中锰钢(含(3%~12%)Mn,质量分数)作为新一代先进高强钢的典型代表[1~4],通过塑性变形过程中亚稳奥氏体发生的孪晶诱导塑性(TWIP)和(或)相变诱导塑性(TRIP)效应[5~9],使其具有优异的强度与塑性匹配,在汽车轻量化技术领域展现出广阔的应用前景[10~12]。目前,中锰钢多通过适量增加Mn含量,形成奥氏体基双相组织[13,14],并调节奥氏体含量和稳定性,使其在较宽应变范围内形成可持续的增强增塑(TWIP + TRIP)效应,获得更优的力学性能[15~17]。然而较高的Mn含量容易使溶质元素分配不均,导致Mn偏析带形成趋势增加[18~20]。陈学双等[21]在冷轧退火9Mn (质量分数,%,下同)中锰钢中利用Mn偏析带奥氏体与逆转变奥氏体的协同TRIP效应,获得了优异的综合力学性能(强塑积> 70 GPa·%)。Lee等[18]和He等[22]分别在热、冷轧后退火的10Mn中锰钢中发现了Mn偏析组织,并指出利用Mn偏析区内粗大奥氏体,可调节TWIP/TRIP动力学条件,改善力学性能。而Zhang等[23]通过合理调控Mn偏析区域,发现Mn偏析区域的微带滑移机制能够实现中锰钢72%的高延伸性。Sun等[24]则发现10Mn中锰钢中的Mn偏析带会降低其力学性能,由此提出通过95%变形的重度热轧工艺改善富Mn偏析带的不利影响。可见,Mn偏析对中锰钢的力学性能具有促进还是抑制作用仍存有争议。此外,当中锰钢中Mn含量进一步提高(特别是当Mn含量 > 10%,质量分数)时,Mn偏析趋势亦进一步增大,但Mn偏析对更高Mn含量级别中锰钢组织和性能的影响及潜在的作用机制尚少见报道。

本工作以一种具有高Mn含量的中锰钢(0.3C-11Mn-2.7A1-1.8Si-Fe)为研究对象,在前期发现其锻造板坯内存有较高比例Mn偏析区基础上,着重研究Mn偏析对其显微组织和力学性能的影响,探究Mn偏析对塑性变形过程中亚结构演化及损伤特征的影响及相关作用机制,以期为轻质高强中锰钢的成分设计与组织和性能调控提供理论与技术参考。

1 实验方法

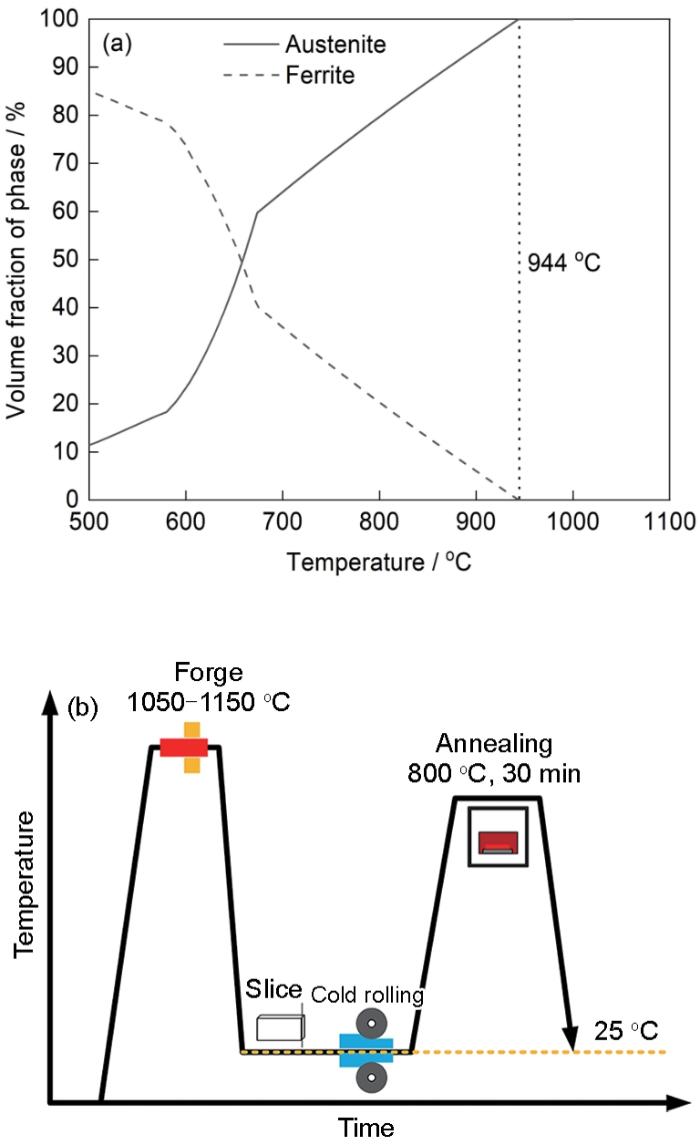

图1为中锰钢计算相图与热机械处理工艺路线示意图。实验选用0.3C-11Mn-2.7A1-1.8Si-Fe中锰钢,将其经过真空感应炉熔炼成铸锭,随后经1150 ℃加热保温后出炉锻造,终锻温度保证在1050 ℃以上(为改善铸态组织,保证整体锻比大于10),最终锻造成截面尺寸为150 mm × 36 mm的矩形坯料。在锻坯不同区域取样观察组织,发现锻坯近表层与心部位置显微组织均匀性存有明显差异。随后分别从锻坯近表层与心部位置沿锻造方向切取厚度为3 mm的板料,将其直接冷轧成厚度为1.2 mm的板材(变形量60%),再将冷轧板材加热到800 ℃、保温30 min进行临界退火,之后空冷(此临界退火温度下中锰钢处于两相区(图1a),力学性能优异[25])。中锰钢热机械处理工艺路线如图1b所示。沿退火后板材轧向切取试样,按照ASTM-E8标准制备拉伸试样(标距25 mm)。在INSTRON 8801型液压伺服疲劳试验机上进行恒应变速率(0.001 s-1)拉伸实验(包括直接拉断以及指定应变下的间断拉伸实验)。

