金属导体材料服役过程中除了需要肩负电能输送的任务之外,通常还需要承担一定的自重载荷和外加载荷。所以,抗拉强度和导电率是金属导体材料最为重要的2个性能指标。高强度可以保证金属导体在服役过程中的安全可靠性,高导电率则有利于降低电力传输过程中的电能损耗。因此,高强度和高导电率是金属导体材料追求的目标[7~11]。研究[12~17]表明:在金属材料中引入各种缺陷,如位错、晶界、析出相和固溶原子等,可以大幅提高其强度。然而,根据Matthiessen定则可知,上述强化金属材料的缺陷均会对电子产生散射,从而减小电子的平均自由程,导致金属材料电阻率的增大和导电率的大幅下降[18,19]。所以,从科学原理来看,金属导体材料的强度与导电率通常相互制约[20~25]。

目前国内外学者改善Al和Cu导体材料强度和导电率制约关系的研究策略大体可分为基体净化和合金元素状态调控。(1) 基体净化:通过添加稀土等合金元素,并与Al或Cu基体中的杂质元素反应,生成沉淀相,从而净化基体,提高Al和Cu的导电率[26~30]。(2) 合金元素状态调控:通过时效热处理方式,控制Al、Cu中的固溶元素以纳米尺度第二相的形式析出,既降低了晶格畸变提高了导电率,又起到了析出强化的作用,实现了强度和导电率的同步提高[31~35]。综上,主要通过调控导体材料内的合金元素来改善强度和导电率的制约关系。而作为金属材料重要的微观组织结构之一的晶粒,却很少被用于调控金属材料的强度和导电率。根据Hall-Petch关系(

对于金属材料,其2种性能相互制约的现象普遍存在,例如强度与塑性或韧性制约关系[40]。研究[41~43]表明,晶粒异构组织在改善金属材料强度和塑性制约关系方面通常能够起到关键的作用。例如,在金属材料内引入梯度晶粒结构、双模结构和部分再结晶结构,实现了金属材料强度和塑性的同步优化[41~43]。因此,晶粒尺寸异构设计有效地解决了金属材料强度和塑性制约关系难题。根据

1 实验方法

采用的实验材料是工业纯Al杆和工业纯Cu杆。工业纯Al杆的化学成分(质量分数,%)为:Al 99.6,Si 0.11,Fe 0.25,Cu 0.01,Mn 0.03。工业纯Cu杆的化学成分(质量分数,%)为:Cu 99.973,P 0.002,Bi 0.001,Sb 0.002,As 0.002,Fe 0.004,Ni 0.002,Pb 0.003,Sn 0.002,S 0.004,Zn 0.003,O 0.002。采用多道次冷拉拔工艺制备了不同变形量的工业纯Al线和工业纯Cu线,拉拔变形量采用下式计算[31]:

式中,ε为拉拔变形量;An 为第n道次拉拔的工业纯Al/Cu线的横截面积;A0为工业纯Al/Cu杆的横截面积。其中,工业纯Al线由初始直径为9.50 mm的Al杆拉拔至最终直径为2.98 mm的工业纯Al线,总变形量为90.2%,并选取变形量为0、24.6%、65.6%、83.1%、86.8%和90.2%的工业纯Al线进行后续的性能测试;工业纯Cu线由初始直径为8.00 mm的Cu杆拉拔至最终直径为3.63 mm的工业纯Cu线,总变形量为79.7%,并选取变形量为0、42.7%、65.1%和79.7%的工业纯Cu线进行后续的性能测试。

室温单轴拉伸实验在Instron 5982拉伸试验机上开展,拉伸速率为1.0 × 10-3 s-1,拉伸试样总长度为200.0 mm,标距尺寸为150.0 mm,每种状态的样品进行3次拉伸实验以保证数据的可重复性。电阻率的测试采用QJ-57型直流双臂电桥,为了保证测量准确性,采用空调调节测试环境温度,将测试温度保持在20℃,测试样品长度为1 m,导电率计算公式如下[31]:

式中,w为导电率;Lw为测试长度;R为电阻;Sw为样品横截面积。

采用电火花线切割机对不同拉拔变形量的工业纯Al/Cu线进行切割,获得工业纯Al/Cu线径向和轴向的样品用于微观组织表征。采用装有电子背散射衍射(electron backscatter diffraction,EBSD)系统的Sigma 500场发射扫描电子显微镜(SEM)对工业纯Al/Cu线进行微观组织观察,工作电压为20 kV,EBSD的工作距离约为17 mm。EBSD样品需经过砂纸研磨、机械抛光以及电解抛光,工业纯Al线的电解抛光液成分是HClO4和C2H6O (体积比为1∶9),电解抛光电压为16.0 V,时间为1.0 min,温度为0℃;工业纯Cu线的电解抛光液为250 mL H2O + 125 mL C2H6O + 125 mL H3PO4 + 25 mL C3H8O和2.5 g CH4N2O的混合溶液,电解抛光电压为10.0 V,时间为1.0 min,温度为室温。使用TECNAI F20透射电子显微镜(TEM)进行微观组织表征,工作电压为200 kV。TEM样品均研磨至厚度50 μm,并采用Tenupol-5化学双喷仪进行化学双喷减薄,工业纯Al线的双喷液成分为HClO4和CH4O (体积比为1∶4),双喷温度为-20℃,双喷电压为13 V;工业纯Cu线的双喷液为125 mL H3PO4 + 125 mL C2H6O + 250 mL H2O的混合溶液,双喷温度为-2℃,双喷电压为10 V。

