钛合金主要的相组成为hcp α-Ti结构和bcc β-Ti结构[1]。目前已经发展出系列近α、α + β双相和近β工业牌号,其成分来自大量工业实践,长期以来人们一直希望澄清这些成分的结构载体,以期实现合金的高效率研发。显然,成分载体必然隐含于固溶体的特征结构——化学近程序,其模型化是结构科学的重要挑战。但是,目前的合金设计方法,如Mo当量和Al当量[2,3]、元素作用[4,5]、d-电子理论[6]乃至第一性原理计算[7]等,均无法回答工业合金牌号成分的理论根源。关键在于长期以来一直缺失描述合金近程序的结构分析方法。建立α + β双相固溶体结构模型,是解决工业钛合金成分的结构根源和优化材料成分的关键。本课题组[8]提出了描述化学近程序的团簇加连接原子模型,已被成功应用到多种工业合金体系的成分设计中。该模型认为,任意一个结构的近程序都可以简化成第一近邻团簇加上若干个位于次近邻的连接原子,表示为团簇式:[团簇](连接原子)。该模型根据组元相互作用模式,从化学近程序结构单元的角度,揭示了合金特定成分的结构根源,包含了体系中几乎所有的关键信息,比如化学成分、平均原子密度、原子间化学结合键等,类似于分子的特点,可以被认为是合金的类分子化学结构单元,承载着合金的成分信息[8~12]。

Ti-6Al-4V具有α + β双相结构,呈现出极好的综合性能以及良好的工艺性,同时液-固两相区较小,适合于增材制造,在航空工业、深海工程、生物医用领域中得到了广泛应用,其用量占钛合金的50%[13~16],是先进制造领域的主体材料之一。值得关注的是,经过近70年的工程实践,Ti-6Al-4V化学成分保持了高度的稳定性,说明该特殊成分的合理性。本课题组[1]前期以该模型为指导完成了Ti-6Al-4V的成分式解析,可以精确表述为:α-{[Al-Ti12](AlTi2)}12 + β-{[Al-Ti14](V2Ti)}5,其中α和β 2相的基础结构单元分别为α-[Al-Ti12](AlTi2)和β-[Al-Ti14](V2Ti),前者团簇为配位数12的hcp孪晶立方八面体(twinned cuboctahedron,图1a)加3个连接原子,后者为配位数14的bcc菱形十二面体(rhombic dodecahedron,图1b)加3个连接原子,2者均以Al为中心、Ti为近邻壳层。针对双相钛合金的双团簇式模型的提出,不仅为理解各类钛合金的成分规律奠定了基础,同时也为进一步提高钛合金性能指出了优化方向。通过改变两相结构单元的比例以及各自合金化,可以全面覆盖各类钛合金,为理解现有合金乃至发展新成分提供了全新路径。

图1

图1

hcp和bcc结构的第一近邻团簇,分别为配位数为12的孪晶立方八面体和配位数为14的菱方十二面体,后者的第一近邻由2层构成

Fig.1

Twinned cuboctahedron with coordination number of 12 (a) and rhombic dodecahedron with coordination number of 14 (b) as the nearest-neighbor clusters of hcp and bcc structures, respectively. The nearest-neighbor shell of the latter cluster is composed of two sub-shells

本工作基于满足α-{[Al-Ti12](AlTi2)}17 - n + β-{[Al-Ti14](V2Ti)}n 的通式,通过改变β结构单元的个数(n = 0~17),探索组织覆盖α到β的Ti-(3.19~7.45)Al-(0~12.03)V (质量分数,%)体系,获得组织和性能演化规律,并找到性能优于Ti-6Al-4V的新成分。

1 实验方法

1.1 成分设计

首先简要总结Ti-6Al-4V成分式的解析流程[1]。依据不同退火温度下α和β相成分,拟合出α相成分式为α-{[Al-Ti12](AlTi2)},共含有16个原子;β相成分式为β-{[Al-Ti14](V2Ti)},共含有18个原子。为进一步确定α和β结构单元的具体数目,将2种团簇视为2个半径不同的硬球,合金结构视为2种硬球的空间堆垛,按照团簇共振模型,完成了Ti-6Al-4V的双团簇式构建:α-{[Al-Ti12](AlTi2)}12 + β-{[Al-Ti14](V2Ti)}5,共包含有12个α-Ti结构和5个β-Ti结构,且结构单元的数目为17。所计算出的成分为Ti-6.05Al-3.94V,几乎就是工业合金牌号的名义成分。

