近年来,先进钢铁材料的组织调控为汽车轻量化、节能减排和性能提升的实现提供了可能,其核心理念之一是对亚稳奥氏体进行调控。例如中锰钢和相变诱导塑性(TRIP)钢主要是利用临界退火工艺调控逆转变奥氏体中的元素分配和组织形貌[1,2];淬火配分(Q&P)钢主要是通过配分过程,C元素向奥氏体中扩散来调控奥氏体稳定性[3~5]。奥氏体稳定性包括机械稳定性[6]及热稳定性[7~12],大量的研究已经为亚稳奥氏体稳定性的调控积累了系统性的经验。基于马氏体相变的亚稳奥氏体调控是组织调控的重要手段之一[13~16]。因此,探究马氏体相变机理是先进钢铁材料研发的关键。马氏体相变主要受外部因素如磁场[17,18]、应力场[19~22]等,内部因素如晶粒尺寸[23,24]、化学成分[25,26]等的影响,其中,通过考虑外场因素(磁场)和内部因素(晶粒尺寸)的协同作用来调控马氏体相变,以其高效、易操作等优点值得深入研究。

相变动力学作为温度诱发马氏体转变的重要方面,主要包括马氏体开始转变温度(Ms)、相变速率及最终转变量。Kakeshita等[17,18,27]发现在Fe-Ni合金体系中强磁场作用明显提升Ms,其作用机制归因于奥氏体相和马氏体相原子磁矩不同而引起的磁化能差异。同时关于晶粒尺寸对Ms的影响研究[28,29]显示,晶粒尺寸越小,Ms越低。晶粒尺寸影响Ms机理方面,从相变形核角度出发,王金亮等[22,30]观察到奥氏体晶粒内层错束及预变形引入的位错缺陷等均可为马氏体相变提供有效的形核质点。晶粒尺寸越大,降温过程中缺陷奥氏体越容易形成,马氏体相变的形核质点越多,Ms越高。从相变能量角度出发,Umemoto和Owen[31]认为奥氏体晶粒尺寸越小,晶内形成的马氏体板条对周围奥氏体的应力集中越大,相变阻力越大;而Brofman等[24]认为小的奥氏体晶粒本身基体强度高,限制了马氏体相变的应变协调,增加了相变阻力。目前关于晶粒尺寸如何影响马氏体相变的热稳定性尚无定论。

相变速率也是反映材料相变过程的重要特征。Martin等[32]研究结果表明,马氏体时效钢施加30 T的强磁场时,等温马氏体的形成可以加速几个数量级。进一步,Choi等[33]对磁场如何加速马氏体相变进行了研究,结果表明,对于γ→α'-马氏体相变过程,磁场强度增加,马氏体相变能垒降低,相变加快;而对于γ→ε-马氏体→α'-马氏体相变过程,磁场强度增加,马氏体形核的临界板条尺寸减小,相变加快。晶粒尺寸对相变速率影响方面,Celada-Casero等[34]研究认为,马氏体相变速率受过冷度影响显著,在14~185 μm范围内,晶粒尺寸较小时,小的过冷度下更容易达到最大的相变速率,且晶粒尺寸越小,相变速率越快。

综上,磁场及晶粒尺寸对马氏体相变影响的表象规律研究已较为全面,但磁场及晶粒尺寸的协同作用对马氏体相变机制的研究较少,现阶段不足以有效为调控材料组织提供理论基础。

相变晶体学特征也是影响马氏体相变的另一重要方面。在低层错能材料中两步切变型相变,α′-马氏体可以通过生成中间相ε-马氏体进一步完成转变,奥氏体与α′-马氏体之间存在Kurdjumov-Sachs (K-S)位向关系[38],奥氏体与ε-马氏体之间存在Shoji-Nishiyama (S-N)位相关系[39,40],所以一个奥氏体晶粒最多能形成4种ε-马氏体变体和对应的24种α′-马氏体变体[41]。Wu等[42]研究结果表明,在一个马氏体板条内,随着C含量的增加,临近的板条簇之间由小角度晶界为主导的晶体学关系转变为大角度晶界为主导的孪生关系。Inoue等[43]则探究了板条群内马氏体变体的种类,结果表明在一个板条群内仅会出现少数马氏体变体,马氏体转变出现了变体选择现象。可见,目前科研人员对马氏体相变的晶体学特征有较清晰的认识。然而,磁场和晶粒尺寸的协同作用对马氏体相变晶体学特征的影响,还需进一步深入探究。

综上分析,磁场和晶粒尺寸作为影响马氏体相变行为的重要因素,目前研究只给出了磁场或晶粒尺寸单独作用下对马氏体相变的影响,并未给出在连续降温过程中,磁场和晶粒尺寸共同作用对相变动力学及晶体学特征的影响及其作用机制。本工作选择SUS321奥氏体不锈钢为研究的基础材料,主要是因其室温下组织较为稳定,不容易发生马氏体转变,同时,在连续冷却过程中,马氏体相变不完全,不完全的马氏体相变为研究除温度影响外,磁场和晶粒尺寸对马氏体相变过程的影响提供了可能。所以该合金体系用于研究磁场作用以及不同晶粒尺寸奥氏体马氏体相变行为较合适。本工作系统研究了磁场和晶粒尺寸协同作用下的马氏体相变行为,详细分析了磁场作用下γ→ε-马氏体→α′-马氏体的相变机制,完善了磁场和晶粒尺寸这2个内外场共同作用下马氏体相变理论,为磁场作用下温度诱发马氏体相变主动调控提供理论指导。

1 实验方法

实验选用SUS321奥氏体不锈钢作为基础材料,其化学成分(质量分数,%)为:Cr 17.6,Ni 9.22,C 0.015,Si 0.52,Mn 1.23,Ti 0.088,Fe余量。钢的制备过程如下:(1) 将铸坯钢锭随炉加热至1473 K,保温2 h后开始锻造,锻造成横截面尺寸为20 mm × 50 mm的锻坯;(2) 将锻坯加热到1473 K保温2 h后在热轧机上将锻坯从20 mm轧到4.0 mm,轧后空冷至室温;(3) 将热轧板放置在Ar气环境中加热到1323 K保温5 h进行固溶处理,随后空冷至室温。

