传统增材制造(additive manufacturing,AM)又称3D打印,其原理是通过二维平面在构建方向逐层叠加形成材料的三维轮廓,是一种净成形技术。与传统的减材成形工艺相比,AM可以有效节约原料,降低生产成本[1,2]。近年来,航空航天领域对于材料性能的要求逐渐提高,零件设计越来越趋于复杂化,传统的减材制造很难满足复杂零件成形的需求。AM由于可以实现零件的一体化制备,一直以来被国内外广泛关注。一体化成形可以减少内部零件的数量和一些连接件的使用,从而有效降低零件的失效风险,并在一定程度上减少工件的重量,实现材料的轻量化生产和应用[3~5]。根据热源的不同,AM分为激光增材、电子束增材和电弧增材,这些增材制造工艺在成形过程中均会经历重熔和再凝固过程,不可避免地会在材料内部产生气孔、热裂纹和偏析等缺陷,从而严重影响材料的性能[6~10]。搅拌摩擦增材制造(friction stir additive manufacturing,FSAM)是一种新型的固态增材制造技术,由搅拌摩擦焊接(friction stir welding,FSW)技术发展而来。FSAM技术将原料板材相互叠加,通过搅拌针高速旋转使界面破碎,使材料发生软化,通过材料在焊接方向和垂直方向的流动使物料混合,最后在轴肩的压力作用下实现上、下板的连接。重复这一过程完成材料的逐层累积,从而获得所需要的构件厚度和形状[11]。搅拌摩擦过程中的峰值温度远低于材料自身的熔点,因此整个成形过程中材料一直保持固态,可以有效避免传统有热源增材过程中材料凝固产生的冶金缺陷[11,12],而且在成形区发生了动态再结晶,使晶粒细化,一定程度上可以改善材料性能。另外,FSAM过程中不需要引入热源,也无有害气体和粉尘产生,具有节能、环保、成本低的特点,因此具备良好的应用和开发前景。

目前,国内外对于FSAM技术的研究尚处于起步阶段,Mao等[13]利用FSAM技术成功实现了5 mm厚7075铝板的9层叠加,发现随着叠加层数的增加,由于上板经历较小的热循环且散热较快,成形区硬度沿增材方向逐渐增大。Palanivel等[14]对1.7 mm厚的WE34镁基合金进行了FSAM成形,发现成形区晶粒尺寸细化到了2~3 μm,时效后成形区硬度(135 HV)可达到2系铝合金的硬度,此外还指出成形缺陷的形成对热输入特别敏感。Li等[15]创新性地提出在水下进行FSAM,可以达到迅速降温的目的,降低峰值温度,从而有效减少增材过程中热循环的影响,抑制晶粒粗化,使得普遍存在的FSAM处理后材料显微硬度由上至下降低的现象得到了改善。

本工作采用FSAM技术对2 mm厚的6061铝板进行了4层增材,通过微观表征手段对成形试样进行分析,重点研究了试件沿构建方向的组织和力学性能变化规律。此外通过对构件进行焊后热处理改善构件性能,并研究了热处理前后的析出相演变。

1 实验方法

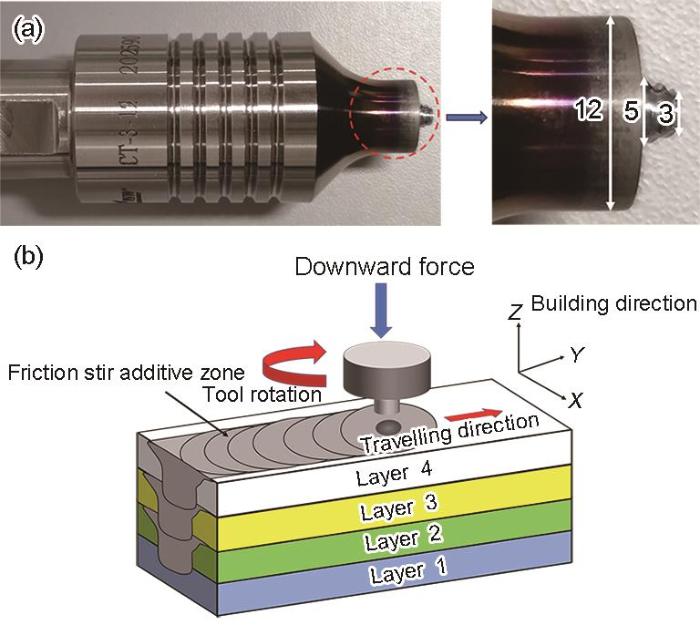

实验选用6061铝板作为基材,铝板尺寸为130 mm × 100 mm × 2 mm,其标称的化学成分(质量分数,%)为:Si 0.596,Fe 0.419,Cu 0.262,Mn 0.113,Mg 1.009,Cr 0.206,Zn 0.057,Ti 0.026,Al余量。采用FSW-3TS-006焊机进行FSAM成形,搅拌头材质为H13工具钢,轴肩直径为12 mm,搅拌针为圆锥形,其根部直径为5 mm,顶部直径为3 mm,针长为2.85 mm,搅拌头具体形状如图1a所示。成形过程中搅拌头倾角为2°,轴肩下压量为0.3 mm,搅拌头转速为1000 r/min,焊接速率为100 mm/min。通过逐层叠加,最终沿构建方向获得4层成形构件,成形过程如图1b所示。为了改善成形区性能,对成形件进行T6焊后热处理(post-weld heat treatment,PWHT),具体工艺为520 ℃固溶1 h后水冷,然后在165 ℃时效18 h后空冷。文中热处理态试样用PWHT表示。

图1

图1

搅拌头形状及搅拌摩擦增材制造(FSAM)成形过程示意图

Fig.1

Photograph of the stir tool (unit: mm) (a) and schematic of friction stir additive manufacturing (FSAM) process (b)

