镍基单晶高温合金具有优越的高温力学性能和蠕变性能,是先进航空发动机和地面燃气轮机涡轮叶片和导向叶片的首选材料。目前工业上通常采用选晶法和籽晶法制备单晶高温合金叶片。选晶法利用镍基合金在<001>晶向上择优生长的特点,通过晶粒间相互竞争淘汰作用获得接近<001>方向的单晶,但不能精确控制单晶的晶体取向[1~3];籽晶法的优势在于能够实现对单晶三维取向的控制,但在籽晶的重熔过程中经常出现杂晶[4~8]。这些杂晶在后续定向凝固过程中将与籽晶晶粒竞争生长,不断扩展甚至进入铸件内部,从而影响单晶的完整性,降低其使用性能[9]。因此,研究定向凝固过程中晶粒的竞争生长规律,从而实现对单晶叶片的晶体取向和杂晶的控制,对高效制备高质量的单晶叶片具有非常重要的意义。

1959年,Walton和Chalmers[10]提出了解释不同取向晶粒间竞争生长现象的一些基本思想。研究人员[11,12]根据透明有机物实验总结概括出了Walton-Chalmers经典晶粒竞争生长模型。该模型认为,对于发散双晶,其晶界处存在较大的空间,择优取向枝晶的分枝作用将导致非择优取向晶粒被逐渐压缩,最终被择优取向晶粒淘汰;对于汇聚双晶,非择优取向晶粒的一次枝晶主干被择优取向枝晶阻挡,汇聚双晶的晶界将平行于热流方向。随后,研究人员[1,13~18]对晶粒竞争生长行为进行了大量的双晶实验和数值模拟研究。对于发散双晶,择优生长的晶粒在晶界处的分枝作用决定了晶粒的淘汰行为[13,16,18~20];对于汇聚双晶,物理阻挡和枝晶尖端的溶质交互作用共同决定了晶粒的淘汰行为[13,21~23]。研究晶粒的竞争生长机制是为了更好地控制晶粒的生长行为,最终获得接近于<001>取向的完整单晶。研究人员[24,25]试图通过调整凝固工艺参数(如温度梯度和抽拉速率)、优化选晶器的几何参数等方法制备出更加集中的取向为<001>的组织。结果表明,这些方法都不能实现对晶体取向的有效控制。为此,尝试通过新的手段控制单晶的晶体取向具有非常重要的科学和工程意义。

磁场作为外加物理场,通常以力和能的形式无接触地作用于金属材料的定向凝固过程中,并对其扩散、流动及凝固界面产生影响,进而对凝固组织和成分分布产生影响,并已成为一个除凝固速率及温度梯度以外的独立可控的工艺参数。大量研究[26~29]表明,在定向凝固过程中施加磁场能够细化一次枝晶,改变凝固界面形貌,影响糊状区长度,促进柱状晶向等轴晶(CET)转变等。其中凝固界面前沿形成的一种新的流动(热电磁对流,TEMC)备受关注[30~33]。本课题组前期研究[27,28]发现,在定向凝固过程中施加0.1 T的横向磁场,就能在凝固界面前沿产生显著的与生长方向垂直的流动。在晶粒定向生长过程中,通过施加磁场产生的流动来改变枝晶间或枝晶尖端的溶质分布,影响枝晶在晶界处的分枝行为,进而控制晶粒的竞争生长,是非常值得探索的课题。第一代单晶高温合金DD483是在美国普惠公司研发的PWA1483合金的基础上发展而来的,具有较好的抗热腐蚀性能,被广泛用于重型燃气轮机叶片和航空涡轮发动机叶片及叶环等热端部件。本工作以镍基高温合金DD483为研究对象,在横向弱磁场下进行了不同拉速的发散双晶竞争生长实验,并初步探讨了热电磁对流对发散双晶竞争生长行为的影响。

1 实验方法

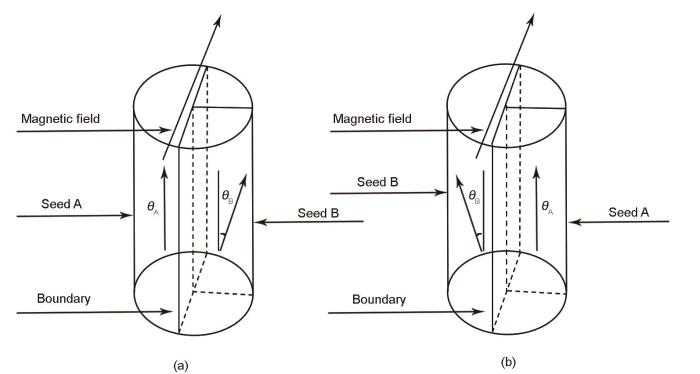

实验所用镍基高温合金籽晶和母合金材料均为第一代单晶高温合金DD483,其化学成分(质量分数,%)为:Cr 12.26,Al 3.48,Ti 4.0,Mo 1.99,Co 9.19,W 3.76,Ta 4.84,Ni余量。从单晶试棒中截取直径6.0 mm、长30 mm的2种晶体取向不同的圆柱状籽晶(A和B)。其中,籽晶A的<001>方向平行于轴向(晶粒A的<001>方向与轴向的夹角θA = 0°),为择优生长的晶粒;籽晶B的<001>方向与轴向呈一定角度(晶粒B的<001>方向偏离轴向的夹角θB = 14°~16°),为非择优生长的晶粒。沿轴向中心将籽晶切开,然后将2个不同位相的半圆柱状籽晶按发散的方式紧密排列组成双晶籽晶。双晶籽晶在横向磁场下的摆放方式如图1所示。沿着横向磁场的方向观察,当择优生长的籽晶A在磁场的左侧,非择优生长的籽晶B在磁场的右侧时(图1a),这种摆放方式称为A-to-B。同理,当非择优生长的籽晶B在磁场的左侧,择优生长的籽晶A在磁场的右侧时(图1b),这种摆放方式称为B-to-A。然后,再将双晶籽晶和母合金棒一起封入内径6 mm、外径8 mm、长160 mm的刚玉管中进行定向凝固实验。

图 1

图 1

发散双晶籽晶在横向磁场下的摆放方式示意图

Fig.1

Schematics of two patterns of the divergent bi-crystal seeds placed in a transverse static magnetic field (θA—tilt angle between the <001> direction of grain A and axial direction, θB—tilt angle between the <001> direction of grain B and axial direction)

(a) pattern A-to-B (b) pattern B-to-A

实验装置见文献[28],由直流电磁体和Bridgman定向凝固装置组成。横向磁场强度可调节,最高可达0.7 T。定向凝固炉装置主要包括加热系统(电极+石墨电阻),液态金属液冷却池(Ga-In-Sn金属液冷却),抽拉系统(拉速在0.5~104 μm/s间连续可调),以及控温测温仪(控温精度为±1 ℃)。实验时,将上述试样用高温胶固定在拉杆上,然后一起上升进入加热炉中;升温速率为10 ℃/min,当炉内温度上升至1500 ℃后保温10 min;调节横向磁场强度达到预定值后,启动抽拉系统,以预定的速率抽拉至一定长度(40 mm)后,将试样迅速下拉至液态金属冷却池中进行淬火,以保留固-液界面形貌。

