对工程结构钢在撞击条件下的微观组织特征已有一些研究[23~25]。一般而言,对高应变率的研究采用分离式Hopkinson压杆(SHPB)实验进行研究[26],而超高应变率的研究采用轻气炮实验[27]或者爆炸加载[28]。Dougherty等[29]利用SHPB实验研究了1018钢在撞击下的微观组织特征,发现冲击压力在13 GPa时1018钢发生了ε相变。Eskandari和Szpunar[30]利用SHPB实验研究了高锰钢在撞击下的微观组织特征,发现高锰钢在撞击条件下发生了马氏体相变,并存在动态再结晶和织构演化行为。Zhang等[31]研究了0.433~1.633 km/s撞击速率下低碳钢的微观组织特征,发现随着撞击应力的提高,断裂模式逐渐从脆性断裂模式转变为韧脆混合断裂模式,甚至完全延性断裂模式。Yang等[32]利用一级轻气炮研究了中碳钢在撞击条件下形成的{332}<113>孪晶的特点。Wang等[33]研究了应变率小于103 s-1时奥氏体不锈钢在撞击下的马氏体相变特点,发现变形速率对变形产生的结构具有重要影响。目前,fcc或bcc晶体结构钢在中、高应变率作用下的微观组织特征已有一些研究,而对于超高应变率作用下的微观组织特征研究较少,且差异性尚不明晰。因此,fcc和bcc晶体结构钢在超高应变率作用下的微观组织特征差异,有待于进一步研究。

二级轻气炮实验是当前研究高/超高应变率下材料动态行为的一个重要方法,可使材料产生104~106 s-1的超高应变率。本工作选取304不锈钢(fcc结构奥氏体钢)和Q345钢(bcc结构铁素体钢)这2种典型的工程结构钢作为研究对象,采用二级轻气炮分别对304不锈钢板和Q345钢板进行超高速撞击实验,利用X射线衍射仪(XRD)对撞击后穿孔附近的钢板进行相结构表征分析,利用电子背散射衍射(EBSD)技术对撞击后钢板的相分布、动态回复再结晶分布、织构以及组织分层情况等进行表征和分析,同时利用透射电镜(TEM)对撞击后的304钢板穿孔附近区域进行微观组织特征及相变特征的表征和分析,为清楚认识2种钢板在撞击条件下的微观组织分布特征差异和撞击机理差异提供参考。

1 实验方法

利用二级轻气炮发射柱形含能破片,使含能破片以2~3 km/s的速率撞击304不锈钢板或Q345钢板。含能破片采用圆柱形,圆柱面直径6 mm、圆柱体长度4 mm。撞击方式采用圆柱底面正撞击钢板表面。304不锈钢板和Q345钢板均采用厚度为2.5 mm的薄钢板,且均经过固溶处理。

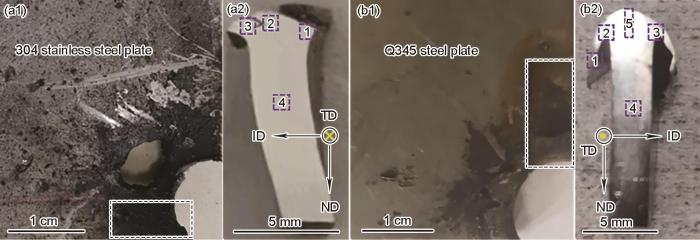

图1

图1

304不锈钢板和Q345钢板的宏观形貌、取样位置与电子背散射衍射(EBSD)测试位置图

Fig.1

Macrostructures and sampling locations (dashed boxes) (a1, b1), electron back scattered diffraction (EBSD) test locations (a2, b2) for 304 stainless steel plate (a1, a2) and Q345 steel plate (b1, b2) (ID—impact direction, ND—normal direction, TD—transverse direction)

首先,利用Supra 扫描电子显微镜(SEM)及其配备的Oxford C-Nano EBSD探头对2种钢板穿孔附近区域样品(图1a2和b2)进行EBSD扫描,扫描步长0.3 μm,使用HKL Channel 5软件对获得的测试数据进行处理,以获得2种钢板穿孔附近区域的微观特征信息。然后,利用Smartlab SE型XRD (Cu靶)对2种钢板的穿孔附近区域和远离穿孔区域的样品进行分析,测试速率5°/min,测试范围25°~95°,以获得撞击对2种钢板相结构的影响特征。最后,利用JEM-F200型TEM对304不锈钢板穿孔附近样品所制成的TEM样品进行显微表征分析,以获得304不锈钢板在撞击后的马氏体相变与奥氏体孪晶特征。

EBSD样品制备方法为:将样品用水磨砂纸逐级打磨到7000号,随后用70%C2H6O + 30%HClO4 (体积分数)电解液进行电解抛光,电压25 V,时间45 s,最后采用振动抛光。TEM样品制备方法为:将304不锈钢板穿孔处样品的测试表面切割成合适尺寸,将切割后的样品用砂纸逐级研磨至厚度小于50 μm,使用原片打孔机从金属薄片中冲出直径约3 mm的圆片,将圆片两面抛光,然后利用Gatan Model691减薄仪进行离子减薄。

