随着海洋资源的深度开发,人类对海洋工程用高品质特厚钢板(以下简称海工特厚板)的需求量和性能要求都越来越高[1~3]。特别是在满足高强度、高韧性、抗疲劳、耐低温冲击以及耐海水腐蚀的同时,还需要在板厚方向上具有较高的组织和性能均匀性[4],这对海工特厚板的材料及其热加工技术提出了挑战。在海工特厚板的实际生产过程中,细化晶粒和提高淬透性是提高钢板截面性能均匀性的基本途径。然而,受实际冷却条件及材料热传导速率的限制,淬火过程中特厚板心部因冷速较低,通常难以得到完全马氏体,从而使其表层与心部区域的组织和性能的差异较大[5]。因此,在确定的冷却条件下,提高淬透性以提高板厚方向组织性能的均匀性是海工特厚板生产的技术关键和难点。

钢的淬透性通常与其化学成分和奥氏体晶粒度有关,而且它们之间的定量关系已经建立[6]。然而,对于与这些定量关系不一致的性能研究(如超淬透性)也有报道[7]。Brown和James[8]发现,在1650 ℃下将BS 970 150M36 (类似于SAE 1340)钢水过热处理后,其淬透性会显著增加,藉此提出了超淬透效应的概念。对于普通合金钢而言,通过在冶炼过程中添加一定量的Al或Ti并提高冶炼温度,可以获得优异的淬透性[9],但是这种改进很难用合金元素含量的提高来计算和解释。Cias[10]研究了超淬透性钢的相变动力学,指出超淬透性钢中铁素体的形核和生长受到抑制,从而延迟了珠光体相变并促进了马氏体相变。还有研究[11]表明,钢的超淬透性与其基础淬透性呈正相关,基础淬透性越好则其超淬透性越明显。可见,影响基础淬透性的Al、Ti、B以及其他合金元素,也会对钢的超淬透性产生影响。

Garbarz和Pickering[12,13]指出,只有当微合金元素不形成化合物,而是以单质形式偏聚到奥氏体晶界时,晶界上的铁素体形核及长大速率才会被抑制。事实上,奥氏体晶界的迁移速率以及V原子的扩散速率都会严重影响V原子的偏聚行为[14]。Garbarz和Pickering[15]指出,可以利用在奥氏体化温度下稳定存在的弥散颗粒来固定奥氏体晶界,以促进V原子向晶界偏聚。但是,V原子往往容易与N原子结合,并以VN颗粒的形式存在于基体中,这会显著降低V对提高淬透性的作用。与V相比,Al具有更强的与N结合的能力,所以适量添加Al元素可以起到固定钢中N (即铝固氮)的作用[16,17],从而解放V原子。同时,AlN颗粒更容易在晶界处析出,能够有效阻碍奥氏体化过程中的晶界迁移。但过高的Al含量也会使钢脆化,而且AlN的析出对温度比较敏感,如果热处理温度不当,Al对N的固定作用可能会受到抑制[18,19]。因此,合理设计钢中的Al / N比以及轧后热处理工艺的制订,对于高品级海工特厚板的生产至关重要。目前关于V元素对大规格航空发动机轴用40CrNiMoV钢、大规格圆环链用23MnNiMoCr54V钢等超淬透性的有益影响已有报道[20,21],但关于V在高品级海工特厚板用钢中的分布特性及对淬透性的影响研究却很少。

本工作重点研究了一种新型的980 MPa级海工特厚板用钢在不同奥氏体化温度条件下,V元素的分布特性与其淬透性的关系,并结合显微组织表征结果,讨论V分布状态对淬透性的影响机制,以期为新型超低碳高强度海工特厚板的开发提供理论依据。

1 实验方法

采用50 kg真空感应炉在5 Pa、1600 ℃条件下熔炼实验用钢锭,再将其改锻成尺寸约为80 mm × 80 mm × 1000 mm的坯料。其化学成分(质量分数,%)为:C 0.096,Si 0.24,Mn 0.73,Ni 4.54,Cr 0.61,V 0.15,T. Al 0.025 (T.Al为总铝量),N 0.0083,Fe余量。

