1988年,Yoshizawa等[1]在Fe-Si-B非晶合金中添加促进α-Fe相形核元素Cu和阻碍原子扩散即抑制α-Fe晶粒长大的Nb、Mo、Ta等前过渡金属(ETM)元素,经结晶化热处理研制出了新一代软磁材料——铁基纳米晶软磁合金(命名为Finemet,代表成分Fe73.5Si13.5B9Nb3Cu1 (原子分数,%,下同));之后,Suzuki等[2]和Willard等[3]分别研发出Fe-ETM-B (Nanoperm)和(Fe, Co)-ETM-B-Cu (Hitperm)系纳米晶合金,奠定了铁基纳米晶软磁合金的基础。这类合金不仅具有与以往软磁材料不同的组织结构,还展现出低矫顽力(Hc)、高磁导率以及低铁损等优异软磁特性,尤其在高频下的软磁性能极佳,引起了学术和产业界的广泛关注[4,5]。铁基纳米晶软磁合金均是通过对其非晶前驱体进行结晶化热处理而形成的由纳米尺度α-Fe相和残余非晶相构成的均匀微细的纳米复相组织;当α-Fe晶粒尺寸低于铁磁交换关联长度(Lex:30~40 nm)时,晶粒间可产生交换耦合效应,从而显著降低合金的平均磁晶各向异性,获得优异软磁性能[5,6]。由于Nanoperm和Hitperm纳米晶合金中稀有金属含量较多,并存在制备工艺复杂、生产成本高等问题,没有获得大规模应用,仅综合性能优良的Finemet系纳米晶合金实现了工业化应用。但Finemet系合金的饱和磁感应强度(Bs)较低(1.24 T)[1],不利于电磁器件的小型化;该系合金中还含有Nb,原材料成本依然较高,从而限制了其应用范围。

2007年,Ohta等[7,8]和Makino等[9,10]相继研发出了新型高Bs的Fe-B-Cu、Fe-Si-B-Cu和Fe-Si-B-P-Cu等系纳米晶软磁合金。这些合金的Fe含量高(> 80%,原子分数,下同),不含稀有金属元素,具有1.80 T以上的Bs和优异软磁性,在电力、电子行业具有广阔的应用前景[7,10]。由于这些高Bs纳米晶合金不含强抑制α-Fe晶粒长大的ETM元素,热处理过程中α-Fe相的生长速率快,易使晶化组织粗大而降低软磁性能。获得微细、均匀的纳米晶组织需借助高速升温(升温速率:180~400 K/s)热处理来实现[8~11],而这在工况条件下难以实施。作者前期工作[12,13]发现,在较高Cu含量(1.7%)的Fe-Si-B-Cu合金非晶前驱体(即快淬合金)中均匀分布着高数密度(Nd)的纳米尺度α-Fe晶粒(预存α-Fe晶,其平均尺寸

高Fe含量的Fe87B13合金经高升温速率(约150 K/s)热处理后,也可获得微细纳米晶组织及优异的软磁性能,其Bs和Hc分别达到1.92 T和6.7 A/m[14]。作者前期工作[15]研究了Cu添加对Fe87B13合金的快淬结构、结晶化组织及磁性能的影响,发现在高Cu含量的Fe85.3B13Cu1.7合金非晶前驱体中同样分布着高Nd的预存α-Fe晶,在低升温速率热处理条件下可获得

本工作以高Fe含量的Fe-B-Cu合金体系为对象,研究了B含量对Fe98.5 - x B x Cu1.5 (x = 12~18)系纳米晶合金非晶前驱体的微结构、热性能、晶化组织和磁性能的影响,探讨了合金成分-前驱体结构-晶化组织-磁性能间的关联,以及不同结构快淬合金的晶化机制,并建立了相应的纳米晶化模型。