2 实验结果与讨论

2.1 fcc和bcc钢板在撞击下的相变差异

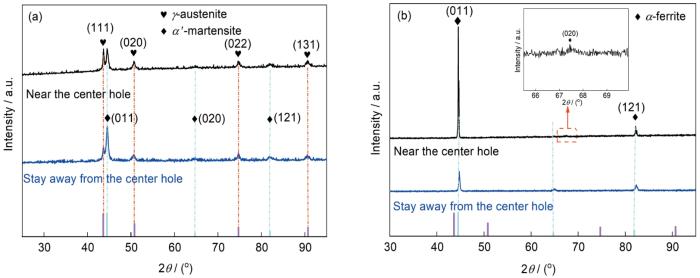

图2a为304不锈钢板穿孔附近、远离穿孔处样品的XRD谱。可以看出,在撞击条件下,304不锈钢部分奥氏体晶粒转变成马氏体晶粒,发生了明显的冲击诱导马氏体相变。根据衍射峰的相对强度分析,在穿孔附近的马氏体转变量小于远离穿孔处的转变量,这是由于钢板在远离穿孔处的应变率低于穿孔附近区域。因此认为高应变率对马氏体转变具有一定的抑制作用。

图2

图2

304不锈钢板和Q345钢板穿孔附近样品冲击方向-法向(ID-ND)面与远离穿孔处样品(位于沿中心穿孔的径向距钢板中心穿孔大约10 cm处)法向-横向(ND-TD)面的XRD谱

Fig.2

XRD spectra for the samples made near the perforation in ID-ND plane and stay away from the perforation in ND-TD plane of 304 stainless steel plates (a) and Q345 steel plates (b) (Inset in Fig.2b shows the locally enlarged spectrum)

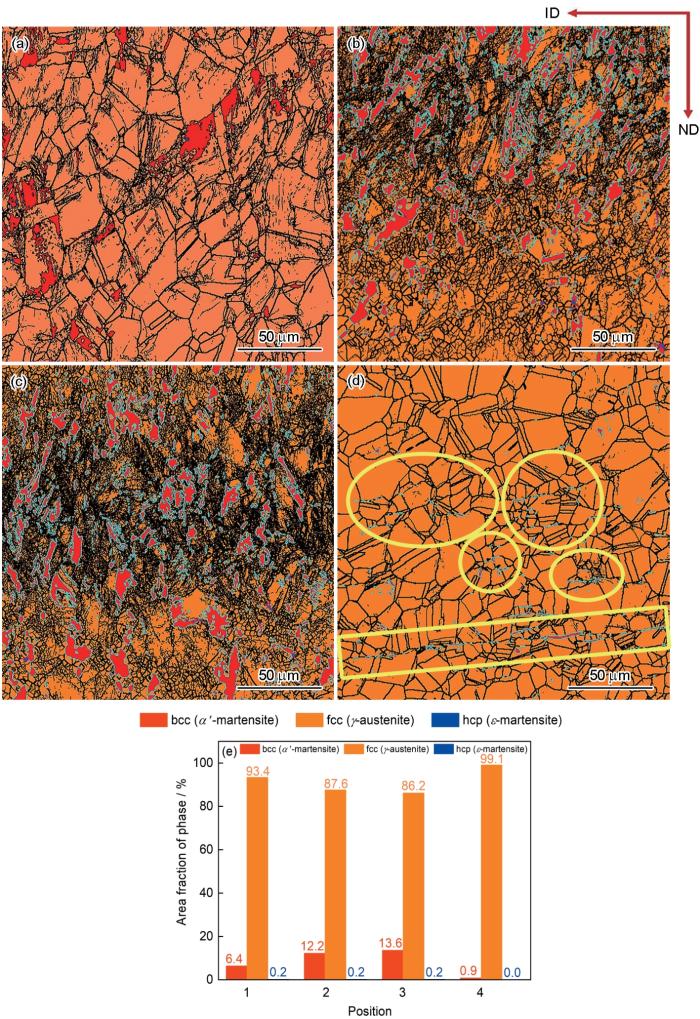

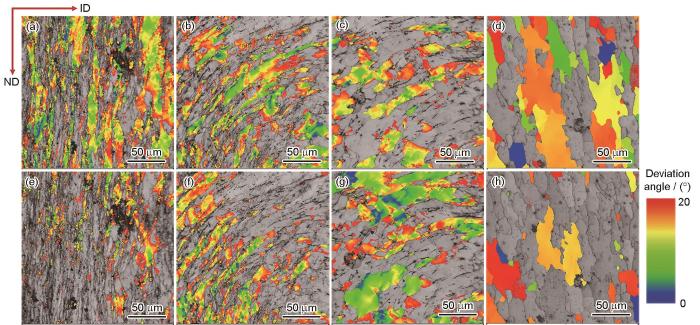

图3为304不锈钢在撞击后穿孔附近不同位置处(图1a2中位置1~4)马氏体相变的EBSD像和相分布。图中橘黄色为γ-奥氏体相,红色为α'-马氏体相,蓝色为ε-马氏体相。可以看出,在304不锈钢穿孔附近的不同位置,发生马氏体相变的面积分数不同,在靠近穿孔的位置1~3发生α'-马氏体相变较多,而在位置4相对较少。4个位置均伴随有极少量的ε-马氏体出现,可以忽略不计。形变诱导马氏体相变与变形量和应变率均有关[34]。虽然位置1~3具有较高的应变率,但变形量同样较大,因此其马氏体相变量高于位置4。从图3a~d还可以看出,马氏体的形核位置大多为奥氏体晶界或者奥氏体孪晶界,并且在形核位置出现了一条马氏体形核条带。这可能是奥氏体不锈钢在超高应变率下表现出一定脆性的原因。在撞击条件下,304不锈钢可能会在晶界、马氏体与奥氏体相界面或孪晶界处产生裂纹形核,这与Rösner等[35]和Quan等[36]通过准原位拉伸观察到的可能出现的裂纹形核位点一致。

图3

图3

304不锈钢穿孔附近不同位置(图1a2中位置1~4)马氏体相变的EBSD表征结果

Fig.3

Phase transformation EBSD characterizations for the sample near perforation of 304 stainless steel

