多孔材料具有与人体骨组织匹配的弹性模量,是解决植入物与人体骨弹性错配的有效手段[5]。多孔材料内部存在的大量孔隙更有利于周围细胞的长入和新骨的生长,从而显著促进骨组织形成能力。因此钛合金多孔植入器械成为金属植入物领域的研究热点。然而,由于钛合金的熔点高,与高温下空气中的O2和N2具有良好的亲和性,很难采用液态发泡法制备多孔钛合金[6],而采用固态金属烧结法又难以控制孔隙结构、孔隙率、孔径尺寸等孔隙参数。最近,增材制造技术(3D打印)被用于制备钛合金多孔材料 [7,8]。这种方法利用工具软件设计多孔结构,然后通过计算机根据程序控制激光束/电子束逐层熔化过程,最终得到与预期结构完全一致的多孔材料。由于该方法可以精确控制多孔结构,并且不受金属高熔点影响,是制备医用钛合金多孔植入器械的较好选择。目前比较成熟的钛合金多孔材料3D打印技术主要包括选区激光熔化(selective laser melting,SLM)和选区电子束熔化(selective electron beam melting,SEBM)技术,关于钛合金多孔材料的增材制备相关研究也主要集中于这2种技术。

为保证金属植入器械在人体内的安全应用,需要其具有优异的力学性能。对于给定成分的金属材料,其力学性能主要由本身的显微组织决定。而3D打印是激光束/电子束高温熔池在固体金属基底“无界面热阻”快速导热、高温度梯度、超高冷却速率条件下的快速凝固及逐层堆积的过程,凝固过程显著不同于常规加工制造技术,形成的组织特性与传统加工方法制备的材料不同,从而其构件力学性能也存在显著差异[9,10]。因此,研究3D打印钛合金多孔材料组织及对应的力学性能,对其在医疗领域的安全应用具有重要意义,受到了国内外学者的广泛关注。本文简要综述了作者团队在3D打印医用Ti-6Al-4V、纯Ti和低模量钛合金多孔材料组织及力学性能方面的研究进展,并对未来发展方向进行了展望。

1 Ti-6Al-4V合金多孔材料

Ti-6Al-4V是一种α + β型钛合金,具有高比强度和良好的生物相容性,是医疗领域应用最广泛的钛合金材料。作者团队采用SEBM制备了Ti-6Al-4V合金多孔材料,并对其组织特性与力学性能开展了研究。

1.1 微观组织与相组成

图1

1.2 弹性模量

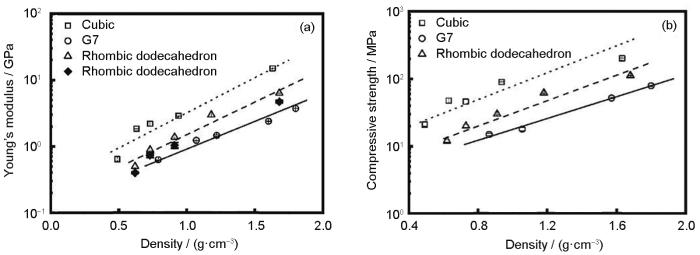

图2

1.3 单向压缩性能

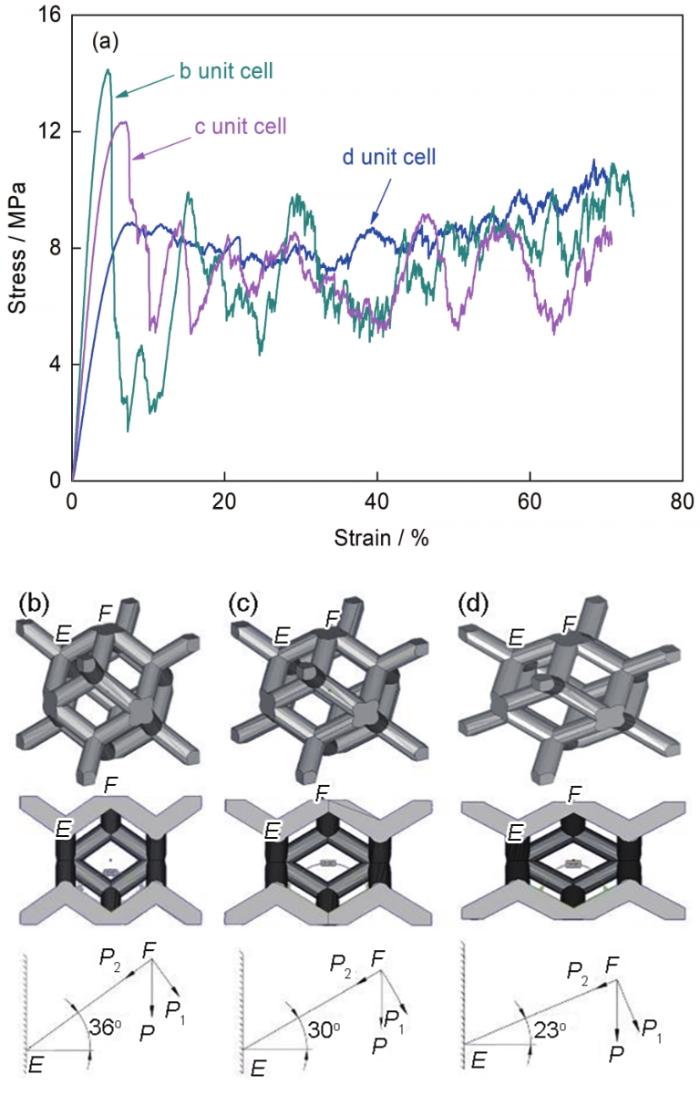

图3

图3

Ti-6Al-4V合金不同孔形菱形十二面体单元结构多孔材料的应力-应变曲线,Materialize软件设计的菱形十二面体单元模型,及增加孔梁受力的弯曲分量的单元模型[13]

