镁合金因其密度低、比强度高、阻尼性能好和良好的可回收性而受到广泛关注[1~6]。然而,与铝合金或钢相比,镁合金的强塑性匹配和耐腐蚀性能较差,因此其在工业领域的广泛应用仍受到限制。合金化是改善镁合金力学性能的有效方法之一[7,8]。加入稀土(RE)元素Gd和Y后,镁合金展现出显著的时效硬化效应,其强度大幅提高,这是由于稀土元素在α-Mg基体中的固溶度随着温度的降低而急剧下降,经时效处理后,大量高密度的亚稳β′相在α-Mg基体棱柱面上析出[9~11]。然而,强化相会使合金塑性急剧下降,时效处理后镁合金的伸长率明显降低[12]。进一步添加Zn元素后,Gd和Y等稀土元素与Zn结合在Mg基体中形成具有长周期堆垛有序(LPSO)结构的第二相[13],具有LPSO相的Mg-RE-Zn合金因其优异的常温和高温力学性能而受到广泛关注。

Mg-RE-Zn合金中常见的LPSO相有多种分类方式:按堆积顺序可分为6H、10H、14H、18R和24R型,其中14H和18R最为常见[14];按相形貌可分为层状LPSO和块状LPSO,其中层状LPSO多分布于α-Mg基体中,而块状LPSO则分布于晶界处[15]。层状LPSO相可通过增加基面滑移的临界分切应力(CRSS),激活α-Mg基体中的非基面滑移,从而同时提高Mg-RE-Zn合金的强度和塑性[16],而块状LPSO相能够通过颗粒诱导再结晶(PSN)机制促进合金的动态再结晶(DRX),有效细化晶粒组织[17]。层状和块状LPSO相的尺寸、分布和体积分数等均会对变形过程中位错的启动和滑移产生影响,并改变后续时效过程中的纳米级β′析出相的数密度等,因此LPSO相对镁合金的强塑性匹配具有重要影响。

镁合金具有hcp晶体结构,通过合金化可有效调控镁合金基体的层错能,进而对LPSO等第二相的析出行为产生影响[15],其中Yb元素是合金化的代表性元素。Zhang等[18]研究表明,铸态Mg-1Zn-0.4Zr-0.2Yb合金具有较低的层错能,这主要归因于微量Yb的添加,该合金具有优异的室温塑性(断裂 伸长率δf = 38.5%)和显著的加工硬化(加工硬化指数n = 0.38)效果。Xie等[19]研究了Yb元素添加对铸造Mg-9Gd-0.5Zn-0.2Zr合金时效析出行为的影响,发现在225 ℃等温时效过程中,Yb含量的增加提高了γ′、β′和β1相的数密度,镁合金的屈服强度增加了约84 MPa。

为进一步提升含LPSO相镁合金的综合力学性能,本工作拟通过添加不同含量的Yb元素,研究Yb含量对Mg-9Gd-4Y-1.2Zn-0.3Zr合金的室温和高温力学性能的影响,并基于多尺度结构表征,阐明新型超高强含Yb镁合金的强塑性机理,以期为高强度镁合金的设计开发提供更丰富的理论依据。

1 实验方法

采用真空熔炼炉熔炼制备Mg-9Gd-4Y-1.2Zn-0.3Zr-xYb合金(简称GWZK-xYb合金,x = 0、0.2、0.5、1.0,质量分数,%,下同),所用原料包括:商业纯Mg (99.998%)、Zn (99.980%)、Mg-30%Gd、Mg-30%Y、Mg-25%Zr和Mg-25%Yb。熔炼过程在CO2和SF6 (100∶1)混合气体的保护下进行,将熔体浇注到预热至350 ℃、直径为47 mm的模具中。铸态样品在520 ℃下均匀化8 h,然后用温水淬火。GWZK-xYb坯料在400 ℃预热15 min后进行反向挤压,挤压比为7∶1,挤出速率为0.3 mm/s,挤压后立即进行水淬,以保持高温下的显微组织。随后,将部分挤压棒材在200 ℃条件下进行峰值时效处理,时长为40 h。

采用Shimazu AG-X Plus拉伸试验机进行室温和高温拉伸实验。沿挤压方向加工狗骨状拉伸试样,其平行段尺寸为直径5 mm、长30 mm。高温拉伸试样在250 ℃下保温10 min后开始进行拉伸,室温及高温拉伸应变速率均为1 × 10-3 s-1,并对每组样品分别进行3次平行测试。

对镁合金试样的纵截面进行抛光和蚀刻(4%酒精硝酸溶液),并通过砂纸打磨、电解双喷和离子减薄制备透射电镜(TEM)分析样品。采用GX71光学显微镜(OM)对其进行金相分析;采用配有能谱仪(EDS)的JEM-7001F扫描电镜(SEM)对精细抛光后的镁合金样品进行微观组织及EDS分析。利用Image J软件对OM和SEM像中的第二相进行统计分析。采用Talos F200i TEM表征合金的晶粒和位错等微观结构,加速电压设置为200 kV。此外,采用高角度环形暗场-扫描透射模式(HAADF-STEM)技术表征合金元素分布。

2 实验结果

2.1 力学性能

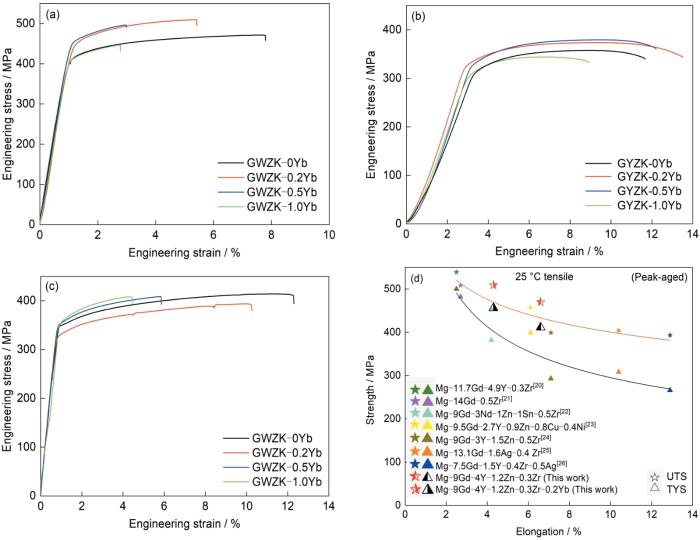

图1

图1

峰时效态GWZK-xYb合金的室温及250 ℃高温工程应力-应变曲线、挤压态GWZK-xYb合金的室温工程应力-应变曲线及高强度Mg-Gd系合金强度对比[20~26]