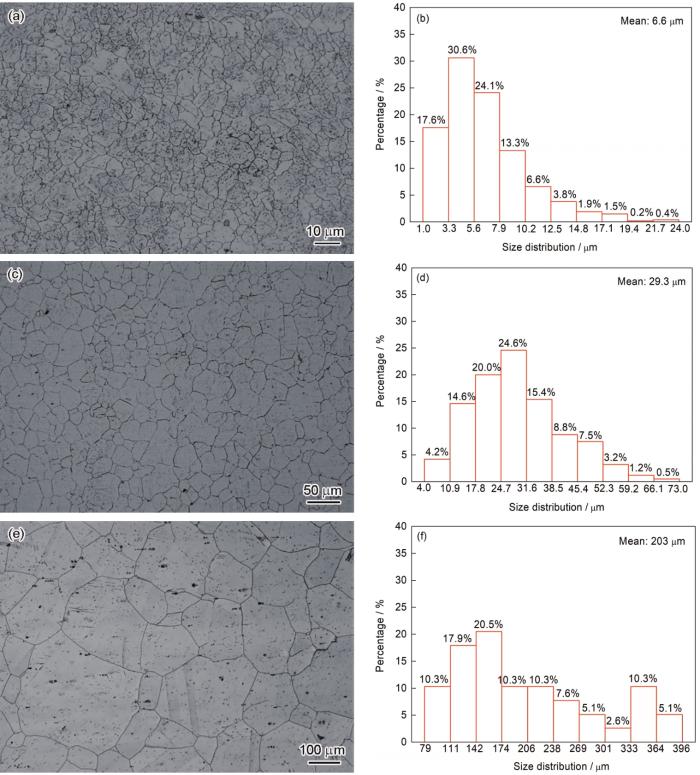

为了获得3组不同晶粒尺寸的SUS321不锈钢,采用大轧制变形结合不同的退火温度进行调控。首先,对固溶处理的热轧板进行多道次冷轧,初始4 mm轧至2 mm;再对2 mm厚的冷轧板做不同温度的退火处理,退火温度分别为1073、1173和1473 K,退火时间均为30 min,随后空冷至室温。利用BX53MRF光学显微镜(OM)对试样进行组织观察,结果如图1所示。利用国标GB/T 6394-2002金属平均晶粒度测定方法中的截点法统计奥氏体的晶粒尺寸。统计结果显示,冷轧板经1073、1173和1473 K退火30 min后,奥氏体平均晶粒尺寸分别为6.6、29.3和203 μm。

图1

图1

50%冷轧板经不同温度退火30 min后的显微组织OM像及平均晶粒尺寸统计结果

Fig.1

OM images (a, c, e) and statistical results of average grain size (b, d, f) of the 50% cold-rolled sheet treated at different annealing temperatures for 30 min

(a, b) 1073 K (c, d) 1173 K (e, f) 1473 K

从3组退火态的SUS321不锈钢材料上制取7 mm × 3 mm × 2 mm的矩形试样,进行磁场环境+连续冷却过程的观察实验,利用Quantum Design PPMS-9综合物性测量系统(PPMS)为实验材料提供1和9 T磁场环境,对试样进行连续冷却处理,降温速率为5 K/min,处理温度为300~4 K。在冷却过程中,利用PPMS实时监控材料磁化强度变化。磁化强度的强弱取决于材料中铁磁性物质(α′-马氏体)的含量,可通过

式中,

室温下对SUS321奥氏体不锈钢进行88.3%压下量的冷轧处理,利用XRD计算冷轧处理的试样α′-马氏体的含量为99.9%,故可认为组织为全马氏体。以全马氏体对应的饱和磁化强度为基准计算不同马氏体转变量。随后利用PPMS测试冷轧变形后试样,得到室温下全马氏体的饱和磁化强度为131.76 emu/g,即Is* = 131.76 emu/g。

采用配备了Instrument Symmetry电子背散射衍射(EBSD)系统的Gemini SEM 300场发射扫描电镜(SEM)对样品进行显微组织观察及晶体学分析,使用其电子通道衬度成像(ECCI)进行组织分析。EBSD的加速电压为20 kV,工作距离16 mm,扫描步长100 nm。

