冲刷腐蚀的发展过程较为复杂,影响因素众多[10~15]。其中沙砾的相关参数(浓度、粒径、冲击角度等)对冲刷腐蚀的影响被广泛关注。Stack等[16]采用旋转圆盘电极研究了NaOH溶液中沙砾粒径对含铬钢冲刷腐蚀的影响,发现含沙量一定时,沙砾粒径在50~100 μm范围内冲刷腐蚀速率与沙砾粒径呈正相关,但当沙砾粒径进一步增大时,2者的相关性降低。Zheng等[17]研究了含有海泥盐溶液中碳钢的冲刷腐蚀行为,发现随着溶液中海泥含量的升高,金属冲刷腐蚀损伤将逐渐降低,该研究表明较小粒径的颗粒(6.6 μm)会在电极表面发生吸附,对冲刷腐蚀起到抑制作用。Luo等[18]研究了带涂层合金钢在含不同粒径沙砾盐溶液中的冲刷腐蚀行为,实验结果表明在一定范围内,冲刷腐蚀损伤速率会随沙砾粒径的增大呈指数形式上升,但当沙砾直径达到临界尺寸后,沙砾粒径的进一步增大将不会对冲刷腐蚀速率有显著影响。姜志超等[19]通过实验发现,对于X80管线钢的冲刷腐蚀也存在临界沙砾粒径,当沙砾尺寸达到临界粒径后,X80管线钢的冲刷腐蚀速率将不再随沙砾粒径的增大而增加。

由此可见,沙砾的尺寸直接影响到碳钢材料在含沙盐溶液中的冲刷腐蚀行为,相同流速和含沙量下,不同的沙砾粒径可能导致机械磨损和电化学腐蚀表现出完全不同的协同作用机制。此外,不同粒径沙砾冲击下碳钢表面的局部冲刷腐蚀行为也会有所不同,导致钢材的冲刷腐蚀发展过程存在较大差异[6]。目前,大多数研究主要围绕宏观上沙砾对冲刷腐蚀的影响展开,并且为了突出沙砾的冲击作用,一般都选择在较高流速下(高于5 m/s)进行研究[20]。而在实际海洋工况下,海水与固定式海洋结构物之间的相对运动速率通常较低(1~4 m/s)[21],单纯的沙砾冲刷不会对碳钢材料造成明显损伤。但研究[22,23]发现,腐蚀作用会大幅降低磨损发生的阈值,在流速为1.8 m/s的含沙盐溶液中,430~800 μm沙砾粒径所造成的碳钢磨损将会达到材料总损伤的40%以上,表明低流速盐溶液中由沙砾冲击所导致的材料损伤不可忽视。因此,理解不同粒径沙砾冲击下海洋工程用钢的冲刷腐蚀行为对海洋结构物在含沙海水中的安全评估和损伤控制具有重要科学意义。本工作通过电化学测量和微观形貌表征研究了EH36海洋工程用碳钢材料在含不同粒径石英砂颗粒盐溶液中的冲刷腐蚀行为,结合计算流体力学(CFD)仿真,获得了沙砾冲击能量对碳钢局部损伤的影响。讨论了不同工况下冲刷与腐蚀的相互促进机制,以及不同粒径沙砾磨损与碳钢表面局部阳极溶解间的协同作用机理。

1 实验方法

1.1 实验装置与材料

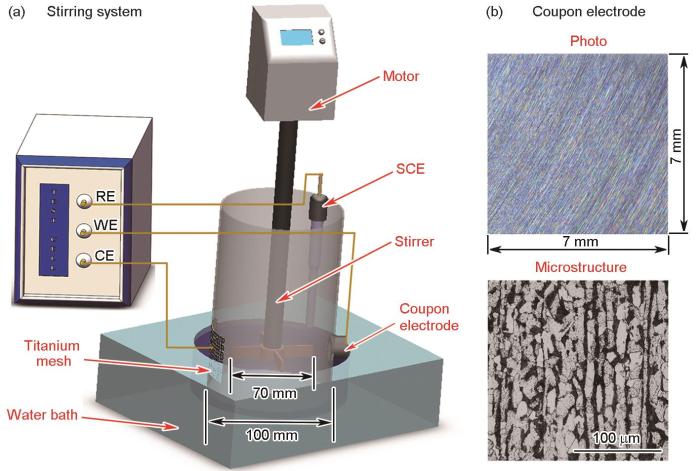

本工作通过图1a中的圆柱形搅拌电解池来模拟冲刷腐蚀环境,电解池直径为100 mm,高度为200 mm,电解池放置于水浴恒温系统中。搅拌器位于电解池底部上方10 mm处,其直径为70 mm,实验中搅拌器处于600 r/min的固定转速(浆叶切向速率为2 m/s),用于模拟较低流速的工作环境。对实际海洋工程用EH36钢板进行切割,制成实验中所用的长方体碳钢工作电极(WE),其尺寸为7 mm × 7 mm × 3 mm。EH36钢的主要化学成分(质量分数,%)为:C 0.06,Si 0.22,Mn 1.48,P 0.009,S 0.002,Nb 0.03,Al 0.04,Cu 0.03,Cr 0.14,Fe余量。从图1b中可以看出,EH36钢主要组织为铁素体和珠光体。通过导电铜胶带将导线固定于WE背面,然后利用环氧树脂对电极进行密封,仅保留7 mm × 7 mm的工作面积用于冲刷腐蚀实验。实验前,依次采用240、400、600、800和1000号砂纸对WE进行打磨,打磨后利用丙酮进一步去除电极表面污渍。在完成WE的准备工作后,首先通过AUW 320精密天平确定其初始重量,然后将其固定在电解池的侧壁,通过热熔胶密封工作电极与池壁之间的缝隙,并保证电极工作面与筒壁平齐,电极中心与搅拌器中心等高。实验中采用钛网作为对电极(CE)并固定在工作电极正对的池壁内部。参比电极(RE)选用饱和甘汞电极(SCE),并通过插入池内的鲁金毛细管减小溶液电阻的影响。实验中通过CS 350电化学工作站将WE、CE和RE进行连接,构成三电极系统用于电化学阻抗谱(EIS)测量。EIS测量采用振幅为10 mV (相对开路电位)的正弦波激励信号,测量频率范围为105~10-2 Hz,测量完成后通过ZView软件对阻抗谱进行拟合分析,从而获得EH36钢在实验周期内的腐蚀速率变化。