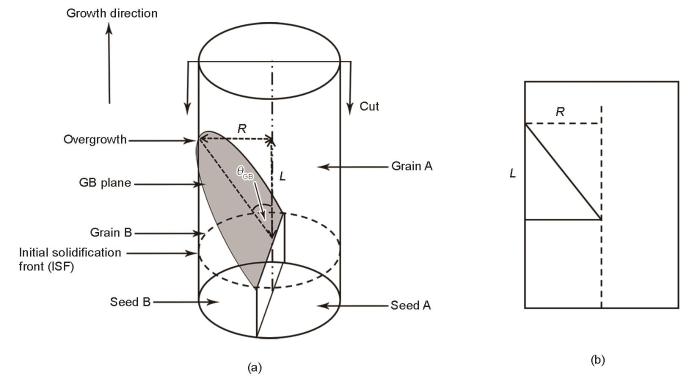

通过宏观腐蚀形貌确定起始凝固位置、晶界位置和晶粒淘汰位置。根据起始凝固位置和晶粒淘汰位置,确定晶界偏离角(θGB,表征晶粒淘汰速率)。θGB由tanθGB = R / L (其中,R是晶界在凝固起始处(籽晶重熔界面)与观察横截面之间的径向位移,L是凝固起始位置与观察横截面之间的距离)计算得到[13],其测量方法如图2所示。如果其中某个晶粒在定向生长过程中完全被淘汰,则R取试样的半径,L为晶粒消失的位置与凝固起始位置之间的长度。为区别不同晶粒的淘汰行为,当择优取向的晶粒A淘汰非择优取向的晶粒B时,晶界偏离角定义为正值;反之,定义为负值。垂直于试样轴向切取不同高度(即距离起始凝固界面的距离)的横截面,并沿试样轴向且垂直于横截面将试样切开。试样经砂纸打磨和抛光后,用8 g FeCl3 + 14 mL HCl + 21 mL H2O腐蚀液对样品进行金相腐蚀,并用DM6000光学显微镜(OM)观察凝固组织。采用面积法[34]统计一次枝晶间距:λ1 = (A / N)0.5 (其中,A为测定的横截面面积,N为测定面积内的枝晶个数)。

图2

图2

晶界偏离角(θGB)测定方法示意图及双晶籽晶纵截面平面图

Fig.2

Schematic of the determination and calculation of θGB (a) and the plane view cut from the centerline perpendicular to the interface of bi-crystal seeds (b) (R—radial displacement of the grain boundary (GB) started from the starting position of solidification (seed crystal remelting interface) to the observation cross section, L—distance between the starting position of solidification and the observation cross section, θGB—GB deviation angle between grain A and grain B)

