高熵合金主元元素多,具有异于传统合金的许多优异特性[1,2,3]。CoCrFeMnNi高熵合金室温下延伸率可达57%以上,其液氮温度下的延伸率更高,可达75%以上,但其强度相对较低,约为380 MPa[4,5,6]。第二相强化是提高合金强度的主要方式之一,而第二相的体积分数、尺寸大小、形状及分布状态等对合金力学性能有很大的影响[7,8,9,10]。Shahmir等[11]对CoCrFeNiMn高熵合金采用变形退火的方法析出纳米晶,抗拉强度和伸长率分别达到了830 MPa与63%。合金中第二相的形成主要有2种方式[12],一是通过添加微粒物质以第二相的形式存在于合金基体中,二是通过添加合金元素在合金中原位生成第二相。Rogal等[13,14]在FeCoNiCrMn 高熵合金中分别添加SiC (20~50 nm)和Al2O3 (5~35 nm)纳米颗粒,压缩屈服强度分别从1180 MPa提高至1940和1600 MPa,但塑性均明显下降。He等[15]在FeCoNiCr高熵合金中添加Ti和Al,析出大量弥散纳米γ'相,其屈服强度提高到650 MPa左右,抗拉强度超过了1000 MPa,具有显著的强化作用。Chen等[16]对Al0.3CrFe1.5MnNi0.5高熵合金进行时效处理后基体中析出了大量ρ相(Cr5Fe6Mn8),这种四方结构的ρ相,与基体界面不共格,能显著强化基体,但对材料塑性影响较大。有研究[17,18]发现,在AlCoCrFeNi和AlCrFeNi高熵合金中添加Mo元素能够形成硬脆的金属间化合物相。Stepanov等[19]对CoCrFeNiMn高熵合金退火处理析出了正方晶系的富Cr相(σ相)。Ming等[20]和Liu等[21]对Cr15Fe20Co35Ni20Mo10和CoCrFeNiMox高熵合金采用热处理的方法,在合金中生成σ相(CrMo相),有效提高了合金强度,但塑性降低较为明显。分析认为,σ相的体积分数、尺寸大小及分布形态对合金力学性能具有显著的影响。

Yao等[22]研究了Mo含量对CoCrFeMnNi高熵合金组织与性能的影响,当Mo含量(质量分数,下同)小于5%时,Mo以置换原子的形态固溶于基体的晶体结构中,合金的强度略有提高,塑性未发生明显变化;当Mo含量大于5%时,合金基体中析出σ相,合金强度略有提高,但塑性明显降低,这说明CoCrFeMnNi高熵合金中Mo元素的固溶度约为5%。Mo与Co、Cr、Fe、Mn、Ni等元素相比原子半径较大,Mo以置换原子的状态存在于合金的晶体结构中,形成置换固溶体,使合金的晶格常数变大、晶格畸变增大[23,24]。因此,本工作在CoCrFeMnNi高熵合金中添加5% (原子分数2.98%)的Mo元素,采用真空电弧熔炼炉制备(CoCrFeMnNi)97.02Mo2.98高熵合金,利用退火的热处理方法在合金中析出第二相,分析退火温度对(CoCrFeMnNi)97.02Mo2.98高熵合金相结构及力学性能的影响规律,揭示(CoCrFeMnNi)97.02Mo2.98高熵合金中第二相的数量、大小、形态及分布随退火温度的演变过程,探究第二相数量、形态及分布对(CoCrFeMnNi)97.02Mo2.98高熵合金力学性能的影响机制,以期提高其综合力学性能。

1 实验方法

选取纯度大于99.9%的Mn、Fe、Cr、Co、Ni、Mo金属材料作为原料,按照等原子比计算CoCrFeMnNi合金成分各元素的质量分数,再添加质量分数为5%的Mo元素,按照质量分数配比进行配料。采用真空电弧炉进行熔炼,真空度为3×10-3 Pa,Ar气保护。反复熔炼至少4次以保证合金成分的均匀性,利用Cu模进行浇注,制备出尺寸为直径60 mm、厚20 mm的(CoCrFeMnNi)97.02Mo2.98高熵合金铸锭,合金设计的名义成分(原子分数,%)为:Co 19.404,Cr 19.404,Fe 19.404,Mn 19.404,Ni 19.404,Mo 2.980。