图1

图1

冲刷腐蚀实验装置

Fig.1

Schematic of the erosion-corrosion test system (a) and microstructure of EH36 steel (working electrode) (b) (RE—reference electrode, WE—working electrode, CE—counter electrode, SCE—saturated calomel electrode)

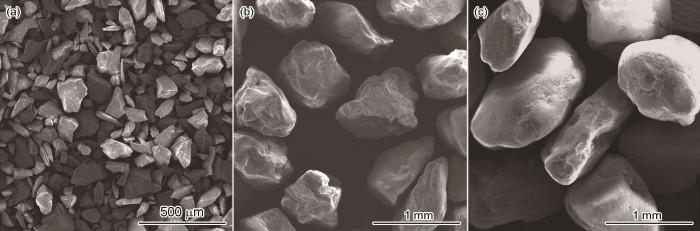

采用质量分数为3.5%的NaCl溶液用于模拟高氯离子含量的海洋环境,实验过程中溶液直接暴露在空气中以确保充足的溶解氧含量,溶液温度通过水浴恒温控制在(28 ± 2)℃以模拟南海的水温环境。采用图2中经过筛选后的3种粒径(平均粒径为100、430和850 μm)的石英砂颗粒(分析纯)用于冲刷腐蚀实验,实验中所采用沙砾在溶液中的质量分数均为10%。

图2

图2

3种不同粒径沙砾的SEM像

Fig.2

SEM images of the three kinds of sand particles with different average diameters

(a) 100 μm (b) 430 μm (c) 850 μm

1.2 流场分析

为了获得600 r/min转速下不同粒径沙砾在工作电极表面的运动轨迹和冲击速率,首先采用ANSYS FLUENT 19.0对搅拌电解池中的含沙流场进行CFD仿真计算。通过前处理软件ICEM对实验装置进行等比例建模,并采用多重参考系法将整个流体区域划分为动态区域和静态区域2个部分,如图3a所示。为了保证计算结果的准确,采用非结构四面体网格对电解池进行划分,同时在壁面处对网格进行细化处理,如图3b所示。经过网格敏感性分析,最终选定的网格模型单元总数量为496041。网格划分完毕后对网格数量进行检验,显示网格质量在0.4以上,整体满足计算要求。选择RNG k-ε (RNG—renormalization group)湍流模型和Euler双流体模型用于含沙溶液的流场计算[24~26]。计算中所采用的溶液密度和黏度分别为1.025 × 103 kg/m3和1.003 ×10-3 kg/(m·s),沙砾密度为2.65 × 103 kg/m3,沙砾的质量分数为10%。

图3

图3

用于计算流体力学(CFD)的搅拌电解池模型

Fig.3

Models of the stirring electrochemical cell used for CFD simulation (CFD—computational fluid dynamics)

(a) geometrical model (b) mesh model

1.3 实验过程

为了获得低流速工况下,不同粒径沙砾冲击下EH36钢的冲刷腐蚀行为,以及沙砾冲击对腐蚀的影响机制,通过实验分别研究了EH36碳钢材料在不含沙盐溶液和含有3种不同沙砾盐溶液中的纯腐蚀和冲刷腐蚀行为。4组实验的周期均为24 h,实验过程中通过EIS测量EH36钢在4种工况下的腐蚀速率变化,测量间隔为1 h。为进一步获得电化学腐蚀对沙砾磨损的作用机制,通过对工作电极施加-850 mV (vs SCE)阴极保护去除腐蚀分量以研究EH36钢在含有3种不同粒径沙砾盐溶液中的纯磨损行为,3组纯磨损实验的周期同样为24 h。实验结束后,首先使用EOS数码相机对碳钢电极进行拍照,然后利用ASTM G1-03酸洗剂对试片表面进行除锈和清理。在表面清洗后,采用OLS 5000激光共聚焦显微镜和EM-20AX Plus扫描电子显微镜(SEM)对电极表面的局部损伤进行观测。对于冲刷腐蚀和纯磨损实验中所采用的电极,通过失重测量获得其金属总损伤速率。为了保证实验数据的可靠性,每组纯腐蚀、冲刷腐蚀和纯磨损实验均重复3次。

