晶界工程(grain boundary engineering,GBE)[1]是通过调整晶界结构或成分来优化材料性能的方法,其中之一是通过恰当形变和退火等组织重构方式在材料中引入原子排列有序度高、能量低、结构稳定性好且比例高的共格Σ3晶界,即共格孪晶界,也称为奇异晶界[2] (singular boundary,SB),来显著提高材料与晶界相关的多种性能,特别是提高晶间腐蚀抗力。这种方法已被广泛应用于中低层错能fcc金属[3]。但是,Al及其合金属于高层错能fcc金属,在形变退火过程中形成奇异晶界的能力很弱,奇异晶界比例一般约为1.0%[4],对改善材料与晶界相关的性能没有明显作用。其原因是,高层错能fcc金属在形变过程中,位错交滑移活跃,难以在{111}面上形成层错或扩展位错,不利于后续退火过程中奇异晶界的形成。因此,对于如Al及其合金这类高层错能fcc金属而言,通过提高奇异晶界比例以显著改善与晶界相关性能这一传统GBE技术路线不再适用。近期,Wang等[5]在研究组织均匀化高纯Al晶界界面匹配(grain boundary inter-connection,GBIC)时发现,相比一般大角度晶界,具有{111}/{111}界面匹配特征的晶界(晶界平行于一对{111}/{111}晶面)具有很高的生成能力;O点阵[6]计算表明此类晶界的原子结构具有更高的面重合密度和特定的位错结构,呈现周期性匹配好区被周期性位错分割特征,可将其归类为一种相比一般晶界能量更低且结构更稳定的近奇异晶界(near singular boundary,NSB)(以下简称{111}/{111}近奇异晶界),这与Bouchet和Priester[7,8]的实验观察及Janssens等[9]的分子动力学模拟结果是一致的。Du等[10]在研究Al-Cu二元合金晶界析出行为时观察到,一般大角度晶界上的析出相通常呈现连续分布,析出相连续布满整个晶界,而{111}/{111}近奇异晶界上的析出相则为不连续分布,析出相在晶界上间隔分布,呈现“串珠”特征;并且,离线原位表面侵蚀实验表明,{111}/{111}近奇异晶界的腐蚀抗力显著高于一般晶界。因此,探索特定形变和退火等组织重构方法,在材料中引入高比例{111}/{111}近奇异晶界将有望显著提升Al及其系列合金的晶界腐蚀抗力,从而极大地拓展某些铝合金(如7000系列铝合金)在航空航天等领域的应用。

显然,要实现Al及其合金{111}/{111}近奇异晶界的能动控制,有必要研究并掌握组织重构对此类晶界的影响。考虑到组织重构包括形变后的再结晶和再结晶后的晶粒长大2个关键环节,而前者涉及热激活条件下的位错运动和形变亚结构(主要包括位错、位错胞、位错胞壁、亚晶和亚晶界等)的演化,是一个非常复杂的行为,本工作重点关注晶粒长大对{111}/{111}近奇异晶界的影响,有关研究结果对调控Al及其合金{111}/{111}近奇异晶界以显著改善此类材料的晶界抗腐蚀性能具有重要意义。为了避免合金元素可能带来的复杂影响,以掌握Al及其合金在晶粒长大过程中{111}/{111}近奇异晶界的本征行为,本工作选用高纯Al作为实验材料。

1 实验方法

1.1 样品制备

实验所用材料为经区域熔炼的纯度为99.99% (质量分数)的高纯Al棒材。从棒材上切下尺寸为20 mm × 20 mm × 40 mm的试块,将其在室温下进行真应变ε = 2.1的多向锻造后,在370℃完成再结晶退火。以上处理过程重复进行4次以上,获得晶粒尺寸均匀且晶体取向随机的初始样品。用精密切割机从初始样品的同一部位切取3个尺寸均为10 mm × 6 mm × 1 mm的试样,在500℃高温条件分别保温1、5和30 min,使晶粒明显长大,获得平均晶粒尺寸递增的3个样品。样品测试面经机械磨制和抛光后,再进行电解抛光。电解抛光液为HClO4∶C2H5OH = 1∶9 (体积比),抛光电压20 V,电流0.6 A,温度10℃以下,抛光时间3 min左右。电解抛光后的样品经分析纯酒精反复清洗并冷风吹干后,置于真空箱中保存,以备电子背散射衍射(EBSD)测定用。

1.2 EBSD测定及{111}/{111}近奇异晶界表征

将电解抛光后的样品放入配有Nordlys Max2附件的Nova Nano SEM450场发射扫描电镜(SEM)中进行EBSD测定,测定参数为:加速电压20 kV,工作距离10 mm,逐点扫描步长2 μm,测定区域2000 μm × 1500 μm。为保证测定结果的统计代表性,依据晶粒尺寸差异,每个样品测定5~10区域不等,保证从每个样品中测定的晶界数量不少于50000条[11]。