2 实验结果

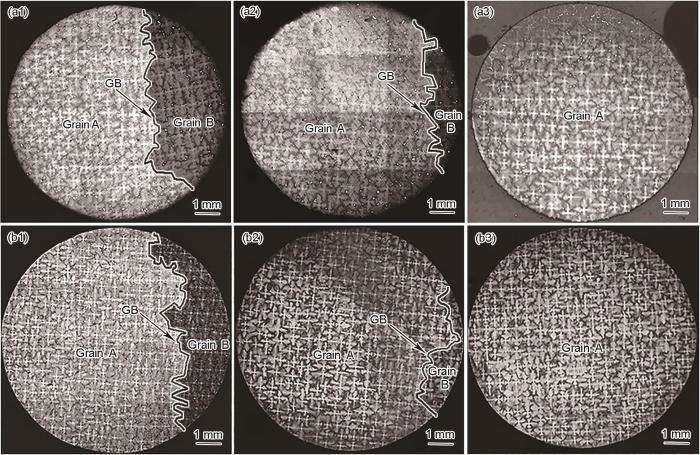

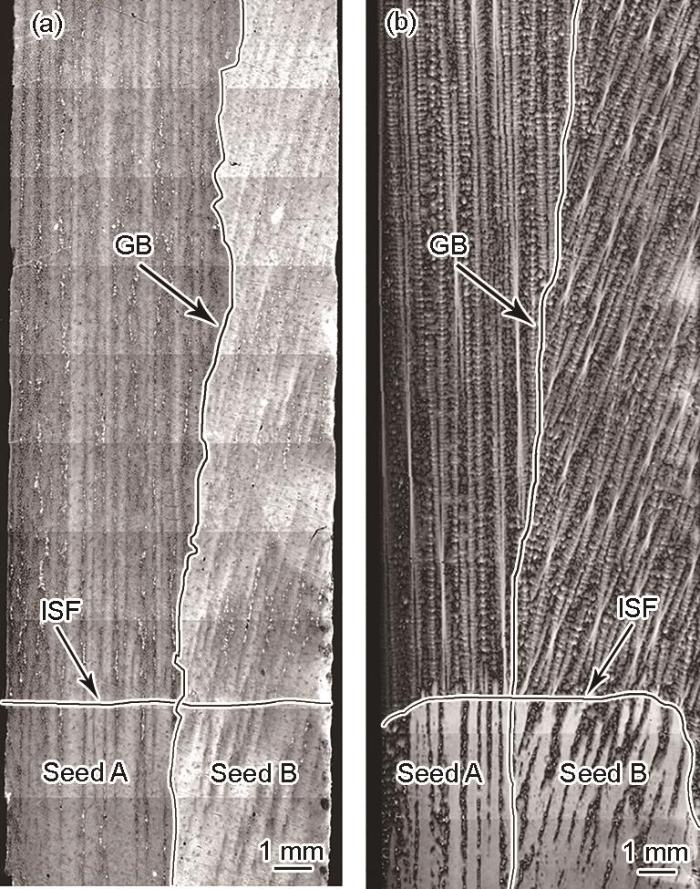

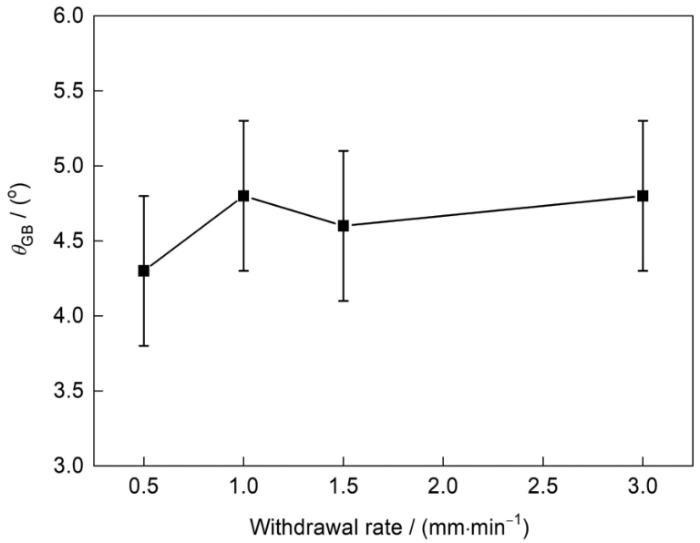

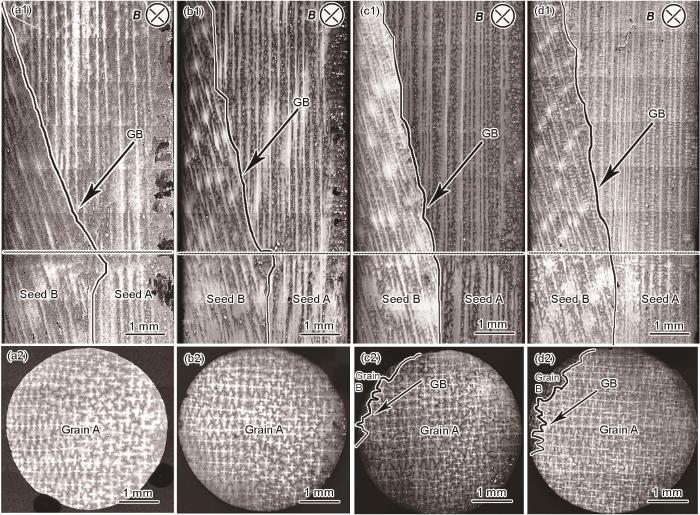

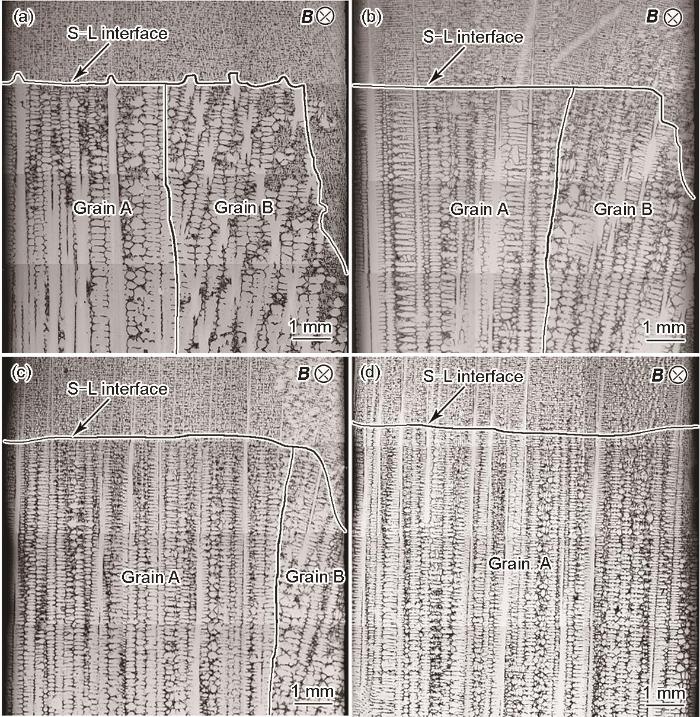

图3给出了无磁场条件下发散双晶试样在1和3 mm/min抽拉速率下晶粒竞争生长的演变过程。在1 mm/min拉速下,从不同高度横截面组织中可以看出,随着凝固距离的增加,晶粒B的面积分数逐渐减小(图3a1和a2),说明择优生长的晶粒A逐渐淘汰非择优生长的晶粒B。如图3a3所示,当截面高度为40 mm (即稳定生长)时,横截面组织中只剩下晶粒A,说明择优生长的晶粒A具有明显的竞争生长优势。双晶在不同拉速下呈现出类似的晶粒淘汰过程(图3b1~b3)。图4给出了拉速分别为0.5和3 mm/min时,发散双晶起始凝固阶段的纵截面组织。可以看出,晶粒A和晶粒B均可以在晶界处发展出新的分枝。由于晶粒A在晶界处的分枝作用,使晶界向晶粒B侧推进,导致晶粒B逐渐被压缩。实验结果与经典的Walton-Chalmers模型相一致。发散双晶晶界偏离角随拉速的变化如图5所示。由图可知,晶界偏离角基本不随拉速变化,保持在4.3°~5.0°范围内。说明在本实验条件下拉速不影响发散双晶的淘汰速率。Zhou等[13]研究表明,晶界偏离角的统计规律满足

图3

图3

无磁场条件下在拉速为1和3 mm/min时发散双晶定向凝固试样不同高度的横截面组织

Fig.3

Cross-sectional microstructures of the divergent bi-crystals directional solidification specimens at different heights without magnetic field at withdrawal rates of 1 mm/min (a1-a3) and 3 mm/min (b1-b3)

(a1, b1) 20 mm (a2, b2) 30 mm (a3, b3) 40 mm

图4

图4

拉速为0.5和3 mm/min时发散双晶起始凝固阶段的纵截面组织

Fig.4

Longitudinal microstructures of the divergent bi-crystals at the initial solidification stage at withdrawal rates of 0.5 mm/min (a) and 3 mm/min (b)

图5

图5

无磁场下发散双晶θGB随拉速的变化

Fig.5

θGB of the divergent bi-crystals as a function of the withdrawal rates without the magnetic field

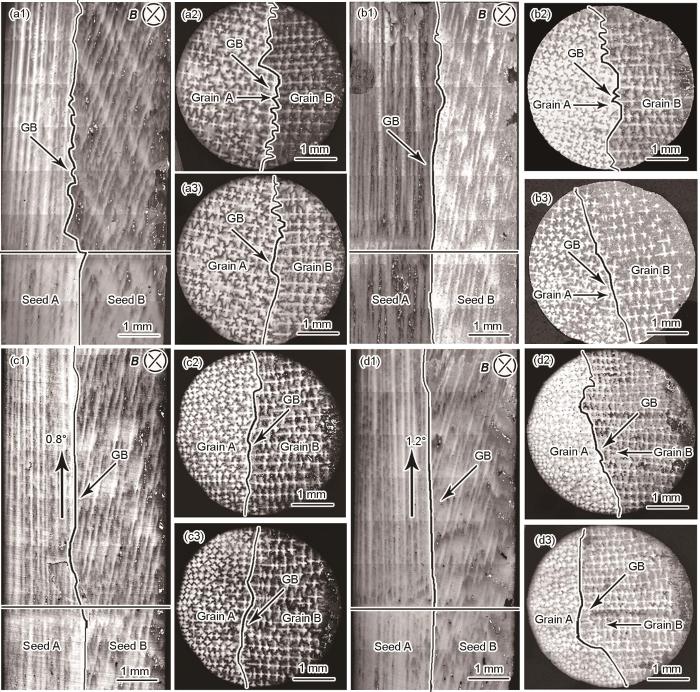

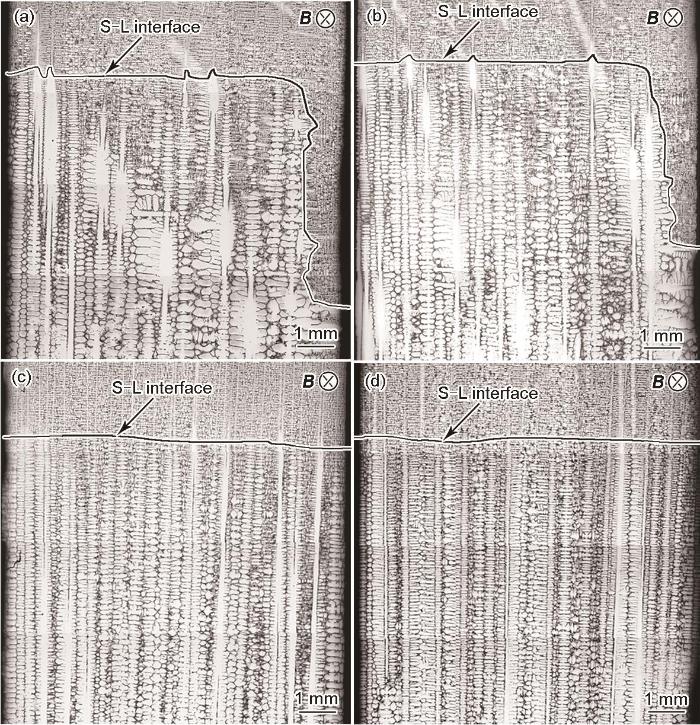

图6给出了发散双晶在横向磁场下按A-to-B方式摆放,当磁场强度B = 0.1 T时,不同拉速下双晶的起始凝固的纵截面和距离起始凝固界面20和30 mm处的横截面组织。从起始凝固的纵截面组织中可以看出,在低拉速(0.5和1 mm/min)下,晶粒A在晶界处基本没有出现新的分枝,晶界平行于热流方向(图6a1和b1)。对比图6a2和a3横截面组织发现,晶粒A和晶粒B在定向生长20和30 mm后没有出现明显的相互吞并的现象。当拉速为1 mm/min时,晶界处小部分区域晶界向晶粒A侧迁移,表明小部分择优取向的晶粒A的枝晶被非择优取向的晶粒B淘汰(图6b2和b3)。以上结果说明,在较低的拉速下,横向磁场的施加减缓了晶粒A淘汰晶粒B的速率。随着拉速的提高,晶粒A在晶界处的分枝作用加强,晶界由晶粒A侧向晶粒B侧迁移,晶粒A逐渐吞噬晶粒B (图6c1和d1)。从相同高度的横截面组织可以看出,随着拉速的增加,晶粒A的面积分数逐渐增大,表明在相同的磁场强度下,晶粒A淘汰晶粒B的速率随着拉速的增加而增加(图6c2、c3、d2和d3)。

