Al-Cu-Li-Mg合金是一种重要的轻量化金属材料,由于其具有密度低、比强度高、抗腐蚀性能好等优点被广泛应用于航空航天领域[1,2]。Al-Cu-Li-Mg合金为可时效强化合金,其优良的力学性能很大程度来源于合金的时效析出强化,但其时效析出行为较为复杂,析出相种类较多,包括T1相、S相、θ'相、GPB(Guinier-Preston-Bagaryatsky)区及原子团簇等[2,3]。T1相(Al2CuLi)为Al-Cu-Li-Mg合金中时效强化效果最好的析出相[4~6],呈盘片状形貌,具有很大的径厚比,惯习面为{111}Al晶面[7,8]。T1相的前驱相为GPT1区,GPT1区与Al基体成完全共格的关系,其具有“三明治”层状排列的原子结构,由两侧的富Cu原子层夹中间的富Al原子层组成[9]。由于Mg元素的添加,Al-Cu-Li-Mg合金中常常会形成S相(Al2CuMg),S相为正交体心晶体结构,晶格常数aS = 0.400 nm,bS = 0.923 nm,cS = 0.714 nm[10]。S相可分为2种形貌:板条状S相与棒状S相,2种形貌的S相均容易沿<100>Al方向长大[11]。θ'相(Al2Cu)为盘片状强化相,惯习面为{100}Al晶面[12]。GPI区为θ'相的前驱相,其原子结构为{100}Al晶面上单层富Cu原子层,与Al基体成完全共格的关系[13]。在Al-Cu-Li-Mg合金中,由于Li元素的添加,δ'相容易在GPI区及θ'相界面处异质形核,形成δ'/GPI/δ'及δ'/θ'/δ'复合相[14]。GPB区化学成分为Mg(2x + 2)Cu(2x + 2)Al(3x - 2),其沿<100>Al方向长大,为一种一维针状形貌的亚稳相,在人工时效过程中容易发生溶解[15~19]。近年来,在Al-Cu-Li-Mg合金中发现Li原子可诱导GPB区原子结构发生改变,形成Li-GPB区变体。相比常规GPB区,Li-GPB区变体形成焓更低,晶体结构更为稳定[20,21]。

淬火态的溶质原子过饱和Al-Li合金将会发生自然时效现象,并析出原子团簇及析出相等。在后续人工时效过程中,自然时效形成的团簇及析出相将会影响人工时效析出行为,进而改变合金的力学性能[3,22~29]。为此,研究铝合金的自然时效析出行为具有重要的科学意义及应用价值。Al-Cu-Li-Mg合金的自然时效析出行为主要受Mg、Li等合金元素成分的影响[22,28~30]。无Mg的Al-Cu-Li合金自然时效响应速率较慢,硬度较低,合金中仅析出少量富Cu原子团簇。添加Mg可明显促进合金的自然时效析出行为,快速形成富Mg、Cu-Mg原子团簇及GPI区等析出相,使合金硬度明显提高。对于高Li含量的Al-Cu-Li-Mg合金,在自然时效过程中除析出富Mg团簇、Cu-Mg原子团簇及GPI区外,还会析出δ'相[28]。

然而,目前有关Al-Cu-Li合金自然时效如何影响后续人工时效析出行为的研究仍然存在很大争议。Decreus等[22]利用原位小角度X射线散射的实验方法,研究了AA2198合金中自然时效形成的Cu-Mg原子团簇在155℃人工时效中的演变规律。他们发现,在强化相析出之前,Cu-Mg原子团簇几乎全部溶解,并认为自然时效原子团簇不会对人工时效析出序列产生影响。相关研究[23]发现,Al-3.95Cu-0.96Li-0.32Mg-0.27Ag-0.15Zr-0.019Mn (质量分数,%)合金自然时效析出的富Cu团簇会促进后续人工时效过程中T1相的析出。他们认为自然时效原子团簇可改变人工时效析出行为,且对合金力学性能的提升起到正面作用。另有工作[24]在Al-4.0Cu-0.9Li-0.2Mg-0.4Ag-0.3Zn-0.2Zr (质量分数,%)合金形变热处理前引入自然时效,发现自然时效形成的富Cu原子团簇会抑制T1相的析出,并同样认为自然时效原子团簇可改变人工时效析出行为,但对合金力学性能的提升起到负面作用。