将所测得的EBSD原始数据进行必要格式转换后,导入TSL-OIM8.0软件完成数据处理,主要包括导出取向成像显微分析(OIM)、基于OIM重构晶界迹线、导出所有晶界迹线的晶体学数据等。晶界迹线的晶体学数据主要包括迹线长度、迹线起点和终点在试样坐标系中的坐标、迹线两侧晶粒的取向(Euler角)等。通过简单程序运算得到每一条晶界迹线所关联的晶界的取向差信息,并以轴角对<uvw>/θ标识(其中,<uvw>为取向差转轴,θ为取向差转角,可以是任意角度,但本工作仅考虑θ > 10°的情形)。然后,再通过简单程序运算,把所有晶界迹线所关联的晶界按其取向差特征过滤分成若干组。以上晶界过滤分成两步进行,即先进行轴过滤,然后进行角过滤。轴过滤是按照晶界取向差转轴<uvw>的不同过滤晶界。依据作者先前的工作[5],{111}/{111}近奇异晶界的旋转轴以<111>、<112>和<122>为主,因此,本工作的轴过滤只考虑这3个旋转轴。实际轴过滤时,设定转轴的偏移量为± 5°。角过滤是把上述已经通过轴过滤的每一组晶界按照其取向差转角的不同再次过滤晶界,过滤出来的每组晶界具有各自固定的轴角对取向差。考虑到在计算晶界取向差时已将其约化到Rodriguez空间的基区内[12],取向差最大转角为62.8°。角过滤以5°间隔从5°开始到60°结束,且每个转角的偏差设定为± 2.5°,例如,过滤出的取向差为<111>/30°的晶界,实际上包含取向差介于<111>/27.5° ~ <111>/32.5°的所有晶界。由于取向差角度小于10°的晶界被定义为小角度晶界,在计算{111}/{111}近奇异晶界比例时,不考虑这部分晶界;此外,取向差为<111>/60°的晶界为孪晶界(Σ3晶界),其中具有{111}/{111}界面匹配特征的部分为共格孪晶界,即SB,也不纳入本工作测定的{111}/{111}近奇异晶界之内。

采用Saylor等[13]和Randle等[14]的基于体视学和统计学的五参数分析法(five parameter analysis,FPA)对过滤出来的每一组具有固定取向差的晶界进行晶界面分布(grain boundary plane distribution,GBPD)表征。GBPD是指晶界面所处晶面之法线方向在晶体学空间的分布,是一种三维分布。为便于分析,GBPD通常被投影在晶体学空间的低指数晶面内,如立方材料投影在(001)内,六方材料投影在(0001)内。由于晶面能存在各向异性(意指不同Miller指数晶面能量不同)[15],GBPD一般不是随机分布,因此,通常以随机分布的倍数(multiple of random distribution,MRD)来计算GBPD分布强度。

式中,(h1k1l1)是GBPD中的取向强点位置,可以参照标准投影图在GBPD中直接读出, R[uvw] / θ 为取向差矩阵。通过

式中,Pi 是该组晶界总长度占总晶界长度的分数,Mi 是从该组GBPD所确定的{111}/{111}近奇异晶界{111}所对应的MRD值,Wi 是在该组晶界加权平均取向差Gaussian分布曲线中的半高宽。显然,本工作所给出的{111}/{111}近奇异晶界比例是指从多组晶界中测定的该类晶界比例之和Ftotal,实际上并非每组晶界都存在{111}/{111}近奇异晶界。

1.3 离线原位分析及TEM观察

为了掌握晶粒长大过程中{111}/{111}近奇异晶界的形成机制,需要对晶粒组织的演化行为进行离线原位观察和分析。主要步骤是:(1) 将初始样品进行机械和电解抛光后,利用显微硬度计完成压痕标记;(2) 在压痕标记的导航下完成EBSD测试,并确定测试区域内每一个晶粒的取向和每一条晶界的取向差,特别关注每一个晶粒与其相邻晶粒之间的取向差关系;(3) 将样品在500℃保温一定时间后取出,在压痕标记的导航下对同一区域再次完成EBSD测试,观察晶粒长大和晶界迁移情况,并利用Wright和Larson[18]的(111)重叠极图晶界迹线分析法对每一条晶界进行分析,确认有无{111}/{111}近奇异晶界生成;(4) 重复第3步,直至发现有{111}/{111}近奇异晶界生成。这里需要说明的是,上述Wright方法最早是用来区分共格和非共格孪晶界的,其准确率达到90%以上,它一样可以用来确定{111}/{111}近奇异晶界。

为了了解{111}/{111}近奇异晶界的原子结构,利用EBSD测试、(111)重叠极图晶界迹线分析和聚焦离子束(FIB)切割等多种手段相结合的方法定点制备了含有{111}/{111}近奇异晶界的高分辨透射电镜(HRTEM)薄膜样品,并采用Themis双球差校正场发射透射电子显微镜(TEM)观察其晶界原子结构。

