近年来,智能器件正向着轻量化、集成小型的方向发展,微电子机械系统(micro electro mechanical system)得到了快速的发展和广泛的应用。形状记忆合金薄膜集温度、应力感知和驱动为一体,由于其比表面积小、输出功率大、响应速率快等优点,可作为驱动器和传感器应用于微机电机械系统[1~4]。由记忆合金薄膜制成的微泵、微阀、微夹持器,在微纳机电系统、航空航天、汽车和生物医学领域中发挥着越来越重要的作用[5~7]。与氮化物、氧化物和铁电体结合的形状记忆合金薄膜可具有优良的表面性能和微尺度振动阻尼,满足苛刻环境中的使用[8]。然而,微驱动器在使用过程中存在较低频率的振动,使设备的稳定运行受到威胁,因此当务之急是获得宽温域高阻尼的记忆合金薄膜。

传统的形状记忆合金薄膜主要以Ti-Ni合金薄膜为主,Ti-Ni记忆合金具有回复率高、回复力大等优点,但相变温度一般小于100 ℃,因而由其制造的器件不能应用于工作温度较高的领域中,例如电流过载保护系统等[9],因此需开发出一种相变温度高、形状记忆效应好的高温形状记忆合金薄膜。在目前常见的高温形状记忆合金薄膜中,富Ti的Ti-Ni基合金薄膜相变温度较高,但易析出Ti2Ni相,对形状记忆效应有影响[10]。Ti-Ni-X (X=Zr、Hf)合金具有较好的记忆效应,虽然原材料成本低,但是其热稳定性不好[11,12]。Ni-Mn基高温记忆合金薄膜具有相变温度高、形状记忆效应好、热稳定性好等优点,但其脆性较大,不利于薄膜的器件化[13,14]。综上所述,目前较为常见的高温形状记忆合金薄膜均存在难以克服的缺点,限制了其发展和应用。Ti-Ta-Zr合金是研发刚起步的高温形状记忆合金,相变温度较高且可通过调节合金成分控制相变温度,具有较好的冷加工性能以及良好的形状记忆效应和较高的热稳定性[15,16],但是添加Zr元素会使合金的塑性下降[17],影响实际工程中的应用。张菲等[18]研究表明,添加Fe元素可以在保证良好的形状记忆效应的前提下提高β-Ti合金的塑性,使其有望应用于高温微型减振器件。然而,Ti-Ta基形状记忆合金薄膜阻尼性能的相关研究目前未见报道。

本工作通过磁控溅射制备Ti-Ta-Zr-Fe形状记忆合金薄膜,研究Fe掺杂对Ti-Ta-Zr合金薄膜的组织结构、马氏体相变、力学性能和阻尼行为的影响规律,以期为Ti-Ta-Zr-Fe形状记忆合金薄膜的应用提供理论基础。

1 实验方法

选用纯度分别为99.95%的海绵Ti、99.95%的Ta棒、99.99%的Zr粒和99.95%的Fe块为原材料,采用真空非自耗电弧熔炼炉熔炼Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0,原子分数,%)合金。为保证靶材的均匀性,熔炼过程中反复熔炼6次并加以磁力搅拌,采用电火花线切割将铸锭切成小块,去除表面氧化层后再重复熔炼2次。将铸锭在900 ℃匀质化处理6 h以保证成分均匀。匀质化处理后的合金在900 ℃下热轧成约4 mm厚的板材,通过电火花线切割将板材切割至靶材所需尺寸:直径68 mm、厚3 mm。

使用ATC-1800F直流磁控溅射仪制备薄膜,靶材和衬底均垂直放置于真空腔体中,靶基距为75 mm,衬底为单晶SiO2,溅射基底温度为室温,腔内本体真空度小于1×10-4 Pa,工作气压0.15 Pa,溅射功率为200 W,溅射时间为120 min,最终可获得厚度约为6 μm的Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜,其实际成分列于表1中。

表1 Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)薄膜的实际成分 (atomic fraction / %)