(a-d) EBSD images at positions 1 (a), 2 (b), 3 (c), and 4 (d) in Fig.1a2 (Yellow areas in Fig.3d indicate martensite tends to nucleate at austenite twin boundary or gain boundary intersection)

(e) phase area fraction distributions

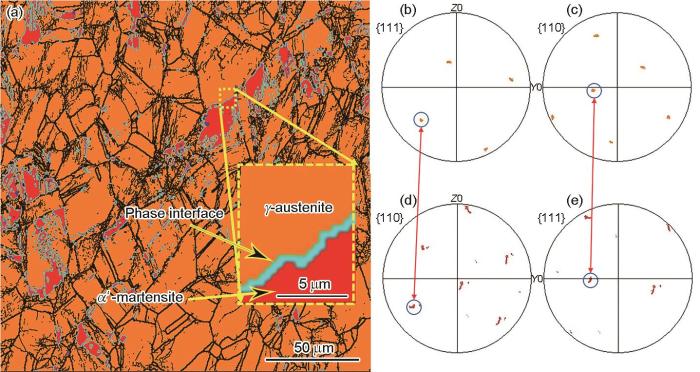

图4

图4

304不锈钢穿孔附近位置1的相分布与相界面图、相界面区域的γ-奥氏体{111}极图和{110}极图、相界面区域的α'-马氏体{110}极图和{111}极图

Fig.4

Phase distribution and phase interface diagram for the sample near perforation of 304 stainless steel at position 1 in Fig.1a2 (a); γ-austenite {111} pole figure (b), γ-austenite {110} pole figure (c) in the phase interface region; and α'-martensite {110} pole figure (d), and α'-martensite {111} pole figure (e) in the phase interface region (Inset in Fig.4a shows the locally enlarged image)

2.2 fcc和bcc钢板在撞击下的动态回复再结晶差异

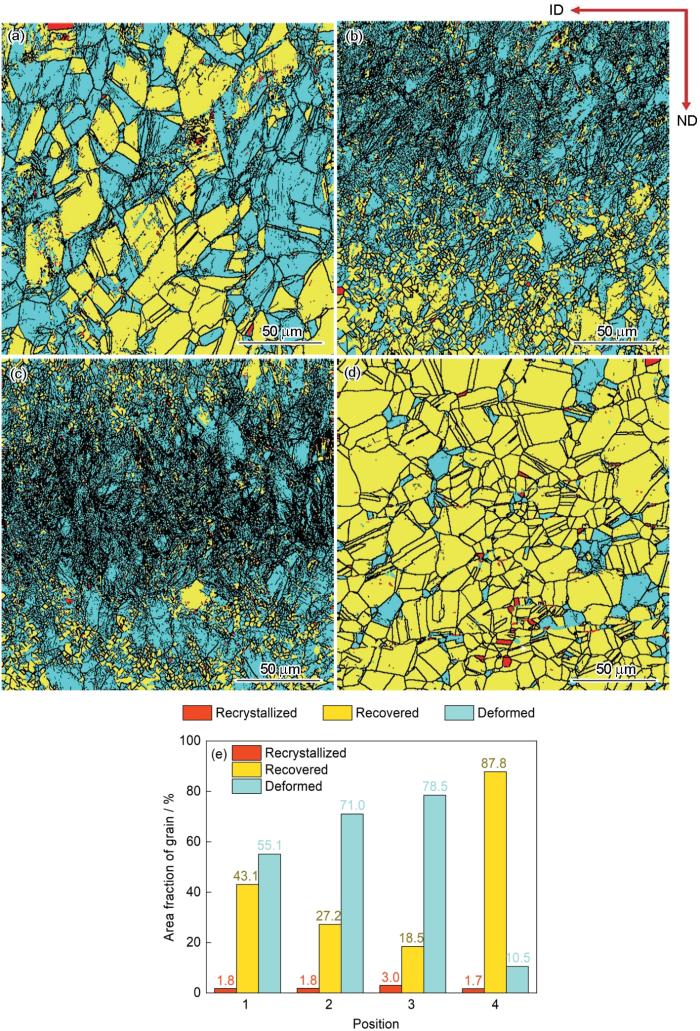

图5

图5

304不锈钢穿孔附近不同位置(图1a2中位置1~4)动态回复再结晶的EBSD表征结果

Fig.5

Dynamic recovery recrystallization EBSD analyses for the sample near perforation of 304 stainless steel

(a-d) EBSD images at positions 1 (a), 2 (b), 3 (c), and 4 (d) in Fig.1a2

(e) area fraction distributions of recrystallized, recovered, and deformed grains