1 实验方法

按照合金名义组分Fe98.5 - x B x Cu1.5 (x = 12~18)称重配料,所用原料及纯度(质量分数)分别为:Fe (99.99 %)、B (99.50%)和Cu (99.99%)。采用非自耗真空电弧炉在Ar气保护下熔炼母合金锭,反复熔炼4遍以保证合金成分均匀,总质量损失低于0.2%。通过单辊甩带法制备快淬合金带材,获得的带材样品宽度约为1 mm,厚度约为15 μm。将带材样品真空封装在石英管中,使用箱式退火炉以20 K/min的升温速率在613~703 K温度范围等温晶化热处理60 min后水淬。采用TA Q20差式扫描量热仪(DSC)分析快淬合金带材的热性能。利用D8 Focus X射线衍射仪(XRD)对样品进行物相分析,CuKα。根据Scherrer公式估算

2 实验结果与讨论

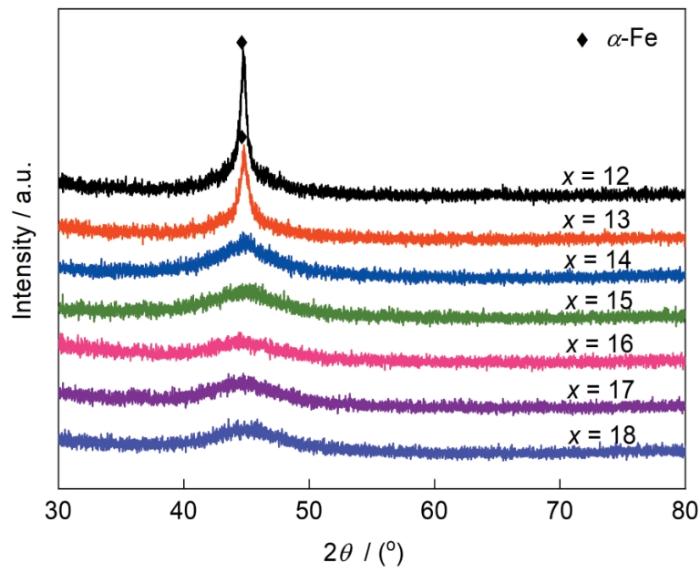

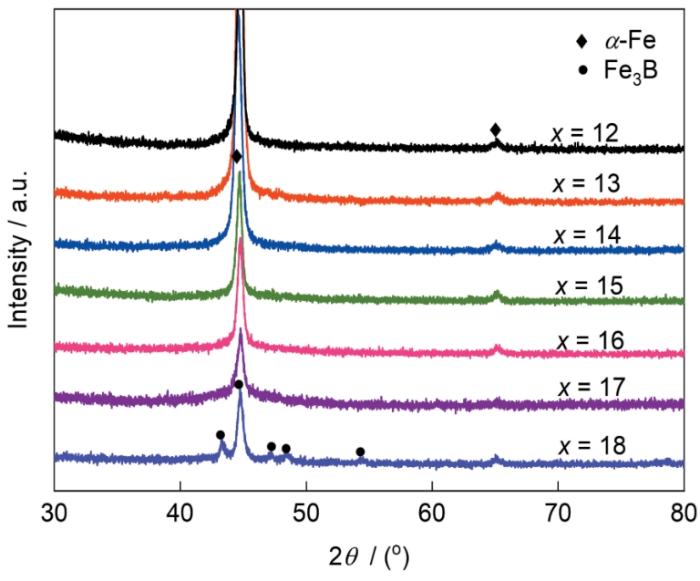

图1为Fe98.5 - x B x Cu1.5 (x = 12~18)快淬合金的XRD谱。可见,x = 12和13时合金存在明显的晶化现象,其XRD谱呈现漫散峰叠加α-Fe (110)衍射峰,表明具有非晶/α-Fe复相结构。经Scherrer公式估算,x = 12和13时合金的

图1

图1

Fe98.5 - x B x Cu1.5 (x = 12~18,原子分数,%)快淬合金的XRD谱

Fig.1

XRD spectra of melt-spun Fe98.5 - x B x Cu1.5 (x = 12-18, atomic fraction, %) alloys