Fig.3

Stress-strain curves of the Ti-6Al-4V reticula-ted meshes with different rhombic dodecahedron unit cells (a), the unit cell designed by the Materialize software (b), unit cells designed to increase the bending component of the load applied on the struts (c, d)[13] (P is the load applied to a strut (EF). P1 and P2 are two components of P along the bending and buckling deformation directions)

式中,

式中,Pi 为弹性模量。根据

(3) 后处理。采用热处理和热等静压等后处理手段可有效改善孔梁基体内α和β相的形貌以及内部缺陷,使多孔材料压缩强度降低,但塑性提高[21]。

1.4 疲劳性能

为保证金属植入材料在人体内长期安全应用,要求其具有优异的疲劳性能。对于SEBM制备的Ti-6Al-4V合金多孔结构,其压缩疲劳强度与密度呈正比例关系[22],疲劳强度随着相对密度的提高而增大(图4a[22])。多孔结构相对疲劳强度(σcomf / σ0,其中,σcomf为多孔材料压缩疲劳强度,σ0为孔梁基材压缩强度)和相对密度(ρ / ρ0,其中,ρ0为孔梁基材密度)具有良好的指数关系(图4b[22]),其n约为2.7,高于Gibson-Ashby模型的理论值(约1.5)以及文献[23]中报道的泡沫铝(约1.8)和泡沫镍(约2.1)等金属多孔材料。由于该多孔材料的孔梁基体含有硬脆马氏体相且其孔梁表面非常粗糙(图1[11]),导致其“疲劳强度/压缩强度”比仅为0.10~0.25,明显低于其致密材料(约0.4)[24]。因此,需要开展相关研究以提高SEBM制备Ti-6Al-4V合金多孔结构的疲劳性能,保证其长期服役性能。

图4

图4

不同密度Ti-6Al-4V合金多孔材料的最大应力-疲劳寿命(S-N)曲线及相对疲劳强度与相对密度的关系[22]

Fig.4

Maximum stress-fatigue life (S-N) curves of the Ti-6Al-4V mesh arrays with different densities (a) and plots of relative compressive fatigue strength versus relative density (b)[22] (σcomf—compressive fatigue strength of Ti-6Al-4V mesh arrays, σ0—compressive strength of Ti-6Al-4V, ρ—density of Ti-6Al-4V mesh arrays, ρ0—density of Ti-6Al-4V)

1.4.1 多孔结构设计

(1) 单元孔形调整。通过单元孔形结构的优化设计,可以使SEBM制备的Ti-6Al-4V合金多孔结构的“疲劳强度/压缩强度”值高于0.4[26],因此单元孔形调整是改善其疲劳性能的有效方法。为解释其疲劳强度的提升,各国学者提出了多种机制。Zargarian等[27]通过数值仿真模拟发现,不同孔形结构的多孔钛合金疲劳强度与循环周次之间符合Basquin关系,其幂函数的系数与结构的相对密度和几何形状有关。Yavari等[28]认为,不同多孔结构增材制备过程中熔池条件不同,导致其孔梁的表面形貌、缺陷特征不同,从而影响多孔材料疲劳过程中多孔结构的受力及疲劳寿命。Zhao等[26]认为,多孔材料循环形变特性与施加于单元孔梁力的屈曲和弯曲分量的耦合作用密切相关。通过调整多孔材料单元孔形状以改变2种分量的匹配,可以改善孔梁基体的局部应力分布,降低其在循环形变过程中每周次的塑性变形累积量,阻滞裂纹在孔梁内的扩展,显著提高其疲劳强度。Ahmadi等[29]指出,对于孔形设计和孔梁基体材料性能2种影响因素,多孔材料疲劳强度更依赖于后者的影响。

图5

图5

梯度Ti-6Al-4V多孔材料循环变形过程中的应变累积曲线和梯度多孔材料循环变形停止在图5a中不同阶段的X射线三维成像照片[30]

Fig.5

Typical variation of accumulated strain with cycle number of the Ti-6Al-4V graded mesh (Insets schematically show the crack initiation and propagation in different constituents during cyclic deformation) (a) and X-ray tomography (XRT) of the graded meshes after being stopped at different stages of cycling shown in Fig.5a (b)[30] (dε1 / dN, dε2 / dN, and dε3 / dN are the cyclic ratcheting rates of graded mesh at different stages during cyclic deformation)

其中,σK 是K组分中的即时应力,εRK 是K组分在σK 下裂纹萌生时对应的应变,σK 和εRK 与各梯度组分所占的体积分数和力学性能相关;CK 和h是K组分的材料相关常数。由

在等应力加载条件下,由于每层多孔结构的力学性能不同,层状梯度多孔材料在循环形变过程中其孔梁普遍存在局部应力不均现象。疲劳裂纹首先在强度最低组分中萌生,而后扩展直至结构失效。在整个过程中,其他层内没有出现明显的疲劳损伤。与等应变加载状态不同,梯度结构的疲劳寿命主要由强度最低组分的特性决定[31]。

1.4.2 后处理

图6

图7

(2) 热等静压处理。金属粉末中残留的气孔以及金属液的挥发是3D打印样品中孔洞缺陷形成的主要原因[32]。对于3D打印Ti-6Al-4V合金致密样品,这些微孔对合金的静态力学性能影响不大,但在循环加载时,却容易优先成为疲劳裂纹源,促进裂纹萌生,从而导致3D打印构件的疲劳性能降低[33]。通过热等静压(hot isostatic pressing,HIP)处理可以封闭这些孔洞,显著提升构件的疲劳性能[33]。对于3D打印Ti-6Al-4V合金多孔样品,HIP处理也能够显著提高多孔材料的疲劳强度[34]。在HIP过程中,静压力可消除孔梁基体内部的孔洞,而高温退火过程则改善了孔梁基体的塑性。在这2个因素中,由于多孔样品中孔洞的存在对疲劳强度并没有显著的影响,因此其疲劳性能的提升主要与孔梁基体塑性的提升有关。

