超高温材料是指在应力、氧化、烧蚀等严苛环境中,以及约在2000℃及以上超高温状态下仍能正常使用的耐热尖端材料。如在材料学领域,从服役环境温度的角度,将在1800℃时仍具有超过200 MPa强度的高温高熵合金称为超高温高熵合金[1]。随着航空航天技术的发展,部分结构部件对材料耐高温性能提出了更为严苛的要求。例如,超音速飞行器在稠密的大气中飞行时,飞行器前端温度会随飞行速率增加而急剧上升,当飞行速率达到8 Ma时,头锥部分温度将升高到接近2000℃[2]。又如,对于推重比高达15~20的发动机的涡轮叶片,其使用温度已接近1900℃。传统镍基单晶高温合金的熔点为1400~1500℃,已无法满足服役要求[3]。对于传统难熔合金,如钨合金、钼合金等,尽管其具有较高熔点,但在2000℃时抗拉强度均低于100 MPa[4]。因此,迫切需要寻找并开发新型的超高温材料,使其在高温仍能保持较高的强度,满足极端环境下的服役要求;同时在室温具有较好的成型能力,以满足复杂精密结构的加工要求。

众所周知,金属材料的强度和塑性存在着本征的倒置关系,即材料强度的提高往往伴随着塑性或韧性的下降,2者之间一般呈现出此消彼长的反向制约关系。在材料软化行为发生前,从室温到高温该倒置关系均广泛存在。因此,对于传统金属材料,协同提高材料的强度和塑性一直是材料科学领域持续研究的热点和难点问题。超高温材料面临着更大的挑战:如何在保持高温优异力学性能的同时,还能兼顾优异的室温塑性和加工成型能力,相比于室温的强度与塑性之间的倒置关系,这2者更加难以协调。

近年来具有bcc结构的难熔高熵合金引起了材料界的广泛关注,其由多种难熔元素以等原子或近等原子比成分混合而成[5~8]。某些bcc结构难熔高熵合金在高温区间表现出较高的强度,甚至优于传统镍基高温合金。例如,等原子比的NbMoTaW和NbMoTaWV高熵合金在1600℃的压缩屈服强度分别高达405和477 MPa[9],HfNbTaTiZr高熵合金在1200℃具有92 MPa的屈服强度[10]。尽管难熔高熵合金表现出优异的高温强度,但是,其在未来使用中仍面临2个主要问题:一方面,多数难熔高熵合金在室温表现出严重脆性,例如,NbMoTaW高熵合金的室温压缩断裂应变不足3%,这为材料的室温成型带来了极大困难。尽管通过引入合金元素(如Ti[11]、Zr[12])或者添加B和C等轻质元素[13],能够在一定程度上提高NbMoTaW高熵合金的室温压缩塑性,但这同时也增加了合金设计的复杂程度和批量熔炼及加工制备的难度。另一方面,通常合金材料在温度高于(0.5~0.6)Tm (Tm为熔点)时会出现软化现象,即强度急剧下降。难熔高熵合金主元个数较多,为了提高其室温塑性,往往含有熔点相对较低的元素,如Ti (1660℃)、Zr (1852℃)等,无法避免在2000℃及以上超高温时潜在的材料软化行为。最近的研究[14]表明,在难熔高熵合金基体中引入共晶碳化物能够显著提高材料的高温强度,制备出的Re0.5MoNbW(TaC) x 合金在1200℃具有1.08 GPa的压缩屈服强度,同时在室温具有8.5%的压缩塑性,这为超高温难熔高熵合金的设计提供了新思路。

针对上述问题,本工作选择了以Ta为基体添加W元素的Ta-W合金,该体系的优势主要表现在以下3个方面:首先,Ta和W的熔点分别为2996和3410℃,2者所形成的置换式连续固溶体合金均具有超过3000℃的高熔点,可望在超高温下仍能保持相当的抗压强度。早期开发的商用Ta-W合金中W含量较低,通常不超过15% (原子分数,下同),获得的高温强度较低[15,16],如Ta-10W合金2000℃时的抗拉强度仅在100 MPa左右[17,18]。而适当增加W含量有望进一步提高高温力学性能,但面临可能带来其室温塑性显著降低的问题[15,16]。其次,Ta具有远低于室温的韧脆转变温度,相比于难熔高熵合金超过4种以上的主元配比,Ta-W二元体系更为简单,且有较为成熟的熔炼与热加工成型工艺作为参考,从而降低了在多维成分空间中搜索合金成分与制备的复杂程度,能够以更短的时间和成本获得具有更为优异力学性能的合金。基于以上考虑,本工作设计并制备了W含量分别为10%、20%、30%、40%和50%的Ta-W合金,测试了该合金体系的室温和2000℃高温压缩性能,以评估其在高温强度和室温塑性方面的潜力。