在L78 RITA膨胀仪上测定相变点和连续冷却转变(CCT)曲线,样品为直径3 mm、长10 mm圆棒,保护气体为He气。将样品以10 ℃/s的速率加热至910 ℃,保持30 min后分别以0.05~50 ℃/s的速率冷却至室温,用FM-ARS 9000型显微硬度计检测显微硬度。利用Thermo-Calc热力学计算软件的TCFE2000数据库计算实验用钢中AlN的析出与再加热温度的关系曲线。根据计算结果和已有研究结果[22],选择析出和不析出AlN的2个奥氏体化温度,分别为850和910 ℃。

采用线切割方法制备直径25 mm、长105 mm圆棒,并机械加工成Jominy末端淬火实验(以下简称Jominy实验)标准样品。根据GB/T 225—2006/ISO 642:1999标准,分别在850和910 ℃奥氏体化30 min后进行末端淬火实验。在距离淬火端分别为1.5、3、5、7、9、11、13和15 mm处,以及其余位置每间隔5 mm用ZHR8150CLK型洛氏硬度计检测硬度。选取端淬试样上每个点5次测量结果的硬度平均值来表示在特定温度下的淬透性,将不同位置的平均硬度与该位置距淬火端的距离绘制成Jominy曲线,并计算2个奥氏体化温度条件下实验用钢的理想临界直径,再结合第二相颗粒的理想化学计量比和溶解度公式估算奥氏体中溶解的V含量。

采用电火花加工方法将经不同温度淬火后的试样切成薄片,经机械研磨和抛光后再用4%硝酸酒精溶液(体积分数)腐蚀,然后进行显微组织观察。原奥氏体晶界用60 ℃下饱和苦味酸与海鸥洗发膏的混合水溶液腐蚀,其中每30 mL饱和溶液添加海鸥牌洗发膏3 g。用Axiover-200MAT金相显微镜(OM)和S4800型扫描电子显微镜(SEM)观察距淬火端不同位置的显微组织和原始奥氏体形貌,使用1720H型电子探针分析仪(EPMA),在电压为15 kV、电流为30 nA的条件下测定钢中V原子的分布特性。其中,X射线分光器数为2~5道,取出角为52.5°,二次电子分辨率为5 nm。用Talos F200x型透射电子显微镜(TEM)观察850和910 ℃下淬火样品的组织和析出物形貌,并对其成分进行线能谱(EDS)分析,加速电压为200 kV。制备TEM样品时,首先用砂纸将实验薄片研磨至约30 μm厚,然后用Gatan精密抛光系统在7%的高氯酸酒精溶液(体积分数)中进行电解减薄(电压为30 V)。

根据GB/T 228.1—2010 《金属材料 拉伸试验(第1部分:室温试验方法)》标准,将实验用钢加工成标准拉伸试样,用CSS44300电子万能试验机在室温下以3 mm/min的速率进行拉伸实验。根据GB/T 229—2020 《金属材料 Charpy摆锤冲击试验方法》标准,将实验用钢加工成标准Charpy U型冲击试样,用CBD-500电子式摆锤冲击试验机进行(-20 ± 5)和(-80 ± 5) ℃下的低温冲击实验。拉伸及冲击实验每组均测试3个试样,取平均值。

2 实验结果

2.1 2个温度奥氏体化后的Jominy曲线

实验用钢在850和910 ℃奥氏体化30 min后的Jominy曲线如图1所示。可以看出,在2个奥氏体化温度下,淬火端附近的硬度基本相同,且均随着距淬火端距离的增加而减小。淬火端附近的硬度相近,表明2种状态下的基础硬度基本相同。随着距淬火端距离的进一步增加,2种状态钢的硬度变化差异显著。当距离超过20 mm后,850 ℃奥氏体化实验用钢的硬度随着距离的增加而急剧下降,且当距离超过30 mm后硬度已低于35 HRC。相比之下,910 ℃奥氏体化实验用钢的硬度随距离的增加变化较为缓慢,直到在距离为55 mm处硬度才低于35 HRC。可见,910 ℃奥氏体化实验用钢的淬透性显著优于850 ℃的淬透性。