图1

图1

0.3C-11Mn-2.7A1-1.8Si-Fe中锰钢计算相图与热机械处工艺路线理示意图

Fig.1

Calculated phase diagram (a) and schematic of thermomechanical process (b) of 0.3C-11Mn-2.7A1-1.8Si-Fe medium Mn steel

制备扫描电镜(SEM)观测样品,依次采用150、400、800、1500和2000号砂纸进行打磨,然后使用颗粒度为2.5 μm的金刚石抛光膏进行机械抛光,最后在5%CuCl2 + 40%HCl + 25%CH3CH2OH + 30%蒸馏水(体积分数)混合溶液中侵蚀12 s。利用配备能谱仪(EDS)的SIGMA 500型SEM分析中锰钢各状态的显微组织和Mn元素分布,加速电压为15 kV。利用JXA-8230型电子探针(EPMA)分析锻态组织中Mn元素分布状态。

电子背散射衍射(EBSD)样品制备采用电解抛光,电解液为93%CH3CH2OH + 7%HClO4 (体积分数)混合溶液,电解电压为15 V,时间为12 s,电解温度为-20 ℃。利用安装在SEM上的C-Nano型EBSD分析中锰钢各状态的显微组织,并采用HKL Channel 5软件分析EBSD数据。

透射电镜(TEM)薄箔样品通过TenuPol-5型双喷射抛光机在25 V、-20 ℃条件下电解双喷制备,双喷液为93%CH3CH2OH + 7%HClO4 (体积分数)混合溶液。利用F200X型TEM观察不同形变状态下的微观组织,操作电压为200 kV。

采用D/MAX-2500/PC X射线衍射仪(XRD,Cu靶)测定奥氏体体积分数,扫描范围为20°~120°,步长为0.02°/min。奥氏体体积分数(Vγ )的计算方法为[26]:

式中,Iγ 为奥氏体(200)、(220)、(311)晶面衍射峰的积分强度平均值,Iα 为铁素体(200)、(211)晶面衍射峰的积分强度平均值。

2 实验结果

2.1 Mn偏析对热锻板坯显微组织的影响

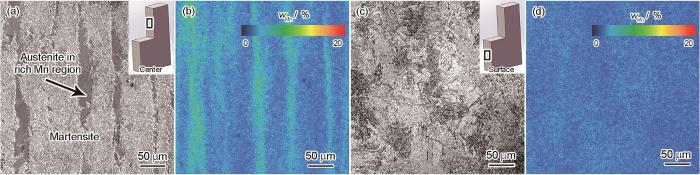

图2为中锰钢锻造板坯心部与表层显微组织的SEM像和Mn元素分布图。可见,2者的基体组织均为细密的马氏体片层组织。值得注意的是,锻坯心部还可见沿锻造伸长方向分布的条带状组织(图2a)。通过EPMA结果(图2b)可知,带状组织区域内Mn含量明显高于马氏体基体,说明在锻坯心部发生了Mn富集,呈现出Mn偏析带组织特征。此Mn偏析带组织与9Mn热轧中锰钢的组织特点类似[21],其形成原因为:在凝固过程中,中锰钢中先凝固的枝晶区Mn浓度过饱和,使Mn元素始终在凝固枝晶前沿富集,最终遗留到最后凝固位置,导致该区域保留到室温并形成富Mn残余奥氏体组织[27]。铸锭心部作为最后凝固的区域,保留了Mn元素富集,即使在较高温度下(1150 ℃)进行强变形(应变高于70%)依然未能消除Mn偏析,从而使锻坯心部表现为沿锻造方向伸长的富Mn带状组织。不同于心部组织,锻坯表层区域组织及Mn元素分布都较为均匀,Mn元素无明显偏析现象(图2c和d)。

图2

图2

中锰钢锻造板坯心部与表层显微组织的SEM像和Mn元素分布

Fig.2

SEM images (a, c) and Mn element distributions (b, d) in the center (a, b) and surface (c, d) of medium Mn steel forged slab (Insets in Figs.2a and c are the schematics of selected positions of the forging block. wMn—mass fraction of Mn)