2 实验结果与讨论

2.1 磁场作用下马氏体相变动力学过程

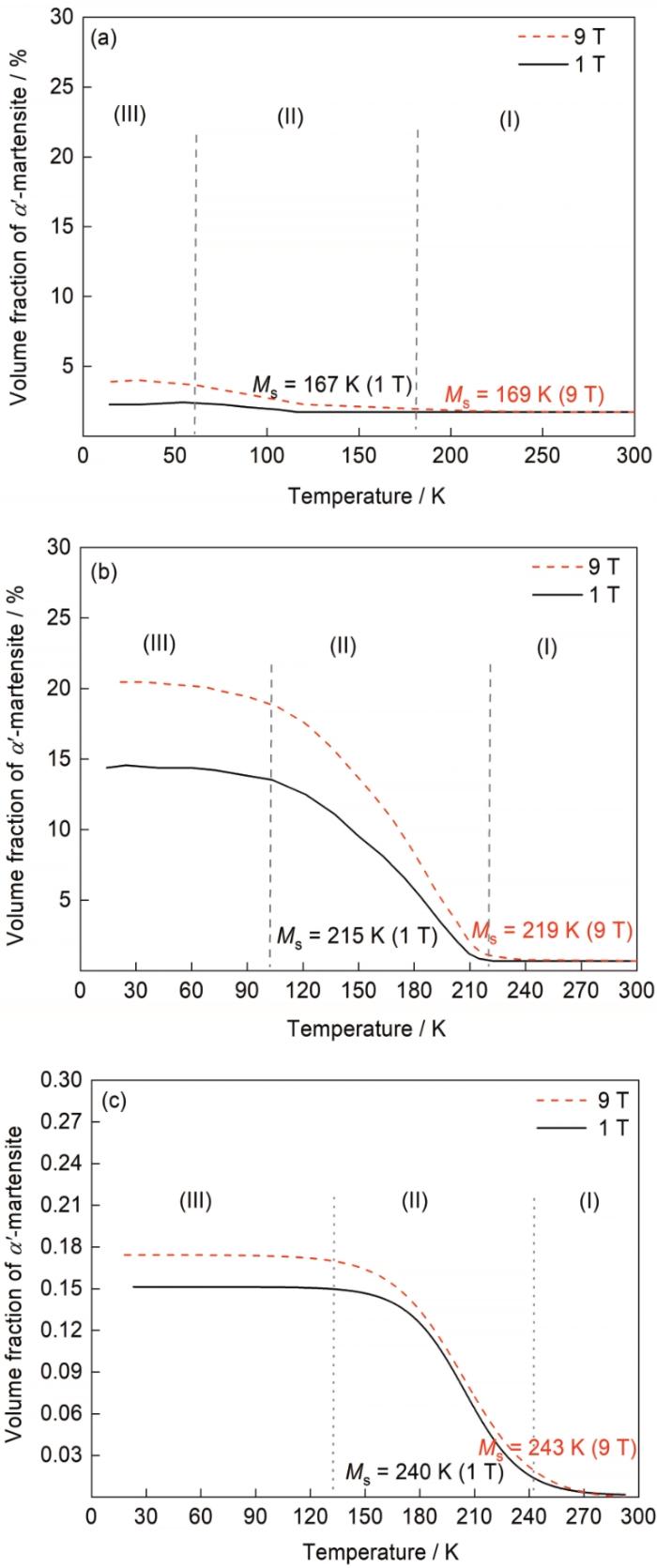

图2给出了外加磁场作用下,不同晶粒尺寸的SUS321不锈钢由300 K冷却至4 K时,材料相变的动力学过程。马氏体相变过程均出现3个阶段:高温段的稳定期、中温段的相变期和低温段的饱和期。所以转变过程中,Ms、相变速率和最终α′-马氏体的相变量均是表征马氏体相变的重要参数。从图2可以看出,在1 T磁场作用下,不同晶粒尺寸的SUS321不锈钢随温度降低,均发生马氏体转变,呈现出3个相变阶段。当晶粒尺寸由6.6 μm增大到203 μm时,Ms点由167 K升高至240 K,α′-马氏体的含量由2.8%增加到15.2%,Ms、相变速率和相变至稳定阶段后的马氏体含量均随着晶粒尺寸的增加而增加。Celada-Casero等[34,44]研究了Fe-0.2C-3.5Mn-1.5Si-0.5Mo合金体系下晶粒尺寸对马氏体相变行为的影响,结果也表明晶粒尺寸越小,马氏体晶核数量越少,奥氏体强度越高,进而导致Ms降低,相变速率减慢。从更微观的角度分析,晶粒尺寸影响晶粒内缺陷奥氏体的形成[45],而缺陷奥氏体为马氏体相变提供形核质点,大晶粒尺寸奥氏体更容易形成缺陷奥氏体,故导致在降温过程中大晶粒尺寸材料形成了更多的α′-马氏体。

图2

图2

在1和9 T磁场下不同晶粒尺寸SUS321不锈钢试样在降温过程中α′-马氏体的含量变化曲线

Fig.2

Variation curves of martensite content under 1 and 9 T magnetic fields of SUS321 stainless steel with different gain sizes during cooling

(a) 6.6 μm (b) 29.3 μm (c) 203 μm

对比弱磁场作用,在9 T磁场作用下,晶粒尺寸显著影响马氏体相变行为,包括Ms、相变速率和马氏体相变量。当晶粒尺寸由6.6 μm增至29.3 μm时,Ms点由169 K升高至219 K,α′-马氏体的含量由4.7%增加到20.8%。随着晶粒尺寸的增加,Ms、α′-马氏体的含量增加。然而,当晶粒尺寸继续增大至203 μm时,材料Ms点升高幅度明显减小,α′-马氏体的含量略微降低仅为18.2%。以上结果表明,施加1和9 T磁场显著影响不同晶粒尺寸的SUS321奥氏体钢的马氏体相变行为。在强磁场作用下,当晶粒尺寸处于6.6~29.3 μm时,磁场极大促进了马氏体相变,对Ms增幅、α′-马氏体的含量影响显著。当晶粒尺寸继续增大时,磁场对马氏体转变影响减弱。

如前所述,温度诱发马氏体相变动力学过程的3个重要特征分别为:Ms、相变动力学和最终相变量。通过以上对比分析可知,晶粒尺寸显著影响马氏体相变动力学。随着晶粒尺寸的增加,亚稳奥氏体热稳定性逐渐降低,使得马氏体相变更容易发生,具体表现为Ms升高,转变速率加快,最终转变量增加。而强磁场作用下,晶粒尺寸影响马氏体相变行为不同于弱磁作用,在冷却过程中,强磁场作用下,存在临界晶粒尺寸,在此临界晶粒尺寸下,奥氏体稳定性最差,马氏体相变最容易进行。超过临界晶粒尺寸后,磁场作用对Ms、相变速率和最终相变量的影响减弱。这可能是由于晶粒尺寸增大,ε变体的各向异性逐渐转变为各向同性,各向同性ε-马氏体的形核质点长大过程中加速了变体之间的硬碰撞,使得晶粒尺寸较大时,马氏体相变受到抑制[46]。相变动力学曲线从宏观现象分析了磁场和晶粒尺寸共同作用对马氏体相变的影响,但是无法给出如何影响相变的微观本质。因此,进一步利用EBSD技术对相变后的晶体结构进行分析。

2.2 磁场作用下马氏体相变后的显微组织

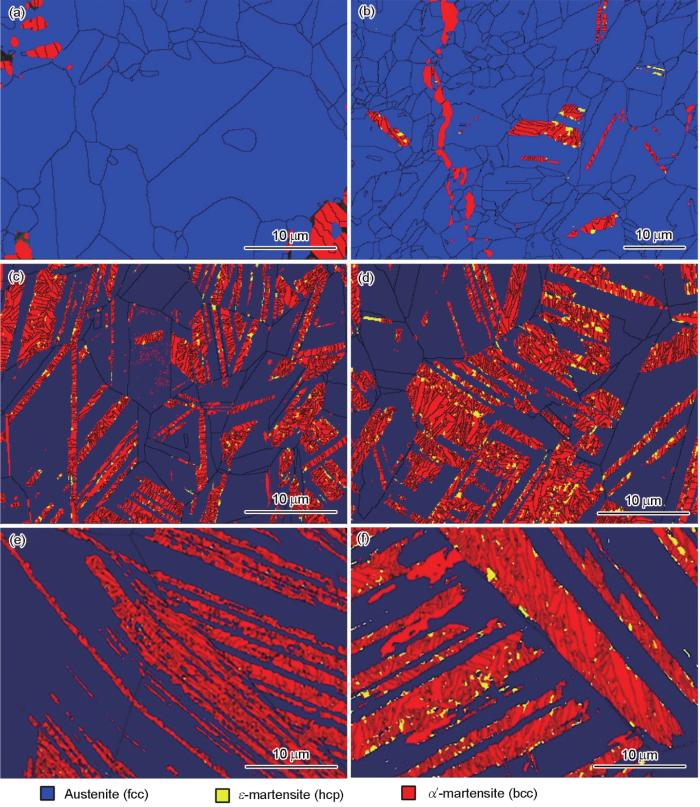

图3给出了施加1和9 T磁场作用下,SUS321不锈钢连续冷却处理后的EBSD观察结果。图中蓝色代表奥氏体,黄色代表ε-马氏体,红色代表α′-马氏体。图示结果显示奥氏体的显微组织为等轴状。

图3

图3

不同晶粒尺寸SUS321不锈钢施加1和9 T磁场作用经连续冷却处理后显微组织的EBSD相图

Fig.3

EBSD phase maps of microstructure evolution of SUS321 stainless steel with different grain sizes during cooling under 1 T (a, c, e) and 9 T (b, d, f) magnetic fields