综上分析,存在争议的原因可分为以下几点:① 自然时效阶段形成的富Mg、富Cu及Cu-Mg原子团簇尺寸均非常细小,仅有几个或几十个原子构成。现有的表征方法难以对原子团簇与析出相之间的作用机制进行直接观察,进而不能提供直接证据说明原子团簇对时效析出行为的影响。② Al-Cu-Li-Mg合金的时效析出序列十分复杂,常常多种析出相之间存在竞争析出,这也给相关表征工作带来了极大的困难。③ 不同的研究工作,其自然时效时间、人工时效温度等实验参数存在不同,原子团簇对人工时效析出行为的影响机制也存在不同。

本工作利用高分辨透射电镜(TEM)、三维原子探针(3DAP)、三维重构(3DET)及力学性能测试等实验方法,系统研究自然时效对Al-Cu-Li-Mg合金在160℃人工时效析出行为及力学性能的影响。对比不同工艺下合金的人工时效析出行为,明确自然时效形成的富Mg、Cu-Mg原子团簇等对人工时效析出行为的作用机制。本工作结果对于制备高性能新型Al-Li合金具有重要指导意义。

1 实验方法

1.1 实验材料及热处理

本实验所用合金成分为Al-2.95Cu-1.55Li-0.57Mg-0.18Zr (质量分数,%)。首先将铸态合金进行均匀化处理,然后依次将合金进行热轧、冷轧处理,制备成2 mm厚板。使用电火花线切割将板材合金切割成10 mm × 10 mm × 2 mm方片型试样,以备后续热处理使用。热处理实验中,首先将所有试样进行495℃、4 h固溶淬火处理,然后取部分试样直接放入油浴炉中进行160℃人工时效处理,此工艺称为单级时效处理,简称为T6处理。另取部分试样在淬火处理后,首先在室温下进行7 d的自然时效处理,然后同样将其放在油浴炉中进行160℃人工时效,该工艺称为双级时效处理,简称为T66处理。通过对比单、双级时效处理工艺,研究自然时效对人工时效析出行为的影响。

1.2 力学性能测试

利用HXD-1000T Vickers硬度测试仪对合金微观硬度进行测量,加载应力4.9 N,加载时间10 s,每种状态试样硬度取5组硬度数据的平均值。使用MTS Landmark 50 kN拉伸试验机对合金进行室温拉伸性能测试,按照ASTM-E51700标准,制备截面为5 mm × 1 mm的拉伸试样,试样纵向轴平行于冷轧方向。拉伸性能指标为相同热处理状态下5组拉伸数据的平均值。

1.3 微观组织表征

使用LEAP 4000X HR 3DAP在激光模式下对试样进行表征,工作频率为200 kHz,仪器检测效率约为37%。利用电火花线切割方法切割出0.5 mm × 0.5 mm方形棒材,然后采用两步电解抛光法[33]制备3DAP样品。使用标准重构算法进行数据重构,通过商用IVASTM 3.6.8软件对3DAP实验数据进行定量分析。

2 实验结果

2.1 力学性能

图1

图1

合金经单、双级时效处理后的力学性能

Fig.1

Mechanical properties of the alloys with T6 and T66 treatment

(a) age-hardening curves vs aging time

(b) engineering stress-strain curves of peak-aged T6 alloys at 96 and 192 h, respectively

(c) engineering stress-strain curves of peak-aged T66 alloys at 96 and 192 h, respectively