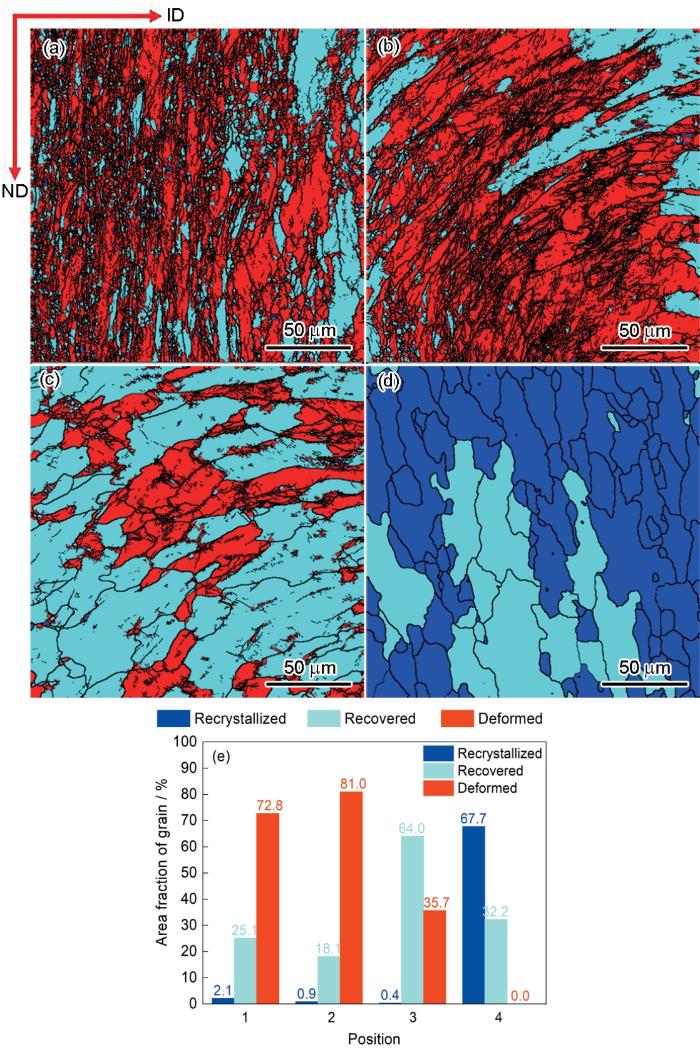

图6

图6

Q345钢穿孔附近不同位置(图1b2中位置1~4)动态回复再结晶的EBSD表征结果

Fig.6

Dynamic recovery recrystallization EBSD analyses for the sample near perforation of Q345 steel (a-d) EBSD images at positions 1 (a), 2 (b), 3 (c), and 4 (d) in Fig.1b2 (e) area fraction distributions of recrystallized, recovered, and deformed grains

综上可以看出,304不锈钢和Q345钢在撞击条件下均发生了动态回复再结晶过程,并且在靠近冲击穿孔处以变形晶粒为主,而在偏离穿孔处一定距离时,以回复晶粒或再结晶晶粒为主。

2.3 fcc和bcc钢板在撞击下的织构差异

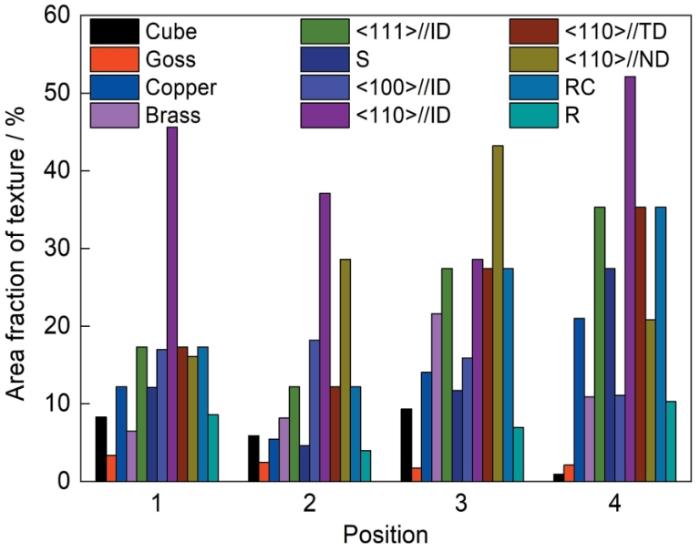

在撞击条件下,由于晶粒发生位错滑移、孪生切变、晶粒转动和拉长等,使晶粒发生了择优取向,会形成织构,因此对2种钢板所形成织构进行统计分析。在结果分析时,设置角度统计偏差为20°。

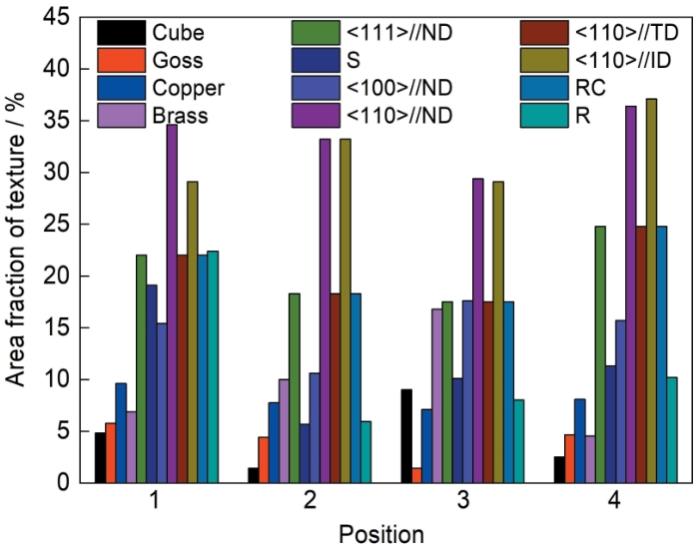

图7

图7

304不锈钢穿孔附近不同位置(图1a2中位置1~4)织构所占的面积分数

Fig.7

Texture area fractions for the sample near perforation of 304 stainless steel at positons 1-4 in Fig.1a2 (S—{123}<

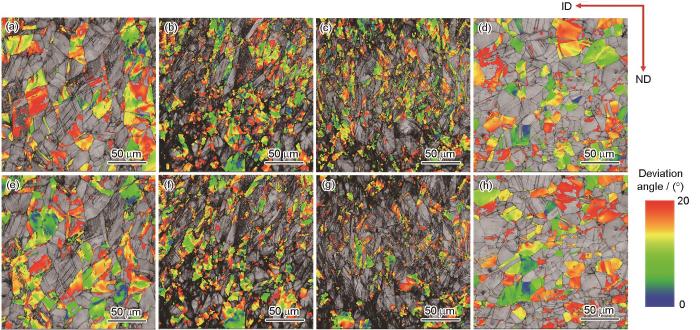

图8

图8

304不锈钢穿孔附近不同位置(图1a2中位置1~4)的<110>//ID与<110>//ND织构分布

Fig.8

<110>//ID texture (a-d) and <110>//ND texture (e-h) distribution maps of the sample near perforation of 304 stainless steel at positions 1 (a, e), 2 (b, f), 3 (c, g), and 4 (d, h) in Fig.1a2