2.2 Mn偏析对冷轧退火后中锰钢组织与力学性能影响

2.2.1 力学性能差异

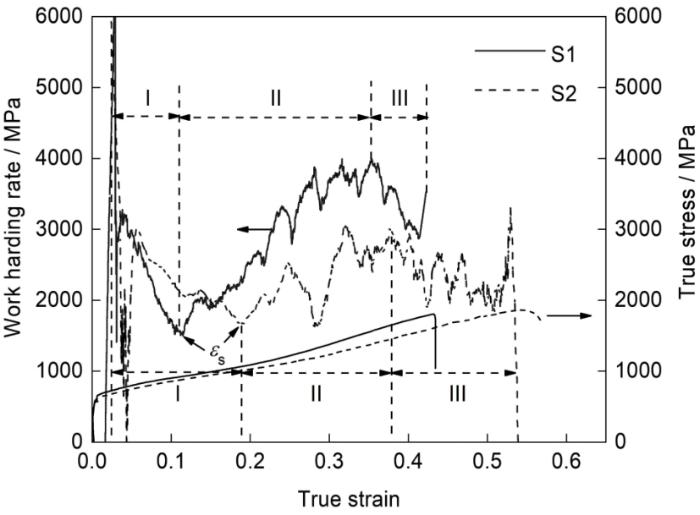

锻坯心部与近表层区域切取的经冷轧+临界退火后的板材分别定义为S1 (有偏析带)与S2 (无偏析带)样品。图3为S1和S2样品在拉伸变形下的力学响应结果。由真应力(σ)-应变(ε)曲线可知,S1和S2 样品均发生了连续屈服。并表现出“三阶段”加工硬化特征,即:加工硬化率(θ)在变形初期先降低;当变形一定程度后,θ再次增加,发生二次硬化;应变进一步增加,θ再次降低,直至断裂。该加工硬化特点表明2种样品在变形过程中均发生了一定程度的马氏体相变,与胡宝佳等[28]的研究结果一致。表1列出了S1和S2样品的力学性能。S1样品的屈服强度、抗拉强度与延伸率分别为665.5 MPa、1172.8 MPa和54.38%,S2样品的屈服强度、抗拉强度与延伸率分别为627.3 MPa、1087.5 MPa和76.88%。由此可知,Mn偏析带的出现虽增加了中锰钢的强度,但明显降低了塑性。值得注意的是:S1样品的加工硬化率再次上升的拐点应变(εs) (如图3中箭头所示,通常可认为其为发生马氏体相变的临界应变[29])低于S2样品,而且当ε > εs时,S1样品的加工硬化率始终高于S2样品(图3中阶段II和III)。这些结果表明,Mn偏析使得S1样品具有更快的马氏体相变进程。但另一方面,S2样品拉伸变形后期存在明显的颈缩现象,而S1样品则在经历一定变形后未发生颈缩而迅速断裂,即过均匀延伸率基本为零。由图3可见,S1样品的θ-ε曲线与σ-ε曲线未表现有交点,不满足Considére准则(θ = dσ /dε = σ),即在宏观颈缩之前就已经发生了过早断裂,该结果也表明Mn偏析降低了中锰钢的断裂韧性。

图3

图3

锻坯心部(S1)与近表层区域(S2)样品加工硬化曲线与真应力-应变曲线

Fig.3

Work-hardening rate curves and true stress-strain curves of the center (S1 represents sample with segregation band) and surface (S2 represents sample without segregation band) samples (εs—critical strain of martensitic transformation)

表1 S1与S2样品的力学性能

Table 1

| Sample | YS / MPa | UTS / MPa | TE / % |

|---|---|---|---|

| S1 | 665.5 | 1172.8 | 54.38 |

| S2 | 627.3 | 1087.5 | 76.88 |

2.2.2 显微组织分析

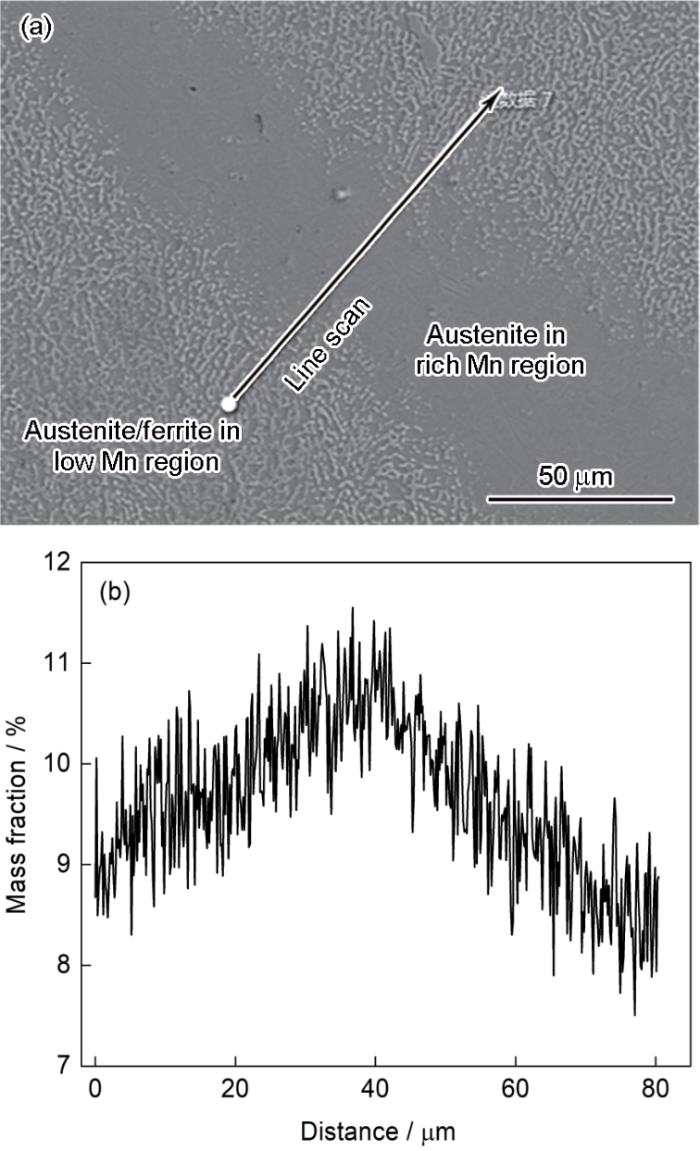

图4

图4

S1样品微观组织的SEM像和Mn元素的EDS线扫描结果

Fig.4

SEM images of S1 sample (a) and corresponding EDS line scanning result of Mn (b)

