近年来,由4种或4种以上主元元素组成的高熵合金凭借其独特的力学性能和形变机制而受到材料学界的关注。这类合金具有多种特殊效应,包括热力学上的高熵效应、动力学上的迟滞扩散效应和晶体学上的晶格畸变效应[1]。目前,已研究的高熵合金主要被分为3类,分别为具有fcc结构的3d过渡族金属合金[2~4]、具有bcc结构的难熔金属合金[5~7]和其他类型的合金[8~10]。等原子比FeCoNiCrMn高熵合金 (又称为Cantor合金[11])为单相fcc结构,因其具有良好的强度与塑性匹配而被广泛研究[12~15]。Li等[16,17]和Deng等[18]在此基础上通过调控元素的种类和比例,开发了综合力学性能更为优越的非等主元亚稳态Fe50Mn30Co10Cr10高熵合金,并阐明了相变诱导塑性(transformation induced plasticity,TRIP)和孪生诱导塑性(twinning induced plasticity,TWIP) 2种效应协同作用对同时提升合金的强度与塑性的重要性。Lu等[19]在对Fe50Mn30Co10Cr10高熵合金的进一步研究中,发现了全新的双向相变诱导塑性(bidirectional transformation induced plasticity,B-TRIP)机制,即形变过程中同时发生了奥氏体向hcp马氏体转变与hcp马氏体向奥氏体的逆转变,共同促进纳米片层结构的形成和合金持久的微结构细化,这是材料具有良好加工硬化能力的重要原因。在Fe-Mn、Fe-Co-Ni或Co-Cr-Ni系高熵合金中,TWIP、TRIP和B-TRIP效应的发生均可使微观组织在变形过程中被动态地细化,从而提高合金的抗拉强度[20~22]。但由于这类合金是以fcc结构为主的单相或双相合金,其屈服强度往往较低(不超过500 MPa),难以满足实际工程应用的需求。因此,在不增加昂贵金属元素的前提下,如何在有效提高以fcc为主要晶体结构的高熵合金屈服强度的同时,使其仍保持良好的均匀塑性变形的能力是材料研究者面临的问题。

目前,多种提高金属材料屈服强度的传统方法已被应用到高强韧性高熵合金的开发中。例如,He等[23]通过在FeCoNiCr高熵合金中加入少量的Al和Ti并进行时效处理,借助析出强化和位错强化机制使屈服强度提高了4倍(由200 MPa提高至1005 MPa),同时合金具有良好的均匀延伸率 (约15%)。Sun等[24]通过对经90%冷轧压下量变形的Cantor合金进行中温退火 (675℃下退火30 min),获得了平均晶粒尺寸约为650 nm的超细晶组织,并主要通过细晶强化使合金的屈服强度由275 MPa提升至798 MPa,同时保持了良好的塑性 (均匀延伸率约为26%)。Li [25]发现在Cantor合金中添加间隙原子C能够抑制合金的再结晶,同时C的添加还促进了晶粒细化和析出相生成。随着C含量增加,合金的屈服强度显著提高但塑性严重损失。当C含量为0.8% (原子分数)时,受固溶强化、细晶强化、位错强化和析出强化等机制的共同作用,合金的屈服强度达到1030 MPa,但均匀延伸率降低至11%。基于上述研究,本工作提出了一种经济、有效的高强韧性高熵合金制备方案,即以非等主元FeMnCoCr高熵合金为模型材料,在不继续添加昂贵金属元素的前提下,通过采用中等形变量冷轧结合中温短时退火的加工工艺,使其获得了良好的强度与塑性匹配。该合金具有由晶粒尺寸为数十微米的形变态晶粒和尺寸约为1 μm的再结晶晶粒组成的非均匀结构,通过分析合金在形变中的微观结构演化,阐明了多种强化机制对宏观力学性能的影响,为高性能金属结构材料的开发提供理论指导。

