目前,Monel K-500合金已形成较为成熟的加工与热处理工艺,相关力学性能调控主要通过改变固溶热处理时间、时效热处理温度和时效时间等参数实现。例如Dey和Mukhopadhyay[5]通过改变时效热处理温度与时间研究了Monel K-500合金热处理过程中的欠时效、峰时效与过时效参数。Es-Said等[10]研究了多步时效热处理对合金力学性能的影响。Nayan等[11]采用有限元模拟结合热压实验研究了Monel 400合金在900~1200 ℃等条件下的热加工性能。Kim等[12]采用机器学习对Monel K-500合金的淬火过程进行了较为准确的预测。由于Monel合金在复杂、苛刻环境下具有良好的应用性能,因而其在海水、HF等环境下的失效机理研究受到了广泛关注。5%NaCl (质量分数)溶液中Monel K-500合金的腐蚀研究[13]表明,TiC与基体的低晶格错配度使得合金发生均匀阳极溶解。

Monel合金具有良好的铸造性能,可通过冷热成型工艺或机械加工进行制备[14],轧制或拉拔等工艺可细化晶粒尺寸从而进一步提高合金力学性能[15]。随着工业中对合金成本和性能需求的提高,先进的凝固技术逐步应用于Monel合金的制备。Chen等[7]和Marenych等[16]采用激光定向沉积技术制备了具有梯度结构的Monel合金,该合金具有各向异性的凝固组织和力学性能,但样品中存在未熔、气孔和裂纹等缺陷。定向凝固(directional solidification,DS)技术是一种通过在凝固过程中控制热量定向传输从而实现凝固组织沿特定方向生长的技术。定向生长的微观组织使得合金具有各向异性的力学、耐腐蚀等性能[17~19]。与其他凝固技术相比,定向凝固过程中的溶质再分配与组织定向分布有效消除了横向晶界、减少了偏析等凝固缺陷[20,21]。而采用定向凝固制备Monel K-500合金的相关研究仍有待开展。同时Monel K-500合金热处理过程中的温度和时间均会影响析出相的尺寸,对其热处理过程中温度的准确控制有利于样品性能的调控。一般情况下,合金凝固和热处理分步进行,样品需要经过多次加热冷却过程。而加热和冷却过程产生的时效作用难以精确控制,因此本工作提出了定向凝固耦合原位热处理进行协控的思路,并基于此开发了定向凝固与固态相变双联协控(DS-TP)技术。相比于DS中合金在凝固冷却后取出再放入加热炉中进行热处理,固态相变双联协控样品定向凝固结束后直接加热至热处理温度,且固溶、时效及淬火过程均在相同的惰性气体环境中连续进行。采用双联协控技术减少了实验过程中的能源损耗、提高了实验效率,有望获得具有柱状晶结构且缺陷较少的样品。

目前,DS-TP条件下合金的微观组织形成规律及其对合金性能的影响尚不明晰,为研究DS-TP技术对合金微观组织与力学性能的作用机制,本工作以Monel K-500合金为研究对象,分别采用DS和DS-TP技术研究了不同生长速率(V)下合金的微观组织与溶质分布规律,并通过单轴拉伸实验分析了合金的力学性能及断裂机制。

