ZM6 (Mg-Nd-Zn-Zr)合金是一种传统的铸造镁合金,具有比强度、比刚度高,减震性能好,机械加工性能和耐热性好等特点[1~4],在航天航空领域得到了广泛的应用[5,6]。但是,由于航空构件结构复杂、制造难度大,加工过程中不可避免会暴露出冶金或机加工缺陷,如不能高质量修复会造成巨大的废品损失;同时在特殊服役工况下会出现构件的异常损伤,返修更换新品时间长,不能满足应急需要。因此,在航空镁合金构件的制造及使用过程中,高效、高质量的修复是亟待解决的关键问题。传统修复方法(氩弧焊等)由于存在操作过程不稳定、尺寸精度差、修复区(repaired zone,RZ)组织粗大等问题[7],难以满足航空结构件的快速、高质量修复需求。激光沉积修复(laser deposition repairing,LDR)技术热量集中、热输入小、成形精度高,可实现复杂形态损伤的高质量修复,已成为航空航天领域高端装备高寿命运行保障的主要手段[8,9]。目前,LDR工艺在钢[10]、高温合金[11]、钛合金[12]、铝合金[13]等金属材料领域的研究日趋成熟,并得到了大量应用。但由于镁合金反射性高、线膨胀系数高,有必要对其激光沉积修复进行深入研究[14]。

固溶时效(T6)是改善镁合金显微组织和提升力学性能的主要手段,Dai等[15]发现T6处理可以有效改善Mg-Y-RE-Zr合金的拉伸性能,修复接头79%的屈服强度归因于T6处理产生的沉淀强化。同样,Singh[16]研究了焊后热处理对AZ31-AZ61镁合金搅拌摩擦焊接头组织和力学特性的影响,发现焊后T6处理的焊接接头中出现异常粗大的晶粒。Tong等[17]和Zhang等[18]研究了T6处理后的Mg-4Y-2Nd-1Gd-0.5Zr (质量分数,%)合金修复接头显微组织和力学性能变化,发现修复接头在固溶处理过程中,熔合区出现了异常粗大晶粒。与传统焊接工艺不同,在LDR过程中,熔池的快速熔-凝会受到超常冶金动力及超高温度梯度的影响,修复区的晶粒形态、尺寸、取向与成分分布存在明显差异,而T6处理工艺对其微观结构演变的影响机理尚不明确。

本工作利用同步送粉的激光沉积工艺对ZM6合金开展修复研究,结合扫描电子显微镜(SEM)、X射线衍射(XRD)、电子背散射衍射(EBSD)及力学性能测试等实验方法,系统研究了LDR试样的显微组织和力学性能,对比分析T6处理前后修复区显微组织的演变,明确了T6处理对晶粒异常粗化行为的作用机制及其对显微硬度及拉伸性能的影响,以期为航空镁合金构件的高质量修复提供理论基础。

1 实验方法

1.1 实验材料

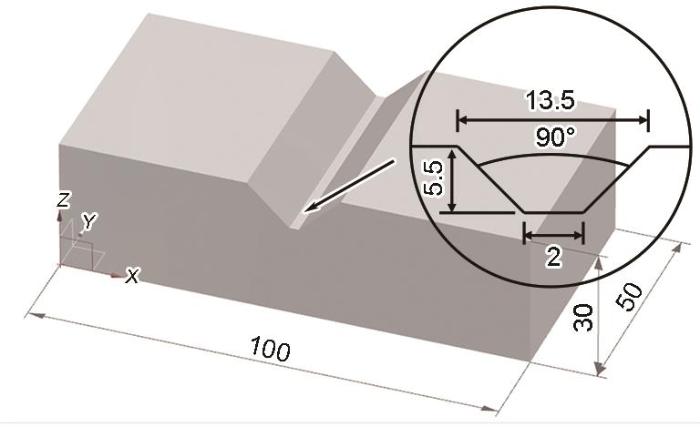

实验所用基材为铸态ZM6合金样块,尺寸为100 mm × 50 mm × 30 mm (长×宽×高) ,具体化学成分(质量分数,%)为:Nd 2.7,Zn 0.5,Zr 0.46,Fe 0.34,Ni 0.066,Si 0.007,Cu < 0.005,Al < 0.02,Be < 0.001,Mg余量。为方便激光沉积修复,将镁合金构件中常见的划伤、裂纹及加工超差等损伤规则化为梯形凹槽,梯形凹槽长度为50 mm、槽深5.5 mm、槽顶宽13 mm、开口角度为45°,如图1所示。实验前,使用600号金相砂纸对凹槽进行打磨,去除表面的氧化层,再用无水乙醇擦拭并吹干。修复所用粉末材料选用平均粒径为80 μm的ZM6球形粉末,其成分与基材相同。实验前,将粉末放入120 ℃的烘干机中保存2 h,以去除水分。

图1

图1

ZM6合金基材及梯形凹槽尺寸示意图

Fig.1

Schematic of the ZM6 alloy plate with a trapezoidal groove (unit: mm)

1.2 LDR过程

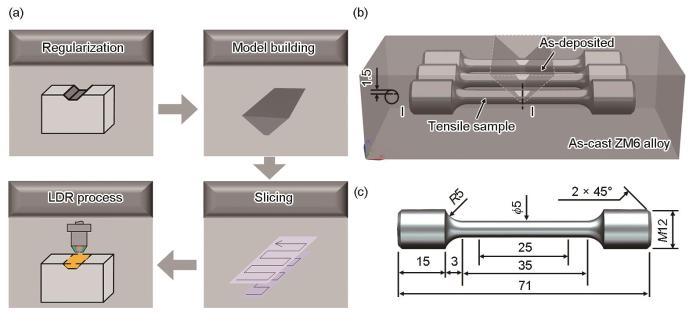

LDR实验在自主搭建的激光沉积制造系统上进行,该系统由RAYCUS激光器、送粉喷嘴、高速机床和RAYCHAM负压机载送粉机等构成,如图2所示。送粉头底部距离基板表面20 mm,在焦点处形成直径约3 mm的激光光斑。在修复过程中,采用Ar气保护使修复试样免受空气氧化。

图2

基于前期单道单层和多道多层实验研究[19],本工作采用优化后的LDR参数进行后续实验,具体工艺参数如下:激光功率1200 W、扫描速率5 mm/s、送粉速率0.6 rad/min、搭接率40%。LDR具体过程如图3a所示,首先基于预制梯形凹槽建立修复部分的数学模型,之后进行分层切片,设置单层扫描路径为短边往复扫描,使用激光沉积设备在梯形槽修复区从下到上逐层沉积,得到修复好的试样。此外,相邻沉积层沉积间隔时间设置为100 s以减少热累积。随后,使用热处理炉对修复试样进行固溶时效(T6:520 ℃、8 h、水冷 + 220 ℃、14 h)处理,沉积态、T6处理态的样品分别记为LDR和LDR-T6。