本工作设计了α-{[Al-Ti12](AlTi2)}17 - n + β-{[Al-Ti14](V2Ti)}n,采用改变n值 (具体见表1),初步探索了组织覆盖α到β的Ti-(3.19~7.45)Al-(0~12.03)V系钛合金的成分-组织-力学性能关系。在Ti-Al-V成分图中,如图2所示,所设计的合金成分精确位于α-{[Al-Ti12](AlTi2)}与β-{[Al-Ti14](V2Ti)}成分式之间的直线(红色)上,区别在于合金成分由不同β团簇式个数所构成。表1给出了不同n时的实验合金的名义化学成分(以下均为质量分数)、Mo当量和Al当量[3],以及通过JMatPro软件模拟计算得到的合金液-固两相温度区间。由表1可以看出,随β团簇式占比提升,即当n由0逐渐提升至17时,合金的Mo当量逐渐提高而Al当量则相应降低,并且合金的液-固两相区范围逐渐增大。合金液-固两相区越小,表明该合金具有较高的熔体与固体结构的相容性,适合于增材制造[17]。本工作根据β结构单元的个数n的不同,试样分别记为n0 (纯α结构单元)、n1、n2、n3、n4、n5 (Ti-6Al-4V)、n7、n8、n12和n17。

表1 不同β团簇式个数n设计的合金化学成分以及Mo和Al当量、估算的液固两相区

Table 1

| Material code | n | Composition / (mass fraction, %) | [Mo]eq | [Al]eq | ∆TL-S / oC |

|---|---|---|---|---|---|

| n0 | 0 | Ti-7.45Al | 0.0 | 7.5 | 4.9 |

| n1 | 1 | Ti-7.16Al-0.82V | 0.6 | 7.2 | 4.9 |

| n2 | 2 | Ti-6.87Al-1.62V | 1.1 | 6.9 | 4.7 |

| n3 | 3 | Ti-6.60Al-2.41V | 1.4 | 6.6 | 4.5 |

| n4 | 4 | Ti-6.32Al-3.19V | 2.1 | 6.3 | 9.4 |

| n5 | 5 | Ti-6.05Al-3.94V | 2.6 | 6.1 | 13.3 |

| n7 | 7 | Ti-5.53Al-5.45V | 3.6 | 5.5 | 20.7 |

| n8 | 8 | Ti-5.28Al-6.14V | 4.1 | 5.3 | 24.3 |

| n12 | 12 | Ti-4.30Al-8.87V | 5.9 | 4.3 | 31.8 |

| n17 | 17 | Ti-3.19Al-12.03V | 8.0 | 3.1 | 35.1 |

图2

图2

Ti-Al-V成分图,包含了设计成分、α-[Al-Ti12]Al1Ti2相成分式和部分β相成分式,其中所设计合金分布于连接α-Al2Ti14和β-Al1Ti15V2的直线上(红色方块)

Fig.2

Ti-Al-V ternary composition chart, where are marked the compositions of the designed series, α-[Al-Ti12]Al1Ti2, and some β formulas. The resigned alloy series lie along the straight line (in red) linking α-Al2Ti14 and β-Al1Ti15V2

1.2 材料的制备

实验以纯Ti (99.9%)、纯Al (99.99%)和纯V (99.99%)为原材料。第一步:首先将原材料放入超声仪中进行酸洗和酒精清洗去除杂质后,采用Mettker Toledo AL204-IC型精密秤按比例称重,随后放置入ZHF-500型非自耗真空熔炼炉中,在高纯Ar气保护下,以工作电流为75~300 A进行熔化,反复熔炼5次,得到合金铸锭。第二步:将合金铸锭放置入ZHF-500型非自耗真空熔炼炉中,在高纯Ar气保护下,真空铜模吸铸成直径为6 mm的棒材。