1 实验方法

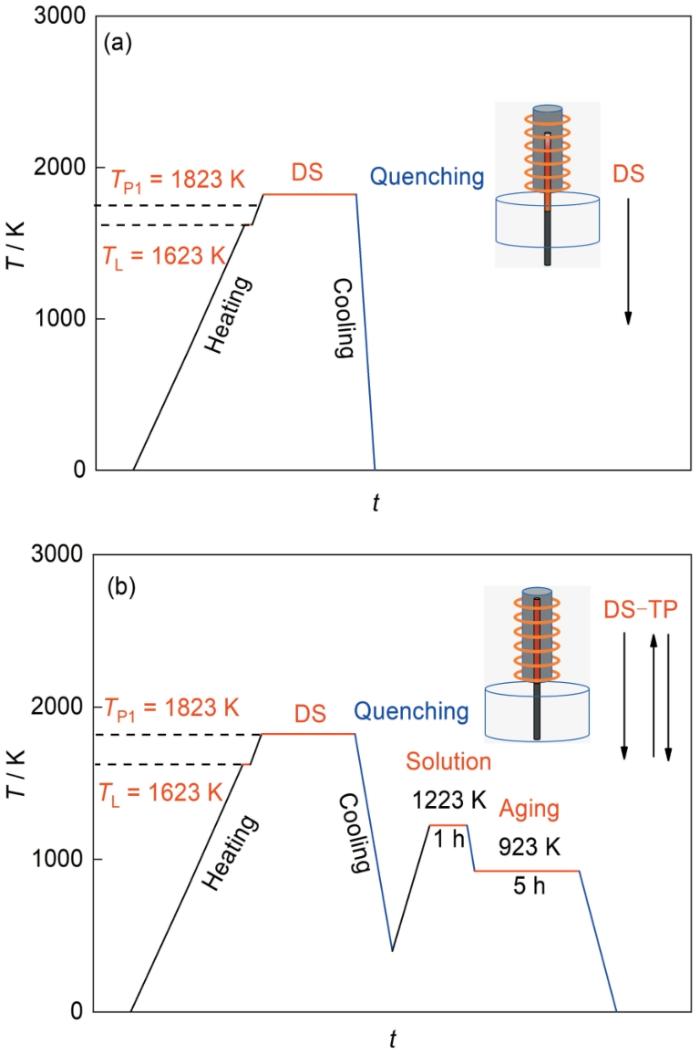

实验所用原料为直径9.2 mm的轧制Monel K-500合金棒。合金的名义成分(质量分数,%)为:Cu 29.6,Al 2.5,Fe 1.78,Mn 0.68,Ti 0.71,Si 0.29,C 0.08,Ni余量。DS和DS-TP实验开始前,将盛有原料的Al2O3坩埚放入内置石墨加热器的电磁感应线圈中,之后将坩埚底部与抽拉杆顶部固定连接。通过真空系统将腔体抽真空至5 × 10-4 Pa后,反充高纯Ar气至约300 MPa。图1a是合金DS实验方案。图中,TL是合金熔化温度,TP1是合金保温和定向凝固温度。DS实验过程中Monel K-500合金样品在加热熔炼单元中升温至熔化后过热200 K,保温20 min后启动定向抽拉机构,样品在抽拉杆作用下以设定的抽拉速率浸入Ga-In-Sn液态金属。当样品移动至预设位置后,启动气缸将样品迅速拉入液态金属中淬火。图1b是DS-TP实验方案。DS-TP实验过程中DS阶段与图1a中的DS方案一致,DS结束时样品还未冷却,此时将样品升高至加热熔炼单元,通过调整加热功率使样品温度达到1223 K,保温1 h后启动气缸将样品迅速拉入液态金属中进行淬火以促进合金内元素均匀分布。合金温度降低至923 K后,再次将样品升高至加热熔炼单元并在923 K进行时效处理,保温5 h后淬火以促进沉淀强化相的析出。待合金温度降至室温后取出,获得直径为10 mm、长为100 mm的棒状Monel K-500合金样品。相比于定向凝固后进行热处理,DS-TP过程中凝固和热处理在单次实验中完成,减少了加热冷却过程和原料的损耗,降低了成本并提高了实验效率。同时原位热处理避免了固溶后降温和时效前升温过程对样品时效结果的影响,有利于对析出相的尺寸和数量进行更加精确的调控。

图1

图1

Monel K-500合金的定向凝固(DS)和定向凝固与固态相变双联协控(DS-TP)实验方案

Fig.1

Experimental schematics of directional solidification (DS) (a) and synergetic modulation of directional solidification and thermal processing (DS-TP) (b) of Monel K-500 alloys (T—temperature of sample, t—time of experiment, TL—melting tempereture, TP1—holding temperature; insets are the schematics of the movement of samples during DS and DS-TP, respectively)

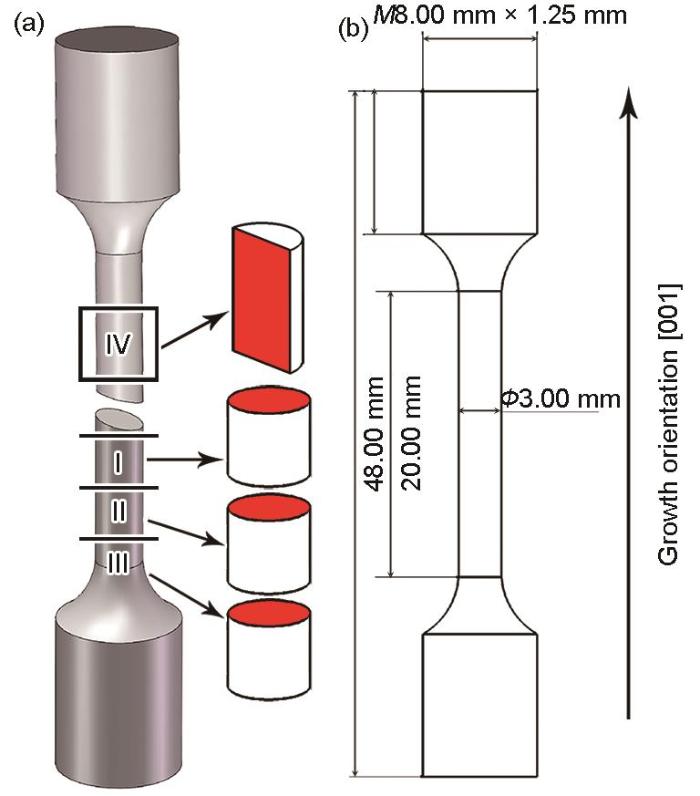

实验结束后,采用电火花线切割将Monel K-500合金样品沿纵向剖开,经打磨、抛光和金相腐蚀后利用GX 51光学金相显微镜(OM)对其组织形貌进行分析。采用Gemini Sigma 300扫描电子显微镜(SEM)对合金进行断口形貌分析,使用INCA Energy 3000能谱仪(EDS)测定样品的元素分布,并利用Nordlys Nan Detector电子背散射衍射仪(EBSD)获得合金稳定生长区纵截面和图2a所示断裂后样品红色区域的晶体学信息。采用Tecnai G2 F30透射电子显微镜(TEM)对双联协控合金的相组成进行分析。沿DS方向制备室温拉伸实验试样,形状及尺寸如图2b所示。依据金属材料室温拉伸试验方法(GB/T 228.1—2021),采用3382电子万能试验机进行室温拉伸实验,加载方向与定向凝固方向平行,拉伸速率为0.75 mm/min,每个参数下进行3次拉伸实验。

图2

图2

Monel K-500合金拉伸试样及EBSD观察取样示意图

Fig.2

Schematics of sampling positions for EBSD analyses (a) and specimen dimensions of Monel K-500 alloy (b) (Red surfaces are the regions of EBSD observation)