图3

图3

激光沉积修复(LDR)过程及拉伸试样的取样位置和尺寸示意图

Fig.3

Schematics of the laser deposition repairing (LDR) process (a), sampling location (b), and dimension (c) for tensile sample (unit: mm)

1.3 试样表征与测量

首先将T6处理前后试样截面研磨和抛光,之后用2% (体积分数)硝酸酒精试剂进行腐蚀,利用GX51型金相显微镜(OM)和Sigma 300场发射SEM观察修复试样截面显微组织,并采用Image J测量第二相面积。采用SEM附带的能谱仪(EDS)对修复区的元素分布进行表征,并用d2-phaser XRD进行物相分析。利用SEM上配备的Oxford EBSD仪分析T6处理前后晶粒尺寸分布、残余应力分布及试样取向差分布情况,扫描步长为2.5 μm。

2 实验结果

2.1 显微组织

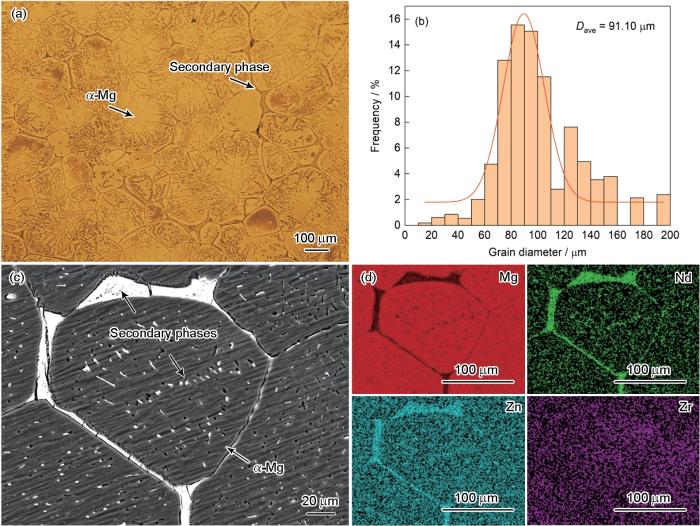

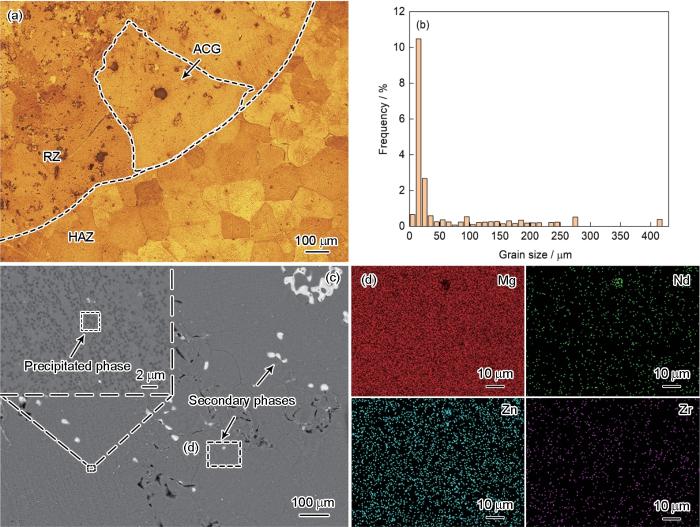

图4

图4

ZM6合金基材的OM像、晶粒尺寸分布、SEM像及EDS分析

Fig.4

OM image (a), grain diameter distribution (b), SEM image (c), and EDS analyses (d) of ZM6 alloy substrate (Dave—average of grain diameter)

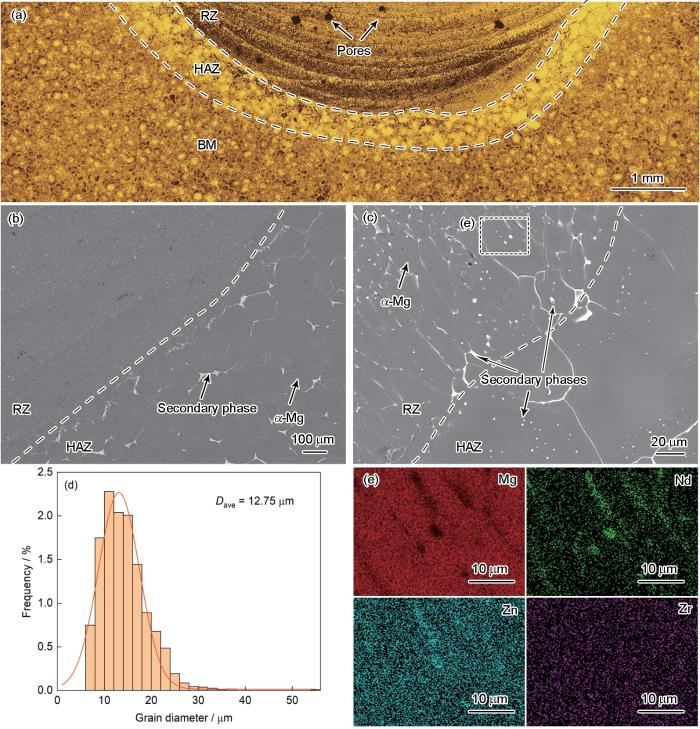

图5为LDR试样OM像、低/高倍下熔合线附近的SEM像、修复区晶粒尺寸分布和EDS分析。由图5a可见,修复区与基材呈现出良好的冶金结合,基于激光沉积修复快速熔化、快速冷却的工艺特点,修复区的晶粒尺寸相比基材更为细小。修复区具有明显的分层,尤其底部分层更加明显,这是由于修复初期底部温度梯度大,有利于外延生长的柱状晶粒形成[22]。此外,在修复区存在明显的气孔,该气孔主要是氢致气孔[24,25],其中的H主要来自粉末和保护气体中的水分,由于H在Mg中的溶解度随温度的降低而明显降低,在凝固过程中H不断从液态金属中析出,最终形成氢气泡。同时,由于镁合金热导性强,熔融金属冷却速率快,导致气泡在熔池冷却时来不及逸出,遗留在修复区中形成气孔。图5b为熔合线附近的SEM像。整体上修复区内的第二相比热影响区更加细小均匀,此外,由于热输入影响,热影响区中部分第二相溶入α-Mg基体相中,导致热影响区中第二相数量较基材更少。修复区组织由小尺寸的α-Mg晶粒及第二相构成(图5c),α-Mg晶粒平均尺寸约为12.75 μm (图5d)。晶界处的第二相呈半连续状分布在晶界处,晶粒内部存在呈点状分布的第二相,且第二相均含Mg、Nd、Zn 3种元素(图5e)。