Fig.1

Engineering stress-strain curves of peak-aged GWZK-xYb alloys (a, b) and extruded GWZK-xYb alloys (c) at different temperatures and comparison of high-strength/peak-aged Mg-Gd series alloys prepared by similar extrusion process[20~26] (d) (Black and red curves are the fitting curves of tensile yield strength (TYS) and untimate tensile strength (UTS) of high strength Mg-Gd series alloys, respectively)

(a, c) at room temperature (25 oC) (b) at 250 oC

表1 峰时效态GWZK-xYb合金的室温和250 ℃高温拉伸性能及挤压态GWZK-xYb合金的室温拉伸性能

Table 1

Alloy | PA RT | PA ET | ES RT | ||||||

|---|---|---|---|---|---|---|---|---|---|

TYS MPa | UTS MPa | EL % | TYS MPa | UTS MPa | EL % | TYS MPa | UTS MPa | EL % | |

| GWZK-0Yb | 411 | 471 | 6.6 | 310 | 357 | 7.7 | 349 | 414 | 11.1 |

| GWZK-0.2Yb | 456 | 509 | 4.3 | 326 | 373 | 10.6 | 324 | 394 | 9.6 |

| GWZK-0.5Yb | 451 | 496 | 1.9 | 327 | 379 | 9.0 | 353 | 409 | 5.0 |

| GWZK-1.0Yb | 418 | 443 | 1.7 | 312 | 344 | 5.8 | 363 | 408 | 3.5 |

如图1a所示,除GWZK-1.0Yb合金外,添加Yb后,经峰值时效处理的GWZK-xYb合金的室温拉伸屈服强度(TYS)和抗拉强度(UTS)同时提升。其中,GWZK-0.2Yb合金具有最高室温强度,其TYS、UTS及延伸率分别为456 MPa、509 MPa及4.3%。

如图1b所示,GWZK-0.2Yb和GWZK-0.5Yb合金的高温强度均高于GWZK-0Yb合金,其中GWZK-0.2Yb合金强塑性匹配最好,其TYS、UTS及延伸率分别为326 MPa、373 MPa及10.6%。相比之下,GWZK-1.0Yb合金的强塑性略有下降。与GWZK-1.0Yb合金相比,GWZK-0Yb合金的UTS和延伸率分别降低了13 MPa和1.9%。

如图1c所示,挤压态GWZK-0Yb合金的室温TYS、UTS及延伸率分别为349 MPa、414 MPa及11.1%;添加微量(0.2%) Yb后,GWZK-0.2Yb合金的TYS和UTS分别降低至324和394 MPa;继续增加Yb含量后,GWZK-0.5Yb和GWZK-1.0Yb合金的TYS分别提升至353和363 MPa,此时合金的延伸率分别为5.0%和3.5%。

2.2 微观结构表征

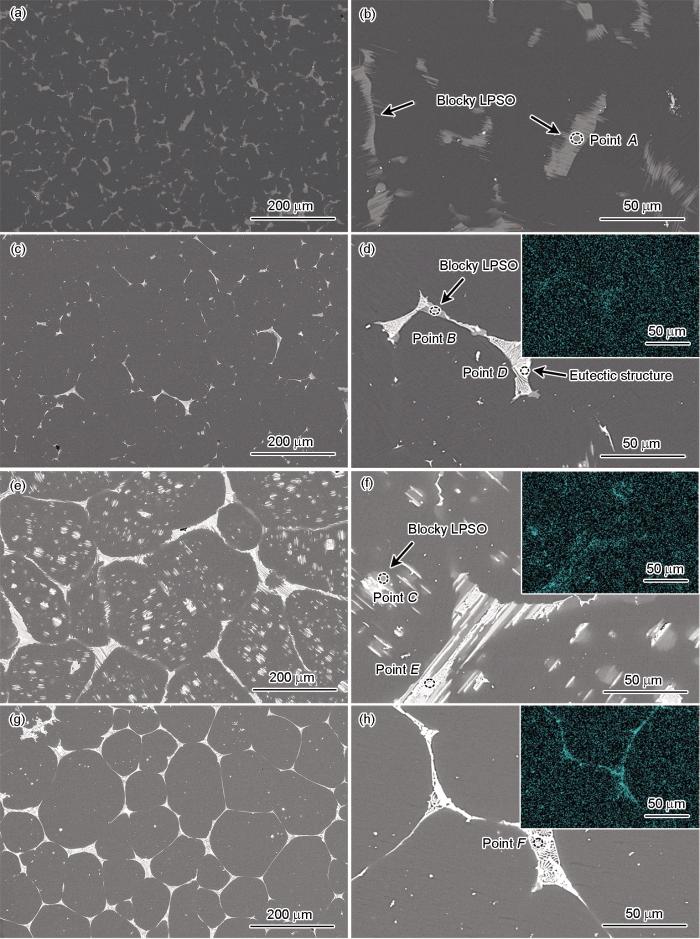

图2

图2

固溶态GWZK-xYb合金的SEM像及Yb元素的EDS面分布图

Fig.2

Low (a, c, e, g) and high magnified (b, d, f, h) SEM images of GWZK-0Yb (a, b), GWZK-0.2Yb (c, d), GWZK-0.5Yb (e, f), and GWZK-1.0Yb (g, h) alloys in the solid solution state (Insets in Figs.2d, f, and h are the corresponding EDS mappings of Yb element; LPSO represent long-period stacking ordered)