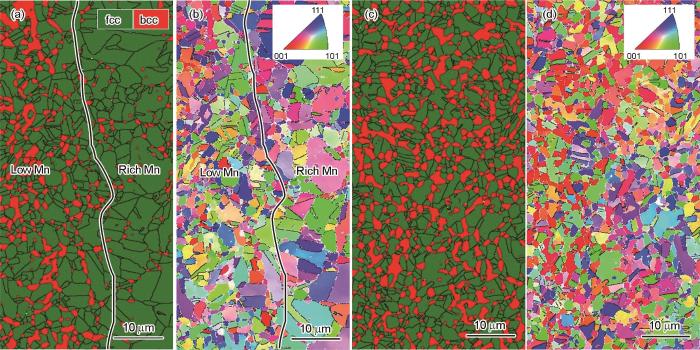

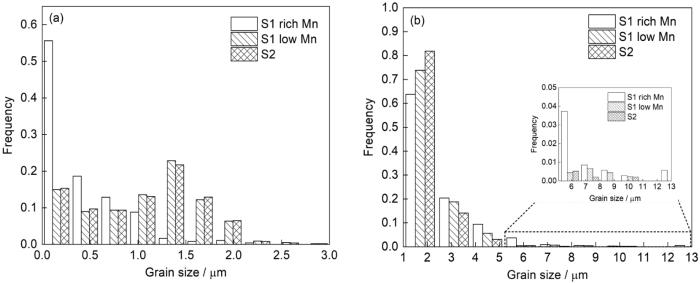

图5为S1和S2样品微观组织的EBSD像和反极图(IPF)。2个样品冷轧退火后组织均由奥氏体(fcc结构)和铁素体(bcc结构)两相组成,两相内晶粒均呈等轴状。S2样品中两相组织均匀(图5c),两相晶粒尺寸与S1样品非偏析带内组织类似,而S1样品Mn偏析带内奥氏体晶粒粗大,铁素体颗粒细小且含量低(图5a)。经统计,S1样品Mn偏析带内奥氏体体积分数达到92.4%,远高于非偏析区奥氏体体积分数(73.1%)与S2样品奥氏体体积分数(69.3%)。S1样品偏析带内两相取向与S2样品(或S1中非偏析区)类似,均呈随机分布,未见明显织构(图5b和d)。图6为S1和S2样品两相晶粒尺寸分布。S1样品Mn偏析带内铁素体晶粒尺寸主要分布在0~1 μm范围,S2样品(或S1中非偏析区)铁素体晶粒尺寸主要分布在1~3 μm范围(图6a)。这主要是由于在一定退火温度和时间下,Mn偏析带内铁素体析出明显延迟,铁素体颗粒来不及长大。Mn偏析带内奥氏体即使经历了冷轧退火,其晶粒尺寸仍未得到细化(图6b),平均晶粒尺寸约为8.52 μm,显著高于S2样品(或S1中非偏析区)的平均尺寸(约1.58 μm)。

图5

图5

S1与S2样品的EBSD像和反极图(IPF)

Fig.5

EBSD images (a, c) and inverse pole figures (IPFs) (b, d) of S1 (a, b) and S2 (c, d) samples

图6

图6

S1与S2样品原始态的铁素体与奥氏体的晶粒尺寸分布

Fig.6

Grain size distributions of ferrite (a) and austenite (b) (Inset in Fig.6b is an enlarged graph of austenite grain size in the range of 6-13 μm) in the initial state of S1 and S2 samples

2.3 不同组织状态下的形变亚结构演化

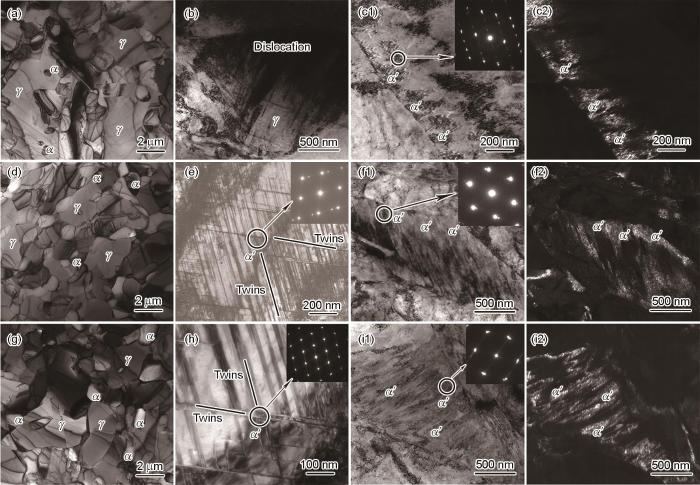

图7为不同应变下S1和S2样品中亚结构的TEM像和选区电子衍射(SAED)花样。对于S1样品而言,退火状态下富Mn奥氏体粗晶内可见少量层错,细小球状铁素体分布其上(图7a);应变为20%时,富Mn奥氏体粗晶内仅可见一定程度的位错,未见形变孪晶和ε马氏体(图7b);应变为40%时,α′马氏体在富Mn奥氏体粗晶界上形核长大(图7c1和c2)。退火状态下低Mn (非偏析区)奥氏体晶粒细小且分布均匀(图7d);样品经20%变形后,低Mn (非偏析区)奥氏体细晶内出现明显交叉分布的形变孪晶(图7e),在形变孪晶交叉点α′马氏体形核,这说明S1样品在20%应变条件下,低Mn (非偏析区)奥氏体细晶已发生马氏体相变,其形核模式为γ→孪晶→α′,表明S1中低Mn (非偏析区)奥氏体变形机制为交替进行的TRIP + TWIP效应[30,31];S1样品应变增加到40%后,低Mn (非偏析区)奥氏体细晶已大部分转变为α′马氏体而少见形变孪晶(图7f1和f2图7f1),该结果表明,S1样品中富Mn奥氏体粗晶内马氏体相变进程落后于低Mn样品(非偏析区)奥氏体细晶。综上可推断,S1样品中Mn偏析带的出现在一定程度上抑制了TRIP效应。对于S2样品,其退火态组织(图7g)与S1样品低Mn (非偏析区)奥氏体相似(图7d),同样在应变为20%时,奥氏体内呈现孪晶交叉形核马氏体的特征,只是孪晶密度有所下降(图7h);在应变为60%状态下(图7i1和i2),奥氏体才基本被形变诱导α'马氏体所替代,相变趋于饱和。此外,2种样品中,铁素体的主要变形机制均为位错滑移。

图7

图7

S1和S2样品不同应变下形变亚结构的TEM像和选区电子衍射(SAED)花样

Fig.7

TEM images and corresponding selected area electron diffraction (SAED) patterns (Insets) of deformed substructures of S1 (a-f) and S2 (g-i) samples with different strains (ε)