图6

图6

当磁场强度为0.1 T,发散双晶按A-to-B方式摆放时,不同拉速下发散双晶的纵截面和横截面组织

Fig.6

Longitudinal microstructures (a1-d1), and transversal microstructures at the positions of 20 mm (a2-d2) and 30 mm (a3-d3) from the directional solidification starting place of the divergent bi-crystals at various withdrawal rates under the magnetic field of 0.1 T with the divergent bi-crystals placed in an A-to-B pattern ( B —transverse magnetic field)

(a1-a3) 0.5 mm/min (b1-b3) 1 mm/min (c1-c3) 1.5 mm/min (d1-d3) 3 mm/min

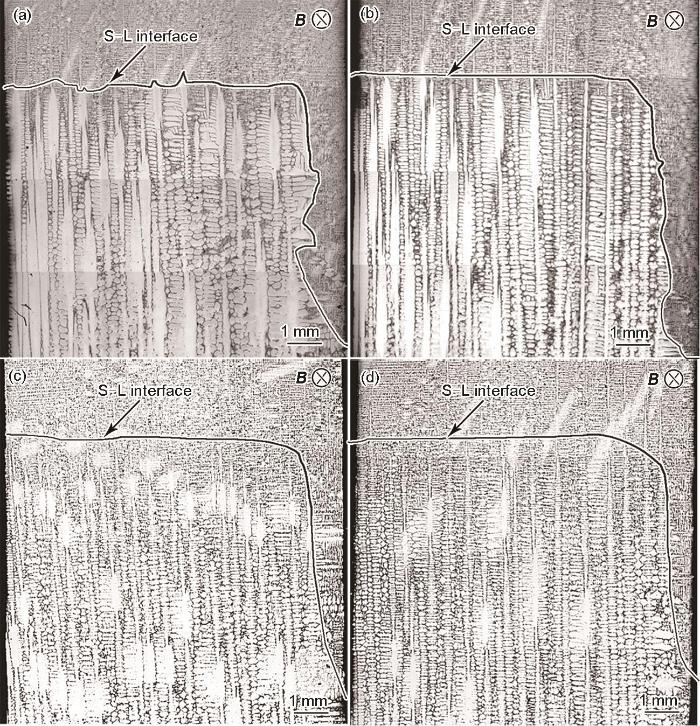

当磁场强度B = 0.1 T,发散双晶按B-to-A方式摆放时,不同拉速下双晶的初始凝固纵截面组织和距离初始凝固界面20 mm高度处横截面组织如图7所示。由图7a1可知,低拉速(0.5 mm/min)下,晶粒B迅速被晶粒A淘汰,由晶粒A发展出的新的分枝占据发散晶界处的空间。定向生长20 mm后的横截面只显示择优生长的晶粒A,晶粒B被完全淘汰(图7a2)。相较于无磁场和按A-to-B方式摆放的情况下,按B-to-A方式摆放时,磁场的施加明显加速了晶粒A淘汰晶粒B的速率。随着拉速从0.5 mm/min增加至3 mm/min,晶粒A的侧枝生长逐渐减弱,晶粒A淘汰晶粒B的速率(简称晶粒A的淘汰速率)逐渐减小(图7b1~d1)。由距离初始凝固界面20 mm处的横截面组织可以看出,随着拉速的增加,晶粒B的面积分数逐渐增加,同样说明晶粒A淘汰晶粒B的速率减小(图7b2~d2)。此外,当拉速较低时,试样纵截面右侧的局部区域观察到“斑状”组织,主要是由于合金元素在试样边部偏析形成的雀斑。

图7

图7

当磁场强度为0.1 T,发散双晶按B-to-A方式摆放时,不同拉速下发散双晶纵截面和横截面组织

Fig.7

Longitudinal microstructures (a1-d1) and transversal microstructures at the position of 20 mm (a2-d2) from the directional solidification starting place of the divergent bi-crystals at various withdrawal rates under the magnetic field of 0.1 T with the bi-crystals placed in a B-to-A pattern

(a1, a2) 0.5 mm/min (b1, b2) 1 mm/min (c1, c2) 1.5 mm/min (d1, d2) 3 mm/min

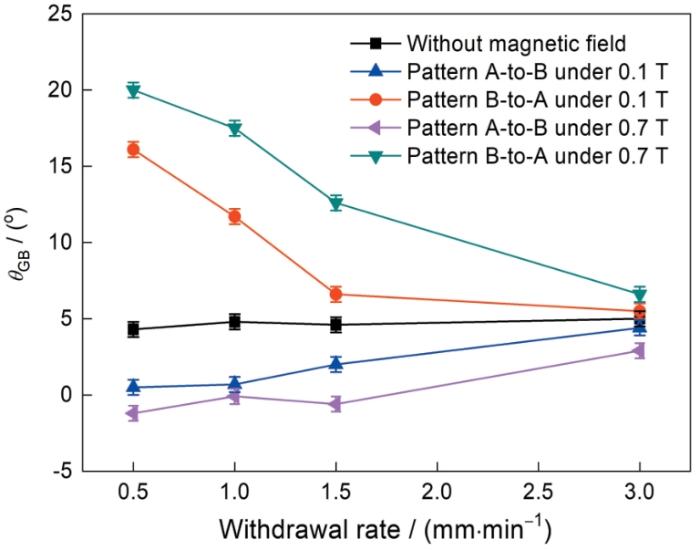

为了更好地表征晶粒的淘汰速率,计算得出各实验条件下的平均晶界偏离角,结果如图8所示。由图可知,当发散双晶在磁场下按A-to-B方式摆放时,与无磁场时相比,施加0.1 T磁场后晶界偏离角明显减小,减缓了晶粒A的淘汰速率。但减缓效果随着拉速的增加逐渐减弱,表现出晶界偏离角随拉速的增加而增大。当拉速提高至3 mm/min时,晶界偏离角接近无磁场时的晶界偏离角,说明在较高拉速下,施加0.1 T的磁场对发散双晶的竞争生长行为的影响减弱。当发散双晶在磁场下按B-to-A方式摆放时,施加0.1 T磁场后晶界偏离角与无磁场时相比增加了约4倍,明显加速了晶粒A的淘汰速率。加速效果随拉速的增加而逐渐减弱,表现出晶界偏离角随拉速的增大而减小。当拉速增大至3 mm/min时,晶界偏离角略大于无磁场时的晶界偏离角,表明磁场对加速晶粒A的淘汰速率的作用依然存在。与施加0.1 T磁场相比,施加0.7 T磁场对减缓晶粒A的淘汰速率的效果更为明显。

图8

图8

磁场强度为0、0.1和0.7 T时发散双晶中θGB随拉速的变化

Fig.8

θGB of the divergent bi-crystals as a function of withdrawal rate under the magnetic fields of 0, 0.1, and 0.7 T