如图2c、e和g所示,固溶处理后,含Yb的GWZK合金晶界处依然有白色共晶组织分布。EDS结果表明(图2d、f、h中点D~F),这些共晶第二相的平均成分为Mg-(12.58 ± 0.9)(Gd, Y, Yb)-(6.2 ± 0.6)Zn (原子分数,%),即形成了富含Yb元素的Mg5(Gd, Y)第二相(简称Mg5RE相),与其他研究[27]的结果一致。通过对比GWZK-xYb合金晶界处Yb含量的变化(图2和表2),可以看出随着Yb含量的增加,金属间化合物Mg5RE相的数量逐渐增加。与此同时,GWZK-0.2Yb和GWZK-0.5Yb合金的晶界处还分布着呈灰色衬度的第二相(图2d和f中点B和C),该第二相成分与LPSO相一致,即该合金中仍存在一定的块状LPSO相;当Yb含量提高至1.0%后(图2g),样品中的灰色块状LPSO相基本消失,此时析出相以白色Mg5RE相为主。总而言之,Yb元素抑制了灰色块状LPSO相的形成,导致GWZK-0.2Yb合金中晶界处块状LPSO相和Mg5RE相的总体积分数变少;随着Yb含量增加至0.5%和1.0%,由于金属间化合物Mg5RE相的数量增加,其块状相的总体积分数逐渐增多。

表2

Table 2

| Point | Mg | Gd | Y | Zn | Yb |

|---|---|---|---|---|---|

| A | 88.73 | 3.49 | 2.95 | 4.82 | 0 |

| B | 89.90 | 3.07 | 2.54 | 4.36 | 0.14 |

| C | 89.11 | 3.65 | 2.67 | 4.36 | 0.22 |

| D | 83.35 | 7.22 | 3.09 | 5.53 | 0.81 |

| E | 81.72 | 6.80 | 3.54 | 7.00 | 0.94 |

| F | 78.51 | 6.31 | 4.07 | 6.14 | 4.98 |

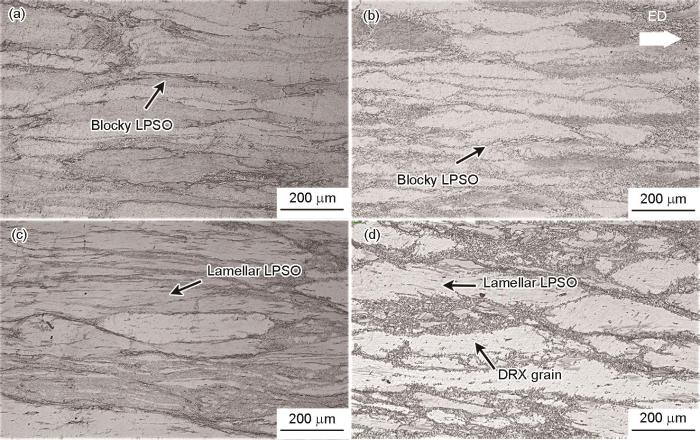

图3为挤压态GWZK-xYb合金的OM像。显微组织的晶粒尺寸呈双峰分布,即由细小的DRX区和粗大的形变区组成。未再结晶区的形变晶粒沿平行于挤压方向(ED)分布,宽度为100~200 μm。经挤压变形后,微米级LPSO相和Mg5RE相沿着ED呈流线型分布。对动态再结晶区域进行统计后发现,GWZK-0.2Yb合金的再结晶比例最高,约为(23.2 ± 0.8)%,而GWZK-0Yb、GWZK-0.5Yb和GWZK-1.0Yb合金的动态结晶区比例分别为(10.0 ± 2.5)%、(12.0 ± 1.5)%和(17.0 ± 0.7)%,即Yb元素的添加影响了GWZK合金的动态再结晶行为,这可能与Yb元素改变了第二相的种类与分布有关。

图 3

图 3

挤压态GWZK-xYb合金的OM像

Fig.3

OM images of as-extruded GWZK-0Yb (a), GWZK-0.2Yb (b), GWZK-0.5Yb (c), and GWZK-1.0Yb (d) alloys (ED—extrusion direction, DRX—dynamic recrystallization)

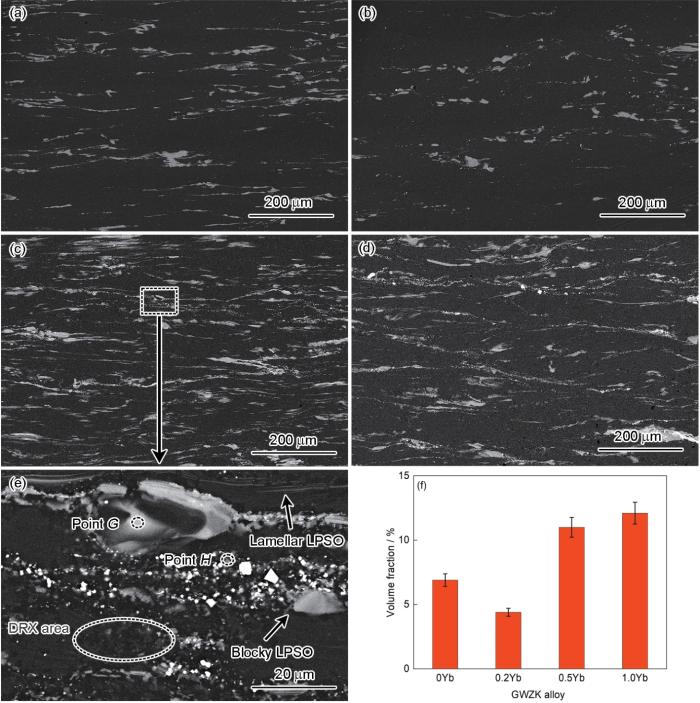

图4为挤压态GWZK-xYb合金的SEM像及合金中微米级块状第二相的体积分数。由于层状LPSO相衬度较弱,因此未统计层状区域体积分数。如图4a和f所示,GWZK-0Yb合金中的条带状LPSO相呈流线型分布,体积分数约为(6.9 ± 0.2)%。如图4b和f所示,添加0.2%Yb元素后,LPSO相的比例有所降低(约(4.4 ± 0.3)%)。当Yb含量为0.5%时,合金中微米级块状第二相的体积分数增加至(11.0 ± 0.3)%,LPSO相仍呈流线型分布(图4c和e中点G,如表3所示),而Mg5RE相经挤压变形后破碎(图4c和e中点H,如表3所示)。如图4d和f所示,GWZK-1.0Yb合金中同样包含沿挤压方向呈流线型分布的块状LPSO相以及破碎的Mg5RE相,这可能源自Mg5RE相经热变形后发生的动态相变,相关文献[30]中也有类似报道,GWZK-1.0Yb合金中微米级块状第二相的体积分数为(12.1 ± 0.3)%。