2 实验结果与分析

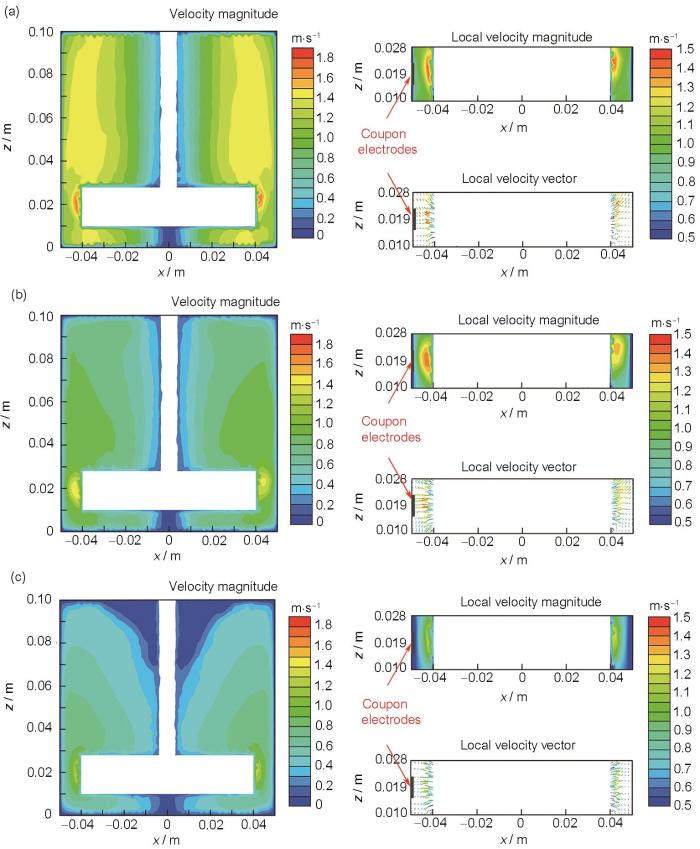

2.1 CFD仿真结果

通过CFD仿真计算得到的不同粒径沙砾在搅拌电解池中的速度和轨迹分布如图4所示。可以看出,在溶液中分别加入相同质量分数的不同粒径沙砾后,沙砾在溶液内的速度分布存在明显差别。如图4a所示,100 μm粒径沙砾在电解池内的速率分布较为均匀。随着沙砾粒径的增大,如图4b和c所示,电解池底部沙砾的运动速率要远高于顶部沙砾。通过局部区域的沙砾迹线和速率分布图可以进一步看出,在3种不同工况下,沙砾在电极表面的运动轨迹均主要沿着较低的掠射角对电极表面进行冲击,100 μm粒径沙砾冲击电极表面的平均速率为0.9 m/s,430 μm粒径沙砾的平均冲击速率为0.7 m/s,850 μm粒径沙砾的平均冲击速率为0.6 m/s。不同粒径沙砾对电极表面的平均冲击能量Ek可通过下式进行估算(假定沙砾为球形):

图4

图4

不同粒径沙砾在搅拌电解池中的迹线和速度分布

Fig.4

Trajectory and velocity distributions of the sand particles with different sizes in the stirring electrochemical cell

(a) 100 μm (b) 430 μm (c) 850 μm

式中,ρs为沙砾的密度,

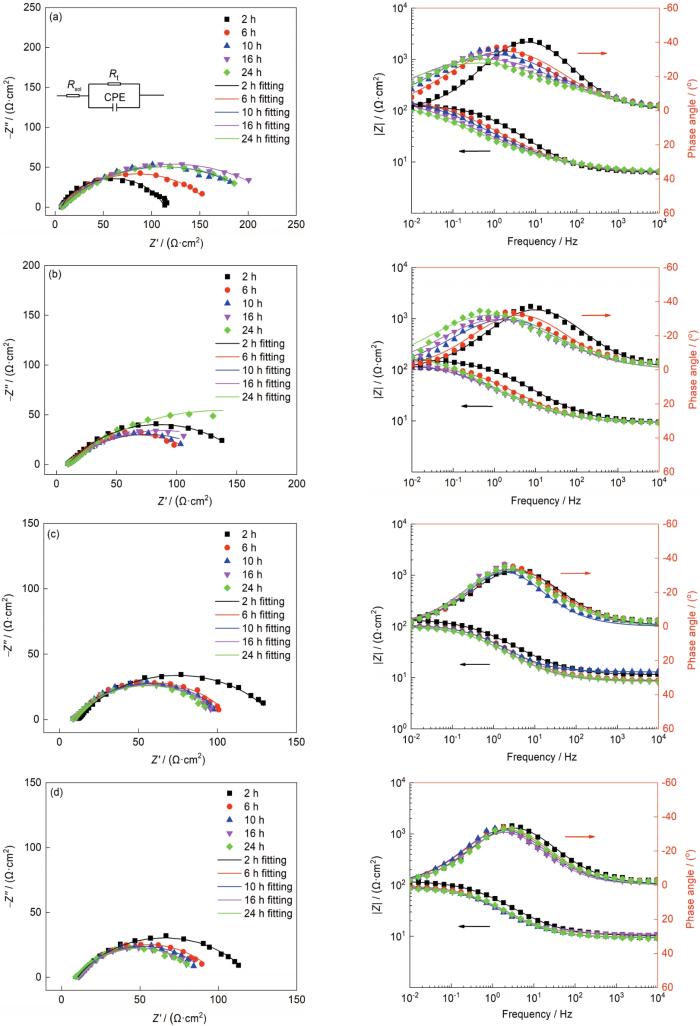

2.2 纯腐蚀和冲刷腐蚀实验结果

图5给出了24 h实验周期内不同时间段的EIS结果。通过Nyquist图可以看出,EH36钢在不含沙和含沙盐溶液中均表现为单一的容抗弧,表明4种情况下的腐蚀反应均由电荷转移过程控制。从图5a中可以看出,在不含沙的流动盐溶液中,EH36钢的容抗弧直径在实验前10 h内逐渐增大,在10~24 h区间内,容抗弧直径变化较小,表明电化学反应在后期逐渐趋于稳定。通过图5a中的Bode图可以看出,高频区相位角随浸泡时间的延长逐渐降低,意味着腐蚀产物在电极表面累积[27]。如图5b所示,在含100 μm粒径沙砾盐溶液中,容抗弧直径呈现出先减小后增大的趋势,表明100 μm粒径沙砾的冲击在初期会加剧腐蚀,但随着腐蚀产物在电极表面的累积,后期腐蚀速率将不断降低。如图5c和d所示,在含430和850 μm粒径沙砾盐溶液中,EH36钢的容抗弧直径在前10 h内会快速减小,表明较大粒径沙砾的冲击在初期会极大促进腐蚀反应,在10~24 h实验区间内,容抗弧直径仍有小幅下降。从图5c和d中的Bode图可以看出,相位角-频率曲线随时间变化不大,表明在较大粒径沙砾冲击下,腐蚀产物难以在碳钢表面积累。

图5

图5

含不同粒径沙砾盐溶液中测量得到的Nyquist图和Bode图

(a) without sand (b) 100 μm (c) 430 μm (d) 850 μm

Fig.5

Nyquist plots (left) and Bode diagrams (right) in the electrolytes containing different kinds of sand particles (Inset in Fig.5a shows the equivalent circuit used to fit the EIS results; Rsol—solution resistance, Rt—charge transfer resistance, CPE—constant phase element)