采用箱式热处理炉将(CoCrFeMnNi)97.02Mo2.98高熵合金铸锭进行退火处理,加热温度分别为700、800、900及1000 ℃,保温时间均为2 h,炉冷至室温。退火处理后,利用线切割切取10 mm×10 mm×10 mm的立方体试样,并用180~2000号的水砂纸逐级进行打磨,采用金刚石研磨膏进行抛光后,利用Quanta 400F型扫描电镜(SEM)观察微观结构,配合X-Max型能谱分析仪(EDS)及XRD-6000型X射线衍射仪(XRD)分析元素分布和相组成,利用402MVD型Vickers硬度仪测试显微硬度。拉伸试样为直径3 mm的棒状样,标距为30 mm,利用DDL300型电子万能试验机测试拉伸性能,采用SEM分析拉伸断口形貌。

2 实验结果与分析

2.1 显微结构形貌

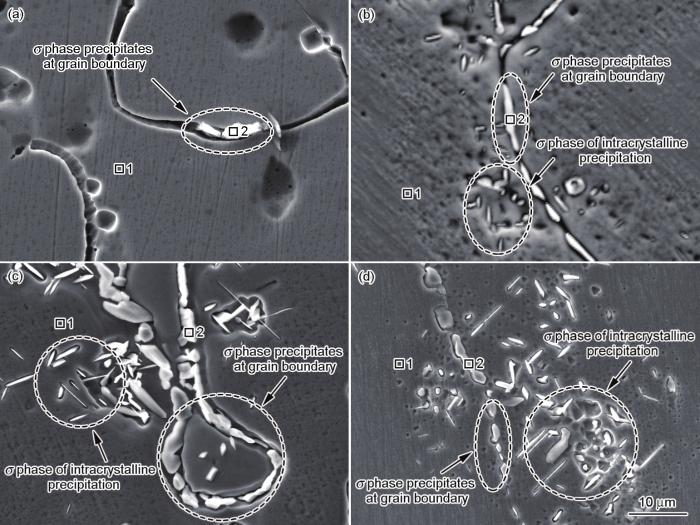

图1为不同退火温度下(CoCrFeMnNi)97.02Mo2.98高熵合金微观组织形貌。可以看出,当退火温度为700 ℃时,在晶界处有少量的短条状第二相析出(图1a);当退火温度为800 ℃时,晶界处第二相析出增多,呈长条状断续分布于晶界,同时,近晶界部位,也有少量的颗粒状第二相析出(图1b);当退火温度为900 ℃时,晶界处析出的第二相粗化、呈连续状分布,近晶界处第二相析出增多,形态变为针状或条片状(图1c);当退火温度为1000 ℃时,晶界处析出第二相细化,变为颗粒状断续分布,而在晶内第二相大量析出,近晶界处呈长针状或条片状、析出量较多,远晶界处呈短小针状、析出量较少(图1d)。这表明,随着退火温度的升高,(CoCrFeMnNi)97.02Mo2.98高熵合金第二相析出量增多,且在晶界处先析出,后在晶内析出,晶界第二相形态由细小条状断续分布,逐渐变为粗大条状连续分布,随着温度进一步升高,由条状连续分布转变为颗粒状断续分布。

图1

图1

不同温度退火热处理后(CoCrFeMnNi)97.02Mo2.98高熵合金微观组织的SEM像

Fig.1

SEM images of (CoCrFeMnNi)97.02Mo2.98 high entropy alloys after annealing at 700 ℃ (a), 800 ℃ (b), 900 ℃ (c) and 1000 ℃ (d)