图5

图5

LDR试样的OM像、低/高倍下熔合线附近的SEM像、修复区晶粒尺寸分布和EDS分析

Fig.5

OM image of LDR sample (a), low (b) and high (c) magnified SEM images around the fusion line, grain diameter distribution in RZ (d), and EDS analyses (e) (RZ—repaired zone, HAZ—heat-affected zone, BM—base material)

图6为LDR-T6试样的OM像、晶粒尺寸分布、SEM像及EDS分析。由图可见,经T6处理后的试样修复区内出现了异常粗大晶粒(图6a),其晶粒尺寸主要分布在300 μm以下,个别晶粒尺寸高达417.2 μm (图6b),远大于热影响区晶粒尺寸,这种现象将严重影响试样力学性能。图6c为T6处理后试样的SEM像。可以看出,LDR-T6试样修复区中的第二相呈团聚形态分布,这些第二相主要含Mg、Nd和Zn元素,如图6d所示。这些相的形成主要是由于固溶时间或温度不足,第二相未能全部溶解,并在固溶、时效过程中聚集、长大,最终呈现团聚形态。此外,晶粒内部出现了大量析出相(图6c),这是由于沉积态试样在固溶过程中晶界处半连续的第二相溶入到基体中,基体处于过饱和状态,系统处于非平衡状态,经过220 ℃、14 h时效处理后,溶质在固溶体中的过饱和度增大,最终在晶粒内部形成大量析出相。

图6

图6

LDR-T6试样熔合线附近的OM像、修复区晶粒尺寸分布、SEM像及EDS分析

Fig.6

OM image around the fusion line of the LDR-T6 sample (ACG—abnormally coarse grain) (a), grain diameter distribution in RZ (b), SEM image in RZ (Insets is the high magnified SEM image) (c), and EDS analyses (d)

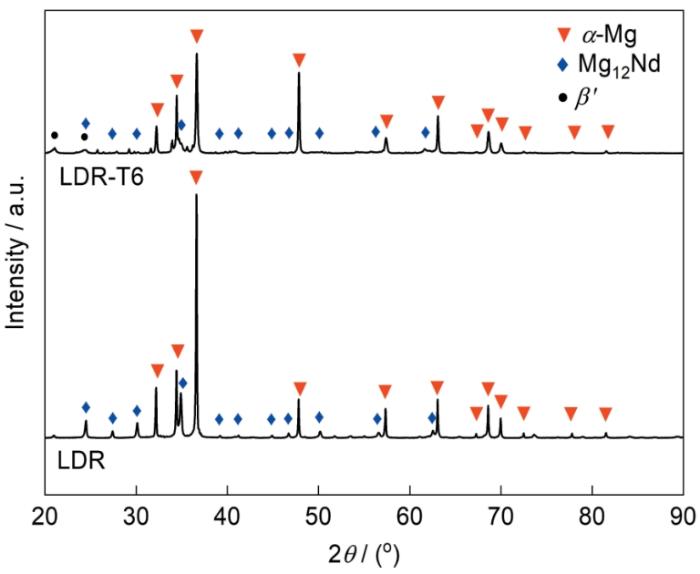

图7为LDR与LDR-T6试样修复区的XRD谱。可见,沉积态试样的修复区由α-Mg、Mg12Nd和Mg12(Nd, Zn)相组成。由于Nd在Mg中的溶解度很大,导致Mg12Nd沉淀相在晶粒内部或晶界处析出,而Zn会溶于Mg12Nd相中,生成比Mg12Nd相更为稳定的Mg12(Nd, Zn)相。但是由于Zn含量较低,Mg12(Nd, Zn)相数量较少,导致修复区的XRD谱中没有检测到Mg12(Nd, Zn)相的存在。经T6处理后修复区的Mg12Nd融入α-Mg基体中,导致Mg12Nd相的衍射峰强度减弱,此外,XRD谱中出现亚稳相β′ (Mg3Nd)相的衍射峰 ,表明T6处理后晶粒内部析出了β′相,该结果与Fu等[26]的研究结果一致。

图7

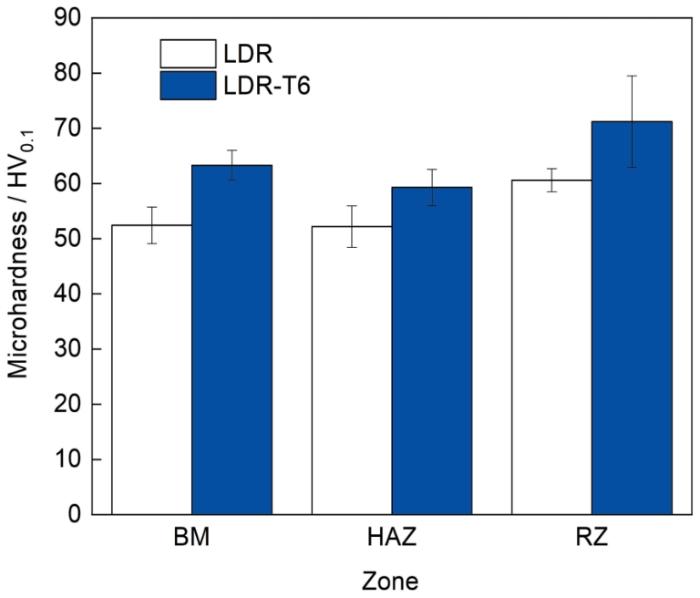

2.2 显微硬度

图8为LDR与LDR-T6试样不同区域的显微硬度分布。可以看出,沉积态试样基材和热影响区的平均硬度相差不大,为(52 ± 3) HV0.1。修复区平均硬度较基材提高了15.6%,达到了(60 ± 2) HV0.1,这是由于激光沉积冷却速率高的特性导致修复区晶粒相比基材更加细小,产生了细晶强化作用。经T6处理后,由于α-Mg基体中细小β′相的弥散析出,阻碍了位错运动,使硬度得到了进一步提升。基材、热影响区和修复区的平均硬度分别提升了20.7%、13.6%和17.5%。但是,经T6处理后的修复区内发生了严重的晶粒长大行为,修复区同时存在的异常粗大晶粒和细小晶粒导致修复区硬度波动较大。