图9

图9

Q345钢穿孔附近不同位置(图1b2中位置1~4)的织构所占的面积分数

Fig.9

Area fractions of the sample texture near perforation of Q345 steel at positions 1-4 in Fig.1b2

图10为Q345钢在撞击后穿孔附近不同位置(图1b2中的位置1~4)的<110>//ID织构和<110>//ND织构的分布图。图10a~d中晶粒颜色越蓝,表明其<110>晶向与ID的平行度更大,晶粒颜色越红,表明其与ID角度偏差越大,最大为20°。图10e~h中晶粒越蓝,表明其<110>晶向与ND平行度更大,晶粒颜色越红,表明其与ND角度偏差越大,最大为20°。可以看出,<110>//ID和<110>//ND这2种织构是Q345钢在撞击下引起的优势织构,但这2种织构在不同位置处的面积分数具有较大的差异,在位置1、2和4处,<110>//ID的丝织构较强,位置3处<110>//ND的丝织构较强。

图10

图10

Q345钢板穿孔附近不同位置(图1b2中位置1~4)的<110>//ID和<110>//ND织构分布

Fig.10

<110>//ID texture (a-d) and <110>//ND texture (e-h) distribution maps of the sample near perforation of Q345 steel at positions 1 (a, e), 2 (b, f), 3 (c, g), and 4 (d, h) in Fig.1b2

分析以上结果可知,在撞击条件下,304不锈钢板和Q345钢板在穿孔处形成织构的相同点是:均形成了一定的晶粒择优取向,并且<110>//ID以及<110>//ND织构均为其优势织构。不同点是:在304不锈钢穿孔附近的不同位置,<110>//ID以及<110>//ND这2种织构所占的面积分数接近,而Q345钢的不同位置处具有不同的优势织构。这是因为,304不锈钢在撞击下主要发生晶粒的破碎、转动,没有出现严重朝宏观变形方向的组织拉长现象;而Q345钢在撞击下发生了明显的晶粒组织拉长现象,沿着主要宏观变形方向形成流线型纤维组织。

2.4 bcc钢板在撞击下的组织形貌分层现象

图11为Q345钢板穿孔处(图1b2中位置5)沿穿孔径向的EBSD表征结果。图11a为沿ND的反极图(IPF),晶粒的不同颜色代表不同的平行于ND的晶粒晶向。图11a中浅绿色<101>晶向族占大多数,可以判断出大部分晶粒沿钢板的ND形成择优取向,因此其择优取向的织构类型为<101>//ND。图11a的晶粒组织形貌具有明显的组织分层现象,从右至左依次为细化的纳米晶或细长条状的变形晶粒、粗长条晶粒、小变形晶粒或近似等轴晶粒等。在超高速撞击条件下,Q345钢位置5处未发生明显的晶体结构类型的改变,即未发生明显的固态相变(图11b),而是形成大量<110>//ND的丝织构(图11c)。如图11d所示,在最右侧区域,形成了高密度位错区域。在两虚线之间的区域,位错密度降低。在最左侧区域,位错密度大幅度减少,并且形成的位错主要集中在晶界处。如图11e所示,从最右侧区域可以看出,其晶粒组织中存在晶粒尺寸较小的黄色亚晶粒,但大部分为变形晶粒,在两虚线之间的区域为晶粒发生塑性变形的变形晶粒区,晶粒沿着撞击方向被拉长。最左侧区域为近似等轴晶粒区,其晶粒的形态改变较小,仍具有一定的塑性变形,其回复晶粒面积分数增多。位置5处主要以变形晶粒为主,所占面积分数为91.76%,回复晶粒所占面积分数为6.42%,再结晶晶粒所占面积分数为1.82%。根据以上结果分析,Q345钢板在穿孔附近位置5的变形以位错的滑移为主,且发生了一定程度的动态回复再结晶。晶粒组织形态沿穿孔的径向,从穿孔表层至距穿孔表面大约2 mm位置处,微观组织呈分层变化,并且形成了大量<110>//ND的丝织构。图11f为图11d中晶粒的局部取向差分布。可以看出,其晶粒的局部取向差集中于0°~3°。

图11

图11

Q345钢板穿孔径向处(图1b2中位置5)的EBSD表征结果

Fig.11

EBSD characterizations for the sample near perforation of Q345 steel at positon 5 in Fig.1b2

(a) inverse pole figure (IPF) along ND

(b) phase distribution map

(c) <110> silk texture parallel to ND

(d) kernel average misorientation (KAM) map

(e) dynamic recrystallization distribution map

(f) relative frequency distribution of local misorientation angle within a certain angle range of 0°-5°