(a, b) 6.6 μm (c, d) 29.3 μm (e, f) 203 μm

从图3a可以看出,1 T磁场作用下,晶粒尺寸为6.6 μm的试样进行连续冷却处理后,组织为奥氏体及少量的α′-马氏体;而在9 T磁场作用下,如图3b所示,试样中出现了ε-马氏体和较多的α′-马氏体。磁场作用增加了最终马氏体转变量,这从显微组织的角度印证了磁场作用的原因。增加奥氏体晶粒尺寸至29.3 μm,相比1 T磁场作用,9 T强磁场作用下,ε-马氏体含量明显增多,如图3c和d所示。晶粒尺寸继续增大至203 μm,9 T强磁场作用下,ε-马氏体含量和α′-马氏体较1 T磁场情况下增多,这说明强磁场(9 T)对3种晶粒尺寸的奥氏体马氏体相变均起促进作用,促进了γ→ε-马氏体相变过程,形成更多的中间态ε-马氏体,为α'-马氏体相变提供形核质点。对于形变诱发马氏体和温度诱发马氏体的形核研究,前期的研究结果[47,48]指出马氏体相变一般会在奥氏体组织的缺陷处形核,此缺陷可以是预先存在于奥氏体晶粒内部的缺陷也可以是在温度场或应力场作用下新形成的缺陷。材料在连续冷却过程中或施加应力场的环境下,促进了材料内部缺陷的产生,而缺陷的产生为中间态ε-马氏体提供了更多的形核质点[30]。通过以上分析,磁场作用也可以为ε-马氏体提供有效的形核质点。这说明,磁场环境与低温或者应力场相似,均能为ε-马氏体提供有效的形核质点,促进相变的进行,从相变机理方面进一步完善了先前研究人员提出的磁场加速马氏体相变的表象研究结果。

2.3 磁场作用下马氏体相变的晶体学特征

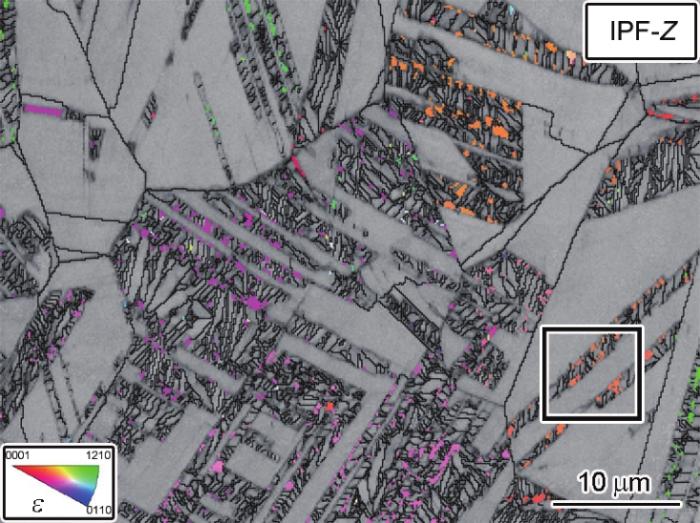

在低碳钢的同一晶粒中,马氏体是以板条束的形式存在。由于马氏体相变为共格切变过程,新旧相之间的晶体学关系是研究马氏体相变机理的一个重要特征,有助于马氏体相变过程的调控。利用EBSD结合ECCI技术进一步分析在γ→ε-马氏体→α′-马氏体相变路径下,ε-马氏体和α′-马氏体的晶体学特征。图4给出了试样在9 T磁场作用下,晶粒尺寸为29.3 μm的奥氏体连续冷却处理后ε-马氏体的反极图(IPF),晶体取向平行于试样的Z轴。可以看出,同一个板条上形成的ε-马氏体具有相同的颜色,表明生成的ε-马氏体变体取向相同。此外,在同一个晶粒内相互平行的ε-马氏体同样具有相同的取向颜色,如黑色方框位置所示。这表明在一个奥氏体晶粒内部,同一个板条及相互平行的板条内部的ε-马氏体取向相同,均属于同一个变体。

图4

图4

晶粒尺寸为29.3 μm的组织中ε-马氏体的反极图

Fig.4

Inverse pole figure (IPF) of ε-martensite in the 29.3 μm austenite grain

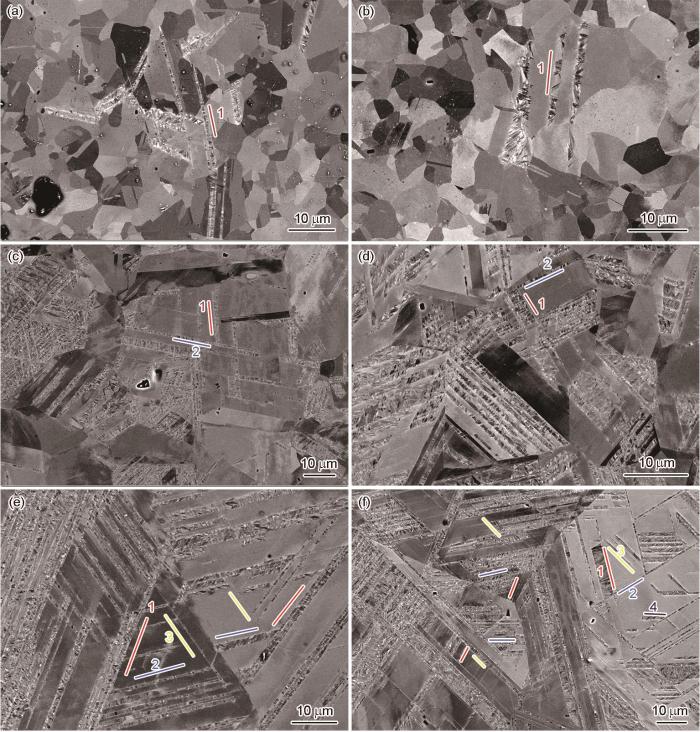

通过上述分析,相互平行的板条具有相同的取向,不平行的板条具有不同的取向,且在同一个晶粒中相互碰撞相交。图5给出了磁场环境下经连续冷却处理后,不同晶粒尺寸试样的显微组织ECCI图。如图5a和b红色线段所示,1和9 T磁场作用下,材料晶粒尺寸为6.6 μm时一个晶粒内均只有1个方向的packet,即有1种ε-马氏体变体;晶粒尺寸为29.3 μm时一个晶粒内有2个方向的packet,即有2种ε-马氏体变体(图5c和d中红色和蓝色线段所示);晶粒尺寸为203 μm时,一个晶粒内有3~4个方向的packet,即有3~4种ε-马氏体变体,如图5e和f所示。以上结果表明磁场作用下,在连续冷却处理过程中ε-马氏体的形成具有强烈的变体选择。ε-马氏体的变体选择对晶粒尺寸的敏感性较高,而磁场影响不显著。晶粒尺寸越大,ε-马氏体的变体选择越弱,倾向于4个ε-马氏体变体全部生成。晶粒尺寸决定了ε-马氏体的变体种类,进而影响了α′-马氏体的变体选择情况。

图5

图5

不同晶粒尺寸的SUS321不锈钢在1 T和9 T磁场作用下连续冷却处理后显微组织的ECCI衬度图

Fig.5

Contrast maps by electron channeling contrast imaging (ECCI) of microstructure evolution of SUS321 stainless steel with different grain sizes during cooling under 1 T (a, c, e) and 9 T (b, d, f) magnetic fields (Numbers 1-4 represent ε-martensite variants)