FSAM过程中焊核区为成形的有效区域,垂直于焊接方向切取长度为12 mm、宽度为5 mm的截面试样进行金相观察和硬度测试,试样包含完整的搅拌区。用砂纸依次打磨至3000号,然后通过机械抛光,使样品表面呈镜面光泽。金相试样在2.5 mL HNO3 + 1.5 mL HCl + 1 mL HF + 95 mL H2O配制成的Keller试剂中侵蚀1~2 min,采用9XB-PC光学显微镜(OM)观察不同位置的微观结构特征及界面结合情况。采用电子背散射衍射(EBSD)系统研究不同层的晶粒尺寸、晶粒取向以及晶界特征,EBSD试样在机械抛光后用体积分数为5%的高氯酸酒精溶液进行电解抛光,电压控制在15~20 V,电流为0.33~0.35 mA,时间1~2 min。采用JEM 2010F型透射电子显微镜(TEM)研究析出相的演变规律,TEM样品通过线切割切成厚度为0.8 mm薄片,用砂纸减薄到80 μm厚后冲击成直径3 mm的圆片,然后通过电解双喷减薄,除去表面的应力层,双喷液为体积分数为30%的硝酸甲醇,控制电压为12 V,温度在-35~-20 ℃。采用EVO 18型扫描电子显微镜(SEM)进行拉伸断口分析。

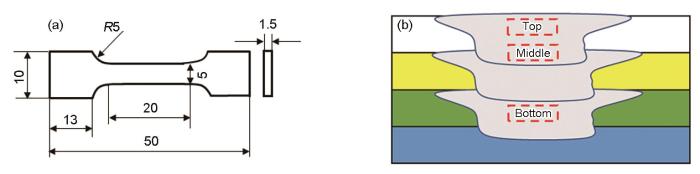

采用401MVDTM显微Vikers硬度计进行硬度测试,纵向硬度测试时在焊缝截面中心线沿构建方向每隔0.25 mm取1个点进行测试,横向硬度测试时分别在距上表面1、3和5 mm水平线处测试,每个测试点间隔0.5 mm。控制载荷为200 g,加载时间为15 s。采用CMT-4015电子万能试验机进行拉伸测试,应变速率1.0 × 10-3 s-1,拉伸试样在成形区顶层、过渡层和底层选取,试样尺寸及取样位置如图2所示。

图2

图2

拉伸试样尺寸及取样位置示意图

Fig.2

Tensile specimen dimension of formed part (unit: mm) (a) and schematic of sampling location of the tensile specimen (b)

2 实验结果和分析

2.1 微观组织

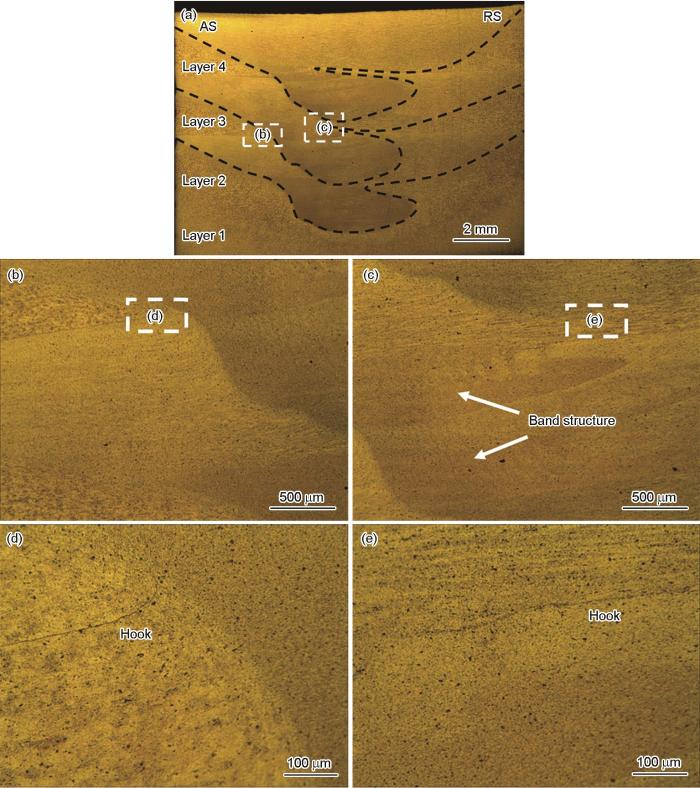

6061铝合金FSAM成形试样截面的OM像如图3所示。由图3a可以看出,不同层基板沿构建方向结合良好,未发现隧道形孔洞、裂纹等缺陷。焊核区为成形的有效区域,其整体轮廓呈单个倒扣“草帽形”,并沿着增材方向叠加。另外可以发现,前进侧(advancing side,AS)的轮廓线与后退侧(retreating side,RS)相比更清晰,这是因为搅拌头在行进过程中,AS侧物料的流动方向与受到的剪切力方向相同,遇到的阻力较大,塑性变形严重,而RS侧的物料沿焊接的反方向运动,物料运动前方是焊接初期形成的空腔,受到的阻力较小,所以边界线不明显。如图3b~e所示,在上、下板界面附近存在典型的钩状缺陷。其中在AS侧,“钩”不断向上弯曲远离焊核区;在RS侧,“钩”不断向焊核区内部延伸。由于FSAM是一个逐层累积的过程,相比于FSW,成形过程中不仅具有沿焊接方向的物料流动,而且还伴随着垂直方向的物料混合,在搅拌过程中,界面两侧的物料先发生破碎,然后下层物料在搅拌头的带动下向上运动与上层物料混合,混合的物料沿着搅拌针螺纹逐渐填充下方空腔,随着搅拌区物料的不断混合和扩大,不断挤压原始界面,使界面向上偏移,形成了类似裂纹的钩状缺陷。由于FSAM的成形特点,钩状缺陷目前无法被完全避免,在一些研究[13,23]中也观察到类似的钩状缺陷。如图3c所示,搅拌区底部可观察到明暗相间的带状组织,这与原始界面存在氧化物、杂质以及工具的搅拌作用不足有关。当搅拌针搅拌不完全时,物料不能充分流动,界面的氧化层破碎不均匀从而形成这种组织。

