Li等[6]和Tan等[7]发现,铸态GH4151合金的组织复杂,包括γ/γ′共晶、η相、Laves相等低熔点脆性相,并对凝固行为及均匀化制度进行了初步探究。高γ′相含量导致GH4151合金γ'相形态和分布同样复杂[2],包含分布在晶界的一次γ′相、晶内的二次γ′相及三次γ′相。目前,GH4151合金的研究尚处于初期阶段,主要集中在凝固偏析行为及均匀化制度优化[6~9]、热加工行为及变形机制[2,4,8]等方面,但针对GH4151合金自身的高度合金化特点与热处理过程中组织演变行为之间的关联性的系统研究,尚未见到报道。高温热处理工艺中的温度及冷却速率,均会对组织产生重要影响。高合金化高温合金的组织对热处理条件非常敏感,工艺参数的波动易导致组织和性能差异。因此深入研究高度合金化特点-组织-热处理条件之间的关联性可为合金制备工艺提供理论指导。本工作主要研究高合金化GH4151镍基变形高温合金在热处理过程中的组织演变行为,阐述高合金化合金的特点与组织演变之间的关系。

1 实验方法

GH4151合金经真空感应加真空自耗熔炼制备,质量为500 kg,其主要化学成分(质量分数,%)为:C 0.04,Cr 11.6,Co 15.1,W 2.7,Mo 4.6,Al 3.8,Nb 3.7,Ti 3.0,V 0.6,Ni余量。从铸锭边缘、1/2半径、中心处取样进行观察,样品尺寸为直径10 mm、高15 mm。取1/2半径位置样品进行高温淬火、高温扩散和过固溶处理+不同冷却速率冷却实验,具体实验过程如下。

(1) 高温淬火实验:分别在1150、1160、1170、1180和1190℃保温10 min后水冷,观察组织演变特征。

(2) 高温扩散实验:分别进行1140℃、10 h;1140℃、20 h;1140℃、20 h + 1170℃、10 h;1140℃、20 h + 1170℃、10 h + 1200℃、20 h热处理后水冷,观察组织演变特征。

(3) 过固溶处理+不同冷却速率冷却实验:选取高温扩散实验1140℃、20 h + 1170℃、10 h + 1200℃、20 h条件下得到的过固溶态样品,分别以水冷(WQ,7888℃/min)、油冷(OQ,2663℃/min)、空冷(AC,220℃/min)、炉冷(FC,15℃/min)、缓冷(SC,10℃/min)、极缓冷(SSC,1℃/min)的冷却速率冷却到室温,其中WQ、OQ和AC的冷却速率基于Newton冷却定律计算得到[10],FC、SC和SSC的冷却速率通过设置加热炉降温速率控制。将均匀化后的GH4720Li及GH4738合金,在1200℃、2 h固溶处理后以SC速率冷却到室温进行组织对比分析。

金相试样采用0.5 g CuCl2 + 10 mL HCl + 10 mL C2H5OH溶液进行侵蚀,利用DMR光学显微镜(OM)观察枝晶形貌。通过150 mL H3PO4 + 10 mL H2SO4 + 15 g CrO3溶液进行电解侵蚀,利用附带INCA X-ACT能谱(EDS)的Supra 55场发射扫描电镜(SEM)观察和分析微观组织及元素分布。采用JMatPro热力学计算软件及该软件内置的Nickel Based Superalloy数据库计算GH4151合金的热力学平衡态、凝固行为及具有不同γ'相形成元素含量的典型镍基高温合金中γ'相析出行为,包括GH4151、GH4720Li、FGH4096、GH4738、GH4282等合金。利用Photoshop软件计算γ'相的尺寸。

2 实验结果

2.1 铸态合金的析出相

基于JMatPro的Sheil-Gulliver模型可计算GH4151合金的凝固行为。图1a是合金凝固过程元素分配情况。随着固相含量的增加,Nb、Mo、Ti、V在残余液相中的含量呈上升趋势,残余液相最终凝固为枝晶间组织,即Nb、Mo、Ti、V偏聚于枝晶间,同理Co、Cr、W、Al偏聚于枝晶干。偏析系数(k)可对合金中的元素偏析程度进行定量描述,k为枝晶间元素质量分数与枝晶干元素质量分数的比值。计算可得Nb、Mo、Ti和W的偏析系数依次为5.41、2.21、1.55和0.18,其中Nb、Mo和W属于难熔元素,Nb、Ti属于γ'相形成元素。热力学计算结果表明GH4151合金偏析严重。图1b为GH4151合金的凝固路径,可得到物相的析出顺序如下:γ基体(1325℃),MC碳化物(1295℃),γ'相(1175℃),η相(1160℃),σ相(1135℃)和Laves相(1095℃)。热力学计算结果表明GH4151合金的铸态组织比较复杂。