2 实验结果

2.1 晶粒长大过程中的显微组织

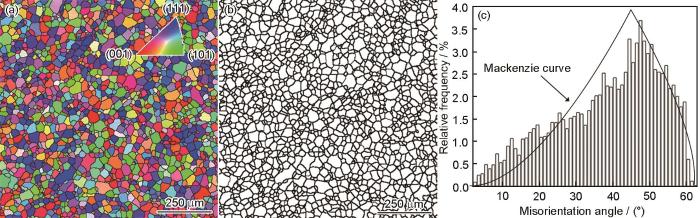

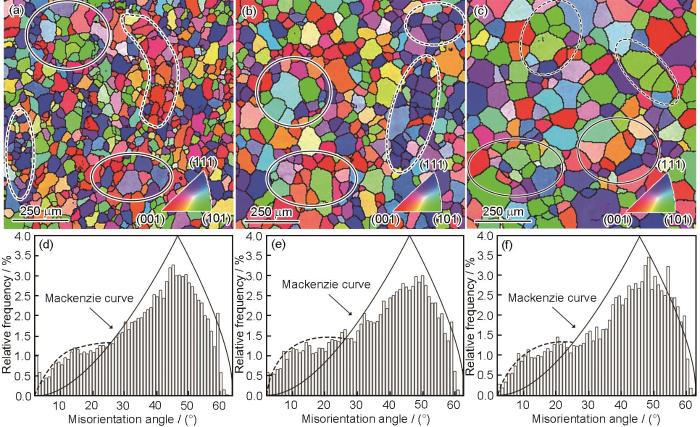

图1给出了经反复多向锻造和再结晶处理后的初始高纯Al样品显微组织的OIM图及晶界取向差分布。可以看出其晶粒细小均匀,平均晶粒尺寸约为25 μm,且无明显织构。图2是高纯Al样品经500℃保温不同时间后显微组织的OIM图和晶界取向差分布。可以看出,随着保温时间的延长,晶粒明显长大,保温1 min (图2a)、5 min (图2b)和30 min (图2c)的样品,其平均晶粒尺寸分别为38、56和77 μm;随着保温时间的延长和晶粒尺寸的增大,晶粒的等轴化程度也在明显增大。从图2还可以看出,虽然平均晶粒尺寸随500℃保温时间的延长显著增大,但每个样品内晶粒尺寸是不均匀的,表现为某些区域的晶粒尺寸明显大于该样品的平均晶粒尺寸,如图2a~c中实线所圈定区域,表明在保温过程中,晶粒长大是非均匀的,即某些晶粒由于其关联晶界(包括三叉结)的特殊性,通过晶界迁移吞并周围晶粒得以快速长大,而有些晶粒的长大则比较迟缓,这符合金属材料组织粗化基本规律[19]。另外,虽然每个样品内各种取向(各种颜色)的晶粒数量大致相当,均没有形成明显的宏观织构,但是每个样品内均出现一定的微观织构,如图2a~c中虚线所圈定区域,分别为<001>//ND、<111>//ND和<011>//ND的微观丝织构(ND为样品测试面法线方向),表明在保温过程中,除了晶粒长大是微观非均匀行为外,织构的演化也是一个微观非均匀行为。此类微观织构导致晶界构成中取向差较小的部分(小角度晶界)明显偏离Mackenzie[20]随机分布,如图2d~f取向差分布图中的虚线包络部分。

图1

图1

经反复多向锻造和370℃再结晶后高纯Al显微组织的取向成像显微分析(OIM)图、晶界重构图及取向差分布图

Fig.1

Microstructure analyses of high purity aluminum after multi-directional forging followed by recrystallization at 370oC

(a) orientation imaging microscopy (OIM) (b) grain boundary networks (GBN) (c) misorientation distribution

图2

图2

再结晶高纯Al在500℃保温不同时间后的OIM图和取向差分布

Fig.2

OIM (a-c) and misorientation distributions (d-f) of high purity aluminum heated at 500oC for 1 min (a, d), 5 min (b, e), and 30 min (c, f) after recrystallization (Solid areas show the uneven grain size zones, and dashed areas show the microtexture zones)

图3

图3

再结晶高纯Al在500℃保温不同时间后的特定转轴晶界取向差分布图

Fig.3

Misorientation distributions of grain boundaries with specific rotation axis in high purity aluminum heated at 500oC for varied time after recrystallization

(a) <111> (b) <112> (c) <122>

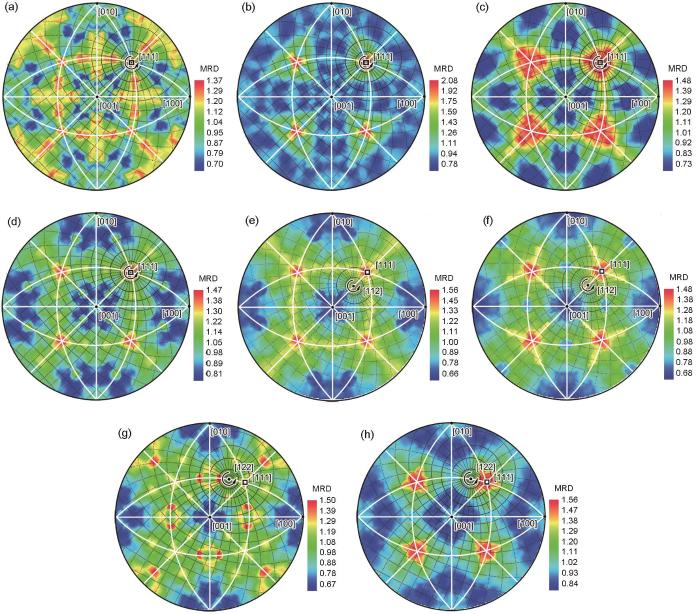

图4

图4

再结晶高纯Al在500℃保温1 min的不同取向差{111}/{111}近奇异晶界的五参数晶界面分布(投影在(001)内)

Fig.4

Grain boundary plane distributions (GBPDs) of {111}/{111} near singular boundary with varied misorientations in the high purity aluminum heated at 500oC for 1 min (projection on (001)) (MRD—multiple of random distribution)

(a) [111]/35° (b) [111]/40° (c) [111]/50° (d) [111]/55°

(e) [112]/20° (f) [112]/30° (g) [122]/15° (h) [122]/40°

图5

图5

再结晶高纯Al在500℃保温5 min的不同取向差{111}/{111}近奇异晶界的五参数晶界面分布(投影在(001)内)

Fig.5

GBPDs of {111}/{111} near singular boundary with varied misorientations in the high purity aluminum heated at 500oC for 5 min (projection on (001))