图3

图3

6061铝合金FSAM成形试样截面微观组织的OM像

Fig.3

Cross-sectional OM images of the 6061 aluminum alloy fabricated by FSAM

(a) the overall morphology

(b) advancing side (AS) (c) retreating side (RS)

(d) hooking defects in AS (e) hooking defects in RS

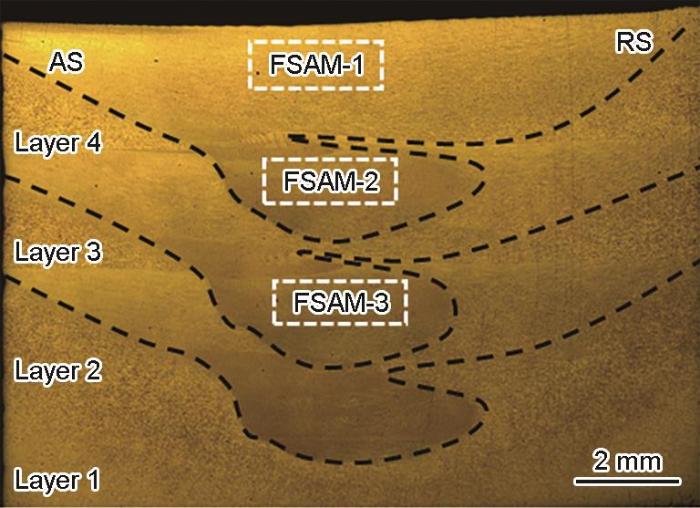

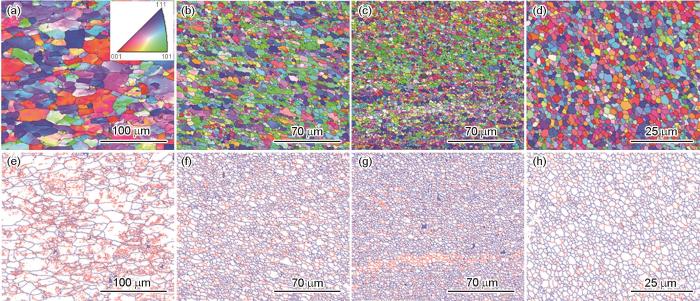

为了研究FSAM过程中晶粒形貌和晶粒尺寸的变化规律以及晶界转变,对母材(BM)和成形件进行了EBSD测试,观察位置如图4所示。所得反极图(IPF)和晶界特征图如图5所示。表1给出了不同位置的平均晶粒尺寸和晶界含量。由IPF (图5a~d)和表1可以看出,BM区主要由尺寸较大的等轴晶晶粒构成,平均晶粒尺寸为20.7 μm。成形区由于受到搅拌针强烈的搅拌作用和发生了动态再结晶,晶粒得到显著细化,FSAM-1区平均晶粒尺寸减小到5.1 μm,过渡区FSAM-2、FSAM-3为先成形区,经历了搅拌头的二次搅拌和多次热循环,晶粒进一步细化,平均晶粒尺寸分别减小到2.6和2.1 μm,虽然FSAM-3区与FSAM-2区相比多经历一次热循环,但是并没有发生明显的晶粒长大。在晶界特征图(图5e~h)中,红线为取向差角在2°~15°范围的小角度晶界(low angle grain boundaries,LAGBs),蓝线为取向差角大于15°的大角度晶界(high angle grain boundaries,HAGBs)。从晶界特征图和表1可知,与BM区相比,FSAM-1、FSAM-2、FSAM-3区大角度晶界的占比均显著增加,即发生了小角度晶界向大角度晶界的转变,这是由于成形过程中焊核区物料受到搅拌头强烈的搅拌作用发生热塑性变形,并伴随位错的塞积和重组,在晶粒内部形成许多亚结构,亚晶界在向外拓展的过程中不断消耗位错,取向差逐渐增大,小角度晶界逐渐转变为大角度晶界,从而发生了连续动态再结晶[24]。焊核区发生的连续动态再结晶使晶粒得到了细化。此外FSAM-2区和FSAM-3区的大角度晶界占比均高于FSAM-1区,这说明FSAM过程中重复搅拌作用可提高过渡区动态再结晶的程度,进一步细化晶粒。

图4

图5

图5

6061铝合金母材及FSAM试样的反极图(IPF)及晶界特征图

Fig.5

Inverse pole figures (IPFs) (a-d) and grain boundary maps (e-h) of 6061 aluminum alloy base metal (BM) and the FSAM samples at different locations shown in Fig.4 (The red lines and blue lines denote low angle grain boundaries (LAGBs) with misorientation angle (θ) 2°-15° and the high angle grain boundaries (HAGBs) with θ ≥ 15°, respectively)

