microstructure, but grain defect formation caused by thermosolutal convection has become an important problem for its application. Magnetic field is always applied to damp the convection which reduces the formation of defects. However, there are hitherto few papers to investigate the effect of magnetic field on grain defects during Co-Al-W-based alloy directional solidification. In this work, The effect of high magnetic field on the solidification structure and macrosegregation in directionally solidified Co-Al-W-based alloy was investigated. The results showed that the application of longitudinal magnetic field can induce convection and cause deformation of the solid-liquid interface shape, forming the macrosegregation and the stray grains in the mushy zone at the pulling rate of 5 μm/s. With the increase of pulling rate, the macrosegregation and the stray grains disappeared gradually at 2 T magnetic field. While the transverse magnetic field was applied, the macrosegregation became serious and the number of the stray grains increased. The macrosegregation further became more serious and the columnar-to-equiaxed transition was induced after adding the Ta element. The main reason of undercooling nucleation and columnar-to-equiaxed transition (CET) was the microsegregation induced by thermoelectric magnetic convention.

静磁场对新型Co-Al-W基高温合金定向凝固组织的影响

[J].以新型Co-Al-W基高温合金为基础,进行了外加静磁场下定向凝固实验,考察了不同磁场强度对凝固组织形貌和偏析的影响。结果显示:在抽拉速率为5 μm/s时,施加纵向强磁场,诱发熔体流动,造成界面失稳,形成“斑状”偏析和游离碎晶;磁场不变(2 T),进一步增加抽拉速率时,边部的游离碎晶和“斑状”偏析组织减少,凝固界面变得平直;施加横向磁场时,诱发更强的界面前沿流动,偏析加剧,碎晶增多;增加偏析合金元素Ta时,偏析进一步加剧,造成过冷形核,诱发柱状晶向等轴晶转变(CET)。磁场下热电磁对流形成偏析,是造成CET的根本原因。

Effect of longitudinal static magnetic field on the columnar to equiaxed transition in directionally solidified GCr15 bearing steel

[J].Columnar to equiaxed transition (CET) generating a fine-grain structure of GCr15 bearing steel with the homogeneity of the solute contents and the rather small amount of internal defects is often desired in solidification processes. In recent years much attention has been paid to the effect of static magnetic fields on the CET of Al base alloys, Pb-Sn alloys and Ni base superalloys. However, there are few papers to investigate the effect of static magnetic fields on the CET of GCr15 bearing steel. The present work investigates how longitudinal static magnetic fields affect the CET in directionally solidified GCr15 bearing steel. Experimental results show that columnar dendrites degenerate and transform into equiaxed dendrites at the edge of the sample as the longitudinal static magnetic field increases at pulling rate of 20 μm/s and temperature gradient of 104 K/cm. The dendritic morphology without the longitudinal static magnetic field is regular and columnar at pulling rate of 5 and 50 μm/s and temperature gradient of 104 K/cm. When the 4 T longitudinal static magnetic field is applied, the dendritic morphology is still regular and columnar at pulling rate of 50 μm/s and temperature gradient of 104 K/cm. However, the CET occurs at low pulling rate of 5 μm/s and temperature gradient of 104 K/cm. This phenomenon is simultaneously accompanied by more uniformly distributed alloying elements. The corresponding numerical simulations verify that the thermoelectric (TE) magnetic force is induced by the interaction between the longitudinal static magnetic field and TE current. Owing to TE magnetic force localized into the root of the dendrite, the dendritic fragments detach from the primary dendrites. Then the TE magnetic convection induced by TE magnetic force acting on the melt transports the fragments from the interdendritic spacing to the region ahead of columnar dendrites. It can be deduced from above phenomena that the TE magnetic force leads to the CET under the longitudinal static magnetic field.

纵向静磁场对定向凝固GCr15轴承钢柱状晶向等轴晶转变的影响

[J].

Improvement in creep life of a nickel-based single-crystal superalloy via composition homogeneity on the multiscales by magnetic-field-assisted directional solidification

[J].The improvement of the creep properties of single-crystal superalloys is always strongly motivated by the vast growing demand from the aviation, aerospace, and gas engine. In this study, a static magnetic-field-assisted solidification process significantly improves the creep life of single-crystal superalloys. The mechanism originates from an increase in the composition homogeneity on the multiscales, which further decreases the lattice misfit of gamma/gamma' phases and affects the phase precipitation. The phase-precipitation change is reflected as the decrease in the gamma' size and the contents of carbides and gamma/gamma' eutectic, which can be further verified by the variation of the cracks number and raft thickness near the fracture surface. The variation of element partition decreases the dislocation quantity within the gamma/gamma' phases of the samples during the crept deformation. Though the magnetic field in the study destroys the single-crystal integrity, it does not offset the benefits from the compositional homogeneity. The proposed means shows a great potential application in industry owing to its easy implement. The uncovered mechanism provides a guideline for controlling microstructures and mechanical properties of alloys with multiple components and multiple phases using a magnetic field.

Reduction in microsegregation in Al-Cu alloy by alternating magnetic field

[J].

Microsegregation formation in Al-Cu alloy under action of steady magnetic field

[J].

Research progress of microsegregation behavior during alloy solidification under steady magnetic field

[J].

稳态磁场下合金凝固过程微观偏析行为研究进展

[J].

High cycle fatigue behavior of a nickel-based single crystal superalloy DD98M at 900oC

[J].

DD98M镍基单晶高温合金900℃高周疲劳行为

[J].

A new model for studing the evaporation behavior of alloy elements in DD98M alloy during electron beam smelting

[J].

Microsegregation measurement: Methods and applications

[J].

Influence of solidification variables on the dendrite arm spacings of Ni-based superalloys

[J].

Effects of electromagnetic stirring during the controlled solidification of tin

[J].

Experimental evidence of the effect of a high magnetic field on the stray grains formation in cross-section change region for Ni-based superalloy during directional solidification

[J].

Columnar-to-equiaxed transitions in Al-based alloys during directional solidification under a high magnetic field

[J].

Influence of thermoelectric effects on the solid-liquid interface shape and cellular morphology in the mushy zone during the directional solidification of Al-Cu alloys under a magnetic field

[J].

Effect of high magnetic field on the primary dendrite arm spacing and segregation of directionally solidified superalloy DZ417G

[J].

Effects of a high magnetic field on the microstructure of Ni-based single-crystal superalloys during directional solidification

[J].

Dendritic solidification of alloys in low gravity

[J].

Dendrite growth at the limit of stability: Tip radius and spacing

[J].

Effect of a high magnetic field on microstructures of Ni-based single crystal superalloy during seed melt-back

[J].

Revealing influence mechanism of a transverse static magnetic field on the refinement of primary dendrite spacing during directional solidification

[J].The refinement mechanism of primary dendrite spacing caused by a transverse static magnetic field during directional solidification was proposed and verified experimentally in this paper. According to the Kurz-Fisher model, this magnetic field-induced refinement is related to the temperature gradient and solute redistribution in the mushy zone during directional solidification. Therefore, the effect of the magnetic field on the temperature gradient was investigated and the solute redistribution induced by the thermoelectric magnetic convection was measured by Rank sort method. The experimental results indicate that the refinement of primary dendrite spacing can be attributed to the solute redistribution rather than the change of temperature gradient.

A technique for characterizing microsegregation in multicomponent alloys and its application to single-crystal superalloy castings

[J].

A comparative study of quantitative microsegregation analyses performed during the solidification of the Ni-base superalloy CMSX-10

[J].

The distribution of solute in crystals grown from the melt. Part I. Theoretical

[J].