式中,icorr为腐蚀电流密度,B为Stern系数(根据文献[29,30],本工作采用26 mV/dec作为B值用于腐蚀速率的计算),

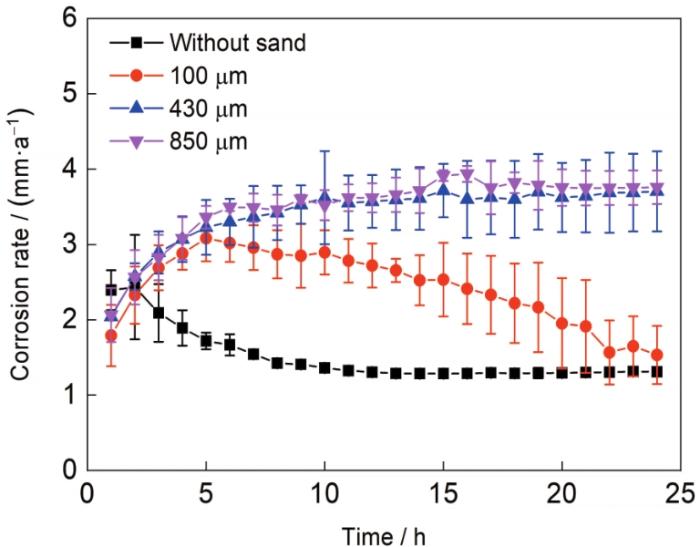

图6

图6

含不同粒径沙砾盐溶液中的EH36钢腐蚀速率变化过程

Fig.6

Time dependence of the corrosion rates of EH36 steel in the electrolyte containing sand particles with different sizes

通过失重测量可以进一步获得碳钢在不同粒径沙砾冲击下的总冲刷腐蚀损伤速率:

式中,

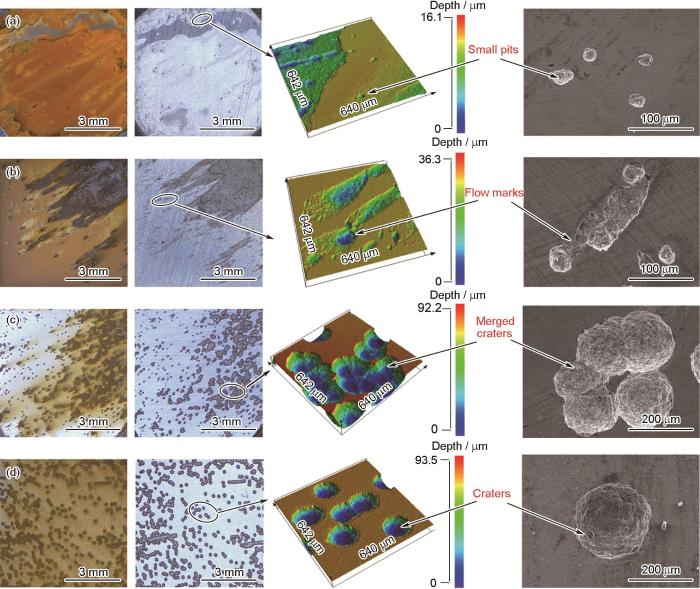

图7给出了含不同粒径沙砾盐溶液中EH36碳钢的冲刷腐蚀形貌。从图7a中可以看出,在不含沙的流动盐溶液中,整个碳钢表面几乎完全被黄褐色铁锈所覆盖,钢材表面以全面腐蚀为主,在局部区域有一些零散的浅坑出现。如图7b所示,在含100 μm粒径沙砾的盐溶液中,碳钢表面的腐蚀面积大幅减小,整体呈现为非均匀腐蚀,腐蚀区域的锈层较薄且呈现为棕褐色。通过三维形貌和SEM观测可以看出腐蚀形貌呈现典型的“沿流体迹线腐蚀”(“flow mark”)[31],尖端出现一个较深的点蚀坑,然后沿着流体的流动方向形成较长且浅的带状或片状腐蚀区域。如图7c所示,当在溶液中加入430 μm粒径沙砾后,碳钢表面的损伤形貌整体表现为明显的冲刷腐蚀坑,从除锈后的照片可以看出电极表面形成了大片的连续冲蚀坑区域,棕黄色的腐蚀产物会在坑内累积,坑的平均深度大约为90 μm。随着盐溶液中沙砾粒径进一步增大到850 μm,如图7d所示,碳钢表面损伤形貌仍然表现为冲刷腐蚀坑,冲蚀坑在电极表面的分布相对独立且更为均匀,冲蚀坑的平均深度也在90 μm左右,与430 μm粒径沙砾冲击下形成的蚀坑深度相近。

图7

图7

不同粒径沙砾冲击下碳钢冲刷腐蚀形貌表征

Fig.7

Photos (with rust layer and after rust removal), 3D profiles, and SEM images of the coupon electrodes in different flowing conditions