2 实验结果

2.1 强度-导电率关系曲线

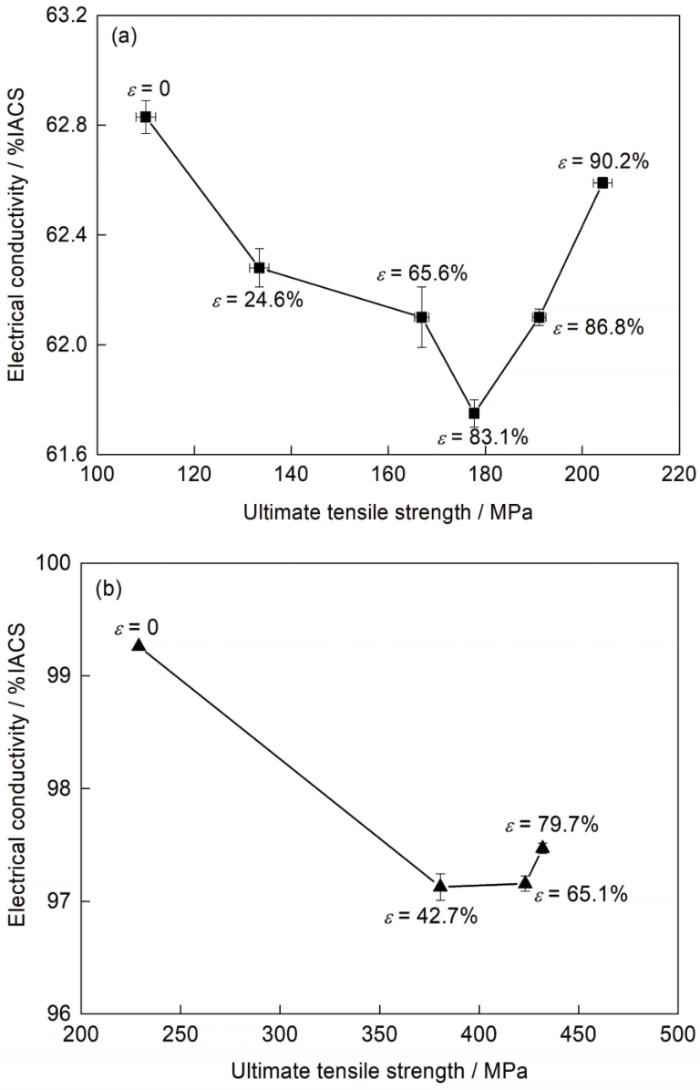

图1给出了不同拉拔变形量工业纯Al线和工业纯Cu线的强度-导电率关系曲线。如图1a所示,当拉拔变形量从0增加到83.1%时,工业纯Al线抗拉强度从110.0 MPa增加到177.7 MPa。同时,导电率从62.83%IACS下降到61.75%IACS,说明拉拔变形量从0增加到83.1%时,工业纯Al线强度和导电率符合倒置关系。当继续增加变形量时,导电率从61.75%IACS逐渐增加到62.59%IACS,与此同时,抗拉强度继续增加到204.2 MPa。类似地,如图1b所示,对于工业纯Cu线,当变形量低于42.7%时,随着变形量的增大,抗拉强度从229.0 MPa逐渐增大至380.5 MPa,导电率则从99.26%IACS下降至97.13%IACS,此时工业纯Cu线强度和导电率仍为制约关系。然而,当变形量从42.7%增加至79.7%时,工业纯Cu线的抗拉强度和导电率分别同步增大至431.9 MPa和97.47%IACS。因此,对于工业纯Al线和工业纯Cu线,抗拉强度始终随着拉拔变形量的增加而增加。然而,导电率随拉拔变形量的增加表现出了先下降再上升的规律。也就是说,当拉拔变形量超过某一临界值时,工业纯Al线和工业纯Cu线的强度和导电率均呈现出了强度和导电率同步提高的现象,这打破了传统的强度和导电率制约关系。

图1

图1

不同拉拔变形量工业纯Al线和工业纯Cu线的强度-导电率关系曲线

Fig.1

Strength-electrical conductivity curves of the commercially pure Al wire (a) and the commercially pure Cu wire (b) with various area reductions (ε)

2.2 TEM组织观察

为了揭示工业纯Al线和工业纯Cu线不同拉拔变形量下强度和导电率相互制约的机制以及强度和导电率同步提高的机制,选取拉拔变形量为24.6%、83.1%和90.2%的工业纯Al线以及拉拔变形量为0、42.7%和79.7%的工业纯Cu线进行微观组织表征。