(a) [111]/15° (b) [111]/30° (c) [111]/35° (d) [111]/40°

(e) [111]/45° (f) [111]/55° (g) [112]/25° (h) [112]/30°

(i) [122]/20° (j) [122]/25° (k) [122]/35° (l) [122]/40°

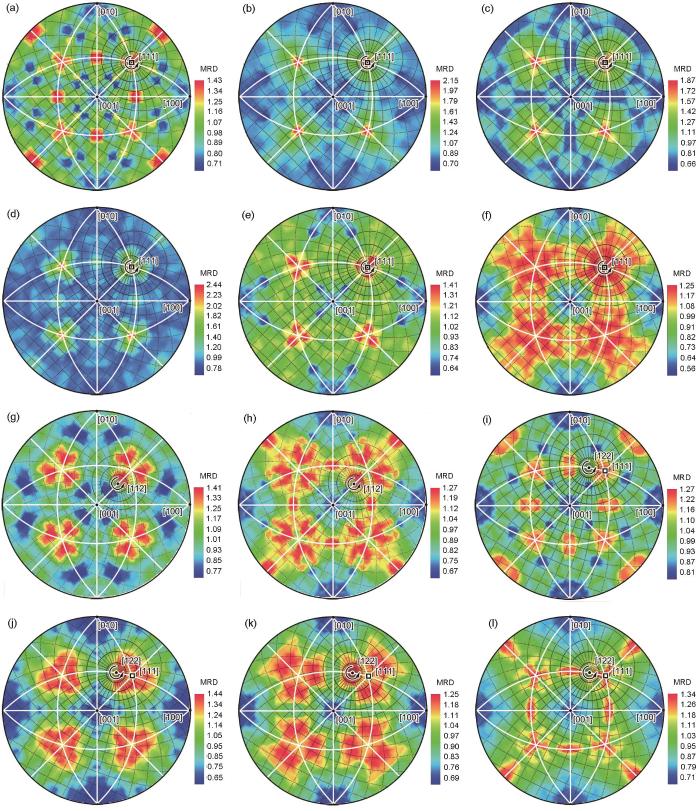

2.2 晶粒长大过程中的{111}/{111}近奇异晶界

针对500℃保温1、5和30 min后每个样品的多幅OIM,经晶界重构及相关晶体学数据处理,分别提取出57660、66093和57025条晶界,经轴过滤得到的旋转轴为<111>、<112>和<122>的晶界数量及其比例详见表1。可以看到,旋转轴为<122>的晶界数量相对较多、比例相对较高;旋转轴为<111>和<112>的晶界数量及比例相对偏低。进一步经角过滤得到的旋转轴为<111>、<112>和<122>的晶界取向差分布如图3所示。可以看出,500℃保温时间的长短对各旋转轴晶界的取向差分布没有明显影响,即晶粒长大不会引起晶界取向差分布发生明显改变,但这并不意味着GBPD和GBIC、特别是{111}/{111}近奇异晶界比例也不发生变化,具体将在下文分析。从图3a中还可以看出,500℃保温1、5和30 min 3个样品中的3晶界的比例均低于1.8%,其中的共格3晶界、即SB (或共格孪晶界)比例仅分别为1.13%、1.07%和1.18%,这再一次表明Al及其合金很难形成SB[21]。

表1 再结晶高纯Al在500℃保温不同时间后取向差转轴为<111>、<112>和<122>的晶界数量及比例统计

Table 1

| Annealing time at 500oC / min | GB rotation axis | GB number | GB | Length fraction / % |

|---|---|---|---|---|

| number fraction / % | ||||

| 1 | <111> | 4313 | 7.48 | 7.70 |

| <112> | 6963 | 12.08 | 12.04 | |

| <122> | 9560 | 16.58 | 16.95 | |

| 5 | <111> | 5228 | 7.91 | 8.24 |

| <112> | 7918 | 11.98 | 12.03 | |

| <122> | 11314 | 17.12 | 17.42 | |

| 30 | <111> | 4659 | 8.17 | 8.801 |

| <112> | 6947 | 12.18 | 12.02 | |

| <122> | 10084 | 17.68 | 18.24 |

通过考察所过滤出的各组GBPD强点位置,并利用

图6

图6

再结晶高纯Al在500℃保温30 min的不同取向差{111}/{111}近奇异晶界的五参数晶界面分布(投影在(001)内)

Fig.6

GBPDs of {111}/{111} near singular boundary with varied misorientations in the high purity aluminum heated at 500oC for 30 min (projection on (001))

(a) [111]/20° (b) [111]/35° (c) [111]/40° (d) [111]/45°(e) [111]/50° (f) [111]/55° (g) [112]/15° (h) [112]/20°(i) [112]/30° (j) [122]/25° (k) [122]/30° (l) [122]/35° (m) [122]/40°

表2 再结晶高纯Al在500℃保温不同时间{111}/{111}近奇异晶界相关数据统计

Table 2

| Annealing time min | [uvw]/θ | Pi / % | Mi | Wi / (°) | Fi / % | Ftotal =Fi / % | |