(a, e) BM (b, f) FSAM-1 (c, g) FSAM-2 (d, h) FSAM-3

表1 6061铝合金母材及FSAM试样不同位置的平均晶粒尺寸和晶界含量

Table 1

| Position | Number fraction / % | Grain size μm | |

|---|---|---|---|

| 2° ≤ θ <15° | θ ≥ 15° | ||

| BM | 62.9 | 37.1 | 20.7 ± 9.6 |

| FSAM-1 | 34.5 | 65.5 | 5.1 ± 2.3 |

| FSAM-2 | 28.2 | 71.8 | 2.6 ± 1.5 |

| FSAM-3 | 23.3 | 76.7 | 2.1 ± 0.8 |

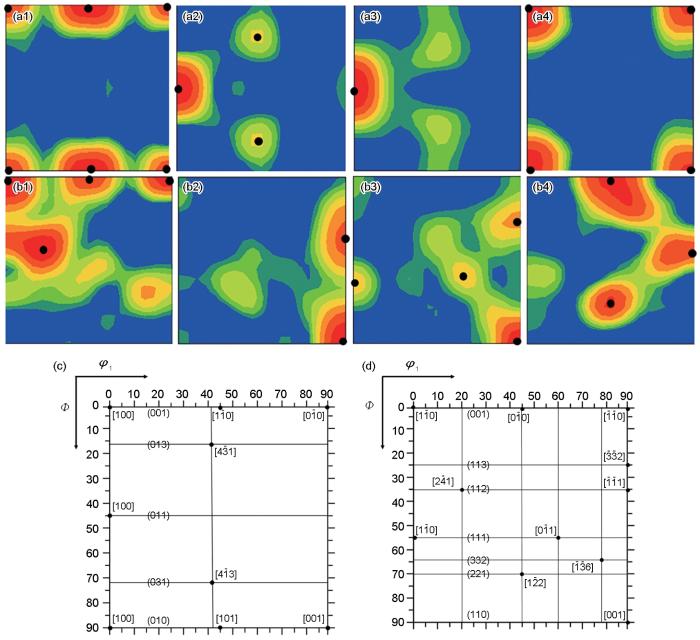

图6为BM、FSAM-1、FSAM-2、FSAM-3区在Euler角φ2 = 0°和φ2 = 45°的取向分布函数(ODF)图及织构分布。可以看出,母材主要以立方织构{001}<100>为主,此外还具有较强的{001}<1

图6

图6

6061铝合金母材及FSAM试样在Euler角φ2 = 0°和φ2 = 45°的取向分布函数(ODF)图及织构分布

Fig.6

Orientation distribution function (ODF) maps and texture distributions (Black dots in Figs.6a1-a4 and b1-b4 corres-pond to the positions of the textures in Figs.6c and d, respectively)

(a1-a4) ODF maps for BM (a1), FSAM-1 (a2), FSAM-2 (a3), and FSAM-3 (a4) at Euler angle φ2 = 0° (b1-b4) ODF maps for BM (b1), FSAM-1 (b2), FSAM-2 (b3), and FSAM-3 (b4) at φ2 = 45° (c) texture at φ2 = 0° (Φ, φ1—Euler angles) (d) texture at φ2 = 45°

2.2 力学性能

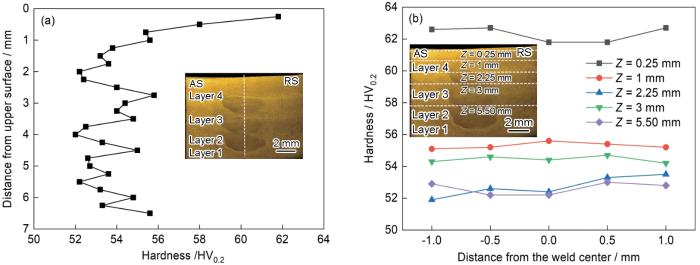

分别测试了6061铝合金FSAM成形试样沿构建方向和垂直于构建方向的硬度,结果如图7所示,插图为硬度测试试样位置和方向。由图7a可以看出,沿构建方向硬度有逐渐增大的趋势,最上层的硬度最高,为61.8 HV,大约为母材硬度的57.5%,此外曲线有3个明显的拐点,拐点处硬度较低,最低硬度为52.2 HV,仅为母材硬度的48.6%。通过其距上表面的距离可以判断,拐点位置均出现在两板界面处。由于钩状缺陷的存在,界面处结合比较弱,另外界面过渡区沉淀相溶解较多,使硬度有所降低。图7b显示,成形区整体硬度在垂直于构建方向波动较小,具有较好的均匀性,其中上表面的硬度依然最高,中间层硬度接近,Z = 2.25 mm和Z = 5.50 mm位置处于界面附近,硬度最低,与图7a的结果一致(Z表示硬度测试位置距离试样上表面的距离)。

图7

图7

6061铝合金FSAM成形试样沿构建方向和垂直于构建方向硬度分布

Fig.7

Hardness distributions of the 6061 aluminum alloy fabricated by FSAM (Insets show the position and direction of hardness test sample, Z—distance between the test position and the upper surface of the sample)

(a) building direction (b) vertical building direction

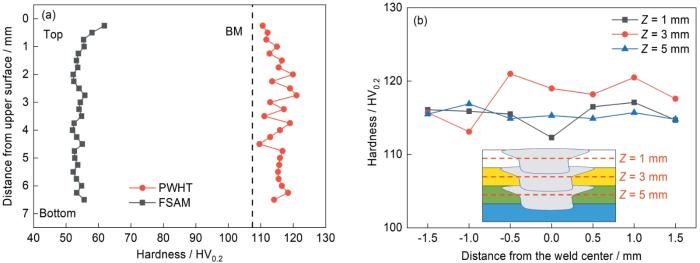

图8

图8

6061铝合金FSAM成形试样及其经焊后热处理(PWHT)后沿构建方向的硬度分布,及PWHT态试样沿垂直于构建方向的硬度分布

Fig.8

Hardness distributions of the 6061 aluminum alloy fabricated by FSAM and followed by post-weld heat treatment (PWHT) along building direction (a) and PWHT sample along vertical building direction (b) (Inset in Fig.8b shows the position and direction of hardness test sample)