(a) without sand (b) 100 μm (c) 430 μm (d) 850 μm

2.3 纯磨损实验结果

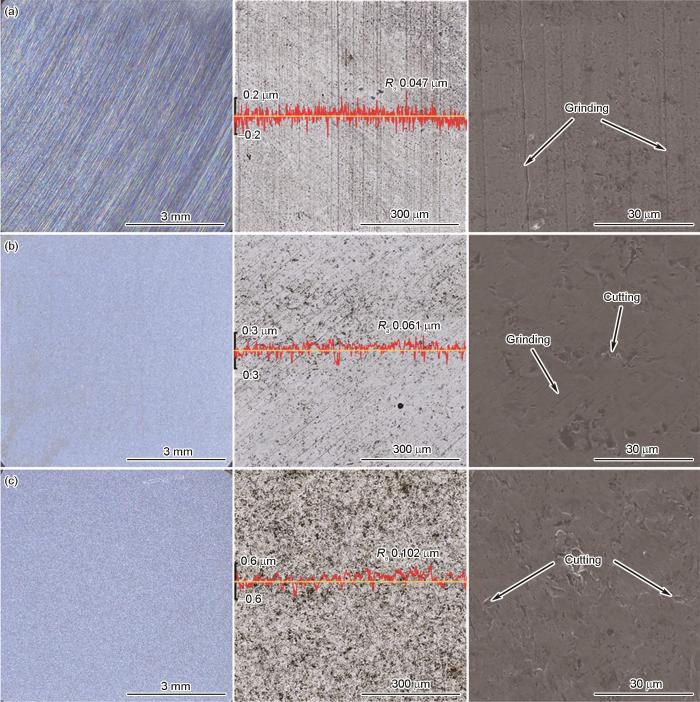

通过对EH36钢在盐溶液中施加阴极保护,结合失重测量获得100、430和850 μm粒径沙砾冲击下碳钢的平均纯磨损速率(

图8

图8

3种不同粒径沙砾冲击下碳钢的纯磨损损伤形貌

Fig.8

Photos, 3D profiles, and SEM images of the coupon electrodes after pure erosion of different size sand particles (Ra—roughness)

(a) 100 μm (b) 430 μm (c) 850 μm

2.4 磨损与腐蚀的协同作用机理分析

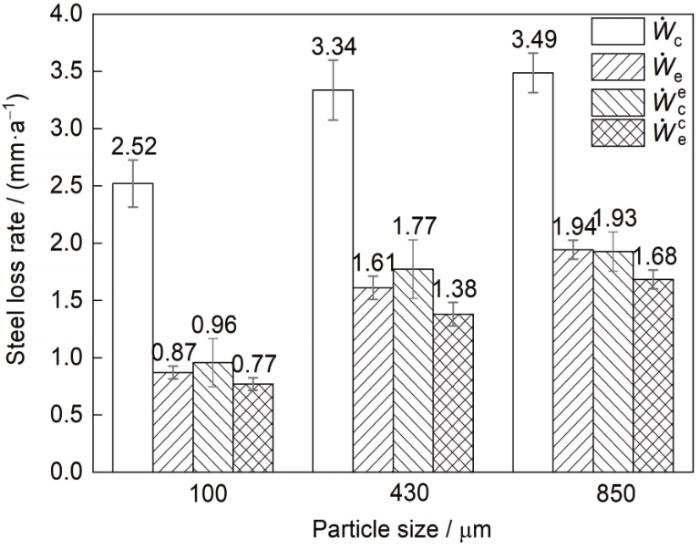

为了进一步讨论不同工况下沙砾磨损与电化学腐蚀的相互促进机制,对EH36钢的冲刷腐蚀损伤中各分量进行了计算。通过每组冲刷腐蚀实验中直接测量得到的

结合不含沙盐溶液中测量得到的纯腐蚀速率(

通过3组平行实验获得的各冲刷腐蚀分量平均值如图9所示,误差棒为3组平行实验的标准差。可以看出,在含有3种不同粒径沙砾的盐溶液中,碳钢的腐蚀分量都远高于磨损分量,表明低流速下电化学腐蚀是导致EH36钢发生冲刷腐蚀损伤的最主要因素。随着沙砾粒径的增加,磨损分量在总损伤中的占比逐渐由100 μm时的26%升高至430 μm时的35%和850 μm时的36%,表明沙砾冲击能量的提升会提高磨损分量在总损伤中的占比。通过解耦腐蚀分量可以发现,在100 μm粒径沙砾的冲击下,由磨损加剧的腐蚀分量为0.96 mm/a,占腐蚀分量的38%。当沙砾粒径达到430和850 μm时,

图9

图9

不同粒径沙砾冲击下碳钢的腐蚀分量、磨损分量、磨损加速腐蚀分量和腐蚀加速磨损分量

Fig.9

Average steel losses induced by corrosion, erosion, erosion enhanced corrosion, and corrosion enhanced erosion under sand particle impacts of different sizes (