1 实验方法

本实验高熵合金名义成分为Fe50Mn30Co10Cr10 (原子分数,%)。使用纯金属(纯度> 99.9%,质量分数)在Ar保护气的真空熔炼炉中进行熔铸,随后在1200℃进行热锻以及在900℃进行压下量为50%的热轧。接着对其在1200℃下进行2 h的均匀化退火后水淬,得到固溶态 (homogenization,HOMO)合金。对HOMO态合金继续进行总压下量为60%的多道次冷轧,随后在箱式炉中分别进行退火温度为650℃、保温时间分别为3、5、7和10 min的短时退火和水淬,得到一系列部分再结晶态 (partially recrystallized,PC)的合金。需要说明的是,本工作中的PC态合金特指在650℃保温5 min后淬火得到的合金。作为对比,对HOMO态合金在900℃下保温3 min并进行水淬,得到完全再结晶态 (fully recrystallized,FC)的合金。

随后使用电火花线切割方法得到狗骨状拉伸试样,标距长度和宽度分别为20和3 mm。通过机械抛光去除样品表面的氧化物和缺陷,使用AG-XPLUS100kN电子万能试验机在室温下对试样沿着轧板轧向进行应变速率为1 × 10-3 s-1的单轴拉伸测试。使用Smartlab X射线衍射仪(XRD)对样品进行表征以确认其物相结构,CuK

使用配备了HKL Nordlys电子背散射衍射(EBSD)探头的JSM-7001F扫描电镜(SEM)对合金变形前后的相分布和取向分布进行表征,工作电压20 kV,电流14 A,扫描步长70 nm。最后通过Channel 5软件对EBSD数据进行后处理。SEM样品制备流程为首先对样品进行机械抛光得到光滑、平整的表面,随后用83.3%OPS + 16.7%H2O2 (体积分数)的混合溶液对其进一步进行机械抛光至轻腐蚀态。使用JEM 2100F透射电镜(TEM)对合金在形变前后的微观组织特征进行进一步表征,工作电压为200 kV。TEM样品制备流程为首先对合金进行机械抛光至80 μm厚,从中冲出直径为3 mm的圆片,随后将圆片继续机械抛光至50 μm厚。使用电解双喷减薄仪在-25℃条件下对箔片进行最终减薄,所用电压为25 V,电解双喷液为10%HClO4 + 90%C2H5OH (体积分数)的混合溶液。本工作将样品坐标系定义为由3个正交方向构成,分别为轧板的轧制方向(rolling direction,RD)、横向(transverse direction,TD)和法向(normal direction,ND)。EBSD样品取自合金的侧轧面(RD-ND平面),TEM样品取自合金的轧面(RD-TD平面)。