2 实验结果与讨论

2.1 Monel K-500合金定向凝固的组织特征和晶体生长取向

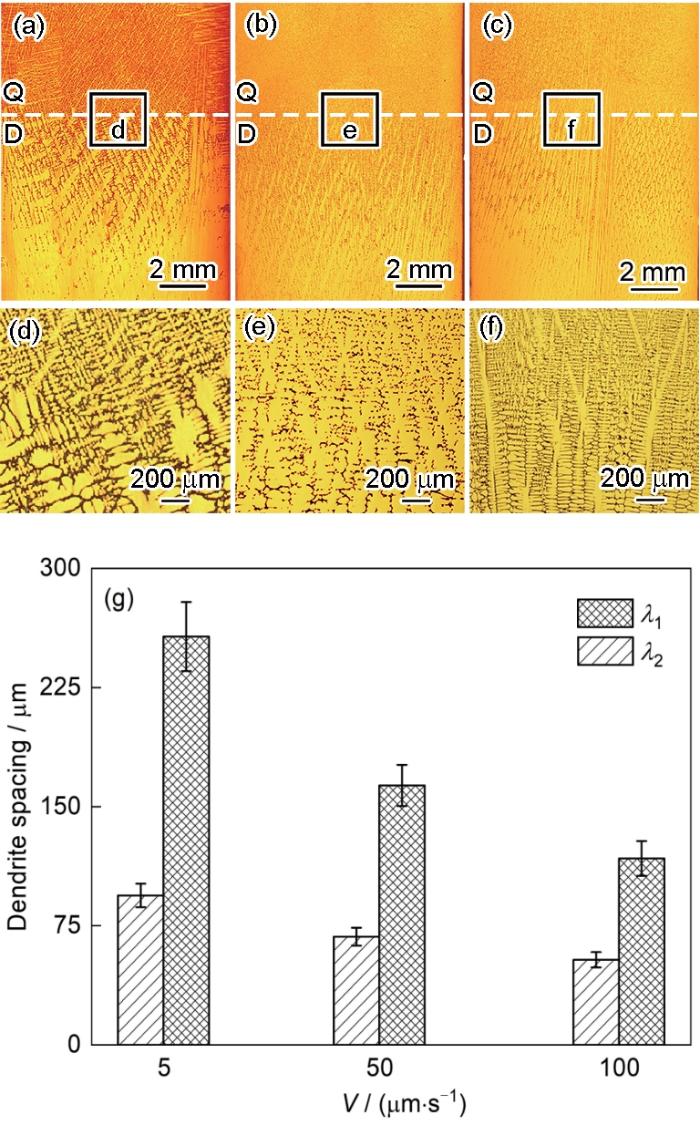

图3a~f是不同生长速率下Monel K-500合金的DS组织形貌。合金的微观组织由γ枝晶构成,根据凝固过程将微观组织划分为淬火凝固(Q)区和定向凝固(D)区。Q区具有显著细化的枝晶组织,且枝晶形貌无序分布;D区中树枝晶平行排列,枝晶主干生长方向均与定向凝固方向有一定夹角且在淬火界面处可观察到部分渗透到Q区的枝晶尖端。对合金DS过程中固/液界面前沿的温度梯度(G)进行测试发现,当V = 5、50和100 μm/s时,G分别为104、60和44 K/cm。受到传热过程的影响,随着V增大,合金在液态金属中的冷却时间减少,当V由5 μm/s增大至100 μm/s时,凝固界面处G减小约42%。研究[22]表明,合金成分一定时,合金定向凝固的微观组织主要受到V与G的影响。定向凝固合金的枝晶主干间距(λ1)与温度梯度和生长速率之间的变化关系满足[23]:

图3

图3

不同生长速率下Monel K-500合金的定向凝固组织形貌及枝晶间距

Fig.3

Microstructures (a-c) and locally high magnified images (d-f) of directionally solidified Monel K-500 alloy at growth rates (V) of 5 μm/s (a, d), 50 μm/s (b, e), and 100 μm/s (c, f), and primary dendrite trunk spacing (λ1) and secondary dendrite arm spacing (λ2) (g) (Q—quenching region, D—directional solidified region)

式中,A为与材料特性参数相关的函数;C0为合金成分。由

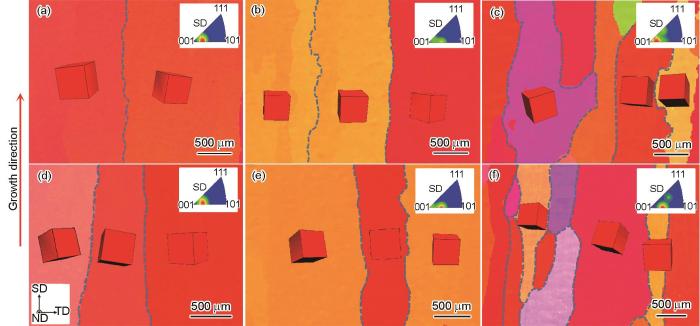

DS过程中,梯度分布的温度场与γ枝晶的竞争生长使得样品中晶粒取向与择优生长方向<001>基本保持一致,如图4所示。当V = 5 μm/s时,大角度晶界平行于凝固方向(SD),γ相位向聚集于反极图<001>极点附近,表明γ相具有<001>纤维织构。V = 50和100 μm/s时,微观组织中晶粒数和横向晶界增多,织构强度降低。这是由于V增大时合金凝固界面前沿的溶质扩散不充分,成分过冷度增大,进而导致形核率增大,合金中形成与择优生长方向不同取向的晶粒[24,25]。DS-TP条件下,合金晶体分布特征依然为平行分布的粗大柱状晶组织,且γ相具有<001>织构。这是因为固溶热处理过程主要降低了单相合金微观偏析,时效温度与时间主要影响了析出相的尺寸和数量。923 K保温过程中,合金发生脱溶反应,基体中γʹ相开始逐渐形核、长大。而在Monel K-500合金中析出相尺寸一般小于100 nm,且均匀分布于基体相中,因此析出相对合金粗大的枝晶组织和晶体结构影响很小,双联协控制备合金的枝晶形貌和晶体分布特征与定向凝固合金基本一致。