2.2 相结构

表1 不同温度退火热处理后(CoCrFeMnNi)97.02Mo2.98高熵合金的EDS结果

Table 1

| Annealing temperature | Position | Atomic fraction / % | |||||

|---|---|---|---|---|---|---|---|

| ℃ | Co | Cr | Fe | Mn | Ni | Mo | |

| 700 | 1 | 19.86 | 20.91 | 21.09 | 16.69 | 18.06 | 3.39 |

| 2 | 16.35 | 28.39 | 17.02 | 15.77 | 10.82 | 11.64 | |

| 800 | 1 | 20.25 | 21.42 | 21.84 | 15.79 | 17.53 | 3.18 |

| 2 | 17.06 | 30.33 | 17.34 | 15.30 | 9.97 | 10.00 | |

| 900 | 1 | 20.73 | 20.66 | 20.73 | 15.92 | 17.56 | 3.40 |

| 2 | 17.18 | 28.33 | 15.84 | 17.06 | 11.12 | 10.47 | |

| 1000 | 1 | 19.47 | 20.42 | 20.71 | 18.62 | 17.72 | 3.06 |

| 2 | 16.41 | 28.67 | 16.26 | 16.29 | 11.75 | 10.63 | |

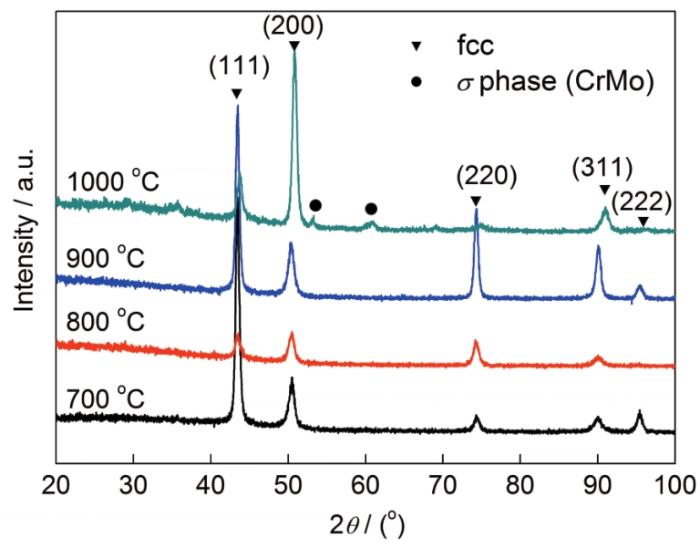

图2是不同退火温度下(CoCrFeMnNi)97.02Mo2.98高熵合金的XRD谱。分析可知,退火处理后的(CoCrFeMnNi)97.02Mo2.98高熵合金仍为fcc结构,在1000 ℃退火处理后出现CrMo相(σ相)衍射峰,结合EDS分析结果可以确定,(CoCrFeMnNi)97.02Mo2.98高熵合金退火处理后析出第二相为富含Cr与Mo元素的σ相。当退火温度低于900 ℃时,XRD谱中未发现σ相峰,从图1微观结构形貌可以看出,退火温度低于900 ℃时,σ相主要在晶界析出,而晶内析出较少,合金中σ相的体积分数较少,因此,在XRD谱中未出现σ相的衍射峰。Yao等[22]对CoCrFeMnNi高熵合金添加Mo元素的研究表明,Mo以置换原子的形态存在于CoCrFeMnNi高熵合金晶格中,形成置换固溶体,由于Mo原子比其它原子的半径大,因此,晶格常数变大。在1000 ℃时,合金内σ相的析出量明显增多,这意味着固溶态的Mo转变为以富含Cr、Mo元素σ相的数量明显增多,即Mo固溶数量显著减小,使晶格常数变小,根据Bragg衍射定律λ=2dsinθ (其中,λ为入射波波长,d为平行原子平面的间距,θ为入射光与晶面之间的夹角)可知,晶格常数变小,相角增大。因此,1000 ℃退火处理后样品(311)的峰位向右(大角度方向)偏移。

图2

图2

不同温度退火热处理后(CoCrFeMnNi)97.02Mo2.98高熵合金的XRD谱

Fig.2

XRD spectra of (CoCrFeMnNi)97.02Mo2.98 high entropy alloys after annealing at different temperatures