2 实验结果与分析

2.1 力学性能

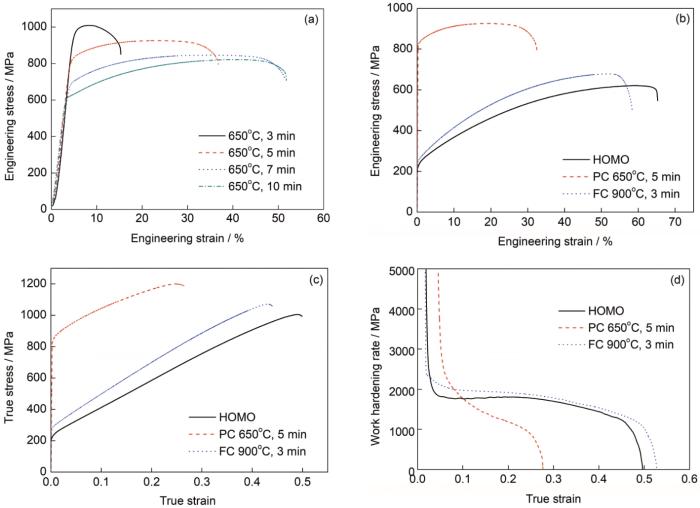

图1a为冷轧Fe50Mn30Co10Cr10合金在650℃下经不同保温时间退火后的工程应力-应变曲线。可以看出,随着退火时间延长,合金的塑性增加但强度降低,其中经5 min退火后的合金 (PC态合金)具有最优的综合力学性能,即屈服和抗拉强度分别为825和928 MPa,均匀延伸率为28.6% (见表1)。图1b为经拉伸变形的HOMO、PC和FC合金的工程应力-应变曲线。与HOMO和FC态的合金相比,PC态合金的屈服强度分别提高了4.0和3.4倍,其综合力学性能甚至与添加了间隙原子C的Fe49.5Mn30Co10Cr10C0.5高熵合金[20] (屈服和抗拉强度分别约为824和1050 MPa,均匀延伸率约为30%)相近。对应的真应力-应变曲线和加工硬化曲线分别如图1c和d所示。在塑性变形初期,PC态合金表现出比HOMO和FC态合金更高的加工硬化能力,直至真应变达到约0.08,PC态合金的加工硬化能力开始低于HOMO和FC态的合金。

图1

图1

Fe50Mn30Co10Cr10高熵合金的室温拉伸力学性能

(a) engineering stress-strain curves of the HEA annealed at 650oC for different time periods

(b) engineering stress-strain curves of the HEA at different states

(c) true stress-strain curves

(d) work hardening curves corresponding to Fig.1c

Fig.1

Mechanical properties of Fe50Mn30Co10Cr10 high-entropy alloy (HEA) under tensile testing at room temperature (HOMO—homogenization, PC—partially recrystallized, FC—fully recrystallized)

表1 不同状态下Fe50Mn30Co10Cr10高熵合金的力学性能

Table 1

| State | Yield stress MPa | Tensile stress MPa | Uniform elongation |

|---|---|---|---|

| % | |||

| HOMO | 208 | 618 | 64.7 |

| FC | 245 | 680 | 54.9 |

| PC | 825 | 928 | 28.6 |

2.2 形变微结构演化

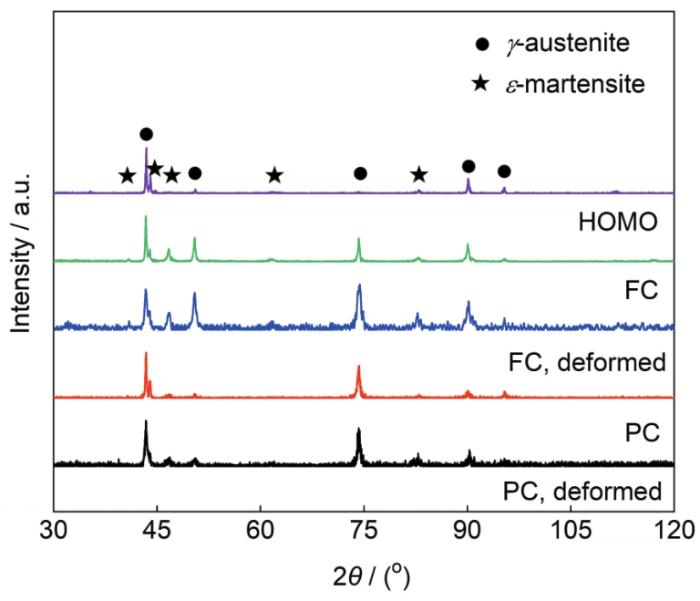

图2为HOMO、FC和PC态合金在形变前后的XRD谱。可以看出,HOMO、FC和PC合金均为γ-奥氏体和ε-马氏体双相组成,且PC合金中的ε-马氏体含量低于HOMO和FC合金。经拉伸变形后,FC和PC态合金中来自ε-马氏体的衍射峰较拉伸前均有增强,且FC态合金中ε-马氏体的衍射峰增强的幅度较大。这表明FC和PC态合金在变形过程中均发生了γ-奥氏体向ε-马氏体转变,其中FC态合金中相转变较多。