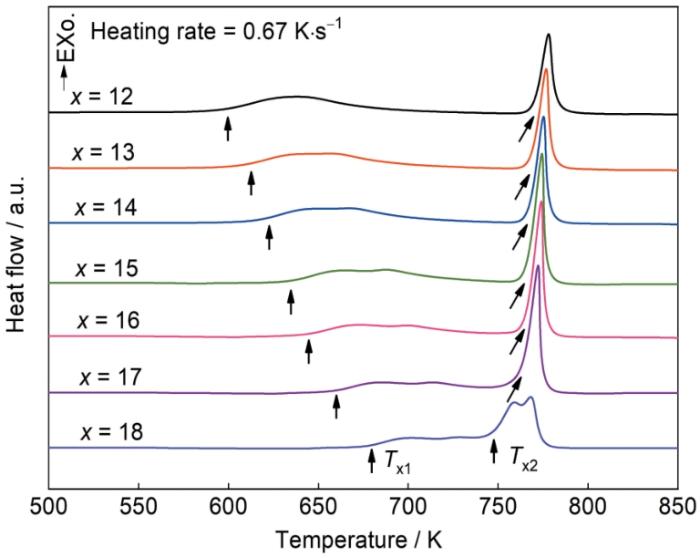

图2为快淬合金带材的DSC曲线。可见,所有合金均存在2个明显的晶化放热峰,其中第一个放热峰对应α-Fe相的析出,第二个放热峰对应Fe-B化合物的形成[14]。随B含量的增加,合金的第一晶化峰起始温度(Tx1)明显增加,第二晶化峰起始温度(Tx2)则逐渐下降,2个放热峰之间的温度区间(ΔT = Tx2 - Tx1)变窄;随x由12增加至18,合金的Tx1由599 K升高至679 K,Tx2从769 K下降到747 K,ΔT由170 K减小到68 K (表1),这说明B含量的增加使非晶相在热处理晶化过程中α-Fe相的析出变得困难,而使Fe-B化合物容易从残余非晶相中析出。此外,各合金对应α-Fe相析出的放热峰由前后2个放热峰叠加构成。这种叠加放热峰的形成往往与快淬合金非晶相中存在的预存α-Fe晶有关。低温侧的放热峰对应着非晶晶化过程中预存α-Fe晶的生长,而高温侧的放热峰对应新生α-Fe晶相的形核与长大[12,13]。x = 18时对应Fe-B化合物形成的放热峰出现了分裂,推测这是由于Fe3B和Fe2B等硼化物不同步相变析出造成的。

图2

图2

Fe98.5 - x B x Cu1.5 (x = 12~18)快淬合金的DSC曲线

Fig.2

DSC curves of melt-spun Fe98.5 - x B x Cu1.5 (x = 12-18) alloys (Tx1—onset temperature of the first crystallization peak, Tx2—onset temperature of the second crystallization peak)

表1 Fe98.5 - x B x Cu1.5 (x = 12~18)快淬合金以及经最佳温度(Toa)热处理60 min后合金的热分析和磁性能分析结果

Table 1

| x | Tx1 K | Tx2 K | ΔT K | Nd m-3 | nm | Toa K | nm | Vα-Fe % | Bs T | Hc A·m-1 |

