AM技术一般可以采用激光束、电子束或电弧为热源进行增材[8~14]。但激光成形件[15~23]材料流动性差会降低成形件的精准度,故对粉体的要求较高,且增材件容易出现零件表面质量粗糙、发生翘曲变形、熔合不良、开裂等宏观缺陷,内部也容易产生残余应力、气孔、夹杂、微裂纹等微观缺陷,还极易出现氧化并产生孔隙,影响力学性能,需要惰性气体的保护等缺点;电弧[24~28]增材制造成形精度较差、成形尺寸难控制、成形过程稳定性差、成形件表面质量较低,一般成形件要再次加工其表面,随着增加沉积层高度,会出现晶粒逐渐粗化、零件热积累严重、难控制堆积层、散热条件变差、熔池过热、难于凝固,且在晶界处严重富集杂质元素等缺点;电子束增材制造[29~31]大尺寸结构件时成形件发生变形会造成应力集中,送丝过程中的熔池流动凝固收缩和丝材摆动会导致难以控制成形件加工精度,且要求真空环境,相对其他增材设备较为复杂的结构也增加了成本。激光、电子束和电弧等传统增材制造技术适用于钛合金等高温合金的制造,但是却难以制造大型高强铝合金整体结构件[32]。因此需要发展更优的AM技术。

搅拌摩擦增材制造(friction stir additive manufacturing,FSAM)技术是一种固相非熔化增材制造方法,不仅能够使构件性能更优异、制造能耗更低、成形尺寸更大、速度更快,而且在增材制造的过程中可以避免其他增材方法在熔化和凝固过程产生的气孔和裂纹等缺陷,增材区的力学性能好,工艺过程十分环保,不会产生有害气体,具有高效、高质和价格优势,在轻质金属增材制造领域具有巨大潜力。本文侧重整理了FSAM技术的各种增材方法,包括每种方法的增材结构和实施方式,为后续开发结构更简单、增材更高效、选材更灵活可控和增材成本更低等优点的搅拌摩擦增材装置提供参考。

1 FSAM技术及其原理

搅拌摩擦焊(friction stir welding,FSW)是由英国焊接研究所(TWI)于1991年发明的固相焊接技术[33,34],广泛应用在铝合金、镁合金等轻金属结构领域[35~41]。FSW不仅可以进行对接、搭接等不同的接头形式的焊接,还可以进行平焊、立焊等不同焊接位置的焊接,且焊接不需要消耗焊剂、焊条、焊丝等材料,也不需要采用Ar气等气体保护,相较于熔化焊,FSW焊接后结构的变形或残余应力就小得多。其原理[42~48]是在搅拌头的高速旋转下将其插入2个工件的接缝处,轴肩压紧在工件表面产生摩擦热,搅拌针搅拌产生附加摩擦热,然后随着搅拌头的移动,接缝处发生塑性变形的材料向焊接方向的后方流动,从而形成FSW焊缝。