图4

图4

挤压态样品的SEM像及不同样品中微米级第二相的体积分数

Fig.4

SEM images of GWZK-0Yb (a), GWZK-0.2Yb (b), GWZK-0.5Yb (c, e), and GWZK-1.0Yb (d) alloys in as-extruded state; and volume fraction of blocky phases in different samples (f)

表3

Table 3

| Point | Mg | Gd | Y | Zn | Yb |

|---|---|---|---|---|---|

| G | 87.80 | 3.50 | 3.55 | 4.95 | 0.20 |

| H | 83.95 | 6.71 | 3.56 | 5.13 | 0.65 |

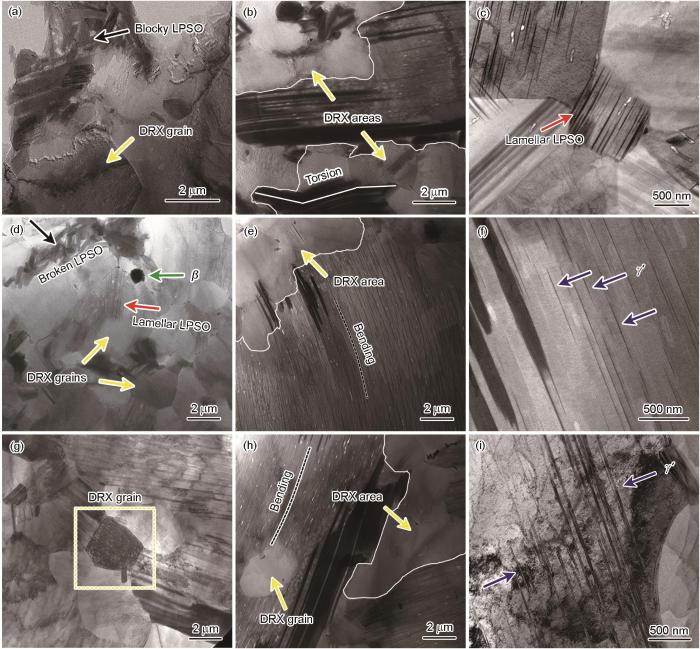

图5为峰时效态GWZK-xYb合金的TEM像。如图5a~c所示,GWZK-0Yb合金的动态再结晶晶粒内部存在有层状LPSO相,该第二相可有效阻碍动态再结晶晶粒的长大,其平均晶粒尺寸约为3.5 μm;此外,大量块状LPSO相分布于动态再结晶晶粒周围,这些块状LPSO经挤压后产生弯曲和扭折,吸收了挤压产生的应力。如图5d~f所示,添加0.2%Yb元素后,合金内部块状LPSO的形状同样极不规则,具有大量的破碎相和扭折带,而层状LPSO相则表现出较小的塑性变形。GWZK-0.2Yb合金中的动态再结晶晶粒数量更多,再结晶程度更高。然而,由于Yb元素增加了Gd、Y的固溶度,导致峰值时效后,基体中析出了更高密度的层状LPSO和γ′相。其中,γ′相是一种呈细针状层错结构的常见相,相关文献[19]中也有报道。高密度纳米级γ′相的析出抑制了动态再结晶晶粒的长大,平均DRX晶粒尺寸约为2.0 μm。如图5g~i所示,继续增加Yb含量至0.5%,合金中的DRX晶粒内部同样存在有高密度层状LPSO相,再结晶晶粒尺寸约为3.0 μm。未再结晶区域同样析出了一定数量的层状LPSO相。与0.2%Yb合金相比,GWZK-0.5Yb合金中层状LPSO相的数量有所降低且γ′相析出较少。

图5

图5

峰时效态GWZK-xYb合金的TEM表征

Fig.5

TEM characterizations of the peak-aged GWZK-0Yb (a-c), GWZK-0.2Yb (d-f), and GWZK-0.5Yb (g-i) alloys (White lines Figs.5b, e, and h represent bending and twisting)

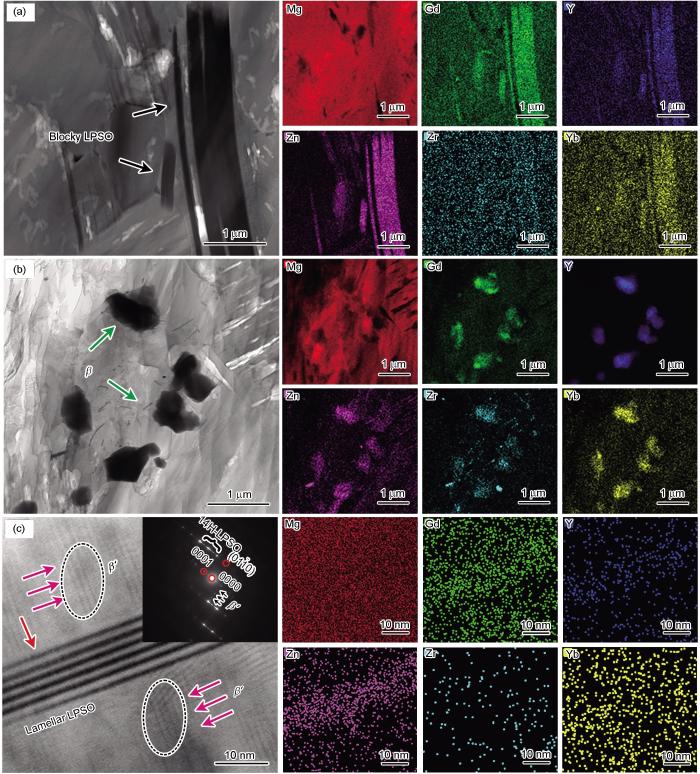

图6为峰时效态GWZK-0.2Yb合金的HAADF-STEM结果。图6a为块状LPSO相的明场像及对应的EDS面分布图。可以看出,Gd、Y、Zn和Yb元素富集在晶界处的块状LPSO相之中。如图6b所示,GWZK-0.2Yb合金中动态析出相的为β相,主要包含Gd、Y、Yb和Zn等元素。图6c为峰时效态GWZK-0.2Yb合金的高倍TEM像及纳米级第二相对应的选区电子衍射(SAED)花样,电子束入射方向( B )平行于[2