Table 1

| x | Ti | Ta | Zr | Fe |

|---|---|---|---|---|

| 0.3 | 69.64 | 15.23 | 14.87 | 0.26 |

| 0.6 | 69.63 | 14.92 | 14.82 | 0.63 |

| 1.0 | 69.91 | 14.39 | 14.76 | 0.94 |

采用PANalytical X'Pert Powder X射线衍射仪(XRD)对薄膜的相组成进行分析,实验条件为CuKα,管电压为40 kV,管电流为40 mA。采用JEM-2100型透射电子显微镜(TEM)对薄膜微观组织进行观察,利用电解双喷进行减薄,电解液配比为6%高氯酸+34%正丁醇+60%甲醇(体积分数)。减薄时电流为30 mA,工作温度为-20 ℃。利用Nanomeasurer软件测量薄膜的晶粒尺寸,通过测量多个晶粒的尺寸最终得到平均数值。采用弯曲法测量薄膜的相变温度,将试样在马氏体状态下弯曲180°并记录下薄膜回弹后的位置,放入装有视窗的热处理炉内加热,记录薄膜回复的位置以及开始回复和回复结束时的温度,对应逆马氏体相变的开始温度(As)和结束温度(Af)。采用DMA-Q800动态热机械分析仪来测试薄膜的力学性能和阻尼性能,薄膜尺寸为20 mm×1.5 mm×6 μm,变温速率为5 ℃/min,拉伸加载速率为200 MPa/min。

2 实验结果与分析

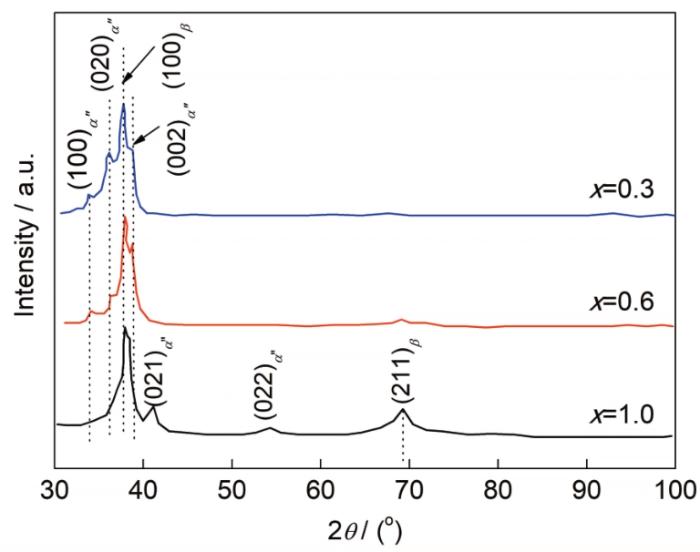

图1为Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜室温下的XRD谱。从图中可以看出,3种成分的沉积态薄膜均已经完全晶化,与Motemani等[19]制得的Ti67Ta33合金薄膜以及Ning等[20]制得的TiTaZr合金薄膜中得到的结果相同,而在其它合金体系含Zr合金的薄膜中不易获得完全晶化的薄膜,因此认为可以用TiTa薄膜的结果来分析Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)薄膜。经过分析Motemani等[19]认为,Ti原子与Ta原子的原子尺寸相差较小,具有较小的混合焓,同时具有较低的晶化活化能和晶化温度,有利于获得晶化的沉积态薄膜。3种成分的Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜在室温下均由正交结构的α′′马氏体相和立方结构的β母相共同组成,随着Fe含量的增加,α′′马氏体相的衍射峰逐渐减弱,当x=0.6时,在2θ=69°附近出现了1个新的衍射峰,经标定为β母相的衍射峰;x=1.0时,2θ=42°和54°附近出现了2个衍射峰,分别为α′′马氏体相的(021)和(022)衍射峰,同时,(211)β衍射峰的相对强度增大,这表明随着Fe含量的增加,薄膜中母相的含量逐渐增加。