2 FSAM技术分类

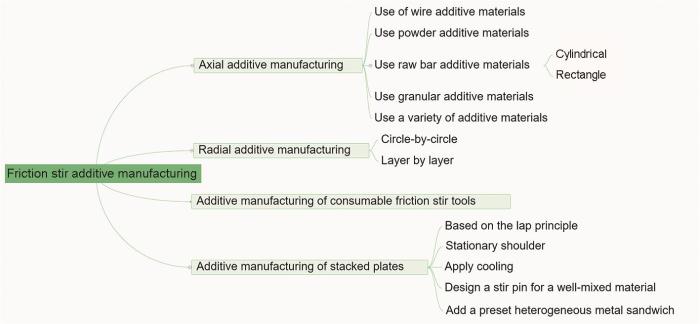

图1

图1

搅拌摩擦增材制造(FSAM)方法分类

Fig.1

Classification of friction stir additive manufacturing (FSAM) methods

2.1 轴向增材制造

2.1.1 采用丝材增材材料

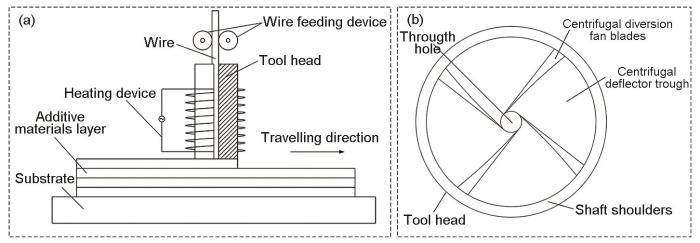

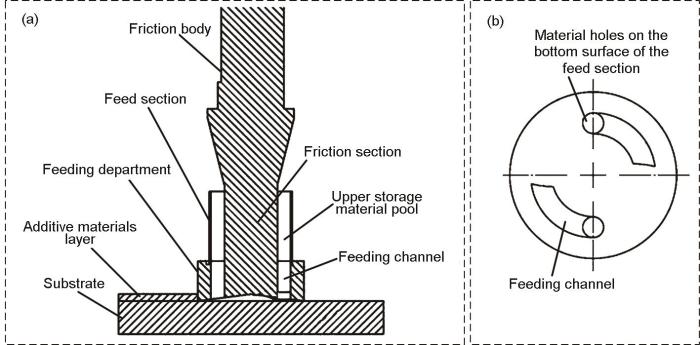

图2

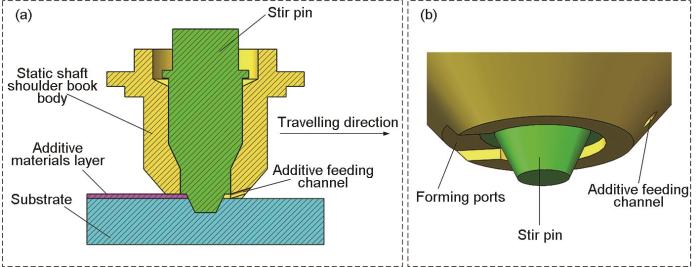

图3

图3

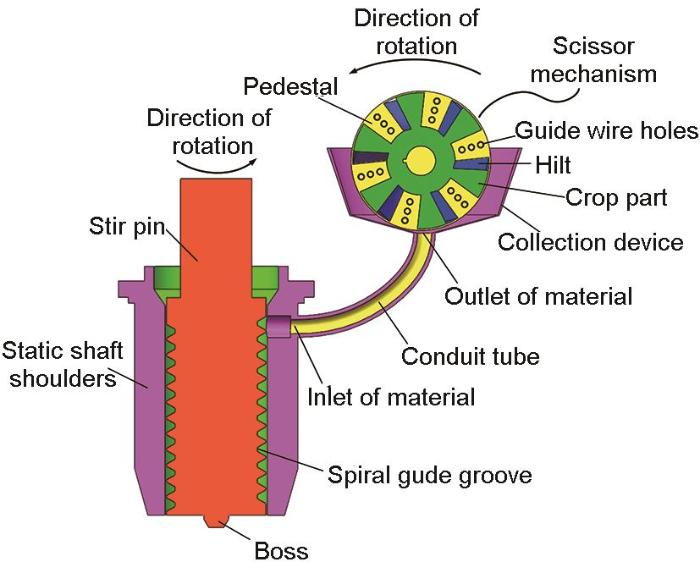

静止轴肩空腔增材装置原理图

Fig.3

Schematics of a stationary shaft shoulder cavity additive device

(a) schematics of additive structure of stationary shaft shoulder cavity

(b) enlarged schematic diagram of cavity and feed hole

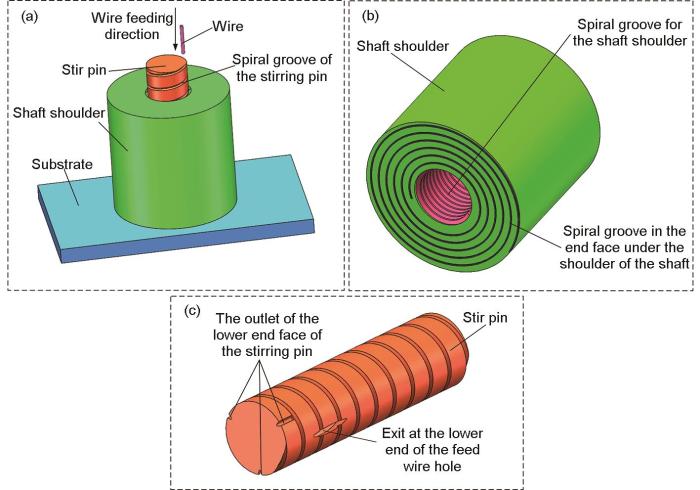

图4

图4

螺旋槽增材装置原理图

Fig.4

Schematics of a spiral groove additive device

(a) device working diagram

(b) lower end face structure of the shaft shoulder

(c) schematic of stirring pin structure

(4) 静轴肩填丝增材。石磊等[59]设计的增材装置结构主要由搅拌针、静轴肩、丝材、静轴肩上的送丝孔和搅拌针侧壁外表面的螺旋槽组成,其中搅拌针的侧壁外表面与静轴肩的通孔内表面相配合,静轴肩的下端面比搅拌针的下端面高,搅拌针侧壁外表面的螺旋槽由其下端面的边线向上设置,螺旋槽高度比静轴肩送丝孔的高度高。首先启动电机使搅拌针旋转,控制整个装置向下移动使搅拌针插入基体中,此时基体在搅拌针的搅拌作用下塑化形成搅拌区,接着向送丝孔中输送丝材,丝材通过送丝孔到达搅拌针的螺旋槽处,并在螺旋槽的剪切作用下破碎,破碎的丝材随着螺旋槽向下传输到基体,并与基体材料混合,接着控制整个装置在待增材区移动,在静轴肩的挤压和搅拌针的搅拌作用下进行增材制造。

2.1.2 采用粉末增材材料

图5

图6

2.1.3 采用原棒料增材材料

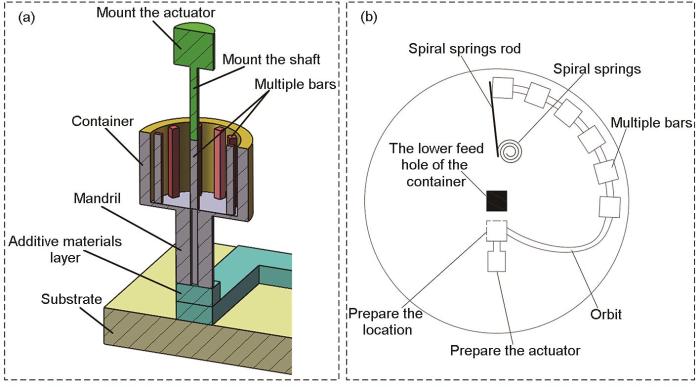

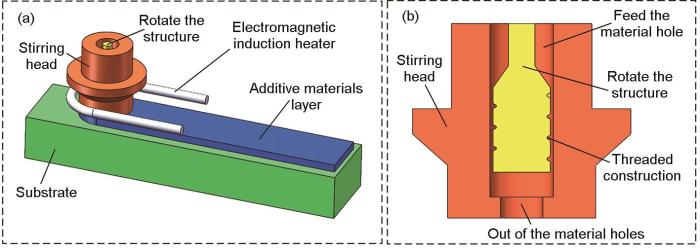

图7

图7

方形原料条增材装置原理图

Fig.7

Schematics of an additive device for square raw material strips

(a) 3D cross-sectional view of the additive device

(b) plane cutaway view of the container of the system

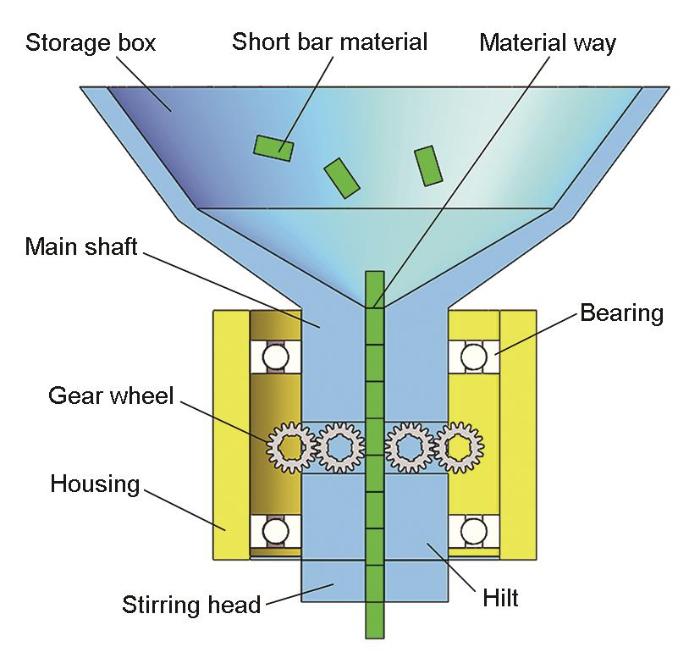

(2) 利用流动摩擦进行增材。赵华夏等[63]设计的增材装置结构主要由圆棒状母材、轴肩、基体、轴肩空腔侧壁螺旋槽、轴肩空腔底面螺旋槽、轴肩空腔底面到轴肩下端面间的中心通孔及轴肩下端面螺旋槽组成。首先将母材放置于轴肩内部的空腔中,母材静止不旋转,且母材与轴肩内部的空腔底面之间存在顶锻力,再将整个装置下降直到轴肩下端面与基体平面相接且存在顶锻力,然后控制轴肩以一定速率旋转并在基体表面待增材区不断移动,由于母材静止与轴肩的空腔底面螺旋槽产生相对旋转,在摩擦作用下母材热塑化,接着热塑化的母材材料从轴肩空腔底面到轴肩下端面间的中心通孔流出,在轴肩下端面螺旋槽与基体表面的相对旋转产生的摩擦和顶锻力作用下,流出的热塑化材料在基体待增材区扩散并沉积,由此来实现增材制造。