|---|---|---|---|---|---|---|---|

| 1 | [111]/35° | 0.51 | 1.37 | 2.50 | 0.26 | 3.91 | |

| [111]/40° | 0.64 | 2.08 | 2.15 | 0.34 | |||

| [111]/50° | 0.12 | 1.48 | 2.17 | 0.59 | |||

| [111]/55° | 1.25 | 1.47 | 2.21 | 0.64 | |||

| [112]/20° | 0.68 | 1.56 | 2.15 | 0.35 | |||

| [112]/30° | 0.98 | 1.48 | 1.89 | 0.51 | |||

| [122]/15° | 0.66 | 1.20 | 2.05 | 0.34 | |||

| [122]/40° | 1.70 | 1.56 | 2.09 | 0.88 | |||

| 5 | [111]/15° | 0.26 | 1.43 | 1.77 | 0.14 | 5.48 | |

| [111]/30° | 0.40 | 2.15 | 2.01 | 0.21 | |||

| [111]/35° | 0.55 | 1.87 | 1.87 | 0.29 | |||

| [111]/40° | 0.73 | 2.44 | 2.40 | 0.39 | |||

| [111]/45° | 1.01 | 1.41 | 2.07 | 0.52 | |||

| [111]/55° | 1.57 | 1.20 | 2.12 | 0.80 | |||

| [112]/25° | 0.77 | 1.25 | 2.28 | 0.39 | |||

| [112]/30° | 1.00 | 1.12 | 2.04 | 0.51 | |||

| [122]/20° | 0.64 | 1.27 | 2.49 | 0.33 | |||

| [122]/25° | 0.83 | 1.34 | 1.97 | 0.43 | |||

| [122]/35° | 1.36 | 1.12 | 2.11 | 0.69 | |||

| [122]/40° | 1.52 | 1.34 | 2.16 | 0.78 | |||

| 30 | [111]/20° | 0.31 | 2.91 | 1.69 | 0.17 | 6.56 | |

| [111]/35° | 0.49 | 1.76 | 2.35 | 0.25 | |||

| [111]/40° | 0.70 | 1.34 | 1.82 | 0.36 | |||

| [111]/45° | 1.02 | 1.72 | 2.09 | 0.53 | |||

| [111]/50° | 1.31 | 1.61 | 2.09 | 0.68 | |||

| [111]/55° | 1.90 | 1.80 | 2.24 | 0.99 | |||

| [112]/15° | 0.69 | 1.60 | 2.23 | 0.36 | |||

| [112]/20° | 0.69 | 1.54 | 2.82 | 0.35 | |||

| [112]/30° | 0.89 | 1.40 | 2.47 | 0.45 | |||

| [122]/25° | 0.77 | 1.70 | 2.01 | 0.40 | |||

| [122]/30° | 1.04 | 1.30 | 2.04 | 0.53 | |||

| [122]/35° | 1.22 | 1.53 | 2.53 | 0.62 | |||

| [122]/40° | 1.70 | 1.41 | 2.20 | 0.87 |

3 分析讨论

3.1 晶粒长大过程中{111}/{111}近奇异晶界形成机制

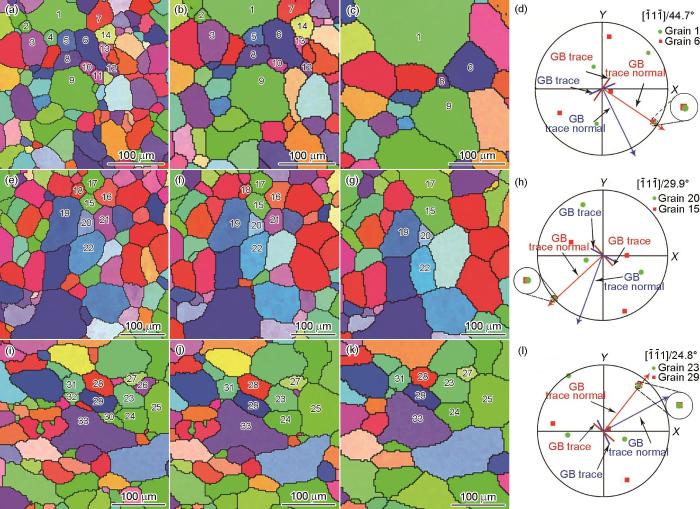

通过离线原位观察发现,在晶粒长大过程中,高纯Al {111}/{111}近奇异晶界主要通过2种机制形成。第一种是如图7所示的具有<111>/θ (θ > 10°)取向差关系的任意2个不相邻晶粒通过自身长大并“吞吃”其邻近晶粒后相遇而形成{111}/{111}近奇异晶界,在此,称其为“相遇”机制。以图7a~c中的第1号和第8号晶粒为例,这2个晶粒的Euler角分别为(289.1° 20.1° 49.0°)和(145.8° 38.1° 48.8°),它们之间的取向差为[

图7

图7

再结晶高纯Al在500℃保温期间具有<111>/θ取向差关系不相邻晶粒长大相遇形成{111}/{111}近奇异晶界离线原位OIM及重叠极图迹线分析

Fig.7

Off-line in situ orientation imaging microscopies and grain boundary trace analyses showing the formation of the {111}/{111} near singular boundaries by the encountering of two nonadjacent growing grains having <111>/θ misorientation in the high purity aluminum heated at 500oC

(a-c) encountering of grain 1 and grain 8 at 2 min (a), 3 min (b), and 5 min (c), respectively

(e-g) encountering of grain 15 and grain 22 at 1 min (e), 2 min (f), and 4 min (g), respectively

(i-k) encountering of grain 26 and grain 37 at 5 min (i), 6 min (j), and 7 min (k), respectively

(d, h, l) overlapped {111} pole figures of grain 1 and grain 8 in Fig.7c (d), grain 15 and grain 22 in Fig.7g (h), and grain 26 and grain 37 in Fig.7k (l), respectively, showing the GB trace normals are passing through the overlapped {111} poles, indicating they have {111}/{111} GBICs

图8

图8

再结晶高纯Al在500℃保温期间具有<111>/θ取向差晶界再取向形成{111}/{111}近奇异晶界离线原位OIM及重叠极图迹线分析

Fig.8

Off-line in situ orientation imaging microscopies and grain boundary trace analyses showing the formation of the {111}/{111} near singular boundaries by the re-orientation of the grain boundaries having <111>/θ misorientation in the high purity aluminum heated at 500oC

(a-c) re-orientation of the boundary between grain 1 and grain 6 at 1 min (a), 2 min (b), and 5 min (c), respectively