图6

图6

GWZK-0.2Yb合金的高角度环形暗场-扫描透射电镜(HAADF-STEM)像、EDS面分布图及SAED花样

Fig.6

Low (a, b) and high (c) magnified HAADF-STEM images and corresponding EDS mappings of the peak-aged GWZK-0.2Yb alloy (Inset in Fig.3c is SAED pattern of the layered region (under B = <2

3 分析讨论

3.1 Yb含量对Mg-9Gd-4Y-1.2Zn-0.3Zr合金微观组织的影响

Yb作为一种重稀土元素,在镁合金中展现出诸多与类稀土元素Y和重稀土元素Gd相似的改性性质,如均在镁合金中有较高的固溶度(> 8%),这一特性与轻稀土元素La、Ce等存在显著差异。因此,Yb可通过固溶强化和析出强化机制显著提高镁合金力学性能。本工作中,Mg-9Gd-4Y-1.2Zn-0.3Zr合金中的微米级第二相主要为LPSO相。随着Yb元素的添加,块状LPSO相的析出逐渐被抑制。与GWZK-0Yb合金相比,GWZK-0.2Yb合金中LPSO相的含量明显减少;GWZK-0.5Yb合金中同时出现了LPSO相与Mg5RE微米级第二相;而Yb含量较高的GWZK-1.0Yb合金中第二相基本均转变为Mg5RE相,其原因可能为Yb元素与Mg、Zn、RE元素之间发生了复杂的热力学交互作用,从而改变了Mg-9Gd-4Y-1.2Zn-0.3Zr合金的相组成[19]。

微米级第二相种类和含量的变化将会对GWZK-xYb合金后续成型过程中的动态再结晶行为产生重要影响[31]。挤压态GWZK-xYb合金呈现出典型的同时包含再结晶和未再结晶区域的双组态晶粒组织,如图2所示。GWZK-xYb合金挤压成型过程中,大量块状LPSO相分布于动态再结晶晶粒周围。然而,由于块状LPSO相具有良好的塑性变形能力(弯曲、扭折等),可有效承载挤压产生的内应变,从而导致由PSN机制引发的周围α-Mg基体的动态再结晶受到限制,即LPSO相可抑制镁合金的动态再结晶。GWZK-0Yb合金中的LPSO相体积分数较高,GWZK-0.5Yb和GWZK-1.0Yb合金中的部分Mg5RE也可以动态转变为LPSO相,因此上述3个合金的再结晶程度相对较低(10%~17%)。相比之下,GWZK-0.2Yb合金经均匀化处理后,基体中LPSO相体积分数较低,对动态再结晶的抑制作用有限。因此,GWZK-0.2Yb合金再结晶程度最高(约23.2%)。

时效处理后,GWZK-0.2Yb合金依据典型的时效析出序列析出纳米级β′相,起到更好的强化效果。此外,固溶至基体中的Yb元素可降低镁合金基体的层错能,因此微量Yb (0.2%)的添加可提高GWZK-0.2Yb合金基体中γ′相析出的数密度,从而提升含Yb合金的综合力学性能。

3.2 Yb添加对Mg-9Gd-4Y-1.2Zn-0.3Zr合金力学性能的影响

本工作通过微量Yb (0.2%)的添加以及后续时效处理,实现了GWZK-0.2Yb合金强塑性的协同提升,与其他同类镁合金相比具有一定的优越性。GWZK-xYb合金的超高强度主要归因于未再结晶晶粒的织构强化、动态再结晶晶粒的细晶强化、微米级LPSO相以及动态析出γ′和β′相等的第二相强化。其中,再结晶程度及其对应的织构强度对于提升变形镁合金的综合力学性能至关重要,这是因为在强织构条件下的拉伸过程中,<c + a>滑移的Schmid因子相对较高因而更易启动,然而,<c + a>位错的滑移阻力高出<a>等滑移数十倍,因此其对应合金的屈服强度会显著增加[32]。

挤压态下,GWZK-0Yb合金在室温下的TYS和UTS分别为349和414 MPa,而GWZK-0.5Yb和GWZK-1.0Yb合金的TYS分别提升至353和363 MPa,这与上述3个合金保持较低的动态再结晶程度结果一致。由于挤压态镁合金的未再结晶区域通常表现为强织构类型,因此具有显著的织构强化效应。挤压态GWZK-0.2Yb合金的再结晶程度更高,因此该合金的TYS和UTS均有所降低,分别为324和394 MPa。在室温条件下,随着Yb含量的增加,挤压态样品的TYS和UTS呈现出先降低后升高的趋势,这是因为此时其固溶强化效果低于LPSO相的强化效果,因此具有较低体积分数块状LPSO相分布的GWZK-0.2Yb合金强度较低。

峰时效处理后,GWZK-0.2Yb合金中析出更多纳米级β′相。在{11

4 结论

(1) Yb的添加对挤压态下GWZK合金强度提升并不明显,但时效后其强度相比于GWZK-0Yb合金显著提升。其中峰时效态GWZK-0.2Yb合金综合力学性能最佳,室温下TYS、UTS及伸长率分别为456 MPa、509 MPa及4.3%,高温下TYS、UTS及伸长率分别为326 MPa、373 MPa及10.6%。峰时效态GWZK-0.2Yb合金的强度提升主要来源于时效后基体内致密析出的层状LPSO相及β′和γ′相。

(2) 微量Yb (0.2%)的添加对Mg-9Gd-4Y-1.2Zn-0.3Zr合金的显微组织有显著影响,主要包括抑制了LPSO相的形成并促进了后续β′和γ′相的析出。

(3) 中等含量Yb (0.5%)的添加会引入更多脆性Mg5RE相,从而影响GWZK-0.5Yb合金的塑性水平,添加1.0%Yb会进一步减少后续时效过程中β′和γ′相的析出而降低强度。

参考文献

Remarkably enhanced mechanical properties of Mg-8Gd-1Er-0.5Zr alloy on the route of extrusion, rolling and aging

[J].