1 实验方法

1.1 样品制备

制备Ta-W合金的原料为高纯W块(99.9%)和Ta块(99.9%),在Ar气保护气氛下通过电弧熔炼使原料熔化,每种合金样品在电磁力的搅拌下反复翻转熔炼10次以保证成分均匀性,分别熔炼出不同W含量的Ta-W合金,即Ta-10%W、Ta-20%W、Ta-30%W、Ta-40%W和Ta-50%W。熔炼后在1600℃下对铸锭进行15 h的均匀化退火。

1.2 微观组织表征

为观察合金的微观组织,试样先后经过机械抛光和电解抛光处理,其中电解液的体积成分配比为H2SO4∶HF∶C2H5OH = 7∶3∶4,电压和电流强度分别为30 V和0.6 A。采用配有Cu靶的D8 ADCANCE型X射线衍射仪(XRD)分析Ta-W合金的相组成,扫描角度为10°~120°,扫描速率0.2°/s。使用配有能谱(EDS)探头的EVO 10型扫描电子显微镜(SEM)观察合金的微观组织。采用Image J软件得到其平均晶粒尺寸。

1.3 力学性能测试

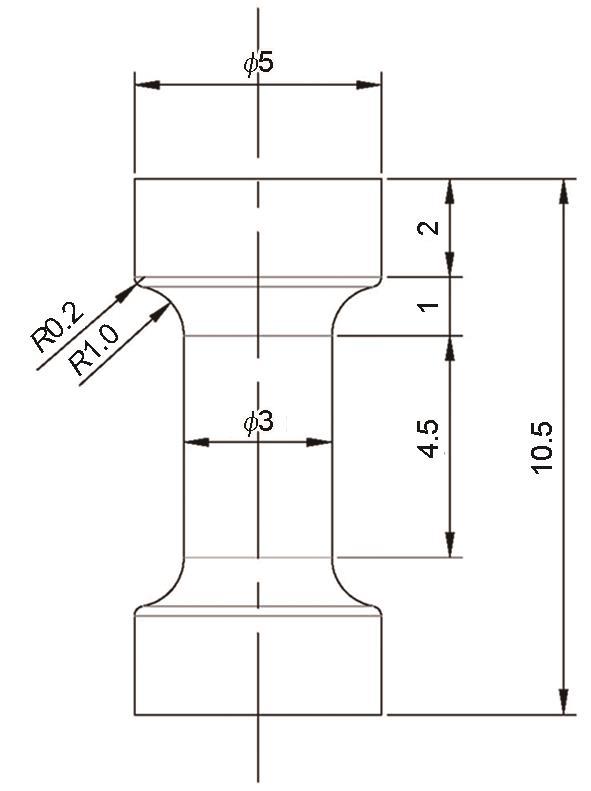

为了保证压缩测试的稳定性,压缩测试采用哑铃状试样,标距段尺寸为直径3 mm × 4.5 mm,如图1所示。利用Instron 5969电子万能材料试验机测试合金室温下的压缩性能,应变速率为3 × 10-4 s-1。利用ZwickRoell Kappa蠕变试验机测试高温压缩性能,试样安装在真空高温炉内,抽真空至1 Pa以下后通Ar气,采用辐射加热的方式以平均约35℃/min的速率升温,达到目标温度后保温10 min后进行压缩实验测试,应变速率约为10-3 s-1。不同成分的合金至少使用2个样品进行测试,以保证测试结果的有效性。

图1

图1

Ta-W合金压缩试样尺寸

Fig.1

Schematic of dimension of the Ta-W specimen for uniaxial compression tests (unit: mm)