(a, b) 6.6 μm (c, d) 29.3 μm (e, f) 203 μm

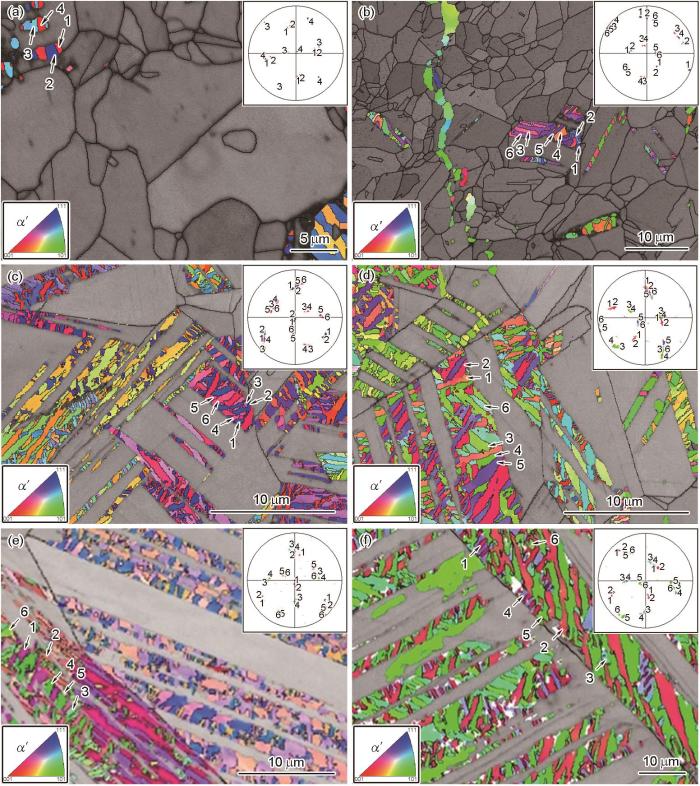

进一步分析磁场作用下,晶粒尺寸对温度诱发α′-马氏体晶体学特征的影响,尤其是相变过程中变体选择的影响。图6给出了1和9 T磁场作用下,不同晶粒尺寸的试样显微组织中α′-马氏体的晶体学特征。可以看出,同一个ε-马氏体条带上出现了多种块状α′-马氏体变体。不同取向颜色代表块状α′-马氏体呈现出不同的取向分布。在γ→ε-马氏体→α′-马氏体相变路径下,ε-马氏体为α′-马氏体提供了有效形核质点。当相变过程中有ε-马氏体出现时,母相奥氏体与ε-马氏体间符合S-N取向关系,即{111} γ //{0002} ɛ,<

图6

图6

不同晶粒尺寸奥氏体不锈钢在磁场作用下组织中α′-马氏体的反极图和极图

Fig.6

IPFs and pole figures (insets) of α′-martensite of SUS321 stainless steel with different grain sizes under 1 T (a, c, e) and 9 T (b, d, f) magnetic fields (Numbers 1-6 represent the α′-martensite variants)

(a, b) 6.6 μm (c, d) 29.3 μm (e, f) 203 μm

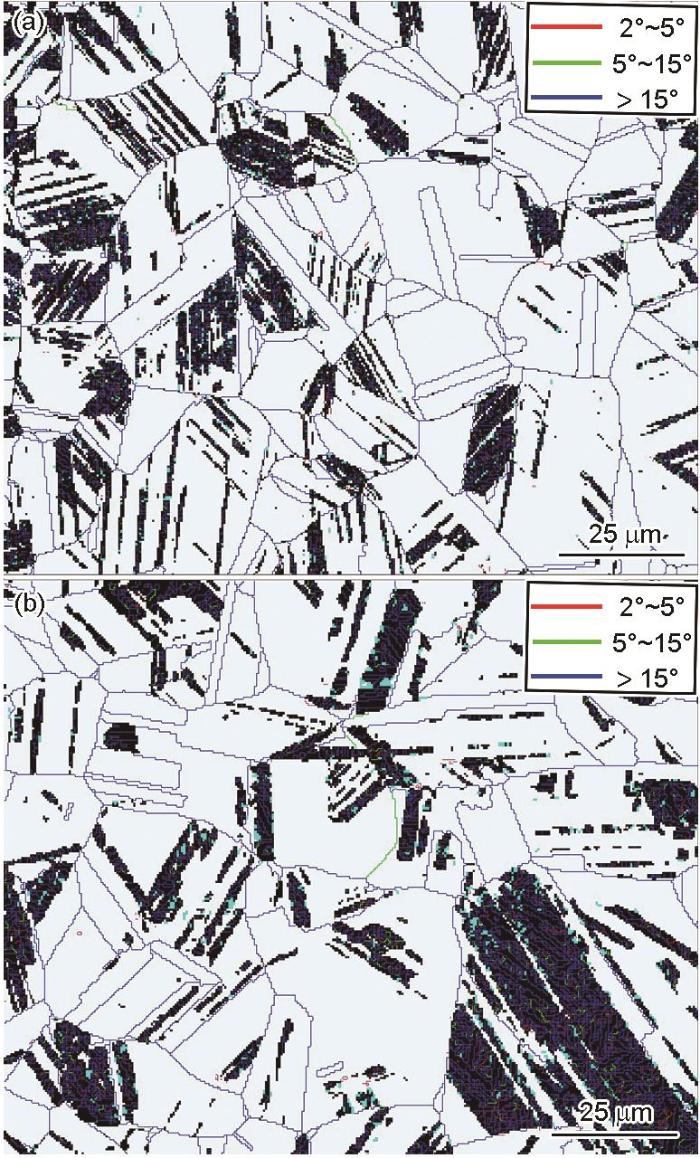

利用EBSD技术对马氏体板条之间的晶体学特性(大小角度晶界、晶界取向角占比)做进一步分析。图7给出了晶粒尺寸为29.3 μm试样晶界角度在2°~5°、5°~15°和15°~65°范围内的分布情况。其中,红、绿、蓝线分别代表晶界角度介于2°~5°、5°~15°和15°~65°之间,白色、青色和黑色分别代表奥氏体相、ε-马氏体和α′-马氏体。随着磁场强度的增加,马氏体相变量增加,这与上述组织观察得到的结果相一致。在SUS321不锈钢合金体系下,无论是弱磁场作用还是强磁场作用,马氏体变体之间均是以大角度晶界为主导。

图7

图7

1和9 T磁场作用下晶粒尺寸为29.3 μm的显微组织的相图及晶界的晶体学信息

Fig.7

Phase maps and the crystallographic information of grain boundary by EBSD for 29.3 μm samples under 1 T (a) and 9 T (b) magnetic fields (White, cyan, and black colors represent austenite, ε-martensite, and α'-martensite, respectively)

