EH36船板钢是一种典型的高强低合金(high strength low alloy,HSLA)钢,作为船舶制造和海洋工程的关键材料,被广泛应用于大型船舶、海洋平台、集装箱等领域[1,2]。在船舶建造过程中,常采用大线能量气电立焊(electro-gas welding,EGW)方法,实现单道次焊缝成形,以提高造船效率,进而缩短造船周期[3,4]。然而,大线能量焊接会带来较高的峰值温度和缓慢的冷却速率,使得奥氏体晶粒粗化,并形成晶界铁素体、侧板条铁素体以及贝氏体等组织,从而大幅降低焊接接头的服役性能[4~7]。因此,传统的HSLA钢及焊接材料将不再适用于大线能量焊接要求。为解决焊接接头性能恶化的难题,研究人员已经研制出适用于大线能量焊接的HSLA钢。但是,配套大线能量船板钢用焊接材料的研究相对匮乏,亟需改进和开发相关焊材[8]。

通常,大线能量EGW的焊接材料和保护气体分别选用药芯焊丝和纯CO2。焊接过程中,药芯焊丝内部焊剂将发生分解反应形成熔渣,并结合CO2气体,对熔池金属形成渣-气保护[9,10]。同时,在电弧作用下,焊剂、熔渣、CO2气体与熔池之间产生激烈的冶金反应[11]。与普通的冶金过程不同,焊接冶金过程是分区域及分阶段连续进行的,且各区域的反应条件存在较大的差异,因而在不同区域及阶段会引发不同的物理及化学反应[12,13]。各区域及阶段冶金反应的共同作用将决定焊缝金属(weld metal,WM)最终的化学成分及微观组织[14,15]。值得注意的是,在各阶段的冶金反应过程中,焊剂都参与其中并发挥重要的作用[16]。

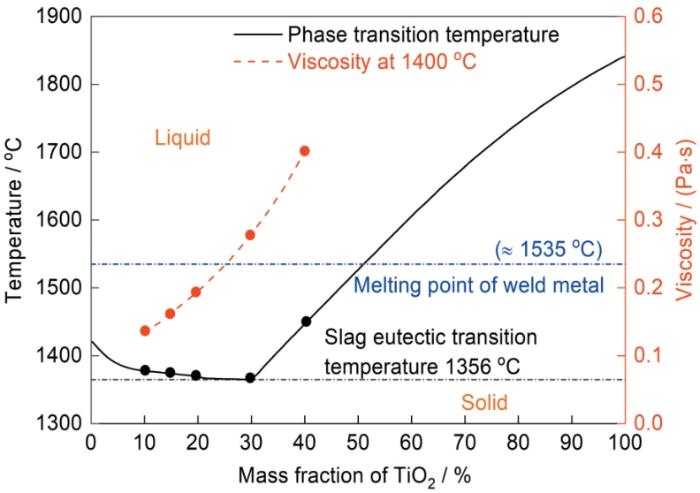

TiO2和CaF2是船板钢焊接药芯焊丝中焊剂成分的关键组元[1,17]。其中,TiO2是一种典型的酸性氧化物,能够增加电弧稳定性,改善熔渣的脱渣性[1,17];CaF2作为唯一不会向熔滴及熔池中供氧的焊剂组元,可有效降低焊剂的熔点和熔渣的黏度[11]。何磊等[17]研究了TiO2含量对CaO-SiO2-CaF2焊接熔渣黏度、熔化温度、表面张力等熔化特性的影响,结果表明,随着TiO2含量增加,焊接熔渣黏度、熔化温度及表面张力会显著降低,熔渣流动性提高。利成宁等[18]以CaF2-Al-Mg为基础渣系,并在药芯焊丝中添加不同比例TiO2组分,发现TiO2能有效改善脱渣性,并与Al、Mg发生冶金反应,导致焊缝金属中Ti含量升高,C、Si和N含量降低。Natalie等[19]设计了CaO-SiO2(40%)-TiO2型焊剂体系,发现焊剂中TiO2中的Ti可向WM中过渡,且随着TiO2含量增加WM中Ti含量增加。Zhang等[1]从热力学角度分析了CaF2-SiO2-Al2O3-MgO-TiO2型焊剂体系中TiO2含量对WM中Ti和O含量的影响,认为高温电弧作用易引起焊剂中的TiO2分解为Ti2O3及O2。阿荣[20]将合金元素Ti、B添加入EGW药芯焊丝中,发现随着Ti含量增加,焊缝微观组织从针状铁素体转变为上贝氏体;此外,添加适量B元素可有效降低界面能,促进针状铁素体形核。然而,目前对于药芯焊丝中焊剂组元对熔渣冶金反应引起合金元素过渡行为的影响规律尚没有系统的研究,且WM中成分变化对微观组织调控机理的影响仍未被阐明。

本工作以EH36船板钢为研究对象,针对大线能量焊接过程引起的焊缝组织恶化及塑韧性差等关键问题,通过设计不同TiO2含量的CaF2-TiO2二元焊剂并应用于药芯焊丝中,重点研究焊接电弧作用下焊剂中TiO2分解规律对WM增氧机制及合金元素过渡的影响,进而阐明合金元素含量变化对WM微观组织及夹杂物特性的影响规律,以期实现对WM微观组织及性能的调控,为大线能量EGW用药芯焊丝的研发以及焊接工艺参数优化提供理论依据。

1 实验方法

图1

表1 CaF2-TiO2焊剂成分配比 (mass fraction / %)

Table 1

Flux number | Designed | Analyzed | ||

|---|---|---|---|---|

| TiO2 | CaF2 | TiO2 | CaF2 | |

| Flux-1 | 10 | 90 | 10.66 | 89.34 |

| Flux-2 | 15 | 85 | 17.04 | 82.96 |

| Flux-3 | 20 | 80 | 21.02 | 78.98 |

| Flux-4 | 30 | 70 | 30.77 | 69.23 |

| Flux-5 | 40 | 60 | 40.89 | 59.11 |

依据船舶行业标准CB/T 3947—2001《气电自动立焊工艺要求》进行对接焊实验。母材选用大线能量EH36船板钢,加工尺寸为600 mm × 200 mm (轧制方向) × 30 mm,单V形坡口角度为26°,根部间隙为4 mm。采用EGW方法,焊接电流为365 A,电弧电压为40 V,焊接速率为6 cm/min,焊接热输入为146 kJ/cm;焊接过程中保护气体为纯CO2,气体流量为20 L/min。EH36船板钢和自制药芯焊丝的化学成分见表2。

表2 EH36船板钢和自制药芯焊丝的化学成分 (mass fraction / %)

Table 2

| Material | C | Si | Mn | Ni | Al | P | Ti | S | O | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Base metal | 0.185 | 0.004 | 1.520 | 0.044 | 0.001 | 0.009 | 0.001 | 0.007 | 0.002 | Bal. |

| Flux-cored wire | 0.068 | 0.306 | 2.504 | 1.260 | 0.777 | 0.004 | 0.052 | 0.003 | 0.002 | Bal. |

WM化学元素测定方法:分别采用ONH836氧氮分析仪和Avio 500电感耦合等离子体发射光谱仪(inductively coupled plasma optical emission spectrometer,ICP-OES)测定WM中O元素和合金元素含量。根据GB/T 13299—1991《钢的显微组织评定方法》,对焊接接头微观组织进行观察;根据GB/T 15749—2008《定量金相测定方法》,采用网格数点法对典型微观组织进行定量分析。使用电火花线切割机将焊接接头从钢板上取样,试样使用砂纸逐级研磨至1500号,使用粒径为0.25 μm的金刚石研磨膏在研磨抛光机上对样品进行抛光处理。使用MIRA3型场发射扫描电子显微镜(SEM)及其附带的能谱仪(EDS)对钢中夹杂物进行尺寸分布统计以及化学成分分析。采用4% (质量分数,下同)硝酸酒精溶液对抛光后样品进行腐蚀处理,腐蚀时间约为6~10 s,使用SEM观察WM微观组织。电子背散射衍射(EBSD)样品制备方法:选用5%HClO4和95%酒精混合溶液对样品进行电解抛光,抛光温度为20 ℃,抛光电压为35 V,抛光时间为20 s。参照GB/T 2654—2008《焊接接头硬度试验方法》测量硬度,使用HXD-1000TMC/LCD型Vickers显微硬度计,实验载荷为4.9 N,保载时间为15 s。参照GB/T 2650—2008《焊接接头冲击试验方法》进行-40 ℃冲击实验,冲击样品尺寸为10 mm × 10 mm × 55 mm矩形块,表面打磨光滑,并在WM处开V型槽;使用SANS-ZBC2452-C全自动摆锤冲击试验机,每组冲击实验取3个平行试样,取平均值作为冲击实验结果。

2 实验结果

2.1 TiO2 含量对焊缝金属元素含量的影响

使用不同TiO2含量的药芯焊丝进行EGW后,所得WM的化学成分如表3所示。可见,随着药芯焊丝中TiO2含量增加,WM中O含量从0.022%增加到0.029%,Ti含量从0.041%增加到0.063%;同时,Si含量从0.206%减少到0.165%,Mn含量从2.080%减少到1.790%。

表3 焊缝金属(WM)的实测化学成分(MA) (mass fraction / %)