图4

图4

DS和DS-TP条件下Monel K-500合金中γ相的晶体取向分布

Fig.4

Crystal orientation distributions of γ phase in Monel K-500 alloys processed by DS (a-c) and DS-TP (d-f) at growth rates of 5 μm/s (a, d), 50 μm/s (b, e), and 100 μm/s (c, f) (SD—solidification direction, ND—normal direction, TD—transverse direction; red cubes are the unit cells of corresponding grain)

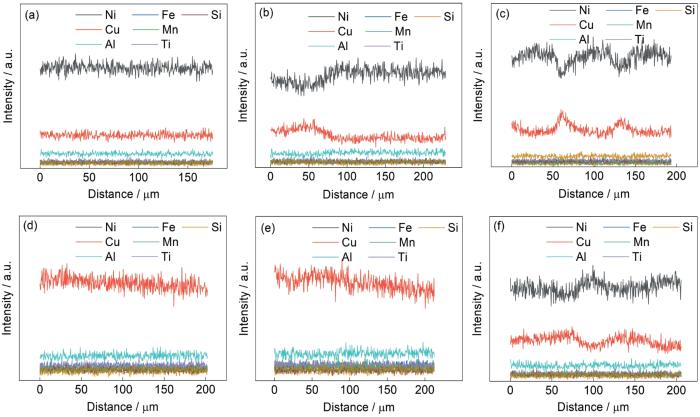

图5

图5

DS和DS-TP条件下Monel K-500合金枝晶界面处的元素分布

Fig.5

Element distributions of dendrite interface in Monel K-500 alloy processed by DS (a-c) and DS-TP (d-f) at growth rates of 5 μm/s (a, d), 50 μm/s (b, e), and 100 μm/s (c, f)

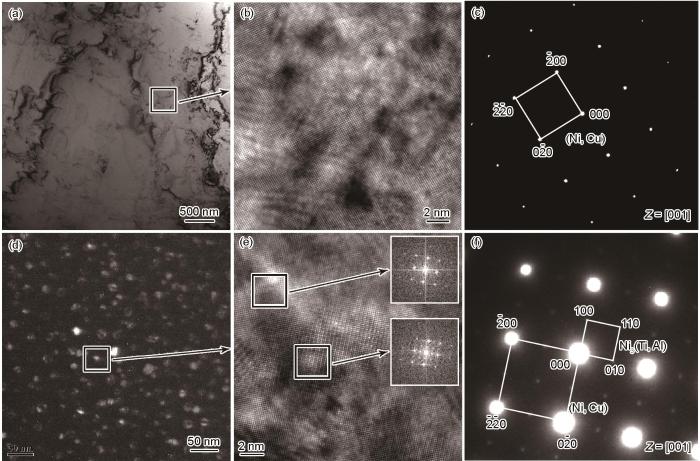

采用TEM进一步分析了DS和DS-TP条件下,V = 5 μm/s时Monel K-500的微观结构。DS条件下,明场(BF)像中观察到试样由单一相构成(图6a)。高分辨TEM (HRTEM)和选区电子衍射(SAED)结果表明,定向凝固合金由(Ni, Cu)相构成(图6b和c)。DS-TP条件下,由TEM暗场(DF)像可见,合金基体中均匀无规则地分布着纳米球状析出相(图6d)。所选区域的HRTEM像中发现析出相与基体相的原子边界较为模糊且部分区域的快速Fourier变换(fast Fourier transform,FFT)图显示出2套衍射花样(图6e)。由析出相的SAED花样可以看出,基体γ相为具有fcc晶体结构的(Ni, Cu)相,析出γʹ相为具有有序L12结构的Ni3(Al, Ti)相,这两相具有共格界面(图6f)。上述结果表明,双联协控Monel K-500合金定向凝固阶段形成基体γ相,经时效热处理后γʹ相在基体中发生脱溶反应析出。这是由于γʹ相在873~973 K经长时间时效热处理后析出[5],定向凝固过程中,试样在液态金属中的迅速冷却不满足γʹ相析出条件。

图6

图6

DS和DS-TP条件下Monel K-500合金微观组织TEM分析

Fig.6

TEM analyses of Monel K-500 alloys processed by DS (a-c) and DS-TP (d-f) at growth rate of 5 μm/s (Insets in Fig.6e show the fast Fourier transform (FFT) patterns) (a, d) bright field (BF) and dark field (DF) images (b, e) high-resolution TEM (HRTEM) images (c, f) selected area electron diffraction (SAED) patterns