2 纯Ti多孔材料

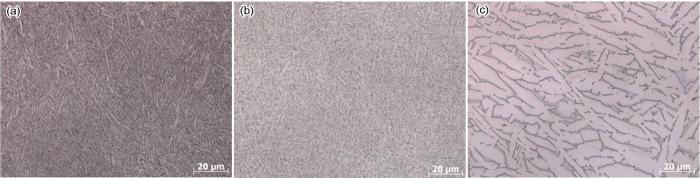

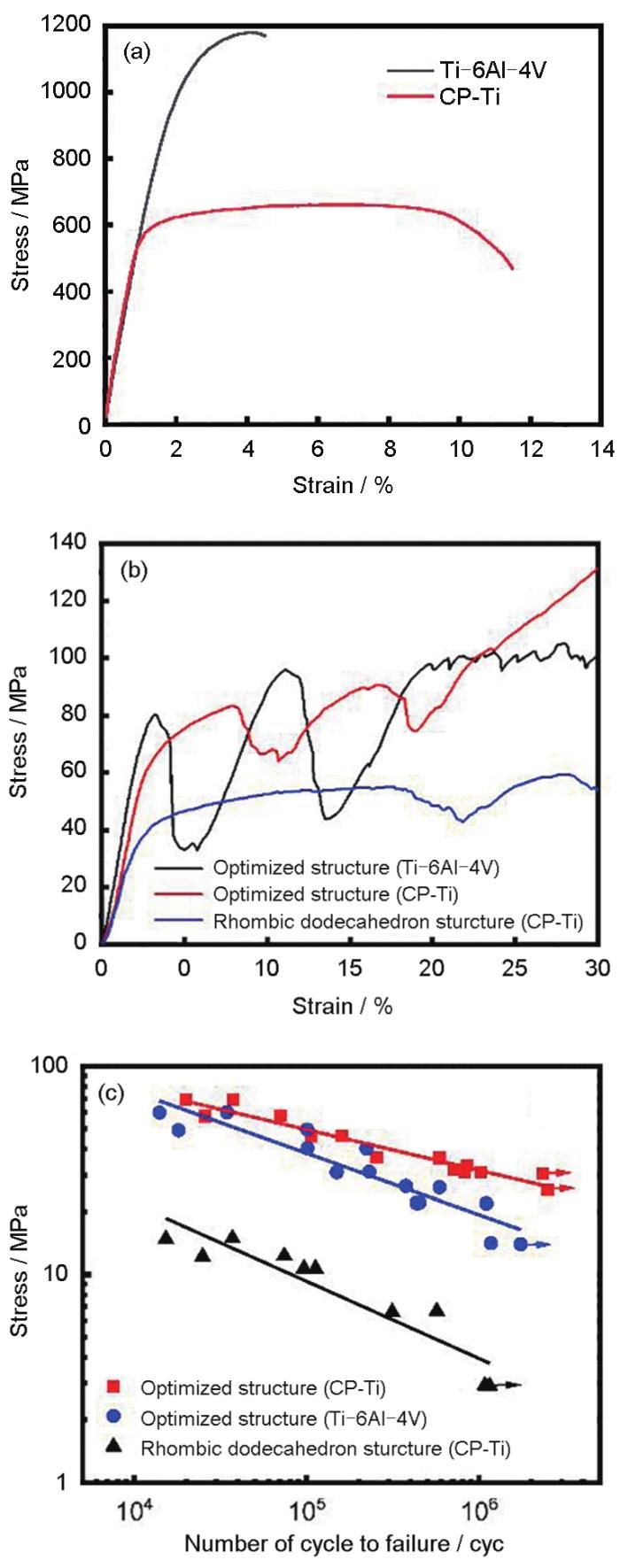

纯Ti由hcp晶体结构的α相构成,具有优异的抗腐蚀特性和人体组织相容性,已被广泛应用于骨板、种植体等领域。Liu等[36]采用SLM技术开展了纯Ti多孔材料增材制备及其力学性能研究。结果表明,纯Ti多孔材料孔梁主要由短片状α相组成,α相均匀分布在基体内。与SLM制备的Ti-6Al-4V合金多孔材料相比,纯Ti孔梁基体的强度较低,塑性显著提升(图8a[36])。多孔材料的静态压缩强度与孔梁基体的强度变化趋势一致,纯Ti多孔材料屈服强度略低,但达到最高强度之前所能承受的塑性变形显著提高(图8b[36])。在循环形变过程中,在纯Ti孔梁基体中发现了形变孪晶,并且裂纹萌生迟于Ti-6Al-4V合金多孔材料。最大应力-疲劳寿命(S-N)曲线测试结果表明,纯Ti多孔材料的疲劳寿命显著优于Ti-6Al-4V合金多孔材料(图8c[36])。疲劳寿命的提升主要与2方面因素有关:一是纯Ti孔梁基体在循环形变过程中出现孪晶,导致其具有较高的应变硬化,这样每周次的塑性应变的累积量减少,抵抗疲劳裂纹萌生的能力增强;二是纯Ti孔梁基体具有较高的塑性,这样在裂纹萌生前,材料可以忍受更高的塑性变形[36]。因此,与Ti-6Al-4V合金相比,纯Ti多孔材料具有更高的疲劳裂纹萌生寿命。

图8

图8

直径为1.2 mm的3D打印纯Ti和Ti-6Al-4V合金圆棒的拉伸曲线,纯Ti和Ti-6Al-4V合金多孔材料压缩曲线及S-N曲线[36]

Fig.8

Tensile curves of 3D printed commercial pure titanium (CP-Ti) and Ti-6Al-4V solid cylinders with a diameter of 1.2 mm (a), compressive stress-strain curves of porous CP-Ti and Ti-6Al-4V samples with topology-optimized and rhombic dodecahedron structures (b), and fatigue S-N curves of topology-optimized and rhombic dodecahedron CP-Ti specimens (c)[36]