图2

图2

不同状态Fe50Mn30Co10Cr10高熵合金的XRD谱

Fig.2

XRD spectra of the Fe50Mn30Co10Cr10 HEA at different states

PC态合金在变形前后的EBSD结果如图3所示。为典型的双峰组织[26],即由形变基体上尺寸为数十微米的大晶粒和尺寸约为1 μm的细小再结晶晶粒组成。相比于FC态合金 (晶粒尺寸约为4.5 μm) [27],PC态合金中细小的晶粒提供了更多的界面以阻碍位错运动,这是材料强度提高的原因之一。此外,PC态合金为由γ-奥氏体和ε-马氏体组成的双相结构。图3a1和b1分别为未变形PC态合金中2个不同区域的相分布图,即再结晶区域和保存了形变基体的区域。通过对3个以上不同区域的EBSD结果进行统计,未变形PC态合金中ε-马氏体的平均面积分数约为10.9%,约为FC态合金(ε-马氏体面积分数约为32%[17])的1/3,这表明晶粒细化抑制了热诱发ε-马氏体的形成[28]。同时发现PC态合金中的ε-马氏体多数存在于形变基体区域(图3b1),满足Olsen和Cohen[29]提出的缺陷促进形核机制,即ε-马氏体在位错密度较高的形变基体区域更易形核。图3a2和b2为相应的取向分布图,其中再结晶区域无明显的晶体取向特征分布,形变基体区域的奥氏体呈现出<111>

图3

图3

PC态Fe50Mn30Co10Cr10高熵合金在拉伸变形前后的EBSD像

(a1, a2) recrystallization region (b1, b2) deformed matrix-preserved region (c1, c2) the region close to the fracture surface of the alloy

Fig.3

Phase distribution maps (a1-c1) and orientation maps (a2-c2) of the Fe50Mn30Co10Cr10 HEA at the PC state before (a1, a2, b1, b2) and after (c1, c2) deformation taken from different regions (In the phase distribution maps, high-angle boundaries with misorientation angles larger than 10° are indicated by thick black lines, low-angle boundaries with misorientation angles between 3° and 10° are indicated by thin black lines, and Σ3 twin boundaries in the fcc phase are indicated by white solid lines, respectively; RD—rolling direction, ND—normal direction, LD—loading direction)

2.3 强韧化机制

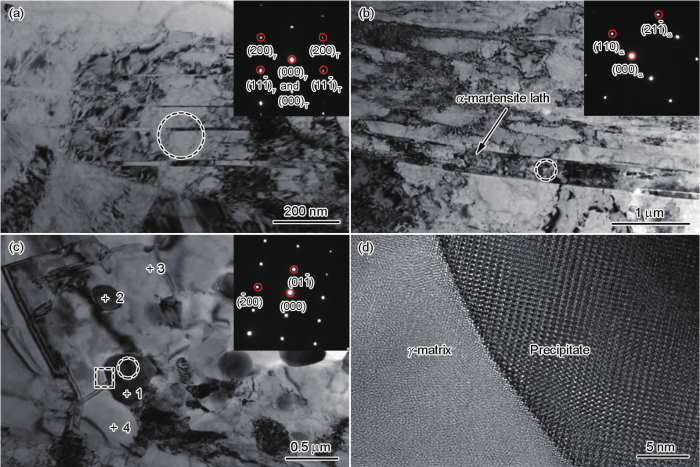

为了进一步揭示PC态合金的强度与塑性来源,对变形前后的PC态合金进行了TEM表征。图4a为在未拉伸PC态合金中的形变基体区域普遍观察到的片层状回复孪晶,该孪晶由冷轧过程中形成的形变孪晶经随后退火演变而成[32],其平均间距约为100 nm,平均厚度约为10 nm。同时,在形变基体区偶然可见平均厚度约125 nm的bcc结构α-马氏体板条。值得说明的是,由于该马氏体板条含量很少,因此在XRD和EBSD结果中未能识别到bcc马氏体的存在。此外,α-马氏体内部塞积有大量位错,如图4b所示。图4c为合金中的再结晶区域,可观察到大量平均直径约200 nm的析出相。综合图中的选区电子衍射(SAED)花样、图4d中析出相和奥氏体基体边界处的高分辨TEM (HRTEM)像以及析出相和基体的EDS结果(表2)可知,析出相与奥氏体基体的界面为非共格,且析出相为富Mn、Cr元素的bcc结构。由此可见,即使PC合金中硬脆相ε-马氏体的含量比FC合金低,但是PC态下的密集位错、回复孪晶、α-马氏体、析出相和细小的再结晶晶粒共同贡献于合金的强化,导致PC态合金的屈服强度较FC态有大幅度提升。