图8

图8

LDR与LDR-T6试样不同区域的显微硬度分布

Fig.8

Microhardness distributions of different zones in LDR and LDR-T6 samples

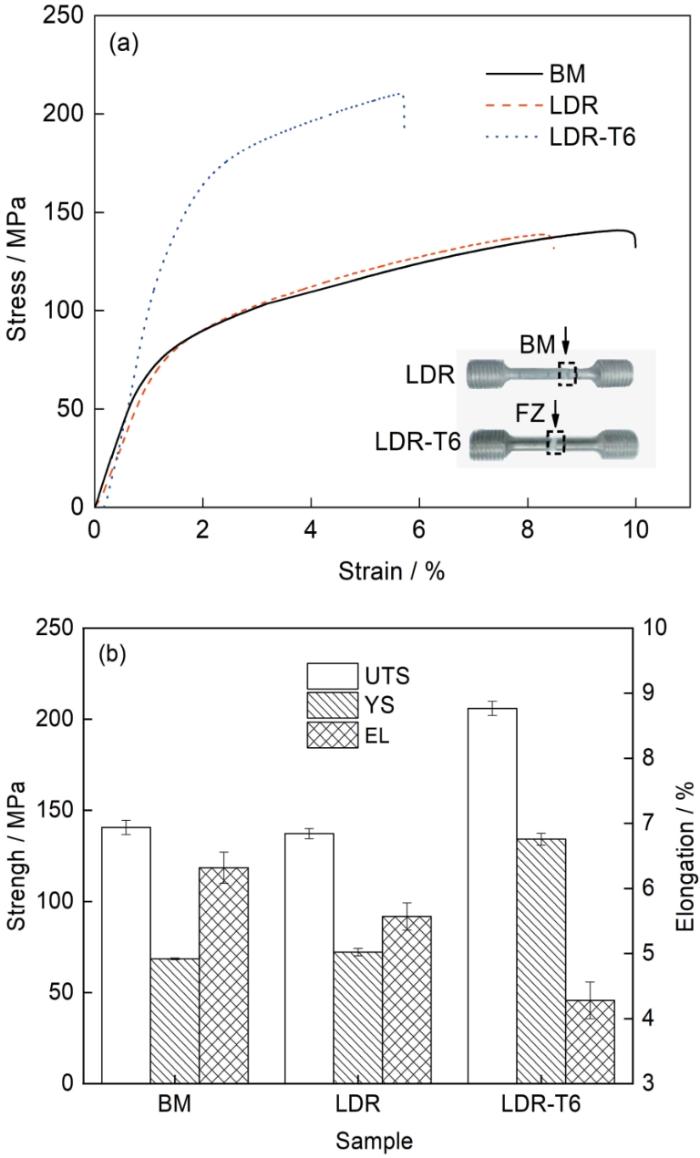

2.3 室温拉伸性能

图9

图9

基材、LDR与LDR-T6试样的工程应力-应变曲线、断裂位置及室温拉伸性能

Fig.9

Engineering stress-strain curves (a) and tensile properties (b) of BM, LDR, and LDR-T6 samples at room temperature (Insets in Fig.8a show the fracture positions; FZ—fusion zone; UTS—ultimate tensile strength, YS—yield strength, EL—elongation)

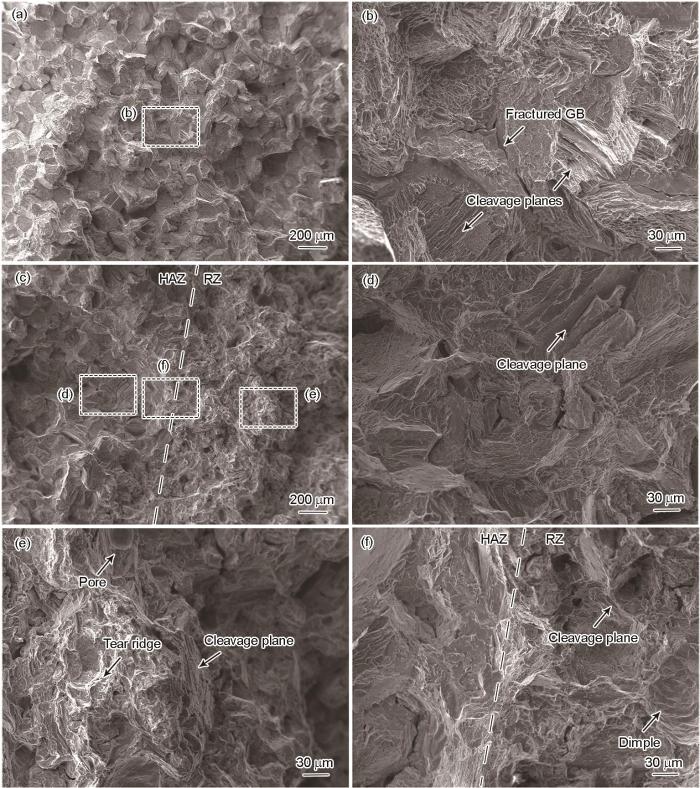

图10为LDR与LDR-T6试样拉伸断口的SEM像。LDR试样的断口形貌如图10a和b所示,断口中存在大量解理面和断裂的晶界,同时晶界处存在大量由于显微空洞形核长大、连接形成的小韧窝。断裂主要以沿晶为主,并伴有少量穿晶断裂。因此,LDR试样的断裂可以理解为是一种沿晶-穿晶混合的脆性断裂模式。图10c~f为LDR-T6试样的断口形貌,断口由基材区、热影响区和修复区3个区域组成。热影响区和基材部分呈现出大量解理台阶(图10d),主要为典型的穿晶脆性断裂。修复区中心部分断口形貌比较复杂,同时存在解理面、气孔和撕裂脊(图10e)和韧窝(图10f),以准解理形貌特征为主,可见修复区提高了LDR-T6试样的韧性。整体来说,LDR-T6试样呈现韧性断裂。

图10

图10

LDR与LDR-T6试样拉伸断口的SEM像

Fig.10

Low (a, c) and high (b, d-f) magnified SEM images showing facture surfaces of LDR (a, b) and LDR-T6 (c-f) samples (GB—grain boundary)