3 低模量钛合金多孔材料

低模量钛合金能够有效改善“应力屏蔽”效应,避免植入物在人体内的过早失效,在医用金属植入物领域具有良好的应用前景。Ti-24Nb-4Zr-8Sn (Ti2448)合金是一种高强度低模量钛合金,通过纳米尺度相分解获得成分调制结构来抑制一阶马氏体转变,其“强度/模量”比高达2%,同时具有良好的可加工性[37~39]。作者团队针对Ti2448合金,采用SEBM和SLM技术制备出多孔材料,研究了孔隙率、孔形等对其组织和力学性能的影响。该合金多孔材料的孔梁基体组织主要由单β相组成,晶粒形貌为柱状晶,在孔梁的边缘存在少量等轴晶[40~42] (图9[42])。这是因为熔池在快速熔化和凝固过程中,不可避免地会在熔池的边缘粘连粉末,这些粘粉可以作为β相的非均匀形核点来影响它们周围的微观结构,从而形成等轴细晶区。多孔材料孔梁形貌和内部缺陷与工艺参数密切相关。通过调节扫描速率,平衡气孔反冲压力与熔池表面张力之间的关系,可以改善孔梁表面粗糙度,减少内部孔洞缺陷[40,41]。在单向压缩过程中,多孔材料呈现出韧性金属多孔材料的变形行为(图10a[42])。在循环压缩加载-卸载过程中,多孔材料呈现出显著的超弹性[42,43]。随着孔隙率的提高,多孔材料的强度和弹性模量降低(图10b[42]),但超弹性提高(图10c[42])。在相同的孔隙率时,Ti2448合金的弹性模量约为Ti-6Al-4V合金的一半,“强度/模量”比远高于Ti-6Al-4V合金多孔材料[42]。

图9

图9

SEBM制备Ti2448合金多孔材料的宏观形貌、菱形十二面体单元、孔梁的表面形貌、基体组织形貌和XRD谱[42]

Fig.9

Morphology of the SEBM Ti2448 porous specimen (a), the single unit of 3D rhombic dodecahedron modeling (b), the surface morphology of hole beam (c), the microstructure of the strut (d), and XRD spectrum of the specimen with the single β phase (e)[42]

图10

该合金多孔材料的S-N曲线表明,疲劳强度与孔隙率之间呈线性关系,随着孔隙率的提高,疲劳强度降低(图11[42])。在相同的弹性模量下,该合金多孔材料的疲劳强度约为Ti-6Al-4V合金的2倍(图11c[42])。Ti2448合金多孔材料疲劳强度的提升与以下因素有关:一是较高的超弹性,导致其在循环形变过程中每周次的循环塑性变形累积量(dε / dN)减少,从而提高了多孔材料的裂纹萌生寿命;二是优异的韧性和塑性,使其裂纹扩展过程中裂纹尖端具有较大的塑性区,抵抗裂纹扩展能力增强,延长了多孔材料疲劳裂纹扩展寿命[42]。上述结果表明,采用低模量髙韧性钛合金制备多孔材料,可以有效提高多孔材料的疲劳性能,保证其在人体内的长期可靠使用。

图11

图11

SEBM制备Ti2448和Ti-6Al-4V合金多孔材料的S-N曲线、归一化S-N曲线以及弹性模量与疲劳强度的关系[42]

Fig.11

S-N curves (a) and normalized S-N curves (b) of the porous Ti2448 and Ti-6Al-4V specimens with different porosities, and the relationship of elastic modulus and the fatigue strength for the SEBM porous Ti2448 and Ti-6Al-4V specimens (c)[42]

4 总结与展望

3D打印技术具有数字化精确制备、效率高、周期短、可订制等优点,在制备复杂结构医用金属多孔植入器械方面拥有明显优势。本文主要介绍了作者团队3D打印医用钛合金多孔材料的组织和力学性能研究概况。结果表明,3D打印技术能够成功制备出复杂结构钛合金多孔材料,其优异的力学性能为保证植入物在人体内的安全应用奠定了基础。鉴于人体组织的复杂性,对金属植入材料的性能提出了更高要求,提高3D打印钛合金多孔材料的使役性能仍面临诸多挑战。

(3) 新型医用金属体系多孔材料研制。人体组织面临的复杂生理环境,对金属植入物的多功能性提出了更高要求。近年来,3D打印新型功能医用金属(如Ti-Ni、Ti-Zr、Ta、镁合金、锌合金)取得了基础研究突破,可以赋予金属植入物有效骨整合、可降解等功能特性。因此开展新型医用金属体系多孔材料的3D打印技术及其性能研究是未来医用金属植入物领域的重要发展方向。

参考文献

Cellular solids

[J].This brief article describes the content of this issue of MRS Bulletin on Cellular Solids. Cork, wood, sponge, and bone are all examples of cellular solids in nature. Engineered honeycombs and foams are now made from polymers, metals, ceramics, and glasses, and their structure gives them unique properties that can be exploited in a variety of applications. The articles in this issue provide an overview of the fabrication, structure, properties, and applications of such porous solids as cellular ceramics, aluminum and other metallic foams, and scaffolds for tissue engineering, as well as discussions of techniques for understanding, modeling, and measuring their behavior and properties.

Titanium as the material of choice for cementless femoral components in total hip arthroplasty

[J].

Low stiffness porous Ti structures for load-bearing implants

[J].The need for unique mechanical and functional properties coupled with manufacturing flexibility for a wide range of metallic implant materials necessitates the use of novel design and fabrication approaches. In this work, we have demonstrated that application of proposed design concepts in combination with laser-engineered net shaping (LENStrade mark) can significantly increase the processing flexibility of complex-shaped metallic implants with three-dimensionally interconnected, designed and functionally graded porosities down to 70vol.%, to reduce effective stiffness for load-bearing implants. Young's modulus and 0.2% proof strength of these porous Ti samples having 35-42vol.% porosity are found to be similar to those of human cortical bone.