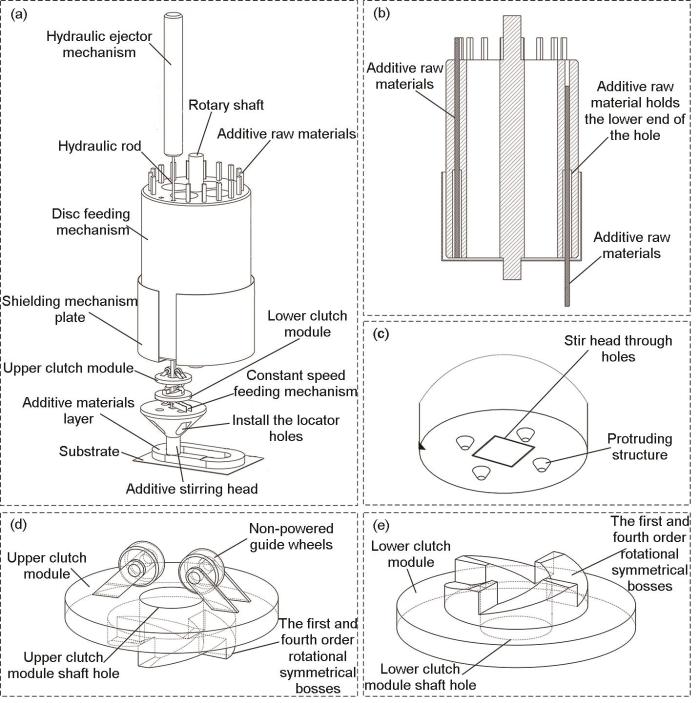

图8

(4) 采用方形原料条连续增材。黄永宪等[65]设计的增材装置如图9[65]所示,首先将增材原料添加到盘式送料机构的容纳孔中,再控制液压顶杆机构将方形原料条通过容纳孔,送入下方的2个离合模块的轴孔中,进一步到达定速送料机构,然后启动驱动电机使搅拌头旋转并压入基板预热一段时间,接着开启定速送料机构将原料条送入搅拌头的通孔中,直到原料条与基板接触摩擦,最后在待增材区移动整个机构,在凸起结构的搅拌和轴肩的挤压作用下,即进行增材制造。当前一根原料条快要用完时,上升上离合模块以脱离下离合模块的同轴旋转,并旋转盘式送料机构将新棒料对准上离合模块的轴线孔,获得新的原料条后再向下运动与下离合模块重新接触恢复旋转,重复此步骤即可进行连续送料。

图9

图9

原料棒连续增材装置原理图[65]

Fig.9

Schematics of a continuous additive device for raw material rod[65]

(a) schematic of the device structure

(b) sectional view of the feeding mechanism

(c) schematic of the end face of the stirring head

(d) schematic of the upper clutch module

(e) schematic of the lower clutch module

(5) FSAM棒材。刘会杰等[66]设计的增材装置结构主要由增材制造的圆柱形棒材、棒材夹持段、棒材摩擦段、增材制造的模具和增材制造的基板组成。首先选定增材的材料类型,并加工成圆柱形棒材,上部开设夹持槽方便安装在搅拌摩擦焊机上,并对加工好的棒材表面进行打磨和清洗。接着选择熔点比所选增材材料熔点高的管材材料,制造一个内径比圆柱形棒材直径大的环状管材模具,再选择熔点比所选增材材料熔点高的板材,制造增材制造的基板。然后对模具和基板打磨和清洗后,采用氩弧焊方法将模具与基板焊接,并将基板和模具固定在焊接设备上。最后将棒材安装在搅拌摩擦焊机上后启动电机使其旋转,控制棒材沿着模具轴线下降,直到与基板接触。棒材与基板发生摩擦,塑化后的棒材材料沉积在基板上,并向四周扩散到模具内表面处,直到所需的增材高度为止。

2.1.4 采用颗粒增材材料

图10

2.1.5 可添加多种增材材料

图11

图11

半固态增材装置原理图

Fig.11

Schematics of a semi-solid-state additive device

(a) device working diagram (b) device sectional view

2.2 径向增材制造

2.2.1 逐圈进行增材制造

姬书得等[69]设计的增材装置如图12[69]所示。首先将模具放到焊接工作台并固定,在模具内壁涂抹脱模剂后,向模具中填满丝材、粉末或块状增材材料。选取一个具有与增材件相同高度搅拌针的搅拌头,将此搅拌头和其他相应配件组装好后安装在焊机上。接着启动电机使搅拌头旋转,对准模具轴线后下压,同时启动辅热垫板和施加超声振动,在辅热垫板加热与搅拌头摩擦搅拌的作用下,材料被加热到半固态,当搅拌针距离辅热垫板0~0.2 mm时停止下压,并保持搅拌头旋转1~60 s后停止旋转,继续保持压力0~1000 s后抽回搅拌头,停止辅热垫板继续加热,此时再施加一段时间的超声振动后也让其停止继续施加振动。待焊机冷却后更换比上述搅拌针直径更小的搅拌头,接着将原材料再次填满由搅拌针回抽而产生的匙孔,重复上述步骤进行第二次径向增材。然后再次更换具有更小搅拌针直径的搅拌头,重复上述步骤直到留下匙孔的深度小于1.5~2 mm时,采用无针的搅拌头来重复上述步骤,由此得到增材制造件。

图12

图12

径向逐圈增材装置原理图[69]

Fig.12

Schematics of a radial circle-by-turn additive device[69]

(a) device structure diagram

(b) bottom view of the stationary shaft shoulder and the stirring head

(c) schematic of stirring head structure

(d) schematic of the structure of the static shoulder body

(e) schematic of the mold structure

(f) schematic of the radial working process

2.2.2 逐层进行增材制造

图13

图13

径向逐层增材装置原理图

Fig.13

Schematics of a radial layer-by-layer additive device

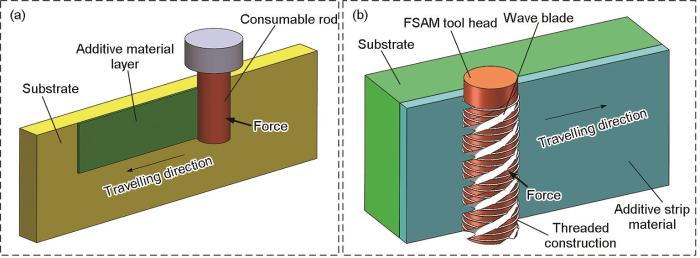

(a) consumable rod lateral additive manufacturing

(b) overlay additive strips for lateral additive manufacturing

2.3 利用消耗型搅拌摩擦工具进行增材制造

华鹏等[72]设计的增材装置由基体和消耗型搅拌摩擦工具组成。首先选择大于所需制备金属材料最大截面积的基体,然后对基体表面进行打磨和清洗等表面处理过程,将基体安装固定在搅拌摩擦焊接工作台上。接着选取同样金属材料的圆棒状搅拌摩擦工具,在其上端开设夹持部后安装到焊接设备上,开机使其旋转,控制搅拌摩擦工具下降至与基板接触,在与基板摩擦作用下,消耗型搅拌摩擦工具塑化并沉积在基体上,从基体上表面开始逐层进行增材制造。