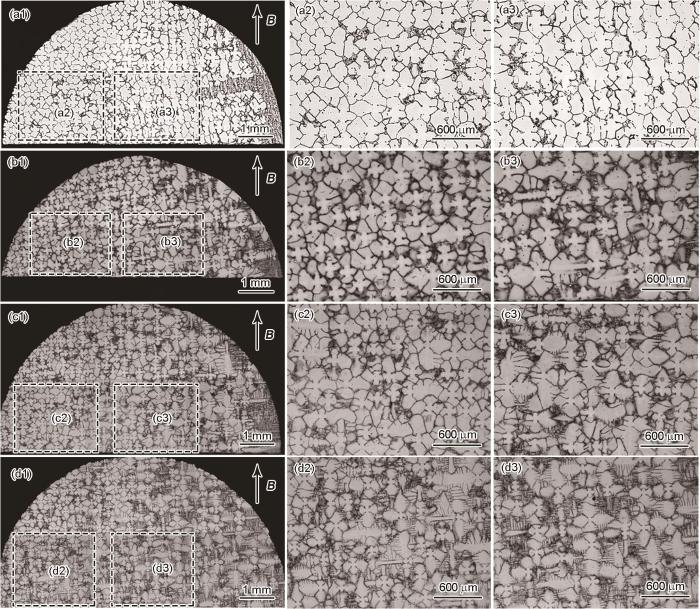

图9为发散双晶在0.1 T磁场下按A-to-B方式摆放时,以不同拉速定向生长40 mm后淬火界面处的纵截面组织。由图9a可知,在低拉速(0.5 mm/min)下,晶粒A和晶粒B在定向竞争生长40 mm后都被保留下来。随着拉速的提高,B晶粒保留下来的面积逐渐减小(图9b和c);当拉速增加至3 mm/min,晶粒B被晶粒A完全淘汰(图9d)。沿着磁场施加方向观察,施加磁场后导致固-液界面向试样右侧边缘凹陷,界面呈“厂”字状(图9a)。随着拉速的增加,固-液界面向右侧凹陷的程度减弱(图9b和c)。当拉速提高至3 mm/min时,固-液界面变得平直(图9d)。图10为发散双晶在0.1 T磁场下按B-to-A方式摆放时,以不同拉速下定向生长40 mm后淬火界面处的纵截面组织。由图可知,在不同拉速下,均只有择优取向的晶粒A被保留下来。与按A-to-B摆放方式类似,施加0.1 T横向磁场后固-液界面向试样右侧边缘处凹陷(图10a),凹陷的程度随着拉速的增加而减小,当拉速提高至3 mm/min时,固-液界面趋于平直(图10d)。当磁场强度增加至0.7 T时,与磁场强度为0.1 T时相比,在相同拉速下固-液界面凹陷程度更深(图11a~d)。随着拉速的增加,固-液界面凹陷的程度减弱。当拉速达到3 mm/min时,固-液界面依然呈“厂”字状(图11d),说明此时0.7 T的磁场依然可以对凝固界面产生影响。从糊状区横截面组织中也可以看出,试样右侧为淬火后的保留下来的液相组织(图12)。此外,在较低拉速下,施加0.1和0.7 T的磁场后,沿着磁场方向观察,一次枝晶左侧的二次枝晶臂发达,而一次枝晶右侧的二次枝晶臂的生长受到抑制,枝晶呈不对称生长(图10a、图11a和b)。

图9

图9

当磁场强度为0.1 T、发散双晶按A-to-B方式摆放时,不同抽拉速率下的纵截面凝固组织

Fig.9

Longitudinal solidification microstructures at various withdrawal rates under 0.1 T magnetic field with the divergent bi-crystals placed in an A-to-B pattern (L—liquid, S—solid)

(a) 0.5 mm/min (b) 1 mm/min (c) 1.5 mm/min (d) 3 mm/min

图10

图10

当磁场强度为0.1 T、发散双晶按B-to-A方式摆放时,不同抽拉速率下的纵截面凝固组织

Fig.10

Longitudinal solidifcation microstructures at various withdrawal rates under 0.1 T magnetic field with the divergent bi-crystals placed in a B-to-A pattern

(a) 0.5 mm/min (b) 1 mm/min (c) 1.5 mm/min (d) 3 mm/min

图11

图11

当磁场强度为0.7 T、发散双晶按B-to-A方式摆放时,不同抽拉速率下的纵截面凝固组织

Fig.11

Longitudinal solidification microstructures at various withdrawal rates under 0.7 T magnetic field with the divergent bi-crystals placed in a B-to-A pattern

(a) 0.5 mm/min (b) 1 mm/min (c) 1.5 mm/min (d) 3 mm/min

图12

图12

磁场强度为0.7 T、发散双晶按B to A方式摆放时,不同抽拉速率下固-液界面处的横截面组织

Fig.12

Low (a1-d1) and high (a2-d2, a3-d3) magnified cross-sectional solidification microstructures near the solid/liquid interface directionally solidified at various withdrawal rates under 0.7 T magnetic field with the divergent bi-crystals placed in a B-to-A pattern

(a1-a3) 0.5 mm/min (b1-b3) 1 mm/min (c1-c3) 1.5 mm/min (d1-d3) 3 mm/min

图13

图13

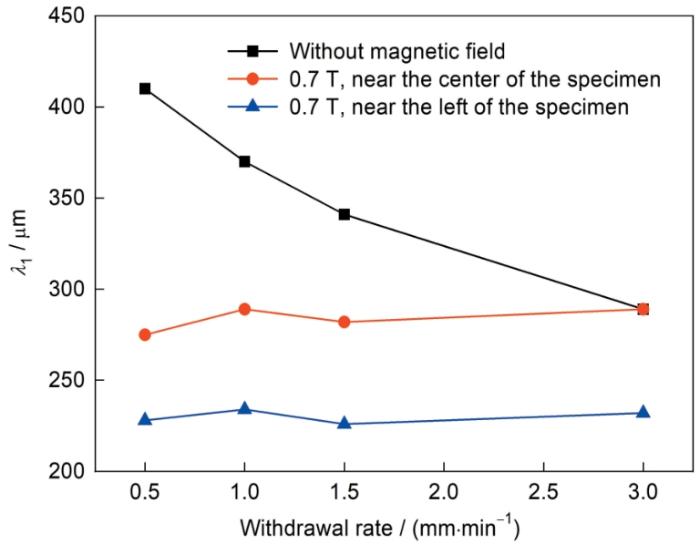

有/无磁场下一次枝晶间距随抽拉速率的变化

Fig.13

Primary dendrite arm spacing (λ1) as a function of withdrawal rate with and without the magnetic field

3 分析与讨论

3.1 凝固参数对发散双晶竞争生长速率的影响

3.2 横向磁场对定向凝固组织和发散双晶竞争生长行为的影响

在定向凝固过程中,凝固界面前沿存在径向的温度梯度,由于固相与液相的热电势不同,将产生热电流。在横向磁场作用下,热电流与磁场交互作用将在枝晶间熔体中产生向右的热电磁力(沿着磁场方向观察),热电磁力驱动熔体产生向右的TEMC;在枝晶间形成的TEMC将在固-液界面处的熔体中诱发出宏观的环流[27,33]。TEMC的存在将显著改变凝固前沿熔体的溶质分布。沿着磁场方向观察,产生的向右侧的宏观TEMC将试样左侧的溶质带到试样的右侧,较重的溶质将下沉,溶质富集抑制了右侧枝晶的生长,所以宏观上固-液界面变倾斜(图9~11)。在糊状区,枝晶间产生的微观TEMC也会将溶质带到试样的右侧,从而使糊状区内局部区域出现一些“斑状”组织(图7a和b)。在宏观TEMC与微观TEMC的共同作用下,溶质将富集在试样右侧边缘,导致固-液界面向右侧凹陷(图9~11)。Li等[27,36]研究表明,横向弱磁场能导致Al-Cu、Sn-Bi、Al-Si等多种合金的凝固界面向一侧凹陷。Wang等[37]通过同步辐射观察Al-Cu合金定向凝固过程,发现自然对流作用导致固-液界面向一侧倾斜,施加横向弱磁场后,倾斜的界面逐渐回复平整,进一步证实了固-液界面处热电磁对流的存在。董建文等[38]在横向磁场下进行了DZ417合金的定向凝固实验,同样观测到向一侧倾斜的固-液界面形貌,且固-液界面凹陷程度与磁场强度和拉速有关。Zhao等[33]研究了弱横向磁场下DD3镍基单晶高温合金的定向凝固微观组织和偏析情况,同样发现施加0.5 T的横向磁场可明显细化一次枝晶臂。这些研究结果都表明,施加横向磁场产生的TEMC对定向凝固的固-液界面具有显著影响。