Table 3

| WM number | C | Si | Mn | Ni | Al | Ti | Mo | O | Fe |

|---|---|---|---|---|---|---|---|---|---|

| WM1 | 0.102 | 0.206 | 2.080 | 0.660 | 0.037 | 0.041 | 0.064 | 0.022 | Bal. |

| WM2 | 0.090 | 0.205 | 2.030 | 0.634 | 0.033 | 0.044 | 0.070 | 0.024 | Bal. |

| WM3 | 0.089 | 0.201 | 1.860 | 0.657 | 0.026 | 0.048 | 0.051 | 0.025 | Bal. |

| WM4 | 0.087 | 0.185 | 1.820 | 0.612 | 0.021 | 0.059 | 0.064 | 0.027 | Bal. |

| WM5 | 0.086 | 0.165 | 1.790 | 0.603 | 0.021 | 0.063 | 0.059 | 0.029 | Bal. |

众所周知,WM是由熔化的焊丝和部分母材经过复杂物理化学反应共同作用的产物。针对某一特定合金元素,通常使用名义成分量化焊丝和母材对WM的化学成分贡献,即仅考虑母材和焊丝经过熔化稀释所得到的化学成分,计算方法如下式所示[12]:

式中,MN为元素的名义成分,MBM为母材中元素成分,Mel为焊丝中元素成分,d为母材稀释率。

式中,ΔM为WM成分变化量,MA为实测成分。

依据上述公式,分别计算出不同TiO2含量条件下WM中O、Ti、Si以及Mn元素过渡交换量的变化值,如表4所示。可见,随着焊剂中TiO2含量从10%增加到40%,ΔO从0.020%增加到0.027%,ΔTi从0.004%增加到0.026%,表明高温电弧作用使得TiO2分解进入熔池;ΔSi从-0.012%减少到-0.046%,ΔMn从-0.138%减少到-0.404%,表明熔池中Si和Mn通过熔渣-熔池界面进入熔渣中。

表4 WM中母材稀释率(d)、典型元素的名义成分(MN)和过渡交换量的变化值(ΔM)

Table 4

| WM number | d % | MN (mass fraction / %) | ΔM (mass fraction / %) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| O | Ti | Mn | Si | O | Ti | Mn | Si | ||

| WM1 | 29.1 | 0.002 | 0.037 | 2.218 | 0.218 | 0.020 | 0.004 | -0.138 | -0.012 |

| WM2 | 28.6 | 0.002 | 0.038 | 2.223 | 0.219 | 0.022 | 0.006 | -0.193 | -0.014 |

| WM3 | 28.2 | 0.002 | 0.038 | 2.228 | 0.221 | 0.023 | 0.010 | -0.368 | -0.020 |

| WM4 | 30.7 | 0.002 | 0.037 | 2.202 | 0.213 | 0.025 | 0.022 | -0.382 | -0.028 |

| WM5 | 31.5 | 0.002 | 0.037 | 2.194 | 0.211 | 0.027 | 0.026 | -0.404 | -0.046 |

2.2 TiO2 含量对焊缝金属中夹杂物特性的影响

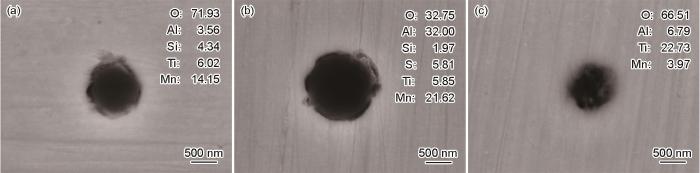

图2

图2

WM中典型夹杂物形貌的SEM像以及相应的EDS元素分析结果

Fig.2

SEM images and corresponding EDS results (atomic fraction, %) of typical inclusions in WMs

(a) O-Ti-Al-Mn-Si (b) O-Ti-Al-Mn-Si-S (c) O-Ti-Al-Mn

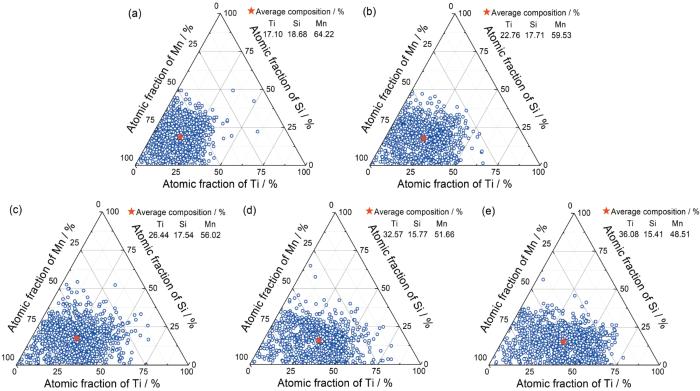

进一步,统计分析不同WM中氧化物型夹杂物的主要组成元素Ti、Si和Mn相对浓度变化情况,如图3所示,其中每个数据点代表一个夹杂物。当焊剂中TiO2的含量小于15%时,大多数夹杂物集中在三元图的左下角,WM1中夹杂物的元素平均成分(原子分数,下同)为Ti 17.10%、Si 18.68%和Mn 64.22% (图3a),WM2中夹杂物的元素平均成分为Ti 22.76%、Si 17.71%和Mn 59.53% (图3b)。当焊剂中TiO2含量增加到20%时,WM3中Ti、Si、Mn的平均成分分别为26.44%、17.54%和56.02% (图3c)。进一步增加焊剂中TiO2含量超过30%时,夹杂物的主要元素在Ti-Si-Mn三元图中的分布向右移动,表明夹杂物中Ti含量逐渐增加,而Mn和Si的含量逐渐减少。具体而言,WM4中夹杂物的Ti、Si、Mn平均成分为Ti 32.57%、Si 15.77%和Mn 51.66% (图3d),WM5中夹杂物的元素平均成分为Ti 36.08%、Si 15.41%和Mn 48.51% (图3e)。从热力学角度分析可知,焊接高温电弧作用使得TiO2发生分解反应,并且随着焊剂中TiO2含量增加,更多的O和Ti元素被转移到WM中[22,24];同时,过量的O溶解进入熔池,可能会与熔池中的Ti、Si和Mn等合金元素发生氧化还原反应,形成相应的氧化物,如Ti2O3、SiO2和MnO等,这些氧化物将部分残留在WM中形成夹杂物[28~30]。

图3

图3

不同WM中夹杂物内Ti、Si和Mn元素的归一化原子百分比

Fig.3

Normalized atomic fractions of Ti, Si, and Mn of inclusions in different WMs

(a) WM1 (b) WM2 (c) WM3 (d) WM4 (e) WM5

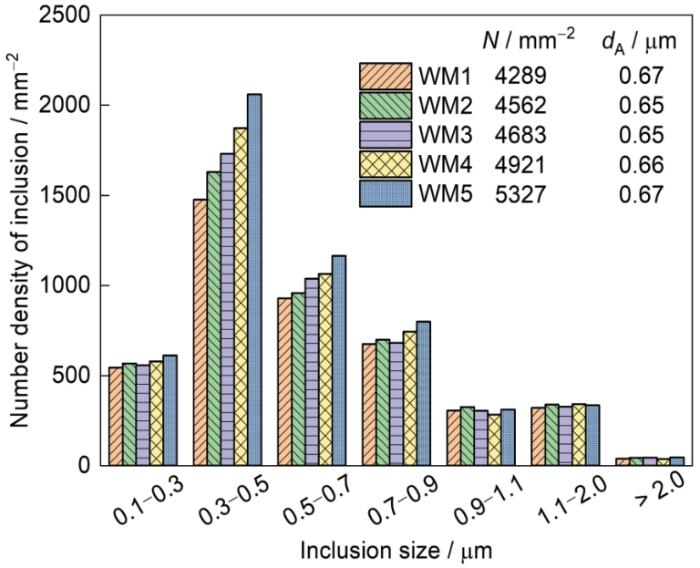

图4为不同WM中夹杂物数量密度的变化情况。可以看出,WM中夹杂物尺寸主要集中在0.3~0.9 μm范围内;不同WM中夹杂物平均尺寸差异不大,均集中在0.65~0.67 μm范围内。焊接过程中,WM经历快速的熔化和凝固,使得熔池中夹杂物的形成和长大在几秒内完成[28,29,31]。通常,夹杂物的长大与溶质原子的扩散和小尺寸夹杂物的碰撞、聚合等因素有关,这都需要足够长的时间[26,28]。在焊接过程中,熔池中的夹杂物没有足够的时间碰撞和长大,使得绝大部分夹杂物的尺寸小于1 μm[28]。此外,在焊接熔池中小尺寸夹杂物的上浮过程中,浮力对其影响可忽略不计,其上升速率远低于钢液中较大尺寸夹杂物,故不遵守Stokes定律[32,33]。因此,熔池中绝大多数的夹杂物都将凝固在WM中。随着焊剂中TiO2含量从10%增加到40%,WM中单位面积的夹杂物数量密度从4289 mm-2增加到5327 mm-2。

图4

图4

不同WM中不同尺寸夹杂物的数量密度

Fig.4

Number densities of inclusions (N) with different sizes in different WMs (dA—average size)