上述结果揭示了磁场和晶粒尺寸的协同作用主要影响ε-马氏体变体的生成,在第二步的相变过程中,ε-马氏体为α′-马氏体提供形核质点,同一板条内所有取向的α′-马氏体具有相同的形核概率,磁场和晶粒尺寸的协同作用对其没有显著影响。因此磁场和晶粒尺寸协同作用,仅影响γ→ε-马氏体转变的变体选择,ε-马氏体→α′-马氏体转变的变体选择不受磁场和晶粒尺寸影响。通过外加磁场手段调控马氏体相变的变体选择情况时,需特别关注材料的晶粒尺寸情况,为组织中亚稳奥氏体的主动调控提供一定的理论指导。

3 结论

(1) 以SUS321不锈钢为研究的基础体系,综合考虑合金体系所处的外部磁场环境及显著影响马氏体相变的晶粒尺寸,探究了马氏体相变行为。弱磁场作用下,随着晶粒尺寸的增加,连续降温过程中的马氏体转变明显被加速,终态马氏体转变量增加;强磁场作用下,随着晶粒尺寸的增加,存在最促进马氏体相变的临界晶粒尺寸,在此临界晶粒尺寸条件下,奥氏体稳定性最差,马氏体相变最迅速,转变量最多。表明晶粒尺寸与磁场对马氏体相变的综合影响并非简单的叠加关系,通过外加磁场手段调控马氏体相变时需特别关注材料的晶粒尺寸情况。

(2) 对比分析马氏体相变微观组织,阐述了磁场和晶粒尺寸共同影响马氏体相变的微观作用机制。无论是小晶粒还是大晶粒,强磁场作用均增加ε-马氏体的形核质点数,进而加速了马氏体相变,促进马氏体的生成。而在强磁场作用下,当晶粒尺寸大于临界值时,生成的ε-马氏体各向异性逐渐转变为各向同性,加速了变体之间的硬碰撞,进而限制了大晶粒尺寸中的马氏体相变。因此存在使奥氏体稳定性最差的临界晶粒尺寸。

(3) 对相变前后晶体学数据进行分析,阐明了磁场和晶体尺寸共同作用对γ→ε-马氏体→α′-马氏体相变的变体选择规律。晶粒尺寸主要影响ε-马氏体的变体选择,磁场对其影响不显著。磁场作用及增加晶粒尺寸均对α′-马氏体的变体选择情况没有明显影响。

参考文献

Anisotropy of retained austenite stability during transformation to martensite in a TRIP‐assisted steel

[J].

Austenite stability and deformation-induced transformation mechanism in cold-rolled medium-Mn steel

[J].

Effect of fresh martensite on the stability of retained austenite in quenching and partitioning steel

[J].

Development of multiphase microstructure with bainite, martensite, and retained austenite in a Co-containing steel through quenching and partitioning (Q&P) treatment

[J].

Heat treatment effects on the microstructure and mechanical properties of a medium manganese steel (0.2C-5Mn)

[J].

Regulation of retained austenite and its effect on the mechanical properties of low carbon steel

[J].

低碳钢中残余奥氏体的调控及对力学性能的影响

[J].采用完全淬火+两相区再加热-淬火-分配(IQ$\&$P)热处理工艺对0.23C-1.8Mn-1.35Si钢进行处理, 获得了具有亚温铁素体、马氏体以及广泛分布于原奥氏体晶界、相界等处的残余奥氏体等构成的多相组织. 利用SEM, XRD以及EBSD等对不同热处理阶段钢的微观组织进行了表征. 结果证实, 该多相组织低合金钢中残余奥氏体的获得主要依赖于以下两点: 一是两相区再加热阶段逆转变奥氏体组织中的富Mn富C, 二是淬火--分配阶段残留奥氏体在分配过程中的二次富C, 通过上述的两步元素富集处理可以使该低碳钢在室温下获得超过10%含量的残余奥氏体, 而残留奥氏体在分配过程中的二次富C则对该类钢中残余奥氏体的形成及其在室温下的稳定化起到了至关重要的作用. 由于广为分布的残余奥氏体在形变过程中的TRIP效应, 使得该类钢种在拉伸变形过程中获得了持续的加工硬化能力, 从而实现了强度与塑性的良好结合. 测试结果表明, IQ&P钢的强塑积超过了26 GPa?%, 屈服强度大于600 MPa, 抗拉强度超过900 MPa, 均匀延伸在16\%以上, 常温半厚冲击韧性达到了39 J.

Design of a novel Mn-based 1 GPa duplex stainless TRIP steel with 60% ductility by a reduction of austenite stability

[J].

Novel medium-Mn (austenite + martensite) duplex hot-rolled steel achieving 1.6 GPa strength with 20% ductility by Mn-segregation-induced TRIP mechanism

[J].

An ultrahigh strength and enhanced ductility cold-rolled medium-Mn steel treated by intercritical annealing

[J].

A novel cold-rolled medium Mn steel with an ultra-high product of tensile strength and elongation

[J].

Characterization of microstructures and mechanical properties of cold-rolled medium-Mn Steels with different annealing processes

[J].

Effect of retained austenite on ductility and toughness of a low alloyed multi-phase steel

[J].High performance steels require not only high strength, but also the combination of high ductility, high toughness and good weldability. Retained austenite in multi-phase steels has been widely reported to be helpful for obtaining high strength, high ductility and high toughness. In this work, steel with multi-phase microstructure consisting of intercritical ferrite, tempered martensite/bainite and different volume fractions retained austenite was obtained by intercritical annealing and tempering at 600~680 ℃. The volume fractions of retained austenite were 2%, 5%, 10% for samples tempered at 600, 650 and 680 ℃, respectively. The effect of retained austenite on ductility and toughness was studied in detail. Results showed that there was no obvious change in strength by varying the volume fraction of retained austenite, yield strength of the steel was 540~590 MPa, tensile strength was 720~780 MPa. Retained austenite could largely improve both the ductility and toughness of the steel. With increasing the volume fraction of retained austenite from 2% to 10%, the uniform elongation and total elongation were enhanced from 10.3% and 23.8% to 20.4% and 33.8%, respectively. The underlying reason for the improvement of ductility was attributed to the transformation induced plasticity of retained austenite by providing sustainable high work hardening rate. The improvement of toughness by retained austenite became more obvious when testing temperature was lower. When impact test temperature was higher than -60 ℃, the Charpy impact energy of samples with 2%~10% retained austenite were larger than 120 J. When test temperature was -80 ℃, Charpy impact energy of sample with 2% retained austenite decreased to 14 J, while that of sample with 10% retained austenite remained as 60~80 J when test temperature was as low as -80 and -100 ℃. Results from instrument impact test indicated that retained austenite was helpful for enhancing plasticity before crack initiation at low temperature, leading to improvement of crack initiation energy, resulting in excellent low temperature toughness.