图1

图1

Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)薄膜室温下的XRD谱

Fig.1

XRD specra of Ti70-xTa15Zr15Fex (x=0.3, 0.6, 1.0) thin films at room temperature

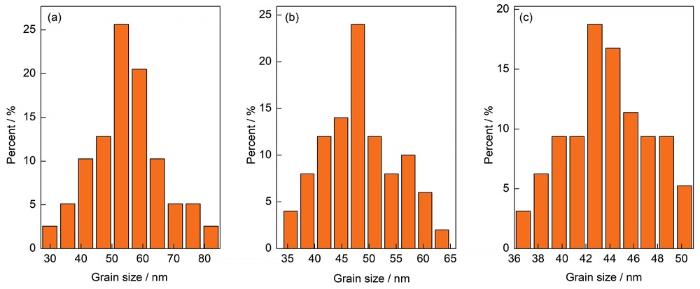

图2为Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜的TEM明场像及相应的SAED花样。从图中可以看出,薄膜的晶粒细小,分布均匀。对不同Fe含量合金薄膜的晶粒尺寸进行了统计,其粒径分布柱状图如图3所示。经统计,x=0.3、0.6和1.0的薄膜平均粒径分别为53.9、47.9和42.5 nm,薄膜的晶粒尺寸逐渐减小,统计误差范围为±0.5 nm。不同Fe含量合金薄膜平均晶粒尺寸的方差分别为136.65、48.21和13.14,可以看出,随着Fe含量的增加,晶粒尺寸分布越来越均匀。Fe元素是一种β相稳定元素,在合金中添加β相稳定元素可以降低马氏体相变温度[21,22],随着Fe含量的增加,合金薄膜中β相增多,与XRD谱的相组成变化趋势相同。Fe元素的原子半径为0.126 nm,小于Ti (0.147 nm)、Ta (0.147 nm)和Zr (0.160 nm)的原子半径,因此添加Fe元素会降低合金的固溶度,促进形核,使晶粒细化。在薄膜的晶粒中可以观察到马氏体板条,通过对SAED花样进行标定可得,x=0.3、0.6和1.0薄膜均为马氏体与母相共存,与XRD谱的结果相符。

图2

图2

Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜的TEM明场像及相应的SAED花样

Fig.2

TEM bright field images and SAED patterns (insets) of Ti70-xTa15Zr15Fex thin films with x=0.3 (a), 0.6 (b) and 1.0 (c) (The twins in the thin films are marked by arrows)

图3

图3

Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜的粒径分布图

Fig.3

Grain size distributions of Ti70-xTa15Zr15Fex thin films with x=0.3 (a), 0.6 (b) and 1.0 (c)

图4为弯曲法测量的Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜随温度的变形过程。测得Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜的As分别为220、190和145 ℃,可见不同Fe含量薄膜的As均高于100 ℃,属于高温形状记忆合金薄膜,随着Fe含量的增大,薄膜的As降低。Fe元素是β相稳定元素,Fe含量的增加有利于马氏体向母相的转变,因此As向低温方向移动。当温度升高至Af以上时薄膜变形停止,在Af+30 ℃时测量薄膜弯曲的角度可发现,Fe元素含量越高,薄膜的形状回复率越大,形状记忆效应越好。待薄膜冷却至室温后薄膜可完全回复到加热之前的位置,3种成分的薄膜均呈现出双程记忆效应。形状记忆合金的双程形状记忆效应通常是由应力场诱导马氏体发生择优取向而产生的。Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜中产生的应力可以归结为2个方面:第一是由于在镀膜过程中,薄膜和基体会同时升温,而在镀膜后温度下降到室温后,由于薄膜和基体的热膨胀系数不同而产生了内应力;第二,磁控溅射过程中薄膜的生长是一个非热平衡的过程,因此在形成过程中会产生较大的内应力,主要与薄膜与基体界面处的晶格错配和生长过程中各种结构缺陷的运动有关。磁控溅射过程中引入的内应力储存在薄膜中,为Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜的双程记忆效应提供驱动力。

图4

图4

弯曲法测量的Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜随温度的变形过程

Fig.4

Transformation processes of Ti70-xTa15Zr15Fex thin films with x=0.3 (a), 0.6 (b) and 1.0 (c) (The measure temperatures from left to righ in the figures are 30 ℃,reverse transformation finish temperature (Af) +30 ℃,30 ℃ (after cooling))