(a) as-annealed microstructure in the coarse-grained region of S1 sample

(b) dislocation in the coarse-grained region of S1 sample with ε = 20% (c1, c2) bright (c1) and dark (c2) field images for α' martensite in the coarse-grained region of S1 sample with ε = 40% (d) as-annealed microstructure in the fine-grained region of S1 sample (e) α′ martensite nucleated at the intersection of twins in the fine-grained region of S1 sample with ε = 20% (f1, f2) bright (f1) and dark (f2) field images for α' martensite in the fine-grained region of S1 sample with ε = 40% (g) as-annealed microstructure in the S2 sample (h) α′ martensite nucleated at the intersection of twins in the austenite of S2 sample with ε = 20% (i1, i2) bright (i1) and dark (i2) field images for α' martensite in austenite of S1 sample with ε = 60%

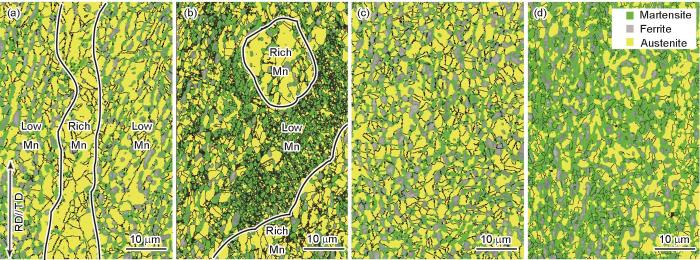

图8为S1和S2样品在不同应变下的EBSD像(为了辨别具有bcc结构的铁素体与马氏体,采用Bandslop参数(= 60)[32]作为区分标准,其主要依据是:与铁素体相比,马氏体含有更高的位错密度,bcc晶格被扭曲,使得2者的Bandslop能带衍射峰值存在差异)。由图可见,应变为15%时,S1样品富Mn奥氏体粗晶内仅出现少量形变诱导马氏体,而在低Mn (非偏析区)奥氏体细晶中,一定数量的马氏体核心在奥氏体晶内及晶界上形成(图8a);此时,S2样品中奥氏体晶内也仅出现少量的马氏体核心(图8c),相变程度低于S1样品低Mn (非偏析区)奥氏体。当应变达到38%时,S1样品中富Mn奥氏体粗晶内的马氏体相变依然有限,一些粗大的奥氏体晶粒内仅在晶界附近可见马氏体核心(图8b)。在S1样品中低的Mn (非偏析区)奥氏体以及S2样品中的奥氏体内均有较多马氏体形成,部分奥氏体被马氏体替代(图8b和d),但整体看,S2样品的相变程度仍略低于S1样品中的低Mn (非偏析区)奥氏体。结果表明,S1样品中富Mn奥氏体粗晶稳定性显著高于低Mn (非偏析区)奥氏体细晶,延迟了形变诱导马氏体相变,而S2样品中奥氏体比S1样品中低Mn (非偏析区)奥氏体细晶更稳定,这与TEM结果(图7)一致。

图8

图8

不同应变下S1和S2样品的EBSD像

Fig.8

EBSD images of the S1 (a, b) and S2 (c, d) samples with strains of 15% (a, c) and 38% (b, d) (RD—rolling direction, TD—tension direction)

图9

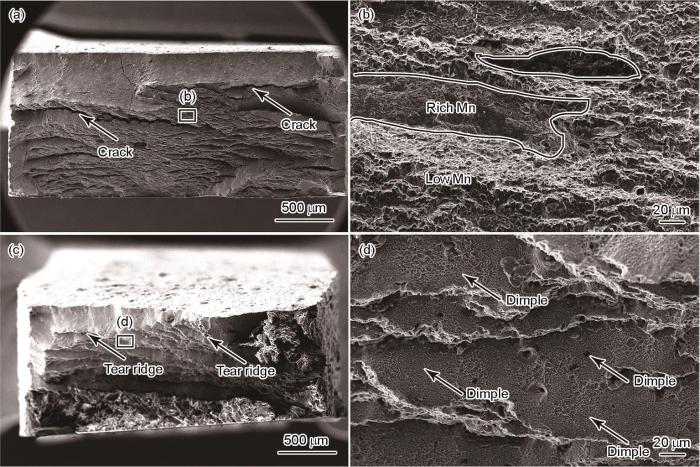

图9

S1和S2样品断口形貌的SEM像

Fig.9

Low (a, c) and high (b, d) magnified SEM images of S1 (a, b) and S2 (c, d) samples

3 分析讨论

3.1 Mn偏析对亚稳奥氏体特征的影响

表2 S1 (粗、细晶区)和S2样品中奥氏体的合金元素含量与晶粒尺寸及奥氏体特征结果

Table 2

| Sample | Composition of austenite | Grain size | Vγ | γSFE | Deformation | ||||

|---|---|---|---|---|---|---|---|---|---|

| (mass fraction / %) | μm | % | oC | mJ·m-2 | mechanism | ||||

| C | Mn | Al | Si | ||||||

| S1 (rich Mn) | 0.74 | 13.12 | 2.12 | 2.10 | 8.52 | 92.4 | 108.33 | 10.44 | TRIP |

| S1 (low Mn) | 0.73 | 11.15 | 2.25 | 1.90 | 1.58 | 73.1 | 123.84 | 16.45 | TRIP + TWIP |

| S2 | 0.73 | 11.72 | 2.23 | 1.93 | 1.56 | 69.3 | 118.91 | 15.62 | TRIP + TWIP |

式中,ρ为奥氏体<111>晶面的摩尔面密度;ΔGγ→ε 为奥氏体转化为马氏体的自由能;σγ/ε 为奥氏体与马氏体之间的界面能,ΔGex为奥氏体由于晶粒尺寸效应导致γSFE的额外增加部分,d为奥氏体的平均晶粒尺寸。由计算的γSFE (表2)可知,S1样品中富Mn奥氏体粗晶中γSFE较低(10.44 mJ/m2),结合TEM结果(图7b、c1和c2)可知,S1样品中富Mn奥氏体粗晶的变形机制主要以马氏体相变引发的TRIP效应为主,而S1样品中低Mn (非偏析区)奥氏体细晶和S2样品中奥氏体的γSFE分别为16.45和15.62 mJ/m2,较S1样品中富Mn奥氏体粗晶的γSFE更高,变形过程中还诱发了形变孪晶,即表现为TRIP + TWIP效应共存。另一方面,采用