图1

图1

在850和910 ℃奥氏体化后实验用钢的Jominy曲线

Fig.1

Jominy curves of test steel after austenitizing at 850 and 910 oC

2.2 CCT曲线和显微组织

图2给出了实验用钢在910 ℃奥氏体化30 min后的CCT曲线及显微硬度随冷却速率的关系曲线。可以看出,该钢的奥氏体转变开始和结束温度(Ac1和Ac3)分别为696和834 ℃。当冷却速率低于0.2 ℃/s时(显微硬度约为272 HV或更低时),发生了贝氏体转变,但当冷速超过0.3 ℃/s时,则发生马氏体转变(图2a)。采用膨胀法测得实验用钢的马氏体转变开始温度(Ms)为438 ℃。实验用钢的显微硬度与冷却速率的关系如图2b所示。显微硬度随着冷却速率的增大而增加,尤其是当冷却速率低于0.5 ℃/s时,显微硬度迅速增加。但当冷却速率超过0.5 ℃/s时,显微硬度随冷却速率的变化明显减小。经非线性拟合得到显微硬度(H)与冷却速率(ν)之间的定量表达式为:

图2

图2

连续冷却转变(CCT)曲线及显微硬度随冷却速率的变化曲线(910 ℃,30 min)

Fig.2

Continuous cooling transformation (CCT) curves (a) and microhardness as a function of the cooling rate (b) of test steel after austenizing at 910 oC for 30 min (M—martensite, B—bainite; Ac1—starting temperature of austenite form-ation, Ac3—finishing temperature of austenite formation, Ms—starting temperature of martensite formation, Mf—finishing temperature of martensite formation, Bs—starting temperature of bainite formation, Bf—finishing temperature of bainite formation, v—cooling rate, R2—goodness of fit)

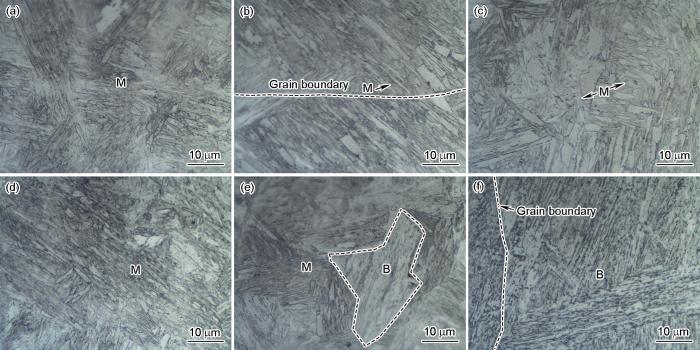

图3给出了910和850 ℃奥氏体化后,实验用钢在距淬火端5、30和55 mm处显微组织的OM像。可以看出,在距淬火端5 mm处,由于910和850 ℃奥氏体化实验用钢的冷却速率均达到甚至超过了发生马氏体相变的临界冷却速率,故相变产物为典型的板条马氏体(图3a和d)。在距离为30 mm处,虽然冷却速率有所降低,但在910 ℃奥氏体化实验用钢中仍然发生了完全马氏体转变,且马氏体板条较宽(图3b),而850 ℃奥氏体化实验用钢中晶界处则出现羽毛状上贝氏体(图3e)。在距离为55 mm处,冷却速率进一步降低,910 ℃奥氏体化实验用钢中的马氏体板条继续变宽(图3c),而在850 ℃奥氏体化实验用钢中观察到了完全的贝氏体组织(图3f)。显然,在2种奥氏体化温度下,不同位置的显微组织结果不仅验证了Jominy实验的硬度分布,而且也表明实验用钢经910 ℃奥氏体化处理后比经850 ℃奥氏体化处理具有更高的淬透性。

图3

图3

910和850 ℃奥氏体化后距淬火端不同位置处实验用钢显微组织的OM像

Fig.3

OM images of test steel at the distances of 5 mm (a, d), 30 mm (b, e), and 55 mm (c, f) from the quenched end after austenitizing at 910 oC (a-c) and 850 oC (d-f)

图4

图4

910和850 ℃奥氏体化30 min后实验用钢原始奥氏体晶界形貌的SEM像

Fig.4

SEM images of original austenite grain bound-aries in test steel after austenitizing at 910 oC (a) and 850 oC (b) for 30 min