采用拉伸实验研究了合金薄膜的力学性能,结果如图5所示。薄膜的拉伸变形曲线分为2个阶段,第1阶段为弹性变形阶段(I),第2阶段时应力-应变曲线的斜率明显减小(II)。这与传统的形状记忆合金的拉伸曲线不同,传统的形状记忆合金包括3个阶段,分别是弹性阶段、马氏体变体再取向阶段以及再取向马氏体的弹塑性阶段。在薄膜的拉伸实验中并未出现Ti-Ni形状记忆合金拉伸时的应力-应变平台,在Ni-Mn-Ga合金[23]和Ti-Ni-Hf合金[24]的拉伸曲线中也出现过类似的情况,这是由于薄膜在变体再取向阶段伴随着塑性变形,出现了加工硬化,导致这一阶段应力随着应变升高。另一原因为拉伸过程中发生了中间马氏体的转变,造成了拉伸过程中的应力的提高。x=1.0时,薄膜的延伸率可达到12.8%,优于Ti-Ta-Zr形状记忆合金薄膜,说明Fe元素的加入可以较大幅度地提高薄膜的塑性。随着Fe含量的增加,薄膜的抗拉强度和延伸率均增加。根据TEM的结果(图2)可知,Fe元素可以起到细晶强化的作用,从而提高薄膜的强度和塑性,这是因为细晶粒受到外力发生塑性变形可分散在更多的晶粒内进行,塑性变形较均匀,应力集中较小;此外,晶粒越细,晶界面积越大,晶界越曲折,越不利于裂纹的扩展。

图5

图5

Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜室温下的拉伸应力-应变曲线

Fig.5

Tensile stress-strain curves of Ti70-xTa15Zr15Fex (x=0.3, 0.6, 1.0) thin films

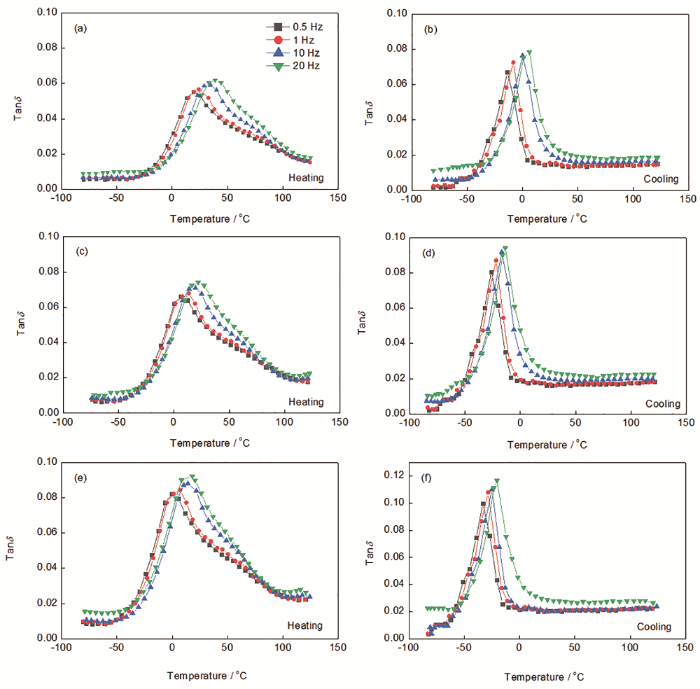

图6为Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜的多频阻尼与温度的关系曲线。从图中可以看出,不同成分薄膜的阻尼-温度曲线形状相似,随着Fe含量的增加,升降温过程中频率为20 Hz的阻尼峰值增大,峰值温度向低温方向移动。在降温过程中频率为20 Hz时,x=0.3薄膜的阻尼最高可达0.078 (图6b),x=0.6薄膜的阻尼最高可达0.094 (图6d),x=1.0薄膜的阻尼最高可达0.116 (图6f)。另外,在x=1.0薄膜的升温过程中发现,如图6e所示,频率为20 Hz时在温度范围-15~75 ℃内,薄膜的阻尼可达到0.04以上,温域较宽(约90 ℃)。在研究阻尼与频率的关系时发现,在升降温过程中,均可以观察到较高的内耗峰,在不同成分薄膜的多频阻尼-温度曲线中,随着频率从0.5 Hz升高到20 Hz,升降温过程中阻尼峰对应的温度均向高温方向移动,低频时,频率升高使得阻尼峰向高温方向移动较多,频率继续升高则移动的温度范围减小。内耗峰的位置对频率有较大的依赖性,峰的位置会随着频率的变化而变化,这与Ti-Nb-Ta-Zr-O等β-Ti合金中的阻尼-温度曲线[25,26]中得到的结论相同,因此可以认为Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜中的内耗峰为弛豫型内耗。弛豫型内耗峰主要来源于晶界、孪晶界、相界、位错等界面的移动,在阻尼峰出现的温度范围内,薄膜主要相组成为马氏体相,晶粒中有较多细小的马氏体板条,存在大量的孪晶界,在振动中孪晶界移动使得机械能转化为内能,阻尼产生的微观机制为孪晶界的黏滞性滑动。随着Fe含量的增加,晶粒尺寸减小,马氏体板条更加细小,孪晶界增加,孪晶界移动消耗的能量也就越高,因此弛豫内耗峰值越大。目前普遍认为记忆合金的弛豫型内耗峰起源于合金中间隙原子与孪晶界面的相互作用,在交变载荷作用下孪晶界发生反复推移,在合适的温度下间隙原子会跟随着孪晶界移动,对该弹性响应有阻滞作用,造成弹性应变响应时间上的弛豫,从而在宏观上表现为弛豫型内耗峰[27,28];而当温度过高时,间隙原子跃迁能力增强,总能迅速地跟随孪晶界移动,阻滞作用微弱,阻尼-温度曲线不显现出内耗峰。而当温度过低时,间隙原子跃迁能力下降,对孪晶界产生钉扎效应,使得弹性模量迅速升高,阻尼性能迅速降低,因此在一定温度内会出现弛豫型内耗峰。当Fe含量为1.0时,获得了最高的弛豫型内耗峰(峰值为0.116),高于Ti-Nb-O (0.09)、Ti-Nb-Ta-Zr-O (0.035)等β-Ti合金的弛豫型内耗峰的峰值,因此可以认为该合金薄膜具有较高的阻尼特性。