图1

图1

GH4151合金凝固过程的元素分布及凝固路径的热力学计算结果

Fig.1

Thermodynamic calculation results of element distribution behavior during solidification (a) and solidification process (b) of GH4151 superalloy

GH4151合金铸态组织OM像如图2a所示,呈现明显的枝晶形貌。通过EDS分析各元素成分,计算得到元素Nb、Mo、Ti和W的k分别为2.29、1.29、1.57和0.55,各元素偏析较为严重,符合图1a中的元素偏析特征。从GH4151合金铸态组织的SEM像可以看出,枝晶干的γ'相呈细小颗粒状,而枝晶间的γ'相呈大尺寸不规则形状,如图2b及c所示。图2d~f表明枝晶间还存在复杂的析出相,其成分如表1所示。结合文献[8]及EDS分析可得,圆润颗粒状A相为Laves相,板条状B相为η相,葵花状C相为γ/γ'共晶相,尖锐棱角颗粒状D相为MC碳化物。合金铸态组织呈现出复杂的相分布特征,枝晶间的Laves相、γ/γ'共晶相和η相作为有害脆性低熔点相会恶化热加工塑性[8,11,12],因此需通过高温均匀化处理予以消除。

图2

图2

GH4151合金铸态组织的OM像及SEM像

Fig.2

OM image of dendritic morphology (a), SEM image of γ′ phase at dendritic region (b), SEM images of precipitations at interdendritic region (c-f) in as-cast GH4151 superalloy

表1 铸态GH4151合金枝晶间各析出相的化学成分 (atomic fraction / %)

Table 1

| Region | C | Al | Ti | V | Cr | Co | Ni | Nb | Mo | W | Phase |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 0 | 1.20 | 1.62 | 0.41 | 21.23 | 22.20 | 25.54 | 12.24 | 13.65 | 2.34 | Laves |

| B | 0 | 6.52 | 8.11 | 0 | 3.63 | 12.62 | 61.02 | 6.36 | 1.15 | 0.51 | η |

| C | 0 | 9.80 | 7.28 | 0 | 2.97 | 12.72 | 69.07 | 3.13 | 1.04 | 0.14 | γ/γ' eutectic |

| D | 56.25 | 0.08 | 10.84 | 0.25 | 0.34 | 0.36 | 1.48 | 28.88 | 0.84 | 0.48 | MC carbide |

2.2 析出相的演变

实际生产中常通过高温扩散热处理消除合金铸态组织中的低熔点相。GH4151合金由于合金化程度高,含有较多的低熔点相,热处理制度选择不当时,合金容易发生初熔,从而恶化其热加工性能。因此研究GH4151合金的析出相演变行为尤为必要。

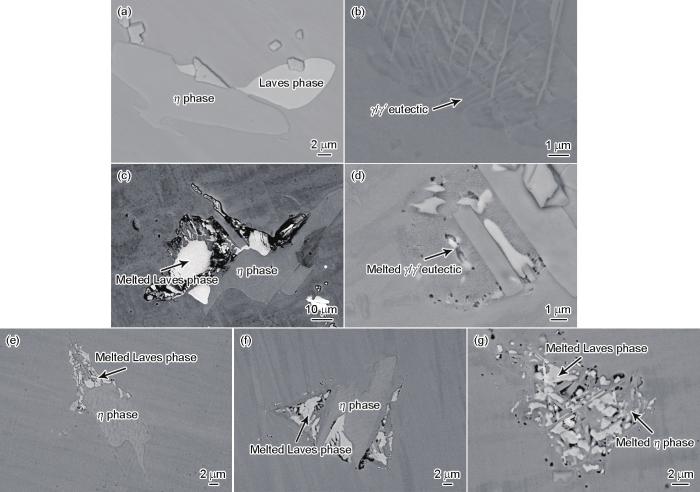

图3为铸态GH4151合金在不同温度下保温10 min后水冷显微组织的SEM像。在1150℃保温时,能明显观察到Laves相及γ/γ'共晶相的边缘变得圆润,表明其发生一定程度的回溶且未发生明显初熔,如图3a和b所示。在1160℃保温时,Laves相与γ/γ′共晶相均发生明显初熔,其中γ/γ'共晶相由葵花状变成絮状,内部出现细小的孔洞,如图3c和d所示,因此,Laves相和γ/γ'共晶相的初熔温度在1150~1160℃之间。在1170和1180℃保温时,Laves相发生明显初熔,但η相仍保持完整,如图3e和f所示。在1190℃保温,η相由原始的板条状变成细密的交叉状,如图3g所示,表明η相发生初熔,因此η相的初熔温度在1180~1190℃范围内。综上可知,铸态GH4151合金热处理的关键温度区间是Laves相、γ/γ'共晶相和η相的初熔温度范围。