图4

图4

PC态Fe50Mn30Co10Cr10高熵合金形变前的TEM像及选区电子衍射(SAED)花样

(a) recovery twins on the austenitic matrix

(b) α-martensite laths in the austenitic matrix

(c) morphology of precipitates in the recrystallized austenite

(d) HRTEM image taken from the interface between precipitate and austenite as indicated in the dotted box in Fig.4c

Fig.4

TEM images and selected area electron diffraction (SAED) patterns (insets) of the Fe50Mn30Co10Cr10 HEA at the PC state before deformation (The SAED patterns are taken from the dotted circle areas in the figures)

表2 图4中PC态Fe50Mn30Co10Cr10高熵合金中基体和析出相的EDS结果 (atomic fraction / %)

Table 2

| Position | Fe | Mn | Co | Cr |

|---|---|---|---|---|

| 1 (precipitate ) | 41.22 | 36.46 | 7.61 | 14.71 |

| 2 (precipitate ) | 41.78 | 36.70 | 7.46 | 14.06 |

| 3 (matrix ) | 47.48 | 32.69 | 9.56 | 10.27 |

| 4 (matrix ) | 47.07 | 32.86 | 9.81 | 10.26 |

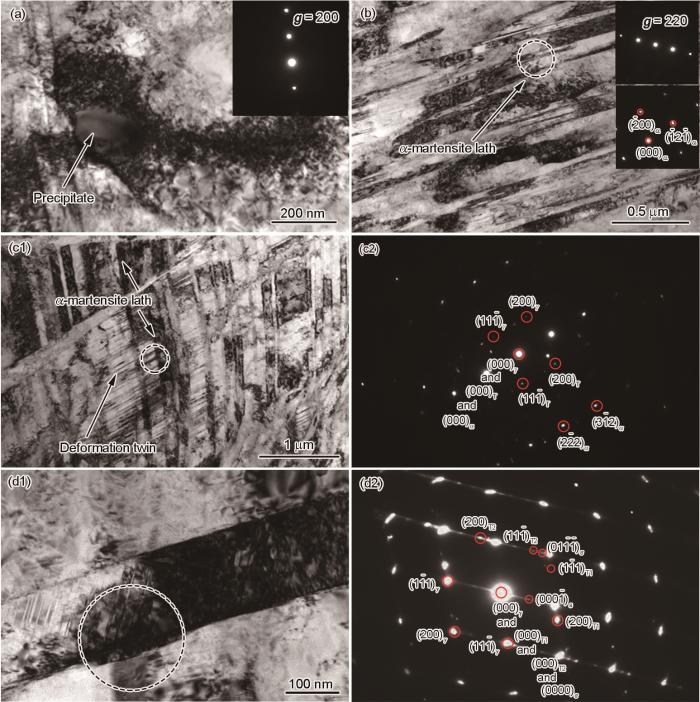

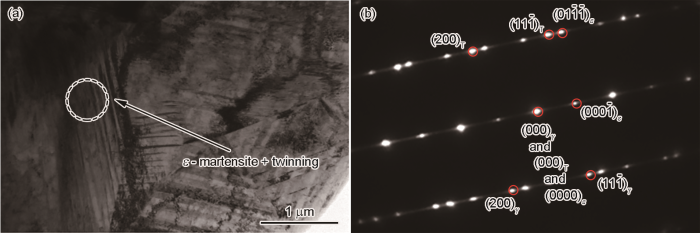

图5为拉伸变形后PC态合金的微观组织的TEM像。图5a和b所示分别为双束条件下富Mn、Cr的析出相和α-马氏体板条的形貌,证明板条状组织为bcc马氏体的SAED花样如图5b插图所示。值得说明的是,由于在由Fe、Mn、Co、Cr等3d过渡族元素构成的高熵合金中析出相的化学成分并不固定,Gludovatz等[3]将其称为富Mn或富Cr的析出相。此外,在析出相边缘和α-马氏体板条的空隙间都塞积了密集的位错。这表明合金在变形过程中,析出相和α-马氏体板条起到了阻碍位错运动作用并导致合金强化。再者,在形变基体区域的α-马氏体板条间形成了大量的形变孪晶(图5c1),且在再结晶区域的退火孪晶内也观察到了密集的形变孪晶片层和ε-马氏体板条的混合组织(图5d1和d2)。细微形变孪晶/马氏体板条的平均间距约为15 nm,平均宽度约5 nm。考虑到该样品中形变孪晶的平均间距小于具有显著TWIP效应的Fe40Mn40Co10Cr10高熵合金(片层状孪晶的平均间距约为32 nm)[31],认为当前PC态合金在变形时发生了更加剧烈的形变孪生。根据本课题组之前研究[27],室温下Fe50Mn30Co10Cr10高熵合金发生孪晶和相变的临界应力值分别为322和520 MPa。因此,结合当前材料的工程应力-应变曲线和加工硬化曲线 (图1b和d)可知,FC态合金在塑性变形开始以后发生了形变孪生和马氏体相变。