Mechanical biocompatibilities of titanium alloys for biomedical applications

[J].Young's modulus as well as tensile strength, ductility, fatigue life, fretting fatigue life, wear properties, functionalities, etc., should be adjusted to levels that are suitable for structural biomaterials used in implants that replace hard tissue. These factors may be collectively referred to as mechanical biocompatibilities. In this paper, the following are described with regard to biomedical applications of titanium alloys: the Young's modulus, wear properties, notch fatigue strength, fatigue behaviour on relation to ageing treatment, improvement of fatigue strength, fatigue crack propagation resistance and ductility by the deformation-induced martensitic transformation of the unstable beta phase, and multifunctional deformation behaviours of titanium alloys.

Biological response of next-generation of 3D Ti-6Al-4V biomedical devices using additive manufacturing of cellular and functional mesh structures

[J].

Manufacture, characterisation and application of cellular metals and metal foams

[J].

Additive manufacturing of titanium alloys by electron beam melting: A review

[J].

Frontiers of 3D printing/additive manufacturing: From human organs to aircraft fabrication

[J].

Location specific solidification microstructure control in electron beam melting of Ti-6Al-4V

[J].

In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance

[J].

Compression deformation behavior of Ti-6Al-4V alloy with cellular structures fabricated by electron beam melting

[J].Ti-6Al-4V alloy with two kinds of open cellular structures of stochastic foam and reticulated mesh was fabricated by additive manufacturing (AM) using electron beam melting (EBM), and microstructure and mechanical properties of these samples with high porosity in the range of 62%∼92% were investigated. Optical observations found that the cell struts and ligaments consist of primary α' martensite. These cellular structures have comparable compressive strength (4∼113 MPa) and elastic modulus (0.2∼6.3 GPa) to those of trabecular and cortical bone. The regular mesh structures exhibit higher specific strength than other reported metallic foams under the condition of identical specific stiffness. During the compression, these EBM samples have a brittle response and undergo catastrophic failure after forming crush band at their peak loading. These bands have identical angle of ∼45° with compression axis for the regular reticulated meshes and such failure phenomenon was explained by considering the cell structure. Relative strength and density follow a linear relation as described by the well-known Gibson-Ashby model but its exponential factor is ∼2.2, which is relative higher than the idea value of 1.5 derived from the model.Copyright © 2012 Elsevier Ltd. All rights reserved.

Next-generation biomedical implants using additive manufacturing of complex, cellular and functional mesh arrays

[J].

Influence of cell shape on mechanical properties of Ti-6Al-4V meshes fabricated by electron beam melting method

[J].Ti-6Al-4V reticulated meshes with different elements (cubic, G7 and rhombic dodecahedron) in Materialise software were fabricated by additive manufacturing using the electron beam melting (EBM) method, and the effects of cell shape on the mechanical properties of these samples were studied. The results showed that these cellular structures with porosities of 88-58% had compressive strength and elastic modulus in the range 10-300MPa and 0.5-15GPa, respectively. The compressive strength and deformation behavior of these meshes were determined by the coupling of the buckling and bending deformation of struts. Meshes that were dominated by buckling deformation showed relatively high collapse strength and were prone to exhibit brittle characteristics in their stress-strain curves. For meshes dominated by bending deformation, the elastic deformation corresponded well to the Gibson-Ashby model. By enhancing the effect of bending deformation, the stress-strain curve characteristics can change from brittle to ductile (the smooth plateau area). Therefore, Ti-6Al-4V cellular solids with high strength, low modulus and desirable deformation behavior could be fabricated through the cell shape design using the EBM technique. Copyright © 2014 Acta Materialia Inc. All rights reserved.

Microstructure and mechanical properties of open-cellular biomaterials prototypes for total knee replacement implants fabricated by electron beam melting

[J].Total knee replacement implants consisting of a Co-29Cr-6Mo alloy femoral component and a Ti-6Al-4V tibial component are the basis for the additive manufacturing of novel solid, mesh, and foam monoliths using electron beam melting (EBM). Ti-6Al-4V solid prototype microstructures were primarily α-phase acicular platelets while the mesh and foam structures were characterized by α(')-martensite with some residual α. The Co-29Cr-6Mo containing 0.22% C formed columnar (directional) Cr(23)C(6) carbides spaced ~2 μm in the build direction, while HIP-annealed Co-Cr alloy exhibited an intrinsic stacking fault microstructure. A log-log plot of relative stiffness versus relative density for Ti-6Al-4V and Co-29Cr-6Mo open-cellular mesh and foams resulted in a fitted line with a nearly ideal slope, n = 2.1. A stress shielding design graph constructed from these data permitted mesh and foam implant prototypes to be fabricated for compatible bone stiffness.Copyright © 2011 Elsevier Ltd. All rights reserved.

The effect of density and feature size on mechanical properties of isostructural metallic foams produced by additive manufacturing

[J].