图6

图6

Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜的多频阻尼-温度曲线

Fig.6

Multi frequency-temperature damping curves of Ti70-xTa15Zr15Fex thin films with x=0.3 (a, b), 0.6 (c, d) and 1.0 (e, f) under heating process (a, c, e) and cooling process (b, d, f) (Tanδ—value of the internal friction)

3 结论

(1) Ti70-xTa15Zr15Fex(x=0.3、0.6、1.0)合金薄膜在室温下均为母相与马氏体共存,晶粒中可观察到板条状马氏体,随着Fe含量的增加,薄膜中母相含量增加,晶粒尺寸减小。

(2) 随着Fe含量升高,Ti70-xTa15Zr15Fex (x=0.3、0.6、1.0)合金薄膜的马氏体逆相变温度降低,薄膜具有双程记忆效应。添加Fe元素可以提高薄膜的塑性和强度,x=1.0的合金薄膜延伸率可达到12.8%。

(3) 在升温降温过程中均观察到明显的弛豫内耗峰,内耗峰受到频率的影响,随频率的增加向右移动,薄膜阻尼产生的机制为孪晶界弛豫。x=1.0时,薄膜阻尼最高值可达0.116,在-15~75 ℃温度区间阻尼值在0.04以上,属于宽温域高阻尼合金薄膜。

参考文献

Physical metallurgy of TiNi-based shape memory alloys

[J].

Shape memory materials

[J].

Characterization of TiNi shape-memory alloy thin films for MEMS applications

[J].

New materials for micro-scale sensors and actuators: An engineering review

[J].

TiNi-based thin films in MEMS applications: A review

[J].

Development of hydraulic linear actuator using thin film SMA

[J].

Microactuators of free-standing TiNiCu films

[J].

Recent developments in shape memory thin film technology

[J].

Crystallization process and shape memory properties of Ti-Ni-Zr thin films

[J].AbstractThe crystallization process of as-deposited Ti–Ni–(10.8–29.5)Zr amorphous thin films was investigated. The Ti–Ni–Zr as-deposited films with a low Zr content exhibited a single exothermic peak due to the crystallization of (Ti,Zr)Ni with a B2 structure. In contrast, a two-step crystallization process was observed in the Ti–Ni–Zr thin films with a high Zr content. Shape memory behavior of Ti–Ni–Zr thin films heat treated at 873–1073 K was investigated by thermal cycling tests under various stresses. The martensitic transformation start temperature increased with increasing Zr content until reaching the maximum value, then decreased with further increasing Zr content. The inverse dependence of transformation temperature on Zr content in the thin films with a high Zr content is due to the formation of a NiZr phase during the crystallization heat treatment. The formation of the NiZr phase increased the critical stress for slip but decreased the recovery strain.]]>

Phase transformation, structural and functional fatigue properties of Ti-Ni-Hf shape memory thin films