2 实验结果

2.1 合金样品及相组成

图2

图2

电弧熔炼制备的不同W含量的Ta-W合金锭

Fig.2

Ingots of Ta-W alloys prepared using arc-melting

(a) Ta-10%W (b) Ta-20%W (c) Ta-30%W (d) Ta-40%W (e) Ta-50%W

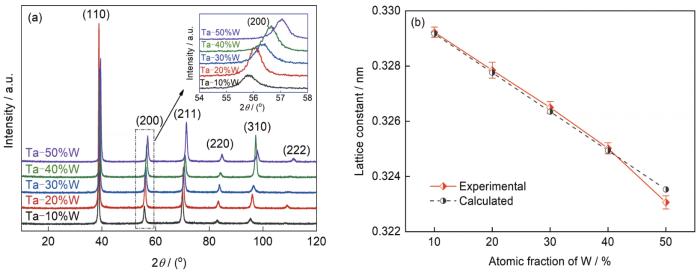

图3

图3

不同W含量Ta-W合金的XRD谱和晶格常数

Fig.3

XRD spectra of the Ta-W alloys (a) and the variation of lattice constant as a function of W concentration (b) (Inset in Fig.3a shows the locally enlarged view)

2.2 微观组织

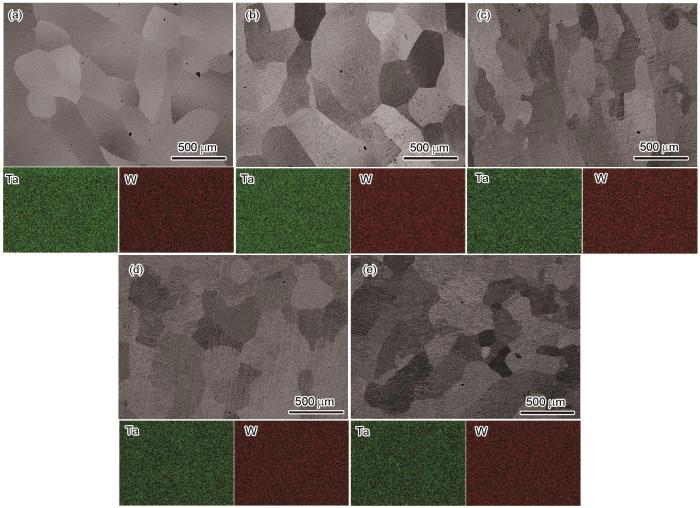

不同W含量Ta-W合金微观组织的SEM像和EDS面扫描结果如图4所示。Ta-W合金以等轴晶为主,少量晶粒呈现粗大的柱状晶形貌。随着W含量的增加晶粒尺寸显著减小,Ta-10%W、Ta-20%W、Ta-30%W、Ta-40%W和Ta-50%W合金的平均晶粒尺寸分别为427、313、276、255和190 μm。利用EDS表征了合金中Ta和W的元素分布,未发现第二相或者微观成分偏析,表明该合金形成了Ta和W均匀互溶的单相固溶体组织。

图4

图4

Ta-W合金的微观组织的SEM像及其EDS面扫描分析

Fig.4

SEM images and EDS mapping of Ta-10%W (a), Ta-20%W (b), Ta-30%W (c), Ta-40%W (d), and Ta-50%W (e) alloys