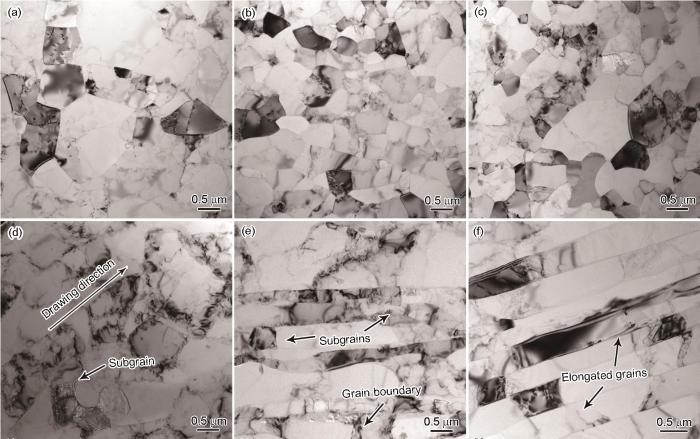

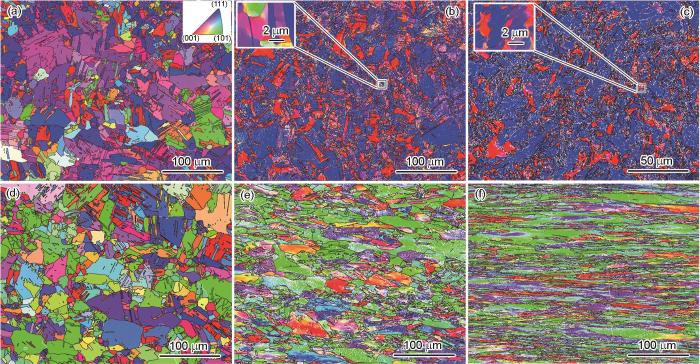

图2给出了不同拉拔变形量工业纯Al线径向和轴向的TEM像。可以看出,径向组织主要是等轴晶粒,随着拉拔变形量增加,径向晶粒逐渐细化,工业纯Al线晶粒内位错数量增加并不明显,这主要是因为Al是一种高层错能的金属材料,所以,变形过程中Al内的位错容易发生交滑移,从而导致位错的回复[44,45]。从纵截面组织来看,如图2d所示,当变形量为24.6%时,工业纯Al线内部晶粒发生了严重变形,可观察到很多亚晶粒。随着变形量的增大,晶粒沿着拉拔方向逐渐被拉长(图2e)。此外,在图2e中可以观察到拉长的晶粒内部存在大量的亚晶界,这是由于在拉长的晶粒内新形成了许多晶界,该晶界将拉长的晶粒分割为大量小尺寸晶粒。所以,工业纯Al线经过83.1%拉拔之后只是局部晶粒被拉长。当拉拔变形量继续增加到90.2% (图2f)时,导线内部组织变得非常均匀和干净,大部分晶粒明显被拉长,形成了又细又长的纤维状组织。

图2

图2

不同拉拔变形量工业纯Al线径向和轴向TEM像

Fig.2

TEM images of the radial sections (a-c) and the axial sections (d-f) of the commercially pure Al wires manufactured with ε = 24.6% (a, d), ε = 83.1% (b, e), and ε = 90.2% (c, f)

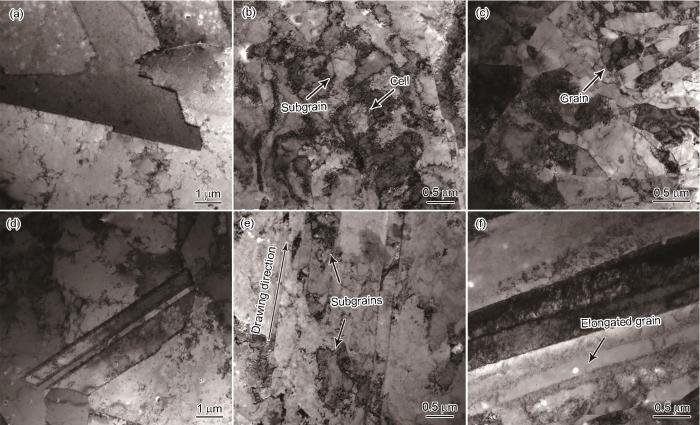

图3

图3

不同拉拔变形量工业纯Cu线径向和轴向TEM像

Fig.3

TEM images of the radial sections (a-c) and the axial sections (d-f) of the commercially pure Cu wires with ε = 0 (a, d), ε = 42.7% (b, e), and ε = 79.7% (c, f)

2.3 EBSD组织观察

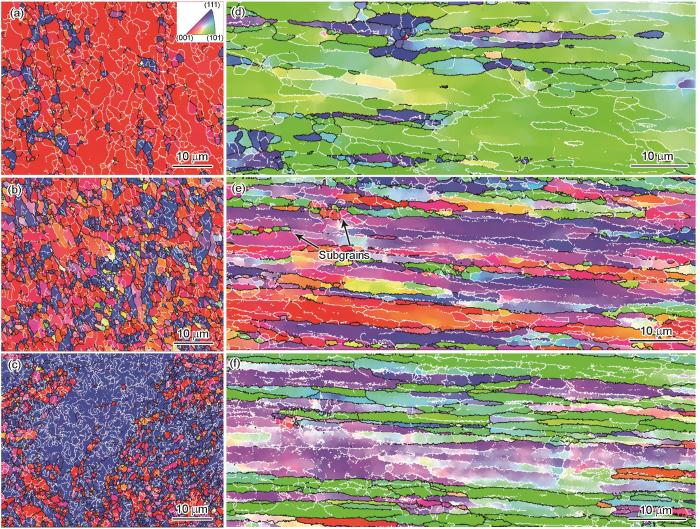

图4a~c所示为不同拉拔变形量工业纯Al线径向EBSD像。可以看出,径向晶粒为等轴状,在经过24.6%拉拔的工业纯Al线内部绝大部分晶粒为<001>取向,少部分晶粒为<111>取向,形成了强<001>织构和弱<111>织构的组织特征。随着变形量的增加,<001>取向晶粒的数量逐渐减少,<111>取向晶粒的数量逐渐增加,说明晶粒取向逐渐由<001>转向<111>。当变形量增加至90.2%时,绝大部分径向晶粒的取向为<111>取向,形成了极强的<111>织构。因此,随着变形量的增大,工业纯Al线径向的织构逐渐从<001>演变为<111>。轴向EBSD像(图4d~f)则表明晶粒无明显择优取向,与TEM观察结果一致,变形量增大,晶粒沿着轴向被逐渐拉长。

图4

图4

不同拉拔变形量工业纯Al线径向和轴向EBSD像

Fig.4

EBSD images of the radial sections (a-c) and the axial sections (d-f) of the commercially pure Al wires with ε = 24.6% (a, d), ε = 83.1% (b, e), and ε = 90.2% (c, f)

图5所示为不同拉拔变形量工业纯Cu线径向和轴向EBSD像。图5a和d表明,工业纯Cu杆内晶粒为随机取向,无明显织构。当变形量逐渐增加至79.7%时,径向晶粒的晶体取向逐渐呈现择优分布特征,晶粒主要为<001>取向和<111>取向,且<111>取向晶粒的数量随着变形量的增大逐渐增大。此外,从图5b和c中的局部放大图可以看到径向晶粒发生了显著的细化。图5d~f显示了工业纯Cu线轴向组织特征,可以看到,变形过程中工业纯Cu线轴向晶粒始终为随机取向。当变形量增加至42.7%时,小部分轴向晶粒沿着拉拔方向被拉长,大部分晶粒仍保持等轴状特点。变形量大幅增加至79.7%时,所有晶粒均沿着轴向被拉长,表现为纤维状晶粒特征。

图5

图5

不同拉拔变形量工业纯Cu线径向和轴向EBSD像

Fig.5

EBSD images of the radial sections (a-c) and the axial sections (d-f) of the commercially pure Cu wires with ε = 0 (a, d), ε = 42.7% (b, e), and ε = 79.7% (c, f) (Insets in Figs.5b and c show the locally enlarged images)