Mechanical evaluation of porous titanium (Ti6Al4V) structures with electron beam melting (EBM)

[J].Patient specific porous implants for the reconstruction of craniofacial defects have gained importance due to their better performance over their generic counterparts. The recent introduction of electron beam melting (EBM) for the processing of titanium has led to a one step fabrication of porous custom titanium implants with controlled porosity to meet the requirements of the anatomy and functions at the region of implantation. This paper discusses an image based micro-structural analysis and the mechanical characterization of porous Ti6Al4V structures fabricated using the EBM rapid manufacturing process. SEM studies have indicated the complete melting of the powder material with no evidence of poor inter-layer bonding. Micro-CT scan analysis of the samples indicate well formed titanium struts and fully interconnected pores with porosities varying from 49.75%-70.32%. Compression tests of the samples showed effective stiffness values ranging from 0.57(+/-0.05)-2.92(+/-0.17)GPa and compressive strength values of 7.28(+/-0.93)-163.02(+/-11.98)MPa. For nearly the same porosity values of 49.75% and 50.75%, with a variation in only the strut thickness in the sample sets, the compressive stiffness and strength decreased significantly from 2.92 GPa to 0.57 GPa (80.5% reduction) and 163.02 MPa to 7.28 MPa (93.54 % reduction) respectively. The grain density of the fabricated Ti6Al4V structures was found to be 4.423 g/cm(3) equivalent to that of dense Ti6Al4V parts fabricated using conventional methods. In conclusion, from a mechanical strength viewpoint, we have found that the porous structures produced by the electron beam melting process present a promising rapid manufacturing process for the direct fabrication of customized titanium implants for enabling personalized medicine.(c) 2009 Elsevier Ltd. All rights reserved.

The topological design of multifunctional cellular metals

[J].

Porous scaffold design for tissue engineering

[J].A paradigm shift is taking place in medicine from using synthetic implants and tissue grafts to a tissue engineering approach that uses degradable porous material scaffolds integrated with biological cells or molecules to regenerate tissues. This new paradigm requires scaffolds that balance temporary mechanical function with mass transport to aid biological delivery and tissue regeneration. Little is known quantitatively about this balance as early scaffolds were not fabricated with precise porous architecture. Recent advances in both computational topology design (CTD) and solid free-form fabrication (SFF) have made it possible to create scaffolds with controlled architecture. This paper reviews the integration of CTD with SFF to build designer tissue-engineering scaffolds. It also details the mechanical properties and tissue regeneration achieved using designer scaffolds. Finally, future directions are suggested for using designer scaffolds with in vivo experimentation to optimize tissue-engineering treatments, and coupling designer scaffolds with cell printing to create designer material/biofactor hybrids.

Functionally graded Ti-6Al-4V meshes with high strength and energy absorption

[J].

Longitudinal compression behavior of functionally graded Ti-6Al-4V meshes

[J].The compressive deformation behavior in the longitudinal direction of graded Ti-6Al-4V meshes fabricated by electron beam melting was investigated using experiments and finite element methods (FEM). The results indicate that the overall strain along the longitudinal direction is the sum of the net strain carried by each uniform mesh constituent and the deformation behavior fits the Reuss model well. The layer thickness and the sectional area have no effect on the elastic modulus, whereas the strength increases with the sectional area due to the edge effect of each uniform mesh constituent. By optimizing 3D graded/gradient design, meshes with balanced superior properties, such as high strength, energy absorption and low elastic modulus, can be fabricated by electron beam melting.

Heat treatment enhancing the compressive fatigue properties of open-cellular Ti-6Al-4V alloy prototypes fabricated by electron beam melting

[J].: In this work, we report the effect of annealing in α+β phase field on the fatigue properties of Ti-6Al-4V alloy meshes fabricated by electron beam melting. The results show that annealing at high temperature near the phase boundary enhances the ductility of the brittle mesh struts due to the formation of coarse α lamellas with a large thickness/length ratio. Accordingly, the fatigue endurance ratio of the studied meshes increases to up to -0.6, which is much superior to that of the as-fabricated counterparts and comparable to those of dense materials.

Compression fatigue behavior of Ti-6Al-4V mesh arrays fabricated by electron beam melting

[J].

Computational prediction of the fatigue behavior of additively manufactured porous metallic biomaterials

[J].

Effects of cell shape and cell wall thickness variations on the elastic properties of two-dimensional cellular solids

[J].

The influence of cell morphology on the compressive fatigue behavior of Ti-6Al-4V meshes fabricated by electron beam melting

[J].Additive manufacturing technique is a promising approach for fabricating cellular bone substitutes such as trabecular and cortical bones because of the ability to adjust process parameters to fabricate different shapes and inner structures. Considering the long term safe application in human body, the metallic cellular implants are expected to exhibit superior fatigue property. The objective of the study was to study the influence of cell shape on the compressive fatigue behavior of Ti-6Al-4V mesh arrays fabricated by electron beam melting. The results indicated that the underlying fatigue mechanism for the three kinds of meshes (cubic, G7 and rhombic dodecahedron) is the interaction of cyclic ratcheting and fatigue crack growth on the struts, which is closely related to cumulative effect of buckling and bending deformation of the strut. By increasing the buckling deformation on the struts through cell shape design, the cyclic ratcheting rate of the meshes during cyclic deformation was decreased and accordingly, the compressive fatigue strength was increased. With increasing bending deformation of struts, fatigue crack growth in struts contributed more to the fatigue damage of meshes. Rough surface and pores contained in the struts significantly deteriorated the compressive fatigue strength of the struts. By optimizing the buckling and bending deformation through cell shape design, Ti-6Al-4V alloy cellular solids with high fatigue strength and low modulus can be fabricated by the EBM technique.Copyright © 2016 Elsevier Ltd. All rights reserved.

Numerical simulation of the fatigue behavior of additive manufactured titanium porous lattice structures

[J].