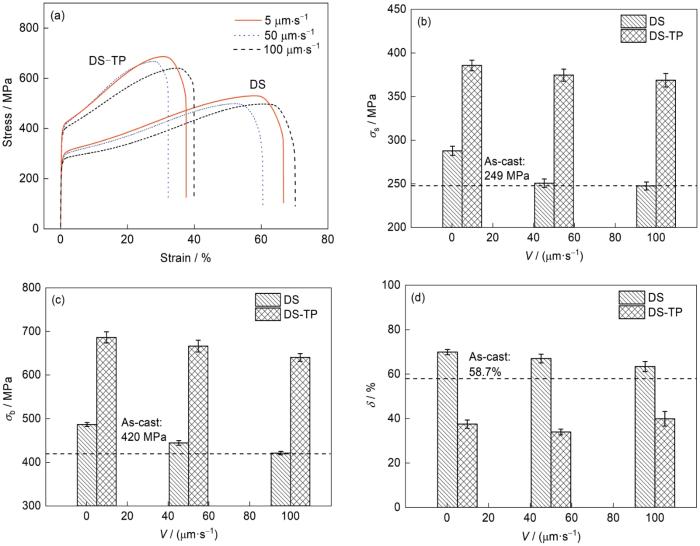

2.2 定向凝固和双联协控条件下Monel K-500合金的力学性能

对DS和DS-TP条件下Monel K-500合金沿定向凝固方向的室温力学性能进行分析,结果如图7所示。图7a表明,相比于DS合金,DS-TP合金的强度和均匀变形阶段的加工硬化率均显著增大,而延伸率减小。γʹ相的析出是合金力学性能提高的主要因素,在合金拉伸变形过程中,可通过绕过或切过机制阻碍位错运动从而提高合金的强度和加工硬化率[28]。图7b和c分别为DS和DS-TP条件下,合金的屈服强度与抗拉强度。DS条件下,随着V增大,元素微观偏析增大,合金的固溶强化作用减小[29],晶界结合力减小,导致力学性能降低。此外,在拉伸变形过程中,横向大角度晶界处易形成应力集中,裂纹在横向晶界处萌生,导致合金力学性能下降。因此,随着V从5μm/s 增大到100 μm/s,DS合金的屈服强度与抗拉强度分别从288和487 MPa减小至248和421 MPa。相比于DS合金,在V = 5、50和100 μm/s时,DS-TP的屈服强度分别提升约34%、49%和49%,抗拉强度分别提升约41%、50%和52%。热处理过程对V = 50和100 μm/s快速定向凝固合金的力学性能提升更加显著。这主要是由于固溶热处理后,快速定向凝固合金的微观偏析减小更加显著,固溶强化作用提高,合金的强度提升更大。图7d是不同条件下Monel K-500合金的延伸率。DS条件下,随着V增大,微观偏析增强和横向晶界增多导致拉伸断裂过程中晶界处更易发生裂纹的萌生和扩展,使得合金的延伸率由69.9%减小至63.4%。DS-TP条件下,随着V增大,合金的延伸率呈现出先减小后增大的特征。仅通过微观偏析和晶界分布特征无法准确解释延伸率变化规律,因此需要对合金塑性变形和断裂机制进行研究以阐明微观组织对合金延伸率的作用机制。

图7

图7

DS和DS-TP条件下Monel K-500合金的拉伸性能

Fig.7

Tensile performances of Monel K-500 alloys processed by DS and DS-TP

(a) stress-strain curves (b) yield strength (σs) (c) ultimate tensile strength (σb) (d) elongation (δ)

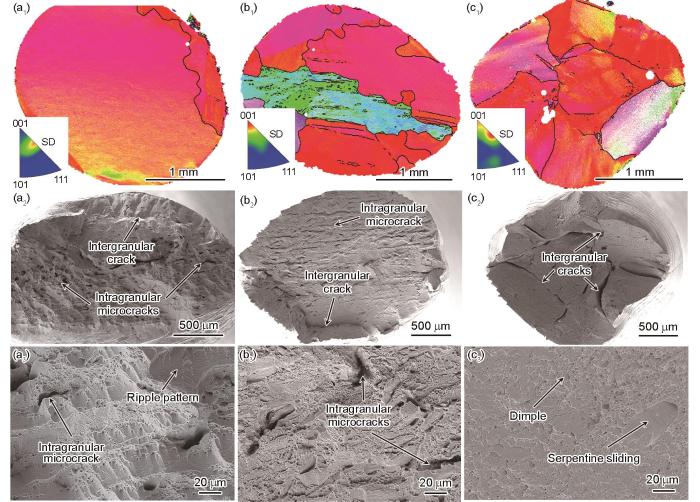

2.3 双联协控条件下Monel K-500合金的断裂机制

图8是双联协控Monel K-500合金在拉伸断裂后靠近断口区(图2a中Ⅰ区) γ相的晶体取向分布。可以看出,沿SD方向晶体取向偏离择优生长方向<001>,且部分晶粒内形成应力诱导的大角度晶界。对比晶粒取向和晶界分布发现,V = 5 μm/s试样截面处主要存在2个晶粒,塑性变形后,粗大晶粒的局部旋转变形使得不同区域取向差较大。在V = 50和100 μm/s试样中,晶粒数量显著增加,但晶粒尺寸仍为数百微米,且不同晶粒尺寸和取向差异较大。粗晶中发生了局部的晶体旋转和变形,而较细晶粒变形相对较小。上述结果表明,不均匀的晶体分布特征和粗大的晶粒尺寸导致合金在塑性变形过程中发生了不均匀变形[30,31],随着V增大,晶粒细化对双联协控合金协调变形能力的提升有限。图8a2~c2表明样品断口中出现了大量微裂纹,将裂纹分布特征与图8a1~c1大角度晶界分布进行对比,发现较大裂纹的形成位置与大角度晶界位置基本对应,表明宽而深裂纹的形成来源于沿大角度晶界的开裂。图8a3~c3是宏观断口的微观形貌,V = 5和50 μm/s合金样品中可以观察到部分窄而短的晶内微裂纹与韧窝交错分布。当V = 100 μm/s时,样品中晶内无微裂纹形成,大量剪切韧窝中夹杂部分蛇形花样。裂纹分布特征表明,随着V增大,晶粒尺寸减小,裂纹由穿晶与沿晶混合扩展模式转变为以穿晶为主的扩展模式。同时,不同V条件下,断口中分布的大量韧窝表明采用双联协控技术制备的合金均发生微孔聚集型断裂且具有良好的塑性。