|---|---|---|---|---|---|---|---|---|---|---|

| 12 | 599 | 769 | 170 | 1.0 × 1023 | 12.6 | 658 | 22.8 | 68.1 | 1.93 | 84.6 |

| 13 | 612 | 767 | 155 | - | - | 658 | 16.2 | 65.7 | 1.91 | 22.7 |

| 14 | 622 | 767 | 145 | - | - | 658 | 15.8 | 61.1 | 1.88 | 20.2 |

| 15 | 634 | 765 | 131 | 5.9 × 1022 | 4.8 | 658 | 16.0 | 60.2 | 1.86 | 18.9 |

| 16 | 644 | 765 | 121 | - | - | 658 | 16.3 | 59.6 | 1.80 | 19.3 |

| 17 | 659 | 762 | 103 | - | - | 658 | 18.7 | 47.0 | 1.67 | 30.1 |

| 18 | 679 | 747 | 68 | 2.7 × 1021 | 2.8 | 673 | 28.2 | 42.9 | 1.44 | 304.1 |

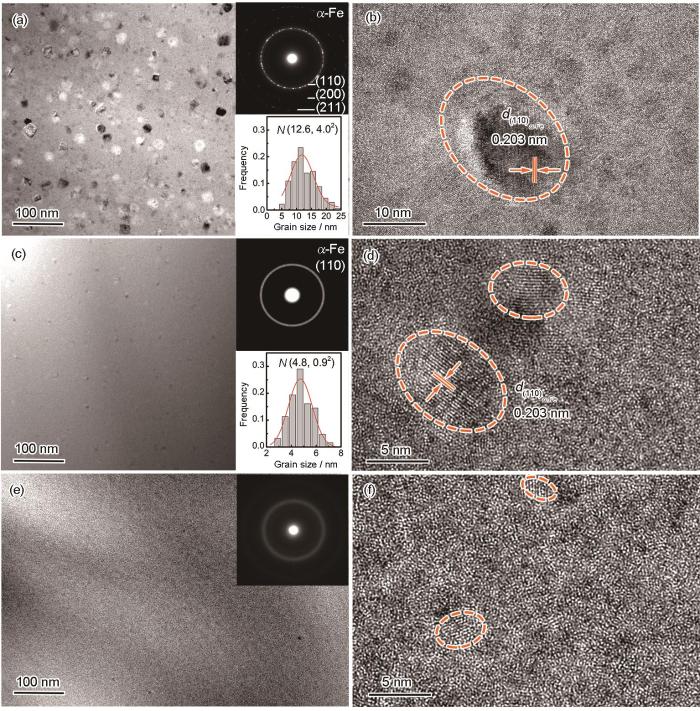

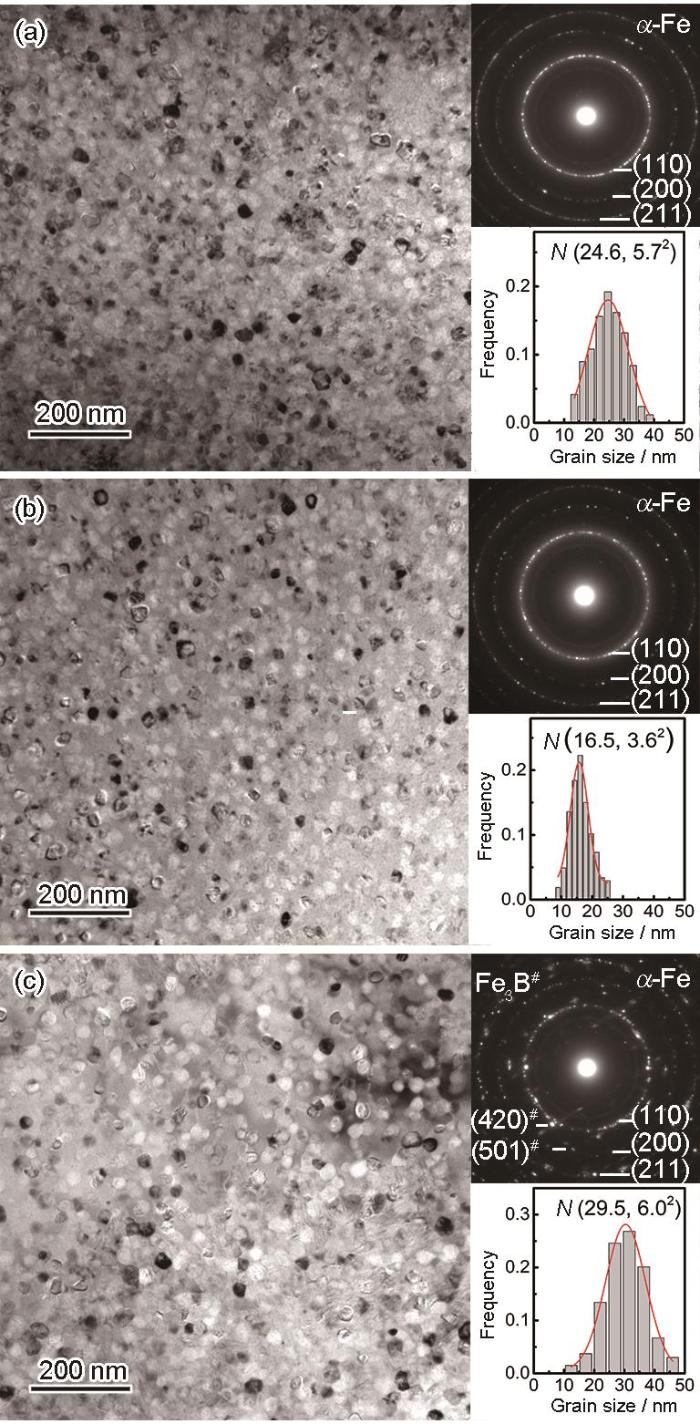

Fe98.5 - x B x Cu1.5 (x = 12、15、18)快淬合金的显微组织如图3所示。x = 12时,合金的TEM明场像中可观察到大量晶相颗粒,选区电子衍射(SAED)花样证实其为随机取向的α-Fe相(图3a),由高分辨TEM (HRTEM)像标定出晶相的晶格间距为0.203 nm,与α-Fe(110)晶面间距一致(图3b虚线区域);估算出该合金的

图3

图3

Fe98.5 - x B x Cu1.5快淬合金的TEM明场像和HRTEM像

Fig.3

Bright-field TEM images and corresponding SAED patterns and grain size distributions with normal fitting (insets) (a, c, e) and HRTEM images (b, d, f) of melt-spun Fe98.5 - x B x Cu1.5 alloys with x = 12 (a, b), x = 15 (c, d), and x = 18 (e, f) (