2.3 室温和高温的压缩性能

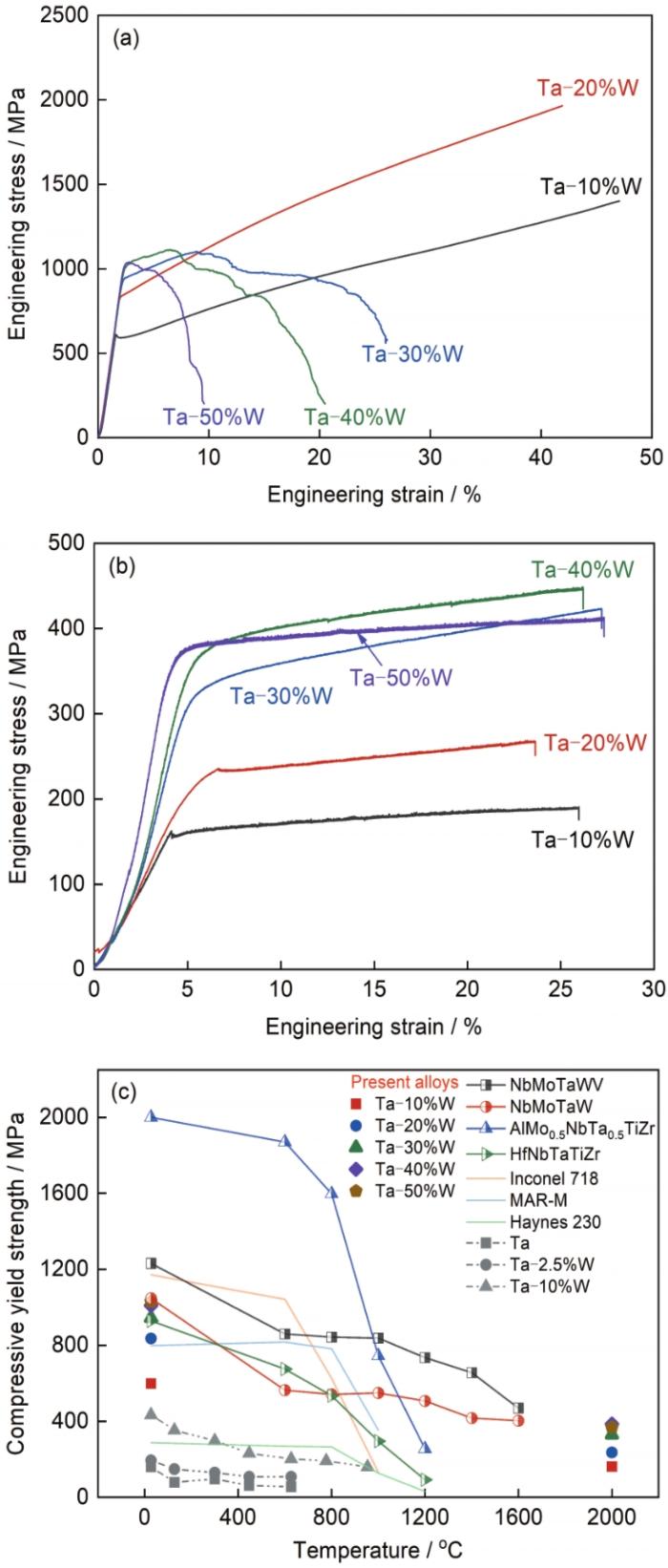

图5a为不同W含量Ta-W合金室温压缩的工程应力-应变曲线。可以看出,Ta-W合金的室温压缩强度随着W含量的增加而逐步升高。其中,Ta-10%W和Ta-20%W合金的屈服强度分别达到599和836 MPa。而进一步增加W含量,样品屈服强度继续增加的幅度并不显著,Ta-30%W、Ta-40%W和Ta-50%W合金的屈服强度分别为944、1010和1030 MPa (表1)。同时,Ta-W合金的压缩塑性也与W含量密切相关,对于Ta-10%W和Ta-20%W合金,当压缩应变超过40%以上时样品仍未断裂,表现出较好的室温压缩塑性。但是,随着W含量的进一步增加,特别是Ta-40%W和Ta-50%W合金的压缩断裂应变显著降低。

图5

图5

Ta-W合金25和2000℃高温压缩性能,以及该合金与文献中Ta-W合金[23]和难熔高熵合金[9,24~29]压缩性能的对比(列出了商业镍基高温合金[30]的拉伸强度作为参考态)

Fig.5

Compressive engineering stress-strain curves of Ta-W alloys at 25oC (a) and 2000oC (b), temper-ature dependence of compressive yield strength of Ta-W alloys in this work, Ta-W alloys[23], typical refractory high-entropy alloys[9,24-29] (The tensile yield strength for commercial Ni-based superalloys[30] are shown for reference) (c)

表1 Ta-W合金在25和2000℃下压缩屈服强度实验测量值与理论预测值 (MPa)

Table 1

| Alloy | 25oC | 2000oC | ||

|---|---|---|---|---|

| Experimental | Predicted | Experimental | Predicted | |

| Ta-10%W | 599 | 457 | 162 | 98 |

| Ta-20%W | 836 | 703 | 236 | 150 |

| Ta-30%W | 944 | 817 | 330 | 187 |

| Ta-40%W | 1010 | 905 | 385 | 224 |

| Ta-50%W | 1030 | 870 | 369 | 218 |

图5c对比了不同温度下本工作的Ta-W合金及文献中Ta-W合金[23]与现有主要难熔高熵合金[9,24~29]和镍基高温合金[30]的压缩(拉伸)屈服强度。可以看出,商用镍基高温合金在温度超过1200℃已失去强度,无法满足更高温度的服役要求。由于当前开发的难熔高熵合金体系较多,本工作仅选择了几个典型的难熔高熵合金用以对比,包括室温强度最高的AlMo0.5NbTa0.5TiZr[29]、室温塑性较好的HfNbTaTiZr[28]以及高温强度最高的NbMoTaW(V)[9]。大多数难熔高熵合金,如AlMo0.5NbTa0.5TiZr和HfNbTaTiZr,在1300℃时屈服强度已低于200 MPa,只有NbMoTaW和NbMoTaWV合金仍能保持较高的高温压缩强度,其在1600℃压缩强度超过400 MPa。相比之下,本工作的Ta-W合金表现出更为优异的高温力学性能,其在2000℃下仍能具有高于200 MPa的压缩强度,可望媲美甚至超过目前高温性能最优异的NbMoTaW(V)难熔高熵合金(其2000℃及以上温区的性能尚未见报道)。而且,相比于难熔高熵合金室温压缩塑性不足3%的局限性,本工作的Ta-W合金能兼具相当的室温加工性能。例如,Ta-20%W合金在室温能够承受超过40%的压缩应变,并可以机加工(见图5a)。