[J].The shape memory thin film system Ti-Ni-Hf was investigated with regard to its structural, phase transformation and functional fatigue properties by means of combinatorial and high-throughput methods. Temperature-dependent resistance measurements revealed a broad compositional region showing a reversible phase transformation. A ternary Laves phase was identified using X-ray diffraction as a precipitate phase within the transforming composition region. With increasing Ti content, the amount of the Laves phase increases, which results in an increase in the thermal hysteresis and a simultaneous decrease in the transformation temperatures. Shape memory properties were characterized by temperature-dependent stress change measurements using micromachined Si cantilever array wafers coated with Ti-Ni-Hf. The recovery stress was found to increase for small amounts of Laves phase precipitates. Strengthening of the matrix due to the Laves phase precipitates is concluded to be responsible for the observed increase in recovery stress and improved functional fatigue properties for (Ti,Hf)-rich alloy compositions (Ti40.0Ni47.5Hf12.5). (C) 2011 Acta Materialia Inc. Published by Elsevier Ltd.

Thermal stability and high-temperature shape memory effect of Ti-Ta-Zr alloy

[J].

Effect of Y addition on the martensitic transformation and shape memory effect of Ti-Ta high-temperature shape memory alloy

[J].

The effects of α″ and ω phases on the superelasticity and shape memory effect of binary Ti-Mo alloys

[J].

Effect of thermo-mechanical process on structure and high temperature shape memory properties of Ti-15Ta-15Zr alloy

[J].

Shape memory alloys for microsystems: A review from a material research perspective

[J].

Microstructures and memory properties of Ti69Zr30Fe1 high-temperature shape memory alloy

[J].

Ti69Zr30Fe1高温形状记忆合金的微观结构和记忆特性

[J].

High-temperature shape memory effect in Ti-Ta thin films sputter deposited at room temperature

[J].

The effect of annealing treatment on microstructure and shape memory behavior of Ti-Ta-Zr thin films

[J].

Effect of ternary alloying elements on the shape memory behavior of Ti-Ta alloys

[J].AbstractThe effect of ternary alloying elements (X = V, Cr, Fe, Zr, Hf, Mo, Sn, Al) on the shape memory behavior of Ti–30Ta–X alloys was investigated. All the alloying elements decreased the martensitic transformation temperatures. The decrease in the martensitic transformation start (Ms) temperature due to alloying was affected by the atomic size and number of valence electrons of the alloying element. A larger number of valence electrons and a smaller atomic radius of an alloying element decreased the Ms more strongly. The effect of the alloying elements on suppressing the aging effect on the shape memory behavior was also investigated. It was found that the additions of Sn and Al to Ti–Ta were effective in suppressing the effect of aging on the shape memory behavior, since they strongly suppress the formation of ω phase during aging treatment. For this reason the Ti–30Ta–1Al and Ti–30Ta–1Sn alloys exhibited a stable high-temperature shape memory effect during thermal cycling.]]>

Structure and mechanical properties of as-cast Ti-5Nb-xFe alloys

[J].

Mechanical and magnetic behavior of oligocrystalline Ni-Mn-Ga microwires

[J].

Microstructure of stress-induced martensite in a Ti-Ni-Hf high temperature shape memory alloy

[J].

Snoek-type high-damping alloys realized in β-Ti alloys with high oxygen solid solution

[J].

Influence of solution-aging treatment on damping and tensile properties of Ti-36Nb-2Ta-3Zr-0.3O alloy

[J].

Internal friction behaviour of Ni-Mn-Ga

[J].

Effects of frequency, composition, hydrogen and twin boundary density on the internal friction of Ti50Ni50-xCux shape memory alloys

[J].AbstractThe internal friction (IF) of Ti50Ni50−xCux polycrystals, which were normally solution-treated, was systematically studied using dynamic mechanical analysis. As a result, the broad peak appearing in B19 martensite was confirmed to be a relaxation peak with an activation energy of 0.67 and 0.76 eV for x = 20 and 16, respectively. Then the broad peak was shown to disappear in a single-crystal experiment, if twin boundaries in martensite are largely eliminated. This is direct evidence to show twin boundaries are indispensable for the broad peak. The effect of hydrogen on IF was also examined using a vacuum system with a mass spectrometer, and the broad peak at 250 K was observed to disappear, while a new small relaxation peak was found at 178 K, when hydrogen was eliminated. These experiments clearly show that there are two essential ingredients to observe the high broad peak: twin boundaries and hydrogen. Based on these results a possible origin for the broad peak is discussed.]]>