式中,ci 和cj 分别为i和j元素的原子分数,ri 为i元素的原子半径,

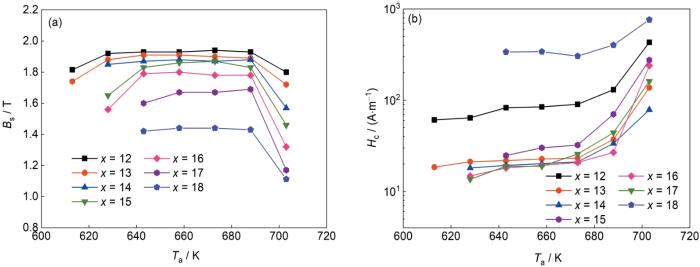

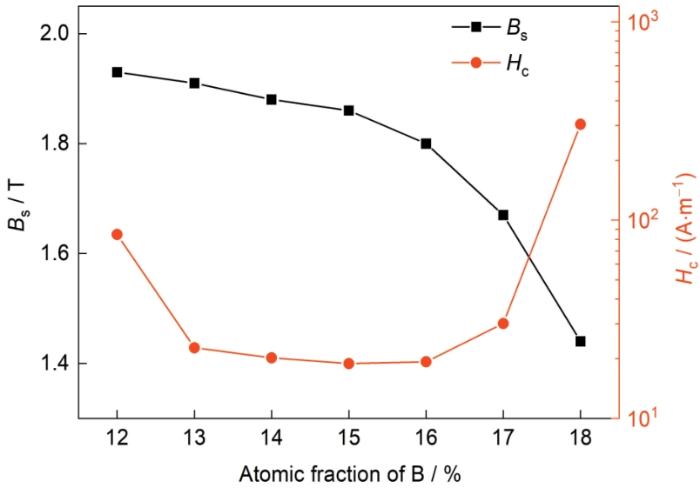

对各快淬合金在不同温度下等温晶化热处理60 min,分析Bs和Hc与热处理温度(Ta)的关系,结果如图4所示。随Ta升高,x = 12~16时合金的Bs先显著增加,随后在较宽的温度范围内保持平稳,而后降低,x = 17和18时合金则呈现先平缓增加后显著下降的趋势;各合金的Hc均随Ta的升高先平缓增加,而后显著提高。各合金在最佳热处理温度(Toa)后的Bs和Hc与B含量的关系如图5所示。可见,合金的Bs由x = 12的1.93 T逐渐下降到x = 18的1.44 T,x = 12~16时合金的Bs均高于1.80 T。随B含量的增加,Hc由x = 12时的84.6 A/m降低至x = 13时的22.7 A/m,Hc在x = 13~17范围内变化平缓,在18.9~30.1 A/m之间,而x = 18时合金的Hc超过了300 A/m,软磁性明显降低;其中,x = 15合金的软磁性最佳,其Bs和Hc分别为1.86 T和18.9 A/m (表1)。

图4

图4

Fe98.5 - x B x Cu1.5 (x = 12~18)合金在不同温度下等温晶化热处理60 min后饱和磁感应强度(Bs)和矫顽力(Hc)与热处理温度(Ta)的关系

Fig.4

Changes in Bs (a) and Hc (b) of Fe98.5 - x B x Cu1.5 (x = 12-18) alloys as a function of annealing temperature (Ta) for 60 min

图5

图5

经Toa热处理60 min后Fe98.5 - x B x Cu1.5 (x = 12~18)合金的Bs和Hc与B含量的关系

Fig.5

Changes in Bs and Hc of Fe98.5 - x B x Cu1.5 (x = 12-18) alloysannealed at Toa for 60 min as a function of B content

合金经Toa热处理60 min后的XRD谱如图6所示。可见,它们均在2θ = 45°和65°附近出现衍射峰,分别对应α-Fe相的(110)和(200)晶面,并且α-Fe(110)衍射峰强度随B含量的增加呈逐渐降低倾向;而x = 18时合金除α-Fe相外,还观察到Fe3B相的衍射峰,这可归因于合金较高的B含量促进了Fe3B相的析出。图7为合金经Toa热处理后的TEM明场像以及SAED谱和晶粒尺寸分布图,所有合金的非晶基体中均析出了大量纳米尺度的晶粒,呈现典型的非晶/纳米晶复相组织结构。其中,x = 12和15时合金为非晶和α-Fe的复相结构,而x = 18时合金的SAED谱也标定出Fe3B相的存在,该合金为非晶、α-Fe和Fe3B的三相混合结构。x = 12、15和18时合金的

图6

图6

经Toa热处理后Fe98.5 - x B x Cu1.5 (x = 12~18)合金的XRD谱

Fig.6

XRD spectra of Fe98.5 - x B x Cu1.5 (x = 12-18) alloys after annealing at Toa

图7

图7

经Toa热处理60 min后Fe98.5 - x B x Cu1.5合金的TEM明场像、SAED谱和晶粒尺寸分布图

Fig.7

Bright-field TEM images with corresponding SAED patterns and grain size distributions with normal fitting (insets) for Fe98.5 - x B x Cu1.5 alloys after annealing at Toa for 60 min