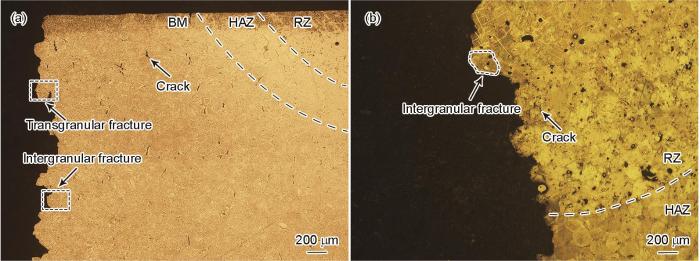

图11

图11

LDR与LDR-T6试样拉伸断口截面的OM像

Fig.11

Cross-sectional OM images showing fractures of LDR (a) and LDR-T6 (b) samples

3 分析与讨论

3.1 异常粗大晶粒形成机理

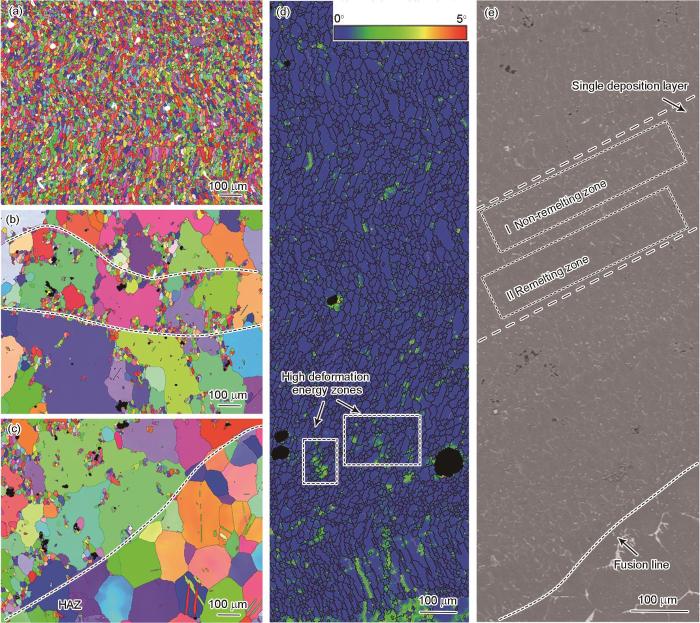

图12为LDR试样修复区、LDR-T6试样修复区和熔合线附近的反极图(IPF),LDR试样修复区的局部取向差(kernel average misorientation,KAM)图和LDR试样SEM像。对比图12a和b可以看出,经过T6处理后,修复区出现大量呈层状分布的异常粗大晶粒。此外,T6处理后试样的修复区与热影响区分界明显,也表明异常粗大晶粒并不会扩散到热影响区中(图12c),这与LDR工艺特性相关。与传统修复技术(氩弧焊)相比,LDR热输入小、冷却速率高,因此LDR区域晶粒尺寸十分细小,晶界数量多,且处于高能量状态,会自发向稳定状态发生转变。此外,由于LDR过程中温度场分布不均匀,修复区发生不均匀的收缩和膨胀,产生较大的应变和应力,导致形变能不均匀地分布在修复区内,为晶粒长大提供能量[27,28],如图12d所示。这些拥有较高形变能区域内的晶粒会率先长大,根据Von Neumann定律,生长速率和相邻晶粒数量(N)之间的关系为[29]:

式中,d为晶粒尺寸,t为时间,m为晶界迁移率,γ为晶界能。率先长大晶粒相邻的晶粒数量较多,因此具有更快的生长速率,导致了小尺寸晶粒与异常粗大晶粒尺寸相差巨大。

图12

图12

LDR试样修复区、LDR-T6试样修复区和熔合线附近的反极图(IPF),及LDR试样修复区的局部取向差(KAM)图和LDR试样的SEM像

Fig.12

Inverse pole figures (IPFs) of RZ in LDR (a) and LDR-T6 (b) samples and region around fusion line of LDR-T6 sample (c), kernel average misorientation (KAM) map of RZ (d), and SEM image of LDR sample (e)

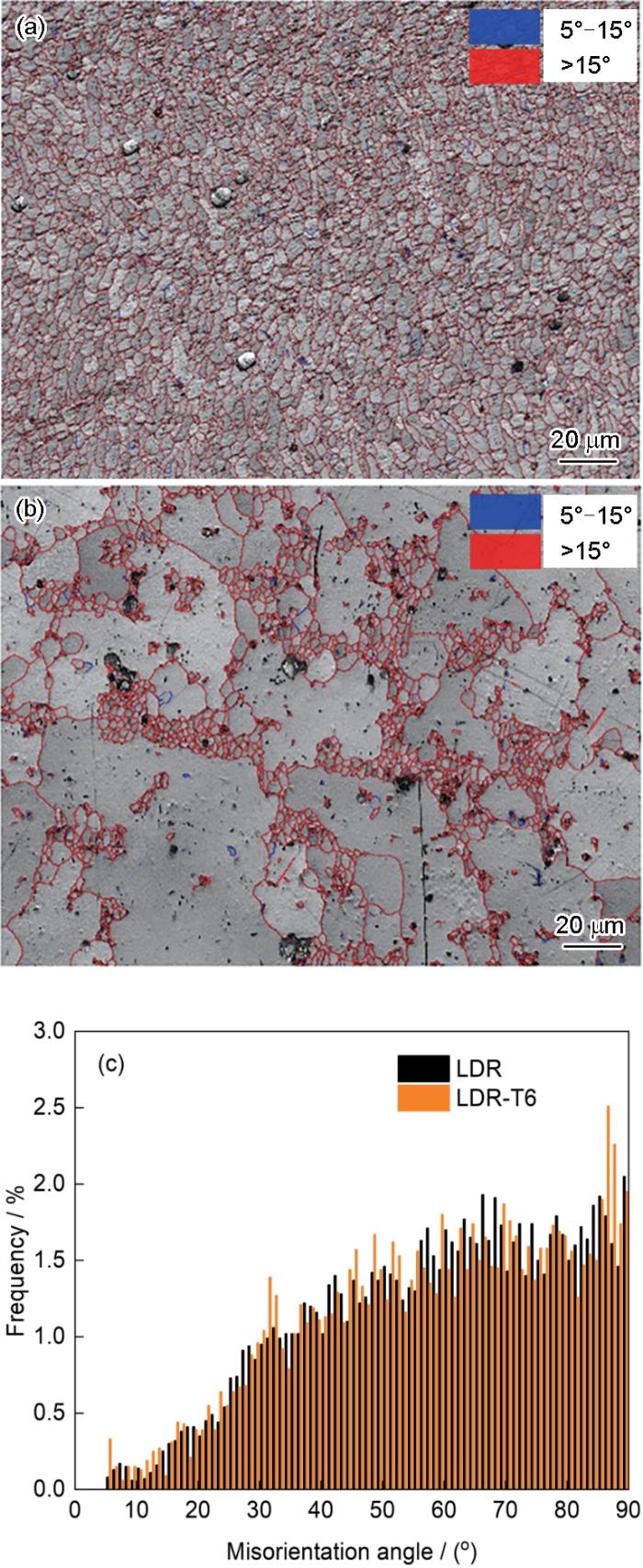

式中,Si 和Sj 为相邻晶粒的取向,θ为取向差角,θRS为最大的小角度晶界角度(15°),r'为HAGB的能量。晶界角度为5°~15°的LAGB比HAGB具有更低的晶界能。修复区内组织因异常粗大晶粒的出现增加了LAGB的占比,LAGB比例的增大降低了系统的能量,使系统转变为稳定状态。