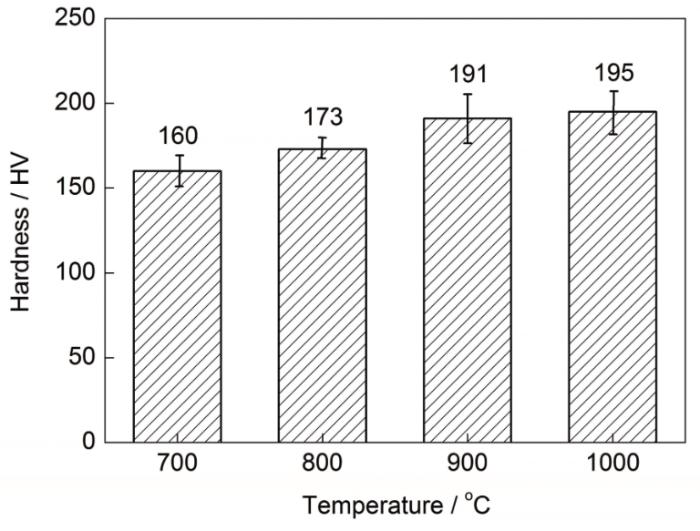

2.3 硬度

图3为(CoCrFeMnNi)97.02Mo2.98高熵合金显微硬度随退火温度的变化。可以看出,随着退火温度的升高,(CoCrFeMnNi)97.02Mo2.98高熵合金的硬度增大。从前述微观结构与相分析可知,退火处理使fcc结构(CoCrFeMnNi)97.02Mo2.98高熵合金中析出σ相,起到第二相强化的作用,随着退火温度升高,σ相析出量增多,第二相强化作用随之增强,因此,(CoCrFeMnNi)97.02Mo2.98高熵合金的硬度增大。当退火温度高于900 ℃时,合金中σ相析出量显著增多,强化效果增强明显,硬度明显升高。

图3

图3

不同温度退火热处理后(CoCrFeMnNi)97.02Mo2.98高熵合金的显微硬度

Fig.3

Microhardness of (CoCrFeMnNi)97.02Mo2.98 high entropy alloys after annealing at different temperatures

2.4 拉伸性能及断裂机理

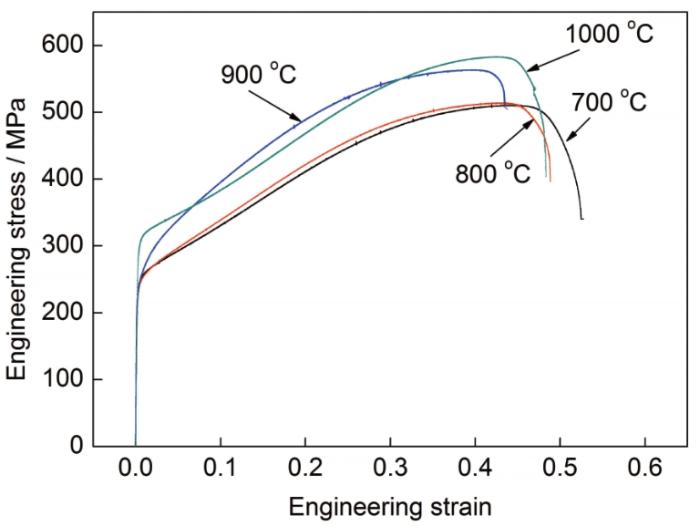

图4

图4

不同温度退火热处理后(CoCrFeMnNi)97.02Mo2.98高熵合金的工程应力-应变曲线

Fig.4

The stress-strain curves of (CoCrFeMnNi)97.02-Mo2.98 high entropy alloys after annealing at different temperatures

表2 不同温度退火热处理后(CoCrFeMnNi)97.02Mo2.98高熵合金的拉伸性能

Table 2

| Temperature / ℃ | σs / MPa | σb / MPa | δ / % |

|---|---|---|---|

| 700 | 253 | 510 | 52.7 |

| 800 | 254 | 513 | 49.4 |

| 900 | 262 | 562 | 43.8 |

| 1000 | 326 | 582 | 48.3 |

Qin等[25]研究了添加Mo对CoCrFeMnNi力学性能的影响表明,随着Mo含量的提高,CoCrFeMnNi高熵合金的强度提高,但是延伸率降低,主要是因为σ相在晶界处析出,且随Mo含量的增大,晶界处析出的σ相的量增多、同时形态变得粗大,从而导致脆性明显增大,延伸率显著降低。从图1中微观组织形貌可以看出,退火温度为700和800 ℃时,合金中析出的σ相较少,第二相强化效果不明显,因此,强度未有明显变化;退火温度为900和1000 ℃时,合金中析出σ相较多,第二相强化作用显著,因此,强度明显提高。退火温度为1000 ℃时,析出σ相相对细小,且晶内大量析出,而900 ℃退火温度下,析出σ相相对粗大,且主要分布在晶界处,这导致了1000 ℃比900 ℃退火处理后合金的延伸率增大、屈服强度显著提高。这表明晶内析出σ相及其细化,有利于合金强度与塑性的同步提高。