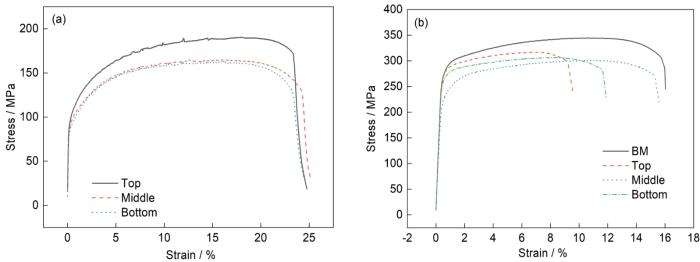

为了研究FSAM过程中多次搅拌及焊后热处理对成形件抗拉强度和延伸率的影响,对成形试样进行了拉伸测试,拉伸曲线如图9所示,对应的抗拉强度、屈服强度、延伸率如表2所示。由图9a和表2可知,经FSAM处理后,与母材相比,成形区的抗拉强度显著降低,延伸率有所增大,其中最上层的抗拉强度最高,为190.5 MPa,约为母材强度的55.2%,中、下层的抗拉强度接近,约为母材强度的47.7%~47.9%,延伸率提高到母材的144.6%~148.8%。这是因为最上层板在成形过程中只经历了一次搅拌作用和热循环,另外靠近上表面散热较快,沉淀相溶解少,所以具有较高的抗拉强度。由于整体的叠加层数较少,中部和下部的散热没有明显区别,且都经历了重复搅拌和重复加热,析出相溶解和粗化严重,所以抗拉强度较小。由图9b可知,成形区经过焊后热处理后抗拉强度均得到显著提高,不同层之间的强度略有差异,其中顶层区域的抗拉强度依然最高(为317.0 MPa),约为母材强度的91.9%,延伸率为10.8%。中、下层抗拉强度接近,中间过渡层略低(为300.7 MPa),约为母材强度的87.2%,但是其延伸率最高可达到17.1%。这可能是因为过渡层包含上、下板的界面,界面附近存在钩状缺陷,对其力学性能产生了一定的影响。此外FSAM成形区试样的拉伸曲线均具有明显的波动,这是由于在FSAM过程中,成形区受到机械力和热循环的共同作用发生了动态时效应变[25]。

图9

图9

6061铝合金母材、FSAM成形态及PWHT态试样的应力-应变曲线

Fig.9

Engineering stress-strain curves of 6061 aluminum alloy samples in different states

(a) FSAM (b) PWHT

表2 6061铝合金母材、FSAM成形态及PWHT态试样的拉伸性能

Table 2

| Sample | UTS / MPa | YS / MPa | EL / % |

|---|---|---|---|

| BM | 344.8 | 276.9 | 16.8 |

| FSAW-top | 190.5 | 99.7 | 24.9 |

| FSAW-middle | 165.2 | 95.3 | 25.0 |

| FSAW-bottom | 164.4 | 90.0 | 24.3 |

| PWHT-top | 317.0 | 277.8 | 10.8 |

| PWHT-middle | 300.7 | 230.5 | 17.1 |

| PWHT-bottom | 306.5 | 267.7 | 13.0 |

图10

图10

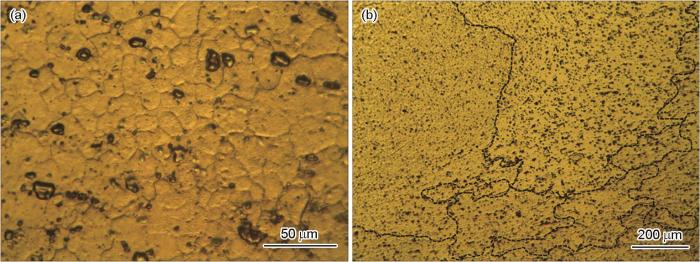

6061铝合金母材及PWHT态试样显微组织的OM像

Fig.10

OM images of the 6061 aluminum alloy BM (a) and 6061 aluminum alloy fabricated by FSAM followed by PWHT (b)

2.3 析出相演变

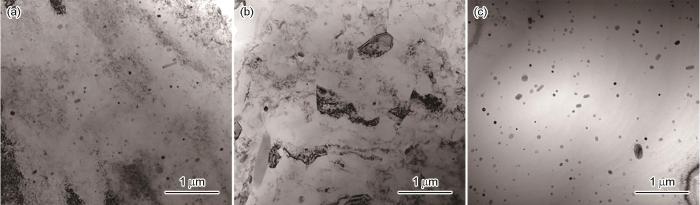

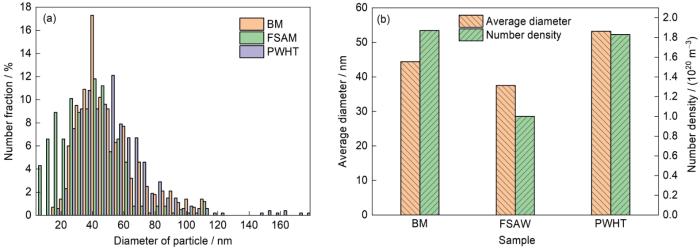

图11为6061铝合金母材、FSAM成形态和PWHT态样品的TEM明场像。可以看出,不同状态基体中的析出相形貌接近,都具有球状、短棒状及不规则的四边形状的析出相,其中以规则的球状析出相为主。析出相在FSAM工艺和热处理过程中发生了明显的变化。分别对析出相尺寸和数密度进行了统计,结果如图12所示。不同状态样品中,析出相尺寸主要集中在20~80 nm之间,其中母材中析出相的平均直径为44.4 nm,数密度为1.87 × 1020 m-3。由于FSAM过程中峰值温度高于析出相的溶解温度,析出相发生大量回溶,FSAM成形区析出相数密度显著减小到1.00 × 1020 m-3,部分细小的析出相在冷却过程中重新析出,平均直径减小到37.5 nm。经焊后热处理后,沉淀相先完全溶解又在时效过程中重新析出,数密度增加到1.83 × 1020 m-3,恢复到接近母材水平,但是热处理过程中析出相略微长大,其平均直径增加到53.2 nm,这可能是成形试样在热处理后强度无法完全恢复到母材强度的原因[20]。