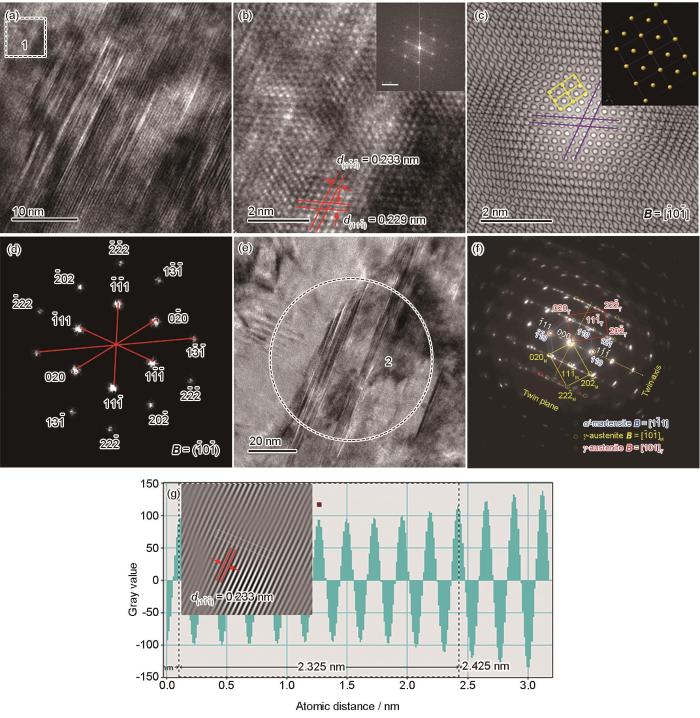

2.5 fcc钢板在撞击下的相变特征

图12a为304不锈钢板穿孔附近的HRTEM像。图12b为图12a中区域1的局部放大像,相应的快速Fourier变换如图12b插图所示。对图12b滤波得到图12c,利用Crystal Maker Demo软件画出fcc [

图12

图12

304不锈钢板撞击后穿孔附近的TEM表征结果

Fig.12

TEM characterizations of 304 stainless steel plate near the perforation

(a) HRTEM image

(b) high magnified image and fast Fourier transform (inset) of region 1 in Fig.12a (d

(c) filtering image of region 1 in Fig.12a (Inset shows the atomic structure image of yellow grid area)

(d) fast Fourier transform spot calibration image of region 1 in Fig.12a

(e) martensitic nucleus and twin in austenite

(f) selected area electron diffraction pattern of region 2 in Fig.12e (Subscripts M and T represent matrix and twin, respectively)

(g) schematic of the d

2.6 fcc和bcc钢板的破碎机理

在超高速撞击下,Q345钢板和304不锈钢板的宏观与微观组织均表现出很大差异。304不锈钢板在穿孔附近未产生严重的翻边现象,其断口表现出明显的脆性断裂特征。Q345钢板在穿孔区域产生较长的流线型塑性翻边,表现出明显的塑性断裂特征。这主要原因为2种钢板的晶体结构不同,导致2种钢板在超高应变率下的响应不同。

在撞击穿孔范围内,钢板主要受到沿撞击方向产生的纵波的影响,从而形成大量破片云。而在穿孔附近区域的钢板,由于处于超高速撞击状态,可以假设钢板在撞击时类似于流体状态,其剪切模量近似为0。而实际上,穿孔附近区域的钢板不可能直接看作流体状态,而是随着撞击速率的提高,逐渐趋近于流体状态的一个过程。那如何才能使钢板的剪切模量在撞击过程处于减小状态,从而类似于流体状态呢?其实就是如何产生具备极快速的塑性变形协调能力来适应撞击所产生的横波(剪切波),即适应协调能力越强,越接近于流体状态。

304不锈钢板具有较低的层错能及fcc晶体结构,本工作中虽然不讨论孪晶,但在穿孔附近区域,奥氏体孪晶与马氏体相变承担了较大部分的沿钢板径向传播的剪切波的协调作用,并且剪切波在晶界处产生透射波,作用于其他晶粒,产生的反射波对此晶粒产生相反方向的切变,使晶粒发生沿孪晶面的切变,从而使晶粒不断细化。虽然形成奥氏体孪晶和马氏体相变产生的晶粒破碎细化对钢板的强度具有强化作用,但在超高速撞击下,其撞击产生的应力远大于材料的强度,使其易于产生沿孪晶界、马氏体相界面或晶界的脆性断裂,从而呈现出较小的翻边,表现出脆性断裂特征。

对于Q345钢板,其为铁素体bcc晶体结构,不容易产生孪晶及相变来协调穿孔附近剪切波的作用。XRD谱的结果表明,{200}晶面发生明显的原子坍塌现象,不断向{110}密排面转化,促使其呈现出晶粒沿着ID不断拉长的现象。并且在拉长后,钢板两表面的拉长组织均形成沿ND翻边,这促使Q345钢在穿孔附近的晶粒组织具有很强的择优取向。使其微观上表现出流线型织构组织,宏观上表现出塑性变形翻边特征。

3 结论

(1) 304不锈钢板在撞击条件下发生了α'-马氏体相转变,并产生了极少量的ε-马氏体,α'-马氏体与母相γ-奥氏体存在K-S关系,并未发生明显的组织形态分层形式,而是发生晶粒细化。Q345钢板在撞击条件下未发生明显的相变,而是发生了明显的组织形态分层现象。

(2) 2种钢板均在穿孔表层区域以变形晶粒占大多数;而略偏离穿孔位置处,304不锈钢中回复晶粒占大多数,Q345钢板中再结晶晶粒占大多数。2种钢板产生的<110>//ID或者<110>//ND的丝织构为其优势织构,但对于穿孔附近的不同位置,304不锈钢板的<110>//ID或<110>//ND优势织构所占的面积分数接近,且不存在或存在少量的Cube、Goss、Copper、Brass、<100>//ND的织构;Q345钢板在位置1、2和4处,<110>//ID的丝织构较强,位置3处<110>//ND的丝织构较强,且不存在或有少量的Cube、Goss、Copper、Brass、<100>//ID等织构。

参考文献

Study on microstructure and properties of heat treatment Q345 steel

[J].

Q345钢热处理组织与性能研究

[J].

Continuous cooling transformation curve of undercooling austenite about Q345 steel

[J].