图3

图3

GH4151合金不同温度保温10 min后水冷组织形貌的SEM像

Fig.3

SEM images of GH4151 superalloy after heat treated at 1150oC (a, b), 1160oC (c, d), 1170oC (e), 1180oC (f), and 1190oC (g) for 10 min and then water quenching

为避免保温过程中炉温波动引起低熔点相的初熔,选择关键温度区间以下10℃作为回溶的温度。本工作中对于Laves相与γ/γ'共晶相、η相,保温温度分别为1140和1170℃。图4a和b为GH4151合金1140℃保温不同时间后的微观组织的SEM像。Laves相与γ/γ'共晶相在保温10 h后仍有少量残余,在保温20 h后基本回溶,但此时仍存在较为明显的η相。在1170℃保温10 h后,η相基本回溶,如图4c所示。枝晶间和枝晶干位置的γ'相均呈规则的球形,且分布致密均匀,表明初始γ′相已基本回溶并在冷却过程中重新析出,但是由于合金中元素偏聚的存在,冷却后枝晶间γ'相尺寸较大。因此需要进一步高温热处理以使元素分布均匀。参考文献[6]的热处理条件,选择在1200℃保温20 h。此时γ'相整体分布均匀,且合金中无明显的初熔孔洞,如图4d所示。在上述热处理中,如果前期热处理温度高于关键温度区间,便会诱导低熔点相发生初熔,初熔孔洞会遗传到后续的热处理过程中。低熔点相未发生初熔且回溶完全后,基体中主要析出相为γ'相与MC碳化物,适当升高热处理温度并不会导致相发生熔化。综上所述,优化铸态组织、获得均匀且无初熔孔洞热处理合金的关键在于前期热处理温度需低于关键温度区间,即Laves相、γ/γ'共晶相和η相的初熔温度。

图4

图4

基于关键温度区间确立的热处理条件下GH4151合金显微组织的SEM像

Fig.4

SEM images of GH4151 superalloy after heat treatment at 1140oC, 10 h (a), 1140oC, 20 h (b), 1140oC, 20 h + 1170oC, 10 h (c), 1140oC, 20 h + 1170oC, 10 h + 1200oC, 20 h (d) based on the key temperature ranges (Insets show the locally enlarged views)

2.3 γ' 相演变行为

GH4151合金中,高含量的γ'相形成元素导致γ'相的析出温度、析出含量等均发生变化。选取γ'相形成元素含量不同的几种典型合金GH4151 (Al + Ti + Nb含量为10.5%)、GH4720Li (Al + Ti含量为7.47%)[13]、FGH4096 (Al + Ti + Nb含量为6.7%)[14]、GH4738 (Al + Ti + Nb含量为4.61%)[15]和GH4282 (Al + Ti + Nb含量为3.67%)[16]进行对比。基于JMatPro软件计算上述合金中γ'相在热力学平衡态下的析出行为。图5a为平衡态下不同合金中γ'相含量与温度的关系。可以看出,随着γ'相形成元素含量的增加,γ'相析出温度提高,γ'相含量也随之增加,其中GH4151合金中γ'相含量与析出温度最高。此外,不同合金析出同样含量的γ'相所需的温差(ΔT)并不相同,如图5b所示,具有更高γ'相形成元素含量的GH4151合金析出相同含量γ'相所需的温差最小,例如GH4151合金在50℃的温差下便可析出20%的γ'相,而具有低γ'相形成元素含量的GH4282合金则需要约350℃的温差。

图5

图5

基于JMatPro热力学软件计算得到不同合金的γ'相析出行为

Fig.5

Mass fraction of γ' phase of different alloys (a) and the relationship between ΔT and γ' phase content (ΔT—difference between current temperature and γ' phase precipitation temperature) (b) based on calculation by using JMatPro software

图6

图6

过固溶态GH4151合金在不同冷却速率下γ'相形貌的SEM像(冷却速率≥炉冷)

Fig.6

SEM images of γ′ phase in GH4151 superalloy after heat treatment at 1140oC, 20 h + 1170oC, 10 h + 1200oC, 20 h and then water quenching (cooling rate v = 7888oC/min) (a), oil quenching (v = 2663oC/min) (b), air cooling (v = 220oC/min) (c), and furnace cooling (v = 15oC/min) (d) when the cooling rate ≥ furnace cooling