2.4 叠加板材进行增材制造

2.4.1 基于搅拌摩擦焊搭接增材制造

2.4.2 静轴肩叠加板材增材装置

2.4.3 施加冷却的增材装置

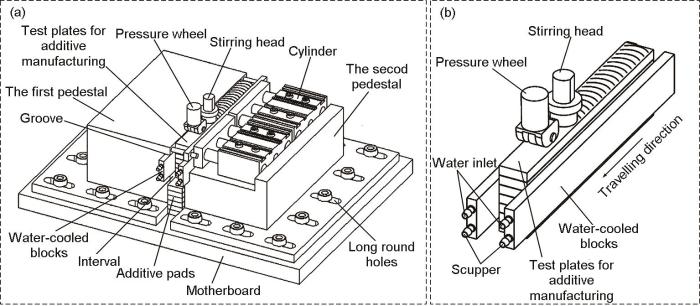

图14

2.4.4 利用凸槽搅拌针增材

许诺等[76]设计的增材装置结构主要由夹持柄、轴肩、搅拌针、螺纹凹槽、竖直凹槽、上层板材和下层板材组成。搅拌针为圆柱形,搅拌针的圆周上开有螺纹凹槽,并且均匀开有4个或8个竖直凹槽,且搅拌针长度大于1个增材基板厚度但小于2个增材基板叠加厚度。首先对板材上下表面进行清洗和打磨,然后依次将下层板材和上层板材放到焊接工作台上,并固定好2个板材。接着将此带有特殊设计搅拌针的搅拌头安装在搅拌摩擦设备上,控制搅拌头焊接2块板即可进行增材制造。接着在上层板材上面放置新板材,重复上述步骤即可进行叠加增材直到所需增材高度。

2.4.5 添加预置异质金属夹层进行增材

张会杰等[77]设计的增材装置结构主要由异质金属夹层、增材复板、增材基板和焊具的搅拌针及轴肩组成。其中增材基板和增材复板材料相同,异质金属夹层材料为纯Pt片,增材基板厚度为2或3 mm,异质金属夹层的厚度为0.02~0.05 mm,增材复板厚度为1或2 mm,搅拌针的长度大于增材复板厚度加上异质金属夹层厚度。首先清理增材基板、增材复板以及异质金属夹层的表面,接着先将增材基板放置焊接工作台上,再放置异质金属夹层,最后是放置增材复板,然后使用夹具固定好增材基板、异质金属夹层和增材复板,进一步将搅拌头移动到初始焊接位置对增材组件进行焊接即可。焊接完成后,在增材复板上再依次放置异质金属夹层和第二块增材复板,重复上述步骤直到所要求高度,即可得到增材制造件。

3 FSAM样品组织、性能及应用

3.1 FSAM样品组织与性能

表1 不同材料FSAM样品性能与组织特点[71,78~80]

Table 1

| Material | FSAM method | Microstructure | Mechanical property | Institute | Ref. |

|---|---|---|---|---|---|

| 304 austenitic stainless steel | Consumable friction stir tool | Equiaxed crystals | The tensile test results show that the yield strength of the original stainless steel bar and the additive deposited part are 380 and 390 MPa, the tensile strength are 710 and 690 MPa, and the elongation are 50 % and 30 %, respectively | Indian Institute of Technology | [78] |

| formed by | |||||

| dynamic | |||||

| recrystallization | |||||

7075 aluminum alloy | Axial addition of rod | The average hardness of the substrate and the additive raw rod is measured to be 164 HV, and most of the deposited materials exhibit a hardness value higher than 140 HV, comparable to the hardness of the raw rod | Virginia Polytechnic Institute and State University | [79] | |

2024 aluminum alloy | Superimposed plate | The microhardness of the substrate is 130 HV, the minimum hardness of the bottom zone of the additive is 74 HV, and the maximum hardness of the top zone of the additive is 99 HV. The changes of the second phase and the grain cause the microhardness of the additive to be lower than that of the substrate | Nanchang Hangkong University | [80] | |

6561 aluminum alloy | Radial layer-by-layer additive | The tensile strength of the substrate and the additive strip is 465.57 MPa, and the maximum tensile strength of the stable additive zone is 203.67 MPa. The microhardness of the substrate and the additive strip is about 155 and 125 HV, respectively. The microhardness of the stable additive zone gradually decreases from the surface of the topmost additve strip to the interior, but the hardness of the stable additive zone is generally stable at about 60 HV | Northeast Forestry University | [71] | |

FSAM与激光、电弧增材样品微观组织如表2[32,81,82]和图15[32,81,82]所示,3种增材方式及每种增材方式不同材料的拉伸数据平均结果汇总如表3[32,74,81~87]所示。当同为2系铝合金但增材方法不同时,与2024-T6平行沉积激光增材件和AA2024-T6沿增材厚度方向电弧增材件相比,以2024-O铝合金为基材的FSAM增材件屈服强度分别降低了2.9%和66.7%,抗拉强度分别降低了11.5%和44.4%,延伸率分别是激光增材件和电弧增材件的5.8和14.8倍;2024-T6沿增材厚度方向电弧增材件比2024-T6平行沉积激光增材件的显微硬度明显增加。当为同种增材方法但取样方式不同时,以2024-T4铝合金为基材进行FSAM增材,沿增材厚度方向取样比沿平行于增材行进水平方向取样屈服强度降低了5.8%,抗拉强度降低了5.7%,延伸率降低了8%;电弧增材AZ31镁合金平行于增材行进水平方向取样与垂直于增材行进水平方向取样相比显微硬度相当。当增材方法和取样方法相同但热处理条件不同时,电弧增材件沿增材厚度方向取样,AA2024铝合金采用T6热处理条件比其采用T4热处理条件下的屈服强度提升了19.7%,抗拉强度提升了3.8%,延伸率降低了58%,显微硬度提升了5.8%。

表2 FSAM与激光、电弧增材样品微观组织特点[32,81,82]

Table 2

| Material | Additive | Stirring center core | Deposition | Deposition cross | Inner deposition | Ref |

|---|---|---|---|---|---|---|

| manufacturing | area | longitudinal | section | region | ||

| (AM) method | section | |||||

2024-O aluminium alloy | FSAM | Uniform equiaxed grains with an average size of about 9.4 μm | - | - | - | [32] |

2024-T6 aluminium alloy | Laser additive manufacturing | - | Stripe shaped microstructures with the ribbon spacing of 0.5 mm | Stripe shaped microstructure | - | [81] |

AA2024 aluminum alloy | Arc additive manufacturing | - | - | - | Banded columnar dendrites, equiaxed dendrites, and equiaxed non-dendrites | [82] |

图15

Fig.15

Comparison of microstructures of samples after additive manufacturing

(a) microstructure of the central core region of friction stir additive 2024 aluminum alloy[32]

(b) cross-sectional microstructure of laser additive manufactured 2024-T6 aluminum alloy[81]

(c) longitudinal sectional microstructure of laser additive manufactured 2024-T6 aluminum alloy[81]

(d) microstructure of arc additive manufactured AA2024 aluminum alloy (ED—equiaxed dendrite, END—equiaxed non-dendrite, CD—columar dendrite)[82]

表3 3种方法增材件的拉伸性能对比[32,74,81~87]