Q345钢奥氏体连续冷却转变曲线(CCT图)

[J].

Hypervelocity impact failure modes of typical spacecraft components

[J].

航天器典型部件超高速撞击失效模式

[J].

Experimental investigation on penetration behavior of reactive fragment against steel plates

[J].

活性破片对钢板侵彻性能的实验研究

[J].

Progress in structural impact dynamics during 2010-2020

[J].

结构冲击动力学进展(2010-2020)

[J].

Strain-induced martensite formation and recrystallization behavior in 304 stainless steel

[J].

Strain-induced martensite formation in austenitic stainless steel

[J].

Understanding the roles of deformation-induced martensite of 304 stainless steel in different stages of cavitation erosion

[J].

Metallurgical phase transformation and behavior of steels under impact loading

[J].

Measurement and modeling of deformation-induced martensitic transformation in a metastable austenitic stainless steel under cyclic loadings

[J].

Effect of strain rate on the strain partitioning behavior of ferrite/bainite in X80 pipeline steel

[J].X80 pipeline steel, which is mainly composed of ferrite/bainite, is an important structural steel for pipeline transportation. The plastic deformation of X80 pipeline steel at different strain rates caused by geological and human factors deteriorates its strength. Microstructural transformation and strain localization during deformation are the fundamental factors that deteriorate the mechanical properties of steel. Therefore, in this study, the strain partitioning behavior and microstructure evolution mechanism of ferrite and bainite in X80 pipeline steel at different strain rates (10-4 s-1 to 10-1 s-1) under 5% deformation were revealed using representative volume element models and electron backscatter diffraction technology. The results show that when the strain rate is low (10-4 s-1 to 10-3 s-1), ferrite has sufficient time to complete the evolution of geometrically necessary dislocations (GNDs) to low-angle grain boundaries (LAGBs) and the transformation of LAGBs to high-angle grain boundaries (HAGBs). Ferrite can release strain distortion energy, which can weaken the strain localization behavior of X80 steel. As the strain rate increases, the strain response time decreases, hindering the transition from LAGBs to HAGBs. This results in the accumulation of high-density GNDs and LAGBs in ferrite, thereby intensifying strain localization. Additionally, when the strain rate is high (10-2 s-1 to 10-1 s-1), the strain partitioning coefficient between ferrite and bainite could be reduced, thereby producing the strain gradient in the vicinity of the interface and resulting in GNDs accumulation and back stress formation. Furthermore, ferrite and bainite could show compressive and tensile stresses, respectively, thus limiting the strain coordination between the two phases significantly, increasing the stress concentration near the interface, and reducing the strain hardening ability. The strain partitioning behavior between ferrite and bainite was further revealed to better understand the plastic deformation of X80 pipeline steel.

应变速率对X80管线钢铁素体/贝氏体应变分配行为的影响

[J].

Changes in martensite fraction of 304SS in tensile deformation [J] J

304不锈钢拉伸变形过程中的马氏体相变

[J].

Study on deformation induced α′-martensitic transformation and fracture mechanism of 304HC stainless steel wire

[J].

304HC不锈钢钢丝形变诱导α′-马氏体相变及断裂机制

[J].

Strain-induced martensite and its influence in stamping of 304 stainless steel sheet

[J].The results of XRD diffraction analysis, magnetic needle analysis, mechanical properties and hardness tests show that the 304 austenitic stainless steel sheet in the cold-rolled (solution treated) condition produces strain-induced martensite(M) during cold forming(deformation) processes, which can reach 35% M for holes expansion and cup protrusion forming, but uni-directional tensile deformation being less than 10% M. On the other hand, it is found that the meta-stable austenite(A) of cold-rolled 304 steel must be driven by a certain degree of strain to be more obviously transformed into martensite. This threshold is about 20% ε during the tension test. The finite element analysis of 304 steel sheet expansion holes forming shows that 22% martensite can be formed at strain of about 10%,those locations with higher hardness, that is, areas with a lot of strain-induced martensite, are also the areas where the expansion holes strain is the largest. The analysis shows that the bi-directional tensile stress state of expansion holes and cupping forming is more conducive to the A→M transformation with volume expansion effect, which can induce a large amount of martensites in the main deformation area (boss, cupping) and the comprehensive hardening effect up to Δ35HRB. The martensite induced in the forming of 304 steel sheet is a very low carbon(<i>w</i><sub>C</sub><0.05%) body-centered cubic tough structure(α'-martensite), which has the effects of increasing <i>n</i> value, promotes deformation propagation, strain homogenization and others, it is conducive to the improvement of the elongation-type forming properties of the stainless steel sheet, the attainment of a high <i>λ</i> value of the expansion holes and the <i>IE</i> value of the cupping,and the promotion of structural strength of 304 stainless steel sheet stamping parts.

304不锈钢板材冲压成形中应变诱发马氏体及其影响

[J].

Twinning and martensite in a 304 austenitic stainless steel

[J].

Progress in dynamic responses and microstructure evolution of the additive manufactured alloys under impact load

[J].

冲击载荷下增材制造金属材料的动态响应及微观结构演化研究进展

[J].

Hypervelocity impact behavior of projectile penetration on spacecraft structure: A review

[J].

A debris cloud model for hypervelocity impact of the spherical projectile on reactive material bumper composed of polytetrafluoroethylene and aluminum

[J].

Deformation twinning in BCC iron under hypervelocity impact

[J].

超高速碰撞下体心立方纯铁的变形孪晶

[J].

Hot deformation characteristics and dynamic recrystallization behavior of H13 steel at high temperature

[J].