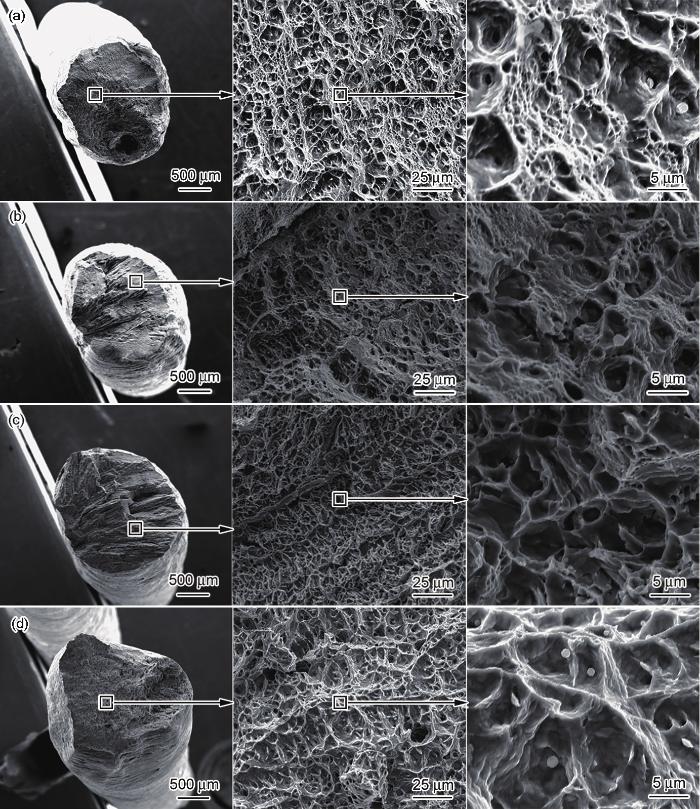

图5是不同温度退火处理后(CoCrFeMnNi)97.02-Mo2.98高熵合金的拉伸断口形貌。从低倍形貌可以看出,不同温度退火处理后的试样断裂部位均有明显的塑性形变和颈缩现象;从高倍形貌图可以看出,断口微观形貌中微聚孔数量相对较多,断口呈现韧窝形貌,为韧性断裂。Fu等[26]和Thurston等[27]分析了CoCrFeNiMn高熵合金的拉伸断口形貌表明,其拉伸断口韧窝形貌呈现了典型的韧性断裂特征。这从断口韧窝形貌特征方面表明了(CoCrFeMnNi)97.02Mo2.98高熵合金经过退火热处理形成σ相第二相强化后,仍然保持了CoCrFeMnNi高熵合金基体塑性良好的韧性断裂特征。在700~900 ℃退火温度范围内,随着退火温度的升高,断口形貌中的微聚孔数量减少,韧窝的尺寸开始增大,且逐渐变浅变平,因此,其所对应的延伸率减小、塑性降低;而1000 ℃退火温度下,韧窝又变深变多,因此,其所对应的延伸率增大、塑性提高。

图5

图5

不同温度退火热处理后(CoCrFeMnNi)97.02Mo2.98高熵合金的拉伸断口形貌

Fig.5

The tensile fracture morphologies of (CoCrFeMnNi)97.02Mo2.98 high entropy alloys after annealing at 700 ℃ (a), 800 ℃ (b), 900 ℃ (c) and 1000 ℃ (d)

3 结论

(1) 随着退火温度的升高,(CoCrFeMnNi)97.02Mo2.98高熵合金析出σ相量增多,且在晶界处先析出,后在晶内析出,晶界第二相形态由细小条状断续分布,逐渐变为粗大条状连续分布,随着温度进一步升高,由条状连续分布转变为颗粒状断续分布。

(2) (CoCrFeMnNi)97.02Mo2.98高熵合金退火处理析出σ相具有明显的第二相强化作用,随着退火温度的升高,σ相析出量增多,硬度及强度均增大,当温度高于900 ℃尤为显著。

(3) (CoCrFeMnNi)97.02Mo2.98高熵合金中σ相在晶界析出,能够起到强化作用,提高合金的强度,但是会导致塑性降低;σ相在晶内析出及其细化,能够促进合金强度与塑性同步提高。

参考文献

Microstructural development in equiatomic multicomponent alloys

[J].

Microstructure and properties of aluminum-containing refractory high-entropy alloys

[J].

Structure and mechanical properties of the AlCrxNbTiV (x=0, 0.5, 1, 1.5) high entropy alloys

[J].