Table 3

| AM method | Additive substrate material | Condition classification | Sampling method of tensile test | Rp0.2 MPa | Rm MPa | A % | H MPa | Ref. |

|---|---|---|---|---|---|---|---|---|

| FSAM | 2024-O | Lap welding | Parallel to the horizontal | 117.2 | 227.8 | 31.1 | - | [32] |

| aluminum alloy | superimposed plate | direction of the additive travel | ||||||

| 7N01-T4 | Along the direction of | 204.0 | 297.0 | 19.4 | 78.0 | [83] | ||

| aluminum alloy | additive thickness | |||||||

| 2024-T4 | Stationary shoulder | Along the direction of | 267.5 | 268.2 | 63.0 | 72.0-92.0 | [74] | |

| aluminum alloy | superimposed plate | additive thickness | ||||||

| Parallel to the horizontal | 283.9 | 284.5 | 68.5 | - | [74] | |||

| direction of the additive travel | ||||||||

| Laser additive | 2024-T6 | Parallel deposition of 2024 aluminum alloy powder | Along the direction of | 120.7 | 257.3 | 5.4 | 90.3 | [81] |

| manufacturing | aluminum alloy | additive thickness | ||||||

Cross deposition of 2024 aluminum alloy powder | 188.3 | 348.3 | 20.5 | 110.8 | [81] | |||

| NZ30K-T5 | Selective laser melting | Parallel to the horizontal | 380.0 | 406.0 | 0.9 | - | [84] | |

| magnesium | of magnesium alloy | direction of the additive | ||||||

| alloy | powder | travel | ||||||

| 6061 aluminum | ER4043 aluminum | Along the direction of | 114.7 | 152.5 | 33.5 | 55.3 | [85] | |

| alloy | silicon alloy wire | additive thickness | ||||||

| Parallel to the horizontal | 119.7 | 158.8 | 33.5 | - | [85] | |||

| direction of the additive travel | ||||||||

| Arc additive | AA2024-T6 | ER2319 Al-Cu alloy | Parallel to the horizontal | 374.0 | 470.0 | 8.2 | 146.0 | [82] |

| manufacturing | aluminum alloy | and ER5087 Al-Mg | direction of the additive travel | |||||

| alloy wire | Along the direction of | 352.0 | 410.0 | 2.1 | 146.0 | [82] | ||

| additive thickness | ||||||||

| AA2024-T4 | Parallel to the horizontal | 310.0 | 458.0 | 12.7 | 138.0 | [82] | ||

| aluminum | direction of the additive travel | |||||||

| alloy | Along the direction of | 294.0 | 395.0 | 5.0 | 138.0 | [82] | ||

| additive thickness | ||||||||

| AZ31 | AZ31B magnesium | Parallel to the horizontal | 77.3 | 235.0 | 26.3 | 52.7 | [86] | |

| magnesium alloy | alloy welding wire | direction of the additive travel | ||||||

| Vertical to the horizontal | 76.0 | 237.0 | 22.0 | 53.2 | [86] | |||

| direction of additive | ||||||||

| manufacturing | ||||||||

| 5556 aluminum | ER5556 aluminum | Along the direction of | - | 310.0 | - | 125.0 | [87] | |

| alloy | alloy welding wire | additive thickness |

3.2 FSAM不同增材方式的优缺点和适用领域

表4 FSAM不同增材方式的优缺点和适用领域[58,59,61~63,65,67,69,71,72,75~77]

Table 4

| FSAM | Additive form | Advantage | Disadvantage | Scope of application | |

|---|---|---|---|---|---|

| method | |||||

| Axial | Wire material | Low cost; multiple wire | Sustainable | Complex | Carrier rockets, ships; automobiles |

| direction | uninterrupted | structure; | and other fields; suitable for | ||

| feeding holes; high | |||||

| aluminum alloy ribbed panel | |||||

| efficiency[59] | additive; | material | |||

| structure, inlet, complex frame | |||||

| high additive | residue in | ||||

| beam structure of high efficiency, | |||||

| efficiency | equipment | ||||

| low cost manufacturing[58] | |||||

| Powder | Changeable molding | Preparation of new alloys difficult to prepare in equilibrium metallurgical processes[61] | |||

| parameters and additive | |||||

| powder ratio[61] | |||||

| Raw material | High material utilization | Ultrafine grained homogeneous | |||

| rod | |||||

| and small processing | AM parts and thermoplastic | ||||

| allowance[63]; expanded | polymers for various metals | ||||

| additive geometry[62] | and alloys[65] | ||||

| Granules | Diversified materials and | FSAM of gradient composites[67] | |||

| sizes[67] | |||||

| Various | Manufactruing of composite | FSAM of gradient composites[67] | |||

| materials can | materials[67] | ||||

| be added | |||||

| Radial | Circle-by-turn | High additive quality; high load-bearing | Low additive | Manufacture of raw materials such | |

| direction | additive components; high bonding strength[69] | efficiency | as metals and metal matrix | ||

| composites with different | |||||

| morphologies[69] | |||||

| Layer-by-layer | High material utilization; non-polluting | Manufacture of dissimilar alloy | |||

| powder raw material; no structural | and light alloy structural parts[71] | ||||

| limitations[71] | |||||

| Consumable | Raw bar | Simple equipment method; simple operation | AM of light metal structures such | ||

| friction | material | steps; low cost; short manufacturing time; | as aluminum alloy and magnesium | ||

| stir tool | fast forming speed[72] | alloy and stainless steel | |||

| Superimposed | Lap based on | Simple additive method; simple operation | Applicable to aerospace, | ||

| plate | FSW | steps; low cost | automotive parts, ships, and | ||

| Stationary | No grinding or cutting after additive | rail transportation fileds; and | |||

| shoulder | manufacturing | AM of aluminum alloy, magnesium | |||

| Apply cooling | Effectively reduceing the thermal effect[75] | alloy and other light metal | |||

| Stirring head | The material mixes more fully[76] | structures, and stainless steel | |||

| with special | |||||

| structure | |||||

| Add preset | High bonding strength; high joint quality; | ||||

| heterogeneous | high fracture strength[77] | ||||

| metal | |||||

| interlayer | |||||

3.3 目前FSAM设备及初步应用

目前的FSAM设备单位及其已经开展的应用汇总如表5所示,主要应用在轻质合金、铜合金、镍基合金及不锈钢方面,如美国弗吉尼亚州MELD制造公司已经研制直径超过1.397 m、长1.4 m的6061铝合金组件,北京工业大学采用填丝增材研制出飞机带筋壁板,哈尔滨工业大学采用Al-5%Si合金丝材为增材原料修复了AA6061-T4铝合金构件,天津大学采用轴向添加原棒料方法进行增材制造分析了6061-T6铝合金增材件内部及界面组织特征。