低合金多相钢中残余奥氏体对塑性和韧性的影响

[J].研究了经临界退火和不同温度回火后多相组织低合金钢中残余奥氏体对塑性和韧性的影响. 结果表明, 实验钢经两相区临界退火和不同温度回火后, 获得了临界铁素体、回火马氏体/贝氏体以及体积分数分别为2%, 5%, 10%的残余奥氏体多相组织. 含有不同体积分数残余奥氏体的多相组织钢强度差异不大, 其屈服强度介于540~590 MPa, 抗拉强度介于720~780 MPa. 残余奥氏体含量对塑性和韧性影响显著. 随着残余奥氏体含量的增加, 实验钢的均匀延伸率和断后延伸率分别从10.3%和23.8%提高到20.4%和33.8%. 塑性的提高主要是由于残余奥氏体在拉伸过程中逐步发生马氏体相变, 从而提供持续的加工硬化能力, 推迟颈缩的发生. 残余奥氏体对韧性的改善随着冲击测试温度的降低变得更加显著. 冲击温度高于-60 ℃时, 不同体积分数的残余奥氏体实验钢的冲击功均在120 J以上, 当冲击实验温度为-80 ℃时, 残余奥氏体含量仅2%的实验钢的冲击韧性仅14 J, 而含有残余奥氏体体积分数约10%的实验钢在-80和-100 ℃的冲击功仍然保持在60~80 J. 残余奥氏体的存在有利于提高低温冲击过程中的塑性变形能力, 延迟起裂, 提高起裂功, 从而有利于获得优异的低温冲击韧性.

Characteristics of bainitic transformation and its effects on the mechanical properties in quenching and partitioning steels

[J].

Revealing the conditions of bainitic transformation in quenching and partitioning steels

[J].

Microstructure-mechanical properties relationships for quenching and partitioning (Q&P) processed steel

[J].

Review: Relations between metastable austenite and fatigue behavior of steels

[J].With the deepening and improvement of the research on the conventional mechanical properties of metallic materials, the long-term service properties, such as fatigue and creep, showed more and more critical influence on the development of metallic materials. As one of the most important engineering structural materials, in order to clarify the fatigue failure mechanism, the research of steels on the relationship between microstructure and fatigue properties has been a hot and difficult problem for a long time. With the rapid development of smelting technology for steels, the research on the influencing factors of fatigue gradually changes from inclusions to microstructures as metastable austenite, precipitates, etc. Therefore, in order to further analyze the feasible direction of the research on the influence of microstructure on fatigue, this paper summarizes the influence and mechanism of metastable austenite on the fatigue property of advanced steel materials. The influence mechanism of metastable austenite on fatigue property by relevant scholars under different service conditions such as low cycle fatigue and high cycle fatigue was reviewed. Based on the experimental results, the relationship between metastable austenite and fatigue properties was quantitatively evaluated by machine learning. The quantitative relationship between the content/stability of metastable austenite and fatigue life was established, which could provide the basis direction for the further study of the mechanism of fatigue for steels.

综述: 钢中亚稳奥氏体组织与疲劳性能关系

[J].随着金属材料常规力学性能研究的不断深化与完善,疲劳、蠕变等长时间服役性能越来越成为制约金属材料发展的瓶颈问题。钢铁材料是最重要的工程结构材料之一,为阐明其疲劳失效机理,关于钢铁材料显微组织与疲劳性能关系的研究更是领域内长久以来的热点和难点问题。随着钢铁冶炼技术的日新月异,对于疲劳性能的组织影响因素研究也逐步从夹杂物向亚稳奥氏体、析出物等特征组织因素转变。因此,为进一步分析疲劳性能的组织影响因素研究的可行方向,本文着重综述了先进钢铁材料中亚稳奥氏体组织对疲劳性能的影响规律,总结了相关学者针对低周疲劳、高周疲劳等不同服役条件提出的亚稳奥氏体对疲劳性能的影响机制,并进一步以已有实验结果为数据支撑,通过支持向量机、BP神经网络等机器学习算法对亚稳奥氏体组织特征与疲劳性能关系进行了定量化评估,初步形成了亚稳奥氏体含量/稳定性与疲劳寿命的定量关系,为钢铁材料疲劳性能的机理研究提供基础与方向性指导。

Composition dependence of magnetic field-induced martensitic transformations in Fe-Ni alloys

[J].

Effect of high magnetic field and uniaxial stress at cryogenic temperatures on phase stability of some austenitic stainless steels

[J].

Effect of cold rolling on the microstructural, magnetic, mechanical, and corrosion properties of AISI 316L austenitic stainless steel

[J].

Deformation-induced martensitic characteristics in 304 and 316 stainless steels during room-temperature rolling

[J].

Quantitative analysis of the martensite transformation and microstructure characterization during cryogenic rolling of a 304 austenitic stainless steel

[J].Advanced material processing techniques have been successfully used to produce metals or alloys with submicro- or nano-sized grain structures with some possibly required harsh working environment that limits their industrial application. Cryogenic deformation might promote extensively severe deformation or distortion of metals or alloys (such as Al or aluminium alloys, Cu or copper alloys, Ti, Zr, etc.) so as to accumulate higher deformation energy (e.g., higher defect density) for the depression of the (dynamic) recovery, which will contribute to the microstructure refinement. Presently, the macro-/micro-structural evolution, the martensitic transformation as well as its effect on the mechanical property during the cryogenic and room temperature rolling of 304 metastable austenitic stainless steel were studied. It shows that the cryogenic rolling can effectively accelerate the martensitic transformation, e.g., after 20% cryogenic rolling the volume fraction of the transformed martensitic is equal to that after 50% room temperature rolling, and finally the cryogenic rolling can promote the complete martensitic transformation. Also the through-thickness uniformity of the martensitic transformation after cryogenic rolling is significantly better than that of the room temperature rolled one, which can help to improve the through-thickness performance uniformity. It is found that the deformation mechanisms are different for cryogenic and room temperature rolling metastable austenitic stainless steel: the martensitic transformation and its deformation occur in the former while austenitic deformation in the latter. The cryogenic rolling can quickly induce higher hardness than that of the room temperature rolled one, and the hardness tends to be equal finally because of the minimized dislocation density difference between these two rolled steels. TEM results indicate that the orientation relationship between the transformed martensite and the old austenite in the cryogenic and room temperature rolled sheets can still keep the K-S (Kurduumov-Sachs) relationship.

304奥氏体不锈钢超低温轧制变形诱发马氏体转变的定量分析及组织表征

[J].研究了304亚稳态奥氏体不锈钢在超低温和室温轧制变形过程中的宏、微观组织演变, 变形引起的马氏体转变及其对合金性能的影响. 结果表明, 超低温轧制比室温轧制能更有效地加速马氏体转变, 其中20%超低温轧制变形便可实现50%室温轧制变形下的马氏体转变量, 且超低温轧制变形最终可实现完全的马氏体转变. 同时, 超低温轧制引起的马氏体转变在板厚方向上较均匀, 显著优于室温轧制板材的板厚方向均匀性, 有助于提高亚稳态奥氏体不锈钢板厚方向性能的均匀性. 分析认为, 亚稳态奥氏体不锈钢在超低温和室温轧制过程中具有不同的变形机理, 前者主要以马氏体转变及其变形为主, 后者以奥氏体变形为主. 超低温轧制所获板材的硬度比室温轧制板材增长迅速, 但随变形量增大位错密度差距缩小, 最终导致两者硬度趋于一致. TEM表征结果表明, 超低温和室温轧制过程中引起的马氏体与母相基体间的取向关系遵循K-S (Kurduumov-Sachs)关系.