图8

图8

DS-TP条件下Monel K-500合金拉伸断裂试样断口附近晶体取向分布和断口形貌

Fig.8

Grain orientation distributions (a1-c1), and low (a2-c2) and high (a3-c3) magnified SEM images of Monel K-500 alloys processed by DS-TP at growth rates of 5 μm/s (a1-a3), 50 μm/s (b1-b3), and 100 μm/s (c1-c3)

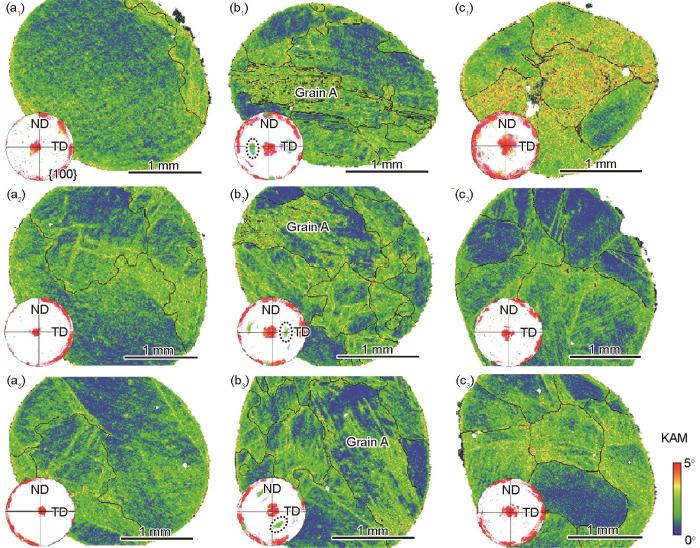

图9为断裂后双联协控Monel K-500合金不同横截面(图2a中Ⅰ~Ⅲ区)的局部取向差角分布图及其对应的法向(ND)-横向(TD)投影面极图。局部取向差角分布图中红色与绿色表示具有较高位错密度的区域。如图9a1~c1所示,在靠近断口区(I区),相比于V = 5 μm/s,V = 100 μm/s时双联协控合金的高位错密度区在整个样品内分布更加均匀。合金失效过程中,相比于均匀变形区,颈缩区会发生更剧烈的塑性变形,且晶粒细化有利于减少晶界处的位错塞积[32],降低应力集中,提高合金延伸率。图9b1中极图表明,V = 50 μm/s合金中A晶粒取向与择优生长方向偏差较大,而且A晶粒的位错密度显著高于相邻晶粒,说明柱状杂晶的存在导致合金内部产生了应力集中,导致合金提前开裂,延伸率降低。试样均匀变形区(Ⅱ和Ⅲ区)中,如图9a2~c3所示,大角度晶界附近和部分晶粒内位错密度较大。晶界处的高位错密度来源于塑性变形过程中晶界对位错运动较强的阻碍能力。随着变形加剧,晶界影响区扩大和不同滑移系位错的交互作用使得部分晶粒内发生了局部的位错塞积[33]。比较Ⅰ区与Ⅱ、Ⅲ区极图发现,均匀变形区试样沿定向凝固方向的晶体取向更加集中于<001>方向,均匀变形阶段合金仍保持较大的织构强度,晶体旋转主要在法向和横向进行。

图9

图9

DS-TP条件下Monel K-500合金拉伸试样不同区域内局部取向差角分布图及其对应的极图

Fig.9

Kernel average misorientation (KAM) distributions and pole figure (insets) in regions I (a1-c1), II (a2-c2), and III (a3-c3) in Fig.2a of the tensile specimen of Monel K-500 alloys processed by DS-TP at growth rates of 5 μm/s (a1-a3), 50 μm/s (b1-b3), and 100 μm/s (c1-c3) (The dotted circles in Figs.9b1-b3 show the projection of grain A on the pole figure)