Grain refinement and strength enhancement in Mg wrought alloys: A review

[J].

Recent research and developments on wrought magnesium alloys

[J].

Development and application of plastic processing technologies of magnesium alloys

[J].China has the most abundant magnesium resources in the world. Magnesium and its alloys have the advantages of low density, high specific strength, good damping property, and exceptional electromagnetic-shielding and energy-storage characteristics. They are one of the most promising lightweight materials. The enhanced applications of magnesium alloys can save energy and reduce emissions and are significant to the new Chinese energy strategy. However, magnesium alloys have a hexagonal close-packed structure and exhibit relatively low ductility. A bottleneck in expanding the application of magnesium alloys is improving the ductility of magnesium alloys. For more than ten years, efforts have been made to improve the ductility and plastic deformation ability. Progress has been made in plastic-processing technologies of magnesium alloys. The novel alloy design theory “solid solution strengthening and ductilizing” and advanced preparation technologies such as “melt self-purification through varying temperature” have been established. Series of new magnesium alloys with good ductility and corresponding alloy grades have been developed, where the impurity content of iron can be reduced to below 10 × 10-6; the elongation was more than 60% for ultrahigh plasticity magnesium alloys and is above 10% for the ultrahigh-strength magnesium alloys (UTS > 550 MPa). New plastic-processing technologies, such as asymmetric extrusion, asymmetric rolling, asymmetric modification, cyclical multipass upsetting and squeezing, expansion control large ratio forging, and extrusion and forging composite forming, have been developed. These newly developed magnesium alloys and processing technologies weaken the basal texture in wrought magnesium alloys, improving the formability of sheets, tubes, profiles, and forgings and their product quality and reducing their product cost. These technologies have been successfully applied in the processing of magnesium sheets, pipe profiles, and forgings.

镁合金塑性加工技术发展及应用

[J].我国是世界上镁资源最为丰富的国家,镁及镁合金具有质轻、比强度高、阻尼减振、电磁屏蔽性能优良、储能特性好等优点,是最有潜力的轻量化材料之一,其推广应用对节能减排和能源转型战略具有重要意义。但镁合金具有密排六方晶体结构,塑性变形能力较差。如何改善镁合金的塑性变形能力是扩大镁合金应用的瓶颈问题之一。本文综述了10多年来,世界各国在改善镁合金塑性、提升镁合金塑性变形能力等方面所做的大量工作,及在镁合金塑性加工技术等方面取得的重要进展。发展了“固溶强化增塑”新型镁合金设计理论和“熔体变温自纯化”等关键制备技术,形成了一批高塑性变形镁合金材料和牌号,其中杂质Fe含量可降到10 × 10<sup>-6</sup>以下,超高塑性镁合金延伸率可达到60%以上,超高强度(抗拉强度大于550 MPa)镁合金延伸率可以达到10%以上;开发了非对称挤压、非对称轧制、非对称改性、往复循环多道次镦挤开坯技术、扩收控制大比率锻造技术、挤锻复合成形技术等一批镁合金新型塑性加工技术。这些合金和技术使变形镁合金基面织构显著弱化,明显提高了变形镁合金板材、管型材和锻件的塑性成形能力和制品质量,产品成本大幅度降低,在板材、管型材和锻件制备加工中实现了成功应用。

Advancement in research of rolled magnesium alloys with high performance

[J].

高性能轧制镁合金研究进展

[J].

Research and applications of magnesium in China

[J].

中国Mg材料研发与应用

[J].经过50多年的发展, 中国已经成为世界上最大的Mg原材料生产国. 2000年, 师昌绪等5位院士联合向国家科技部提出了加速我国Mg工业发展的建议, 促成了科技部启动“十五”科技攻关重大专项“镁合金应用开发及产业化”, 拉开了我国大规模Mg材料研究和应用的序幕. 经过10年的发展, 我国在先进镁合金材料、表面处理技术和镁合金加工技术方面都取得了极大的进步, 正在从Mg生产大国向Mg研发应用的强国迈进.

Microstructure evolution mechanism of new low-alloyed high-strength Mg-0.2Ce-0.2Ca alloy during extrusion

[J].

新型低合金化高强Mg-0.2Ce-0.2Ca合金挤压过程中的组织演变机理

[J].基于Pandat相图设计了一种新型的Mg-0.2Ce-0.2Ca (质量分数,%)三元合金,经常规挤压变形后的屈服强度约364 MPa、总合金化含量约0.4%,实现了高强度、低合金化。对挤压过程中不同阶段的组织进行表征,发现Mg-0.2Ce-0.2Ca合金中的孪晶存在于挤压的整个阶段,表现出了高的孪晶迁移阻力,并且在挤压变形的中后期,部分动态再结晶晶粒沿着孪晶变体交割区域形核,导致孪晶界面比例显著降低。Mg-0.2Ce-0.2Ca合金在挤压变形的早期阶段即存储了大量<c + a>位错,这些位错的运动阻力大,因此位错主导的回复再结晶机制直至挤压变形的后期才大量启动,并直接促进了该阶段镁合金中高比例超细晶粒的形成。分析认为,Mg-Ce-Ca合金挤压过程中微观组织演变的主要原因是Ca元素的添加提升了Mg基体孪晶运动阻力,且Ce、Ca元素的共添加诱导了多系滑移。