3 分析讨论

如上所示,W的添加能够有效提高Ta-W合金室温和高温的压缩强度。下面分析Ta-W合金的强化机制,揭示W对Ta-W合金压缩强度的影响规律。

3.1 晶界强化机制

3.2 固溶强化机制

式中,

图6

图6

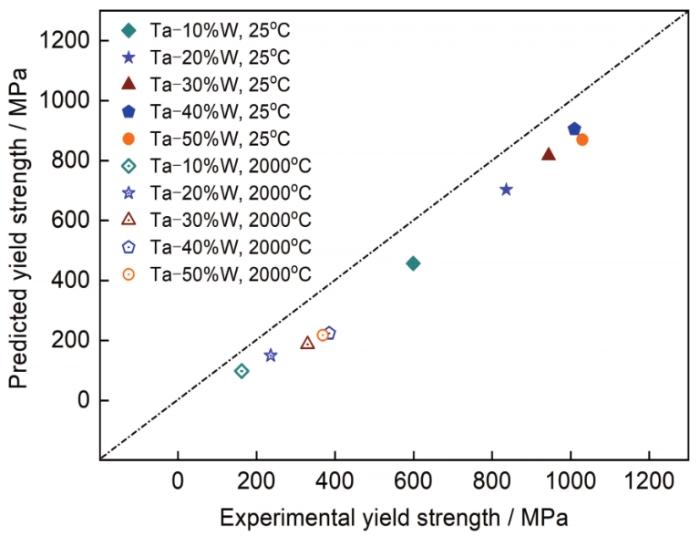

25和2000℃下Ta-W合金理论模型预测和实验测量的压缩屈服强度的对比

Fig.6

Comparisons of the predicted and experimental values for compressive yield strength at 25 and 2000oC in Ta-W alloys

4 结论

本工作设计并通过电弧熔炼制备了系列Ta-W合金(W含量为10%~50%),该合金为单相的bcc结构固溶体。随着W含量的增加,Ta-W合金的晶格常数和晶粒尺寸逐渐减小。W含量的增加显著提高了Ta-W合金的室温和高温压缩强度。Ta-20%W合金2000℃的压缩屈服强度超过200 MPa,且兼具较好的室温压缩塑性和成型能力。该合金体系有望作为新一代超高温承载材料,应用于制备航空航天的关键承载耐高温部件。

参考文献

Research progress in novel high-temperature high entropy alloys

[J].

新型高温高熵合金材料研究进展

[J].

Hypersonic airbreathing propulsion

[J].

Recent progress in research and development of Nickel-based single crystal superalloys

[J].

镍基单晶高温合金的研发进展

[J].

Research development of refractory metal materials used in the field of aerospace

[J].

航天航空用难熔金属材料的研究进展

[J].

A critical review of high entropy alloys and related concepts

[J].

Refractory high-entropy alloys

[J].

Research progress of refractory high-entropy alloys

[J].

难熔高熵合金的研究进展

[J].

Research progress of low-density and high-entropy alloys

[J].

低密度高熵合金的研究进展

[J].

Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys

[J].

Comprehensive data compilation on the mechanical properties of refractory high-entropy alloys

[J].This data article presents the compilation of mechanical properties for 122 refractory high entropy alloys (RHEAs) and refractory complex concentrated alloys (RCCAs) reported in the period from 2010 to the end of January 2018. The data sheet gives alloy composition, type of microstructures and the metallurgical states in which the properties are measured. Data such as the computed alloy mass density, the type of mechanical loadings to which they are subjected and the corresponding macroscopic mechanical properties, such as the yield stress, are made available as a function of the testing temperature. For practical use, the data are tabulated and some are also graphically presented, allowing at a glance to access relevant information for this attractive category of RHEAs and RCCAs.

Microstructures and mechanical properties of Ti x NbMoTaW refractory high-entropy alloys

[J].