表5 FSAM设备单位及其开展的应用

Table 5

| FSAM | Additive raw material | Additive raw | FSAM method | Preliminary application |

|---|---|---|---|---|

| equipment unit | material form | |||

| Meld Manufacturing | Aluminum alloy, | Metal powders | Axial direction | Printing large metal parts, coating |

| Company, USA | copper alloy, nickel | and raw | applications; component repair; metal | |

| base alloy, titanium | materials rod | connection; custom metal alloy and metal | ||

| alloy | matrix composite blanks and parts | |||

| Harbin Institute of | Light alloy parts | Wire | Forming a few meters of aluminum alloy | |

| Technology, China | components; application in aerospace | |||

| field; battlefield repair for amphibious | ||||

| vehicles | ||||

| Tianjin University, | Aluminum alloy, | Raw materials | Forming a few meters of aluminum | |

| China | aluminum lithium | rod | alloy components | |

| alloy, dissimilar | ||||

| aluminum alloy | ||||

| Beijing University of | Aluminum alloy, | Wire | Aluminum alloy stiffened panel structure | |

| Technology, China | magnesium alloy | |||

| Nanchang Hangkong | Aluminum alloy | Plate | Static shoulder | Study on microstructure and |

| University, China | superimposed | mechanical properties of | ||

| plate | additive parts | |||

| Indian Institute of | Austenitic stainless | Consumable | Consumable | |

| Technology, Indian | steel | raw bar | friction stir tool | |

| material | ||||

| Virginia Polytechnic | Aluminum alloy | Raw materials | Axial direction | |

| Institute and State | rod | |||

| University, USA | ||||

| Northeast Forestry | Aluminum alloy | Additive strips | Radial direction | |

| University, China | ||||

| Beijing Institute of | Aluminum alloy | Plate | Superimposed | |

| Technology, China | plate based on | |||

| FSW lap | ||||

| principle | ||||

| Catholic University of | Metal alloys of | Mixture of | - | FSAM of gradient composites |

| Louvain, Belgium | different materials | multiple | ||

| materials |

4 结论

(1) FSAM主要针对轻质合金、铜合金、镍基合金及不锈钢等材料,在航空航天、汽车、船舶、轨道交通等领域具有广阔的应用前景,其实现增材的方法有很多种,大致可以分为轴向增材制造、径向增材制造、消耗型搅拌摩擦工具增材制造和叠加板材增材制造4大类。

(2) 采用消耗型搅拌摩擦工具方法增材和采用轴向添加原棒料方法增材,沉积材料都表现出与增材原料相当的力学性能。采用轴向叠加板材增材和采用径向叠加板材增材也表现出一个相同的趋势,即增材的显微硬度从顶部板向低部板逐渐减小。

(3) FSAM沉积区微观组织为等轴晶;激光增材沉积区微观结构为明暗交替且较为平直的纹带组织;电弧增材沉积区微观组织由柱状树枝晶、等轴树枝晶和等轴非树枝晶组成。

(4) 未来设计的FSAM装置的发展可以重点考虑以下几个方面:结构更简单,更容易批量制造,操作步骤更简便;可实现持续增材制造,节省时间,提高工作效率;使用增材成本低的增材材料,选材更加灵活多样化;增材后制造件的上表面成形良好,故不再需要进行减材,即打磨工序,提高生产效率;形成的增材件材料比较紧密,从而不容易产生夹杂气泡、小孔等缺陷;增材层的宽度和厚度可以自由灵活控制;设计更优形状的搅拌针,可使所增材料与基材充分结合,使加工过程更为顺利,提高增材制造成形质量;设计可以充分利用增材材料的装置,防止浪费材料的现象出现。

参考文献

Research status and development tendency of additive manufacturing

[J].

增材制造的研究现状与发展趋势

[J].

Fundamental mechanics problems in metal additive manufacturing: A state-of-art review

[J].

金属增材制造若干关键力学问题研究进展

[J].

Development of the additive manufacturing (3D printing ) technology

[J].

增材制造(3D打印)技术发展

[J].

Developments of additive manufacturing technology

[J].

增材制造技术的发展

[J].

Analysis of classifications and characteristic of additive manufacturing (3D print)

[J].

增材制造(3D打印)分类及研究进展

[J].

Overview of the present situation and application of additive manufacturing

[J].

增材制造的现状与应用综述

[J].

A review of powder additive manufacturing processes for metallic biomaterials

[J].

Research and development in materials and processes of superalloy fabricated by laser additive manufacturing

[J].The research and development progress of laser additive manufacturing technology in superalloys are summarized in this paper. The technical characteristics and application of additive manufacturing in superalloys, formation mechanism, and the types of microstructure and metallurgical defects are introduced in detail. Moreover, the defect control methods of additive manufacturing of superalloys are summarized from the aspects of laser parameters and composition design, and the direction of laser process parameter optimization and composition optimization is clarified. Finally, the future development trend and research direction of laser additive manufacturing in superalloys are summarized and prospected from the aspects of process optimization and material design.

激光增材制造高温合金材料与工艺研究进展

[J].概述了激光增材制造技术在高温合金中的进展。介绍了增材制造高温合金的技术特点和应用、微观组织及冶金缺陷的形成机制与种类,并从激光参数以及成分设计2个方面综述了增材制造高温合金的缺陷控制方法,明确了激光工艺参数优化与成分优化的方向。最后,从工艺和材料2个方面对激光增材制造在高温合金中的未来发展趋势与研究方向进行了展望。

High performance metal additive manufacturing technology applied in aviation field

[J].

应用于航空领域的金属高性能增材制造技术

[J].

Research status of metal additive manufacturing technology

[J].

金属增材制造技术的研究现状

[J].

Overview of laser additive manufacturing technology and status

[J].

激光增材制造技术及现状研究

[J].

Summary of development trend of metal additive manufacturing technology

[J].

金属增材制造技术发展趋势综述

[J].

Development of 3D printing wire DY590 for additive manufacturing

[J].

增材制造用3D打印丝材DY590的开发

[J].

Refractory metal materials made by additive manufacturing and its application progress

[J].

增材制造难熔金属材料及其应用研究进展

[J].

Research status and prospects of additive manufacturing technology at home and abroad

[J].

增材制造技术国内外研究现状与展望

[J].

Progress in additive manufacturing on complex structures and high-performance materials

[J].With the characteristics of point by point melting and layer by layer manufacturing, additive manufacturing (AM), on one hand, can fabricate the three-dimensional complex structure parts rapidly; on the other hand, it can realize the high performance of materials. Based on the technological advantages and important application prospects of AM technology, the recent efforts and advances in AM on complex structures including:lattice structures, large thin-walled structures, complex surface structures, integrated structures; and materials including:iron-based alloys, titanium-based alloys, nickel-based alloys, aluminum-based alloys, intermetallic compounds, functionally gradient materials, ceramics are presented and reviewed. The development trend of AM on structure design, special materials system, new materials, repairing and remanufacturing, data base and standards are also forecasted.

复杂结构与高性能材料增材制造技术进展

[J].

Innovative potential of additive friction stir deposition among current laser based metal additive manufacturing processes: A review

[J].

Research status of laser additive manufacturing material system for aluminum alloy

[J/OL].

铝合金激光增材制造材料体系研究现状

[J/OL].

Research progress on powder-based laser additive manufacturing technology of ceramics

[J]. J.