2.3 TiO2 含量对焊缝金属微观组织的影响

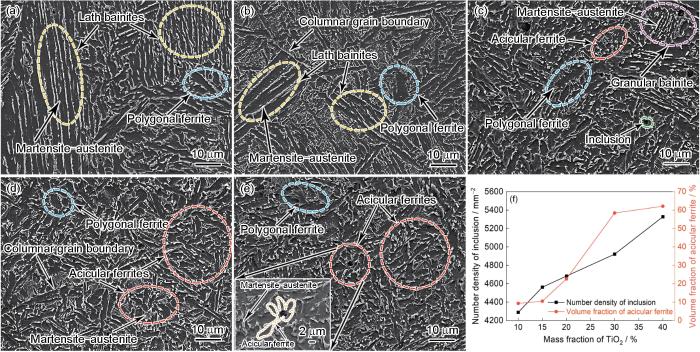

图5a~e为使用不同TiO2含量药芯焊丝焊接所得WM的SEM像,量化分析典型组织的平均晶粒尺寸如表5所示。当焊剂中TiO2含量小于15%时,WM中显微组织主要是板条贝氏体,且有少量的晶界铁素体、多边形铁素体、粒状贝氏体和针状铁素体,如图5a和b所示。值得注意的是,相互平行的贝氏体板条沿着柱状奥氏体晶界形成,并朝向晶粒内部长大,且在相互平行的贝氏体板条之间观察到细长的马氏体-奥氏体(martensite-austenite,M-A)组元[34]。通常,该类型长条状M-A组元属于脆-硬组织,当裂纹扩展到该处时,易发生脱落,使得WM的冲击韧性降低[35]。从表5可见,WM1和WM2中板条贝氏体包的平均晶粒尺寸分别为(53 ± 14)和(49 ± 11) μm,贝氏体板条之间析出的长条状M-A组元的平均尺寸分别为(12 ± 7)和(10 ± 6) μm。当焊剂中TiO2的含量增加到20%时,WM中微观组织主要由粒状贝氏体和少量的板条贝氏体组成,如图5c所示。通常,粒状贝氏体由大块状的铁素体(平均晶粒尺寸为(31 ± 10) μm)和内部随机分布的多边形状M-A组元(平均尺寸为(4 ± 3) μm)构成。当解理断裂发生时,粒状贝氏体对裂纹扩展的抑制能力较弱,WM的冲击韧性差[35~37]。随着焊剂中TiO2的含量进一步增加直到超过30%时,WM中微观组织主要是细小的针状铁素体,伴随有少量的粒状贝氏体、晶界铁素体和多边形铁素体,如图5d和e所示。同时,在交叉互锁的针状铁素体交界处随机分布着多边形状M-A组元,如图5e中插图所示。统计分析可知,WM4和WM5中针状铁素体的平均晶粒尺寸分别为(12 ± 6)和(10 ± 5) μm,多边形状M-A组元的平均尺寸为(3 ± 2) μm。

图5

图5

不同WM的SEM像和夹杂物数量密度及针状铁素体体积分数的变化

Fig.5

Typical SEM images of WM1 (a), WM2 (b), WM3 (c), WM4 (d), and WM5 (e); number densities of inclusions and volume fractions of acicular ferrites (AFs) in different WMs as a function of TiO2 content (f) (Inset in Fig.5e shows the formation of AFs induced by the typical complex inclusions in the WM)

表5 不同WM中微观组织的平均晶粒尺寸 (μm)

Table 5

| WM | Average | Average size of |

|---|---|---|

| number | grain size | martensite-austenite |

| constituent | ||

| WM1 | 53 ± 14 | 12 ± 7 |

| WM2 | 49 ± 11 | 10 ± 6 |

| WM3 | 31 ± 10 | 4 ± 3 |

| WM4 | 12 ± 6 | 3 ± 2 |

| WM5 | 10 ± 5 | 3 ± 2 |

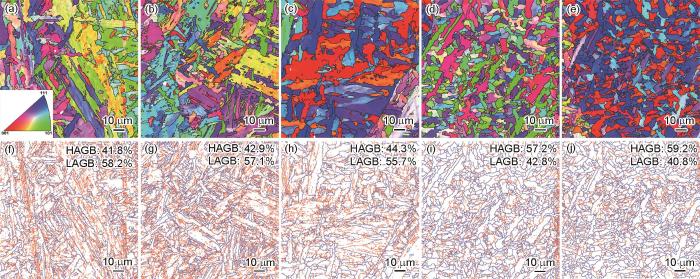

图6为不同CaF2-TiO2药芯焊丝所得WM的EBSD分析结果。图6a~e为WM的反极图。在WM1和WM2中,柱状奥氏体晶粒内部不同的贝氏体包呈现出不同的颜色,代表不同的晶体取向。但是,同一个贝氏体包内相互平行的贝氏体板条展现出相同的颜色,这表明其晶体取向相同,如图6a和b所示。在WM3中,如图6c所示,粗大的粒状贝氏体包展现出相同的晶体取向。然而,在粒状贝氏体内部随机分布的多边形状M-A组元表现出不同的晶体取向。在WM4和WM5中,互锁分布的针状铁素体表现出不同的晶体取向,且相邻的针状铁素体取向差异很大,如图6d和e所示。不同WM的晶界分布情况如图6f~j所示。此处,将取向差角大于15°的晶界定义为大角度晶界(high angle grain boundary,HAGB),将取向差角介于2°~15°的晶界定义为小角度晶界(low angle grain boundary,LAGB),分别用蓝色和红色线代表[3]。在WM1和WM2中,贝氏体包的晶界表现为蓝色的HAGB,而在贝氏体包的内部相互平行的贝氏体板条表现为红色的LAGB,如图6f和g所示。通常,在奥氏体-贝氏体相变过程中,贝氏体和原奥氏体之间遵循经典Kurdjumov-Sach (K-S)取向关系[6,40]。在奥氏体晶界处,优先形核的贝氏体板条初生取向满足变体选择规则,且同一贝氏体包内板条取向相近,相互之间晶界为LAGB;然而,单个奥氏体晶粒内部不同的贝氏体包在碰撞过程中易形成HAGB[6]。WM3中粒状贝氏体块的晶界为HAGB,而其内部的亚晶界或者随机分布的多边形状M-A组元的边界表现为LAGB,如图6h所示。在WM4和WM5中,交叉分布的针状铁素体晶界表现为固有的HAGB,如图6i和j所示。众所周知,针状铁素体优先在奥氏体晶粒内部夹杂物表面形核和长大;并且,针状铁素体板条在生长过程中易发生相互交织碰撞,形成具有较高晶界取向差的HAGB,最终呈现出交叉互锁、紧密排列的结构[30,33]。

图6

图6

不同WM的EBSD分析

Fig.6

Crystallographic characteristics in WM1 (a, f), WM2 (b, g), WM3 (c, h), WM4 (d, i), and WM5 (e, j) analyzed by EBSD

(a-e) inverse pole figures (f-j) grain boundary distribution maps (The blue and red lines denote the high angle grain boundaries (HAGBs) with misorientation angle > 15° and low angle grain boundaries (LAGBs) with misorientation angle 2°-15°, respectively)

2.4 TiO2 含量对焊缝金属力学性能的影响

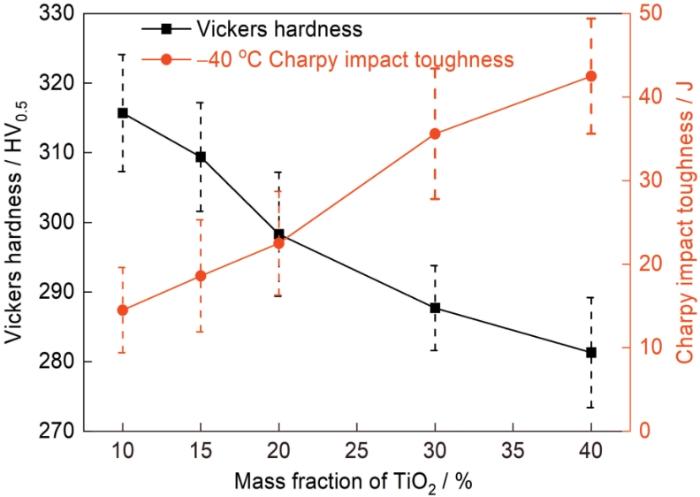

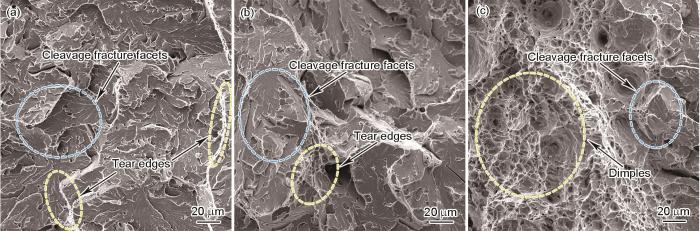

焊剂中TiO2含量对WM的Vickers硬度和Charpy冲击韧性的影响如图7所示。随着焊剂中TiO2含量从10%增加到40%,WM的Vickers硬度从(315.7 ± 8.4) HV0.5降低到(281.3 ± 7.9) HV0.5;-40 ℃环境下的Charpy冲击韧性从(14.5 ± 5.1) J增加到(42.5 ± 6.9) J。不同WM断口形貌的SEM像如图8所示。WM硬度和冲击韧性的变化与微观组织演变有关。当焊剂中TiO2含量低于20%时,WM典型微观组织主要表现为板条贝氏体或者粒状贝氏体。通常,板条贝氏体或者粒状贝氏体的硬度相对较高;但是,其对裂纹扩展阻碍能力相对较差,表现为较低的冲击韧性[35,42]。从图8a和b可以看出,WM1和WM3冲击断口表面为典型的解理断裂面和相邻解理面间少量分布的韧性断裂带。通常,解理面不能抑制裂纹的扩展,而韧性断裂带可能会促使裂纹发生偏转,进而抑制其扩展[40]。当焊剂中TiO2含量超过30%时,WM中包含大量硬度较低的针状铁素体组织,并且互锁分布的针状铁素体可有效抑制裂纹扩展,提高WM冲击韧性[4,43,44]。从图8c所示的WM5冲击断口形貌可以看出,断口表现为细而深的韧窝组织,且韧窝分布较为均匀,该种组织特征可以有效抑制裂纹的扩展[45,46]。