图7

图7

过固溶态GH4151合金在不同冷却速率下γ′相形貌的SEM像(冷却速率<炉冷)

Fig.7

Low (a, c) and high (b, d) magnified SEM images of γ' phase in GH4151 superalloy after heat treatment at 1140oC, 20 h + 1170oC, 10 h + 1200oC, 20 h and then slow cooling (v = 10oC/min) (a, b), super slow cooling (v = 1oC/min) (c, d) when the cooling rate < furnace cooling (Oval regions show the γ' phases with irregular morphologies)

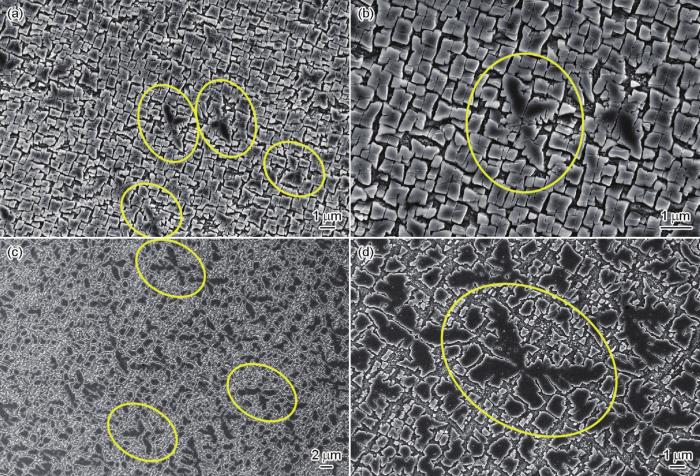

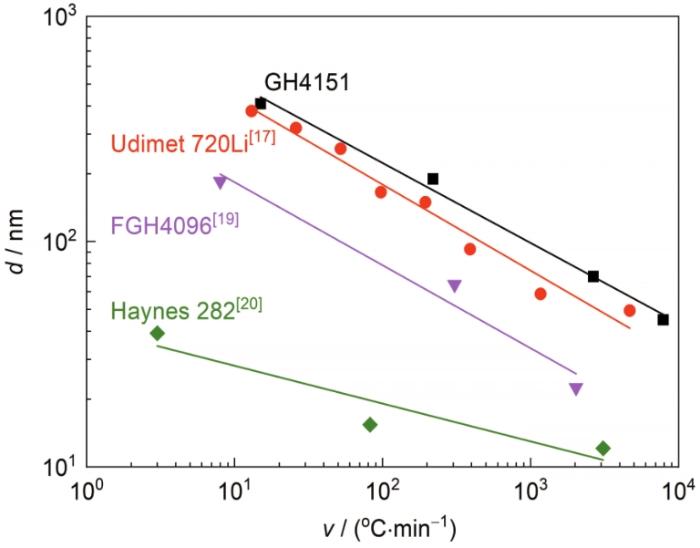

冷却速率大于炉冷时,GH4151合金中的γ′相尺寸随冷却速率变化较为明显。图8为不同合金的冷却速率与γ'相平均尺寸的关系。GH4151合金的冷却速率与γ'相直径的拟合关系为lgd = -0.35lgv + 3.06 (d为γ'相直径,v为冷却速率),双对数坐标下能够较好地满足线性关系。该拟合公式是基于普适意义的动力学推导而来,适用于高温合金中γ'相的长大行为[17,18]。对比其他γ'相形成元素含量更低的合金,如Udimet 720Li (对应国内牌号GH4720Li,Al + Ti含量为7.49%)[17]、FGH4096 (Al + Ti + Nb含量为6.62%)[19]和Haynes 282 (Al + Ti + Nb含量为3.71%)[20],可以明显看出,随着γ'相形成元素含量的增加,在GH4151合金中γ'相规则生长的冷却速率范围内(7888~15℃/min),GH4151合金的γ'相含量更高,在相同冷却速率下更易长大。

图8

图8

不同合金γ'相平均尺寸与冷却速率的关系

Fig.8

Relationship between the average size of γ' phase (d) and v

冷却速率慢于炉冷可诱发γ'相不规则生长。本工作定义不规则因子ξ (irregularity coefficient)来表征不规则程度。ξ的定义式如下式所示:

式中,L为沉淀相的周长;L0为周长为L的二维区域等效成同等面积的圆形区域时,所对应的圆形区域周长。ξ越大表明沉淀相的形状越不规则。ξ与γ'相形成元素的含量存在关联。为对比不同合金的γ'相不规则程度,以GH4738、AD730[21]、GH4720Li和GH4151合金为例进行分析。图9为上述合金在过固溶态以10℃/min冷却速率冷却后的SEM像与ξ值。GH4738合金呈现较为规则的细小γ'相,AD730合金的γ'相发生轻微的不规则生长,GH4720Li和GH4151合金中γ'相均发生了不同程度的不规则生长,且GH4151合金中大尺寸γ'相的不规则程度更高。对比上述4种合金的ξ值可以看出,γ'相的不规则程度随着γ'相形成元素含量的增加而增大,与其他合金相比,GH4151合金γ'相形貌具有较高的冷却速率敏感性。

图9

图9

过固溶态的不同高温合金以10℃/min冷却后的SEM像和不规则因子(ξ)

Fig.9

SEM images and irregularity coefficients (ξ) of different superalloys after cooling at 10oC/min from the super-solvus state

3 分析与讨论

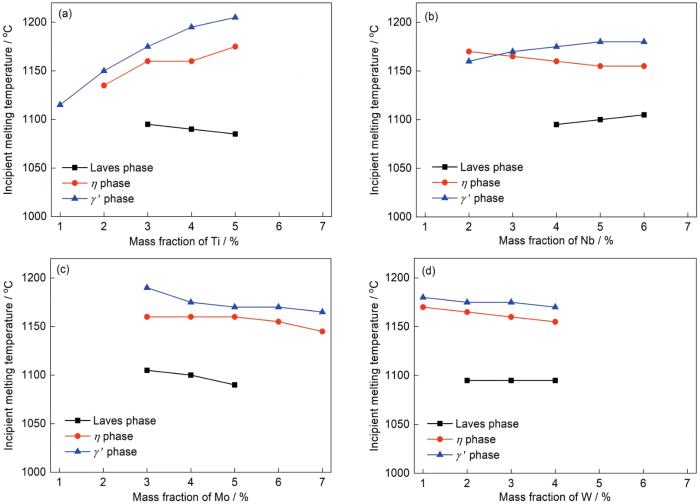

GH4151合金元素较多且含量高,元素含量的波动会导致低熔点相的初熔温度变化。由于Ti、Nb、Mo和W在凝固期间的偏聚较为严重,并且枝晶间析出相的形成与偏析元素关系密切,因此本工作主要对上述4种偏析元素进行了探讨。图10为Ti、Nb、Mo和W含量对低熔点相初熔温度的影响。Ti含量较低时,η相的初熔温度明显降低,容易导致η相发生初熔。Ti含量降低导致Laves相的初熔温度升高,因此对Laves相的初熔影响较小,如图10a所示。Nb含量降低,η相的初熔温度可高于γ'相的析出温度,这可能导致γ'相完全回溶后,仍残余η相,如图10b所示,此时Laves相的初熔温度也降低。提高Nb含量会导致η相的初熔温度降低,这是由于Nb含量增加导致γ'相回溶温度升高。γ'相在高温下析出时,会吸收基体的Ti元素,导致η相形成的Ti元素含量降低。Ti元素偏析在枝晶间,因此需要通过降低温度促进枝晶的生长,来提升残余液相中Ti元素的偏析程度,从而促进η相的形成,因此提升Nb元素含量会对降低η相的初熔温度起到一定的促进作用。Nb含量增加,可提升Laves相的初熔温度。Mo含量的增加,也会导致Laves相和η相的初熔点降低,如图10c所示。W含量对析出相的影响不明显,如图10d所示。综上,GH4151合金中Nb、Ti元素含量对低熔点相的初熔温度影响较大,Mo含量的影响相对较小,W含量的影响不明显。降低Ti含量,提高Nb、Mo含量可降低η相的初熔温度;提高Ti、Mo含量,降低Nb含量可降低Laves相的初熔温度。

图10

图10

偏析元素Ti、Nb、Mo和W含量对低熔点相初熔温度的影响

Fig.10

Influences of the contents of Ti (a), Nb (b), Mo (c), and W (d) on the incipient melting temperature of the low-melting phases