(a) x = 12 (b) x = 15 (c) x = 18

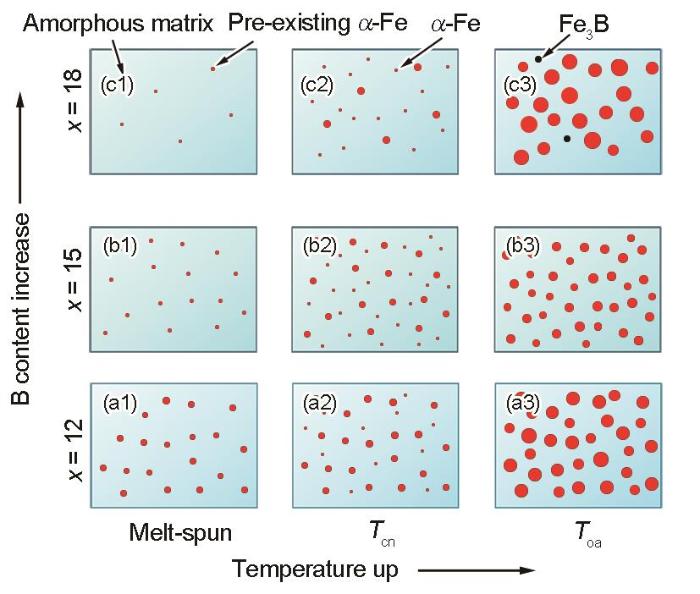

基于Fe98.5 - x B x Cu1.5系合金热处理前后的显微组织,提出了不同B含量快淬合金的结晶化过程模型,如图8所示。Fe原子与Cu原子间具有较大的正混合焓(+13 kJ/mol)[18],2者存在较强的相分离倾向。该系合金中Cu含量相对较高,Cu原子更容易富集而形成Cu团簇,充当α-Fe相的异质形核点,从而促进α-Fe晶粒在非晶基体中析出[12,13]。由于x = 12时合金的AFA较低,在快淬过程中难以抑制α-Fe相的形成和长大,使得非晶基体析出了Nd高达1.0 × 1023 m-3且

图8

图8

Fe98.5 - x B x Cu1.5快淬合金的结晶化过程示意图

Fig.8

Schematics of crystallization process of melt-spun Fe98.5 - x B x Cu1.5 alloys (Tcn—nucleation temperature)

(a1-a3) x = 12 (b1-b3) x = 15 (c1-c3) x = 18

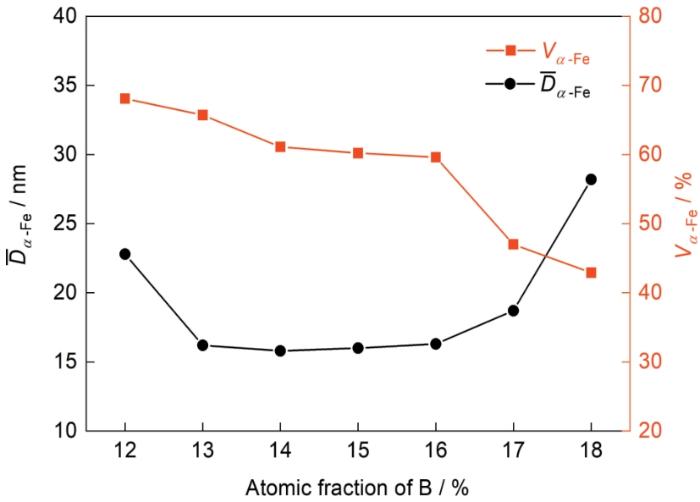

根据热处理后纳米晶合金的XRD结果(图6)估算Vα-Fe。图9为Fe98.5 - x B x Cu1.5纳米晶合金的Vα-Fe和

式中,Bsα-Fe和Bsa分别代表α-Fe和非晶相的Bs。随x由12增加至18,该系纳米晶合金中Vα-Fe由68.1%逐渐降低至42.9%。因Bsα-Fe高于Bsa,加之B替代Fe也会使非晶基体中总磁矩数量减少、Bsa降低,故纳米晶合金的Bs随B含量的升高由1.93 T不断降低至1.44 T。根据Herzer[5,6]提出的随机各向异性模型,当纳米晶合金中

图9

图9

Fe98.5 - x B x Cu1.5 (x = 12~18)纳米晶合金在Toa热处理60 min后α-Fe的体积分数和平均尺寸与B含量的关系

Fig.9

Changes in Vα-Fe and

通过调节Fe-B-Cu纳米晶合金B含量影响其AFA,实现了对快淬合金微结构及其晶化组织和磁性能的调控,为设计、制备具有优异软磁性和良好工艺性的高Bs纳米晶合金提供了新思路。

3 结论

(1) B含量的增加可提高Fe98.5 - x B x Cu1.5 (x = 12~18)纳米晶合金的AFA,抑制快淬合金中α-Fe相的析出,使其前驱体由非晶/预存α-Fe结构逐渐向非晶态转变;x由12增加至18时,分布在非晶基体中的预存α-Fe晶的

(2) 经适当热处理后,x = 12~17合金为非晶/α-Fe纳米晶双相,而x = 18时合金形成了非晶/α-Fe/Fe3B纳米复相结构。x = 13~16时合金具有微细的纳米晶组织和良好软磁性能,其

(3) 高B含量的合金(x = 18)软磁性能明显下降,Hc高达304.1 A/m,这与其快淬非晶基体中预存α-Fe晶Nd低,热处理晶化过程α-Fe晶间的竞争生长效应弱,使得纳米晶组织微细化程度较低以及磁晶各向异性较高的Fe3B相的析出有关。

参考文献

New Fe-based soft magnetic alloys composed of ultrafine grain structure

[J].