图7

图7

焊剂中TiO2含量对WM的Vickers硬度和Charpy冲击韧性的影响

Fig.7

Effects of TiO2 content in CaF2-TiO2 flux on the Vickers hardness and impact energy of WMs

图8

图8

不同WM断口形貌的SEM像

Fig.8

SEM images showing the impact fracture morphologies of WM1 (a), WM3 (b), and WM5 (d)

3 分析与讨论

3.1 TiO2 对典型元素过渡的调控

表6

熔渣中TiO2的活度(α

Table 6

| WM number | α | ΔG / (J·mol-1) |

|---|---|---|

| WM1 | 0.102 | -347767 |

| WM2 | 0.121 | -350996 |

| WM3 | 0.137 | -353342 |

| WM4 | 0.167 | -357084 |

| WM5 | 0.198 | -360302 |

根据表6中计算结果可知,不同TiO2含量条件下的ΔG均为负值,表明反应(3)向右移动,焊剂中TiO2发生分解反应,Ti和O元素向熔池中过渡。并且,随着TiO2含量从10%增加到40%,相应的ΔG从-347767 J/mol逐渐减小到-360302 J/mol,表明反应(3)向右偏移,促进更多的Ti和O从焊剂向熔池中过渡。

与此同时,随着焊剂中TiO2含量从10%增加到40%,ΔMn从-0.138%减少到-0.404%,ΔSi从-0.012%减少到-0.046%。通常,当焊剂中添加更多的TiO2将增大焊剂氧势,导致熔池中更多的脱氧型合金元素Mn和Si通过熔渣-熔池界面流失进入熔渣中[51~53]。值得注意的是,Mn和Si可联合其他合金元素与O反应,形成氧化物型夹杂物,促进针状铁素体形成,从而提高WM韧性[14]。此外,Si可固溶于奥氏体和铁素体中,起到固溶强化的作用,从而提升WM强度和硬度[2,54]。因此,在设计焊丝成分时,需考虑焊接过程中Mn和Si元素的损失,以避免因Mn和Si元素减少而导致WM的塑韧性降低[2,13,54]。

3.2 TiO2 诱导焊缝金属显微组织演变机制

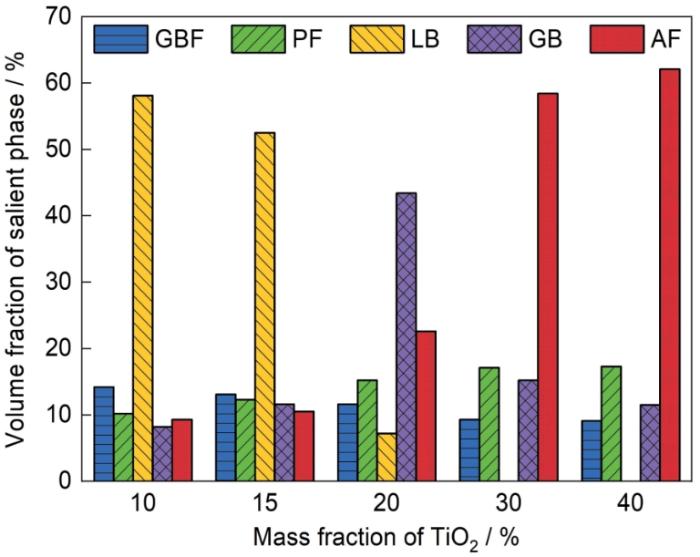

对WM中各相的含量进行统计分析,结果如图9所示。当焊剂中TiO2含量为10%和15%时,WM1和WM2中主要微观组织为板条贝氏体,其体积分数分别为58.1%和52.5%。当焊剂中TiO2含量增加到20%时,WM3中粒状贝氏体为主要微观组织,其体积分数为43.4%,针状铁素体体积分数为22.6%。随着焊剂中TiO2含量进一步增加到30%和40%时,WM4和WM5中主要微观组织为针状铁素体,其相对含量分别为58.4%和62.1%。可见,随着焊剂中TiO2含量增加,WM中典型微观组织演变从板条贝氏体,到粒状贝氏体,再到针状铁素体。众所周知,WM中的组织特征对其低温冲击韧性有重要影响,其中HAGB体积分数和M-A组元形貌是主要影响因素,决定裂纹形核和扩展路径[4,55]。依据前文统计结果可知,随着焊剂中TiO2含量增加,WM中针状铁素体的体积分数从9.3%增加到62.1%,相应的HAGB体积分数从41.8%提升到59.2%。通常,HAGB可有效地抑制裂纹的扩展,提高冲击吸收能量[4]。M-A组元形貌从长条状演变为多边形状,平均尺寸从(12 ± 7) μm减小到(3 ± 2) μm。贝氏体板条间大尺寸长条状的M-A组元易在裂纹扩展时发生脱落,从而降低WM的冲击韧性;反之,小尺寸、多边形状的M-A组元可作为脆硬相,与针状铁素体共同构成韧-脆相混合组织,从而提高WM的强韧性[35,55]。

图9

图9

不同WM中典型相的体积分数与TiO2含量的关系

Fig.9

Volume fractions of salient phases in different WMs as a function of TiO2 content (GBF—grain boundary ferrite, PF—polygonal ferrite, LB—lath bainite, GB—granular bainite)

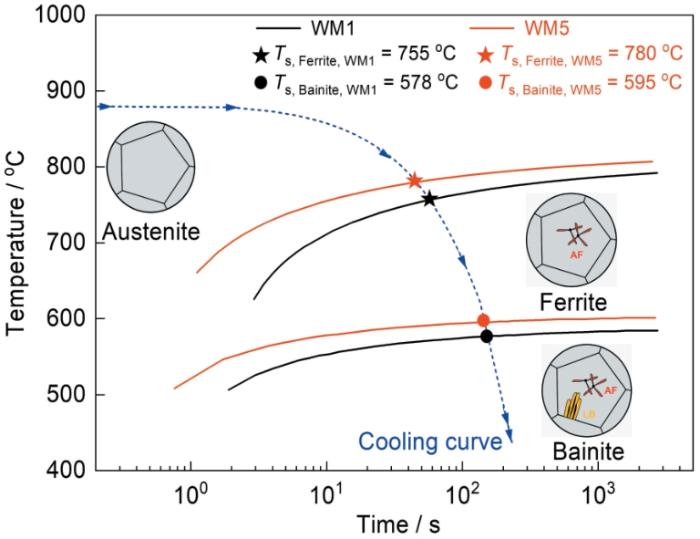

WM的组织和性能取决于合金成分和焊接热输入量,而本工作除填充材料药芯焊丝中添加不同比例TiO2,其他焊接条件均相同。由表3可见,随着药芯焊丝中TiO2含量增加,WM中O含量从0.022%增加到0.029%;同时,C含量从0.102%减少到0.086%,Si含量从0.206%减少到0.165%,Mn含量从2.080%减少到1.790%,导致衡量WM淬透性的C当量(Ceq)降低[56,57]。进一步采用JMatPro热力学分析软件描述不同成分条件下WM的连续冷却转变(continuous cooling transformation,CCT)行为,如图10所示,分析奥氏体分解产物的形成顺序及其形成温度范围[58,59]。可以看出,随着药芯焊丝中TiO2含量从10%增加到40%,对应的CCT曲线向左上方移动,过冷奥氏体转变成铁素体的温度区间从755~578 ℃逐渐增大到780~595 ℃,表明WM中过冷奥氏体转变成铁素体的时间延长,有利于更多的铁素体组织形成。图10中插图展示了WM中典型微观组织的形成路径。结合微观组织观察可知,当焊剂中TiO2含量低于15%时,过冷奥氏体转变为铁素体的温度区间减小;同时,贝氏体可持续相变的温度区间增大,促使更多的过冷奥氏体转变成为贝氏体组织。在焊接冷却过程中,在柱状晶界处优先形核长大的贝氏体板条增多,并逐渐长大粗化,最终相互平行的贝氏体板条组成大尺寸板条贝氏体组织[60,61]。当焊剂中TiO2含量增加到20%时,过冷奥氏体转变为铁素体的温度相对升高,易形成大块状的铁素体组织,并在铁素体的内部随机分布着多边形状M-A组元,共同构成粒状贝氏体组织[41]。进一步增加TiO2含量超过30%时,过冷奥氏体转变为铁素体的温度区间增大,有利于更多的铁素体组织形成。