图13

图13

LDR与LDR-T6试样修复区晶界分布图及取向差统计图

Fig.13

Grain boundary distribution maps of RZ in LDR (a) and LDR-T6 (b) samples and the corresponding misorientation statistical diagram (c)

3.2 T6处理对修复试样力学性能的影响

式中,σy为屈服强度,σ0为摩擦应力,k为位错的Hall-Petch线性关系的斜率。从

图14

图14

LDR与LDR-T6拉伸试样的断裂机制示意图

Fig.14

Schematics of fracture mechanisms of the LDR (a) and LDR-T6 (b) samples

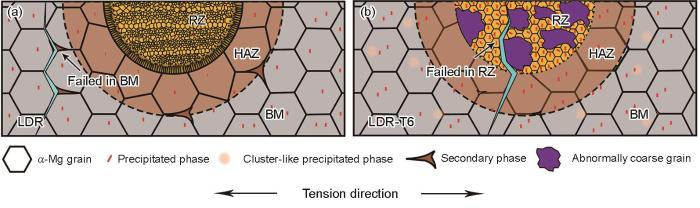

经T6处理后,修复试样基材区域的硬度相较于沉积态试样提高了21%。由于修复区内同时存在异常粗大晶粒和细小晶粒,导致修复区的硬度分布不均匀,但由于β′相的析出,使固溶处理后的试样修复区平均硬度总体上仍比沉积态试样提高了17.5%。此外,经T6处理后,试样的抗拉强度和屈服强度较沉积态分别提高了75.6%和49.8%,但伸长率较低,仅为4.28%,较沉积态下降了23.2%。这是由于LDR-T6试样中弥散分布的β′相会阻碍位错的运动,起到弥散强化效应,使试样强度升高,但伸长率降低。此外,根据

4 结论

(1) 激光沉积修复试样呈现良好的冶金结合,修复区为细小的等轴晶组织,平均晶粒尺寸远小于基材。第二相Mg12Nd和Mg12(Nd, Zn)主要呈网状分布在晶界处,少量以点状及棒状形态分布在晶粒内部。经过T6处理后,修复区出现晶粒异常长大现象,同时未完全溶解的第二相团聚、长大,并且晶粒内部析出了β′相。

(2) LDR试样修复区硬度为(60 ± 2) HV0.1,较基材提高了15.6%。经T6处理后试样修复区硬度提高了17.5%,同时存在的细小晶粒和异常粗大晶粒使修复区硬度波动较大。

(3) 激光沉积修复试样的抗拉强度和屈服强度与基材相近,经T6处理后修复试样的抗拉强度和屈服强度分别提升了49.8%和75.6%,但延伸率有所下降,这与晶粒内部β′相的弥散析出密切相关。

(4) LDR试样断裂位置在基材,断口存在大量解理面,呈现典型的沿晶-穿晶混合的脆性断裂模式。LDR-T6试样的断裂位置在修复区,断口呈现出2种断裂模式,修复区部分主要为准解理断裂,基材和热影响区是典型的穿晶脆性断裂,异常粗大晶粒是引起断裂的主要原因。

参考文献

Latest research advances on magnesium and magnesium alloys worldwide

[J].

Overview of advancement and development trend on magnesium alloy

[J].Magnesium alloys are characterized by their low density (approximately 1.8 g/cm 3 for magnesium alloys), high strength, large modulus of elasticity, good heat dissipation, good shock absorption, greater ability to withstand impact load than aluminum alloys, good corrosion resistance to organic matter and alkalinity. According to the statistical analysis of literature data collected by Web of Science Core Collection, it can be found that the growth rate of publications on magnesium alloy during 2008-2018 is significantly higher than the overall growth rate of alloy research papers. In the past 11 years, the Web of Science Core Collection has collected 21,440 papers on magnesium alloys, averaging nearly 2000 papers annually, of which 2768 papers were collected in 2018, an increase of 206% over 2008, accounting for more than one fifth of the total literature on alloy research. Magnesium alloys have become an important lightweight metallic structural material and have been widely studied worldwide. As the only journal focusing on magnesium alloy research which devoted to the coverage and dissemination of global research on magnesium alloys. This article statistically analyzes all the academic articles published by Journal of Magnesium and Alloys (JMA) from 2013 to 2018 and compares them with all the articles containing magnesium alloy in their titles on the Web of Science during this period. The development trends of magnesium alloys are summarized based on these articles, and the influence and academic value of the articles published by JMA are summarized as well. This paper hopes to better realize the value of JMA, help better spread the academic research of magnesium alloys, and promote the development of global magnesium alloy research. (C) 2019 Published by Elsevier B.V. on behalf of Chongqing University.

Research advances in magnesium and magnesium alloys worldwide in 2020

[J].Research on magnesium alloys continues to attract great attention, with more than 3000 papers on magnesium and magnesium alloys published and indexed in SCI in 2020 alone. The results of bibliometric analyses show that microstructure control and mechanical properties of Mg alloys are continuously the main research focus, and the corrosion and protection of Mg alloys are still widely concerned. The emerging research hot spots are mainly on functional magnesium materials, such as Mg ion batteries, hydrogen storage Mg materials, and bio-magnesium alloys. Great contributions to the research and development of magnesium alloys in 2020 have been made by Chongqing University, Chinese Academy of Sciences, Central South University, Shanghai Jiaotong University, Northeastern University, Helmholtz Zen-trum Geesthacht, etc. The directions for future research are suggested, including: 1) the synergistic control of microstructures to achieve high-performance magnesium alloys with concurrent high strength and superior plasticity along with high corrosion resistance and low cost; 2) further development of functional magnesium materials such as Mg batteries, hydrogen storage Mg materials, structural-functional materials and bio-magnesium materials; 3) studies on the effective corrosion protection and control of degradation rate of magnesium alloys; 4) further improvement of advanced processing technology on Mg alloys. (C) 2021 Chongqing University. Publishing services provided by Elsevier B.V.