图11

图11

6061铝合金母材、FSAM成形态和PWHT态试样的TEM明场像

Fig.11

TEM bright field images of the 6061 aluminum alloy BM (a), 6061 aluminum alloy fabricated by FSAM (b), and then followed by PWHT (c)

图12

图12

6061铝合金母材、FSAM成形态和PWHT态试样中析出相粒径分布、平均直径和数密度

Fig.12

Particle size distributions (a) and average diameters and number densities of precipitates (b) for 6061 aluinum alloy BM, 6061 aluminum alloy fabricated by FSAM, and then followed by PWHT

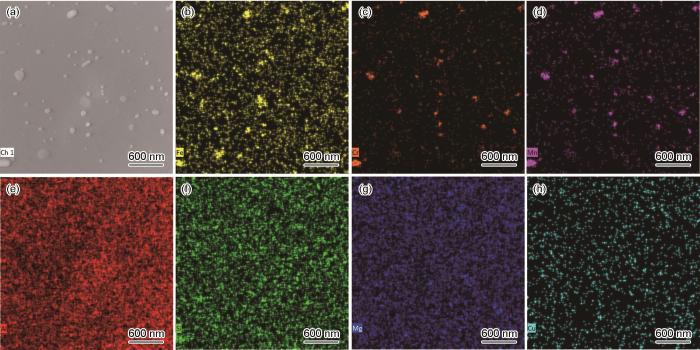

图13为PWHT态试样中析出像的高角环形暗场(high-angle annular dark-field,HAADF)像及EDS元素面分布图。可以看出,不同形状的沉淀相中均具有明显的Fe、Cr、Mn元素富集。图14为图13中短棒状和球状颗粒析出相的TEM像和EDS分析结果,初步推测可能是Al(FeCrMn)Si的化合物。Al-Si-Mg-Cu系铝合金中通常含有一定的杂质Fe元素,其在基体中的溶解度很低,通常以针状的β-AlFeSi相存在,严重影响基体的塑性和耐腐蚀性能,当基体中含有一定的Mn、Cr元素时,其容易与Fe形成化合物,改变β-Fe的存在形态,从而削弱Fe元素的影响[28]。当结晶相在基体中弥散分布时也可以起到一定的强化作用。

图13

图13

PWHT态试样的高角环形暗场(HAADF)像及EDS元素面分布图

Fig.13

High-angle annular dark-field (HAADF) image (a) and corresponding EDS element distribution maps of Fe (b), Cr (c), Mn (d), Al (e), Si (f), Mg (g), and Cu (h) for 6061 aluminum alloy fabricated by FSAM followed by PWHT

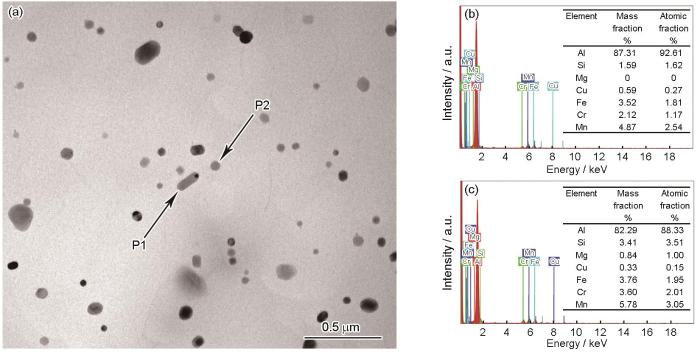

图14

图14

PWHT态试样中析出相的TEM像及EDS分析结果

Fig.14

TEM image (a) and EDS analysis results of precipitated phases P1 (b) and P2 (c) in Fig.14a for 6061 aluminum alloy fabricated by FSAM followed by PWHT

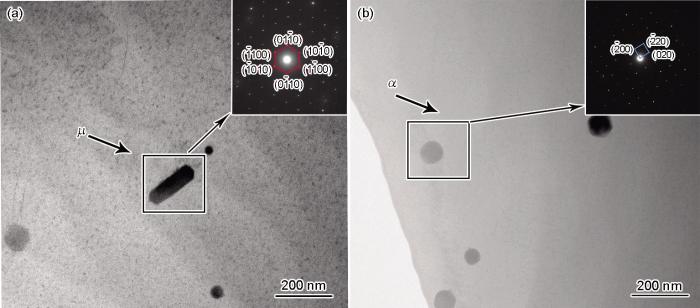

棒状和球状沉淀相的TEM像和选区电子衍射(SAED)花样如图15所示。通过对衍射斑进行标定并结合文献[26],确定棒状析出相为μ相,其为六方结构,晶格常数a = 0.670 nm、c = 0.808 nm,主要为Al、Si、Mn、Fe的化合物。球状析出相为α-Al(MnCrFe)Si,具有立方结构,a = 1.85 nm。文献[26]中显示,棒状μ相可在β' (Mg2Si)相上形核,作为β'向α-Al(MnCrFe)Si转化的中间相,之后α-Al(MnCrFe)Si在μ相上非均匀形核,将棒状析出相分解成许多不同形态的稳定相。这个过程中有少量μ相得到保留,结合本工作中力学性能结果可知,基体中大量存在的α-Al(MnCrFe)Si稳定相对材料力学性能具有明显的强化效果。

图15

图15

PWHT态试样中不同析出相的TEM明场像及对应的选区电子衍射花样

Fig.15

TEM bright field images and corresponding selected area electron diffraction (SAED) patterns (insets) of rod-like (a) and spherical (b) precipitates for 6061 aluminum alloy fabricated by FSAM followed by PWHT