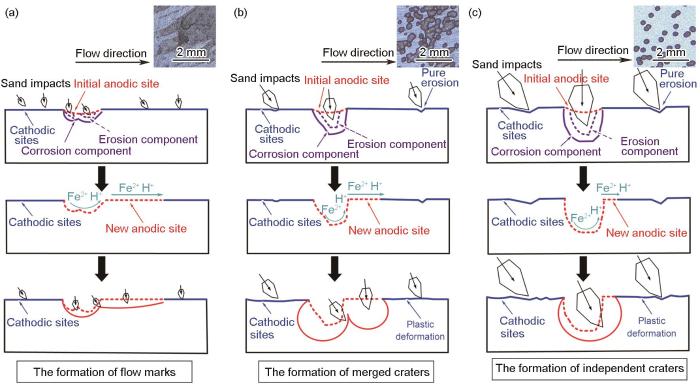

通过对比分析含3种不同粒径沙砾条件下的冲刷腐蚀损伤形貌可以发现,随着沙砾粒径从100 μm升高至430 μm,损伤形式由典型的“flow mark”转变为连续的冲蚀坑形貌,显然沙砾冲击能量的提升引起了局部腐蚀机制的转变。对于高速纯流体中“flow mark”的形成机制在参考文献[31]中进行了详细介绍,“flow mark”初始尖端点蚀坑内的阳极液会随流体向下游转移,导致下游局部pH值降低进而发展成为新的阳极区,随着流体能量在下游耗散,最终形成带状和片状的腐蚀区域。如图10a所示,虽然100 μm粒径沙砾冲击在局部阳极溶解的协同作用下可以对材料造成机械磨损,但是较低的冲击能量所形成的撞击坑深度较浅,由于此工况下的腐蚀速率是磨损速率的3倍,撞击形成的浅坑会很快溶解,无法形成有效的壁垒抑制阳极液的转移。此时,局部湍流仍然是控制腐蚀发展的最主要因素,导致与高速纯流体环境中相似“flow mark”形貌的出现。随着沙砾的粒径从100 μm增加至430 μm,沙砾的冲击能量提高了48倍,如图10b所示,当沙砾冲击在电极表面的初始阳极点时可以导致较深撞击坑的形成,较深的撞击坑在短时间内无法被快速溶解,从而形成壁垒,导致初始阳极点内部的阳极液无法向下游进行大面积转移。腐蚀产物和阳极液在撞击坑内的积累为局部腐蚀的发展提供了闭塞空间,最终导致撞击坑发展为稳定的点蚀坑。由于阳极液只能被流体带动到撞击坑的临近区域,所以新的阳极区只能围绕初始的撞击坑发展,当沙砾进一步撞击在新的阳极区时,将导致连续冲蚀坑的出现。对比100和430 μm粒径沙砾冲击下的局部冲刷腐蚀行为可以发现,存在一个介于5.61 × 10-4~2.7 × 10-2 μJ之间的临界冲击能量,导致碳钢的腐蚀机制由非均匀腐蚀转变为点蚀,点蚀坑的形成也会加速局部的阳极溶解,从而加剧磨损对碳钢损伤的作用。随着沙砾粒径进一步增大至850 μm,沙砾的冲击能量进一步提升,具有更高动能的沙砾冲击在初始阳极点时会形成更深的撞击坑,如图10c所示,导致阳极液更加难以向下游转移,最终形成更为离散和均匀分布的点蚀形貌。

图10

图10

不同粒径沙砾冲击下碳钢局部冲刷腐蚀发展机理

Fig.10

Schematics of local erosion-corrosion development mechanism under sand particle impacts with different sizes and the typical erosion-corrosion morphologies (insets)

(a) 100 μm (b) 430 μm (c) 850 μm

基于不同粒径沙砾冲击下EH36钢的局部损伤发展规律,可以进一步理解图6中不同工况下腐蚀速率随时间的变化过程。在不含沙工况下,由于EH36钢以全面腐蚀为主,整个电极表面几乎都处于活化溶解状态,导致其在纯流体中的初始腐蚀速率较高,但由于低流速下纯流体的切应力难以将腐蚀产物带走,伴随着腐蚀产物在电极表面的吸附和积累,电极表面在纯流体中的阴极反应被有效抑制,从而使腐蚀速率在2 h后迅速降低。在含100 μm粒径沙砾盐溶液中,钢材表面发生非均匀腐蚀,浸泡初期阳极面积随着“flow mark”的发展而增加,导致腐蚀速率在前5 h内持续上升。但100 μm粒径沙砾的冲击能量还不足以将电极表面的腐蚀产物完全清除,随着一层较薄的腐蚀产物在电极表面形成(图7b),电极的腐蚀速率在达到峰值后出现显著下降。当溶液中的沙砾粒径进一步增大到430和850 μm后,EH36钢的腐蚀机制将从全面腐蚀和非均匀腐蚀转变为点蚀,此时沙砾的冲击作用促使电极表面的初始阳极点逐渐发展成点蚀坑,电极的腐蚀速率在前5 h内随着点蚀坑的形成快速上升。随着腐蚀产物在点蚀坑内积累形成局部闭塞空间,点蚀进入稳定发展阶段。由于较大粒径的沙砾冲击能量能够有效清除坑外阴极区的腐蚀产物,使阴极反应速率几乎不受影响,电极的腐蚀速率将随着稳态点蚀坑的发展进一步呈现小幅提升。由此可见,海洋工程用碳钢材料在含沙海水中的损伤机制可以通过其初期的腐蚀速率变化规律进行定性分析。

研究不同粒径沙砾冲击下的局部损伤机理可以得到低流速下EH36钢的点蚀萌发条件。与EH36钢相类似,大部分碳钢材料在海水环境中都处于活性溶解状态,因此,针对不同类型的碳钢材料都将存在临界沙砾冲击能量,导致其局部损伤机制由全面腐蚀或非均匀腐蚀转变为点蚀。一旦点蚀发生,钢材将快速损伤穿孔,进而威胁整个钢制海洋结构物的安全,所以有效获得造成不同碳钢材料出现点蚀损伤的临界沙砾冲击能量具有重要意义。而在以往的冲刷腐蚀研究中,通过电化学与失重联合测量得到的磨损分量和腐蚀分量只能用来分析磨损与腐蚀在宏观层面的交互影响机制,无法有效考虑局部沙砾冲击和微区阳极溶解在钢材表面的协同作用,导致目前对含沙流动海水中碳钢材料的点蚀临界发生条件缺乏系统认知。在今后的研究中,需要在明晰磨损与腐蚀宏观层面的交互影响基础上,进一步结合微区电化学测量和微观形貌表征来分析碳钢材料在实际含沙流动海水环境中的局部冲刷腐蚀损伤机制,从而获得不同类型海洋工程用碳钢材料在含沙海水中的点蚀萌发条件,指导实际海洋工程的材料选择。

3 结论

(1) CFD计算结果表明,在低流速环境(2 m/s)中,沙砾粒径的提高(100~430 μm)可以有效增加沙砾的质量,导致冲击能量快速上升,但随着沙砾粒径的进一步增加(430~850 μm),沙砾的运动速率降低,导致冲击能量的提升受限。

(2) 在含有不同粒径沙砾的低流速盐溶液中,腐蚀分量在总损伤中的占比均超过60%,表明腐蚀是导致EH36钢在含沙盐溶液中材料损伤的最主要因素。随着沙砾粒径从100 μm升高至850 μm,磨损分量在总损伤中的占比从26%升高至36%,表明沙砾尺寸的增大能够加剧磨损损伤在总损伤中的占比。