Research progress of materials design for metal laser additive manufacturing

[J].Laser additive manufacturing is widely recognized to be an effective method to form complicated and custom metallic components. The existing research on metal additive manufacturing utilizes traditional alloy grades, which are designed based on the assumption that solidification occurs at equilibrium; thus, these materials are not well suited to the nonequilibrium metallurgical dynamics that are present in additive manufacturing techniques. Common issues, such as high crack susceptibility, low toughness, and low fatigue capability, as well as anisotropy, frequently occur during the fabrication of additively manufactured metallic parts. It is therefore necessary to conduct research on the design of new materials designed specifically for laser additive manufacturing in order to fully realize the potential advantages and value of the ultrafast solidification conditions. In this article, the technical bottlenecks, material design methods, and the development of new materials that are applicable to laser additively manufactured metal materials are reviewed; these materials include aluminum alloys, titanium alloys, iron-based alloys, and magnesium alloys. Finally, the potential future direction of research related to laser metal additive manufacturing is discussed.

金属激光增材制造材料设计研究进展

[J].

Recent developments and applications on high-performance cast magnesium rare-earth alloys

[J].

Research progress of additively manufactured magnesium alloys: A review

[J].Mg alloys are attractive in the fields of aerospace, automotive, and biomedical engineering, owing to the advantages of light weight, high specific strength, excellent damping property, good biocompatibility, and in vivo degradable property. However, conventional methods for manufacturing Mg alloys, such as casting and deformation processing, yield low-quality large-scale monolithic and complex structures, which hinder the applications of Mg parts. Additive manufacturing (AM) is a burgeoning alternative to manufacture monolithic parts through layer-by-layer deposition of metallic materials using 3D model data. In this paper, the latest research progress in AM of Mg alloys, which focuses on technological processes and influencing factors, macro and microstructures, mechanical properties, and corrosion properties of parts manufactured primarily by selective laser melting (SLM) and wire and arc AM (WAAM), are comprehensively reviewed. Currently, additively manufactured Mg parts with a relative density > 99% have been achievable through both SLM and WAAM after process optimization, and their mechanical properties and corrosion resistance have been comparable to those of casting and wrought parts, indicating a great potential for engineering applications. Finally, the future development trend and research direction of AM of Mg alloys are proposed from the perspectives of materials design, process improvement, and performance evaluation.

增材制造镁合金技术现状与研究进展

[J].镁合金具有轻质、比强度高、阻尼减振、生物相容性好、体内可降解等优点,在航空航天、汽车轻量化、生物医疗等领域应用潜力巨大。然而传统的镁合金铸造成形和变形加工技术在制备一体化复杂结构件上具有一定的局限性,制约了镁合金在上述领域的应用普及。增材制造是一种根据三维模型数据逐层熔化沉积的先进技术,有望成为镁合金复杂构件制备的重要技术途径。本文概述了近年来增材制造镁合金的研究进展,重点对选区激光熔化(SLM)和电弧增材制造(WAAM) 2种主要增材制造的工艺研发现状和影响因素、微观组织、力学性能及耐蚀行为进行分析与总结。研究表明,工艺优化后SLM和WAAM等技术均可获得致密度> 99%的镁合金试件,并且能够获得与传统制造镁合金相当的力学性能和耐蚀性能,增材制造镁合金表现出极大的工程应用潜力。最后,从材料优化、工艺改进及性能评价等方面对增材制造在镁合金中的未来发展趋势与研究方向进行了总结与展望。

Comparative study on microstructure and properties of laser welding and argon arc welding Hastelloy C-276/SS304 with filler wire

[J].

Microstructure and tensile properties of DD32 single crystal Ni-base superalloy repaired by laser metal forming

[J].In this work, the microstructure and tensile properties of DD32 single-crystal (SC) superalloy repaired by laser metal forming (LMF) using pulsed laser have been studied in detail. The microstructures of the deposited samples and the tensile-ruptured samples were characterized by optical microscopy (OM), transmission electron microscope (TEM) and scanning electron microscope (SEM). Due to high cooling rate, the primary dendrite spacing in the deposited area (17.2 μm) was apparently smaller than that in the substrate area (307 μm), and the carbides in the deposited samples were also smaller compared with that in the substrate area. The formation of (γ+γ′) eutectic in the initial layer of repaired SC was inhibited because of the high cooling rate. As the deposition proceeded, the cooling rate decreased, and the (γ+γ′) eutectic increased gradually. The (γ+γ′) eutectic at heat-affected zone (HAZ) in the molten pool dissolved partly because of the high temperature at HAZ, but there were still residual eutectics. Tensile test results showed that tensile behavior of repaired SC at different temperatures was closely related to the MC carbides, solidification porosity, γ′ phase, and (γ+γ′) eutectic. At moderate temperature, the samples tested fractured preferentially at the substrate area due to the fragmentation of the coarse MC carbide in the substrate area. At elevated temperature, the (γ+γ′) eutectic and solidification porosity in the deposited area became the source of cracks, which deteriorated the high-temperature properties and made the samples rupture at the deposited area preferentially.

Microstructure and mechanical properties of laser forming repaired 17-4PH stainless steel

[J].

Integrated approach to stainless steel 316L parts repair for pitting corrosion using laser metal deposition

[J].

Microstructure and mechanical properties of a directionally solidified superalloy DZ411 plate sample repaired by laser melting deposition

[J].

Investigation of the microstructure and mechanical properties of Ti-6Al-4V repaired by the powder-blown underwater directed energy deposition technique

[J].

Microstructure and micro-hardness of laser deposition repair ZL114A aluminum alloy

[J].

激光沉积修复ZL114A铝合金的显微组织及显微硬度研究

[J].

Additive manufacturing of magnesium alloys by selective laser melting technology: A review

[J].Selective laser melting (SLM) additive manufacturing technology holds the broad prospect for the preparation of high-performance complex metal components owing to its high processing accuracy, short manufacturing cycle, and high material usage. Magnesium (Mg) alloys are the lightest metal structural material and provide the benefits of low density, substantial specific strength and specific stiffness, good damping and shock absorption performance, and good biodegradability. Thus, it is worthwhile to employ SLM to manufacture Mg alloys, which is predicted to widen the application scope of Mg alloys. In this study, a comprehensive review on SLM of Mg alloys focusing on the preparation of Mg alloy powders, SLM process parameters, metallurgical defects, microstructure and mechanical properties of the as-built state, post-processing, and special equipment developed for SLM of Mg alloys is given. Finally, the future development trends of the SLM of Mg alloys are explored.