A novel ZrNbMoTaW refractory high-entropy alloy with in-situ forming heterogeneous structure

[J].

Solving oxygen embrittlement of refractory high-entropy alloy via grain boundary engineering

[J].

Metal-carbide eutectics with multiprincipal elements make superrefractory alloys

[J].

Numerical simulation and experimental investigation of micro plasma arc welding of tantalum tungsten alloy thin sheets

[D].

钽钨合金薄板微束等离子弧焊数值模拟与实验研究

[D].

Industry applications of tantalum and tantalum alloy

[J].

钽及钽合金在工业装备中的应用

[J].

Mechanical properties of alloy Ta-10W at elevated temperature

[J].

Ta-10W合金的高温力学性能

[J].

New applications for tantalum and tantalum alloys

[J].

Preparation, structures and properties of tungsten-containing refractory high entropy alloys

[J].

含钨难熔高熵合金的制备、结构与性能

[J].

Manufacture of WNbMoTa high performance high-entropy alloy by laser additive manufacturing

[J].With the universal improvement of the manufacturing requirements of temperature-resistant high-end equipment in industry,the existing alloy systems and traditional manufacturing processes have difficulties in meeting the current requirements. High-entropy alloys and laser additive manufacturing technology are coupled to provide a new solution for the overall manufacturing of large-size and complex high-end equipment parts in China. On the one hand, a variety of high-entropy alloys such as WNbMoTa and NbMoTa are formed by the laser cladding deposition. The grain size of the formed alloys is small and the constitutional segregation is not obvious. Among them, the yield strength of NbMoTa alloy under 1 000℃ reaches to 530 MPa, higher than GH4169, DZ125 high-temperature alloys used in domestic aero-engine turbine blades and T111, C103, Nb-1Zr refractory alloys used in domestic aerospace industry. On the other hand, the thermal stress and strain during high-entropy alloys forming are simulated based on FD-FE simulation, solving the problem that the samples are easy to warp in the process of selective laser melting.

激光增材制造WNbMoTa高性能高熵合金

[J].随着工业实践中高端装备耐温部件整体制造要求的提高,现有合金材料体系、制造工艺难以满足需求。研究将高熵合金材料与激光增材制造技术耦合,为我国大尺寸、复杂高端装备零部件的整体制造提供了新的解决方案。一方面,通过激光熔覆沉积技术成形了WNbMoTa、NbMoTa等多种高性能高熵合金,成形的高熵合金晶粒尺寸细小且无微观成分偏析。其中NbMoTa高熵合金1 000℃下屈服强度达到530 MPa,高于国内应用于航空发动机涡轮叶片的GH4169、DZ125高温合金和应用于航空航天工业的T111、C103、Nb-1Zr难熔合金。另一方面,通过基于有限差分-有限元数值模拟的方法对高熵合金材料成形过程中的热应力与应变进行数值模拟,解决了选区激光熔化成形高熵合金过程中样件易翘曲的问题。

Effects of Boron on the microstructure and mechanical properties of NbMoTiVSi0.2 refractory high entropy alloys

[J].

B对NbMoTiVSi0.2难熔高熵合金组织与力学性能的影响

[J].

The effect of grain boundaries on the athermal stress of tantalum and tantalum-tungsten alloys

[J].

Effect of aluminum on the microstructure and properties of two refractory high-entropy alloys

[J].

Microstructure and properties of a refractory NbCrMo0.5Ta0.5TiZr alloy

[J].

Mechanical properties of low-density, refractory multi-principal element alloys of the Cr-Nb-Ti-V-Zr system

[J].

Microstructure and mechanical properties of refractory MoNbHfZrTi high-entropy alloy

[J].

Microstructure and elevated temperature properties of a refractory TaNbHfZrTi alloy

[J].

Development of a refractory high entropy superalloy

[J].

High-entropy alloys: Potential candidates for high-temperature applications—An overview

[J].

Effect of grain size on the tensile behavior of V10Cr15Mn5Fe35Co10Ni25 high entropy alloy

[J].

A unified constitutive model for quasi-static flow responses of pure Ta and Ta-W alloys

[J].

Vanadium is an optimal element for strengthening in both fcc and bcc high-entropy alloys

[J].

Mechanistic origin of high strength in refractory BCC high entropy alloys up to 1900 K

[J].

Theory of strengthening in fcc high entropy alloys

[J].

First-principles-based prediction of yield strength in the RhIrPdPtNiCu high-entropy alloy

[J].