图10

图10

TiO2含量诱导WM的连续冷却转变(CCT)图变化

Fig.10

Continuous cooling transformation (CCT) diagram shift for the WMs induced by TiO2 content (Insets show the schematics of forming paths of salient phases in the weld metals) (Ts, Ferrite, WM1 and Ts, Ferrite, WM5—starting temperatures at which supercooled austenite transforms into ferrite in WM1 and WM5, respectively; Ts, Bainite, WM1 and Ts, Bainite, WM5—starting temperatures at which supercooled austenite transforms into bainite in WM1 and WM5, respectively)

关于WM中夹杂物特性对针状铁素体含量的影响,由上文可知,WM中富Ti型夹杂物主要包括O-Ti-Al-Mn-Si型、O-Ti-Al-Mn-Si-S型和O-Ti-Al-Mn型。Yuan等[28]研究发现,WM中促进针状铁素体形核的TiO x 型夹杂物包括TiO、Ti2O3、Ti3O5和TiO2,或者由这些Ti的氧化物相复合而成的多相夹杂物。Yamada等[62]和Takada等[63]研究发现,夹杂物表面的TiO相与针状铁素体板条之间具有良好的晶格匹配性,可有效降低铁素体板条与夹杂物之间的界面能,促进针状铁素体形核。而Ti2O3和Ti3O5相内含有大量Ti3+空位,由于Mn3+与Ti3+的离子半径接近,其可在不引起自身结构发生严重晶格畸变的情况下,吸收周围基体中的Mn,形成能够降低针状铁素体与夹杂物之间界面能的贫Mn区。TiO2相会消耗周围基体中的C,形成贫C区。通常,O-Ti-Al-Mn-Si型夹杂物促进针状铁素体形核可归因于其由多个氧化物相组成,为针状铁素体板条提供多个形核面。不同相的形成可引起局部化学成分的变化,导致针状铁素体的形核能垒降低[28,64]。

式中,σγα 表示奥氏体与新形核铁素体之间单位面积界面自由能,ΔGV表示单位体积相变所需的Gibbs自由能差。通常,夹杂物的半径(ri)等于或大于r*,才能满足针状铁素体在夹杂物表面形核的要求。Yang等[64]研究发现,在奥氏体向铁素体转变过程中,铁素体形核相变驱动力为507.56~287.88 J/mol,其对应的r*为0.21~0.37 μm。本工作研究的不同WM中夹杂物尺寸主要集中在0.3~0.9 μm范围内,且平均尺寸在0.65~0.67 μm范围内,表明夹杂物均可成为针状铁素体的有效形核位点。由前文可知,随着焊剂中TiO2含量增加,更多的TiO2分解促使WM中O含量升高,赋存于WM中的氧化物夹杂物的数量密度从增加4289 mm-2增加到5327 mm-2;更多的夹杂物可作为针状铁素体的形核质点,使得WM中针状铁素体含量从9.3%增加到62.1%[31,38,39]。因此,WM中夹杂物的数量密度也将直接影响针状铁素体含量。

4 结论

(1) 随着焊剂中TiO2含量的增加,ΔO从0.020%增加到0.027%,ΔTi从0.004%增加到0.026%,表明焊剂中的TiO2在高温电弧作用下分解进入熔池中;同时,ΔSi从-0.012%减少到-0.046%,ΔMn从-0.138%减少到-0.404%,表明熔池中更多的Si和Mn元素通过熔渣-熔池界面流失进入熔渣中。

(2) 随着焊剂中TiO2含量的增加,焊缝金属中过冷奥氏体转变为铁素体的相变温度区间从755~578 ℃提升到780~595 ℃;同时,焊缝金属中形成O-Ti-Al-Mn型、O-Ti-Al-Mn-Si型和O-Ti-Al-Mn-Si-S型氧化物夹杂物的数量密度从4289 mm-2增加到5327 mm-2,促使过冷奥氏体优先在晶粒内部转变为针状铁素体。焊缝金属中针状铁素体含量从9.3%增加到62.1%。

(3) 随着焊剂中TiO2含量的增加,焊缝金属组织形貌演变从平行状板条贝氏体,到平面状粒状贝氏体,再到交织状针状铁素体,典型组织晶粒尺寸从(53 ± 14) μm减小到(10 ± 5) μm,大角度晶界体积分数从41.8%提升到59.2%;同时,随机分布的M-A组元形貌从长条状演变为多边形状,平均尺寸从(12 ± 7) μm减小到(3 ± 2) μm。焊缝金属的Vickers硬度从(315.7 ± 8.4) HV0.5降低到(281.3 ± 7.9) HV0.5,冲击韧性从(14.5 ± 5.1) J增加到(42.5 ± 6.9) J。

参考文献

Tuning weld metal mechanical responses via welding flux optimization of TiO2 content: Application into EH36 shipbuilding steel

[J].

The effect of trace elements on the microstructure and properties of coarse grain heat affected zone of EH36 ship steel with super large heat input

[J].

微量元素对超大线能量EH36船板热影响区粗晶区组织和性能的影响

[J].

On the heterogeneous microstructure development in the welded joint of 12MnNiVR pressure vessel steel subjected to high heat input electrogas welding

[J].Microstructure features of 12MnNiVR pressure vessel steel welded joint deposited by the high heat input electrogas welding have been systematically investigated. It is revealed that the welded joint is featured by a heterogeneous juxtaposition. The coarse grained heat-affected zone (CGHAZ) primarily consists of lath bainites and minor granular bainites. The fine grained heat-affected zone (FGHAZ) is dominated by polygonal ferrites, pearlites, and fine cementite particles. Moreover, electron backscatter diffraction results further demonstrate that the CGHAZ is populated by coarse prior austenite grains (PAGs) with high frequency (61.3%) of low angle grain boundaries (LAGBs). On the other hand, the FGHAZ is filled with fine PAGs with a lower frequency (19.6%) of LAGBs. Such microstructural differences may likely contribute to differed mechanical properties for samples tested at designed positions.

Heterogeneous microstructure-induced mechanical responses in various sub-zones of EH420 shipbuilding steel welded joint under high heat input electro-gas welding

[J].

Microstructure and mechanical properties of 1500 MPa grade ultra-high strength low alloy steel

[J].

1500 MPa级低合金超高强钢的微观组织与力学性能

[J].设计了一种新型1500 MPa级Si-Mn-Cr-Ni-Mo多组元系低合金超高强度结构钢, 对比研究了控轧+控冷(TMCP)、控轧+空冷、控轧+直接淬火、控轧+直接淬火+250 ℃回火4种不同工艺对其微观组织和力学性能的影响. 结果表明: 直接淬火态钢板抗拉强度最高, 可达1890 MPa, 屈服强度为1280 MPa, 延伸率为13\%; 250 ℃回火30 min后抗拉强度降低为1820 MPa, 而屈服强度升高为1350 MPa, 分析认为这归因于位错亚结构的回复软化过程与残余奥氏体分解为马氏体、析出ε-碳化物强化机制的综合作用; 空冷与TMCP工艺获得板条贝氏体+马氏体+少量残余奥氏体的复相组织, 贝氏体分割马氏体板条束, 使实验钢具有良好的强塑性. 低碳马氏体相变过程存在C扩散现象. 研究发现, 回火过程不仅包含残余奥氏体分解, 也包含C从马氏体或贝氏体向奥氏体的分配过程. 证明了立方结构的析出粒子在奥氏体中形核, 在整个冷却过程长大、粗化, 而相变后的马氏体或贝氏体未出现大量第二相析出核心.

Influence of solid-state phase transformation and softening effect on welding residual stress of ultra-high strength steel

[J].In recent years, ultra-high strength steel (UHSS) has been widely utilized in engineering structures, mining machinery, and military equipment. However, UHSS is prone to brittle fracture and fatigue failure due to high strength and relatively low plasticity. Moreover, residual stress induced by welding process affects both brittle fracture and fatigue failure. In this work, a single-pass butt-welded joint was fabricated by metal inert-gas welding. The base metal was 1600 MPa grade UHSS with a 5 mm thickness, and the filler metal was ER307Si. The distributions of welding residual stress and hardness of the butt-welded joint were measured using the hole drilling method and a microhardness tester, respectively. Based on measured values of hardness in the heat-affected zone (HAZ) and softening zone (SZ), SYSWELD software was used to develop an advanced computational approach with consideration of “thermal-metallurgical-mechanical” coupling behaviors. In addition to the strain hardening and annealing effects of weld metal, the established computational model accounted for both the solid-state phase transformation (SSPT) of HAZ and softening effect of SZ. The temperature field and residual stress distribution of the UHSS single-pass butt-welded joint were simulated. Furthermore, the simulated results were compared with the corresponding measured data. The simulation results revealed the effect of SSPT and softening on welding residual stress. The numerical results indicated that SSPT has a strong influence on both the magnitude and distribution of the longitudinal residual stress; however, it has a limited effect on transverse residual stress. Meanwhile, the softening effect drastically affects the peak values of the longitudinal residual stress, while it hardly influences transverse residual stress. When both SSPT and softening effects are simultaneously considered in the numerical model, the computed results of welding residual stress are in good agreement with the experimental measurements.