1.3 表征方法

采用BX51光学显微镜(OM)和Supra 55扫描电子显微镜(SEM)进行显微组织分析。OM和SEM试样腐蚀剂为3%HF + 7%HNO3 + 90%H2O。采用D8 Focus X射线多晶衍射仪(XRD)进行物相分析,工作电压和电流分别为40 kV和40 mA,扫描角度20°~80°,扫描速率4°/min。采用JMatPro软件计算得到合金的液-固两相温度区间。采用XS64型密度计进行密度测试,测试结果取3次的平均值。采用Image-Pro Plus软件对OM和SEM形貌图(至少3张)进行α'马氏体和β相体积分数的统计分析。

采用UTM5504-G电子万能试验机进行室温拉伸实验,加载速率为0.25 mm/min。试样为标准拉伸试样(标距为15 mm,直径为3 mm)。测试结果取至少3个试样的平均值。采用HVS-1000型Vickers显微硬度仪进行硬度测试,载荷300 g,保载时间15 s,测试结果取至少12个位置的平均值。

2 实验结果与分析

2.1 显微组织

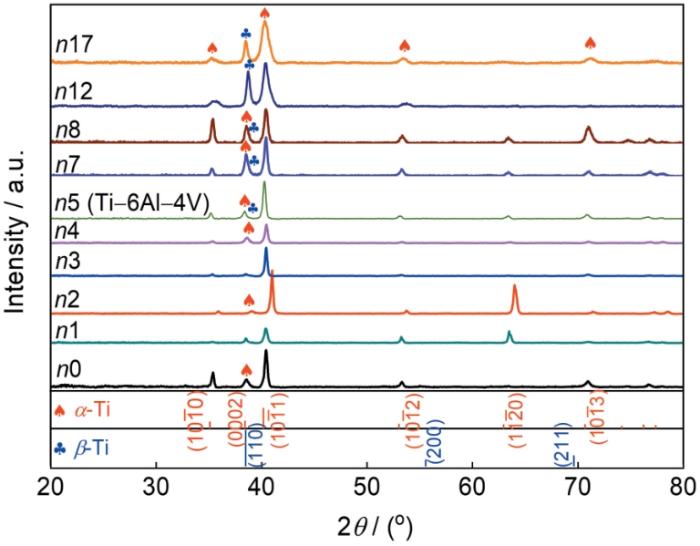

图3为铸态Ti-Al-V合金的XRD谱。可以看出,当n = 0~4时,仅观察到α-Ti对应衍射峰,没有发现β-Ti衍射峰。当n = 5时,Ti-6Al-4V合金的XRD谱中开始出现了β相衍射峰,由此可见,该合金位于显著出现β相的临界点。随着n值逐渐增大,β相衍射峰逐渐增强,尤其是n12和n17合金的β相衍射峰十分明显。这主要是因为该合金中含有较多的β相稳定元素V,促使在快速冷却过程中大量β相在基体中得以保留。与淬火过程类似,在真空铜模吸铸快冷条件下,原始β相完全转变为α相+ α'马氏体,随着n增大,即β团簇式占比提升,α相逐渐减少而α'马氏体数量显著上升。当n = 12时,合金组织中α相完全消失,仅为β相和少量α'马氏体。可见,该成分处于α相完全消失的临界成分点。当n = 17时,合金此时已加入了大量β相稳定元素V (12%),而Al含量小于3.2%,可以使得高温β相完全保留至室温。相比于n0 (纯α结构单元)合金,n17 (纯β结构单元)合金中由于β结构单元完全取代了α结构单元,导致n17合金主要为单一β相,而n0合金以单一α为主。

图3

图4为6种典型铸态Ti-Al-V合金显微组织的OM像。可以看出,随n值增大,即β团簇式占比提升,α'马氏体数量呈先上升后下降的趋势,其形态由板条状逐渐转变为细片状和针状。这些真空铜模吸铸快冷生成的α'马氏体,其组织形态主要与合金元素含量有关。邓安华[18]总结发现了铸造快冷条件下钛合金的α'马氏体主要有2种组织形态,当合金元素浓度较低时,α'马氏体形貌呈大板条状;合金元素浓度较高时,α'马氏体形貌呈针状。这是由于β相稳定元素越高,导致相变过程中晶格重构的阻力越大,相变所需的过冷度也越大,越有利于针状α'马氏体的形成。从图4b~d可以看出,β相主要分布于α'马氏体相界,其形貌呈黑色短棒状,基体α相呈白色带状。当n = 5时(图4c)可以明显观察到黑色短棒状β相。当n进一步提升至12和17时,α'马氏体数量大幅下降,β相数量逐渐增多。图4e和f的统计结果表明,n12和n17合金中β相的体积分数分别约为91%和98%。尤其当n = 17时,合金几乎为单一β相组织。