(3) 随着沙砾粒径从100 μm升高至850 μm,磨损加速腐蚀在腐蚀分量中的占比从38%升高至55%,表明沙砾粒径的增加能够显著促进腐蚀的进行。在3种粒径沙砾的冲击下,腐蚀加剧磨损在磨损分量中的占比均超过86%,表明腐蚀是导致显著磨损发生的前提条件,粒径增加可以导致磨损量进一步升高。沙砾磨损与电化学腐蚀的协同作用是造成EH36钢冲刷腐蚀的最主要原因。在低流速工况下,沙砾粒径的增加会加剧磨损与腐蚀的耦合作用。

(4) 在低流速下,沙砾粒径的增加会导致EH36碳钢材料的损伤更为局部,100 μm粒径沙砾的冲击会导致非均匀腐蚀(“flow mark”)的形成,随着沙砾粒径增加到430和850 μm,碳钢表面有点蚀坑形成。沙砾撞击阳极点所形成的深坑可以有效阻止阳极液转移,流场作用下阳极液转移和沙砾冲击共同决定了冲刷腐蚀的局部发展过程。当沙砾粒径为100 μm时,冲刷腐蚀的发展主要由流体带动阳极液的转移为主导,冲刷腐蚀形貌呈现为典型的“flow mark”。当沙砾粒径升高至430和850 μm时,沙砾冲击和阳极溶解耦合作用下形成的较深撞击坑将有效阻碍阳极液的转移,导致稳定点蚀的形成与发展。碳钢材料在含沙盐溶液中的腐蚀速率变化趋势可以用来定性判断腐蚀的发生类型。

参考文献

Inhibition of the erosion-corrosion of a 90° low alloy steel bend

[J].

Corrosion degradation of ship hull steel plates accounting for local environmental conditions

[J].

Corrosion behavior of X80 steel welded joint in simulated natural gas condensate solutions

[J].Carbon steels are widely used as transportation pipelines in oil and gas fields and welding is one of the main ways of connecting pipeline steel. The welded joints are easily corroded due to the difference in composition, structure and properties of the various components. The effect of content of HAc, Cl-, ethylene glycol (MEG) and temperature (T) on the corrosion behavior of welded joint of X80 steel in a simulated natural gas condensate saturated with CO2 was studied by the orthogonal experimental design, weight loss experiment and electrochemical experiment. It is demonstrated that the corrosion rate of the welded joint is significantly higher than that of the base metal because of the formation of macroscopic corrosion galvanic cells, and the corrosion of the weld metal as an anode region is accelerated to become a weak link of the welded joint. The significance of the four factors on the corrosion process is: c(HAc)>T $\gg$c(Cl-)>c(MEG), c(HAc) and T are the main factors affecting the corrosion behavior, and c(Cl-) and c(MEG) are secondary factors. Base metal and weld metal corrosion tendencies increase with increasing temperature. Because ferrous acetate is less protective as a corrosion product, as the c(HAc) increases, the impedance of the base metal and weld metal decreases, and the corrosion rate increases. Based on the results of orthogonal experiments, a multivariate linear regression equation was established.

X80钢焊接接头在模拟天然气凝析液中的腐蚀行为

[J].

Corrosion behaivour of X65 low carbon steel during redox state transition process of high level nuclear waste disposal

[J].

地质处置低氧过渡期X65低碳钢腐蚀行为研究

[J].利用实验室自行搭建的低氧手套箱电化学测试体系系统,长期监测X65低碳钢在模拟地质处置过渡期80 ℃低氧饱和膨润土中的电化学腐蚀行为,发现X65低碳钢的开路电位在150 d内逐渐降低,阻抗模逐渐增加,腐蚀类型从初期的点蚀转变为均匀腐蚀;利用SEM、EDS和μ?XRD表征了X65低碳钢腐蚀产物的形貌、元素组成和物相组成,发现腐蚀产物有颗粒状、片状、杆状和胞状4种类型,腐蚀产物中的元素均匀分布,产物物相由Fe<sub>3</sub>O<sub>4</sub>和α-Fe<sub>2</sub>O<sub>3</sub>组成;使用失重法测量X65低碳钢平均腐蚀速率,发现腐蚀速率(V)在150 d内逐渐从195.88 μm/a降低到20.58 μm/a,V随时间(t)的变化规律符合降幂函数关系式V=8.34t<sup>-0.88</sup>,腐蚀过程受扩散控制。

Review—Electrochemical noise applied in corrosion science: Theoretical and mathematical models towards quantitative analysis

[J].

An overview of major experimental methods and apparatus for measuring and investigating erosion-corrosion of ferrous-based steels

[J].This paper firstly provides an overview of major efforts made over the past several decades on developing the test apparatus for the study of erosion-corrosion of ferrous-based steels. The merits and the application range of the set-ups, i.e., rotating disc/cylinder electrode system, slurry jet impingement rig, and test flow loop, are introduced. Secondly, the advantages and limitations of both non-electrochemical and electrochemical methods used for the measurement of erosion-corrosion are presented. Thereafter, the interaction between erosion and corrosion using a cyclic erosion-corrosion method was introduced. The synergy between erosion and corrosion for the steels under the passive state were analyzed on the basis of the breakdown and restoration of the passive film. In addition, the difference between the obtained erosion-enhanced corrosion and the corrosion-enhanced erosion using different experimental methods for steels under active corrosion was discussed. Finally, the interaction between the localized corrosion and erosion was studied through the dynamic change of the local current distribution revealed by the wire beam electrode.

A novel system for corrosion protection of reinforced steels in the underwater zone

[J].

Detecting and monitoring erosion-corrosion using ring pair electrical resistance sensor in conjunction with electrochemical measurements

[J].

Review-material degradation assessed by digital image processing: Fundamentals, progresses, and challenges

[J].

Effect of impact angle on the critical flow velocity for erosion-corrosion of 304 stainless steel in simulated sand-containing sea water

[J].

Erosion-corrosion and its mitigation on the internal surface of the expansion segment of N80 steel tube

[J].

In situ study of flow accelerated corrosion and its mitigation at different locations of a gradual contraction of N80 steel

[J].

On the critical flow velocity for erosion-corrosion in local eroded regions under liquid-solid jet impingement

[J].