(d) diagram of tensile properties

2.2 微观组织

2.2.1 160℃单级时效试样的微观组织

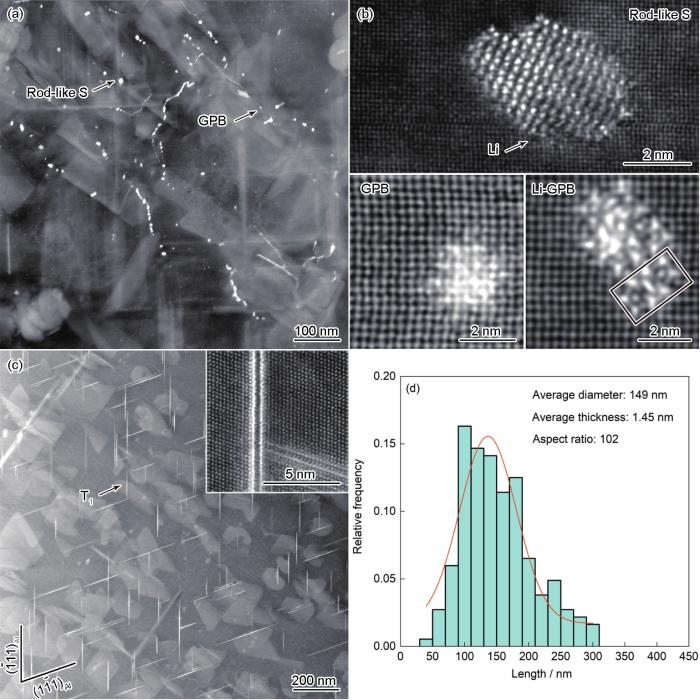

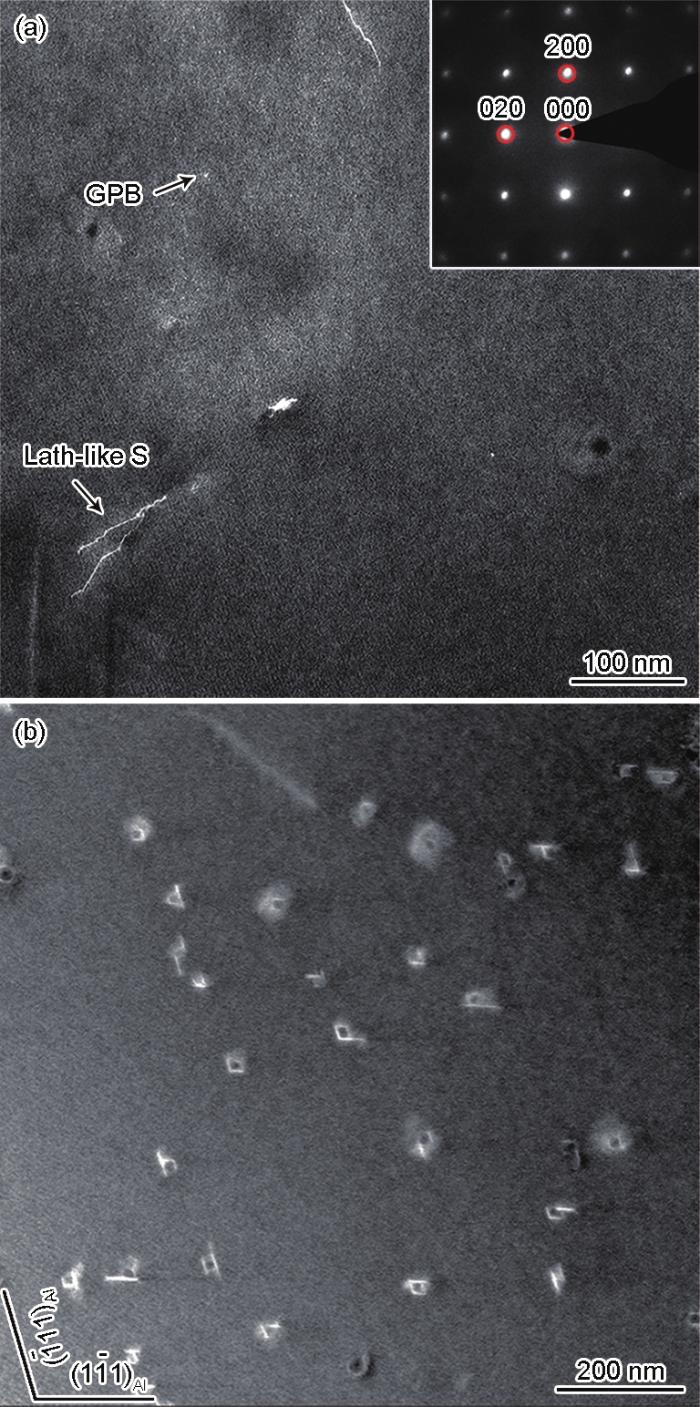

图2

图2

单级时效96 h峰值试样的微观组织分析

Fig.2

Microstructures and T1 diameter distribution of the peak-aged T6 sample for 96 h

(a) HAADF image of precipitates viewed along the [001]Al direction

(b) atomic-resolution HAADF images of rod-like S precipitates and GPB zones viewed along the [001]Al direction

(c) HAADF image of T1 precipitates viewed along the [110]Al direction (Inset is the atomic-resolution image of a T1 precipitate)

(d) T1 diameter distribution

图3

图3

单级时效192 h峰值试样的微观组织分析

Fig.3

Microstructures and T1 diameter distribution of the peak-aged T6 sample at 192 h

(a) HAADF image of precipitates viewed along the [001]Al direction (Inset is the corresponding atomic-resolution HAADF image of a δ'/θ'/δ' composite precipitate)