图4

图4

典型铸态Ti-Al-V合金的OM像

Fig.4

OM images of typical Ti-Al-V alloys of n1 (a), n2 (b), n5 (c), n8 (d), n12 (e), and n17 (f)

图5

图5

典型铸态Ti-Al-V合金的SEM像

Fig.5

SEM images of typical as-cast Ti-Al-V alloys of n1 (a), n2 (b), n5 (c), and n8 (d)

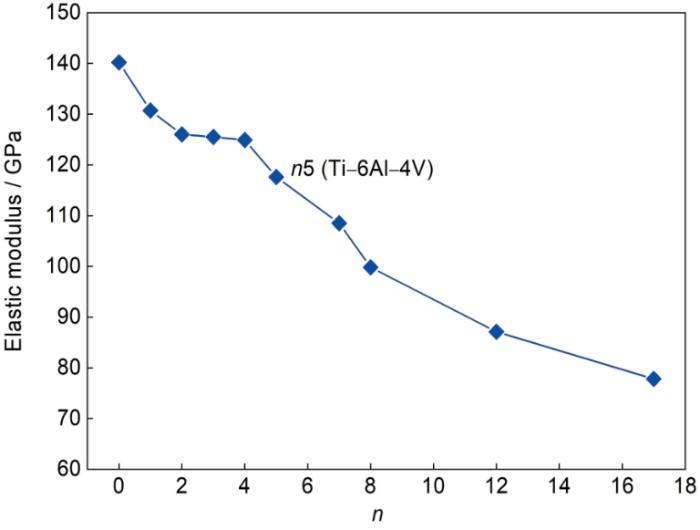

2.2 力学性能

图6为所设计合金的室温拉伸力学性能。其中,图6a为室温拉伸工程应力-应变曲线。从图6b可以看出,当n从0逐渐提升至17,即β团簇式占比逐渐提升,合金的强度呈现先上升而后下降的趋势,而塑性变化趋势则相反。当n = 8时,合金的强度达到最大,抗拉强度(UTS)约为1019 MPa,屈服强度(YS)约为867 MPa,伸长率(δ)约为4.1%,其强度相比于n5合金提升了90 MPa,为n5合金的1.1倍,而伸长率则基本保持一致。这说明n5合金不是体系中最高强的点。当n为5~8时,包括n5合金在内的合金强度处于整个体系的高峰区;当n位于5~8两侧,即当n小于5或大于8时,合金则具有较高的塑性,越接近两端,塑性则越高,n0 (纯α结构单元)合金和n17 (纯β结构单元)合金伸长率大于13%,是n5合金的3倍,强度则略降低。

图6

图6

铸态Ti-Al-V合金的室温拉伸力学性能

Fig.6

Room-temperature mechanical properties of as-cast Ti-Al-V alloys

(a) engineering stress-strain curves

(b) ultimate tensile strength and elongation

图7

Ti-Al-V合金强度的提高主要与固溶强化和第二相强化等强化效应有关。特别是,n8合金的显微组织出现了大量细小的针状α'马氏体,这种细小针状α'马氏体不利于位错滑移[14],有利于提高合金的强度,但会导致合金塑性较差。相比而言,n0和n1合金的组织几乎呈现出单一α相(α'马氏体体积分数小于1%);n17合金的组织几乎呈现出单一β相(β相体积分数大于98%)和少量α'马氏体组织。这种单相的α相或β相固溶体组织有利于提高合金的塑性,使得Ti-Al-V合金的伸长率大于12%。

图8

图9为铸态Ti-Al-V钛合金的Vickers硬度和质量密度以及相应比硬度(硬度/密度)和比强度(抗拉强度/密度)图。从图9a和c可以看出,Vickers硬度和比硬度随n增大均呈先上升后下降的趋势。其中,当n为8时,合金的Vickers硬度和比硬度均达到最高,分别为343 HV和0.76 GPa·cm3/g,相比于n5合金的硬度和比硬度(分别约为320 HV和0.72 GPa·cm3/g),该合金的Vickers硬度和比硬度分别提升了7%和5%。这主要是因为n8合金出现了大量细小的针状α'马氏体,而n5合金的组织主要为细片状α'马氏体,这种大量细小的针状α'马氏体组织可以有效提升合金的Vickers硬度。此外,Ti-Al-V合金的Vickers硬度变化规律与抗拉强度变化规律一致,2者数值关系近似满足:抗拉强度(MPa) = 2.9H (H为Vickers硬度,HV)。