On the critical flow velocity for erosion-corrosion of Ni-based alloys in a saline-sand solution

[J].

Influence of

通过阳极极化曲线、EIS、Mott-Schottky (M-S)以及恒电位极化测量研究了不同pH值模拟混凝土孔隙溶液中SO<sub>4</sub><sup>2-</sup>对Q235B钢筋钝化和腐蚀行为的影响。极化曲线测量结果表明,在pH值高于11的模拟孔隙液中,SO<sub>4</sub><sup>2-</sup>对Q235B钢的钝化膜没有破坏作用,而在pH值为10的模拟孔隙液中,少量SO<sub>4</sub><sup>2-</sup>的存在就会造成Q235B钢表面钝化膜的破裂,从而导致点蚀的萌发。EIS和M-S测量结果表明,碳钢表面的钝化膜在低pH值的模拟孔隙液中稳定性较差并具有更高的缺陷浓度,从而促进了SO<sub>4</sub><sup>2-</sup>对碳钢的侵蚀性。结合恒电位极化测试和SEM观测进一步研究了SO<sub>4</sub><sup>2-</sup>对碳钢钝化膜的破坏作用。在高pH值的模拟孔隙液中,SO<sub>4</sub><sup>2-</sup>在钝化膜的形成阶段能够抑制钝化膜的生长,造成亚稳态点蚀的出现,而在低pH值的模拟孔隙液中,SO<sub>4</sub><sup>2-</sup>可以聚集在钝化膜的缺陷处,造成钝化膜的破损和稳态点蚀的发展。

Erosion-corrosion of chromium steel in a rotating cylinder electrode system: Some comments on particle size effects

[J].

Effect of the sea mud on erosion-corrosion behaviors of carbon steel and low alloy steel in 2.4%NaCl solution

[J].

Slurry erosion resistance of fusion-bonded epoxy powder coating

[J].

Erosion corrosion behavior of X80 steel in multiphase flow with different sand particle sizes

[J].

X80钢在不同砂粒粒径下的多相流中的冲刷腐蚀行为

[J].

Effect of groove depth on the slurry erosion of V-shaped grooved surfaces

[J].

Corrosion behavior of long-time immersed rusted carbon steel in flowing seawater

[J].

带锈碳钢在流动海水中的长期腐蚀行为

[J].

Exploring the effects of sand impacts and anodic dissolution on localized erosion-corrosion in sand entraining electrolyte

[J].

Understanding the propagation of nonuniform corrosion on a steel surface covered by marine sand

[J].The corrosion progression of X65 pipeline steel, which was partly covered by a mineral deposit layer, was investigated in oxygen-containing artificial seawater using a multielectrode array (MEA) and electrical resistance method. Results show that the deposit covered area would act as the anodes due to the oxygen concentration difference between the bare steel area and deposit covered area. The most serious corrosion would occur at the bare steel area which was close to the sand deposit due to the diffusion of the cations from the deposit covered area to the bare steel area, leading to the decrease of local pH. Once the diffusion path between the bare steel area and the deposit covered area was blocked, the bare steel area would act as a constant cathode, resulting in the formation of a protective calcium carbonate layer on the bare steel surface.

CFD assessment of the hydrodynamic performance of two impellers for a baffled stirred reactor

[J].When converting a baffled stirred reactor to work with a different fluid, usually the original impeller must be replaced with a customized one. If the original impeller was designed for mixing liquids, its performance for liquid–solid suspensions may not be satisfactory. A case study is presented, where a two-blade original impeller is replaced with a new three-blade design. The new impeller shows clear improvements in mixing a liquid–solid suspension, while keeping the shaft power practically at the same level. As a result, a practically homogenous liquid–solid mixture is obtained, thus ensuring the required quality of the final product. The present numerical investigations employ the Eulerian multiphase model with renormalization (RNG) k–ε turbulence model to simulate the three-dimensional unsteady free-surface liquid–solid flow in a stirred tank. A sliding mesh approach was used to account for the impeller rotation within the expert code, FLUENT 16. The comparative quantitative analysis of the solid phase distribution and the relevant velocity profiles show that the new design of three-blade-impeller is significantly increasing the sedimentation time of the solid phase beyond the chemical reaction specific time. The necessary power to drive the new impeller has a slightly higher value than for the original impeller but it can be sustained by the existing driving system.

Exploring the corrosion performances of carbon steel in flowing natural sea water and synthetic sea waters

[J].

The roles of fluid hydrodynamics, mass transfer, rust layer and macro-cell current on flow accelerated corrosion of carbon steel in oxygen containing electrolyte

[J].The flow accelerated corrosion (FAC) of EH 36 carbon steel in the oxygen containing flowing electrolyte is studied using multi-electrode array arranged in a jet rig system. The FAC of the working electrodes (WEs) under both uncoupled and coupled conditions are investigated in conjunction with computational fluid dynamics (CFD) simulation. Results show that a higher mass transfer rate would lead to a higher FAC rate when the WEs are uncoupled. The rust layer could retard the oxygen diffusion, resulting in the FAC rate decreasing. The mass transfer process and the distribution of the rust layer are significantly influenced by the fluid hydrodynamics. However, when the WEs are coupled together, serious FAC damage would occur on the WEs where lower mass transfer rates are registered. The macro-cell currents would become the main lead of FAC propagation at coupled conditions.

Understanding the influences of temperature and microstructure on localized corrosion of subsea pipeline weldment using an integrated multi-electrode array

[J].

Electrochemical polarization: I. A theoretical analysis of the shape of polarization curves

[J].

Electrochemical characteristics of the dynamic progression of erosion-corrosion under different flow conditions and their effects on corrosion rate calculation

[J].

Visualising the dynamic processes of flow accelerated corrosion and erosion corrosion using an electrochemically integrated electrode array

[J].

Probing the initiation and propagation processes of flow accelerated corrosion and erosion corrosion under simulated turbulent flow conditions

[J].

Interaction of mechanical and electrochemical factors in erosion-corrosion of carbon steel

[J].