(e-g) re-orientation of the boundary between grain 15 and grain 20 at 1 min (e), 4 min (f), and 6 min (g), respectively

(i-k) re-orientation of the boundary between grain 23 and grain 29 at 0 min (i), 1 min (j), and 4 min (k), respectively

(d, h, l) overlapped {111} pole figures of grain 1 and grain 6 in Fig.8c (d), grain 15 and grain 20 in Fig.8g (h), and grain 23 and grain 29 in Fig.8k (l), respectively (Blue and red GB traces are the GB positions before and after re-orientation, respectively, showing all the GB trace normals are passing through the overlapped {111} poles after GB re-orientation, indicating they have {111}/{111} GBICs)

实际上,具有<111>/θ取向差关系的2个不相邻晶粒在相遇初期,其晶界不一定处在{111}上,需要再取向才能到达{111},并形成{111}/{111}近奇异晶界,因此,以上2种机制可合并为一种机制,即“相遇-再取向”机制。这一机制能否发生,主要取决于具有<111>/θ取向差关系的2个不相邻晶粒各自与其相邻晶粒之间晶界的迁移特性,即晶界迁移率M,M与温度之间通常服从Arrhenius关系[23]:

式中,M0为常数,k为Boltzmann常数,T为绝对温度,Q为晶界迁移激活能。显然,在一定温度下,晶界迁移率大小、或晶界能否迁移主要决定于该晶界迁移激活能的高低。尽管晶界迁移激活能可以通过测定任意2个不同温度下晶界的迁移速率按如下公式[24]确定:

式中,v1和v2分别为2个不同温度T1和T2下晶界的迁移速率,R为气体常数。但是,Q直接决定于晶界能E,并与晶界能之间存在反相关关系,即E越低,Q越高,M越小,晶界越不容易迁移;反之亦然。因此,在一定温度下,晶界的迁移率、或晶界能否迁移的直接因素是晶界能。对于小角度晶界,其能量决定于取向差,并且可以用位错理论定量描述[25]。然而,对于大角度晶界,其能量的影响因素很复杂,至今未能对其进行定量描述。一般而言,大角度晶界的能量主要决定于取向差、GBIC和晶界偏聚等;在不考虑GBIC和晶界偏聚的情况下,取向差越大,晶界处原子的排列越混乱,晶界能量越高,晶界也越容易迁移(这当然是一种很粗略的定性考量,界面取向关系特殊和界面匹配关系特殊以及低ΣCSL (coincidence site lattice,重位点阵)晶界的情况除外)。因为实验材料为高纯Al,本工作重点考察了分别与图7a~c中第1号和第8号、图7e~g中第15号和第22号以及图7i~k中第26号和第37号等晶粒相邻的各晶粒的取向(Euler角)及其相邻晶界的取向差(表3)。可以看到,发生迁移的晶界基本具有大的、或较大的取向差,这是晶界迁移引发晶粒长大过程中形成{111}/{111}近奇异晶界的关键。此外,晶界再取向会受到与其两端关联三叉晶界处各晶界特征的影响和制约,为此,本工作也重点考察了分别与图8a~c中的第1号和第6号、图8e~g中的第15号和第20号以及图8i~k中的第23号和第29号等晶粒相邻的各晶粒的取向(Euler角)及其相邻晶界的取向差(表4)。从表4并未发现与晶界再取向有关的晶界取向差变化规律,这可能与晶界再取向仅仅是一种局部调整或自协调行为有关[26]。

表3 再结晶高纯Al在500℃保温期间具有<111>/θ取向差关系不相邻晶粒及其邻近各晶粒取向统计(对应图7)

Table 3

| Grain No. | Euler angle of growing grain | Euler angle of the grain adjacent to growing grain | Misorientation between growing grain and the adjacent grain |