图9

图9

铸态Ti-Al-V钛合金的Vickers硬度和密度以及比硬度和比强度

Fig.9

Vickers hardnesses (a), mass densities (b), specific hardnesses (c), and specific strengthes (d) of Ti-Al-V alloys (Specific hardness denotes the hardness-over-density ratio, and specific strength denotes the ultimate tensile strength-over-density ratio, respectively)

从图9b可以看出,理论质量密度和实验质量密度值比较接近(误差小于0.2%)。合金的理论质量密度(ρ)可以通过计算原子密度(ρa)获得[22]:

2.3 断口形貌

图10为铸态Ti-Al-V合金的室温拉伸断口形貌。可以看出,各铸态Ti-Al-V合金室温拉伸断口表面均呈现由解理断裂、韧窝和撕裂棱组成的混合断裂特征,而微裂纹主要沿解理面和撕裂棱的边界分布。当n = 1时(图10a和b),合金断口存在较多的韧窝区,韧窝的产生可以有效释放材料内部的内应力,合金表现出较高的塑性[26]。相比而言,n5 (图10c和d)和n8 (图10e和f)合金的断口表面存在粗大的撕裂棱,而且撕裂棱分布相对集中。撕裂棱边界容易产生位错塞积,是微裂纹形核的主要形核点,将会导致材料的塑性降低。因而,n5和n8合金的塑性较差。当n = 12时,如图10g和h所示,合金断口的韧窝数量增加,而撕裂棱数量则明显减小,合金的塑性得以提高。

图10

图10

铸态Ti-Al-V钛合金的室温拉伸不同倍数断口形貌

Fig.10

Low (a, c, e, g) and high (b, d, f, h) magnified fracture morphologies of as-cast Ti-Al-V alloys

(a, b) n1 (c, d) n5 (e, f) n8 (g, h) n12

3 结论

(1) 在团簇式框架内,在前期解析Ti-6Al-4V的双团簇式通式α-{[Al-Ti12](AlTi2)}17 - n + β-{[Al-Ti14](V2Ti)}n 的基础上,采用改变n值的方法,研究了Ti-(3.19~7.45)Al-(0~12.03)V系钛合金成分-组织-力学性能关联。随n值增大,铸态组织由单一α相逐渐转变为α + α'马氏体相、α + α'马氏体+少量β相及β +少量α'马氏体相。其中,α'马氏体数量呈先上升而后下降的趋势,且其形态由板条状逐渐转变为细片状和针状。当n为8时,α'马氏体数量最多且其形态主要呈针状;当n为5时开始出现β相,其数量随n增大而逐渐增多;当n为12时为α相完全消失的临界成分点。

(2) 随β团簇式占比增大,室温拉伸强度呈先上升后下降的趋势,塑性的变化趋势则相反,这源自细小针状α'马氏体提升强度而降低塑性的作用。当n为8时,合金的强度达到最大。当n为5~8时,包括Ti-6Al-4V (n5)合金在内的合金强度处于整个体系的高峰区;当n小于5或大于8时,合金具有较高的塑性,n0 (纯α结构单元)和n17 (纯β结构单元)合金的伸长率大于13%,是Ti-6Al-4V (n5)合金伸长率的3倍。

(3) 随β团簇式占比增大,比强度和比硬度均呈先上升后下降的趋势,弹性模量逐渐降低而密度逐渐增大。n8合金的比强度和比硬度均最高,分别达到了230 kN·m/kg和0.76 GPa·cm3/g,相比于Ti-6Al-4V (n5)合金分别提升了9%和5%。

(4) Ti-6Al-4V组织为α +细片状α'马氏体+少量β相,其UTS、YS、E及硬度分别约为925 MPa、793 MPa、117.6 GPa和320 HV,液-固两相区约为13.3℃,密度约为4.38 g/cm3。相比而言,n8合金组织为α +大量针状α'马氏体+少量β相,其UTS、YS、E及硬度分别约为1019 MPa、867 MPa、99.8 GPa和343 HV,液-固两相区约为24.3℃,密度约为4.42 g/cm3,特别是该合金的强度相比于Ti-6Al-4V (n5)合金提高了90 MPa,而伸长率与之持平,约为4%。

参考文献

Composition formulas of Ti alloys derived by interpreting Ti-6Al-4V

[J].