式中,wC、wMn和wSi分别为奥氏体中C、Mn、Si的质量分数;l为奥氏体晶粒的平均线截距长度。尽管S1样品中富Mn奥氏体晶粒粗化会降低其稳定性,但由于Mn富集更大程度地提高了富Mn奥氏体粗晶稳定性,从而使S1样品中富Mn奥氏体粗晶的

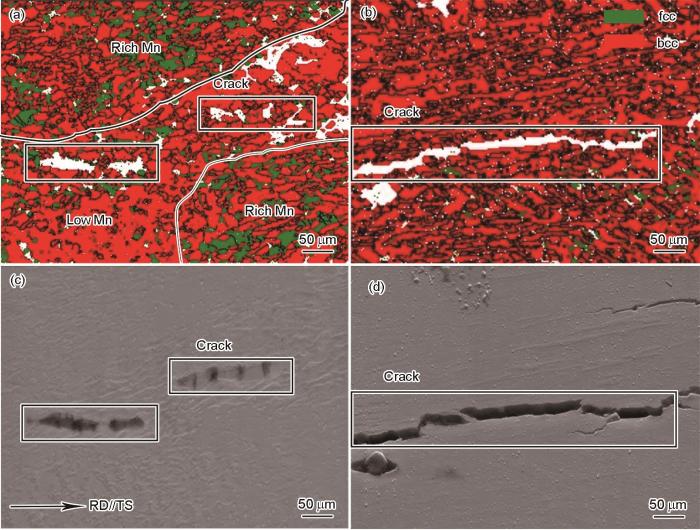

3.2 不同组织状态下的损伤机制

为区分EBSD图中未解析区域与裂纹区域,针对EBSD测试位置进行了SEM下的对照区分表征。图10为S1和S2样品端面(断口附近)裂纹特征。由图可见,2种样品中裂纹扩展方向均与轧制方向(RD)平行。其中,S1样品中裂纹多分布在部分发生相变的富Mn奥氏体粗晶区与低Mn (非偏析区)奥氏体细晶区分界处的局部区域,同时,全部发生转变的低Mn (非偏析区)奥氏体细晶区内也可见裂纹(图10a和c)。S2样品中的裂纹则贯穿于α铁素体/α′马氏体内(图10b和d)。如图7所示,S1样品中富Mn奥氏体粗晶与低Mn (非偏析区)奥氏体细晶具有不同的马氏体转变速率,这容易使粗/细晶区变形不均匀,而在粗/细晶区分界的局部微区则容易发生应变局域化从而诱发损伤[37];同时,Mn的局部富集会弱化原奥氏体晶界结合力及提高相变马氏体的脆性[38],从而在粗/细晶分界处萌生裂纹并迅速扩展,诱发脆性撕裂,显著降低S1样品断裂韧性。尽管S1样品中未转变的奥氏体与铁素体具有相对较高的塑性,在富Mn准解理断裂区内可形成局部韧窝(图9b),但由于Mn偏析导致的脆性增加使得样品在颈缩失稳前过早发生断裂。另一方面,不同于S1样品低Mn (非偏析区)奥氏体快速发生至饱和的马氏体相变,S2样品中马氏体转变速率相对较慢,一定程度上延迟了由于α铁素体与α′马氏体间错配引发的裂纹萌生;此外,S2样品塑性变形发生失稳时仍有一定量残存的奥氏体,在后续的变形中这些残存的奥氏体可进一步发生马氏体相变耗散一定程度的能量,延缓裂纹进一步扩展[20],这也是S2样品较S1样品具有更高断裂韧性的另一原因。

图10

图10

S1与S2样品断口端面裂纹的EBSD像和SEM像

Fig.10

EBSD images (a, b) and SEM images (c, d) of cracking features near the fracture surface of S1 (a, c) and S2 (b, d) samples

4 结论

(1) Mn偏析使得0.3C-11Mn-2.7Al-1.8Si-Fe中锰钢的屈服强度、抗拉强度及加工硬化率增加,但明显降低了塑性和断裂韧性。均质非偏析的0.3C-11Mn-2.7Al-1.8Si-Fe中锰钢则具有均匀细小的双相组织和优异的综合力学性能,抗拉强度和延伸率分别达到1087.5 MPa和76.88%。

(2) Mn偏析使得中锰钢显微组织中形成了遗传性强的富Mn偏析带。富Mn偏析带内奥氏体晶粒(约8.52 μm)较低Mn (非偏析区)奥氏体晶粒(约1.58 μm)粗大,铁素体含量低。Mn偏析使富Mn奥氏体粗晶稳定性升高,延迟了马氏体相变,抑制了TRIP效应,而低Mn (非偏析区)奥氏体在变形过程中先后发生孪生和马氏体相变,表现出交替的TRIP + TWIP效应;但由于含Mn富集区的中锰钢中低Mn (非偏析区)奥氏体细晶稳定性更低,加速了马氏体相变进程,使含Mn富集区的中锰钢样品加工硬化的持续性较差。而均匀持续的TRIP + TWIP效应耦合作用使均质无偏析中锰钢具有更稳定的加工硬化能力。

(3) Mn偏析使得中锰钢断口表面呈现出一定程度的准解理断裂特征与较多的二次裂纹。同时,由于含Mn富集区的中锰钢中低Mn (非偏析区)奥氏体向马氏体转变速率较快,增加了在α铁素体/α'马氏体界面微区的应力/应变集中,从而降低了塑性和断裂韧抗性,断裂先于颈缩失稳发生。而均质非偏析中锰钢样品发生了颈缩,断口为韧窝型断口。

参考文献

Medium Mn transformation-induced plasticity steels: Recent progress and challenges

[J].