|---|---|---|---|

| 1 | (289.1° 20.1° 49°) | - | - |

| 2 | (0.8° 36.4° 84.6°) | [ | |

| 3 | (170.8° 42.3° 10.5°) | [ | |

| 4 | (257.9° 43.3° 16°) | [123]/40.5° | |

| 5 | (79.1° 33° 64.7°) | [ | |

| 6 | (343.6° 39.8° 7.1°) | [ | |

| 7 | (358.2° 43.7° 60.3°) | [432]/43.5° | |

| 8 | (145.8° 38.1° 48.8°) | - | - |

| 1 | (289.1° 20.1° 49°) | [ | |

| 2 | (0.8° 36.4° 84.6°) | [ | |

| 7 | (358.2° 43.7° 60.3°) | [ | |

| 10 | (153.5° 47.8° 30.7°) | [ | |

| 11 | (32° 47.2° 64.6°) | [ | |

| 12 | (300.7° 26.6° 54.2°) | [ | |

| 9 | (139.4° 53° 47.2°) | [ | |

| 13 | (286.4° 25.9° 4.7°) | [ | |

| 14 | (342° 32.3° 71.3°) | [ | |

| 15 | (149.1° 33.3° 38.8°) | - | - |

| 16 | (334.8° 19.4° 26.3°) | [ | |

| 17 | (286.4° 32.6° 16.5°) | [ | |

| 18 | (36.3° 32° 31.9°) | [ | |

| 19 | (77.3° 32.1° 64.3°) | [ | |

| 20 | (89.2° 30.2° 64.3°) | [ | |

| 21 | (262° 44.9° 50.6°) | [ | |

| 22 | (281.3° 29.4° 49.1°) | - | - |

| 15 | (149.1° 33.3° 38.8°) | [ | |

| 21 | (262° 44.9° 50.6°) | [ | |

| 23 | (20.2° 18.4° 57.4°) | [ | |

| 24 | (92.7° 41.7° 67.3°) | [233]/44.3° | |

| 25 | (236° 39.7° 25.4°) | [ | |

| 26 | (256.8° 26.1° 29.7°) | - | - |

| 27 | (268.1° 32.1° 31.3°) | [ | |

| 28 | (247.6° 31.6° 37.2°) | [310]/7.1° | |

| 29 | (117.8° 35.8° 22.2°) | [ | |

| 30 | (203.9° 3° 82.7°) | [ | |

| 31 | (248.3° 10.3° 57.6°) | [ | |

| 32 | (207.7° 36.6° 58.9°) | [ | |

| 33 | (168.2° 38.5° 4.5°) | [ | |

| 34 | (66.4° 10.3° 65.7°) | [111]/43.9° | |

| 35 | (322.3° 36.4° 41.9°) | [ | |

| 36 | (271.3° 29.1° 34.3°) | [ | |

| 37 | (81.1° 30° 65.4°) | - | - |

| 26 | (256.8° 26.1° 29.7°) | [ | |

| 32 | (207.7° 36.6° 58.9°) | [ | |

| 38 | (19.1° 11.3° 65.1°) | [ | |

| 39 | (29.5° 18.9° 25.5°) | [149]/23.2° | |

| 40 | (38.1° 24.4° 15.7°) | [ | |

| 33 | (168.2° 38.5° 4.5°) | [ |

表4 再结晶高纯Al在500℃保温期间具有<111>/θ取向差关系相邻晶粒及其邻近各晶粒取向统计(对应图8)

Table 4

| Grain No. | Euler angle of adjacent grains | Euler angles of grains around two adjacent grains | Misorientation between grains and two adjacent grains |

|---|---|---|---|

| 1 | (82.3° 35.5° 10.9°) | - | - |

| 2 | (97.1° 39.8° 1°) | [ | |

| 3 | (12° 28.3° 40.7°) | [ | |

| 4 | (5.7° 44° 16.6°) | [111]/57.1° | |

| 5 | (45.3° 43.2° 58.4°) | [ | |

| 6 | (231° 43.7° 50.2°) | [ | |

| 7 | (347.2° 11.8° 71.1°) | [ | |

| 6 | (231° 43.7° 50.2°) | - | - |

| 5 | (45.3° 43.2° 58.4°) | [ | |

| 8 | (55.8° 36.3° 36.9°) | [ | |

| 10 | (157.8° 24.9° 50.5°) | [ | |

| 11 | (172.8° 25.8° 34.9°) | [ | |

| 12 | (221.9° 32.3° 43.2°) | [ | |

| 13 | (234.5° 24.6° 33.2°) | [ | |

| 14 | (240.2° 27.6° 11.1°) | [ | |

| 7 | (347.2° 11.8° 71.1°) | [ | |

| 15 | (337.4° 36.7° 9.2°) | - | - |

| 16 | (335° 18° 68.7°) | [ | |

| 17 | (176.5° 39.3° 88.9°) | [ | |

| 18 | (163.5° 7.7° 85.8°) | [071]/44.9° | |

| 19 | (2.3° 47.5° 57.7°) | [313]/30.1° | |

| 20 | (142.2° 37.9° 29.3°) | [ | |

| 21 | (196.9° 27.1° 40°) | [ | |

| 20 | (142.2° 37.9° 29.3°) | - | - |

| 19 | (2.3° 47.5° 57.7°) | [ | |

| 22 | (41.6° 45.2° 60.7°) | [ | |

| 21 | (196.9° 27.1° 40°) | [ | |

| 23 | (195.4° 38.7° 73.3°) | - | - |

| 24 | (160.7° 43.3° 1°) | [ | |

| 25 | (318.3° 32.6° 88.2°) | [ | |

| 26 | (259.4° 29° 46.6°) | [ | |

| 27 | (279.6° 29.5° 78.1°) | [ | |

| 28 | (305.7° 7.1° 8.9°) | [ | |

| 29 | (329.1° 48.9° 43.7°) | - | - |

| 23 | (195.4° 38.7° 73.3°) | [ | |

| 28 | (305.7° 7.1° 8.9°) | [233]/53.3° | |

| 31 | (292.6° 44.3° 18.2°) | [203]/46.9° | |

| 32 | (264.2° 41.1° 13.6°) | [ | |

| 33 | (217.9° 34.7° 53°) | [ | |

| 30 | (184.2° 38.8° 83.4°) | [ |

显然,本工作所观察到的具有<111>/θ取向差关系的任意2个不相邻晶粒(如图7a~c中第1号和第8号、图7e~g中第15号和第22号以及图7i~k中第26号和第37号等晶粒)能够通过其晶界迁移“吞吃”邻近晶粒并相遇后形成{111}/{111}近奇异晶界,是一种随机行为。因为其他迁移率高的晶界也可能导致其他取向的晶粒快速长大,并“吞吃”掉具有<111>/θ取向差关系的任意2个不相邻晶粒中的1个或2个。本工作之所以能够获得{111}/{111}近奇异晶界比例随晶粒长大而显著增加的结果,应该与{111}/{111}近奇异晶界的“锚定”作用有关。也就是说,尽管{111}/{111}近奇异晶界是基于其他晶界的随机迁移并通过“相遇-再取向”机制形成的,但是,此类晶界结构有序度高、能量低且不易迁移[9],它们一旦形成,就会对其周围关联晶界起到“锚定”作用,同时使自身得以保留下来,并表现为晶粒长得越大,此类晶界的比例越高,这与本工作的实验结果是一致的。当然,这一现象也可以从另外一个角度理解,那就是,尽管晶粒长大导致单位体积内晶界的面积减小(假定所有晶界均为一层原子面),但在保留下来的晶界中,像{111}/{111}近奇异晶界这类低能晶界相对增加(即比例增加),这种状态对晶粒的继续长大产生了更大的阻力,这符合材料组织演化热力学基本规律[27]。