Redefining the β-phase stability in Ti-Nb-Zr alloys for alloy design and microstructural prediction

[J].

Effect of germanium and silicon additions on the mechanical properties of a near-α titanium alloy

[J].

Phase transformation and structural evolution in a Ti-5at.%Al alloy induced by cold-rolling

[J].

In-situ microstructural investigations of the TRIP-to-TWIP evolution in Ti-Mo-Zr alloys as a function of Zr concentration

[J].Aiming at overcoming the strength-ductility trade-off in structural Ti-alloys, a new family of TRIP/TWIP Ti-alloys was developed in the past decade (TWIP: twinning-induced plasticity; TRIP: transformation-induced plasticity). Herein, we study the tunable nature of deformation mechanisms with various TWIP and TRIP contributions by fine adjustment of the Zr content on ternary Ti-12Mo-xZr (x = 3, 6, 10) alloys. The microstructure and deformation mechanisms of the Ti-Mo-Zr alloys are explored by using in-situ electron backscatter diffraction (EBSD) and transmission electron microscopy (TEM). The results show that a transition of the dominant deformation mode occurred, going from TRIP to TWIP major mechanism with increasing Zr content. In the Ti-12Mo-3Zr alloy, the stress-induced martensitic transformation (SIM) is the major deformation mode which accommodates the plastic flow. Regarding the Ti-12Mo-6Zr alloy, the combined deformation twinning (DT) and SIM modes both contribute to the overall plasticity with enhanced strain-hardening rate and subsequent large uniform ductility. Further increase of the Zr content in Ti-12Mo-10Zr alloy leads to an improved yield stress involving single DT mode as a dominant deformation mechanism throughout the plastic regime. In the present work, a set of comprehensive in-situ and ex-situ microstructural investigations clarify the evolution of deformation microstructures during tensile loading and unloading processes.

Design of new biomedical titanium alloy based on d-electron alloy design theory and JMatPro software

[J].

Ti-5Al-5Mo-5V-3Cr and similar Mo equivalent alloys: First principles calculations and experimental investigations

[J].

From clusters to phase diagrams: Composition rules of quasicrystals and bulk metallic glasses

[J].

Exploration of phase structure evolution induced by alloying elements in Ti alloys via a chemical-short-range-order cluster model

[J].The prominent comprehensive properties of solid-solution- and intermetallic-based Ti alloys are derived from their diverse microstructures induced by multi-component alloying, which results in a chemical composition complexity. A cluster-plus-glue-atom model, characterizing the chemical short-range orders, was introduced to explore the relationships among the local atomic distributions of alloying elements in different phase structures of Ti alloys, including α-Ti, β-Ti, ω-Ti, α-TiAl, γ-TiAl, O-TiAlNb, and B2-Ti(Al,Nb). Specific cluster structural units, i.e., cluster formulas, for these phases were determined with the guide of the Friedel oscillation theory for electron-structure stabilization. It is due to the change of cluster structural units that induces the phase transformation, which is attributed to the amounts of primary alloying elements of Al and Nb. The total atom number (Z) values in these cluster structural units, calculated by the Fermi vector k, are all very close to the integer of Z = 16. Furthermore, the composition rules of industrial multi-component Ti alloys based on these phases were generalized in light of the cluster formula approach, which will open up a new route towards designing high-performance Ti alloys with complex compositions.

Review of structural models for the compositional interpretation of metallic glasses

[J].

Chemical units in solid solutions and alloy composition design

[J].

固溶体中的化学结构单元与合金成分设计

[J].

Dual-cluster interpretation of binary eutectics associated with hexagonal close-packed solid solution phases

[J].