形变后合金中的形变孪晶和ε-马氏体如图6所示。对于屈服强度高达825 MPa的PC态合金,其形变孪生和相变则是在弹性变形阶段就已经开动,且密集的形变孪晶界、ε-马氏体相界在变形前期 (真应变低于0.1)就为其提供了高于HOMO和FC态合金的加工硬化能力。当真应变大于0.1时,PC态合金微观结构中密集的片层状结构使得TWIP和TRIP效应很快达到饱和,从而引起合金的加工硬化能力随着应变继续增加而迅速下降。另外,在图5d1的退火孪晶中还发现了ε-马氏体的存在,尽管在形貌上难以区分亚稳合金经准静态变形形成的形变孪晶和ε-马氏体板条[27],但这依然为PC态合金在形变过程中发生了奥氏体向ε-马氏体的转变提供了证据。

图5

图5

PC态Fe50Mn30Co10Cr10高熵合金经拉伸变形后断口附近区域的TEM像及SAED花样

(a, b) dislocations accumulated around the precipitates and α-martensite laths under the double beam condition, respectively. The SAED pattern in Fig.5b confirms the existence of α-martensite laths (c1, d1) dense deformation twins formed between α-martensite laths and in the interior of annealing twins, respectively (c2, d2) the corresponding SAED patterns to Figs.5c1 and d1, respectively

Fig.5

TEM images and corresponding SAED patterns of the region close to the fracture surface of the deformed Fe50Mn30Co10Cr10 HEA at PC state (The SAED patterns are taken from the dotted circle areas in the figures)

图6

图6

FC态Fe50Mn30Co10Cr10高熵合金经拉伸变形后断口附近区域的TEM像及SAED花样

Fig.6

TEM image (a) and corresponding SAED pattern (b) of the region close to the fracture surface of the deformed Fe50Mn30Co10Cr10 HEA at FC state showing ε-martensite laths and deformation twins

综上,PC态高熵合金中的高密度位错、晶粒细化、析出相、ε-马氏体、α-马氏体、回复孪晶和变形过程中持续发生的形变孪生、ε-马氏体相变共同贡献于其与FC态合金相比较高的屈服强度(提升约580 MPa)。当PC态合金开始发生塑性形变后,由TWIP和TRIP效应引起的组织动态细化继续贡献于合金的流变应力提升。除位错滑移外,TWIP和TRIP效应协同作用,这贡献于合金良好的均匀塑性变形能力。本工作提出的对合金施加中等形变量冷轧和中温短时退火相结合的加工工艺简单,经济且有效地提高了合金的综合力学性能。因此,可期望被应用于其他低层错能fcc金属及合金的制备中,例如钢铁、铜合金和其他体系的高熵合金。