3 分析与讨论

3.1 实验用钢的超淬透性

钢的理想临界直径(DI)一般可通过端淬曲线确定。对于低碳钢,50%马氏体的硬度(

由

Grossman[23]指出,钢的淬透性仅与化学成分和奥氏体晶粒尺寸有关,并据此建立了淬透性评价标准。藉此得到的计算理想临界直径(

式中,MFGS为原始奥氏体晶粒尺寸的倍增因子,其他MF参数为钢中C含量和其他合金元素的倍增因子。据此计算出实验用钢的

3.2 超淬透性机制

图5

图5

实验用钢中AlN和VN析出曲线的Thermo-Calc计算结果

Fig.5

AlN and VN precipitation curves in test steel calculated by Thermo-Calc

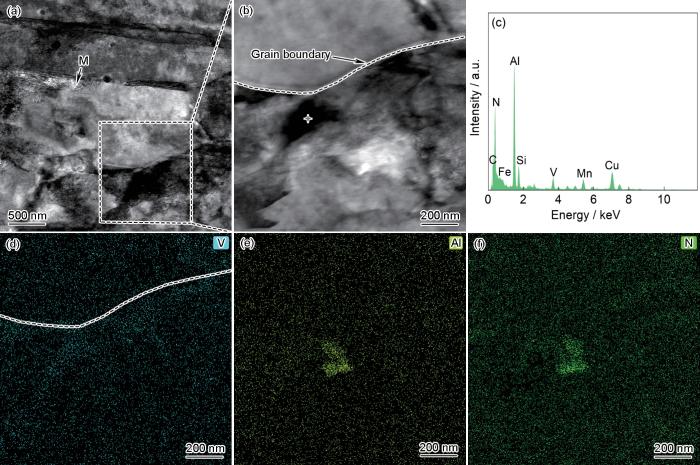

图6

图6

实验用钢经910 ℃奥氏体化30 min后淬火的TEM像及EDS分析结果

Fig.6

TEM images and EDS analyses of the test steel quenched after austenitizing at 910 oC for 30 min

(a) bright field TEM image

(b) local enlargement of Fig.6a

(c) EDS result of precipitate in Fig.6b (d-f) elemental mappings of V (d), Al (e), and N (f) of Fig.6b

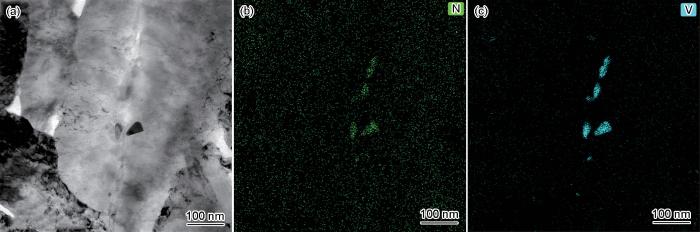

图7

图7

实验用钢经850 ℃奥氏体化30 min后淬火的TEM明场像和元素分布面扫图

Fig.7

Bright field TEM image (a) and elemental mappings of N (b) and V (c) of the test steel quenched after austenitizing at 850 oC for 30 min

EPMA常被用于表征材料中金属元素的偏聚行为[20,28~32]。图8给出了实验用钢在910和850 ℃奥氏体化30 min后,淬火态样品原始奥氏体晶界形貌和对应的V分布EPMA检测结果。图8a中标记出了部分原奥氏体晶界的位置,图8b为相应位置的V元素含量。可见,在910 ℃奥氏体化时,偏聚在晶界上的V原子浓度远高于其他位置(晶内)。然而,在850 ℃奥氏体化条件下,V原子的分布在晶界和晶内基本上是均匀的(图8c和d)。这2种条件下V原子的分布特性完全不同,V原子只有在原奥氏体晶界处偏聚才能获得更好的淬透性,由此可见910和850 ℃奥氏体化后实验用钢的淬透性差异较大(图1)。该结果与Mostert和Van Rooyen[33]报道的结果基本一致,并且B原子在钢中的类似行为已被报道[34]。因此,实验用钢的超淬透性可以通过奥氏体晶界处的V偏聚来获得,而这又需要通过调整V、Al和N等合金元素的含量及热处理工艺才能实现。

图8

图8

不同温度奥氏体化30 min后淬火的原奥氏体晶界及对应的V分布EPMA结果

Fig.8

Grain boundaries (a, c) and corresponding distributions (EPMA) of V (b, d) quenched after austenitizating at 910 oC (a, b) and 850 oC (c, d) for 30 min