A fracture-resistant high-entropy alloy for cryogenic applications

[J].High-entropy alloys are equiatomic, multi-element systems that can crystallize as a single phase, despite containing multiple elements with different crystal structures. A rationale for this is that the configurational entropy contribution to the total free energy in alloys with five or more major elements may stabilize the solid-solution state relative to multiphase microstructures. We examined a five-element high-entropy alloy, CrMnFeCoNi, which forms a single-phase face-centered cubic solid solution, and found it to have exceptional damage tolerance with tensile strengths above 1 GPa and fracture toughness values exceeding 200 MPa·m(1/2). Furthermore, its mechanical properties actually improve at cryogenic temperatures; we attribute this to a transition from planar-slip dislocation activity at room temperature to deformation by mechanical nanotwinning with decreasing temperature, which results in continuous steady strain hardening.

The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy

[J].

Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures

[J].High-entropy alloys are an intriguing new class of metallic materials that derive their properties from being multi-element systems that can crystallize as a single phase, despite containing high concentrations of five or more elements with different crystal structures. Here we examine an equiatomic medium-entropy alloy containing only three elements, CrCoNi, as a single-phase face-centred cubic solid solution, which displays strength-toughness properties that exceed those of all high-entropy alloys and most multi-phase alloys. At room temperature, the alloy shows tensile strengths of almost 1 GPa, failure strains of ∼70% and KJIc fracture-toughness values above 200 MPa m(1/2); at cryogenic temperatures strength, ductility and toughness of the CrCoNi alloy improve to strength levels above 1.3 GPa, failure strains up to 90% and KJIc values of 275 MPa m(1/2). Such properties appear to result from continuous steady strain hardening, which acts to suppress plastic instability, resulting from pronounced dislocation activity and deformation-induced nano-twinning.

Phase equilibria, mechanical properties and design of quaternary refractory high entropy alloys

[J].

High-temperature tensile strength of Al10Co25Cr8Fe15Ni36Ti6 compositionally complex alloy (high-entropy alloy)

[J].

Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys

[J].A series of AL(x)Co(1.5)CrFeNi(1.5)Ti(y) high-entropy alloys with different Al and Ti contents were designed, and their phase and microstructure were investigated. The adhesive wear behavior and mechanism were also studied and compared with the conventional wear-resistant steels SUJ2 and SKH51. The amounts of Al and Ti strongly affect the phase and microstructure, particularly the amount and morphology of the hard eta-(Ni, Co)(3)Ti phase. It was found that the wear resistance of the Co1.5CrFeNi1.5Ti and Al0.2Co1.5CrFeNi1.5Ti alloys is at least two times better than that of conventional wear-resistant steels with similar hardness. The excellent anti-oxidation property and resistance to thermal softening in these high-entropy alloys are proposed to be the main reasons for the outstanding wear resistance. (C) 2011 Acta Materialia Inc. Published by Elsevier Ltd.

Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes

[J].

Effect of annealing on mechanical properties of a nanocrystalline CoCrFeNiMn high-entropy alloy processed by high-pressure torsion

[J].

Deformation behavior and toughening of high-entropy alloys

[J].

高熵合金的变形行为及强韧化

[J],

Effect of SiC nano-particles on microstructure and mechanical properties of the CoCrFeMnNi high entropy alloy

[J].

CoCrFeMnNi high entropy alloy matrix nanocomposite with addition of Al2O3

[J].

A precipitation-hardened high-entropy alloy with outstanding tensile properties

[J].

Microstructure and properties of age-hardenable AlxCrFe1.5MnNi0.5 alloys

[J].

Microstructures and compressive properties of multicomponent AlCoCrCuFeNiMox alloys

[J].

Microstructure and mechanical properties of multi-component AlCrFeNiMox high-entropy alloys

[J].

Second phase formation in the CoCrFeNiMn high entropy alloy after recrystallization annealing

[J].

Precipitation strengthening of ductile Cr15Fe20Co35Ni20Mo10 alloys

[J].

Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases

[J].

Effects of Mo element on microstructure and mechanical properties of CoCrFeMnNi high entropy alloys

[J].

Effect of heat treatment on microstructure and properties of CoCrFeMnNi-5%Mo high entropy alloy

[J]. J

热处理对CoCrFeMnNi-5%Mo高熵合金组织及性能的影响

[J].

Structural features and solid-solution hardening of high-entropy CrMnFeCoNi alloy

[J].

Strengthening FCC-CoCrFeMnNi high entropy alloys by Mo addition

[J].

Effect of thermomechanical processing on microstructure and mechanical properties of CoCrFeNiMn high entropy alloy

[J].

Temperature and load-ratio dependent fatigue-crack growth in the CrMnFeCoNi high-entropy alloy

[J].