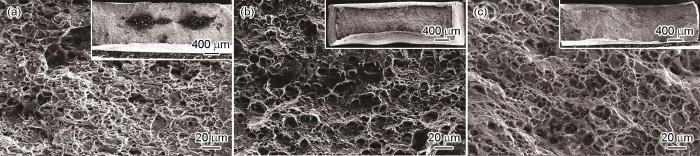

2.4 断口形貌

图16

图16

6061铝合金母材、FSAM成形态和PWHT态试样拉伸断口宏观形貌和显微组织的SEM像

Fig.16

SEM images of macroscopic morphology (insets) and microstructure of tensile fracture for 6061 aluminum alloy BM (a), 6061 aluminum alloy fabricated by FSAM (b), and then followed by PWHT (c)

3 结论

(1) 采用搅拌摩擦增材制造技术成功实现了4层无孔洞缺陷6061铝合金增材件的制备,在界面过渡处观察到典型的钩状缺陷。整个成形区由于受搅拌头的机械搅拌作用和发生动态再结晶,晶粒发生明显细化,过渡区由于受到后续成形过程中重复搅拌和重复加热作用,晶粒尺寸进一步减小到2.1~2.6 μm。FSAM过程中,晶粒的取向发生了改变,母材原有的{001}<100>立方织构在FSAM处理后部分转变为Goss织构{110}<001>和强度较弱的Cu织构{112}<111>。

(2) 6061铝合金母材和FSAM试样中起强化作用的析出相均以球状的α-Al(MnCrFe)Si相为主,FSAM处理后,沉淀相部分回溶,数密度由1.87 × 1020 m-3减小到1.00 × 1020 m-3,平均直径由44.4 nm减小到37.5 nm。由于强化相的减少,成形区硬度整体较低,并沿构建方向逐渐增加,最上层具有最高的硬度(61.8 HV),相当于母材硬度的57.5%,界面过渡区由于重复加热过程析出相溶解较多,硬度最低为52.2 HV。FSAM处理后,6061铝合金的抗拉强度减小到母材强度的47.7%~55.2%,延伸率提高到母材的144.6%~148.8%。

(3) 经过520 ℃固溶1 h,165 ℃时效18 h后,强化相充分析出,数密度增加到1.83 × 1020 m-3,平均直径略有增大(53.2 nm),与FSAM态试样相比,焊后热处理试样的力学性能显著提高,硬度完全恢复,抗拉强度恢复到母材的87.2%~91.9%。成形区部分细化的等轴晶在热处理过程中发生了晶粒的异常长大。

参考文献

Challenges in additive manufacturing of high-strength aluminium alloys and current developments in hybrid additive manufacturing

[J].

A critical review on the additive manufacturing of aluminium alloys

[J].

A part consolidation design method for additive manufacturing based on product disassembly complexity

[J].

Additive manufacturing method and different welding applications

[J].Additive manufacturing (AM) technology, in other words layered manufacturing or 3D printer technology has been developing rapidly in recent years. Unlike the traditional manufacturing method (TM), the working principle of AM technology is to create layer-based production by deposition the layers on top of each other. Owing to its advantages such as material saving, lower cost, the ability to produce parts without the need for molds and the design flexibility in complex shaped parts, it has brought a breath of fresh air to the areas where it is used primarily medical, aerospace and automotive. However, the parts produced by AM method have dimensional limitations. According to recent studies, in order to eliminate this problem, metal materials produced with AM can be combined with commonly used by different welding methods so that large parts can be obtained. In this study, these welding methods are explained and recent researches are examined. AM technology and methods are introduced. The usage areas of the method are described. In addition, the welding parameters and the effects of this new method on the mechanical properties and microstructures are investigated. (C) 2020 Published by Elsevier B.V.

A novel droplet + arc additive manufacturing for aluminum alloy: Method, microstructure and mechanical properties

[J].

Experimental and numerical analysis of friction stir additive manufacturing of 2024 aluminium alloy

[J].

Functionally graded material of 304L stainless steel and Inconel 625 fabricated by directed energy deposition: Characterization and thermodynamic modeling

[J].

Potentials and strategies of solid-state additive friction-stir manufacturing technology: A critical review

[J].

Review of high-strength aluminium alloys for additive manufacturing by laser powder bed fusion

[J].

Porosity in wire arc additive manufacturing of aluminium alloys

[J].

Research progress of friction stir additive manufacturing technology

[J].This paper summarizes the research progress of friction stir additive manufacturing (FSAM) technology at home and abroad. FSAM is fast-forming, has high additive efficiency, and provides environmental protection. In addition, as a solid-phase additive technology, it effectively avoids shrinkage, porosity, and other defects caused by other melt-additive methods during molding. Currently, reported FSAM methods can be roughly divided into four categories: axial additive manufacturing, radial additive manufacturing, consumable friction-stir tool additive manufacturing, and superimposed plate additive manufacturing. The microstructures and properties of friction stir, laser, and arc additive samples are listed in detail. The advantages and disadvantages of the different additive methods and their application fields are expounded. The companies of friction stir additive equipment, the preliminary applications, and the development direction of friction stir additive equipment designed in the future are introduced. It lays a foundation for further application of friction stir additive technology.

搅拌摩擦增材制造技术研究进展

[J].本文归纳总结了国内外的搅拌摩擦增材制造(FSAM)技术的研究进展,搅拌摩擦增材制造具有成形快、增材效率高、过程绿色环保等特点。此外,其作为一种固相增材技术,能够有效避免其他熔化增材方法成形过程中引起的缩松、孔隙等缺陷。目前报道的搅拌摩擦增材制造方法,大致可以分为4大类:轴向增材制造、径向增材制造、消耗型搅拌摩擦工具增材制造和叠加板材增材制造。详细列举了搅拌摩擦增材与激光、电弧增材样品微观组织与性能,阐述了不同增材方法的优缺点和适用领域,介绍了搅拌摩擦增材设备单位及已经开展的初步应用和未来设计的搅拌摩擦增材装置的发展方向,为搅拌摩擦增材技术的进一步应用奠定了基础。

Formation characteristic, microstructure, and mechanical performances of aluminum-based components by friction stir additive manufacturing

[J].