对于不同奥氏体化温度条件下实验用钢奥氏体中溶解的V含量,可以利用碳化物中C和微合金元素的理想化学计量比及固溶度公式计算[16]:

式中,[M]为元素M (M = V、C)在固溶体中的质量分数,T为绝对温度。910 ℃时奥氏体中溶解的V和C的含量可以表示为:

此外,VC中V与C的比例应保持以下理想化学计量比:

式中,VVC表示VC中V含量的占比,用实验用钢中V的总含量减去奥氏体中溶解的V含量表示,即0.147 -

利用

材料获得超淬透性的关键是某些原子向点阵缺陷处的偏聚[15]。在含V钢中,当V原子在晶界偏聚时,其倾向于占据晶体缺陷位置(如空位或位错附近),这些缺陷通常是新相(如铁素体)形成时的优先形核位置。V原子的偏聚作用不仅物理上占据了这些缺陷位置,减少了形核的有效位点,而且还通过改变局部的化学环境和电子结构,影响了相变过程中所需的能量、成分和结构波动。首先,这种局部环境的改变使得在晶界附近形成新相的能量壁垒增加,从而阻碍了先共析铁素体在晶界的形核[34];其次,铁素体的生长依赖于奥氏体/铁素体界面的迁移。如果晶体缺陷位置被V原子等固溶元素占据,这些界面的能量会降低,界面周围的原子排列变得更加稳定。这种稳定性降低了界面的迁移能力,因而减缓了铁素体的生长速率。此外,V原子的偏聚还会影响其偏聚区附近的晶格畸变,进而影响奥氏体相界面的迁移速率。

因此,在含V钢的奥氏体化过程中,确保有V单质原子的偏聚是获取超淬透性的关键。AlN的形成消耗了钢中的N原子,减少了N原子与V原子形成VN的机会,使得V原子更多地以单质形式在奥氏体晶界偏聚。这种偏聚不仅影响了先共析铁素体的形核和生长,而且在连续冷却过程中,降低了形核和生长的速率,这对于促进马氏体的转变至关重要。马氏体相变的起点是结构涨落,这种涨落在能量波动的配合下形成马氏体晶核[35],V原子的偏聚能够有效提高奥氏体的稳定性,增大过冷度,降低马氏体转变的临界冷速,从而使其在连续冷却过程中能够在更宽的冷速范围(对应于更厚的钢板截面)内获得马氏体,而且组织和性能均匀性更好、强韧性匹配度更高,这是新型海工特厚板钢获得超淬透性的重要机制。

经测试,实验用钢在910 ℃奥氏体化条件下表现出的超淬透性使其获得了良好的力学性能。910 ℃淬火后再进行600 ℃回火处理,实验用钢的屈服强度达到1060 MPa,延伸率为17.8%,而在-80 ℃下的超低温冲击功为108 J,表现出了优异的综合力学性能[36]。

4 结论

(1) 奥氏体化温度显著影响新型海工特厚板用钢的淬透性。910 ℃奥氏体化条件下的理想临界直径(247 mm)是850 ℃奥氏体化条件下(163 mm)的1.52倍。

(2) 不同奥氏体化温度所导致的V原子分布差异显著影响新型海工特厚板用钢的淬透性,且V原子的晶界偏聚显著提高其淬透性,该钢最适宜的奥氏体化温度为910 ℃。

(3) V在奥氏体晶界的偏聚有效阻碍了C原子的扩散,降低了先共析铁素体的形核和长大速率,抑制了先共析铁素体转变,这是新型海工特厚板用钢获得超淬透性的主要机制,而以Al固N则是确保V原子在晶界偏聚的技术关键。

参考文献

Effect of through-thickness microstructure inhomogeneity on mechanical properties and strain hardening behavior in heavy-wall X70 pipeline steels

[J].

Effects of processing optimisation on microstructure, texture, grain boundary and mechanical properties of Fe-17Cr ferritic stainless steel thick plates

[J].

Enhanced properties and homogeneity of Al-Zn-Mg-Cu alloy thick plate by non-isothermal aging

[J].

Impact of multi-level microstructures on the strength and yield ratio of extra-thick ultra-high-strength steel

[J].

Effect of hardenability on microstructure and property of low alloy abrasion-resistant steel

[J].

Calculation of hardenability of structural steels from their chemical composition

[J].