The effects and mechanisms of pre-deformation with low strain on temperature-induced martensitic transformation

[J].Pre-deformation with low strain can effectively control the thermal stability of metastable austenite. Till now, research has mainly focused on the effect of pre-deformation on martensitic transformation at one or more temperatures. However, research is still lacking on the effect of pre-deformation on the temperature at which martensite is formed (Ms), the final martensite content, and the transformational kinetics during continuous cooling. Furthermore, the mechanism underlying how pre-deformation affects martensitic transformation has not been reported. In this work, the influence rule and the corresponding effect of pre-deformation with low strain on martensitic transformation induced by temperature under continuous cooling from 300 K to 4 K was studied with 321 stainless steel samples by using the quasi-in-situ observation technique. The results show that Ms and the final amount of martensite increased under pre-deformation with low strain, and the martensitic transformation during continuous cooling was simultaneously accelerated. The quasi-in-situ observation demonstrated that the slip bands introduced by pre-deformation effectively provided nucleation sites for ε-martensite transformation. Accordingly, the formed ε-martensite increased the number of α'-martensite nucleation sites during continuous cooling, and finally promoted α'-martensite transformation. This builds on the theory proposed by other researchers that the dislocation defects introduced by pre-deformation directly provide the nucleation sites for α'-martensite transformation, and thus, promote martensitic transformation. In addition, by analyzing the nucleation behavior and nucleation priority at slip band defects, it is shown that the nucleation behavior of slip bands introduced by the pre-deformation was similar to that of faulted austenite induced by temperature. However, it is worth noting that the slip bands introduced by pre-deformation had a relatively higher nucleation priority. The crystallography of α'-martensite in the pre-deformed samples was analyzed, and it was found that the slip bands effectively changed the variant selection of α'-martensite so that the texture of α'-martensite was modified. This study advances the existing theory of martensitic transformation and provides theoretical guidance for the proactive control of temperature-induced martensitic transformation.

低应变预变形对变温马氏体相变行为的影响规律及作用机制

[J].以321型不锈钢为实验材料,利用伪原位观察技术研究了300~4 K连续冷却过程中低应变预变形对变温马氏体相变行为的影响规律及作用机制。结果表明,在连续冷却过程中,低应变预变形提高了马氏体相变开始温度和最终的马氏体转变量,同时也加速了整个连续冷却过程中的马氏体相变。通过伪原位观察揭示了预变形引入的滑移带能有效地提供温度诱发ε-马氏体相变的形核质点,促进ε-马氏体转变,进而提高连续冷却过程中α'-马氏体相变的形核质点数量,促进α'-马氏体相变,完善了预变形引入的位错缺陷直接提供α'-马氏体相变的形核质点,促进α'-马氏体相变这一理论。此外,通过对滑移带缺陷的形核行为和形核优先性分析,揭示形变引入的滑移带与温度诱发的缺陷奥氏体具有相同的形核行为,但预变形引入的滑移带具有更高的形核优先性。同时对预变形试样中α'-马氏体的晶体学特征分析发现,滑移带能有效地改变α'-马氏体的变体选择,进而改变α'-马氏体的相变织构。

Effect of grain size on thermal and mechanical stability of austenite in metastable austenitic stainless steel

[J].

On the effect of fine grain size on the Ms temperature in Fe-27Ni-0.025C alloys

[J].

Effect of the chemical composition to martensitic transformation in Ni-Mn-Ga-Fe alloys

[J].

The stability of retained austenite at different locations during straining of I&Q&P steel

[J].

Effects of magnetic field and hydrostatic pressure on martensitic transformation

[J].

Austenite grain size and the martensite-start temperature

[J].

Predicting the Ms temperature of steels with a thermodynamic based model including the effect of the prior austenite grain size

[J].

New insights on nucleation and transformation process in temperature-induced martensitic transformation

[J].

Effects of austenitizing temperature and austenite grain size on the formation of athermal martensite in an iron-nickel and an iron-nickel-carbon alloy

[J].

The isothermal martensite formation in a maraging steel: A magnetic study

[J].

Effect of magnetic field on successive γ→ε'→α' isothermal martensitic transformation in a SUS304L stainless steel

[J].

The role of the austenite grain size in the martensitic transformation in low carbon steels

[J].

Effects of heat treatment, pre-strain and magnetic field on the formation of α martensite in Fe-25.5Ni-4Cr and 304L steels

[J].

Effects of pre-strain, heat treatments and magnetic fields on α' martensite formation in Fe-25.5%Ni-3-5%Cr alloys

[J].

Effect of grain refinement on thermal stability of metastable austenitic steel

[J].

Martensitic transformation

[J].

马氏体相变

[J].

Analysis of the γ-ɛ-α′ variant selection induced by 10% plastic deformation in 304 stainless steel at -60oC

[J].

Experimental and numerical analysis of the martensitic transformation in AISI 304 steel sheets subjected to perforation by conical and hemispherical projectiles

[J].

Comparing the deformation-induced martensitic transformation with the athermal martensitic transformation in Fe-Cr-Ni alloys

[J].

Toughening of martensite matrix in high strength low alloy steel: Regulation of variant pairs

[J].

The fracture of a low carbon tempered martensite

[J].

The influence of the austenite grain size on the microstructural development during quenching and partitioning processing of a low-carbon steel

[J].

A review of the thermal stability of metastable austenite in steels: Martensite formation

[J].Metastable austenite plays a critical role in achieving improved combinations of high strength and high ductility/toughness in the design of advanced high-strength steels (AHSS). The thermal stability of metastable austenite determines the transformation characteristics of AHSS and thus primarily determines the microstructure evolution during complex processes, e.g., the quenching and partitioning process, to achieve the desirable microstructure. This study provides a review of the thermal stability of austenite and its influence on martensitic transformation from both experimental and theoretical modeling perspectives. From the experimental perspective, factors affecting the thermal stability are analyzed, the relative sensitivities are compared, and their corresponding mechanisms are discussed. From the theoretical modeling perspective, the most representative kinetic models that describe athermal and isothermal martensitic transformation are reviewed. The advantages, shortcomings, and applicability of each model are discussed. The systematic review of both experimental and theoretical aspects reveals critical factors in tailoring the stability of metastable austenite and, therefore, provides guidance for the design of advanced steels.

Analysis of solid state phase transformation kinetics models and recipes

[J].

Martensitic transformations induced by plastic deformation in the Fe-Ni-Cr-C system

[J].

A nucleation model for martensitic transformations in iron-base alloys

[J].