3 结论

(1) 通过对亚稳态FeMnCoCr双相高熵合金施加中等形变量冷轧与中温短时退火相结合的简单加工工艺,获得了优异的强度与塑性匹配。获得了由晶粒尺寸约为1 μm的再结晶晶粒和数十微米的形变基体组成的双峰结构的部分再结晶态材料。该材料由奥氏体、ε-马氏体和α-马氏体组成,表现出825 MPa的屈服强度、928 MPa的抗拉强度和28.6%的均匀延伸率。其综合力学性能优于已报道的晶粒平均尺寸为4.5 μm的完全再结晶态FeMnCoCr合金。

(2) 形变前已存在于部分再结晶态合金的高密度位错、细小的再结晶晶粒、析出相、ε-马氏体、α-马氏体和回复孪晶等微观结构特征为材料提供了一定的强度。并且,低于屈服点就已开动的形变孪生和ε-马氏体相变亦贡献于合金屈服和抗拉强度的提升。

(3) 部分再结晶态的合金在塑性变形过程中发生了形变孪生和奥氏体向ε-马氏体转变,这是其具有良好塑性变形能力的根本原因。

参考文献

Alloy design strategies and future trends in high-entropy alloys

[J].

A novel, single phase, non-equiatomic FeMnNiCoCr high-entropy alloy with exceptional phase stability and tensile ductility

[J].

A fracture-resistant high-entropy alloy for cryogenic applications

[J].

Tensile properties of high- and medium-entropy alloys

[J].

Role of configurational entropy in body-centred cubic or face-centred cubic phase formation in high entropy alloys

[J].

Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high entropy alloys

[J].

Enhanced mechanical properties of HfMoTaTiZr and HfMoNbTaTiZr refractory high-entropy alloys

[J].

A hexagonal close-packed high-entropy alloys: The effect of entropy

[J].

High-entropy alloys with a hexagonal close-packed structure designed by equi-atomic alloy strategy and binary phase diagrams

[J].

Hexagonal high-entropy alloys

[J].

Microstructural development in equiatomic multicomponent alloys

[J].A

The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy

[J].

Microstructure evolution and critical stress for twinning in the CrMnFeCoNi high-entropy alloy

[J].

Lattice distortions in the FeCoNiCrMn high entropy alloy studied by theory and experiment

[J].

Effects of nitrogen alloying and friction stir processing on the microstructures and mechanical properties of CoCrFeMnNi high-entropy alloys

[J].

Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off

[J].

A TRIP-assisted dual-phase high-entropy alloy: Grain size and phase fraction effects on deformation behavior

[J].

Design of a twinning-induced plasticity high entropy alloy

[J].

Bidirectional transformation enables hierarchical nanolaminate dual-phase high-entropy alloys

[J].

Hierarchical microstructure design to tune the mechanical behavior of an interstitial TRIP-TWIP high-entropy alloy

[J].

Exceptional phase-transformation strengthening of ferrous medium-entropy alloys at cryogenic temperatures

[J].

On the mechanical response and microstructure evolution of NiCoCr single crystalline medium entropy alloys

[J].

A precipitation-hardened high-entropy alloy with outstanding tensile properties

[J].

Ultrahigh cryogenic strength and exceptional ductility in ultrafine-grained CoCrFeMnNi high-entropy alloy with fully recrystallized structure

[J].

Interstitial equiatomic CoCrFeMnNi high-entropy alloys: Carbon content, microstructure, and compositional homogeneity effects on deformation behavior

[J].

High tensile ductility in a nanostructured metal

[J].

The effect of strain rate on mechanical properties and microstructure of a metastable FeMnCoCr high entropy alloy

[J].

Effects of austenite grain size on ε martensitic transformation in Fe-15mass%Mn alloy

[J].

Dislocation theory of martensitic transformations

[A].

Carbon and nitrogen co-doping enhances phase stability and mechanical properties of a metastable high-entropy alloy

[J].

Joint contribution of transformation and twinning to the high strength-ductility combination of a FeMnCoCr high entropy alloy at cryogenic temperatures

[J].

In-situ SEM observation of phase transformation and twinning mechanisms in an interstitial high-entropy alloy

[J].