研究[13,21~23]表明,枝晶尖端的微弱流动可以改变枝晶周围的溶质场和温度场,从而影响枝晶的生长。Tong等[39]用相场法模拟了外加流场下枝晶的生长,发现施加某一方向的流动后,迎流侧枝晶的生长加快,而逆流侧枝晶的生长受到抑制,从而导致枝晶的不对称生长。随着流速的增加,枝晶的不对称生长越发明显,发达的二次枝晶臂甚至分枝出三次枝晶。Yuan等[40]研究表明,枝晶尖端的流动将枝晶生长所排出的溶质带走,引起过冷度增加,从而促进了枝晶的生长。枝晶的生长速率与枝晶尖端局部的过冷度成正比,流动一方面可以带走枝晶尖端释放的潜热而提高局部过冷度,另一方面可将排出的溶质带走而使枝晶尖端局部过冷度增加。在枝晶生长过程中,流动对溶质的影响比对热量的影响更为显著。Zhong等[41]在纵向磁场下进行Al-Cu合金定向凝固实验,发现施加磁场后在枝晶间形成的TEMC涡流导致三次枝晶不对称性生长,且在0~6 T磁场强度范围内,随着磁场强度的增加,这种不对称性逐渐增加,当磁场强度为6 T时,枝晶形貌呈“纸风车”状。在定向凝固过程中,施加横向磁场后,枝晶左侧的二次枝晶尖端排出的溶质将被TEMC带走,表现出迎流生长,而另一侧二次枝晶尖端的溶质受TEMC的影响较弱,生长受到抑制,最终导致枝晶的不对称性生长(图10和11)。

Lehman等[35]给出了一次枝晶间距与流动速率(u)的关系:

式中,λ0为无对流时的一次枝晶间距,G为生长速率。从

施加磁场对一次枝晶的细化程度在试样尺度上有所差异:沿磁场方向观察,试样左侧的一次枝晶比试样中部和右侧的细小(图12)。一次枝晶尺度的不均匀性与TEMC引起的溶质分布不均匀相关。Li等[36]研究了Al-0.85%Cu (质量分数)合金糊状区内距固-液界面1 mm处Cu元素的分布情况,发现施加磁场后,溶质Cu分布不均匀,其含量从试样中部到试样一侧逐渐增加。溶质分布的不均匀将导致枝晶生长条件不同,试样左侧枝晶间TEMC引起局部过冷度较大,一次枝晶分枝作用明显,且一次枝晶间的溶质被带走后有利于新枝晶的生长,枝晶细化效果显著;试样中部和右侧存在溶质偏聚导致枝晶间溶质浓度较高,新的分枝容易被“淹没”而不能成为新的枝晶,因此枝晶细化效果减弱。

对于发散双晶,经典的Walton-Chalmers模型[11]认为,非择优取向的晶粒B和择优取向的晶粒A在晶界处都能分枝出新的枝晶,由于择优取向枝晶的分枝作用导致晶界向非择优取向晶粒一侧推进,使得非择优取向的晶粒最终被淘汰(图14a)。研究[16,18]表明,在无磁场条件下,发散双晶的竞争生长速率取决于择优取向晶粒在晶界处的分枝行为,且与抽拉速率无关。晶界处存在较大的自由空间,某一方向的流动势必会影响这一空间内溶质的分布,从而影响晶粒在晶界处的分枝行为。因此,应当从TEMC影响发散双晶晶界处的分枝行为的角度分析磁场对晶粒竞争生长速率的影响。根据上述关于流动对枝晶形貌影响的分析可知,枝晶的分枝行为与流动的方向有关,迎流侧二次枝晶臂发达容易分枝出三次甚至高次枝晶,而逆流侧二次枝晶生长受到抑制,难以分枝出新的枝晶。因此,其竞争生长行为受发散双晶在磁场下摆放方式的影响。

图14

图14

有/无磁场下发散双晶竞争生长示意图

Fig.14

Schematics showing the competitive growth of divergent bi-crystals with and without weak transverse static magnetic field (ΔZA—temperature gradient of grain A, ΔZB—temperature gradient of grain B, TEMC—thermoelectric magnetic convection)

(a) without the magnetic field (Walton-Chalmers model)

(b) A-to-B pattern

(c) B-to-A pattern

施加横向磁场后,沿着磁场方向观察,将在固-液界面前沿和枝晶尖端液体中产生从左往右的TEMC[6]。当发散双晶按A-to-B方式摆放时(图14b),由于受到从左往右的TEMC的影响,晶界处晶粒A的二次枝晶臂生长受到抑制,使其难以发展出三次枝晶。然而,晶界处晶粒B的二次枝晶臂处于迎流生长状态,获得生长优势并且不断分枝出高次枝晶。与此同时,晶粒B中快速生长的枝晶臂会排出大量溶质,溶质富集在靠近晶界处晶粒A的二次枝晶臂周围,进一步抑制了晶粒A的二次枝晶臂的生长。因此,施加磁场后产生的TEMC通过抑制晶粒A在晶界处的分枝作用减缓了晶粒A淘汰晶粒B的速率(图6)。随着拉速的增大,磁场的作用时间变短,TEMC对抑制晶粒A在晶界处的分枝作用减弱,晶粒A逐渐获得竞争生长优势。

4 结论

(1) 无磁场时,拉速不影响发散双晶的竞争生长速率。发散双晶竞争机制取决于晶界处择优生长晶粒的分枝作用。

(2) 磁场能显著影响固-液界面的形貌,细化枝晶,使一次枝晶呈不对称生长。固-液界面液相前沿产生的垂直于磁场方向的TEMC导致固-液界面向一侧凹陷。随着拉速的提高,固液界面趋于平直。TEMC促进枝晶一侧的二次枝晶臂的生长而抑制了另一侧二次枝晶臂的生长,使一次枝晶呈不对称生长。

(3) 磁场能显著影响发散双晶的竞争生长速率,且发散双晶的竞争生长行为受双晶在磁场下摆放方式和抽拉速率的影响。当发散双晶在磁场下按A-to-B方式摆放时,施加磁场在枝晶间产生的TEMC抑制了晶粒A在晶界处的分枝,减缓了择优取向晶粒A的淘汰速率。当发散双晶按B-to-A方式摆放时,施加磁场在枝晶间产生的TEMC进一步促进了择优取向晶粒A在晶界处分枝的生长,加速了晶粒A的淘汰速率。

参考文献

Grain structure development in directional solidification of nickel-base superalloys

[J].

Morphological aspects of competitive grain growth during directional solidification of a nickel-base superalloy, CMSX4

[J].

Numerical simulation of dendrite growth in Ni-based superalloy casting during directional solidification process

[J].

Seeding of single crystal superalloys—Role of seed melt-back on casting defects

[J].

Defect grains in the melt-back region of CMSX-4 single crystal seeds

[A].