基于粉末成形的激光增材制造陶瓷技术研究进展

[J].陶瓷以其优异的热物理化学性能在航空航天、能源、环保以及生物医疗等领域具有极大的应用潜力。随着这些领域相关技术的快速发展, 其核心零件部件外形结构设计日益复杂、内部组织逐步走向定制化、梯度化。陶瓷具有硬度高、脆性大等特点, 较难通过传统的加工成形方法实现异形结构零件的制造, 最终限制了陶瓷材料的工程应用范围。激光增材制造技术作为一种快速发展的增材制造技术, 在复杂精密陶瓷零部件的制造中具有显著优势: 无模、精度高、响应快以及周期短, 同时能够实现陶瓷零件组织结构灵活调配, 有望解决上述异形结构陶瓷零件成形问题。本文综述了多种基于粉末成形的激光增材制造陶瓷技术: 基于粉末床熔融的激光选区烧结和激光选区熔化; 基于定向能量沉积的激光近净成形技术。主要讨论了各类激光增材陶瓷技术的成形原理与特点, 综述了激光选区烧结技术中陶瓷坯体后处理致密化工艺以及激光选区熔化和激光近净成形技术这两种技术中所打印陶瓷坯体基体裂纹开裂行为分析及其控制方法的研究进展, 对比分析了激光选区烧结、激光选区熔化以及激光近净成形技术在成形陶瓷零件的技术特征, 最后展望了激光增材制造陶瓷技术的未来发展趋势。

Laser additive manufacturing of metallic components: Materials, processes and mechanisms

[J].

Laser additive manufacturing on metal matrix composites: A review

[J].

Laser 3D micro-manufacturing

[J].

An overview of defects in laser melting deposition forming products and the corresponding controlling methods

[J].

激光熔化沉积成形缺陷及其控制方法综述

[J].

Research progress of wire and arc additive manufacturing (end)

[J].

电弧熔丝增材制造研究进展(续完)

[J].

Basic study on wire-arc additive manufacturing of magnesium alloy fabricated by cold metal transfer heat source

[D].

基于冷金属过渡的镁合金电弧增材制造技术基础研究

[D].

Status and development prospects of forming control technology in arc-based additive manufacturing

[J].

电弧增材制造成形控制技术的研究现状与展望

[J].

Research status of wire and arc additive manufacture and its application in aeronautical manufacturing

[J].

电弧增材制造研究现状及在航空制造中应用前景

[J].

Microstructure and mechanical properties of 5356 aluminum alloy fabricated by TIG arc additive manufacturing

[J].5356 aluminum alloy has been widely applied in transportation, aerospace and other fields owing to its low density, excellent fatigue property, and superior corrosion resistance. Aluminum alloy is widely manufactured by the arc additive technique that operates at a fast manufacturing speed with simple equipment and high material utilization. The property of 5356 aluminum alloy is closely related to its microstructure. To better control the property of this alloy for the additive manufacturing of forming parts, it is necessary to study the evolution of its microstructure. In this work, 5356 aluminum alloy forming parts were produced by tungsten inert gas welding (TIG) arc additive manufacturing, and their microstructures and mechanical properties were analyzed. The 5356 aluminum alloy formed by TIG additive manufacturing was composed of α-Al matrix and β(Al3Mg2) phase. As the deposition height increased, the layer microstructure transformed from equiaxed grains to columnar grains and tended to stabilize at thermal equilibrium. The top layer exhibited a dendritic microstructure with serious segregation of the Mg element. The middle and lower microstructures were varied and included equiaxed grains, columnar grains, and a mixture of these, with improved Mg-element segregation. As the deposition height increased, the microhardness in the layer first decreased and then stabilized. The microhardness was larger in the interlayers than in the deposition layers. The pores gathered in the interlayers might explain the lower yield strength of the thin-walled parts than the theoretically calculated value. The tensile strength, yield strength, and elongation were all anisotropic, and the tensile property was better in the transverse than in the longitudinal direction. This result was attributable to pore accumulation between the layers of the thin-walled parts and to the uneven microstructure.

5356铝合金TIG电弧增材制造组织与力学性能

[J].采用钨极惰性气体保护焊(TIG)电弧增材制造工艺制备5356铝合金成形件,并对成形件的组织和力学性能进行研究。结果表明,5356铝合金增材制造的相组成为α-Al基体和β(Al<sub>3</sub>Mg<sub>2</sub>)相;随沉积高度增加,沉积层显微组织由等轴晶向柱状晶转变,达到热平衡状态后趋于稳定,这是因为增材制造具有热积累效应;最顶层组织呈现树枝状,且Mg元素偏析严重;中下部组织形态多样,包括等轴晶组织、柱状晶组织及其混合组织,同时Mg元素偏析得到改善。力学性能测试结果显示,随沉积高度的增加,层内显微硬度先降低后趋于稳定,这是因为沉积层组织在增材制造过程中经历逐渐粗化的过程,导致显微硬度下降,达到热平衡状态后显微组织相对稳定,显微硬度也趋于稳定。沉积层层间位置的硬度大于层内,这是因为层间结合处为细小的等轴晶组织。聚集在层间的气孔可能是导致薄壁件屈服强度低于理论计算值的原因。抗拉强度、屈服强度以及伸长率都表现了各向异性,横向拉伸性能优于纵向,这是因为薄壁件层间气孔聚集以及显微组织不均匀。

Study on microstructure and mechanical properties of additive manufactured titanium alloy based on electron beam melting

[D].

电子束增材制造钛合金组织与力学性能研究

[D].

Review on equipment and application of electron-beam based additive manufacturing

[J].

电子束增材制造设备及应用进展

[J].

Research progress and prospect of electron beam freeform fabrication

[J].

电子束熔丝增材制造研究进展及展望

[J].

Investigation on the processing and mechanism of friction stir additive manufacturing of high strength aluminum alloy

[D].

高强铝合金搅拌摩擦增材制造成形机理和工艺研究

[D].

Current progress and prospect of friction stir welding

[J].

搅拌摩擦焊研究进展及前景展望

[J].

Research status of friction stir welding

[J].

搅拌摩擦焊及其研究现状

[J].

Research progress in aluminum alloy additive manufacturing

[J].

铝合金增材制造技术研究进展

[J].

Research status and prospect of friction stir welding technology of Al alloy

[J].

铝合金搅拌摩擦焊接技术的现状与展望

[J].

Friction stir welding of aluminium alloys

[J].

Friction stir welding of magnesium alloys

[J].

Research progress on friction stir welding process of aluminum/magnesium dissimilar alloys

[J].

铝/镁异种合金搅拌摩擦焊工艺研究进展

[J].

Status and prospect of friction stir welding of magnesium alloys

[J].

镁合金搅拌摩擦焊的研究现状与展望

[J].

Friction stir welding of magnesium alloys: A review

[J].In recent years, the increasing application demand for Mg alloys in automobile, rail transport, aviation and aerospace industries brings about the growing prominence of seeking reliable techniques to join Mg alloys. As a solid state welding method, friction stir welding (FSW) exhibits unique advantages in joining Mg alloys, and thus arouses widespread research interest. This paper emphatically reviewed the research status of conventional friction stir butt-welding of Mg alloys, and highlighted the welding process, microstructure evolution, texture characteristics, mechanical behavior and their interaction mechanisms. It was indicated that the texture plays a vital role in FSW joint performance of wrought Mg alloys, which is quite different from that in the FSW Al alloy joints. The specific strong texture formed in the weld is the main factor that gives rise to the impediment to achieving equal-strength joints to base materials. At the same time, some focuses like the weldability and the factors that influence joint performance in other types of FSW like lap welding, spot welding and double-sided welding; the weldability, interface bonding mechanism, joint performance and its affecting factors and optimization methods in dissimilar FSW between Mg alloys and other materials like Mg alloys of other grades, Al alloys and steels, were summarized and discussed. Finally, the future research and development directions in FSW of Mg alloys were prospected.