Relationship between unit cell type and porosity and the fatigue behavior of selective laser melted meta-biomaterials

[J].Meta-materials are structures when their small-scale properties are considered, but behave as materials when their homogenized macroscopic properties are studied. There is an intimate relationship between the design of the small-scale structure and the homogenized properties of such materials. In this article, we studied that relationship for meta-biomaterials that are aimed for biomedical applications, otherwise known as meta-biomaterials. Selective laser melted porous titanium (Ti6Al4V ELI) structures were manufactured based on three different types of repeating unit cells, namely cube, diamond, and truncated cuboctahedron, and with different porosities. The morphological features, static mechanical properties, and fatigue behavior of the porous biomaterials were studied with a focus on their fatigue behavior. It was observed that, in addition to static mechanical properties, the fatigue properties of the porous biomaterials are highly dependent on the type of unit cell as well as on porosity. None of the porous structures based on the cube unit cell failed after 10(6) loading cycles even when the applied stress reached 80% of their yield strengths. For both other unit cells, higher porosities resulted in shorter fatigue lives for the same level of applied stress. When normalized with respect to their yield stresses, the S-N data points of structures with different porosities very well (R(2)>0.8) conformed to one single power law specific to the type of the unit cell. For the same level of normalized applied stress, the truncated cuboctahedron unit cell resulted in a longer fatigue life as compared to the diamond unit cell. In a similar comparison, the fatigue lives of the porous structures based on both truncated cuboctahedron and diamond unit cells were longer than that of the porous structures based on the rhombic dodecahedron unit cell (determined in a previous study). The data presented in this study could serve as a basis for design of porous biomaterials as well as for corroboration of relevant analytical and computational models. Copyright © 2014 Elsevier Ltd. All rights reserved.

Fatigue performance of additively manufactured meta-biomaterials: The effects of topology and material type

[J].Additive manufacturing (AM) techniques enable fabrication of bone-mimicking meta-biomaterials with unprecedented combinations of topological, mechanical, and mass transport properties. The mechanical performance of AM meta-biomaterials is a direct function of their topological design. It is, however, not clear to what extent the material type is important in determining the fatigue behavior of such biomaterials. We therefore aimed to determine the isolated and modulated effects of topological design and material type on the fatigue response of metallic meta-biomaterials fabricated with selective laser melting. Towards that end, we designed and additively manufactured Co-Cr meta-biomaterials with three types of repeating unit cells and three to four porosities per type of repeating unit cell. The AM meta-biomaterials were then mechanically tested to obtain their normalized S-N curves. The obtained S-N curves of Co-Cr meta-biomaterials were compared to those of meta-biomaterials with same topological designs but made from other materials, i.e. Ti-6Al-4V, tantalum, and pure titanium, available from our previous studies. We found the material type to be far more important than the topological design in determining the normalized fatigue strength of our AM metallic meta-biomaterials. This is the opposite of what we have found for the quasi-static mechanical properties of the same meta-biomaterials. The effects of material type, manufacturing imperfections, and topological design were different in the high and low cycle fatigue regions. That is likely because the cyclic response of meta-biomaterials depends not only on the static and fatigue strengths of the bulk material but also on other factors that may include strut roughness, distribution of the micro-pores created inside the struts during the AM process, and plasticity.Meta-biomaterials are a special class of metamaterials with unusual or unprecedented combinations of mechanical, physical (e.g. mass transport), and biological properties. Topologically complex and additively manufactured meta-biomaterials have been shown to improve bone regeneration and osseointegration. The mechanical properties of such biomaterials are directly related to their topological design and material type. However, previous studies of such biomaterials have largely neglected the effects of material type, instead focusing on topological design. We show here that neglecting the effects of material type is unjustified. We studied the isolated and combined effects of topological design and material type on the normalized S-N curves of metallic bone-mimicking biomaterials and found them to be more strongly dependent on the material type than topological design.Copyright © 2017 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Compressive and fatigue behavior of functionally graded Ti-6Al-4V meshes fabricated by electron beam melting

[J].

Mechanistic understanding of compression-compression fatigue behavior of functionally graded Ti-6Al-4V mesh structure fabricated by electron beam melting

[J].

Effect of metal vaporization behavior on keyhole-mode surface morphology of selective laser melted composites using different protective atmospheres

[J].

Comparison of the microstructures and mechanical properties of Ti-6Al-4V fabricated by selective laser melting and electron beam melting

[J].

Fatigue and biological properties of Ti-6Al-4V ELI cellular structures with variously arranged cubic cells made by selective laser melting

[J].Traditional implants made of bulk titanium are much stiffer than human bone and this mismatch can induce stress shielding. Although more complex to produce and with less predictable properties compared to bulk implants, implants with a highly porous structure can be produced to match the bone stiffness and at the same time favor bone ingrowth and regeneration. This paper presents the results of the mechanical and dimensional characterization of different regular cubic open-cell cellular structures produced by Selective Laser Melting (SLM) of Ti6Al4V alloy, all with the same nominal elastic modulus of 3GPa that matches that of human trabecular bone. The main objective of this research was to determine which structure has the best fatigue resistance through fully reversed fatigue tests on cellular specimens. The quality of the manufacturing process and the discrepancy between the actual measured cell parameters and the nominal CAD values were assessed through an extensive metrological analysis. The results of the metrological assessment allowed us to discuss the effect of manufacturing defects (porosity, surface roughness and geometrical inaccuracies) on the mechanical properties. Half of the specimens was subjected to a stress relief thermal treatment while the other half to Hot Isostatic Pressing (HIP), and we compared the effect of the treatments on porosity and on the mechanical properties. Fatigue strength seems to be highly dependent on the surface irregularities and notches introduced during the manufacturing process. In fully reversed fatigue tests, the high performances of stretching dominated structures compared to bending dominated structures are not found. In fact, with thicker struts, such structures proved to be more resistant, even if bending actions were present.Copyright © 2017 Elsevier Ltd. All rights reserved.

Surface modification of Ti6Al4V open porous structures produced by additive manufacturing

[J].

Enhanced fatigue characteristics of a topology-optimized porous titanium structure produced by selective laser melting

[J].