Formation and evolution of stray grains on remelted interface in the seed crystal during the directional solidification of single-crystal superalloys assisted by vertical static magnetic field

[J].Nickel-based superalloys, especially single-crystal (SC) ones, have long been recognized as important materials for turbine blades used in aerospace and gas engines. Static magnetic fields are effective at controlling the material forming. The use of static magnetic fields during solidification has evolved as a sophisticated approach for efficiently controlling the microstructures and mechanical performance of metallic materials. In recent years, studies have shown that static magnetic fields have a complex effect on dendrites in SC superalloys. However, the mechanism of static magnetic fields regulating stray grains on remelted interface needs to be investigated further. This work studied the generation of stray grains near the seed remelted zone and the evolution mechanism during the directional solidification of the SC superalloy assisted by a magnetic field by tracing the solidification microstructure. The stray grains of large orientation that deviated from the <001> direction appeared on the remelted zone interface of the solidification microstructure when the magnetic field was applied, accompanied by the formation of a large-angle grain boundary (LAGB). Most of the stray grains were distributed at the sample edge. The increase in magnetic field intensity and pulling speed increased the number of stray grains and the length of the LAGB. As the solidification progressed, the large-orientation stray grains and the LAGBs were eliminated at a fast speed and evolved into small-orientation dendrites. During the following solidification, the orientation of the dendrites became even smaller and the evolution speed decreased sharply. The increase in withdrawal speed intensified the evolution process. The stray grains formed in the remelted zone can be attributed to the twisting dendrite by the thermoelectric magnetic force. The distribution of more stray grains around the sample was caused by the circulation from thermoelectric magnetic convection at the macroscopic scale.

纵向静磁场下单晶高温合金定向凝固籽晶回熔界面杂晶的形成与演化

[J].通过对单晶高温合金定向凝固生长过程中显微组织的考察,研究了磁场下杂晶在籽晶回熔区附近的产生及其在生长过程中的演变机制。磁场使得定向凝固籽晶重熔区界面上出现大取向杂晶和大角度晶界,其多分布于样品边缘,磁场强度和抽拉速率的增大均增加了杂晶数量和大角度晶界长度。凝固起始阶段形成的大取向杂晶和大角度晶界以较快速率被淘汰,演化成小取向枝晶和小角度晶界;随着凝固继续进行,枝晶取向和晶界角度进一步减小,但是演化速率急剧降低,拉速的增大强化了此演变过程。重熔区界面上杂晶的形成是由于热电磁力对枝晶的扭断,而宏观尺度上的热电磁环流在凝固过程挟制着扭断碎晶,使得碎晶演化成较多分布于样品边缘的杂晶。

Sliver defect formation in single crystal Ni-based superalloy castings

[J].

Formation mechanisms and control method for stray grains at melt-back region of Ni-based single crystal seed

[J].

Epitaxy and new stray grain formation mechanism during epitaxial laser melting deposition of Inconel 718 on directionally solidified nickel-based superalloys

[J].

The origin of the preferred orientation in the columnar zone of ingots

[J].

Prediction of grain structures in various solidification processes

[J].

A 3D cellular automaton algorithm for the prediction of dendritic grain growth

[J].

Mechanism of competitive grain growth in directional solidification of a nickel-base superalloy

[J].

Structure evolution in directionally solidified bicrystals of nickel base superalloys

[J].

双晶镍基高温合金定向凝固过程的结构演化

[J].研究了双晶镍基高温合金IN792定向凝固过程的结构演化. 对于汇聚生长晶粒, 非择优取向枝晶在晶界处能够阻挡择优取向枝晶的生长, 从而导致晶界从非择优取向晶粒向择优取向晶粒倾斜, 竞争长大的结果是择优取向晶粒消失, 非择优取向晶粒获胜; 对于发散生长晶粒, 晶界处会形成新的枝晶, 从而导致晶界从择优取向晶粒向非择优取向晶粒倾斜, 竞争长大的结果是择优取向晶粒获胜, 非择优取向晶粒消失.

Research on diverged bi-crystal competitive growth in directional solidification

[J].Grain selection in directional solidification is a fundamental process in single-crystal super alloy production. In fact, many factors can influence this process. This work only focuses on the effect of pulling rates on competitive divergence in directional solidification. The competitive growth of bi-crystal atdifferent pulling rates was observed during 2D directional solidification using the transparent model alloy SCN-1.7%Eth (mass fraction). The results show that as the pulling rate increases, it becomes harder for preferred grain to eliminate slant grain. This is because the increase of pulling rate decreases primary dendrite arm spacing and slightly reduces the frequency of new primary dendrite arms. When the growth direction of preferred grain is not well aligned with temperature gradient, the preferred grain can also be eliminated by the slant grain at specific pulling rates.

定向凝固发散双晶的竞争生长研究

[J].采用SCN--1.7%Eth(质量分数)透明模型合金, 应用自制的晶粒择优取向角度可控的透明模型合金双籽晶试样盒, 对定向凝固中双晶竞争生长的微观组织演化进行了实时观察, 研究了二维条件下, 抽拉速率和晶粒取向对发散晶粒竞争淘汰的影响. 结果表明, 对于发散双晶, 随抽拉速率的提高, 择优取向晶粒淘汰非择优取向晶粒的速度变慢, 其主要原因在于, 抽拉速率增大会减小一次枝晶间距并降低择优取向晶粒一次臂新增频率; 当择优取向晶粒优先生长方向与热流方向不完全一致时, 在特定抽拉速率下, 择优取向晶粒由于受到型壁的制约, 最终亦可能被淘汰.

Growth competition of columnar dendritic grains: A phase-field study

[J].

Mechanism of competitive growth during directional solidification of a nickel-base superalloy in a three-dimensional reference frame

[J].

Branching-induced grain boundary evolution during directional solidification of columnar dendritic grains

[J].

Competitive growth of diverging columnar grains during directional solidification: A three-dimensional phase-field study

[J].

Influence of secondary orientation on competitive grain growth of nickel-based superalloys

[J].Directional solidification (DS) has been widely used to produce aero-engine and gas turbine blades of nickel-based superalloys. The preferred crystallographic orientation of nickel-based superalloys is [001], so the [001] columnar-grain structure can form after DS. Due to the low Young's modulus and the elimination of transverse grain boundaries, the [001] columnar-grain structure has beneficial mechanical behavior. The competitive grain growth dominates the production of columnar grains. There are two views about competitive grain growth, which are consistent for diverging grains but not consistent for converging grains. In the case of convergence of the first view, the grain boundary (GB) was parallel to the favorably aligned dendrites, which indicates that the favorably aligned grain cannot be eliminated. For converging grains of the second view, not only the favorably aligned dendrites could block unfavorably aligned ones, but also the unfavorably aligned dendrites could block favorably aligned ones. Thus, the converging grain boundary moved from unfavorably aligned grain to favorably aligned grain. Finally, the favorably aligned grain may be eliminated. The study about the two views was carried out in the case of the same secondary orientation but did not taken into account the secondary orientation. Up to now, the literatures about the effect of secondary dendrite orientation on competitive growth is rarely and their views contradict with each other. In this work, the bi-crystal and ter-crystal plates with different secondary orientations were produced to study the influence of secondary orientation on competitive grain growth. For the bi-crystal with the same primary orientation, as the secondary GB angle increased, the GB was nearly at the middle of the plate sample, which indicated that the competitive grain growth was weak and could be neglected. For the ter-crystal with different primary orientations, not the secondary orientation but the primary orientation could obviously affect competitive grain growth. In the case of converging grains, the change of secondary dendrite orientation had no effect on the competitive growth behavior and grain growth rate; the favorably and unfavorably aligned dendrites could block each other, which disagreed with Walton-Chalmers model and in good agreement with the results of Zhou. In the case of diverging grains, the result agreed with Walton-Chalmers model and Zhou's result.