Grain refinement of as-cast Mg-RE alloys: Research progress and future prospect

[J].Magnesium rare-earth (Mg-RE) alloy castings with a large size and complex structure exhibit versatile prospects in critical aircraft, aerospace, and defense fields owing to their ultralow density, excellent specific strength, and high-temperature resistance. The grain refinement of cast Mg-RE alloys can significantly improve their strength, plasticity, toughness, and casting performance, which are critical for expanding their applications. In this work, the grain refinement mechanism of Mg alloys by introducing RE elements and heterogeneous particles is first discussed based on the classical theory of constitutional supercooling and heterogeneous nucleation. Various grain refinement technologies for Mg-RE alloy casting using chemical and physical methods are comprehensively summarized. Further, the influence of grain refinement on the casting performance, mechanical properties, and corrosion properties of Mg-RE cast alloys is thoroughly discussed. Finally, the deficiencies and development trends of the current grain refinement of Mg-RE alloys are discussed from the point of actual application requirements.

铸造Mg-RE合金晶粒细化行为研究现状与展望

[J].轻质高强耐热的镁稀土(Mg-RE)合金大型复杂铸件在航空航天、国防军工装备轻量化等方面展现出独特的优势。对铸造Mg-RE合金进行晶粒细化处理能够显著改善合金的强度、塑韧性以及铸造工艺性能,对拓宽其应用领域意义重大。本文首先基于成分过冷和异质形核,探讨了稀土元素及外加颗粒对镁合金晶粒细化的影响。归纳了适用于铸造Mg-RE合金的化学、物理细化方法及其作用机制,并系统论述了晶粒细化对铸造Mg-RE合金铸造工艺性能、力学性能及腐蚀性能的影响。最后面向Mg-RE合金的实际应用需求,对其细化处理方面存在的不足和发展趋势进行了探讨。

Precipitation and hardening in magnesium alloys

[J].

Enhanced strength and ductility of Mg-Gd-Y-Zr alloys by secondary extrusion

[J].

A new class of ordered structure between crystals and quasicrystals

[J].This paper briefly reviews the development and research history of strutures of the solid matters, and highlight two new strcutures of precipitates in Mg alloys found by our group recently. (1) The isothermally aged (Mg, In)2Ca "Laves phase" contains two separate unit cells promoting the formation of five tiling patterns. The bonding of these patterns leads to the generation of the present phase but without any six-fold rotational symmetry in a long-range on the (0001)L basal plane, constrainted by the Penrose geometrical rule, completely different from the known Laves phases. (2) The MgZn five-fold nanodomain structure is self-assembled by two separate unit cells (72° rhombus structure: MgZn2, and 72° equilateral hexagon structure: MgZn) under the Penrose geomotrical constraints, containing 2D five-fold symmetry locally and short-range ordered C14 and C15 Laves structures. These two special structures without any translational symmetry on the normal plane while periodical arrangement along the normal direction, are a new class of intermediate structures between crystals and quasicrystals. And thus, they does not belong to any crystals or 2D ordered structures in quasicrystals or quasicrystal approximants.

一类介于晶体与准晶体之间的有序结构

[J].本文简要介绍了固态物质结构研究的发展历程,并着重介绍了作者课题组最近在凝聚态结构物质上的新发现。(1) 与传统的Laves结构不同,等温时效析出的(Mg, In)<sub>2</sub>Ca “Laves相”包含2种晶胞单元,这2种单胞沿6个特定的方向排列,构成5种拼砌图案,这5种拼砌模型随机键合在一起,形成一个在(0001)<sub>L</sub>基面长程范围内不具有6次旋转对称的“C14”型Laves相。(2) Mg-Zn二元合金等温时效析出的纳米棒状相是由2种最小结构单元,即72°菱形结构单元(MgZn<sub>2</sub>)和72°等边六边形结构单元(MgZn),沿5个方向自组装而成的一个包含C14、C15等短程有序的Laves晶体相和二维5次旋转对称结构的纳米畴结构。(Mg, In)<sub>2</sub>Ca Laves相和Mg-Zn 5次纳米畴结构沿法线方向具有周期性的原子排列,然而在法平面上不具有任何平移周期性,是一类既不属于晶体相也不同于任何已发现的准晶体或准晶近似相的二维有序结构。

Ultra high-strength Mg-Gd-Y-Zn-Zr alloy sheets processed by large-strain hot rolling and ageing

[J].

LPSO structure and aging phases in Mg-Gd-Zn-Zr alloy

[J].

Mg-Gd-Zn-Zr合金中的LPSO结构和时效相

[J].为了研究Mg-Gd-Zn-Zr合金中的长周期堆垛有序(LPSO)结构的形成及其演化, 对铸态、固溶态和时效态Mg<sub>96.32</sub>Gd<sub>2.50</sub>Zn<sub>1.00</sub>Zr<sub>0.18</sub>合金的显微组织进行了观察. OM, SEM和TEM观察表明, 合金铸态组织由α-Mg固溶体、晶内层片状14H-LPSO结构和晶界处树枝状α-Mg+β-(Mg, Zn)<sub>3</sub>Gd共晶相组成; 500 ℃/35 h固溶处理后, 晶界处发生β→X的固态相变, 层片状X相也具有14H-LPSO结构; 再经200 ℃/128 h 峰时效处理后, 晶内析出椭球状$\beta^{\prime}$相和片状$\beta_{1}$相与14H-LPSO结构共存. 室温拉伸实验和Vickers硬度测试表明, 500 ℃/35 h+200 ℃/128 h处理改善了合金的力学性能, 抗拉强度为290.7 MPa, 屈服强度为162.5 MPa, Vickers硬度为108.0 HV, 延伸率为10.4%. 力学性能的改善与晶界、晶内的14H-LPSO结构及时效相等复合强韧化作用有关.

Achieving high strength-ductility synergy in a Mg97Y1Zn1Ho1 alloy via a nano-spaced long-period stacking-ordered phase

[J].

Compressive creep behavior of extruded Mg-4Sm-2Yb-0.6Zn-0.4Zr alloy

[J].