固态相变和软化效应对超高强钢焊接残余应力的影响

[J].以板厚为5 mm的1600 MPa级超高强钢为研究对象,采用熔化极惰性气体保护焊(MIG)焊接方法和ER307Si焊丝制备了单道对接接头,分别利用盲孔法和显微硬度仪测量残余应力和接头硬度分布。基于接头热影响区和软化区的硬度测量结果,以SYSWELD软件为平台,开发了考虑超高强钢固态相变和软化效应以及焊缝金属加工硬化和退火软化的“热-冶金-力学”多场耦合的有限元计算方法。采用该方法模拟了超高强钢单道对接接头的温度场及残余应力,并与实验结果进行了比较。基于数值模拟结果探讨了固态相变和软化效应对焊接残余应力的影响机制。数值模拟结果表明,固态相变对纵向残余应力的大小和分布有显著影响;对横向残余应力的大小和分布有一定程度的影响。软化效应对纵向残余应力的峰值有较显著的影响,对横向残余应力几乎没有影响。将数值模拟结果与实验结果比较可知,在同时考虑固态相变和软化效应的情况下,平板对接接头的焊接残余应力计算结果与实验测量结果最为吻合。

Effects of heat input on the microstructure and impact toughness of weld metal processed by a new fluxnovel flux cored wire weld

[J].

热输入量对一种新型药芯焊丝熔敷金属组织及冲击韧性的影响

[J].采用自行研究开发的一种新型药芯焊丝, 通过实验室大热输入焊接实验, 研究分析了热输入量对焊缝熔敷金属组织与冲击韧性的影响规律. 结果表明: 在大热输入焊接条件下, 熔敷金属中形成了大量细小、弥散分布的夹杂物, 夹杂物周围诱导生成的大量相互交叉互锁的针状铁素体晶粒, 这是焊缝熔敷金属具有较高低温冲击韧性的主要原因; 随着焊接热输入量的增加, 尺寸为1 μm以下的夹杂物数量减少, 1 μm以上夹杂物分布无显著变化, 针状铁素体形核点减少, 熔敷金属中针状铁素体晶粒尺寸略有增加、低温冲击韧性略有降低.

Influence of shielding gas composition on microstructure characteristics of 1000 MPa grade deposited metals

[J].In recent years, high and ultra-high strength steels have been developed and used in light-weight constructions such as the structural members of mobile equipment in order to reduce weight and fabrication costs and to enhance the performance. Welding of steels with yield strength of more than 900 MPa is particularly challenging because of the toughness requirements for the weld metal, which calls for welding consumables of high strength and good toughness. Weld metals have been produced for a variety of welding methods with yield strength up to or above 1000 MPa, but their impact toughness remained only at medium yield strengths. Proper microstructure is the key to meeting this requirement, and its final microstructure depends on the chemical composition and cooling rate. For the deposited metal produced by gas metal arc welding (GMAW), the composition is dependent on the welding wire and shielding gas. The cooling rate of the weld metal is controlled by a combination of heat input and heat extraction. It is known that the addition of CO2 to argon based shielding gas is effective for improvement of productivity in GMAW welding of steel. Through the chemical reaction in the welding arc, CO2 in the shielding gas can affect the chemical composition of the weld metal, and its microstructure. The 1000 MPa grade deposited metals was welded with GMAW, and the effects of shielding gas composition (Ar+(5%~30%)CO2, volume fraction) on the general compositional and microstructural characteristics of deposited metals, including nonmetallic inclusions, were experimentally characterized with SEM, EBSD and TEM. The microstructure of the deposited metals is mainly composed of martensite and bainite. With the increase of CO2 content (5%~30%), the strength of the deposited metals decrease slightly and the impact toughness increases first and then decreases. Meanwhile, the transformation range (B50-Ms) of the deposited metal increases, the bainite content increases (8%~29.6%) with the quantity of inclusions that are suitable for bainite nucleation increases, and the nucleation position changes from the original austenite grain boundary to the common nucleation on the original austenite grain boundary and inclusions within the grain. At the same time, the microstructure morphology of the deposited metal changes from parallel to intertexture, which presented an intersected configuration and microstructure refinement.

保护气成分对1000 MPa级高强熔敷金属组织特征的影响

[J].通过附带EDS的FEGSEM、EBSD、TEM等实验方法,研究了保护气成分(Ar+5%CO<sub>2</sub>、Ar+10%CO<sub>2</sub>、Ar+20%CO<sub>2</sub>、Ar+30%CO<sub>2</sub>,体积分数)对1000 MPa级高强熔敷金属组织特征的影响,阐明了保护气成分对组织转变的影响机制。结果表明,随着保护气中CO<sub>2</sub>含量增加,1000 MPa级熔敷金属强度略有下降,而冲击韧性先升高后降低。不同保护气熔敷金属均由马氏体/贝氏体混合组织及板条间残余奥氏体组成。随着保护气中CO<sub>2</sub>含量增加,熔敷金属中贝氏体相变体积分数为50%时的温度(B<sub>50</sub>)与马氏体相变开始温度(M<sub>s</sub>)相变温度区间增大,适宜贝氏体形核的夹杂物数量增多,随贝氏体含量(体积分数)由8%增加到29.6%,其形核位置从原始奥氏体晶界向原始奥氏体晶界及晶内夹杂物处共同形核转变,熔敷金属组织形貌由“平行状”向“交织状”转变,分割细化组织,有利于高强熔敷金属强韧性的改善。

Influence of shielding gases in the welding of metals

[J].

Fine-tuning weld metal compositions via flux optimization in submerged arc welding: An overview

[J].

埋弧焊中焊剂对焊缝金属成分调控的研究进展

[J].

Effect of alloy elements partitioning behavior on retained austenite and mechanical property in low carbon high strength steel

[J].The C content in high strength steel must be controlled at a lower level for the good weldability. However, the lower level of C content will reduce the C partitioning efficiency and influence the stability of retained austenite, which leads to the decrease of the product of tensile strength and elongation of high strength steel. A novel preparation mechanism of high strength steel is to employ some kind of substitutional alloying elements, for example Mn, instead of C to partitioning to enhance the austenitic stability, which would not remarkably reduce the weldability of the steel. One low alloy C-Si-Mn steel was used in present work. The Mn partitioning behavior and its effect on the stability of the retained austenite and the mechanical property were studied by means of intercritical annealing, subsequent austenitizing, then quenching and partitioning process (I&Q&P). The results show that in the process of intercritical annealing at 760 ℃, by extending the annealing time, austenite volume fraction increases gradually until it reaches the saturation, meanwhile the Mn partitioning behavior occurs and Mn content increases gradually from ferrite to austenite until it reaches the chemical potential balance in two phases. The sample is heated to 930 ℃ for 120 s, then rapidly quenching to 220 ℃, the carbon diffuses from martensite to austenite phase in the process of partitioning. After I&Q&P process, the tensile strength of experimental steel is 1310 MPa, elongation up to 12%, the product of strength and elongation up to more than 15000 MPa.%. The steel only contains a small amount of retained austenite by only C partitioning after traditional Q&P process, while the steel contains more Mn-rich retained austenite after I&Q&P process. Hence, the content and stability of retained austenite of steel can be improved significantly, which enhance the formability at room temperature.

低碳高强钢合金元素配分行为对残余奥氏体和力学性能的影响

[J].采用双相区保温+奥氏体化淬火+低温退火的热处理工艺, 研究了合金元素配分行为对C-Si-Mn系高强钢微观组织和力学性能的影响. 结果表明, 在760 ℃随着保温时间的延长, 双相区中奥氏体相的体积分数逐渐增多直至达到饱和, 而铁素体向奥氏体扩散的Mn元素含量也逐渐增多直至在两相间达到化学势平衡, 后加热至930 ℃保温120 s, 再淬火至220 ℃, 配分过程中发生了C从马氏体向奥氏体中的扩散偏聚. 经该工艺处理后实验用钢的抗拉强度为1310 MPa, 延伸率可达12%, 强塑积达到15720 MPa.%, 相比传统淬火+碳配分工艺, 双相区保温+奥氏体化淬火+低温退火的热处理工艺过程中Mn配分和C配分共同作用能够显著提高钢中残余奥氏体的含量和稳定性, 从而提高高强钢的室温成形能力.

Effect of Mn, Ni, Mo proportion on microstructure and mechanical properties of weld metal of K65 pipeline steel

[J].

Mn/Ni/Mo配比对K65管线钢焊缝金属组织与力学性能的影响

[J].以Mn-Ni-Mo-Ti-B为主要合金系, 研制出适用于低温服役环境下的高强高韧管线钢埋弧焊丝, 并应用于30.8 mm厚K65管线钢现场焊接实验. 结果表明, 焊缝金属屈服强度达到583~689 MPa, 抗拉强度达到714~768 MPa, -40 ℃冲击功均在90 J以上, 焊缝具有优异的强韧性匹配. 焊丝直径为4.0 mm, 适用于四丝双面埋弧焊, 效率高, 且热影响区(HAZ) 低温韧性优异(-40 ℃冲击功>100 J). 采用OM, TEM和LePera方法对焊缝金属组织的观察表明, 焊缝组织主要为精细的针状铁素体、少量的先共析晶界铁素体、侧板条铁素体和弥散分布的细小马氏体/奥氏体(M/A) 岛状颗粒. 焊缝金属中0.2%Mo可以有效抑制先共析晶界铁素体及侧板条铁素体的生成, 晶粒细化作用显著. Mn和Ni的适量增加会促进针状铁素体的形成, 显著提高焊缝金属低温韧性. 但Mn, Ni配比不当而超过某个范围时将会导致马氏体或其它低温相变产物形成, 削弱低温韧性. 当K65焊缝金属中含(1.5%~2.0%)Mn, (0.9%~1.2%)Ni, (0.2%~0.25%)Mo时, 可以使其具有高强度的同时低温冲击韧性优异, 且在Mn与Ni配比含量不越过马氏体形成线(M<sub>s</sub>线)的前提下, 可以采用加Mn减Ni的方法配比其合金含量.