Rapid solidification of Ti-6Al-4V alloy micro-droplets under free fall condition

[J].Especially in the past decades, Ti-6Al-4V alloy has received much attention, not only due to its high melting temperature, good corrosion resistance, low density and high hardness, but also because of the diverse and complicated microstructures formed under different conditions. This makes Ti-6Al-4V a potential candidate in both aerospace industries and fundamental research. It is well known that the solidified microstructures of alloy have a great influence on their mechanical properties. Therefore, it is crucial to investigate the mechanical properties of Ti-6Al-4V solidified under different conditions, in particular in the undercooling conditions. However, it is noted that most research on the solidification of Ti-6Al-4V alloy was carried out under equilibrium condition. With respect to Ti-6Al-4V alloy solidified under substantial undercooling conditions, few studies could be found. Thus, it is interesting to study two points: (1) the feature of the microstructure of Ti-6Al-4V alloy solidified under highly undercooled conditions and large cooling rate, (2) the influence of undercooling and cooling rate on the mechanical property of Ti-6Al-4V alloy. To address these two problems, Ti-6Al-4V alloy was rapidly solidified in a drop tube. The main results are summarized as follows. The microstructure of the Ti-6Al-4V alloy solidified under free fall condition displays "lamellar α+β→α dendrites→basket-weave α'+β→ needle-like α'→ needle-like α'+ anomalous β " transformation with decreasing the droplets diameter. And the needle-like α' phase in the original boundaries of equiaxed β grains is transformed into a continuous distribution and anomalous structure of β phase when the droplet size is less than about 400 μm. The microhardness of this alloy ranges from 506 kg/mm2 to 785 kg/mm2 when the droplet diameter decreases from 1420 μm to 88 μm, which is much higher than that of the master alloy. For "lamellar structure of α+β phases", "needle-like α' phase" and "needle-like α' phase+ anomalous β phase", the microhardness increases with the decrease of droplet diameter. But for 'basket-weave' microstructure, the microhardness diminishes with the decrease of droplet diameter.

自由落体条件下Ti-6Al-4V合金微液滴的快速凝固研究

[J].

Deformation mechanism of bimodal microstructure in Ti-6Al-4V alloy: The effects of intercritical annealing temperature and constituent hardness

[J].The so-called bimodal microstructure of Ti-6Al-4V alloy, composed of primary α grains (αp) and transformed β areas (βtrans), can be regarded as a “dual-phase” structure to some extent, the mechanical properties of which are closely related to the sizes, volume fractions, distributions as well as nano-hardness of the two constituents. In this study, the volume fractions of primary α grains (vol.%(αp)) were systematically modified in three series of bimodal microstructures with fixed primary α grain sizes (0.8 μm, 2.4 μm and 5.0 μm), by changing the intercritical annealing temperature (Tint). By evaluating the tensile properties at room temperature, it was found that with increasing Tint (decreasing vol.%(αp)), the yield strength of bimodal microstructures monotonically increased, while the uniform elongation firstly increased with Tint until 910 °C and then drastically decreased afterwards, thereby dividing the Tint into two regions, namely region I (830-910 °C) and region II (910-970 °C). The detailed deformation behaviors within the two regions were studied and compared, from the perspectives of strain distribution analysis, slip system analysis as well as dislocation analysis. For bimodal microstructures in region I, due to the much lower nano-hardness of βtrans than αp, there was a clear strain partitioning between the two constituents as well as a strain gradient from the αp/βtrans interface to the grain interior of αp. This activated a large number of geometrically necessary dislocations (GNDs) near the interface, mostly with <c+a> components, which contributed greatly to the extraordinary work-hardening abilities of bimodal microstructures in region I. With increasing Tint, the αp/βtrans interface length density gradually increased and so was the density of GNDs with <c+a> components, which explained the continuous increase of uniform elongation with Tint in this region. For bimodal microstructures in region II, where the nano-hardness of βtrans and αp were comparable, neither a clear strain-partitioning tendency nor a strain gradient across the αp/βtrans interface was observed. Consequently, only statistically stored dislocations (SSDs) with <a> component were activated inside αp. The absence of <c+a> dislocations together with a decreased volume fraction of αp resulted into a dramatic loss of uniform elongation for bimodal microstructures in region II.

A novel Ti-4.13Al-9.36V alloy of high ductility designed on base of α″-microstructure for laser solid forming

[J].