Friction stir additive manufacturing for high structural performance through microstructural control in an Mg based WE43 alloy

[J].

Correlation of local microstructures and mechanical properties of Al-Zn-Mg-Cu alloy build fabricated via underwater friction stir additive manufacturing

[J].

Microstructures and mechanical properties of thin plate aluminium alloy joint prepared by high rotational speed friction stir welding

[J].Aluminium alloys were widely applied in rail transit, ships and aerospace owing to their unique properties, such as low density, high strength and stiffness, outstanding corrosion resistance and low temperature performance. As a type of structure material, aluminium alloy joining was inevitable. However, these alloys were often considered very difficult to weld using traditional fusion welding technique since the welding seams were often accompanied with metallurgical defects, large deformation and stress. Friction stir welding (FSW), an innovative solid-state welding technology invented at the welding institute (TWI), was seen by designers as an effective joining methods in welding aluminium alloys due to low heat input, small stress-strain and environment friendly. In this work, 0.8 mm thick plate of 6061-T6 aluminium alloy was successfully welded by use of high rotational speed fiction stir welding technology. The microstructure and mechanical property of the butt joints prepared by high rotational speed friction stir welding were analysed in detail. The results show that the well surface topography and excellent bonding interface existed in the nugget zone (NZ) were observed. Both of the microhardness of the weld seam was lower than that of the substrate. The lowest microhardness of the butt joints located between the thermo-mechanically affected zone (TMAZ) and heat affected zone (HAZ). Compared with the conventional rotational speed, the number of β-Mg2Si, Al2CuMg and Al8Fe2Si precipitated phases existed in the NZ was more, which made the microhardness in the NZ improved significantly. The rod-shaped precipitates (Mg2Si) have the greatest influence on the microhardness. The excellent mechanical properties were obtained at the rotational speed of 8000 r/min and welding speed of 1500 mm/min. The maximum tensile strength was 301.8 MPa, which was 85.8% of the as-received 6061-T6 (351.7 MPa). And the toughness-brittleness fracture mode appeared.

铝合金薄板高转速搅拌摩擦焊接头组织与力学性能

[J].采用高转速微型搅拌摩擦焊接工艺实现了0.8 mm厚6061-T6铝合金薄板对接。利用OM、SEM、TEM及EBSD等测试技术探讨了高转速对接头微观组织及力学性能的影响规律。结果表明,高转速焊接6061-T6薄板时,焊缝表面成型良好,焊缝各区域组织呈连续均匀过渡。与常规搅拌摩擦焊相比,高转速工艺下,焊缝区β-Mg<sub>2</sub>Si、S相(Al<sub>2</sub>CuMg)和Al<sub>8</sub>Fe<sub>2</sub>Si析出相数量增多,特别是长条状β-Mg<sub>2</sub>Si数量增多,焊缝区显微硬度值明显提升;转速8000 r/min、焊速1500 mm/min条件下,接头最大抗拉强度高达301.8 MPa,是母材抗拉强度(351.7 MPa)的85.8%;转速对6061-T6铝合金超薄板高转速搅拌摩擦焊对接接头抗拉强度影响较小,接头断裂模式为脆性断裂为主的韧-脆混合断裂。

Effect of post weld heat treatment on the 6061 aluminum alloy produced by ultrasonic additive manufacturing

[J].

Microstructure and mechanical properties of pulse MIG welded 6061/A356 aluminum alloy dissimilar butt joints

[J].The microstructure and mechanical properties of pulse metal inert-gas (MIG) welded dissimilar joints between 4 mm thick wrought 6061-T6 and cast A356-T6 aluminum alloy plates were investigated. The tensile strength of the joints reached 235 MPa, which is 83% of that of 6061 aluminum alloy, and then decreased with the increase of travel speed while keeping other welding parameters constant. The microstructure, composition and fractography of joints were examined by the optical microscopy (OM), scanning electron microscopy (SEM) and electron probe microanalysis (EPMA). Grain boundary liquation and segregation occurred in the partially melted zone (PMZ) on 6061 aluminum alloy side, and brittle Fe-rich phases were observed in partially melted zone on A356 aluminum alloy side. The minimum microhardness appeared in heat-affected zone (HAZ) near A356 aluminum alloy substrate. The samples during tensile test failed mainly in PMZ and HAZ on A356 aluminum alloy side through mixed fracture mode with quasi cleavage and dimples on fracture surface.

Experimental and numerical studies of re-stirring and re-heating effects on mechanical properties in friction stir additive manufacturing

[J].

Optimization of processing-microstructure-properties relationship in friction-stir welded 6061-T6 aluminum alloy

[J].

Chemical composition effect on microstructures and mechanical properties in friction stir additive manufacturing

[J].

Interfacial bonding features of friction stir additive manufactured build for 2195-T8 aluminum-lithium alloy

[J].

Hook formation and mechanical properties in AZ31 friction stir spot welds

[J].

Microstructure evolution during friction stir welding of 2024 aluminum alloy

[J].

2024铝合金搅拌摩擦焊过程组织演化分析

[J].

Fatigue and dynamic aging behavior of a high strength Al-5024 alloy fabricated by laser powder bed fusion additive manufacturing

[J].

Precipitation of dispersoids containing Mn and/or Cr in Al-Mg-Si alloys

[J].

Relationship between welding conditions, abnormal grain growth and mechanical performance in friction-stir welded 6061-T6 aluminum alloy

[J].