(b) HAADF image of T1 precipitates viewed along the [110]Al direction

(c) T1 diameter distribution

2.2.2 160℃双级时效合金析出行为

在160℃人工时效前引入自然时效,合金力学性能演变及时效析出行为均十分复杂。为此,本工作采用3DAP、3DET等表征方法,分别对自然时效7 d试样、双级时效初期试样(8 h)、第一处峰值(96 h)、谷值(144 h)及第二处峰值(192 h)多个试样的微观组织进行表征,并将其与160℃单级时效试样进行对比,讨论自然时效对合金人工时效析出行为的影响。

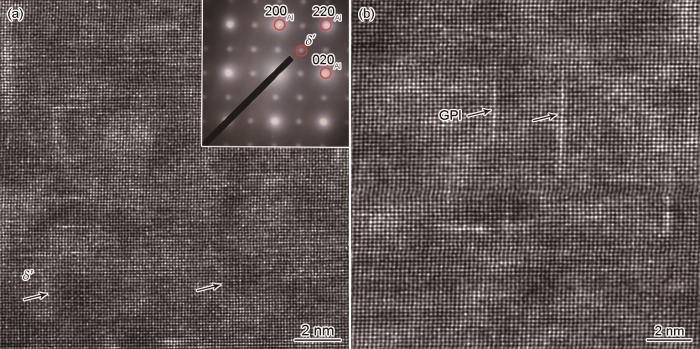

图4

图4

自然时效7 d试样微观组织的TEM像和选区电子衍射(SAED)花样

Fig.4

TEM images of microstructures of the sample which is natural aged (NA) for 7 d

(a) atomic-resolution HAADF image of δ'-phase precipitates viewed along the [001]Al orientation (Inset is the selected area electron diffraction (SAED) pattern)

(b) atomic-resolution HAADF image of GPI zones viewed along the [001]Al orientation

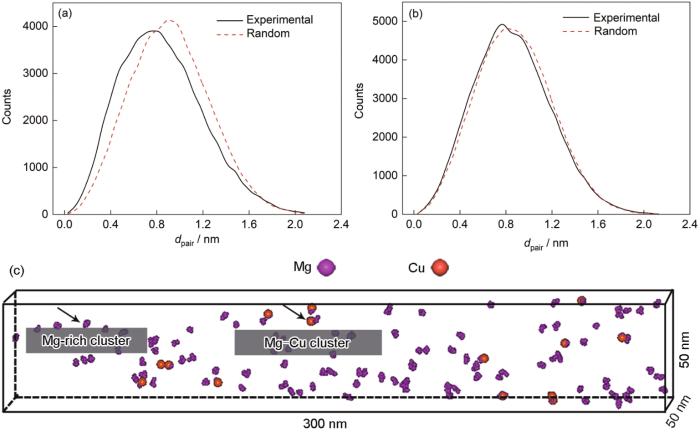

图5

图5

自然时效7 d试样中原子团簇的3DAP分析

Fig.5

3DAP analyses of atomic clusters in the sample which is natural aged for 7 d (dpair—distance between nearest-neighbor atoms)

(a) nearest-neighbor analysis of Mg (b) nearest-neighbor analysis of Cu

(c) distribution of Mg clusters and Mg-Cu co-clusters

通过以上观察可知,自然时效阶段合金硬度上升的主要原因为富Mg、Cu-Mg原子团簇、δ'相及GPI区的析出。

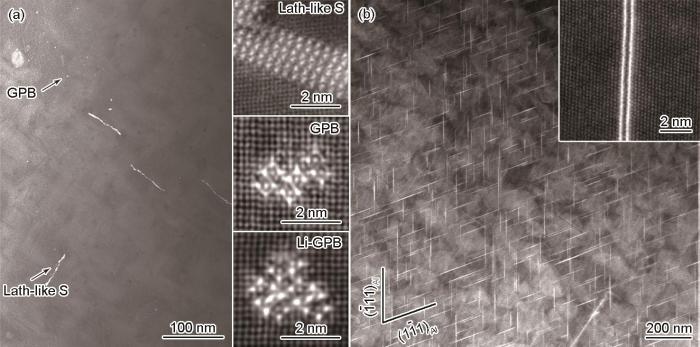

(2) 双级时效试样TEM表征。图6给出了双级时效初期(8 h)试样的微观组织及SAED花样。从[001]Al方向对合金进行观察,未发现δ'相及GPI区,相应的SAED花样中也未出现δ'相的衍射斑点,说明自然时效阶段形成的δ'相及GPI区在人工时效初期均发生溶解,可推断δ'相及GPI区的溶解引起了人工时效初始阶段合金硬度降低。另外,从[001]Al方向还可以观察到少量GPB区及板条状S相。从[110]Al方向对样品进行观察,可发现一些正在形核析出的T1相。