基于α″组织设计适于激光立体成形的新型高塑性Ti-4.13Al-9.36V合金

[J].为了提高Ti-6Al-4V合金的加工硬化率和塑性,基于其团簇成分式12[Al-Ti<sub>12</sub>](AlTi<sub>2</sub>)+5[Al-Ti<sub>14</sub>](V<sub>2</sub>Ti)设计成分式为4[Al-Ti<sub>12</sub>](AlTi<sub>2</sub>)+12[Al-Ti<sub>14</sub>](V<sub>2</sub>Ti)的(Ti-4.13Al-9.36V, %)合金,采用激光立体成形工艺制备Ti-4.13Al-9.36V和Ti-6.05Al-3.94V(对比合金),研究了沉积态和固溶温度对其显微组织和力学性能的影响。结果表明,沉积态Ti-4.13Al-9.36V和Ti-6.05Al-3.94V合金的显微组织均由基体外延生长的初生β柱状晶和晶内细小的网篮α板条组成。Ti-6.05Al-3.94V合金的初生β柱状晶的宽度约为770 μm,α板条的宽度约为0.71 μm;而Ti-4.13Al-9.36V合金的初生β柱状晶的宽度显著减小到606 μm,α板条的宽度约为0.48 μm。经920℃固溶-淬火处理后Ti-6.05Al-3.94V样品的显微组织为α'+α相,其室温拉伸屈服强度约为893 MPa,抗拉强度约为1071 MPa,延伸率约为3%。经750℃固溶-淬火处理后Ti-4.13Al-9.36V样品的显微组织为α''+α相,与α'马氏体相比,应力诱发的α''马氏体能显著地提高合金的加工硬化能力,其室温拉伸屈服强度约为383 MPa,抗拉强度约为 989 MPa,延伸率达到了17%。这表明,根据团簇理论模型调控α''+α的显微组织能有效提高激光立体成形Ti合金的加工硬化能力和塑性。

Bonding zone microstructure and mechanical properties of forging-additive hybrid manufactured Ti-6Al-4V alloy

[J].

锻造-增材复合制造Ti-6Al-4V合金结合区显微组织及力学性能

[J].在Ti-6Al-4V合金锻造成形双态组织基材上采用激光立体成形方法(送粉式激光增材制造)沉积块体试样,研究了不同线能量密度输入下基材与增材结合区的微观组织特征及形成机制。结果表明,结合区内不同高度部位由于热源影响程度存在差异,形成了从下到上的非均匀组织。其中下部区域由于峰值温度较低,仍保持初始双态组织形貌,但发生一定粗化;中部区域随着温度升高以及保温时间延长,形成等轴α相、层片α相及大量次生α相的混合组织;而上方靠近增材区的峰值温度超过β相转变温度,完全转变为由层片α相形成的魏氏体组织,并伴随着由于元素扩散不充分而形成的阴影结构。对包含基材区和增材区的结合试样进行拉伸测试发现,在设定的能量密度范围内,断裂位置均远离结合区,表明增材区与基材区结合良好,结合区强度超过基材区及增材区强度。此外,对比不同能量密度复合制造Ti-6Al-4V试样的拉伸测试结果发现,线能量密度为100 J/mm时,结合区以及增材区α相特征尺寸较小,复合制造试样的屈服强度和抗拉强度最大。随线能量密度的增大,复合制造试样屈服强度和抗拉强度均减小,而延伸率增加。

Design for Ti-Al-V-Mo-Nb alloys for laser additive manufacturing based on a cluster model and on their microstructure and properties

[J].

Martensitic transformation of titanium alloys

[J].

钛合金的马氏体相变

[J].

Effect of oxygen content on the mechanical properties of TC4 titanium alloy

[J].

氧含量对TC4钛合金力学性能的影响

[J].

Effect of element Fe on mechanical properties of TC4ELI alloy

[J].

Fe元素对TC4ELI合金力学性能的影响

[J].

β-Ti Alloys with low young's moduli interpreted by cluster-plus-glue-atom model

[J].

Composition design procedures of Ti-based bulk metallic glasses using the cluster-plus-glue-atom model

[J].

High specific strength Mg-Li-Zn-Er alloy processed by multi deformation processes

[J].

Properties of high specific strength Al-4wt.%Al2O3/B4C nano-composite produced by accumulative roll bonding process

[J].

Preparing process of ZL101A alloy by vacuum casting and its properties

[J].

真空熔铸法制备ZL101A合金工艺及性能研究

[J].

Investigation of the tensile properties of heat treated Ti-Mo alloys

[J].