2.4 晶粒尺寸演化

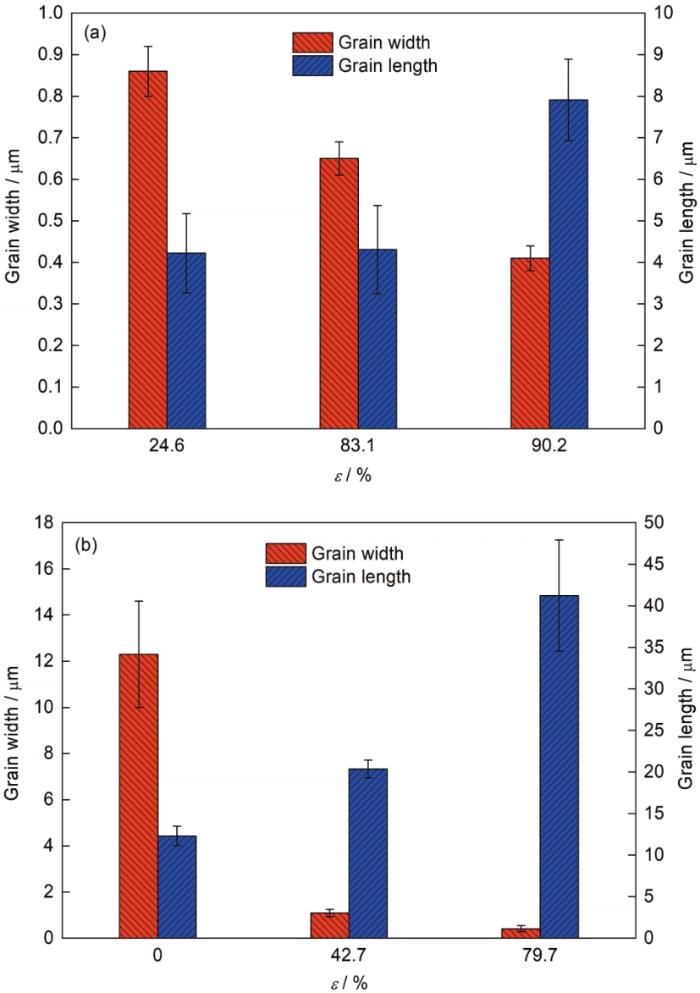

上述微观组织观察表明,随着拉拔变形量的增加,工业纯Al线和工业纯Cu线内的晶粒均沿着轴向被拉长,这种晶粒形状的演化与性能的变化规律密切相关。因此,为了准确地呈现晶粒的演化,本工作用晶粒宽度和晶粒长度2个参数来描述晶粒的尺寸。径向晶粒尺寸定义为晶粒宽度,轴向沿着拉拔方向相邻2个晶界间的尺寸定义为晶粒长度。基于上述的TEM和EBSD观察结果,统计了不同变形量的工业纯Al线和工业纯Cu线内晶粒宽度和晶粒长度,并建立了晶粒宽度和晶粒长度与拉拔变形量的关系(图6)。可以看出,工业纯Al线和工业纯Cu线的晶粒宽度均随着变形量的增大而逐渐减小。然而,在拉拔变形量从24.6%增加到83.1%的过程中,工业纯Al线的晶粒长度并没有显著变化,而经过90.2%变形量拉拔之后晶粒的长度明显增大。这与上文TEM观察结果(图2)一致,主要是因为晶粒在拉长的同时,内部也会形成新的晶界,这种晶界会将拉长的晶粒分割成许多小晶粒,从而导致平均晶粒长度变化不大。对于工业纯Cu线,当变形量从0增加至42.7%时,晶粒长度则从12.3 μm增加至20.4 μm;继续增大变形量至79.7%时,工业纯Cu线晶粒长度则大幅增加至41.2 μm。综上,对于工业纯Al和工业纯Cu线,晶粒宽度随着变形量的增大逐渐减小,晶粒长度则在变形初期表现为缓慢增加,在变形后期则大幅增加。

图6

图6

工业纯Al线和工业纯Cu线内晶粒宽度和晶粒长度随拉拔变形量变化规律

Fig.6

Evolutions of the grain width and grain length of the commercially pure Al wires (a) and the commercially pure Cu wires (b) related to ε

2.5 织构演化

工业纯Al线和工业纯Cu线径向织构的形成将对其强度产生影响。织构体积分数通过下式计算[49]:

式中,f<hkl>是<hkl>取向织构的体积分数,S<hkl>是<hkl>取向晶粒的总面积,S0是统计部分总面积。

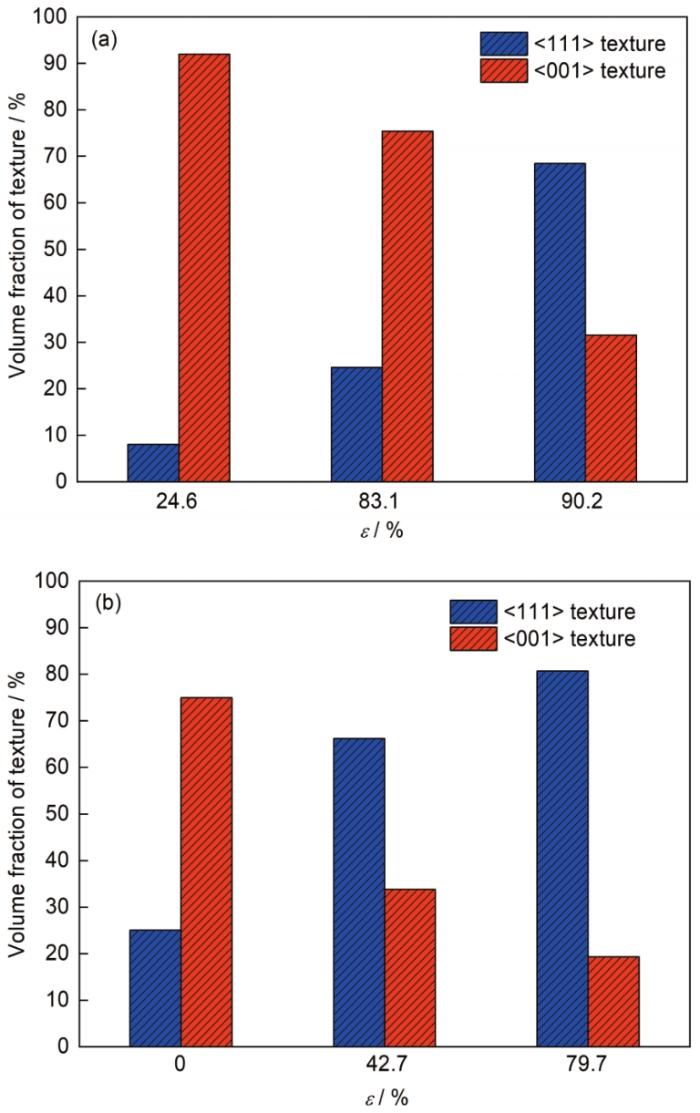

对于工业纯Cu杆,其内部存在少量的<101>取向晶粒,由于<101>取向晶粒和<001>取向晶粒具有相同的Schmid因子。因此,为了便于统计,本工作将工业纯Cu杆内<101>取向晶粒的体积分数计入<001>取向织构的体积分数,统计结果见图7。经过24.6%变形量拉拔的工业纯Al线中<111>织构体积分数仅为8.0%,<001>织构体积分数则高达92.0%。随着拉拔变形量的增加,<111>织构体积分数逐渐增加,<001>织构体积分数逐渐减小。当变形量增加至90.2%时,<111>织构体积分数达到68.5%,而<001>织构体积分数则减少到31.5%。对于工业纯Cu线,当变形量逐渐增加至79.7%时,工业纯Cu线内<001>织构体积分数下降至19.3%,而<111>织构的体积分数则显著增大至80.7%。

图7

图7

工业纯Al线和工业纯Cu线织构体积分数与变形量的关系

Fig.7

Relations between the volume fractions of texture and ε of the commercially pure Al wires (a) and the commercially pure Cu wires (b)

上述的微观组织观察和定量统计结果表明,在变形初期,工业纯Al线和工业纯Cu线的微观组织处于演化阶段,尚未形成明晰的微观组织特征。而在变形后期,随着拉拔变形量的不断增大,晶粒形状和晶体取向演化趋于稳定,工业纯Al线和工业纯Cu线内部晶粒均演化为纤维状的晶粒,即在径向为等轴状,在轴向为拉长状的晶粒。此外,在径向形成了明显的<111>织构。所以,拉拔加工的工业纯Al线和工业纯Cu线内形成了晶粒形状异构和晶体取向异构的微观组织特征。

3 分析讨论

3.1 强化机制

对于具有织构的金属材料,其强化机制主要包括固溶强化、析出强化、晶界强化、织构强化和位错强化。由于本工作的研究对象为工业纯Al线和工业纯Cu线,其内部合金元素含量较低,因而可以不考虑固溶原子和析出相对强度的影响。

式中,Ω<hkl>和σ<hkl>分别表示<hkl>取向的Schmid因子和屈服强度。对于一种材料,临界分切应力是固定值,那么屈服强度与Schmid因子成反比例关系。Schmid因子越大,其屈服强度越小,反之亦然[51]。<111>取向的Schmid因子是0.272,<001>取向和<101>取向的Schmid因子都是0.484,所以<111>取向的Schmid因子小于<101>取向和<001>取向。那么,与<001>取向和<101>取向相比,<111>取向可以称作硬取向[52]。从图7可以看到,随着变形量的增大,<001>织构的体积分数逐渐下降,<111>织构的体积分数逐渐增加,这种软取向织构向硬取向织构转变的现象必然会提高材料的强度。

综上,晶粒宽度减小导致的细晶强化和<111>织构形成引起的织构强化是工业纯Al线和工业纯Cu线的强化机制,此外,位错强化也是工业纯Cu线强度提高的一方面原因。

3.2 导电机制

根据Matthiessen定则,金属材料的电阻率由2部分组成:与温度相关的ρT项和与温度无关的ρR项。与温度无关的项主要包括金属材料中的缺陷,如位错、晶界、析出相和固溶原子。因此,金属的电阻率(ρ)可以表示成下式[55]:

式中,ρmatrix是纯基体的电阻率,ρd是位错导致的电阻率,ρss和ρp分别是固溶原子和析出相引起的电阻率。

由于本工作研究的工业纯Al线和工业纯Cu线内部存在较少的固溶原子和析出相,并且在拉拔变形过程中未观察到第二相的回溶和析出,所以本工作只需考虑晶界和位错对工业纯Al线和工业纯Cu线导电性能的影响。研究[56~58]表明,经过大塑性变形加工的工业纯Al内位错密度达到饱和时,位错所引起的电阻率仅为2.7 × 10-11 Ω·m,为纯Al电阻率的0.1%。所以,位错引起的电阻率通常可以忽略不计。另外,在本工作中,工业纯Al线的位错密度始终处于较低的水平,工业纯Cu线虽在变形初期观察到位错数量的大幅增加,但在变形后期位错数量并未观察到显著变化。因此,对于工业纯Al线和工业纯Cu线,晶界是影响导电率演化规律的主要因素,这一观点在Sauvage等[59]和Miyajima等[39]的研究工作中也得到了验证。所以,本工作重点讨论晶界对工业纯Al线和工业纯Cu线导电率的影响机制。

由于工业纯Al线和工业纯Cu线内晶粒在拉拔作用下被明显拉长,并且晶粒轴向方向与电流方向平行,因而,工业纯Al线和工业纯Cu线内的晶界按照与电流方向的位向关系可以分为平行晶界和垂直晶界,即分别为与电流方向平行的晶界和与电流方向垂直的晶界。因此,工业纯Al线和工业纯Cu线内晶界的电阻率可以用下式描述[39]:

式中,

3.3 高强高导机制

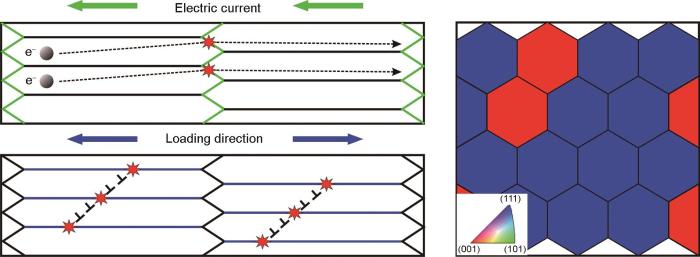

基于以上关于工业纯Al线和工业纯Cu线强化机制和导电机制的分析,本工作进一步提出了工业纯Al线和工业纯Cu线的高强高导机制。晶粒形状演化对工业纯Al线和工业纯Cu线强度和导电率的影响较为显著。微观组织观察表明,工业纯Al线和工业纯Cu线内晶粒沿着轴向方向被拉长,如图8所示,平行晶界与电流方向平行,对电子散射作用较小,但会起到明显的晶界强化效果。垂直晶界能够明显地散射电子,但不会影响工业纯Al线和工业纯Cu线的强度。因此,当减小晶粒宽度时,即增加平行晶界,能够起到细晶强化的效果,但损失的导电率较小;当晶粒长度增加时,即垂直晶界数量减少,能够降低晶界对电子的散射,提高导电率的同时并不损失强度。此外,当织构类型从<001>转向<111>时,可以起到织构强化效果,并且,晶体取向的转动不会额外增加晶体的缺陷,因而不损害导电率。所以,晶粒形状异构和晶体取向异构的组织是工业纯Al线和工业纯Cu线强度和导电率同步提高的根本原因。此外,这种晶粒异构设计的思路在理论上也可应用于实现其他金属导体丝线的高强高导。

图8

图8

高强高导金属线材晶粒异构设计原理示意图

Fig.8

Schematic of heterogeneous grain design principle for metallic metal wire achieving high strength and high electrical conductivity

4 结论

(1) 工业纯Al线和工业纯Cu线的导电率随拉拔变形量的增加呈现出先下降后上升的规律,即在变形初期,强度和导电率呈现制约关系,但是当拉拔变形量超过某一临界值后,强度和导电率出现同步提升的现象,打破了传统认识中的强度-导电率制约关系。

(2) 随着拉拔变形量的增大,工业纯Al线和工业纯Cu线轴向晶粒被逐渐拉长,径向等轴状晶粒逐渐细化,此外,径向组织中<001>织构逐渐向<111>织构转变,最终在工业纯Al线和工业纯Cu线内形成了晶粒形状异构和<111>晶体取向异构的微观组织。

(3) 径向晶粒宽度主要影响强度,轴向晶粒长度主要影响导电率,<111>织构提高强度但不损害导电率,进而提出晶粒形状异构和晶体取向异构打破强度-导电率制约关系的微观组织设计原则。

参考文献

Microstructure evolution and strengthening mechanisms of cold-drawn commercially pure aluminum wire

[J].

A high-strength, ductile Al-0.35Sc-0.2Zr alloy with good electrical conductivity strengthened by coherent nanosized-precipitates

[J].

Ductility and electrical conductivity of metallic materials are inversely correlated with their strength, resulting in a difficulty of optimizing all three simultaneously. We design an Al-Sc-Zr-based alloy using semisolid extrusion to yield a good trade-off between strength and ductility along with excellent electrical conductivity. The Al-0.35Sc-0.2Zr wire with a diameter of 3?mm exhibited the best combined properties: a tensile strength of 210?±?2?MPa, elongation of 7.6%?±?0.5%, and an electrical conductivity of 34.9?±?0.05?MS/m. The average particle size of nanosized Al3(Sc, Zr) precipitates increased from 6.5?±?0.5?nm to 25.0?±?0.5?nm as the aging time increased from 1?h to 96?h at 380?°C, accompanied by the corresponding volume fraction variation from (6.2?±?0.1)?×?10-4 to (3.7?±?0.1)?×?10-3. As proved by transmission electron microscopy observation, the high strength originates from the effective blockage of dislocation motion by numerous nanosized Al3(Sc, Zr) precipitates whilst both electrical conductivity and ductility remain at a high level due to the coherent precipitates possessing an extremely low electrical resistivity.

Enhancement of strength and electrical conductivity for a dilute Al-Sc-Zr alloy via heat treatments and cold drawing

[J].Developing heat-resistant conductors with high strength and high electrical conductivity is a key issue in the electrical conductor industries, as the ever-increasing power transmission poses higher requirement on the thermal stability of electrical conductor wires. Dilute Al-Sc-Zr alloys are considered as promising candidates due to the excellent heat resistance and high electrical conductivity, but the low strength always limits their application on electrical wires. Yet, few efforts on process design have been made in dilute Al-Sc-Zr alloys to enhance the strength. Here, various kinds of processing paths via combination of cold drawing, ageing and/or annealing were conducted to improve the strength and electrical conductivity of a dilute Al-Sc-Zr alloy. Results show that enhanced strength and electrical conductivity were obtained after cold drawing + ageing or pre-ageing + cold drawing + annealing treatments processes. Optimal properties (194 MPa in ultimate tensile strength and 61% IACS in electrical conductivity) were obtained through cold drawing followed by ageing. Microstructure evolution which affects strength and electrical conductivity was systematically investigated using TEM and 3DAP. The enhanced strength was mainly attributed to the suitable interactions between strain strengthening and precipitation strengthening. The enhancement in electrical conductivity was caused by precipitation of solute atoms and recovery of defects. These results provide foundations for the processing design of Al-Sc-Zr conducting wires with good properties and push forward their potential application in heat resistant conductor industries.

Effects of La addition on the mechanical properties and thermal-resistant properties of Al-Mg-Si-Zr alloys based on AA 6201

[J].