图6

图6

双级时效初期(8 h)试样HAADF-STEM像及SAED花样

Fig.6

HAADF-STEM images and SAED pattern of the T66 sample aged for 8 h

(a) morphology of precipitates viewed along [001]Al direction and SAED pattern (inset)

(b) morphology of T1 precipitates viewed along [110]Al direction

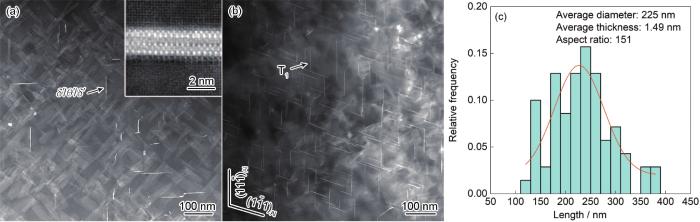

图7

图7

双级时效第一处峰值(96 h)试样的HAADF-STEM像

Fig.7

HAADF-STEM images of the first-peak-aged T66 sample at 96 h

(a) morphology of precipitates viewed along the [001]Al direction

(b) atomic-resolution HAADF images of the precipitates viewed along the [001]Al direction

(c) morphology of T1 precipitates viewed along the [110]Al direction (Inset is the atomic-resolution HAADF image of a T1 precipitate)

图8

图8

160℃双级时效谷值(144 h)试样的HAADF-STEM像

Fig.8

HAADF-STEM images of the valley-aged T66 sample at 144 h

(a) morphology of precipitates viewed along the [001]Al direction (Insets are the corresponding atomic-resolution HAADF images of the precipitates)

(b) morphology of T1 precipitates viewed along the [110]Al direction (Inset is the atomic-resolution HAADF image of a T1 precipitate)

图9

图9

160℃双级时效第二处峰值(192 h)试样的HAADF-STEM像

Fig.9

HAADF-STEM images of the second-peak-aged T66 sample at 192 h

(a) morphology of precipitates viewed along the [001]Al direction (Inset is the atomic-resolution HAADF image of a lath-like S precipitate)

(b) morphology of T1 precipitates viewed along [110]Al direction (Inset is the atomic-resolution HAADF image of a T1 precipitate)

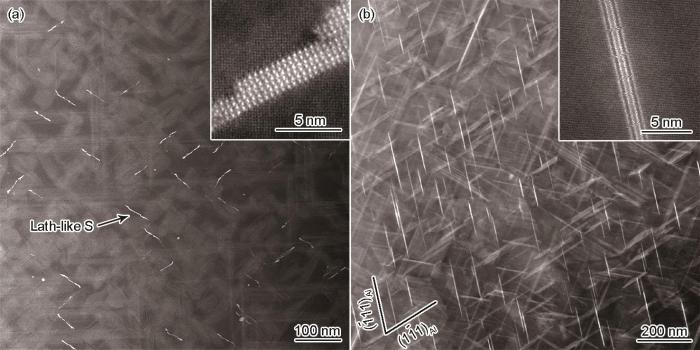

(3) T1相尺寸统计。在双级时效过程中,不同时效状态合金中均存在大量T1相的析出,T1相为盘片状析出相,其径厚比对合金的析出强化具有重要影响[6]。分别对双级时效峰一(96 h)、谷值(144 h)、峰二(192 h)试样中T1相的平均直径、平均厚度及径厚比进行统计,结果如图10所示。第一处峰值试样平均直径为169 nm,平均厚度1.52 nm,径厚比111;谷值试样平均直径为189 nm,平均厚度1.54 nm,径厚比123;第二处峰值试样平均直径为201 nm,平均厚度1.43 nm,径厚比140。根据统计结果可知,随时效时间延长,T1相直径逐渐增大,平均直径由169 nm增加至201 nm,但T1相平均厚度基本保持不变,均为1.5 nm左右。随时效时间延长,T1相径厚比逐渐增大,由111增加至140 (图10d)。