二次枝晶取向对镍基高温合金晶粒竞争生长行为的影响

[J].采用精密铸造法制备板状双晶和三晶试样,研究晶粒的二次枝晶取向对晶粒竞争生长的影响。结果表明,对于一次枝晶取向相同的双晶,随二次晶界角增大,晶界位置始终位于板状试样的中间,2个晶粒之间几乎不存在竞争生长。对于一次枝晶取向不同的三晶,汇聚晶粒和发散晶粒的竞争生长情况不同。在汇聚生长的情况下,择优取向枝晶与非择优取向枝晶互相阻挡,导致晶界向择优取向晶粒倾斜,这与经典的Walton-Chalmers模型不一样。并且二次取向不影响汇聚晶粒的竞争生长。在发散生长的情况下,择优取向枝晶与非择优取向枝晶都能分枝出新的枝晶,使晶界向非择优取向晶粒倾斜,这与Walton-Chalmers模型一样。此外,二次取向不影响发散晶粒的竞争生长。

Phase-field study of competitive dendritic growth of converging grains during directional solidification

[J].

Two-dimensional phase-field simulations of dendrite competitive growth during the directional solidification of a binary alloy bicrystal

[J].

Anomalous overgrowth of converging dendrites during directional solidification

[J].

Orientation controlling of Ni-based single-crystal superalloy by a novel method: Grain selection assisted by un-melted reused seed

[J].

Dendrite growth and defects formation with increasing withdrawal rates in the rejoined platforms of Ni-based single crystal superalloys

[J].

Effect of a high magnetic field on the morphological instability and irregularity of the interface of a binary alloy during directional solidification

[J].

Effect of a weak transverse magnetic field on solidification structure during directional solidification

[J].

Modification of liquid/solid interface shape in directionally solidifying Al-Cu alloys by a transverse magnetic field

[J].

Effect of a high magnetic field on microstructures of Ni-based superalloy during directional solidification

[J].

Investigation of thermoelectric magnetic convection and its effect on solidification structure during directional solidification under a low axial magnetic field

[J].

Influence of longitudinal static magnetic field on microstructure and microsegregation during directional solidification of DD98M alloy

[J].Nickel-based superalloys have been widely used in gas turbines, aerospace, and other fields owing to their excellent high-temperature strength and creep resistance. Advanced directional-solidification techniques allow crystals to grow along specific directions, which can eliminate most or all of the transverse grain boundaries to obtain columnar- or single-crystal superalloys, which further improve the high-temperature mechanical properties. A strong magnetic field can modify the mass-transfer behavior during solidification via magnetic-damping or thermoelectromagnetic effect without contacting the material, thus improving the microstructure and microscopic segregation. In order to further refine the microstructure of nickel-based single crystal superalloys and improve the degree of homogenization of element distribution, the influence of longitudinal static magnetic field with a magnetic field intensity (B) that ranges from 0 to 4 T on the microstructure and microsegregation of liquid-metal-cooling directionally solidified nickel-based single-crystal superalloy DD98M was investigated. OM and SEM were applied to characterize the microstructure. Microsegregation was evaluated using a microsegregation coefficient and isoconcentration contour maps based on different data collection modes embedded in EDS. The results showed that with an increase in B, the primary dendrite spacing, average size of γ/γ' eutectic organization, and size of the γ' phases decreased. Meanwhile, the γ' phase in the interdendrite became more regularized. The microstructure refinement under static magnetic fields was attributed to the decrease in ΔT' / G (ratio of the temperature difference between the nonequilibrium solid-phase line and dendrite tip to the temperature gradient based on the Kurz-Fisher model) or the increase in subcooling of the melt surrounding the dendrites due to thermoelectric-magnetic convection. The relationship between ΔT' / G and B was revealed. The reduction in the γ' phase size was caused by the increase in the nucleation rate of the γ' phase due to the introduction of magnetic free energy difference (ΔGM) under a magnetic field. The magnetic field depressed the microsegregation of solutes, i.e., as B increased, the segregations of Al, Ta, Co, and W decreased. The effective partition coefficient (ke) of the dendritic scale and the average effective partition coefficients of the dendritic and interdendritic areas were obtained. It was found that the decrease in macrosegregation was essentially due to the effective distribution coefficient that approached 1 that due to the magnetic field.

纵向静磁场对DD98M合金定向凝固微观组织与偏析的影响

[J].

Flow and solidification microstructure in metal melts driven by a combined magnetic field

[J].In recent years, solidified structures in metal alloys driven by combined electromagnetic fields have received considerable attention. In this study, the effect of combined magnetic field (CMF) formed by pulsed magneto oscillation (PMO) and static magnetic field on the melt flow of Ga-20%In-12%Sn (mass fraction) and solidification structure of Al-7%Si alloy was investigated. Results of numerical simulations and flow experiments show that the flow pattern is single rolled in the direction parallel to the static magnetic field and double rolled in the direction perpendicular to the static magnetic field, which is different from the double-rolled flow pattern of the melt when the PMO is activated alone. The distribution and evolution of the electromagnetic forces in the melt under CMF are numerically simulated to explain the formation of the flow pattern. Moreover, the experimental results of solidification show that the grain size of the CMF-treated Al-7%Si alloy is smaller than that obtained when PMO is applied. Finally, the grain refinement mechanism of the Al-7%Si alloy under the influence of electromagnetic fields is discussed in relation to the effects of induced currents, electromagnetic forces, and forced flow based on the previously proposed mechanism of grain refinement in solidified metals driven by electromagnetic fields.

复合磁场对金属熔体流动及凝固组织影响研究

[J].

Tailoring microstructure and microsegregation in a directionally solidified Ni-based SX superalloy by a weak transverse static magnetic field

[J].

Effect of solidification rate on competitive grain growth in directional solidification of a nickel-base superalloy

[J].

Modification of interdendritic convection in directional solidification by a uniform magnetic field

[J].

Effects of thermoelectric magnetic convection on the solidification structure during directional solidification under lower transverse magnetic field

[J].

Thermoelectric magnetic flows in melt during directional solidification

[J].

Effect of horizontal magnetic field on the microstructure of directionally solidified Ni-based superalloy

[J].

横向磁场对镍基高温合金定向凝固组织的影响

[J].研究了横向磁场对镍基高温合金DZ417G定向凝固显微组织的影响. 在较低生长速率条件下, 磁场显著影响合金的枝晶生长和宏观偏析. 施加磁场后一次枝晶间距减小并在沿磁场方向试样的左侧出现了“斑状”偏析. 随着生长速率的增加, 磁场的影响减弱. 从磁场在合金熔体中诱发热电磁对流, 并影响枝晶生长的角度对实验结果进行了分析.

Phase-field simulations of dendritic crystal growth in a forced flow

[J].

Nondestructive effect of the cusp magnetic field on the dendritic microstructure during the directional solidification of nickel-based single crystal superalloy

[J].The mechanical-property improvement of directionally-solidified Nickel-based single crystal (SC) superalloy with the single-direction magnetic fields is limited by their destructiveness on the dendritic microstructure. Here, the work present breaks through the bottleneck. It shows that the application of the cusp magnetic field (CMF) ensures that the dendrites are not destroyed. This feature embodies that the primary dendrite trunks arrange regularly and orderly, as well the secondary dendrite arms grow symmetrically. By contrast, both the unidirectional transverse and longitudinal magnetic field destroy the dendrite morphology, and there are a number of stray grains near the totally-remelted interface. The nondestructive effect is achieved mainly by the combined action of the thermoelectromagnetic force on the dendrites and thermoelectromagnetic convection in the melt during directional solidification. The investigation should contribute a new route for dramatically and effectively improving the crystal quality and mechanical properties of the directionally-solidified alloys.

Effect of interdendritic thermoelectric magnetic convection on evolution of tertiary dendrite during directional solidification

[J].