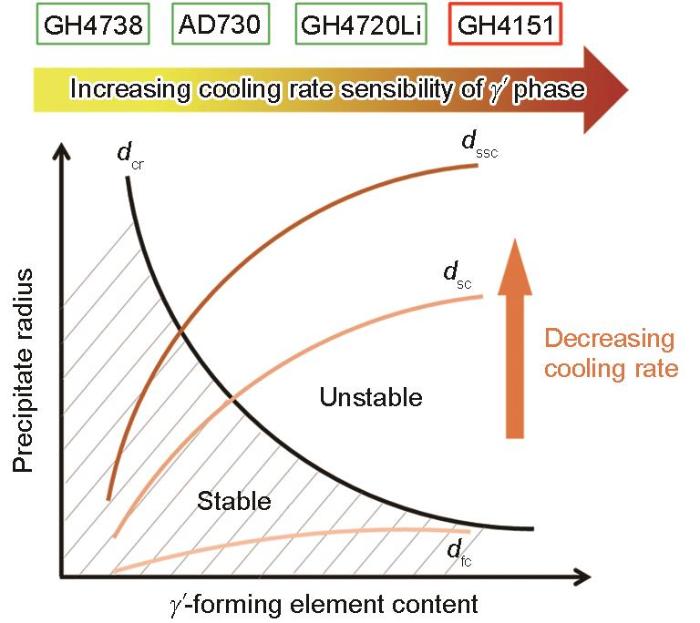

式中,dcr为稳定临界尺寸,K为沉淀相相关的材料常数,T为温度,S为T温度下的过饱和度[26]。γ'相形成元素含量高的合金完全固溶后冷却到同一温度,γ'相形成元素过饱和度也会更高。γ'相形成元素含量与S呈现正相关的关系,因此相同温度下,dcr与γ'相形成元素含量存在一定的反比例关系,即γ'相形成元素含量增加后,dcr降低。在2者综合作用下,提高γ'相形成元素含量易导致γ'相不规则生长。根据前文可知,高合金化的GH4151合金在冷却过程中析出尺寸更大的γ'相,且γ'相形状不规则程度提升,相比其他合金呈现出冷却速率敏感性的特征。这与其他高含量γ'相合金的报道相同[27]。γ'相冷却速率敏感性-合金化程度-冷却速率关联性的示意图如图11所示。随着γ'相形成元素含量的增加,γ'相发生不规则生长的临界稳定尺寸减小,相同冷却速率下γ'相尺寸越大,其越容易发生不规则生长。冷却速率15℃/min是GH4151合金γ'相不规则生长的阈值:冷却速率低于该阈值将会发生γ′相不规则生长的行为。粗大不规则形貌的γ'相会损害合金的热塑性和应力断裂性能[28]。大锭型GH4151合金的中心及边缘区域的冷却速率不均匀,容易导致γ'相的形态分布不均匀。因此过固溶态GH4151合金冷却时需控制冷却速率在15℃/min以上,以避免γ'相不规则生长。

图11

图11

γ'相冷却速率敏感性-合金化程度-冷却速率关联性示意图

Fig.11

Schematic of relationship between cooling rate sensibility of γ' phase, degree of alloying, and cooling rate (dcr—critical diameter of γ' phase growing irregularly; dssc, dsc, and dfc are the diameters of γ' phase under super slow cooling, slow cooling, and fast cooling, respectively)

4 结论

(1) 高合金化导致铸态GH4151合金偏析严重,相组成复杂,主要包括Laves相、γ/γ'共晶、η相、MC碳化物以及不均匀分布的γ'相等。低熔点相初熔的顺序为Laves相+ γ/γ'共晶、η相。热处理前期需要避开上述低熔点相的初熔温度区间。

(2) 铸态GH4151合金中偏析元素Nb、Ti含量对低熔点相初熔温度的影响较大,Mo含量的影响相对较低,W含量的影响不明显。降低Ti含量,提高Nb和Mo含量可降低η相的初熔温度,提高Ti、Mo含量,降低Nb含量可降低Laves相的初熔温度。

(3) GH4151合金中γ'相的析出温度更高,临界稳定尺寸更小。冷却速率15℃/min是γ'相不规则生长的临界值。相比于具有低含量γ'相形成元素的其他合金,冷却速率高于15℃/min时,GH4151合金的γ'相尺寸更大,冷却速率与γ'相直径在双对数坐标系下呈线性关系;冷却速率低于15℃/min时GH4151合金的γ'相不规则程度有所提升。

参考文献

As-cast microstructure characteristic and homogenization of a newly developed hard-deformed Ni-based superalloy GH4975

[J].

难变形高温合金GH4975的铸态组织及均匀化

[J].

Research on hot deformation behavior and microstructure-properties control of GH4151 alloy

[D].

GH4151合金高温变形行为及组织与性能控制研究

[D].

Recent development of nickel-based disc alloys and corresponding cast-wrought processing techniques

[J].

变形高温合金盘材及其制备技术研究进展

[J].