Microstructure and properties of a novel Cu-Mg-Ca alloy with high strength and high electrical conductivity

[J].

Research on the microstructure and properties of in situ (TiB2-TiB)/Cu composites

[J].

原位(TiB2-TiB)/Cu复合材料组织与性能研究

[J].采用机械合金化和热压烧结相结合的方法制备出原位TiB<sub>2</sub>颗粒和TiB晶须混杂增强的铜基复合材料,利用XRD、OM、SEM、TEM研究了复合材料的微观组织,分析了热压烧结过程中的原位反应机理及微观组织对复合材料硬度、导电率及致密度的影响规律。结果表明:原位反应过程为Cu和Ti原始粉末在800 ℃开始反应生成Cu<sub>3</sub>Ti中间相,在850 ℃时达到Cu<sub>3</sub>Ti中间相的熔点并在基体中形成液相微区,然后B原子扩散至该液相微区,在继续加热过程中原位析出硼化钛增强相。TiB晶须含量相对较多的复合材料具有较高的硬度,TiB<sub>2</sub>颗粒含量相对较多的复合材料具有较高的导电率,TiB晶须和TiB<sub>2</sub>颗粒混杂增强的铜基复合材料则同时兼备了以上2种复合材料的性能优势,其综合性能得到优化。所得烧结态3%(TiB<sub>2</sub>-TiB)/Cu混杂增强复合材料的硬度和导电率分别达到86.6 HB和70.4% IACS。

Additive manufacturing of high strength copper alloy with heterogeneous grain structure through laser powder bed fusion

[J].

Optimization of the balance between high strength and high electrical conductivity in CuCrZr alloys through two-step cryorolling and aging

[J].

Quantitative mechanisms behind the high strength and electrical conductivity of Cu-Te alloy manufactured by continuous extrusion

[J].The microstructure, mechanical performance, and electrical conductivity of Cu-Te alloy fabricated by continuous extrusion were quantitatively investigated. The results demonstrate that the grain size of the Cu-Te alloy is refined significantly by incomplete dynamic recrystallization. The Cu2Te phase stimulates recrystallization and inhibits subgrain growth. After extrusion, the tensile strength increases from 217.8 ± 4.8 MPa to 242.5 ± 3.7 MPa, the yield strength increases from 65.1 ± 3.5 MPa to 104.3 ± 3.8 MPa, and the yield to tensile strength ratio is improved from 0.293 ± 0.015 to 0.43 ±.0.091, while the electrical conductivity of room temperature decreases from 95.8 ± 0.38% International Annealed Cu Standard (IACS) to 94.0% ± 0.32% IACS. The quantitative analysis shows that the increment caused by dislocation strengthening and boundary strengthening account for 84.6% of the yield strength of the extruded Cu-Te alloy and the electrical resistivity induced by grain boundaries and dislocations accounts for 1.6% of the electrical resistivity of the extruded Cu-Te alloy. Dislocations and boundaries contribute greatly to the increase of yield strength, but less to the increase of electrical resistivity.

Modification of AA-6201 alloy for manufacturing of high conductivity and extra high conductivity wires with property of high tensile stress after artificial aging heat treatment for all-aluminium alloy conductors

[J].

Mechanical properties of novel aluminum metal matrix metallic composites: Application to overhead conductors

[J].

Microstructure strengthening mechanisms in different equal channel angular pressed aluminum alloys

[J].

Improvement of strength of magnesium alloy processed by equal channel angular extrusion

[J].

Microstructure of the post-ECAP aging processed 6061 Al alloys

[J].

Microstructural evolution in pure aluminum processed by high-pressure torsion

[J].

Strengthening mechanisms in nanostructured high-purity aluminium deformed to high strain and annealed

[J].

Novel ultra-high straining process for bulk materials-development of the accumulative roll-bonding (ARB) process

[J].

Coupling between phonon-phonon and phonon-impurity scattering: A critical revisit of the spectral Matthiessen's rule

[J].

Mechanical and electrical properties of mechanically alloyed nanocrystalline Cu-Nb alloys

[J].

Nanostructured Al and Cu alloys with superior strength and electrical conductivity

[J].

Nanostructured aluminium alloys produced by severe plastic deformation: New horizons in development

[J].

A nanostructural design to produce high-strength Al alloys with enhanced electrical conductivity

[J].

Mechanical and electrical properties of an ultrafine grained Al-8.5wt.% RE (RE = 5.4wt.% Ce, 3.1wt.% La) alloy processed by severe plastic deformation

[J].

Enhanced mechanical properties and electrical conductivity in ultrafine-grained Al alloy processed via ECAP-PC

[J].

Effect of ECAP combined cold working on mechanical properties and electrical conductivity of Conform-produced Cu-Mg alloys

[J].

Inoculation of transition elements by addition of AlB2 and AlB12 to decrease detrimental effect on the conductivity of 99.6% aluminium in CCL for manufacturing of conductor

[J].

Effect of cerium on mechanical performance and electrical conductivity of aluminum rod for electrical purpose

[J].

Effects of grain refinement and boron treatment on electrical conductivity and mechanical properties of AA1070 aluminum

[J].

Effect of Ce addition on castability, mechanical properties and electric conductivity of Al-0.3Si-0.2Mg alloy

[J].

Investigation on the Cu-Cr-RE alloys by rapid solidification

[J].

Three principles for preparing Al wire with high strength and high electrical conductivity

[J].<p>The trade-off relation between the strength and the electrical conductivity has been a long-standing dilemma in metallic materials. In the study, three key principles, i.e. elongated grains, sharp texture and nano-scale precipitates, were presented for preparing Al wire with high strength and high electrical conductivity based on the specially designed experiments for breaking the mutually exclusive relation between the strength and the electrical conductivity. The results show that the elongated grains could lead to a higher electrical conductivity in Al wire without sacrificing the strength; while, the <111> sharp texture can efficiently strengthen the Al wire without influencing the electrical conductivity. Furthermore, nano-scale precipitates with proper size can simultaneously improve the strength and electrical conductivity of Al alloy wire. Under the guidance of the above three key principles, Al wires with high strength and high conductivity were prepared.</p>

Nano-scale precipitates: The key to high strength and high conductivity in Al alloy wire

[J].