Estimating the hardenability of carbon steels

[J].

Superhardening in medium-carbon steel

[J].

Effects of Al and Ti on age-hardenability of 40Cr-Ni alloy

[J].

40%Cr-Ni合金の時効硬化性におよぼすAlとTiの単独添加の影響

[J].

Phase transformational kinetics and hardenability of low-carbon, boron-treated steels

[J].

Relationship between hardness and microstructure of continuously cooled C-Mn-V steels

[J].

Strengthening in pearlite formed from thermomechanically processed austenite in vanadium steels and implications for toughness

[J].

Influence of vanadium microalloying on isothermal transformation behavior of eutectoid steel

[J].

Effect of vanadium and austenitising temperature on hardenability of (0.2-0.3)C-1.6Mn steels with and without additions of titanium, aluminium, and molybdenum

[J].

Nitride-inclusion characterization in lightweight steel and re-precipitation behavior of AlN during heat treatment: Effect of Al content

[J].

Effect of Al on hardenability and microstructure of 42CrMo bolt steel

[J].42CrMo steel has a good combination of strength and toughness after quenching and tempering treatment, which make it an ideal candidate material for high strength bolt. Nevertheless, with the increase of bolt diameter in wind power field, the hardenability of 42CrMo steel is inadequate to manufacture the high strength bolt with diameter over 36 mm. Recent study indicates that Al addition is an economical and effective way to affect the phase transformation product during quenching process. In order to improve the hardenability of 42CrMo bolt steel, the effect of Al on the hardenability of 42CrMo was investigated by Jominy test and cross section hardness distribution test. OM and SEM were used to analyze the morphology of the grain size; chemical phase analysis test was used to detect the precipitation in Al addition steels; the isothermal transformation diagram (TTT curve) was measured to study the phase transformation of the steels; the three dimensional atom probe (3DAP) was used to analyze the Al distribution in matrix; the tensile and impact toughness properties of Al addition steels were also examined. It was found that the hardenability of 42CrMo bolt steel could be improved significantly by Al-Ti and Al-B addition, the hardness was increased by 6 HRC at the position of 25 mm from quenched end, the center hardness in diameter of 42, 48 and 56 mm was increased by 7, 10 and 14 HRC, respectively. The improvement of hardenability for Al-Ti addition steel can be attributed to the increasing dissolved Al content in the matrix because of the Ti addition, which suppresses the formation of bainite during the quenching process. The hardenability of Al-B addition steel is better than that of Al-Ti addition steel, which can be ascribed to the dissolved Al and B inhibiting the phase transformation of ferrite and pearlite. Moreover, Al can play an important role in increasing dissolved B content by means of AlN formation, in which the dissolved Al dispersive distribution in matrix is favorable to improve the hardenability of 42CrMo steel. Meanwhile, the tensile strength and Charpy V-notch impact energy at -40 ℃ of Al addition steels are adequate to manufacture grade 12.9 high strength bolt.

Al对42CrMo螺栓钢淬透性及组织的影响

[J].在42CrMo钢基础成分中配合添加Al-Ti和Al-B元素,通过末端淬火实验和截面硬度实验对比分析3种42CrMo钢淬透性的差异,并通过OM、SEM等手段观察晶粒形貌以及不同部位淬火后显微组织,利用三维原子探针(3DAP)分析元素分布,通过常规力学性能实验检测其常温拉伸和低温冲击性能。结果表明,Al-Ti、Al-B的添加均使42CrMo钢淬透性提高,Al-B钢增加淬透性作用更大,淬火后距淬火端25 mm处的硬度增加6 HRC,直径42、48和56 mm截面的心部硬度分别增加7、10和14 HRC,并且使钢的抗拉强度R<sub>m</sub>≥1200 MPa,-40 ℃下冲击吸收功KV<sub>2</sub>≥27 J,力学性能满足低温环境下螺栓用钢的使用要求。通过化学相分析实验和TTT曲线测定,表明Al-Ti配合添加,Ti发挥固氮作用形成TiN,使Al固溶于铁素体中,抑制贝氏体产生;Al-B配合添加,一部分Al发挥固氮作用,另外一部分Al与B共同固溶于钢中,抑制珠光体和铁素体的转变,增加实验用钢在较低的冷速下获得马氏体的能力,提高钢的淬透性。通过3DAP实验分析钢中各元素的分布情况,其中Al元素在钢中弥散分布,抑制C的扩散,从而抑制贝氏体的形成,提高钢的淬透性。实验结果表明,Al在钢中添加既可作为固N元素促进B的固溶,也可由其自身固溶于钢中,提高材料的淬透性。

Precipitation behaviors of AlN inclusion in high-Al steel

[J].