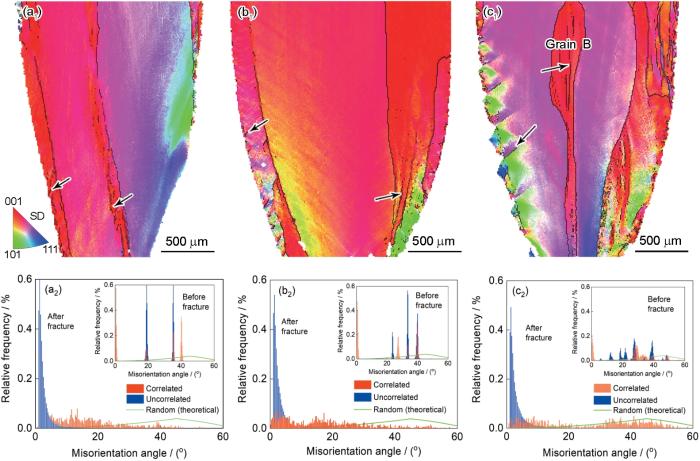

对断裂后试样颈缩区纵截面(图2a中Ⅳ区)晶体取向进行分析,以研究粗大柱状晶组织对合金力学性能的影响机制。图10a1~c1是不同V条件下Monel K-500合金的晶体取向分布图。可以看出,拉伸变形后柱状晶粒细化并拉长,在靠近断口处变形加剧且晶粒局部取向朝<111>方向偏转。颈缩过程中,试样表面发生更加剧烈的塑性变形从而诱发晶界形成。大角度晶界附近形成的晶界则来源于晶界影响区逐渐向晶体内的扩展。变形过程中,位错塞积首先产生在晶界处,在晶界附近萌生低角度晶界。低角度晶界处更易发生应力集中,随着变形加剧,低角度晶界取向差增大并转变为大角度晶界[34]。因此,图10a1~c1中箭头标注的应力诱导大角度晶界主要分布于晶界附近与样品表面。对比不同V条件下晶界形态和分布发现,V = 5 μm/s时,试样的粗大柱状晶粒中横向晶界很少且主要分布于大角度晶界附近。这主要是由于位错沿定向凝固方向运动受晶界阻碍作用较小,从而在晶粒内形成平行于定向凝固方向的应力诱导大角度晶界。而当V = 100 μm/s时,双联协控合金样品中存在大量横向晶界。以晶粒B为例,晶粒中的位错沿定向凝固方向运动受阻,易在晶粒内形成位错塞积,导致晶粒B内形成的大角度晶界数显著大于相邻晶粒。图10a2~c2是断裂前后样品的取向差角分布图。可以看出,与断裂前样品相比,断后样品晶体取向差角分布由高角度向低角度偏移,相邻晶粒取向差在低角度形成强峰,无关晶粒取向差形成多个面包峰且逐渐与随机晶体取向分布趋势一致,说明双联协控合金塑性变形过程中柱状晶体旋转变形倾向于以取向差减小和织构强度减弱的方式进行。

图10

图10

DS-TP条件下Monel K-500合金断口纵截面晶体取向及断裂前后样品的取向差角分布图

Fig.10

Grain orientation distributions of longitudinal fracture section (Arrows show the grain boundaries formed during plastic deformation) (a1-c1) and misorientation distributions (a2-c2) of Monel K-500 alloys processed by synergetic modulation at growth rates of 5 μm/s (a1, a2), 50 μm/s (b1, b2), and 100 μm/s (c1, c2) (Insets show the misorientation distributions of Monel K-500 alloys before fracture)

3 结论

(1) 在定向凝固条件下,Monel K-500合金中γ相具有<001>纤维织构。随着生长速率减小,DS合金横向晶界减少和织构强度增强的同时微观偏析减弱。当生长速率由100 μm/s降低至5 μm/s时,DS合金的屈服强度、抗拉强度和延伸率分别增大至288 MPa、487 MPa和69.9%。

(2) 在定向凝固与固态相变双联协控条件下,γ相中生成均匀分布的γʹ沉淀强化相,相比于定向凝固,DS-TP合金的微观偏析显著减弱。当生长速率为5 μm/s时,DS-TP合金的屈服强度与抗拉强度分别提高了34%和41%。随着生长速率增大,DS-TP合金的屈服强度与抗拉强度均减小,而延伸率先减小后增大。

(3) 双联协控Monel K-500合金的拉伸断裂形式为微孔聚集型断裂。拉伸断裂过程中,偏离择优生长方向的杂晶中更易产生应力集中,导致合金提前开裂。晶粒细化能够促进颈缩区内位错的均匀分布,而横向晶界阻碍了位错沿拉伸方向运动,导致晶粒内部产生位错塞积。粗大柱状晶晶界协调变形能力差,晶界处应力高度集中,随着生长速率增大,合金裂纹扩展由沿晶与穿晶混合扩展模式转变为穿晶为主的扩展模式。

参考文献

Effect of applied potential on the tribocorrosion behaviors of Monel K500 alloy in artificial seawater

[J].

Pitting corrosion behaviour of Monel-400 alloy in chloride solutions

[J].

Pitting corrosion behavior of Monel-400 alloy in 3.5 wt pct NaCl sodium chloride solution has been investigated using the cyclic potentiodynamic anodic polarization technique. The effects of chloride ion concentration, pH values and different temperatures on the pitting parameters were determined. The morphology of the pits produced after anodic polarization treatments were inspected by scanning electron microscope (SEM). The results indicated that, the increase in chloride ion concentration shifts Epit and Eprot of the alloy toward negative values and the pitting potential is much more dependent on pH value in the basic region. The breakdown of passivity with increasing temperature may be due to kinetic changes of passivating films and dissolution rate of the alloy in its passive state.

Corrosion failure analysis on the copper alloy flange by experimental and numerical simulation

[J].

Microstructure and corrosion resistance of Ni-Cu alloy fabricated through wire arc additive manufacturing

[J].

Precipitation in the Ni Cu-base alloy Monel K-500

[J].

Precipitation of strengthening phase in 718Plus alloy during early aging

[J].

718Plus合金时效初期强化相的析出规律

[J].

Microstructure and mechanical properties of a Monel K-500 alloy fabricated by directed energy deposition

[J].

The effect of isothermal heat treatment on hydrogen environment-assisted cracking susceptibility in Monel K-500

[J].

Failure analysis of K-Monel 500 (Ni-Cu-Al alloy) bolts

[J].

Hot workability and microstructure control in Monel®400 (Ni-30Cu) alloy: An approach using processing map, constitutive equation and deformation modeling

[J].

High-resolution prediction of quenching behavior using machine learning based on optical fiber temperature measurement

[J].

Effect of TiC precipitation on the corrosion behavior of Monel K500 alloy in 3.5 wt.% NaCl solution

[J].

Hot workability of cast and wrought Ni-42Cu alloy through hot tensile and compression tests

[J].

Dynamic recrystallization in Monel400 Ni-Cu alloy: Mechanism and role of twinning

[J].

Effect of chemical composition on microstructure, strength and wear resistance of wire deposited Ni-Cu alloys

[J].