Microstructure evolution and properties of a Cu-Cr-Zr alloy with high strength and high conductivity

[J].

A high strength and high electrical conductivity Cu-Cr-Zr alloy fabricated by cryogenic friction stir processing and subsequent annealing treatment

[J].

Enhanced strength and electrical conductivity of Cu-Zr-B alloy by double deformation-aging process

[J].

What is behind the inverse Hall-Petch effect in nanocrystalline materials?

[J].

The deformation and ageing of mild steel: III Discussion of results

[J].

The Hall-Petch relation in aluminium and its dependence on the grain boundary structure

[J].

Change in electrical resistivity of commercial purity aluminium severely plastic deformed

[J].

The conflicts between strength and toughness

[J].The attainment of both strength and toughness is a vital requirement for most structural materials; unfortunately these properties are generally mutually exclusive. Although the quest continues for stronger and harder materials, these have little to no use as bulk structural materials without appropriate fracture resistance. It is the lower-strength, and hence higher-toughness, materials that find use for most safety-critical applications where premature or, worse still, catastrophic fracture is unacceptable. For these reasons, the development of strong and tough (damage-tolerant) materials has traditionally been an exercise in compromise between hardness versus ductility. Drawing examples from metallic glasses, natural and biological materials, and structural and biomimetic ceramics, we examine some of the newer strategies in dealing with this conflict. Specifically, we focus on the interplay between the mechanisms that individually contribute to strength and toughness, noting that these phenomena can originate from very different lengthscales in a material's structural architecture. We show how these new and natural materials can defeat the conflict of strength versus toughness and achieve unprecedented levels of damage tolerance within their respective material classes.

Microstructure and mechanical properties of a FeMnCoCr high-entropy alloy with heterogeneous structure

[J].Growing attention has been placed on high-entropy alloys (HEAs) owing to their promising mechanical properties. Particularly, HEAs in which the main crystal structure is fcc are attracting significant attention. Although such alloys exhibit a good combination of strength and ductility, they cannot meet the increasing demands of applications because of limited yield strengths. In recent years, researchers have tried to improve yield strengths of HEAs by refining grains and introducing interstitial atoms. However, the processing cost is high and is often accompanied by the significant loss of ductility. In this study, we propose a simple processing route incorporating cold rolling at medium thickness reductions and short-time annealing at medium temperatures to obtain a heterogeneous structure in Fe-Mn based HEAs consisting of deformed grains with an average diameter of several tens of microns and recrystallized ultrafine grains. By simultaneously introducing multiple strengthening mechanisms, including the strengthening contributed by the microstructural characteristics of dense dislocations, grain refinement, precipitates, ε-martensite, α-martensite, and recovery twins, as well as the strengthening induced by deformation twinning and ε-martensite phase transition that occurs continuously during deformation, the yield strength of the alloy significantly increases compared with that of the fully recrystallized material and reaches 825 MPa. Simultaneously, due to the activation of significant deformation twinning and deformation-induced martensitic transformation, the uniform elongation of the alloy is about 28.6%. The proposed material fabrication method is simple, cost-effective, and can effectively improve the mechanical properties of Fe-Mn based HEAs, providing new insight into optimizing the mechanical properties of low stacking fault energy alloys of the fcc structure.

非均匀组织FeMnCoCr高熵合金的微观结构和力学性能

[J].提出了一种简单的高熵合金加工工艺,即对Fe-Mn系高熵合金采用中等形变量冷轧和中温短时退火相结合的方法,获得了由晶粒尺寸为数十微米的形变晶粒和超细尺度再结晶晶粒组成的非均匀结构。通过向合金中同时引入由高密度位错、晶粒细化、析出相、ε-马氏体、α-马氏体和回复孪晶等微观结构特征及变形过程中持续发生的形变孪生、ε-马氏体相变引起的多种强化机制,使屈服强度较充分再结晶态显著提升并达到825 MPa。同时,在塑性变形过程中由于发生了显著的形变孪生和一定的由形变诱发的奥氏体向ε-马氏体转变,合金仍具有约28.6%的均匀延伸率,合金的综合力学性能得到有效提升。该工艺为优化以fcc结构为主的低层错能合金的力学性能提供了新思路。

Heterogeneous materials: A new class of materials with unprecedented mechanical properties

[J].

Perspective on hetero-deformation induced (HDI) hardening and back stress

[J].

Enhanced cyclic deformation responses of ultrafine-grained Cu and nanocrystalline Cu-Al alloys

[J].

Fundamental factors on formation mechanism of dislocation arrangements in cyclically deformed fcc single crystals

[J].

Effect of intermediate annealing time on microstructure, texture and mechanical properties of Al-Mg-Si-Cu alloy

[J].

Texture evolution by shear on two planes during ECAP of a high-strength aluminum alloy

[J].

Influence of deformation and annealing on electrical conductivity, mechanical properties and texture of Al-Mg-Si alloy cables

[J].

Effects of annealing treatment on the microstructure evolution and the strength degradation behavior of the commercially pure Al conductor

[J].

Breaking the trade-off relation of strength and electrical conductivity in pure Al wire by controlling texture and grain boundary

[J].

Contribution to size effect of yield strength from the stochastics of dislocation source lengths in finite samples

[J].

Texture evolution in equal-channel angular extrusion

[J].

The dislocation distribution, flow stress, and stored energy in cold-worked polycrystalline silver

[J].

Microstructure and flow stress of polycrystals and single crystals

[J].

On the influence of temperature on the electric conducting-power of alloys

[J].

Assessment of strain energy by measuring dislocation density in copper and aluminium prepared by ECAP and ARB

[J].

Quantification of internal dislocation density using scanning transmission electron microscopy in ultrafine grained pure aluminium fabricated by severe plastic deformation

[J].

Microstructure development and hardening during high pressure torsion of commercially pure aluminium: Strain reversal experiments and a dislocation based model

[J].