Elastic deformation behaviour of Ti-24Nb-4Zr-7.9Sn for biomedical applications

[J].In this paper, the elastic deformation behaviour of a recently developed beta-type titanium alloy Ti-24Nb-4Zr-7.9Sn (wt.%) that consists of non-toxic elements and is intended for biomedical applications is described. Tensile tests show that this alloy in the as hot-rolled state exhibits peculiar non-linear elastic behaviour with maximum recoverable strain up to 3.3% and incipient Young's modulus of 42GPa. Solution treatment at high temperature has trivial effect on super-elasticity but decreases strength and slightly increases the incipient Young's modulus. Ageing treatment in the (alpha+beta) two-phase field increases both strength and Young's modulus and results in a combination of high strength and relatively low elastic modulus. In spite of the formation of the alpha phase, short time ageing has no effect on super-elasticity, whereas the non-linear elastic behaviour transforms gradually to normal linear elasticity with the increase of ageing time. We suggest sluggish, partially reversible processes of stress-induced phase transformation and/or incipient kink bands as the origin of the above peculiar elastic behaviour.

Elastically confined martensitic transformation at the nano-scale in a multifunctional titanium alloy

[J].

Spinodal decomposition coupled with a continuous crystal ordering in a titanium alloy

[J].

Electron beam melted beta-type Ti-24Nb-4Zr-8Sn porous structures with high strength-to-modulus ratio

[J].Electron beam melting (EBM) has been used to manufacture β-type Ti-24Nb-4Zr-8Sn porous components with 70% porosity. EBM-produced components have favorable structural features (i.e. smooth strut surfaces, fewer defects) and an (α?+?β)-type microstructure, similar to that subjected to aging treatment. EBM-produced components exhibit more than twice the strength-to-modulus ratio of porous Ti-6Al-4V components having the same porosity. The processing-microstructure-property relationship and deformation behavior of EBM-produced components are discussed in detail. Such porous titanium components composed of non-toxic elements and having high strength-to-modulus ratio are highly attractive for biomedical applications.

Microstructure, defects and mechanical behavior of beta-type titanium porous structures manufactured by electron beam melting and selective laser melting

[J].

Compressive and fatigue behavior of beta-type titanium porous structures fabricated by electron beam melting

[J].

Recoverable strain in a new biomedical Ti-24Nb-4Zr-8Sn alloy with cellular structure fabricated by electron beam melting

[J].

Improved corrosion behaviour of electron beam melted Ti-6Al-4V alloy in phosphate buffered saline

[J].

Electrochemical behavior of open-cellular structured Ti-6Al-4V alloy fabricated by electron beam melting in simulated physiological fluid: The significance of pore characteristics

[J].The cellular structured titanium alloys have attracted significant attention for implants because of their lower Youngʼs modulus, which is comparable to human bone and has the capability of providing space for bone tissue in-growth. However, there is a gap in the knowledge in regard to the relationship between the pore characteristics and the electrochemical performance of open-cellular structured titanium alloys. In this study, we elucidate the influence of pore characteristics on the electrochemical performance of open-cellular structured Ti-6Al-4V alloys produced by electron beam melting (EBM). Intriguingly, the passive film formed on cellular structured Ti-6Al-4V alloy with a larger pore size was more stable and protective, and the corrosion performance was superior compared to the samples with a smaller pore size in phosphate buffered saline (PBS), mainly because of relatively smaller exposed surface area and unlimited flow of electrolyte. However, in acidic PBS containing fluoride ions, the pore characteristics did not play an important role in the corrosion resistance. It was considered that the protective film breaks down such that the corrosion performance of cellular structured alloys was comparable to each other in this harsh environment.

In-situ monitoring of the electrochemical behavior of cellular structured biomedical Ti-6Al-4V alloy fabricated by electron beam melting in simulated physiological fluid

[J].Ti-6Al-4V alloys with cellular structure fabricated by additive manufacturing are currently of significant interest because their modulus is comparable to bone and the cellular structure allows the cells to penetrate and exchange nutrients, promoting osseointegration. We describe here a unique simulation device that replaces the traditional steady electrochemistry approach, enabling in-situ study of variation of ion concentration and surface potential with pore depth for cellular structured Ti-6Al-4V alloys fabricated by electron beam melting (EBM) in phosphate buffered saline (PBS). This approach addresses the scientific gap on the electrochemical behavior of cellular structured titanium alloys. The study indicated that concentration of H and Cl increased with the increase of pore depth, while the surface potential decreased. The exposed surface of inner cellular structure was not corroded but passivated after immersing in PBS at 37 °C for 14 days, which was independent of pore depth. Furthermore, X-ray photoelectron spectroscopy (XPS) and Mott-Schottky (M-S) studies suggested that a thinner passive film containing a greater donor density was formed on the surface of cellular structured Ti-6Al-4V alloy at the deepest pore depth. This is attributed to insufficient oxygen supply and Cladsorption on the surface inside the pores. STATEMENT OF SIGNIFICANCE: Porous titanium alloys are promising implants in biomedical applications. However, it is a challenge to accurately characterize the corrosion behavior of porous titanium alloys with complex pore structure using traditional electrochemical methods. In this study, we have adopted a special device to simulate the environment within the pore structure. The variation in ion concentration and surface potential of Ti-6Al-4V fabricated by EBM with pore depth was in-situ monitored. After immersing in PBS for 14 days, Ti-6Al-4V exhibited good corrosion properties and the samples with less than 60 mm pore depth were not corroded but passivated. Also, we analyzed the difference in corrosion property at different pore depth. This type of in-situ corrosion performance monitoring in EBM-produced Ti-6Al-4V has not been previously studied.Copyright © 2020. Published by Elsevier Ltd.

In-situ monitoring of the electrochemical corrosion behavior in fluoride environment of cellular structured Ti6Al4V alloy fabricated by electron beam melting

[J].

Effect of low-intensity pulsed ultrasound on the biological behavior of osteoblasts on porous titanium alloy scaffolds: An in vitro and in vivo study

[J].

Functional response of osteoblasts in functionally gradient titanium alloy mesh arrays processed by 3D additive manufacturing

[J].

The functional response of bioactive titania-modified three-dimensional Ti-6Al-4V mesh structure toward providing a favorable pathway for intercellular communication and osteoincorporation

[J].