镁合金选区激光熔化增材制造技术研究现状与展望

[J].选区激光熔化(SLM)增材制造技术由于其加工精度高、制造周期短、材料利用率高等优点,在制备高性能复杂金属构件方面具有广阔的应用前景。镁合金是最轻的金属结构材料,具有密度低、比强度和比刚度高、阻尼减震性能好、生物降解性良好等优点。因此,采用SLM技术制备镁合金具有重要的研究价值,有望拓宽镁合金的应用范围。本文针对镁合金SLM增材制造技术,详细介绍了镁合金粉末制备、SLM工艺参数、冶金缺陷、SLM态的显微组织和力学性能、后处理、镁合金专用SLM设备方面的研究进展,并展望了未来镁合金SLM研究的发展方向。

Effects of heat treatments on laser welded Mg-rare earth alloy NZ30K

[J].

Effect of post-welding heat treatment on mechanical and microstructural properties of friction stir welded dissimilar magnesium alloys

[J].

Addressing the abnormal grain coarsening during post-weld heat treatment of TIG repair welded joint of sand-cast Mg-Y-RE-Zr alloy

[J].

Research on the post-weld heat treatment of TIG repair welded joint of sand-cast Mg-Y-RE-Zr alloy

[J].

Evolution of microstructure of WE43 magnesium alloys fabricated by laser deposition manufacturing with subsequent friction stir processing

[J].

The Microstructural evolution and grain growth kinetics of fine-grained extruded Mg-Nd-Zn-Zr alloy

[J].

Microstructure analysis of Mg-2.54Nd-0.26Zn-0.32Zr alloy

[J].

Mg-2.54Nd-0.26Zn-0.32Zr合金组织分析

[J].

The effect of grain size on the tensile and creep properties of Mg-2.6Nd-0.35Zn-xZr alloys at 250 °C

[J].

Evolutions in microstructure and mechanical properties of laser lap welded AZ31 magnesium alloy via beam oscillation

[J].

Analysis on welding characteristics of ultrasonic assisted laser welding of AZ31B magnesium alloy

[J].

Pore formation mechanism and its mitigation in laser welding of AZ31B magnesium alloy in lap joint configuration

[J].

Effects of heat treatments on the microstructures and mechanical properties of Mg-3Nd-0.2Zn-0.4Zr (wt.%) alloy

[J].

Abnormal grain growth induced by <1120> orientation of AZ31 magnesium alloy

[J].

Normal and abnormal grain growth in magnesium: Experimental observations and simulations

[J].Commercial purity as-cast magnesium was hot rolled and subsequently annealed at different temperatures in order to investigate its grain growth behavior and link it to the texture evolution. Annealing at an intermediate temperature of 220 °C gave rise to abnormal grain growth with a few grains reaching a grain diameter 10 times larger than the mean. Increasing the annealing temperature to 350 °C yielded normal grain growth. Both types of grain growth revealed a strengthening of the (0001) <$11\bar{2}0$> texture component. It is hypothesized that a dislocation density gradient after recrystallization grants (0001) <$11\bar{2}0$> grains a size advantage during early stages of growth. The type of growth will be, however, determined by the mobility of the present grain boundaries and triple junction drag, which are strongly dependent on the annealing temperature. The above hypothesis of the interplay between these parameters was explored through curvature- and residual dislocation-density-gradient-driven grain growth simulations using a formerly developed level-set approach. The simulation outcome suggests that application of such a modeling approach in microstructure studies of magnesium can provide valuable new insights into the problem of grain growth and associated texture evolution.

Formation of abnormal coarse grains and its effects on corrosion behaviors of solution treated ZK60 Mg alloy

[J].

Influence of undissolved second-phase particles on dynamic recrystallization behavior of Mg-7Sn-1Al-1Zn alloy during low- and high-temperature extrusions

[J].This study investigates the effects of fine and coarse undissolved particles in a billet of the Mg-7Sn-1Al-1Zn (TAZ711) alloy on the dynamic recrystallization (DRX) behavior during hot extrusion at low and high temperatures and the resultant microstructure and mechanical properties of the alloy. To this end, partially homogenized (PH) and fully homogenized (FH) billets are extruded at temperatures of 250 and 450 °C. The PH billet contains fine and coarse undissolved Mg2Sn particles in the interdendritic region and along the grain boundaries, respectively. The fine particles (<1 μm in size) retard DRX during extrusion at 250 °C via the Zener pinning effect, and this retardation causes a decrease in the area fraction of dynamically recrystallized (DRXed) grains of the extruded alloy. In addition, the inhomogeneous distribution of fine particles in the PH billet leads to the formation of a bimodal DRXed grain structure with excessively grown grains in particle-scarce regions. In contrast, in the FH billet, numerous nanosized Mg2Sn precipitates are formed throughout the material during extrusion at 250 °C, which, in turn, leads to the formation of small, uniform DRXed grains by the grain-boundary pinning effect of the precipitates. When the PH billet is extruded at the high temperature of 450 °C, the retardation effect of the fine particles on DRX is weakened by their dissolution in the α-Mg matrix and the increased extent of thermally activated grain-boundary migration. In contrast, the coarse Mg2Sn particles in the billet promote DRX during extrusion through the particle-stimulated nucleation phenomenon, which results in an increase in the area fraction of DRXed grains. At both low and high extrusion temperatures, the extruded material fabricated using the PH billet, which contains both fine and coarse undissolved particles, has a lower tensile strength than that fabricated using the FH billet, which is virtually devoid of second-phase particles. This lower strength of the former is attributed mainly to the larger grains and/or absence of nanosized M2Sn precipitates in it.

Avoiding abnormal grain growth in thick 7XXX aluminium alloy friction stir welds during T6 post heat treatments

[J].

Effect of multiple thermal cycles on the microstructure evolution of GA151K alloy fabricated by laser-directed energy deposition

[J].

Microstructure and mechanical property analysis of ZL114A aluminum alloy repaired by laser deposition

[J].

激光沉积修复ZL114A铝合金组织和力学性能分析

[J].

Transition of dominant deformation mode in bulk polycrystalline pure Mg by ultra-grain refinement down to sub-micrometer

[J].