SiO2-bearing fluxes induced evolution of γ columnar grain size

[J].

Metallurgical design rules for high-strength steel weld metals

[J].

Effect of TiO2 and Al2O3 on melting characteristics of CaO-SiO2-CaF2 base welding slag

[J].

TiO2和Al2O3对CaO-SiO2-CaF2基础焊接渣系熔化特性的影响

[J].

Effect of TiO2 in the self-shielded flux-cored wire on microstructures and properties of deposited metal

[J].

TiO2对自保护药芯焊丝熔敷金属组织与性能的影响

[J].

Physical and chemical behavior of welding fluxes

[J].

Improvement of microstructure and toughness in high heat input weld

[D].

大热输入钢焊缝组织及韧性改善

[D].

Element transfer behaviors of fused CaF2-TiO2 fluxes in EH36 shipbuilding steel during high heat input submerged arc welding

[J].

Influence of shielding gas on undercutting formation in gas metal arc welding

[J].

Slag-metal reactions during flux shielded arc welding

[D].

Effects of the chemical composition of the gas shield on the properties of flux-cored wire welds

[J].

Quantifying MnS inclusion evolution behaviors during 1473 K heating in EH36 shipbuilding steel with Zr addition

[J].

Overview: Inclusion assisted microstructure control in C-Mn and low alloy steel welds

[J].

Characterizing inclusions in the weld metal of EH36 shipbuilding steel processed by CaF2-30 wt pct TiO2 flux

[J].

Influence of Ti on non-metallic inclusion formation and acicular ferrite nucleation in high-strength low-alloy steel weld metals

[J].

Factors affecting the inclusion potency for acicular ferrite nucleation in high-strength steel welds

[J].

Model for inclusion formation in low alloy steel welds

[J].

The role of inclusions in controlling HSLA steel weld microstructures

[J].

The mechanism of acicular ferrite in weld deposits

[J].

Detailing microstructural evolution roadmap in the weld metal of EH420 shipbuilding steel subjected to varied reheating inputs

[J].

Microstructural evolution and toughness of the various HAZs in 1300-MPa-grade ultrahigh-strength structural steel

[J].

Grain refinement in coarse-grained heat-affected zone of Al-Ti-Mg complex deoxidised steel

[J].

Microstructural characteristics and impact toughness in YS690MPa steel weld metal for offshore structures

[J].

TiO2-assisted microstructural variations in the weld metal of EH36 shipbuilding steel subject to high heat input submerged arc welding

[J].

The contribution of intragranular acicular ferrite microstructural constituent on impact toughness and impeding crack initiation and propagation in the heat-affected zone (HAZ) of low-carbon steels

[J].

Correlation between microstructure and low-temperature impact toughness of simulated reheated zones in the multi-pass weld metal of high-strength steel

[J].

Effects of heat input on microstructure and fracture toughness of simulated coarse-grained heat affected zone for HSLA steels

[J].

Microstructural evolution and its influence on toughness in simulated inter-critical heat affected zone of large thickness bainitic steel

[J].

Effect of inclusions on microstructure and toughness of deposited metals of self-shielded flux cored wires

[J].

Microstructure and impact toughness of welding heat-affected zones of a Fe-Cr-Ni-Mo high strength steel

[J].Marine engineering steel is the key material for the construction of major marine infrastructure projects. Due to the harsh environment in the deep sea, the mechanical properties such as strength, low temperature toughness and so on of the marine steel are required to be higher. In this work, the weldability of a Fe-Cr-Ni-Mo high-strength steel was studied, and the microstructure and impact toughness of the steel after welding thermal cycling at different peak temperatures were analyzed. The results show that the average impact toughness of characteristic heat affected zone under different temperatures increases first and then decreases with the increase of peak temperature (Tp). The microstructures of coarse grain heat-affected zone (CGHAZ, Tp=1320 ℃) and fine grain heat-affected zone (FGHAZ, Tp=1020 ℃) are quenched martensite. Because of the coarse grain size, the impact toughness of CGHAZ is poor, which is lower than that of FGHAZ. The microstructure of inter-critical heat-affected zone (ICHAZ, Tp=830 ℃ and Tp=760 ℃) is composed of quenched martensite and tempered martensite. Due to the randomness of the proportion of the interfaces between the mixed microstructures near the V-notch, the impact energy values of ICHAZ fluctuates greatly. The homogeneous fine grain structure in ICHAZ (Tp=830 ℃) has a crack arrest effect during the impact deformation, which makes the characteristic zone have the best impact toughness. Although the grain size in ICHAZ (Tp=760 ℃) is also fine, the existence of the ultra-fine grain zones (the grain size in which is only 1~2 μm) benefits the formation of secondary voids under the impact load. The undissolved M2C and MC precipitations in matrix promote the connecting of secondary voids and then form the secondary cracks. As a result, the impact toughness of the characteristic zone is poor, and becomes the weak region of HAZ.

一种Fe-Cr-Ni-Mo高强钢焊接热影响区的显微组织与冲击韧性研究

[J].研究了一种Fe-Cr-Ni-Mo高强钢经不同峰值温度(T<sub>p</sub>) (760、830、1020和1320 ℃)焊接热循环后的显微组织与冲击韧性。结果表明,随着T<sub>p</sub>的升高,特征热影响区的平均冲击功先增大后减小。粗晶区(CGHAZ,T<sub>p</sub>=1320 ℃)和细晶区(FGHAZ,T<sub>p</sub>=1020 ℃)的显微组织为淬火马氏体。由于晶粒粗大,造成CGHAZ冲击韧性较差,低于晶粒细小的FGHAZ冲击韧性。部分相变区(ICHAZ,T<sub>p</sub>=760 ℃和T<sub>p</sub>=830 ℃)的显微组织为淬火马氏体和回火马氏体组成的混合组织,由于冲击试样V型缺口处的混合组织界面所占比例具有随机性,造成ICHAZ冲击功波动较大。ICHAZ (T<sub>p</sub>=830 ℃)中均匀的细晶组织对冲击裂纹具有止裂作用,使得该微区具有最佳的冲击性能。尽管ICHAZ (T<sub>p</sub>=760 ℃)晶粒细小,但存在的极细晶组织(尺寸为1~2 μm)在遭受冲击载荷时易形成密集分布的次生微孔,基体中未溶的M<sub>2</sub>C及MC析出相促使微孔连接形成裂纹,导致该微区冲击韧性最差,成为热影响区的薄弱区域。

Effect of welding heat input on microstructure and impact toughness of the simulated CGHAZ in Q500qE steel

[J].As China's economy enters a stage of high-quality development, it is important to study high-performance bridge steels with high strength, high toughness, high efficiency, and easy welding. Presently, coarse-grained heat-affected zones (CGHAZs) of high-performance bridge steels are prone to coarse-grain embrittlement, which reduces its impact toughness. To improve their low-temperature toughness, the relationship between their microstructure and impact toughness has been extensively researched and discussed. However, the control connection and internal mechanism between the bainite microstructure and impact toughness have not been clarified. In this study, the simulated samples of CGHAZs in Q500qE steel with varying heat inputs, from 15 to 30 kJ/cm, were reproduced in Gleeble 3500 thermal simulation-testing machine. The effect of different heat inputs on the microstructure, impact toughness of CGHAZs, and their inherent mechanism was discussed and analyzed in-depth using OM, SEM, and EBSD. The results indicate that the microstructure of each simulated sample of CGHAZs in Q500qE steel was composed of lath-like bainite (LB) and granular-like bainite (GB). The LB increased, the GB reduced, phase-transition temperature (Ar3) declined, and the bainitic packet/block substructure refined as the welding heat input decreased. In addition, with the decreased heat inputs, the Charpy impact energy (KV2) at -40oC of CGHAZs is enhanced because of the refined microstructure. The impact fracture of all samples showed cleavage fracture characteristics, and the cleavage face size of the simulated samples of CGHAZs decreased due to the reduced heat inputs. Compared with prior austenite grain boundary and bainite block, the bainite packet is the most effective microstructural unit for controlling the impact toughness of CGHAZs in Q500qE steel, and its boundary effectively facilitates the prevention of further propagation of a secondary crack.