Dislocation structure in rapidly solidified Mg97Zn1Y2 alloy with long period stacking order phase

[J].

Achieving an ultra-high strength and moderate ductility in Mg-Gd-Y-Zn-Zr alloy via a decreased-temperature multi-directional forging

[J].

Excellent ductility and strong work hardening effect of as-cast Mg-Zn-Zr-Yb alloy at room temperature

[J].

The role of Yb content on the microstructural evolution and mechanical characteristics of cast Mg-9Gd-0.5Zn-0.2Zr alloy

[J].

Microstructure evolution and mechanical properties of a high strength Mg-11.7Gd-4.9Y-0.3Zr (wt%) alloy prepared by pre-deformation annealing, hot extrusion and ageing

[J].

Effects of Sm addition on microstructure evolutions and mechanical properties of high-strength Mg-Gd-Sm-Zr extruded alloys

[J].

Fabrication of high-strength Mg-Gd-Nd-Zn-Sn-Zr alloy via extrusion and aging

[J].

A novel Mg-Gd-Y-Zn-Cu-Ni alloy with excellent combination of strength and dissolution via peak-aging treatment

[J].

Effect of aging treatment on the precipitation behavior and mechanical properties of Mg-9Gd-3Y-1.5Zn-0.5Zr alloy

[J].

Achieving ultra-high strength in Mg-Gd-Ag-Zr wrought alloy via bimodal-grained structure and enhanced precipitation

[J].Mg-13.1Gd-1.6Ag-0.4 Zr (wt%) alloy was either iso-thermally extruded at 350 °C or differential-thermally extruded with respectively pre-heated billet at 500 °C and die at 350 °C. The iso-thermal extrusion leads to a near fully recrystallized structure and a [0001]//ED (extrusion direction) texture. In contrast, the differential-thermally extruded alloy develops a bimodal-grained structure composed of fine equiaxed recrystallized grains and coarse elongated unrecrystallized grains with a 011ˉ0//ED texture. The differential-thermally extruded alloy has a higher number density of precipitates after post-extrusion ageing than that of the iso-thermally extruded counterpart. Moreover, precipitation in the differential-thermally extruded alloy is further enhanced with cold rolling before ageing. Finally, the alloy obtains room temperature tensile yield strength of 421 MPa and ultimate tensile strength of 515 MPa via differential-thermal extrusion, cold rolling and ageing, mainly ascribed to the coupled strengthening from the bimodal-grained structure and enhanced precipitation. Strength of the alloy is noticeably higher than those of Mg-Gd(-Y)-Ag extruded alloys with similar compositions reported previously and is comparable to those of other high-strength Mg wrought alloys. The findings suggest that differential-thermal extrusion plus strain ageing is a suitable approach for achieving high strength in age-hardenable Mg alloys.

Effects of extrusion process on microstructure, precipitates and mechanical properties of Mg-Gd-Y-Zr-Ag alloys

[J].

Microstructure and mechanical properties of large-scale Mg-Gd-Y-Zn-Mn alloys prepared through semi-continuous casting

[J].Large-scale Mg-8Gd-4Y-1Zn-Mn (wt.%) alloy ingot with a diameter of 315 mm and a length of 2410 mm was prepared through semi-continuous casting. Chemical composition, microstructure and mechanical properties at different locations of the samples with as-cast, T4 and T6 heat-treated states, respectively, were investigated. No obvious macro segregation has been detected in the high-quality alloy ingot. The main eutectic structures at all different locations are composed of α-Mg, Mg3RE-type, Mg5RE-type and LPSO phases. At the edge of ingot, the unusual casting twins including $\text{ }\!\!\{\!\!\text{ 10}\bar{1}\text{2 }\!\!\}\!\!\text{ }$ extension twins and $\text{ }\!\!\{\!\!\text{ 10}\bar{1}\text{1 }\!\!\}\!\!\text{ }$ compression twins were observed due to the intensive internal stress. In T4 heat-treated alloy, the micro segregation was eliminated. The remained phases were α-Mg and LPSO phase. Combined with the remarkable age-hardening response, T6 samples exhibits improved mechanical properties at ambient temperature, which derives from the dense prismatic β' precipitates and profuse basal γ' precipitates.

Comparative studies on evolution behaviors of 14H LPSO precipitates in as-cast and as-extruded Mg-Y-Zn alloys during annealing at 773K

[J].

First-principles study of long-period stacking ordered-like multi-stacking fault structures in pure magnesium

[J].

Improved mechanical performance of double-pass extruded Mg-Gd-Er-Zr alloys with various rare earth contents

[J].

Multimodal microstructure of Mg-Gd-Y alloy through an integrated simulation of “process-structure-property”

[J].

“工艺-组织-性能”模拟研究Mg-Gd-Y合金混晶组织

[J].以Mg-8Gd-3Y-0.5Zr (GW83K)镁合金为研究对象,探索通过调控混晶显微组织来提高其力学性能的途径。将具有混晶组织的合金抽象为一种不同尺寸的晶粒嵌入到晶界中的颗粒复合体模型,在该模型中基体相为晶界,不同的颗粒相是不同尺寸的晶粒;然后基于Taylor关系的非局部塑性理论修正不同粒子嵌入到基体后对基体性能的影响,建立具有混晶组织特征的有限元平面应变细观力学模型。采用该模型模拟了含有混晶组织的GW83K镁合金在拉伸条件下的应力-应变行为,模拟结果对比实验数据验证了模型的有效性。在此基础上,通过真实时空相场模拟出的不同退火工艺下的混晶组织作为力学模型的几何输入参数,建立“工艺参数-混晶组织-力学性能”之间的关系。模拟结果对比发现,具有混晶组织的GW83K镁合金强度随平均晶粒尺寸的变化符合Hall-Petch关系,粗晶含量和分布显著影响着合金的塑性,当合金在623 K下退火90 min后对应的混晶组织可在保持高强度的同时有效提升塑性,为混晶组织的设计提供了参考。

Cold rollability improvement by twinning and twin-slip synergy in an Mg-Zn-Gd alloy with rare earth texture

[J].