Superplastic deformation and dynamic recrystallization of a novel disc superalloy GH4151

[J].The superplastic deformation of a hot-extruded GH4151 billet was investigated by means of tensile tests with the strain rates of 10−4 s−1, 5 × 10−4 s−1 and 10−3 s−1 and at temperatures at 1060 °C, 1080 °C and 1100 °C. The superplastic deformation of the GH4151 alloy was reported here for the first time. The results reveal that the uniform fine-grained GH4151 alloy exhibited an excellent superplasticity and high strain rate sensitivity (exceeded 0.5) under all experimental conditions. It was found that the increase of strain rate resulted in an increased average activation energy for superplastic deformation. A maximum elongation of 760.4% was determined at a temperature of 1080 °C and strain rate of 10−3 s−1. The average activation energy under different conditions suggested that the superplastic deformation with 1 × 10−4 s−1 in this experiment is mainly deemed as the grain boundary sliding controlled by grain boundary diffusion. However, with a higher stain rate of 5 × 10−4 s−1 and 1 × 10−3 s−1, the superplastic deformation is considered to be grain boundary sliding controlled by lattice diffusion. Based on the systematically microstructural examination using optical microscope (OM), SEM, electron backscatter diffraction (EBSD) and TEM techniques, the failure and dynamic recrystallization (DRX) nucleation mechanisms were proposed. The dominant nucleation mechanism of dynamic recrystallization (DRX) is the bulging of original grain boundaries, which is the typical feature of discontinuous dynamic recrystallization (DDRX), and continuous dynamic recrystallization (CDRX) is merely an assistant mechanism of DRX. The main contributions of DRX on superplasticity elongation were derived from its grain refinement process.

Thermodynamic calculations of precipitation of TCP phase and carbide phase of Ni-Fe base superalloys for ultra-supercritical power plants

[J].

超超临界电站用镍铁基高温合金TCP相和碳化物相析出的热力学计算

[J].

Segregation and homogenization for a new nickel-based superalloy

[J].

Element segregation and solidification behavior of a Nb, Ti, Al Co-strengthened superalloy ЭК151

[J].

Investigation of solidification and high-temperature deformation behavior of Ni-base alloy ЭК151

[D].

新型镍基高温合金ЭК151凝固偏析及高温变形行为研究

[D].

Segregation behavior and investigation on homogenization for a new difficult-to-deform superalloy ЭК151 ingot

[J].

新型难变形高温合金ЭК151的偏析行为及均匀化工艺研究

[J].

Effect of B and C on solidification segregation and hot ductility of U720Li alloy

[D].

B和C对U720Li合金凝固偏析和热加工塑性的影响

[D].

Research progress of precipitated phase in GH4720Li superalloy

[J].

GH4720Li合金中析出相的研究进展

[J].

Effect of heat treatment parameters on microstructure and hot workability of as-cast fine grain ingot of GH4720Li alloy

[J].GH4720Li was Ni-Cr-Co base precipitation strengthened superalloy and widely used for high performance applications such as disks and blades of either aircraft engines or land-based gas turbines attributing to its excellent properties including resistance to creep and fatigue, together with corrosion, fracture and microstructural stability for the intended applications. Compared with the double-melting process (vacuum induction melting (VIM)+electroslag remelting (ESR) or VIM+vacuum arc remelting (VAR), a triple-melting process (VIM+ESR+VAR) can eliminate the segregation coefficient of the alloying elements and reduce the content of impurity elements, while the ingot fabricated by the triple-melting process also exhibited lots of shortcomings, such as the coarse grains, dendritic structure, microstructure defects and high forging temperature. The as-cast fine grain ingot prepared by grain refining casting process can eliminate the microscopic shrinkage, reduce the differences among three crystalline regions and improve the hot workability as a result. However, it was hardly to avoid the microstructure defects by simply improving the casting process attributing to its large number of alloying elements. Therefore, the homogenization treatment was always performed on the superalloy ingot. In this work, the optimized homogenization parameter was identified according to the investigation on the microstructure evolution under various homogenization treatment conditions and hot workability of as-cast fine grain ingot after homogenization treatment. The relationships of one-stage as well as two-stage homogenization treatment parameters and segregation coefficient as well as volume fraction of eutectic phase were investigated indepth. The hot workability of the homogenized samples under various conditions was also analyzed with the help of hot compression tests. Experimental results revealed that the increased homogenization treatment temperature and extended holding time were able to decrease the volume fraction of eutectic phase and segregation coefficient of the alloying element significantly. Hot compression tests by the Gleeble 3800 dynamic thermal-mechanical testing machine indicated that the samples suffered two-stage homogenization treatment followed by the slowly cooling rate (1140 ℃, 12 h+1170 ℃, 10 h, 0.2 ℃/min furnace cooling to 1010 ℃, and then air cooling) exhibited better hot workability (the maximum reduction rate of 50% deformed at 1120 ℃, 1 s-1). Discontinuous dynamic recrystallization was identified as the mainly nucleation mechanism of the alloy, and the recrystallized grains preferred to nucleate at the boundaries of the original grains according to the microstructure observation of hot compressed samples. In additions, the M(C, N) type precipitates were able to promote the occurrence of dynamic recrystallization behavior. Homogenization treatment experiments and microstructure observation suggested that the optimized treatment parameters of the as-cast fine grain ingot was 1140 ℃, 12 h+1170 ℃, 10 h, 0.2 ℃/min furnace cooling to 1010 ℃, and then by air cooling.