3.2 {111}/{111}近奇异晶界结构特征

图9给出了高纯Al样品中2个{111}/{111}近奇异晶界的HRTEM像和选区电子衍射(SAED)花样。这2个晶界的取向差分别为[

图9

图9

高纯Al{111}/{111}近奇异晶界HRTEM像和SAED花样

Fig.9

HRTEM images and SAED patterns (Insets) of {111}/{111} near singular boundaries in the high purity aluminum (d{111}—interplanar spacing)

(a) with a misorientation of [

(b) with a misorientation of [

4 结论

(1) 晶粒长大有利于高纯Al {111}/{111}近奇异晶界比例的提高。

(2) 晶粒长大过程中,{111}/{111}近奇异晶界主要通过具有<111>/θ取向差关系的任意2个不相邻晶粒的长大、相遇和晶界再取向形成。

(3) {111}/{111}近奇异晶界在晶粒长大过程中一旦形成,便容易保留下来。

参考文献

An approach to grain boundary design for strong and ductile polycrystals

[J].

Textures and grain boundary character distributions in a cold rolled and annealed Pb-Ca based alloy

[J].

Effects of recovery treatment after large strain on the grain boundary character distributions of subsequently cold rolled and annealed Pb-Ca-Sn-Al alloy

[J].

Study on Σ3 boundaries in an cold rolled and recrystallized Al-Cu alloy

[J].

冷轧变形Al-Cu合金再结晶Σ3晶界研究

[J].

Grain boundary inter-connections in polycrystalline aluminum with random orientation

[J].

Application of the O-lattice model to the calculation of the interfacial dislocations

[J].

O点阵模型及其在界面位错计算中的应用

[J].介绍了描述O点阵特征的基本参量:主O点阵基矢、主O点阵面和O胞壁的定义和计算公式.提供了一般界面上周期位错结构的矩阵方法和计算特殊界面位错结构的简易矢量方法.还分析了O点阵描述界面位错的条件和局限,讨论了一般界面和大错配界面上位错结构的计算.

Intergranular segregation and crystallographic parameters of grain boundaries in nickel-sulfur system

[J].

Grain boundary plane and intergranular segregation in nickel-sulfur system

[J].

Computing the mobility of grain boundaries

[J].As current experimental and simulation methods cannot determine the mobility of flat boundaries across the large misorientation phase space, we have developed a computational method for imposing an artificial driving force on boundaries. In a molecular dynamics simulation, this allows us to go beyond the inherent timescale restrictions of the technique and induce non-negligible motion in flat boundaries of arbitrary misorientation. For different series of symmetric boundaries, we find both expected and unexpected results. In general, mobility increases as the grain boundary plane deviates from (111), but high-coincidence and low-angle boundaries represent special cases. These results agree with and enrich experimental observations.

The dependence of precipitate morphology on the grain boundary types in an aged Al-Cu binary alloy

[J].

The distribution of internal interfaces in polycrystals

[J].

Orientation mapping: 1987 MRS fall meeting von Hippel award lecture

[J].

Measuring the five-parameter grain-boundary distribution from observations of planar sections

[J].

Five-parameter grain boundary analysis of a titanium alloy before and after low-temperature annealing

[J].

Structure-energy correlation for grain boundaries in F.C.C. metals—I. Boundaries on the (111) and (100) planes

[J].

The near singular boundaries in BCC iron

[J].

Quantitative determination of grain boundary inter-connections

[P].

晶界界面匹配定量表征方法

[P].

Extracting twins from orientation imaging microscopy scan data

[J].Automated electron backscatter diffraction or orientation imaging microscopy (OIM) provides spatially specific measurements of crystallographic orientation. These measurements are typically collected on regular grids. By inspecting the misorientation between neighbouring measurements on the grid, potential twin boundaries can be identified. If the misorientation is within some given tolerance of a specified twin misorientation, the boundary separating the two measurements may be identified as a potential twin boundary. In addition, for a coherent twin, the twinning planes must be coincident with the grain boundary plane. As OIM scans are inherently two‐dimensional, the scan data provide only limited information on the boundary plane. Thus, it is not possible to ascertain definitively whether the twinning planes are coincident with the boundary plane. Nonetheless, the alignment of the surface traces of the twinning planes with the trace of the boundary provides a partial indication of coincidence. An automated approach has been developed that allows data concerning both twin criterion to be extracted from OIM scans. Application of the methodology to deformed zirconium suggests that the twinning planes remain coherent during deformation. The methodology was also used to improve grain size distributions measured by OIM. These results more closely match those obtained by conventional metallography.

Thermodynamics and kinetics of grain boundary triple junctions in metals: Recent developments

[J].

Second paper on statistics associated with the random disorientation of cubes

[J].

Preferred orientation of grain boundary plane in recrystallized high purity aluminum

[J].

高纯铝再结晶晶界面的择尤取向

[J].

Grain-boundary plane reorientation in copper

[J].

Testing thermal gradient driving force for grain boundary migration using molecular dynamics simulations

[J].

In situ measurements of growth rates and grain-averaged activation energies of individual grains during recrystallization of 50% cold-rolled aluminium

[J].

Energy of low angle grain boundaries based on continuum dislocation structure

[J].

Thermodynamics and structural aspects of grain boundary segregation

[J].