Superhardenability behavior of vanadium in 40CrNiMoV steel

[J].

Effect of vanadium on superhardenability of 23MnNiMoCr54V steel for round-link chain in mining applications

[J].The effect of vanadium on the hardenability and microstructure of 23MnNiMoCr54V steel was investigated after austenitizing at 950 and 1050 degrees C by dilatometry and end-quenching Jominy tests, combined with nitrogen removal with aluminum. Electron probe micro-analysis, scanning electron microscopy and transmission electron microscopy techniques were used to characterize the microstructure and existence state of vanadium atoms in the steel. The presence of aluminum-stabilized nitrogen by aluminum nitride production, which promoted the segregation of solid solution vanadium atoms at grain boundaries, delayed the transformation of ferrite and improved the austenite stability. Thus, vanadium addition could improve the hardenability, and an excellent steel performance could be obtained during slower cooling. This process could be used to produce heavy section steel components, such as round-link chains for mining applications.

Hardenability calculated from chemical composition

[J].

Effect of vanadium and austenitising temperature on hardenability of (0.2-0.3)C-1.6Mn steels with and without additions of titanium, aluminium, and molybdenum

[J].

Quantitative laser-induced breakdown spectroscopy mapping of centerline segregation via optical emissions of Mn and Cr in steel wire rod products

[J].

Quantification of complex-phase steel microstructure by using combined EBSD and EPMA measurements

[J].

Elemental mapping and quantitative characterization of dendrite structure in IN718 supperalloy based on micro beam X-ray fluorescence and EPMA

[J].

Towards relieving center segregation in twin-roll cast Al-Mg-Si-Cu strips by controlling the thermal-mechanical process

[J].Serious center segregation greatly limits the application of twin-roll casting (TRC) technology for producing 6xxx alloy strips. Herein, Al-0.9Mg-0.6Si-0.2Cu-0.1Fe (wt.%, 6061) strips with different thicknesses were fabricated by TRC, and we found that the center segregation was well relieved with the thickness increased from 3 mm to 4 mm. To reveal the mechanisms of mitigation of center segregation in the 4 mm strip, various techniques including solidification simulation, crystallographic calculation, electron backscatter diffraction (EBSD), and electron probe micro-analyzer (EPMA) were utilized. The results disclosed that the Fe-containing phase in the 3 mm strip was π-AlFeMgSi, while the counterpart in the 4 mm strip was α-AlFeSi. The α-AlFeSi could serve as nucleation substrates for Mg<sub>2</sub>Si and Q-AlCuMgSi phases, thus promoting the uniform distribution of elements and preventing the accumulation of phases in the center region. Three matching planes between the α-AlFeSi and Q/Mg<sub>2</sub>Si were examined as: (11$\bar{2}$0)<sub>α-AlFeSi</sub> // (0001)<sub>Q,</sub> (0001)<sub>α-AlFeSi</sub> // (110)<sub>Mg2Si,</sub> and (11$\bar{2}$0)<sub>α-AlFeSi</sub> // (1$\bar{1}$0)<sub>Mg2Si</sub>. Meanwhile, the smaller roll separating force during the TRC process in the 4 mm strip could weaken the force-induced liquid flow behavior in the semi-solid region, which is the other reason for the alleviation of center segregation. Owing to the elimination of the center segregation, a more excellent fracture elongation was achieved in the as-homogenized 4 mm strip (∼29%) compared with the counterpart of the 3 mm strip (∼20%). This work may provide a strategy to eliminate the center segregation, thus further promoting the application of TRC process and producing high-performance Al alloy strips efficiently.

XPS, EPMA and microstructural analysis of a defective industrial plasma-nitrided steel

[J].

A quantitative assessment of the hardenability increase resulting from a superhardenability treatment

[J].

Hardenability effect of boron on carbon steels

[J].

Isothermal decomposition of austenite in presence of martensite in advanced high strength steels: A review

[J].