热处理工艺对GH4720Li合金细晶铸锭组织与热加工性能的影响

[J].

Effect of thermal processing on critical grain growth of extruded FGH4096 alloy

[J].

热加工工艺对挤压态FGH4096合金临界晶粒长大的影响

[J].

Study on microstructure and properties of shaped ring parts for super alloy GH4738

[J].The forming process of shaped ring part for super alloy GH4738 was numerically simulated by the finite element method, and the microstructure and properties of shaped ring part were characterized under two schemes of pre-rolling and final rolling at 1060℃ and pre-rolling and final rolling at 1080℃, respectively. The results show that the distribution of equivalent strain for the whole ring part varies along the axial gradient, but the uniformity of equivalent strain distribution is lower to make the ring form difficultly. However, the method of pre-rolling and final rolling at 1080℃ is more conducive to obtaining uniform microstructure, and the equivalent strain required to obtain uniform microstructure at this temperature is no more than 0.5. Furthermore, the tensile strength, plasticity and creep properties under two schemes are basically the same, and the yield strength at room temperature under 1080℃ is slightly lower, while the yield strength at high temperature is higher, and the stress rupture property is 1.8 times of that at 1060℃. Therefore, under the condition that the equivalent strain of rolling is no less than 0.5 and the scheme of pre-rolling and final rolling at 1080℃ is adopted, the shaped ring part of super alloy GH4738 is rolled, and the uniform microstructure is obtained to help to improve the stress rupture property of ring parts.

GH4738高温合金异形环件组织与性能研究

[J].

Solidification and segregation behavior of nickel-based superalloy GH4282

[J].

镍基高温合金GH4282的凝固和偏析行为

[J].

Multimodal size distributions of γ′ precipitates during continuous cooling of UDIMET 720 Li

[J].

A comparison of the precipitation behavior in PM γ-γ' nickel-base superalloys

[J].

Dependence of creep performance and microstructure evolution on solution cooling rate in a polycrystalline superalloy

[J].

Effects of heat treatment on the microstructure evolution and the high-temperature tensile properties of Haynes 282 superalloy

[J].

Kinetics and mechanisms of γ' reprecipitation in a Ni-based superalloy

[J].The reprecipitation mechanisms and kinetics of gamma' particles during cooling from supersolvus and subsolvus temperatures were studied in AD730TM Ni-based superalloy using Differential Thermal Analysis (DTA). The evolution in the morphology and distribution of reprecipitated gamma' particles was investigated using Field Emission Gun Scanning Electron Microscopy (FEG-SEM). Depending on the cooling rate, gamma' particles showed multi or monomodal distribution. The irregularity growth characteristics observed at lower cooling rates were analyzed in the context of Mullins and Sekerka theory, and allowed the determination of a critical size of gamma' particles above which morphological instability appears. Precipitation kinetics parameters were determined using a non-isothermal JMA model and DTA data. The Avrami exponent was determined to be in the 1.5-2.3 range, suggesting spherical or irregular growth. A methodology was developed to take into account the temperature dependence of the rate coefficient k(T) in the non-isothermal JMA equation. In that regard, a function for k(T) was developed. Based on the results obtained, reprecipitation kinetics models for low and high cooling rates are proposed to quantify and predict the volume fraction of reprecipitated gamma' particles during the cooling process.

High-throughput fabrication of nickel-based alloys with different Nb contents via a dual-feed additive manufacturing system: Effect of Nb content on microstructural and mechanical properties

[J].

The thermal stability of topologically close-packed phases in the single-crystal Ni-base superalloy ERBO/1

[J].

Development of typical hard-to-deform nickel-base superalloy for turbine disk served above 800oC

[J].

800℃以上服役涡轮盘用难变形镍基高温合金研究进展

[J].

Morphological instability of spherical γ′ precipitates in a nickel base superalloy

[J].

The dendritic growth of γ′ precipitates and grain boundary serration in a model nickel-base superalloy

[J].

An approach toward understanding unstable gamma prime precipitate evolution and its effect on properties

[A].