Third generation of AHSS: Microstructure design concepts

[A].

Current opinion in medium manganese steel

[J].

M3 microstructure control theory and technology of the third-generation automotive steels with high strength and high ductility

[J].

高强度高塑性第三代汽车钢的M3组织调控理论与技术

[J].高强度、高塑性是汽车钢的重要发展方向,本文综述了高强度高塑性第三代汽车钢的“多相(multiphase)、亚稳(metastable)和多尺度(multiscale)” M<sup>3</sup>组织性能调控理论和技术,以及面临的新挑战。M<sup>3</sup>组织与性能调控理论为高强度高塑性钢提供了理论支持,亚稳奥氏体的相变诱发塑性(TRIP)效应能够提高加工硬化率并推迟颈缩的发生,从而提高了钢的强度与塑性,同时产生了剪切边裂纹敏感性提高,氢致延迟断裂性能下降,循环载荷下亚稳奥氏体的转变行为复杂等新的问题和挑战。当前,含亚稳奥氏体高强度高塑性钢的质量一致性和应用基础研究缺乏,而汽车钢作为量大面广的产品,需要从它的成分设计和组织调控-冲裁切割-成形制造-连接涂装-服役评价等全链条环节中开展组织演变和性能评估,充分考虑产品的技术适用性和成本,进而为组织调控理论和技术的完善提供依据。

Novel 1.4 GPa-strength medium-Mn steel with uncompromised high ductility

[J].

Effect of solution treatment temperature on microstructure evolution and tensile property of a medium Mn steel having a lamellar structure

[J].

Microstructural evolution and mechanical behavior of a novel heterogeneous medium Mn cold-rolled steel

[J].

Improved mechanical properties of V-microalloyed dual phase steel by enhancing martensite deformability

[J].A good combination of ultimate tensile strength (UTS) up to 1365 MPa and total strain to failure (StF) to 15.5 % has been achieved due to deformable martensite in the invented vanadium-microalloyed dual-phase (DP) steel, which was manufactured by two-stage annealing of cold rolled steel strip. The employed extensive characterizations revealed that the ductile martensitic phase in this DP steel differentiated from ordinarily low-carbon martensitic lath in both morphology and lattice structure. Complex coherent orientation relationships between ferrite, reverse austenite, martensitic phase and vanadium carbide (VC) do exist, leading to a new martensitic transformation mechanism and resultant dual-phase microstructure. Besides, a detailed characterization including essential phase transformation analysis in combination with in situ TEM observation, shows that, all the essential processing including recrystallization, reverse austenitic and martensitic transformation, in debt to the particular effects of VC, can be recognized as phase transformations with higher thermodynamic driving force and higher kinetic energy barrier as compared to previously common processing, which actually changes the microstructure and, indirectly leads to higher strength and higher ductility. This synergy of thermodynamics and kinetics can be generalized to improve mechanical properties of present steels.

Super-high-strength and formable medium Mn steel manufactured by warm rolling process

[J].

Deformation mechanisms of a novel Mn-based 1 GPa TRIP/TWIP assisted lightweight steel with 63% ductility

[J].

Influence of microstructural morphology on the continuous/discontinuous yielding behavior in a medium manganese steel

[J].

A systematic study on microstructure evolution, mechanical stability and the micro-mechanical response of tensile deformed medium manganese steel through interrupted tensile test

[J].

Enhancing strength-ductility synergy in medium Mn steel with hetero-structured austenite developed by two-stage cyclic thermomechanical treatment and flash annealing

[J].

Tailoring hetero-grained austenite via a cyclic thermomechanical process for achieving ultrahigh strength-ductility in medium-Mn steel

[J].

High strength-high ductility medium Mn steel obtained through CALPHAD based alloy design and thermomechanical processing

[J].

Tailoring the metastable reversed austenite from metastable Mn-rich carbides

[J].

Twinning-induced plasticity (TWIP) steels

[J].

Novel medium-Mn (austenite + martensite) duplex hot-rolled steel achieving 1.6 GPa strength with 20% ductility by Mn-segregation-induced TRIP mechanism

[J].

Effects of solute segregation on tensile properties and serration behavior in ultra-high-strength high-Mn TRIP steels

[J].

Revealing fracture mechanisms of medium manganese steels with and without delta-ferrite

[J].

Microstructure regulation and strengthening mechanisms of a hot-rolled & intercritical annealed medium-Mn steel containing Mn-segregation band

[J].Recently, medium-Mn steel, used in the automotive industry, has attracted increasing attention as the one of the most promising candidates for the third generation of advanced high strength steels owing to its reasonable cost and excellent mechanical properties. In this study, the effect of intercritical annealing temperature on the microstructure and mechanical properties of a new composition steel was investigated, and its strengthening mechanism and related reasons were analyzed. In addition, a ultra-high product of strength and plasticity (> 70 GPa·%) of hot rolled medium manganese steel with a segregation band was eventually obtained. The results show that the grain size and orientation in the packet (defined by the original austenite grain boundary) significantly affect the mechanical properties and deformation microstructure of the material obtained under different temperatures. The obvious precipitation and dissolution processes of carbides occur at higher temperatures, and thus influence the mechanical stability of reversed austenite. During the tensile process, because it is easier to deform, the favorable packets in the non-segregation zone form an elongated-strip fine-grain zone along the loading direction, while the unfavorable packets form fragmentary grain regions. Moreover, martensite transformation preferentially occurs at the obvious orientation inside the austenite grain and the boundaries where large strain is accumulated. Through coordinated deformation, the adjacent packets eventually tend to form alternate distribution of the two kinds of micro-zone substructures, which is accompanied by the significant evolution of low-angle grain boundaries related to the dislocation activity. Due to the wide distribution of grain size in one packet, the reversed austenite in the non-segregation zone can withstand large deformation, which makes the austenite in the segregation zone undergo sufficient strain-induced martensitic transformation (SIMT), to obtain excellent combination of strength and toughness.