Low core losses of nanocrystalline Fe-M-B (M = Zr, Hf, or Nb) alloys

[J].

Structure and magnetic properties of (Fe0.5Co0.5)88Zr7B4Cu1 nanocrystalline alloys

[J].

Amorphous and nanocrystalline materials for applications as soft magnets

[J].

Modern soft magnets: Amorphous and nanocrystalline materials

[J].

Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets

[J].

Improvement of soft magnetic properties in (Fe0.85B0.15)100 - x Cu x melt-spun alloys

[J].

Effect of heating rate on soft magnetic properties in nanocrystalline Fe80.5Cu1.5Si4B14 and Fe82Cu1Nb1Si4B12 alloys

[J].

FeSiBPCu nanocrystalline soft magnetic alloys with high Bs of 1.9 tesla produced by crystallizing hetero-amorphous phase

[J].

Low core losses and magnetic properties of Fe85 - 86Si1 - 2B8P4Cu1 nanocrystalline alloys with high B for power applications (invited)

[J].

Competition driven nanocrystallization in high Bs and low coreloss Fe-Si-B-P-Cu soft magnetic alloys

[J].

Soft magnetic Fe-Si-B-Cu nanocrystalline alloys with high Cu concentrations

[J].

Formation and crystallization behavior of Fe-based amorphous precursors with pre-existing α-Fe nanoparticles—Structure and magnetic properties of high-Cu-content Fe-Si-B-Cu-Nb nanocrystalline alloys

[J].

Effect of heating rate during primary crystallization on soft magnetic properties of melt-spun Fe-B alloys

[J].

Optimization of the structure and soft magnetic properties of a Fe87B13 nanocrystalline alloy by additions of Cu and Nb

[J].

Nanocrystalline soft magnetic Fe-Si-B-P-Cu alloys with high B of 1.8-1.9 T contributable to energy saving

[J].

The influence of Si substitution on soft magnetic properties and crystallization behavior in Fe83B10C6 - x Si x Cu1 alloy system

[J].

Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element

[J].

Effect of the atomic size distribution on glass forming ability of amorphous metallic alloys

[J].

Roles of minor additions in formation and properties of bulk metallic glasses

[J].

Kinetics of the amorphous-to-nanocrystalline transformation in Fe73.5Cu1Nb3Si13.5B9

[J].

The role of Cu content on structure and magnetic properties of Fe-Si-B-P-Cu nanocrystalline alloys

[J].

Phase diagram of amorphous and crystallized Fe-B alloy system

[J].

Solid-solution phase formation rules for multi-component alloys

[J].

Mechanical properties of Fe-Si-B amorphous wires produced by in-rotating-water spinning method

[J].

Effects of tuning Fe/B contents on crystallization behaviors and magnetic properties in novel Si-free Fe-B-C-Cu-Nb Alloys

[J].

Effects of boron content on crystallization, formability and magnetic properties of Fe91 - x Zr5B x Nb4 amorphous alloys

[J].

硼含量对Fe-Zr-B-Nb非晶合金的晶化、形成能力和磁性能的影响

[J].

Soft magnetic properties of bulk nanocrystalline Fe-(Nb, Zr, Hf)-B alloys produced by extruding amorphous powders

[J].

High Bs nanocrystalline Fe84 - x - y Cu x Nb y-Si4B12 alloys (x = 0.0-1.4, y = 0.0-2.5)

[J].

Three-dimensional atom probe study of Fe-B-based nanocrystalline soft magnetic materials

[J].