H13钢高温热变形特征与动态再结晶行为

[J].利用Gleeble-3800热模拟试验机在加热温度900~1150℃、应变速率0.01~10 s<sup>-1</sup>下对H13钢进行了单道次热压缩实验,依据热压缩实验获得的真应力-真应变曲线构建了H13钢的高温本构方程、热加工图、动态再结晶动力学模型和动态再结晶晶粒尺寸模型,并结合微观组织研究了H13钢的动态再结晶行为。结果表明,在低温低应变速率时(900~950℃,0.01 s<sup>(</sup>-1)),动态再结晶出现峰值应力点。在高温低应变速率时(1050~1150℃,0.01 s<sup>(</sup>-1)),不存在明显的峰值应力,随着变形量的增加,出现了不同程度的二次硬化。温度较高时(1050℃),随着应变速率的增加,二次硬化效果显著。热变形激活能Q为419853.623 J·mol<sup>-1</sup>,最佳热加工工艺参数为温度1050~1150℃,应变速率0.1~1 s<sup>-1</sup>。根据微观组织分析结果可知,在低温高应变速率下,晶粒为长条形,温度升高到1050℃后,再结晶体积分数增加,呈现出动态再结晶特征。而在高温低应变速率(1150℃,0.01 s<sup>-1</sup>)下,动态再结晶程度较高会使微观组织粗化,不利于材料的热加工成形。在变形温度为900~970℃、应变速率为0.1~10 s<sup>-1</sup>和变形温度为970~1150℃、应变速率为1.3~10 s<sup>-1</sup>时,H13钢易发生流变失稳,在变形温度为1050~1150℃、应变速率为0.1~1 s<sup>-1</sup>时,H13钢发生完全再结晶,且晶粒组织细小均匀,应优先选择为再结晶区域。

Deformation effects in shocked metals and alloys

[J].

Experimental survey on the behaviour of AISI 304 steel sheets subjected to perforation

[J].

Modeling spontaneous shear bands evolution in thick-walled cylinders subjected to external high-strain-rate loading

[J].

Strain rate sensitivity and activation volume of AISI 321 stainless steel under dynamic impact loading: Grain size effect

[J].

Twinning and martensitic transformations in nickel-enriched 304 austenitic steel during tensile and indentation deformations

[J].

Microstructure and property of TWIP steel under high speed dynamic test

[J].

高速冲击条件下TWIP钢组织和性能的研究

[J].

Deformation behavior of near-β Ti-5553 alloy under the impact of light gas gun

[J].

Ti-5553合金在轻气炮冲击下的变形行为

[J].

Surface hardening and numerical simulation on AISI304 stainless steel plates by explosive impact treatment

[J].

爆炸加载下AISI304不锈钢板表面硬化和数值模拟

[J].

The impact of peak shock stress on the microstructure and shear behavior of 1018 steel

[J].

Microstructure and texture of high manganese steel subjected to dynamic impact loading

[J].

Effects of shock-induced phase transition on spallation of a mild carbon steel

[J].

Impact-induced twinning and phase transition in a medium carbon steel

[J].

Microstructural characterization and mechanical properties of duplex and super austenitic stainless steels under dynamic impact deformation

[J].

The influence of strain rate on the microstructure transition of 304 stainless steel

[J].

In situ transmission electron microscopic observations of deformation and fracture processes in nanocrystalline palladium and Pd90Au10

[J].

Mechanism of crack nucleation analysed by in situ observation on Mg-Al-Zn alloy

[J].

Dynamic recrystallization analysis on austenitic stainless steel 321 alloy at different strain rates

[J].

奥氏体不锈钢321合金不同应变速率下动态再结晶分析

[J].

Application of EBSD in the investigation of the deformation microstructure induced during high-strain rate loading

[J].

背散射电子衍射在高应变率变形结构研究中的应用

[J].

本文是作者对背散射电子衍射技术在高应变率态载荷下诱发的几种晶体(包括Fe----Cr----Ni单晶、304不锈钢和纳米铜)变形结构演化的最新研究结果, 以及对相关研究进展的简要评述. 具体内容包括: (1)进一步辨认剪切带中再结晶现象, 澄清长期来学者们对该问题看法上的分歧; (2)采用Meyers等提出的结构演化模型对再结晶予以合理的解释; (3)在实验基础上, 根据位错动力学理论, 对局部化过程中再结晶的晶粒生长予以定量描述, 其结果与实验事实吻合.

Characterization of coarse and ultrafine-grained austenitic stainless steel subjected to dynamic impact load: XRD, SEM, TEM and EBSD analyses

[J].

Microstructural characterization of the shear bands in Fe-Cr-Ni single crystal by EBSD

[J].<p>An investigation has been made into the microstructural characterization of the shear bands generated under high-strain rate (≈104 s-1) deformation in Fe-15%Cr-15%Ni single crystal by EBSD-SEM (electron backscat-ter diffraction-scanning electron microscopy), TEM (transmission electron in microscopy) and HREM (high-resolution electron microscopy). The results reveal that the propagation of the shear band exhibits an asymmet-rical behavior arising from inhomogenous distribution in plasticity in the bands because of different resistanceto the collapse in different crystallographic directions; The γ–ε–α′ phase transformations may take place inside and outside the bands, and these martensitic phases currently nucleate at intersections either between the twins and deformation bands or between the twins and ε-sheet. Investigation by EBSD shows that recrystallization can occur in the bands with a grain size of an average of 0.2 μm in diameter. These nano-grains are proposed to attribute to the results of either dynamic or static recrystallization, which can be described by the rotational recrystallization mechanism. Calculation and analysis indicate that the strain rate inside the shear band can reach 2.50×106 s-1, which is higher, by two or three orders of magnitude, than that exerted dynamically on the specimen tested.</p>