Distinct difference between peri-eutectic and eutectic growth in ternary Fe-Ni-Ti alloy

[J].

Effect of solution cooling rate on microstructure evolution and mechanical properties of Ni-based superalloy ATI 718Plus

[J].

Corrosion behaviour of stainless steels and a single crystal superalloy in a ternary LiCl-KCl-CsCl molten salt

[J].

An integrated microporosity model of 3D X-ray micro-tomography and directional solidification simulations for Ni-based single crystal superalloys

[J].

Effect of solidification processing parameters on the cellular spacings in the Al-0.1wt% Ti and Al-0.5wt% Ti alloys

[J].

Effects of solidification rate and temperature gradient on microstructure and crystal orientation of Co32Ni40Al28 alloys

[J].

Microstructure and mechanical properties of CoCrCuFeNiTi0.8 high-entropy alloy prepared by directional solidification

[J].

定向凝固CoCrCuFeNiTi0.8高熵合金的组织与力学性能

[J].

Effect of growth rate on microstructure evolution in directionally solidified Ti-47Al alloy

[J].

Formation of dendrites and strengthening mechanism of dual-phase Ni36Co30Fe11Cr11Al6Ti6 HEA by directional solidification

[J].

Microstructure, microsegregation pattern and the formation of B2 phase in directionally solidified Ti-46Al-8Nb alloy

[J].

Bulk tracer diffusion in CoCrFeNi and CoCrFeMnNi high entropy alloys

[J].

Design of cuboidal γ/γ' coherent microstructure and its stability in low-density Co-Ni-Al-Mo-Cr-Ti/Nb/Ta superalloys

[J].

低密度Co-Ni-Al-Mo-Cr-Ti/Nb/Ta系列高温合金方形γ/γ'共格组织设计及其稳定性

[J].

Formation mechanism and coupling prediction of microporosity and inverse segregation: A review

[J].Microporosity and inverse segregation are two common casting defects mainly caused by solidification shrinkage, which are detrimental to the mechanical properties of components, especially to the fatigue performance and ductility. Numerous efforts have been put into the investigation on microporosity and inverse segregation independently. However, few work has been done to establish a theoretical model for predicting the two defects simultaneously, whereas they often interact with each other and the formation of microporosity may exert a beneficial effect on inverse segregation. In this review, the coupling models for prediction of microporosity and inverse segregation were introduced. Firstly, the mechanisms and the predicting models for the two defects were summarized separately. Microporosity is a resultant of solidification shrinkage and gas segregation. Therefore, the porosity was previously categorized into two types: shrinkage porosity and gas porosity. More recent porosity models have combined the effect of pressure drop induced by feeding, the evolution of pores radius, the decrease of gases solubility in the liquid and the gas rejection at the solid/liquid interface, which provide rather good approximation to experimental results. As for inverse segregation, it is mainly caused by the suction of interdendritic liquid which is generally rich in solute. Therefore, determination of the feeding velocity is crucial for most inverse segregation models. Then, through the analysis of the underlying interaction between microporosity and interdendritic feeding flow, the coupling methods for prediction of the two defects were reviewed. Most of the models have added porosity into the continuity equation to amend the feeding velocity and utilized the “local solute redistribution equation” to get the solute concentration profiles. A new coupling model recently proposed by the present authors, based on analyses of the redistribution of gases element as well as the alloying element, is also in this route. The result shows that for Al-4.5%Cu (mass fraction) alloy solidified in a columnar dendrites structure, the predicted fraction of microporosity is a little smaller than that of Poirier's model, and the increase of initially dissolved hydrogen in the melt will decrease the solute enrichment in the interdendritic liquid. Microporosity seems to reduce the flow needed to compensate the solidification shrinkage, thus the solute segregation gets reduced. Finally, several suggestions were proposed, including the treatment of pore radius, eutectic shrinkage and gas porosity precipitated during eutectic reaction, etc.

微观孔洞和逆偏析缺陷的形成机理与耦合预测研究进展

[J].本文首先分别总结了微观孔洞和逆偏析2种凝固缺陷的形成机理及各自预测模型的发展,然后对二者的耦合预测模型发展做了概括总结,最后重点介绍了近期作者所建立的一个新的耦合预测模型。该模型首先利用气体元素在液-固-气三相中的分配规律,结合因液相在枝晶间补缩通道内流动受阻引起的局部压降,建立了一个新的微观孔洞预测模型;然后结合微观孔洞的析出对糊状区枝晶间补缩液流的影响规律,对经典的“局部溶质再分配方程”进行修正,得到一个新的逆偏析解析模型。针对以柱状枝晶方式定向凝固的Al-4.5%Cu (质量分数)合金的计算结果表明,凝固过程中微观孔洞的形成,会补偿糊状区中的凝固收缩,从而减少枝晶间的补缩液流,使糊状区枝晶间溶质富集程度减小,最终使逆偏析得到缓解。

Orientation anisotropy and strain localization during elevated temperature tensile deformation of single crystal and bi-crystal Ni-based GTD444 superalloy

[J].

Microstructures and tensile deformation behavior of directionally solidified Mg-xGd-0.5Y alloys

[J].

定向凝固Mg-xGd-0.5Y合金的微观组织及拉伸变形行为

[J].

Correlation between microstructure heterogeneity and multi-scale mechanical behavior of hybrid LPBF-DED Inconel 625

[J].

Atomistically informed crystal plasticity analysis of deformation behavior of alloy 690 including grain boundary effects

[J].

Investigation of deformation mechanisms in an advanced FeCrAl alloy using in-situ SEM-EBSD testing

[J].