热输入对Q500qE钢模拟CGHAZ微观组织和冲击韧性的影响

[J].采用Gleeble-3500热模拟试验机模拟了Q500qE钢在不同热输入(E<sub>j</sub> = 15~30 kJ/cm)下的焊接热循环过程,结合OM、SEM以及EBSD等手段探讨了热输入对粗晶热影响区(CGHAZ)微观组织和冲击韧性的影响规律及其作用机理。结果表明,随着焊接热输入的降低,板条贝氏体(LB)增多,粒状贝氏体(GB)减少,相变温度A<sub>r3</sub>降低,贝氏体块(packet)和贝氏体束(block)明显细化;CGHAZ的冲击功KV<sub>2</sub> (-40℃)随着热输入的降低而提高,冲击断口均表现出明显的解理断裂特征,其解理面尺寸D<sub>f</sub>随着热输入的降低而减小;贝氏体packet是Q500qE钢中控制CGHAZ冲击韧性最有效的结构单元。

FactSage thermochemical software and databases, 2010-2016

[J].

Reconsidering the basicity of a FCAW consumable-Part 1: Solidified slag composition of a FCAW consumable as a basicity indicator: A basicity index for a flux cored electrode was developed, taking into consideration the metal sheath, fill ingredien

[J].

Reconsidering the basicity of a FCAW consumable-Part 2: Verification of the flux/slag analysis methodology for weld metal oxygen control: The prediction model is verified by experimental results

[J].

Addressing weld metal compositional variations in EH36 shipbuilding steel processed by CaF2-SiO2-CaO-TiO2 fluxes

[J].

Element transfer behaviors of fused CaF2-SiO2-MnO fluxes under high heat input submerged arc welding

[J].

Bond characteristic-dependent viscosity variations in CaF2-SiO2-Al2O3-MgO welding fluxes

[J].

Effects of Si content on microstructure and toughness of the 800 MPa grade high-strength low-alloy deposited metals

[J].

Si元素对800 MPa级HSLA钢焊材熔敷金属组织及韧性的影响

[J].

Elemental distribution in the martensite-austenite constituent in intercritically reheated coarse-grained heat-affected zone of a high-strength pipeline steel

[J].

In situ observation of acicular ferrite growth behavior differences in weld metals subjected to varied CaF2-TiO2 flux-cored wires

[J].

Synergistic strengthening of high-Cr martensitic heat-resistant steel and application of thermo-mechanical treatments

[J].By virtue of their high thermal conductivity, low thermal expansion coefficient, and excellent high-temperature creep strength, high-Cr (mass fraction: 9%-12%) martensitic heat-resistant steels are the putative main constituents of the key equipment in ultra-supercritical (USC) power plants. However, the harsh environment caused by enhancing the steam parameters has recently challenged the high-temperature properties and the continually deteriorating creep strength during service has seriously threatened the safety and reliability of these steels. Previously, the creep strength of high-Cr martensitic heat-resistant steels was enhanced by optimizing the alloying compositions to promote the dispersed precipitation of strengthening phases, but the enhancement effect of reinforced single-precipitate strengthening is limited. In recent years, synergistic strengthening reinforcement of dislocation-precipitate-interface has emerged as a promising solution because the introduced dislocations promote various precipitations and the phase transformation can be controlled to tailor the lath structure, thus reinforcing the dislocation-precipitate-interface interactions and synergistically enhancing various strengthening effects. This paper overviews the synergistic strengthening of dislocation-precipitate-interface and microstructure control in high-Cr martensitic heat-resistant steels subjected to thermo-mechanical treatments. The review covers alloying optimization to improve the creep strength, the phase transformations during heating treatments, and the mechanism of microstructural degradation at high temperatures. It also compares the effects of single-precipitate and synergistic strengthening processes on creep strength and introduces microstructure control in welded joints by thermo-mechanical treatments in terms of creep failure behaviors. This research aims to guide the design and engineering applications of high-Cr martensitic heat-resistant steels and other precipitate-strengthening heat-resistant steels for USC power plants.

高Cr马氏体耐热钢的协同强化机制及形变热处理应用

[J].高Cr (9%~12%,质量分数)马氏体耐热钢因其较高的热导率、较低的热膨胀系数以及优异的高温蠕变强度等优点而被认为是超超临界火电机组关键设备升级改造的主选材料。然而,服役过程中高Cr马氏体耐热钢高温蠕变强度的不断弱化严重影响了其安全可靠性。以往提升高Cr马氏体耐热钢高温蠕变强度的主要手段是通过合金成分优化设计来促进沉淀相弥散析出,但单一析出强化效应对蠕变强度的提升效果非常有限。近年来,位错-沉淀相-界面协同强化效应在提升高Cr马氏体耐热钢高温蠕变性能方面表现出显著效果。其原理是通过形变热处理引入位错来促进多种沉淀相弥散析出,同时通过控制相变来细化板条组织,增强位错、沉淀相及界面3者之间的交互作用,从而实现多类蠕变强化效应的协同提升。本文总结了高Cr马氏体耐热钢的协同强化机制及形变热处理组织调控,从高温蠕变强度提升角度回顾了合金成分的优化历程,阐述了热处理过程中的相变行为及高温组织退化机理,对比分析了单一析出强化效应及形变热处理后位错-沉淀相-界面协同强化效应对其高温蠕变强度的影响规律,并基于焊接接头蠕变失效行为探索了形变热处理对焊接热影响区的组织调控机制,以期为高Cr马氏体耐热钢及其他火电机组用沉淀型强化耐热钢的材料设计及工程应用提供指导。

Acicular ferrite and bainite in C-Mn and low-alloy steel arc weld metals

[J].

Effect of solid-state phase transformation on stress and distortion for Fe-Co-Ni ultra-high strength steel components during welding and vacuum gas quenching processes

[J].

固态相变对Fe-Co-Ni超高强度钢长臂梁构件焊接-淬火过程应力和变形的影响

[J].建立了Fe-Co-Ni超高强度钢板电子束焊热源模型和“热-冶金-力学”耦合有限元模型,通过焊缝截面形貌和残余应力的模拟结果和实测结果对比,验证了耦合有限元模型的可靠性。利用耦合有限元模型模拟了Fe-Co-Ni超高强度钢长臂梁构件的“电子束焊-真空气淬”过程,预测了在焊接-淬火过程中组织转变规律和应力与变形。研究发现,真空气淬是导致超高强度钢构件产生明显变形的主要原因,考虑固态相变的真空气淬过程模拟结果可以获得准确的变形方向和大小。

Phase transformation behaviors in the heat-affected zones of ferritic heat-resistant steels enabled by in situ CSLM observation

[J].Fossil-fired thermal power generation has dominated China's electricity production for a long time, contributing to around 70% of the total capacity. Developing long-life ultra-supercritical thermal power units is essential for improving coal-fired power generation efficiency, reducing harmful gas emissions, and achieving national energy conservation and emission reduction targets. The assembly and manufacture of advanced heat-resistant steel grades are required to address the above demands, serving as crucial components driving the technological advancement of thermal power units. Heat-resistant steel grades P11, P22, and P91, which are Cr-Mo based ferritic, possess a range of highly attractive properties, such as excellent mechanical properties, excellent corrosion resistance, and relatively low construction costs. These steel grades are widely used in pressure vessels and pipelines focused on high-temperature applications. Fusion welding techniques are invariably necessary to weld such heat-resistant-grade steels before they are positioned in high-temperature service. However, it is worth noting that drastic solid-state phase transformations in the heat-affected zones (HAZs) during thermal welding cycles can profoundly influence the heterogeneous microstructures of welded joints, determining their final mechanical properties to a large extent. Furthermore, it seriously threatens the safe and stable operation of thermal power plants. High-temperature confocal scanning laser microscopy (CSLM) revolutionized traditional metallographic experiments, enabling real-time morphology and quantitative analysis tracking. This innovation has facilitated investigations into the kinetic phase transformation process and microstructure evolution in steels at high temperatures. In this work, the kinetics of phase transformation and microstructural evolution in the HAZs of P11, P22, and P91 ferritic heat-resistant steels during continuous cooling processes were systematically investigated using CSLM. The results revealed that bainite laths preferentially nucleate in the order of increasing difficulty in the energy barrier on austenite grain boundaries, inclusions, internal grain distortion areas, previous bainite laths, and grain interiors. Meanwhile, the growth characteristics of bainite/martensite laths were documented as the phase transformation progressed. It is revealed that bainite laths attach to prior austenite grain boundaries and the previous bainite, while martensite laths grow radially inside the prior austenite grains. Both bainite and martensite laths cease growing when they encounter grain boundaries or other laths, eventually forming an interlocking microstructure. Additionally, the growth rates of bainite/martensite laths in the HAZs of P11, P22, and P91 ferritic heat-resistant steels exhibited considerable variations as the temperature decreased. The analysis revealed that as the temperature decreased, the growth rate of laths in the coarse-grained heat-affected zone was considerably higher than that in the fine-grained heat-affected zone, which can be attributed to the increase in the degree of supercooling and prior austenite grain size.

铁素体系耐热钢焊接热影响区相变行为的CSLM原位观察

[J].

In situ observation of kinetic processes of lath bainite nucleation and growth by laser scanning confocal microscope in reheated weld metals

[J].

Relation between inclusion surface and acicular ferrite in low carbon low alloy steel weld

[J].

Crystallographic analysis for acicular ferrite formation in low carbon steel weld metals

[J].

In situ observation of acicular ferrite nucleation and growth at different cooling rate in Ti-Zr deoxidized steel

[J].