图10

图10

双级时效试样T1相尺寸统计

Fig.10

Statistics of T1 precipitate diameter of samples with T66 treatment

(a) first-peak-aged sample (b) valley-aged sample

(c) second-peak-aged sample (d) aspect ratios of T1 phases

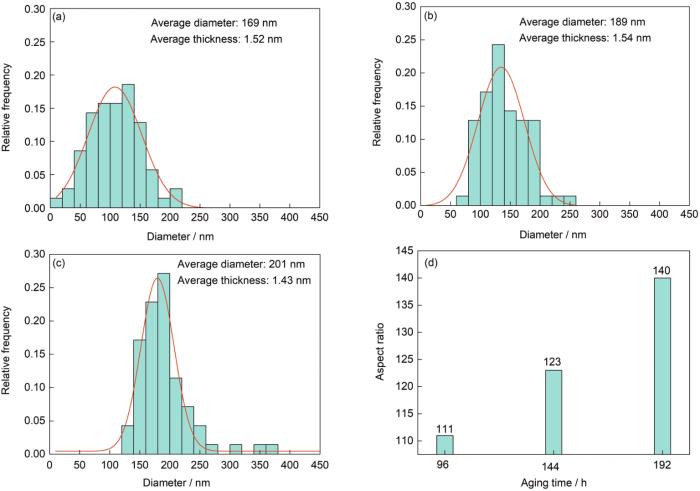

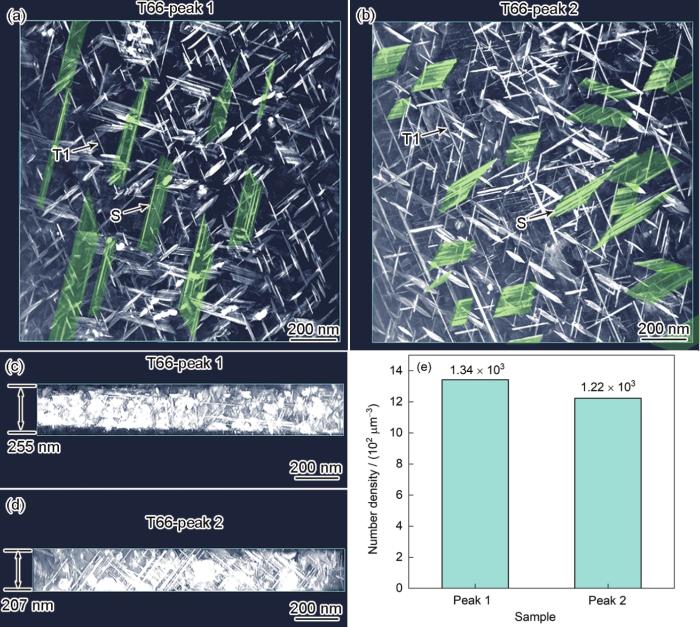

(4) T1相数量密度统计。使用TEM三维重构的实验方法,对双级时效2处峰值试样中T1相数量密度进行统计。图11a和b分别为第一及第二峰值试样的三维重构图像(动态视频见视频1和2),由于T1相是{111}Al惯习面上的盘片状析出相[9],板条状S相为{210}Al惯习面上的析出相[10],2种析出相的惯习面及形貌均存在不同,进而在三维图像中可以清晰地对2种析出相进行区分。由图11a和b可知,相比第一峰值试样,第二峰值试样中T1相直径明显增大,板条状S相数量增多。利用三维重构表征方法对样品厚度进行测量,第一、二峰值试样的样品厚度分别约为255和207 nm (图11c和d),通过三维重构图像可以直接获得所选区域内T1相的数量,由此可计算出T1相的数量密度,结果如图11e所示。第一峰值试样中T1相数量密度为1.34 × 103 μm-3,第二峰值中T1的数量密度为1.22 × 103 μm-3,第二峰值试样中T1相数量密度略低于第一峰值试样中T1的数量密度,其原因可能为:第一峰值试样中存在一些尺寸细小的T1相及其亚稳相,其并不稳定,随时效进行部分尺寸细小的T1相及其亚稳相发生溶解,因此第二处峰值试样中T1相的数量密度较低。根据前文所述,第一峰值和第二峰值试样中T1相平均直径分别为169和201 nm。虽然第二峰值试样中T1相的数量密度略有降低,但其平均直径明显增加,说明T1相体积分数增加。

图11

图11

双级时效2处峰值试样的三维重构图像及T1相的数量密度统计结果

Fig.11

3DET images of precipitates in the two peak-aged T66 samples and the number density of T1 precipitates