一种含富锰偏析带的热轧临界退火中锰钢的组织调控及强化机制

[J].对含偏析带的热轧中锰钢进行临界退火处理,通过合理控制非偏析带区的逆奥氏体转变程度,获得了超高强塑积(PSE > 70 GPa·%)。结果表明,经不同温度热处理后,包(由原奥氏体晶粒边界定义)内晶粒的尺寸、取向显著影响中锰钢的力学性能和变形组织。在拉伸过程中,沿着拉伸方向,非偏析带内有利取向的包倾向形成拉长的条状细晶区,而不利取向的包倾向形成碎块状晶区。通过协调变形,相邻包将最终倾向形成上述2种微区亚结构的交替分布。非偏析带内的逆转变奥氏体因晶粒尺寸广泛分布而可承受较大的变形,从而使得偏析带内奥氏体发生足够的应变诱发马氏体相变(SIMT),最终获得优异的强度和韧性匹配。

Revealing the intrinsic nanohardness of retained austenite grain in a medium Mn steel with heterogeneous structure

[J].

Achieving heterogeneous TWIP/TRIP steel with 1 GPa strength and 72% ductility by introducing austenite + martensite lamella structure

[J].

Improved Mn-segregation bands and its influence on deformation behavior in a severely warm-rolled 10Mn lightweight steel

[J].

Study on the effect of critical annealing on the microstructure and properties of Fe-11Mn-3Al-2Si-0.3C medium manganese steel and its mechanism

[D].

临界退火对Fe-11Mn-3Al-2Si-0

.3C中锰钢组织性能影响及作用机理研究 [D].

A rapid X-ray method for the determination of retained austenite

[J].

Solidification, segregation, and banding in carbon and alloy steels

[J].

Recrystallization controlling in a cold-rolled medium Mn steel and its effect on mechanical properties

[J].Owing to the excellent combination of specific strength and ductility, medium Mn steels (MMSs) with Mn contents of 3%-12% (mass fraction) are considered the most promising candidates for the third-generation advanced high-strength steel. The combination of excellent strength-ductility is mainly attributed to the active transformation-induced plasticity effect of the metastable retained austenite during deformation. Therefore, producing a considerable amount of retained austenite with reasonable stabilities in the steel by various heat treatment schedules is always important. In this study, granular- and lamellar-structured retained austenites were developed in a cold-rolled 0.15C-5Mn MMS by introducing a technical process of precontrolling ferrite recrystallization in the annealing schedule. The microstructures of the annealed samples were analyzed using SEM, EBSD, and TEM. The results show that duplex microstructures comprising various amounts of recrystallized ferrite and fresh martensite can be obtained in the cold-rolled MMS when controlling the occurrence of recrystallization at different intercritical temperatures by a preannealing process. When this microstructure is used for the final austenite reverted transformation annealing, the resultant ultrafine duplex microstructure with recrystallized ferrite and two types of heterogeneous retained austenite, i.e., lamellar and granular, is produced. The heterogeneous-structured austenite shows more sensitivity to increasing strain, i.e., various mechanical stabilities, which enable an excellent strength-ductility combination and reduced Lüders strain in the cold-rolled medium Mn steel.

冷轧中锰钢的再结晶调控及其对力学性能的影响

[J].为探究铁素体再结晶对冷轧中锰钢微观组织与力学性能的影响规律,以0.15C-5Mn (质量分数,%)冷轧中锰钢为研究对象,采用两步临界区退火的热处理方法,利用SEM、TEM和EBSD等表征手段和力学性能测试方法,研究了铁素体再结晶调控对冷轧中锰钢多样化残余奥氏体形成及其力学性能的影响。结果表明,通过在不同温度预先调控冷轧中锰钢中的铁素体再结晶,可获得由不同比例的等轴状再结晶铁素体和马氏体组成的双相细晶组织。经常规退火处理后,在终态组织中形成了不同体积分数的超细晶再结晶铁素体和呈等轴状/板条状形貌的多样化细晶残余奥氏体,使中锰钢在拉伸变形过程中表现出多样化的TRIP效应,在提升冷轧中锰钢强塑性能的同时,其Lüders变形也获得改善。

Microstructural characteristics and tensile behavior of medium manganese steels with different manganese additions

[J].

Tensile behavior of intercritically annealed 10 pct Mn multi-phase Steel

[J].

Influence of intra-granular ferrite on the tensile behavior of intercritically annealed 12 pct Mn TWIP + TRIP steel

[J].

In-situ EBSD study of deformation behaviour of 600 MPa grade dual phase steel during uniaxial tensile tests

[J].

Damage in dual phase steel DP1000 investigated using digital image correlation and microstructure simulation

[J].

Annealing temperature dependence of the tensile behavior of 10 pct Mn multi-phase TWIP-TRIP steel

[J].

Novel ferrite-austenite duplex lightweight steel with 77% ductility by transformation induced plasticity and twinning induced plasticity mechanisms

[J].

The influence of manganese content on the stacking fault and austenite/ε-martensite interfacial energies in Fe-Mn-(Al-Si) steels investigated by experiment and theory

[J].

The influence of silicon additions on the deformation behavior of austenite-ferrite duplex medium manganese steels

[J].

Bone-like crack resistance in hierarchical metastable nanolaminate steels

[J].Fatigue failures create enormous risks for all engineered structures, as well as for human lives, motivating large safety factors in design and, thus, inefficient use of resources. Inspired by the excellent fracture toughness of bone, we explored the fatigue resistance in metastability-assisted multiphase steels. We show here that when steel microstructures are hierarchical and laminated, similar to the substructure of bone, superior crack resistance can be realized. Our results reveal that tuning the interface structure, distribution, and phase stability to simultaneously activate multiple micromechanisms that resist crack propagation is key for the observed leap in mechanical response. The exceptional properties enabled by this strategy provide guidance for all fatigue-resistant alloy design efforts.Copyright © 2017, American Association for the Advancement of Science.