镁合金搅拌摩擦焊接的研究现状与展望

[J].近年来,镁合金在汽车、轨道交通、航空航天等领域的应用需求快速增长,其可靠连接的重要性愈发突出。作为固相焊接技术,搅拌摩擦焊(FSW)对镁合金焊接具有独特优势,因此得到了广泛关注。本文重点综述了镁合金常规对接FSW的研究进展,就焊接工艺、微观组织演化、织构分布特征、接头力学性能及其之间的相互作用机制进行了详细分析与评述。研究表明,不同于铝合金,在变形镁合金FSW时,织构是影响接头性能的关键因素,焊后形成的特殊强织构分布是导致接头难以达到与母材同等强度的主要原因。同时,对其它焊接形式如搭接焊、点焊、双面焊的可焊性及接头性能的影响因素与变化规律进行了讨论,并对镁合金与其它镁合金、铝合金以及钢之间异种焊的可焊性、界面结合机制、接头性能的影响因素及调控方法进行了评述。最后,对镁合金FSW的未来研究方向进行了展望。

The principle and application of the friction stir welding

[J].

搅拌摩擦焊的原理与应用

[J].

New wielding technology—FSW

[J].

一种新型焊接工艺——搅拌摩擦焊

[J].

A new welding method of ship building—The principle and application of the friction stir welding

[J].

新型船舶焊接技术——搅拌摩擦焊的原理与应用

[J].

Hybrid friction stir welding technology for steel

[D].

钢的复合搅拌摩擦焊技术

[D].

The characteristic of friction stir welding and its application in the aluminum alloy structure of ship

[J].

搅拌摩擦焊在船用铝合金结构中的应用

[J].

Development of friction stir welding in China

[J].

搅拌摩擦焊在中国的发展

[J].

Research of friction stir welding tool

[J].

搅拌摩擦焊工具的研究现状

[J].

Friction stir based welding and processing technologies-processes, parameters, microstructures and applications: A review

[J].

The overview of friction stir additive manufacturing

[J].

摩擦搅拌增材制造发展概述

[J].

Research progress of metal solid phase additive manufacturing based on friction stir

[J].

基于搅拌摩擦的金属固相增材制造研究进展

[J].

Metal additive manufacturing using friction stir engineering: A review on microstructural evolution, tooling and design strategies

[J].

Friction stir-based additive manufacturing

[J].

Friction additive manufacturing technology: A state-of-the-art survey

[J].

Friction surfacing deposition by consumable tools

[J].

An additive manufacturing device based on hot wire friction micro-forging and the application method

[P].

一种基于热丝摩擦微锻的增材制造装置及制造方法

[P].

A device and method for FSW additive manufacturing using static shoulder cavity

[P].

一种利用静止轴肩空腔进行FSW增材制造的装置及方法

[P].

Wire filling friction stir additive manufacturing device and additive manufacturing method

[P].

一种填丝搅拌摩擦增材制造装置及增材制造方法

[P].

A wire-filled static shoulder friction stir welding and additive manufacturing device and method

[P].

一种填丝静轴肩搅拌摩擦焊接与增材制造装置及方法

[P].

A new friction stir additive manufacturing machine

[P].

一种新型的搅拌摩擦增材制造机

[P].

Friction head and friction stir additive manufacturing method with adjustable components and synchronously feeding material

[P].

一种组分可调同步送料的摩擦头及摩擦增材制造方法

[P].

Methods and containers for loading raw material rods into additive friction stir deposition machines

[P].

用于将原料棒装载到增材摩擦搅拌沉积机中的方法和容器

[P].

Friction flow additive manufacturing device and additive manufacturing method

[P].

一种流动摩擦增材制造装置及增材制造方法

[P].

A additive manufacturing mechanism and manufacturing method based on short rod materials

[P].

一种基于短棒物料增材制造机构及制造方法

[P].

Continuously feeding friction stir additive manufacturing device and method

[P].

一种连续进给送料搅拌摩擦增材制造装置及增材制造方法

[P].

A method of friction stir welding additive manufacturing bar

[P].

一种搅拌摩擦焊增材制造棒材的方法

[P].

A granule friction stir additive manufacturing device and method

[P].

一种颗粒式搅拌摩擦增材制造装置及方法

[P].

A semi-solid additive manufacturing device and method

[P].

一种半固态增材制造装置及方法

[P].

A device and method for radial additive manufacturing of friction stir welding

[P].

一种搅拌摩擦焊径向增材制造的装置与方法

[P].

A novel approach to friction surfacing: Experimental analysis of deposition from radial surface of a consumable tool

[J].

Study on technology and microstructure performance of side friction stir additive manufacturing

[D].

侧向搅拌摩擦增材制造工艺与组织性能研究

[D].

A method of additive manufacturing by consumable stirring friction tools

[P].

一种通过消耗型搅拌摩擦工具增材制造的方法

[P].

Microstructure of 2024 aluminum alloy by stationary shoulder friction stir additive manufacturing

[J].

静轴肩搅拌摩擦增材制造2024铝合金的组织特征

[J].

Study on additive manufacturing technology based on the principle of stationary shoulder friction stir welding

[D].

基于静轴肩搅拌摩擦焊的增材制造技术研究

[D].

A cooling friction stir additive manufacturing device and method

[P].

一种施加冷却的搅拌摩擦增材制造装置及方法

[P].

A stirring tool for friction stir additive manufacturing

[P].

一种用于搅拌摩擦增材制造的搅拌头

[P].

A friction stir additive manufacturing method for preset heterogeneous metal interlayers

[P].

一种预置异质金属夹层的搅拌摩擦增材制造方法

[P].

A new additive manufacturing process based on friction deposition

[J].

Additive friction stir-enabled solid-state additive manufacturing for the repair of 7075 aluminum alloy

[J].

Study on microstructure and properties of 2024 aluminum alloy by stationary shoulder frictional stir additive manufacturing

[D].

2024铝合金静轴肩搅拌摩擦增材组织及性能研究

[D].

Microstructure and properties of high strength aluminum alloy Al 2024 laser additive manufacturing

[D].

高强度铝合金Al 2024激光增材制造组织与性能研究

[D].

Microstructure and mechanical properties of wire + arc additively manufactured 2024 aluminum alloy components: As-deposited and post heat-treated

[J].

The microstructure and properties adjustment of friction stir additive manufactured build for 7N01 aluminum alloy

[D].

7N01铝合金搅拌摩擦增材体显微组织与性能的控制

[D].

Basic research on selective laser melting additive manufacturing process of NZ30K magnesium alloy

[D].

NZ30K镁合金激光选区熔化增材制造成型工艺基础研究

[D].

The laser additive manufacturing technology of aluminum alloy with melting wire

[D].

铝合金激光熔丝增材制造工艺研究

[D].

Microstructure and mechanical properties of wire arc additive manufacturing of AZ31 magnesium alloy

[J/OL].

电弧增材制造AZ31镁合金组织与力学性能分析

[J/OL] 材料科学与工艺,