(a, b) plain view of peak 1 (a) and peak 2 (b), respectively

(c, d) top-down view of peak 1 (c) and peak 2 (d), respectively

(e) number density of T1 precipitates

3 分析讨论

3.1 单级时效合金

合金在160℃单级时效时,硬度逐渐升高,时效时间为96 h时,硬度达到峰值平台,继续延长时效时间至192 h,合金硬度、强度基本保持不变,但合金塑性降低。单级时效过程中T1相为主要强化相,T1相、S相及少量GPB区的析出引起合金硬度、强度的升高。延长时效时间至192 h时,相比时效96 h试样,虽然T1相径厚比有所增加,但合金中形成了大量明显粗化的δ'/θ'/δ'复合相,δ'/θ'/δ'复合相的粗化对合金力学性能明显不利[14],所以尽管合金的硬度和强度基本不变,但塑性有所降低。

3.2 双级时效合金

对双级时效工艺而言,合金在自然时效阶段析出了富Mg、Cu-Mg原子团簇,δ'相及GPI区。在160℃人工时效初期,自然时效形成的原子团簇、δ'相及GPI区溶解,GPB区和T1相相继析出;随着时效的继续进行,GPB区溶解而板条状S相和T1相长大。同时,合金的力学性能随微观组织的演变而相应变化。

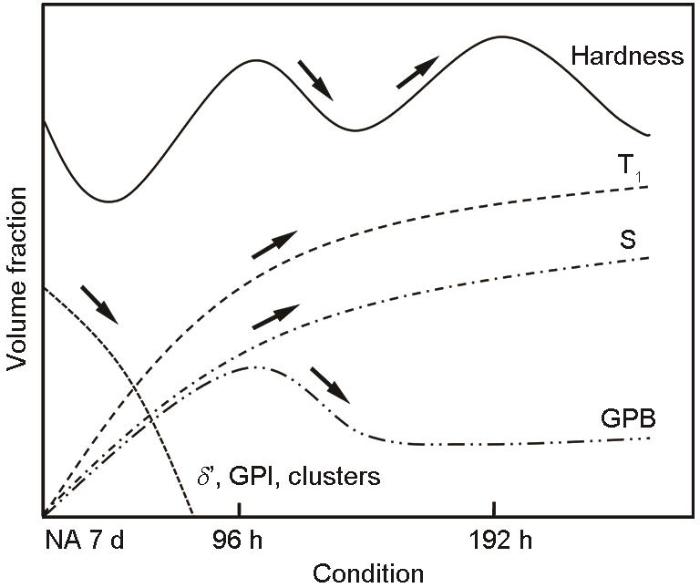

研究[35~38]表明,Al-Cu-Mg-(Ag)合金时效初期容易形成大量富Mg及Cu-Mg原子团簇,在后续时效过程中原子团簇逐渐演变为GPB区,自然时效原子团簇被认为是GPB区的前驱体。在本工作中,尽管自然时效析出的原子团簇在后续人工时效初期发生了溶解,但是双级时效96 h试样中GPB区的数量明显高于相同时间的单级时效试样,因此,可以推测富Mg及Cu-Mg原子团簇溶解后形成的富溶质原子区域有利于160℃人工时效中GPB区的析出。另外,由于合金中存在较多的Li原子,Li原子可诱导常规GPB原子结构发生改变,形成Li-GPB区[20],因此,双级时效合金中可以观察到较多Li-GPB区。图12为双级时效合金力学性能及其微观组织演变示意图。时效前期GPB区及T1相的析出引起合金硬度升高,使其出现第一强化峰。然而,GPB区为亚稳相,并不稳定,随时效时间延长,大部分GPB区逐渐溶解,引起强度的降低,时效至谷值阶段,合金中GPB区的数量已经非常少。GPB区的溶解为板条状S相的析出提供了Cu、Mg、Li等原子,继续延长时效时间,T1相尺寸长大,板条状S相的数量增加,合金强度再次升高,并出现第二个时效强化峰。当时效时间继续延长,出现过时效,硬度降低。

图12

图12

双级时效合金力学性能及微观组织演变示意图

Fig.12

Schematic of mechanical properties and microstructure evolution of the T66 alloy

4 结论

(1) 160℃单级时效处理时,合金硬度逐渐升高,随时效时间延长,达到峰值硬度平台。160℃人工时效前引入自然时效,合金时效硬化行为发生明显改变,出现双峰时效强化现象。

(2) 单级时效96 h峰值平台试样中,析出相包括T1相、棒状S相及微量GPB区,延长时效时间至192 h,合金中形成了较多粗化的δ'/θ'/δ'复合相,引起合金塑性降低。

(3) 合金在自然时效阶段析出了富Mg、Cu-Mg原子团簇、δ'相及GPI区;在人工时效初期,自然时效形成的原子团簇、δ'相及GPI区溶解,GPB区、板条状S相和T1相相继析出。双级时效第一峰值试样(96 h)以GPB区、T1相为主要强化相;延长时效时间,GPB区溶解,合金硬度降低,出现谷值(144 h);继续延长时效时间,T1相体积分数及板条状S相的数量增加,合金硬度再次升高,出现第二个强化峰(192 h)。

文中视频可通过以下网址在线观看:

参考文献

The evolution of Al-Li base products for aerospace and space applications

[J].

Fabrication methods to manufacture isotropic Al-Li alloys and products for space and aerospace applications

[J].

Complex precipitation sequences of Al-Cu-Li-(Mg) alloys characterized in relation to thermal ageing processes

[J].

Quantification and modelling of the microstructure/strength relationship by tailoring the morphological parameters of the T1 phase in an Al-Cu-Li alloy

[J].

The role of plastic deformation on the competitive microstructural evolution and mechanical properties of a novel Al-Li-Cu-X alloy

[J].

Quantification of the influence of increased pre-stretching on microstructure-strength relationships in the Al-Cu-Li alloy AA2195

[J].

Refinement of the crystal structure of hexagonal Al2CuLi

[J].

Heterogeneous Zr solute segregation and Al3Zr dispersoid distributions in Al-Cu-Li alloys

[J].

Formation mechanism of precipitate T1 in AlCuLi alloys

[J].

The structure and the properties of S-phase in AlCuMg alloys

[J].

The coexistence of two S (Al2CuMg) phases in Al-Cu-Mg alloys

[J].

Transmission electron microscopy study of the early stage of precipitates in aged Al-Li-Cu alloys

[J].

Guinier-Preston (GP) zone revisited: Atomic level observation by HAADF-TEM technique

[J].

Interfacial structure evolution of the growing composite precipitates in Al-Cu-Li alloys

[J].

Origins of hardening in aged Al-Cu-Mg-(Ag) alloys

[J].

Origin of the initial rapid age hardening in an Al-1.7at.%Mg-1.1at.%Cu alloy

[J].

GPB zones and composite GPB/GPBII zones in Al-Cu-Mg alloys

[J].

Structural relationship between one-dimensional crystals of Guinier-Preston-Bagaryatsky zones in Al-Cu-Mg alloys

[J].

Ab initio analysis of Guinier-Preston-Bagaryatsky zone nucleation in Al-Cu-Mg alloys

[J].

Li-atoms-induced structure changes of Guinier-Preston-Bagaryatsky zones in AlCuLiMg alloys

[J].

Dislocation-induced precipitation and its strengthening of Al-Cu-Li-Mg alloys with high Mg

[J].

The influence of Cu/Li ratio on precipitation in Al-Cu-Li-x alloys

[J].

Pre-strain-dependent natural ageing and its effect on subsequent artificial ageing of an Al-Cu-Li alloy

[J].

The effect of thermo-mechanical treatment on the formation of T1 phase and δ'/θ'/δ' composite precipitate in an Al-Cu-Li-Mg alloy

[J].

Natural-aging-induced reversal of the precipitation pathways in an Al-Mg-Si alloy

[J].

Mechanisms controlling the artificial aging of Al-Mg-Si Alloys

[J].

Reversal of the negative natural aging effect in Al-Mg-Si alloys

[J].

Influence of Mg and Li content on the microstructure evolution of Al-Cu-Li alloys during long-term ageing

[J].

Rapid hardening during natural aging of Al-Cu-Li based alloys with Mg addition

[J].

Clustering kinetics during natural ageing of Al-Cu based alloys with (Mg, Li) additions

[J].

Incoherent imaging using dynamically scattered coherent electrons

[J].

Detector geometry, thermal diffuse scattering and strain effects in ADF STEM imaging

[J].

Nano-precipitates evolution and their effects on mechanical properties of 17-4 precipitation-hardening stainless steel

[J].

The influence of lithium on the ageing precipitation behavior of Al-Cu-Mg alloys

[D].

合金元素锂对Al-Cu-Mg合金时效析出行为的影响

[D].

Trace element effects on precipitation in Al-Cu-Mg-(Ag, Si) alloys: A computational analysis

[J].

An FP-CVM calculation of pre-precipitation clustering in Al-Cu-Mg-Ag alloys

[J].

The thermodynamics of and strengthening due to co-clusters: General theory and application to the case of Al-Cu-Mg alloys

[J].