随着海洋资源的大力开发及海洋基础设施建设需求增加,对满足恶劣条件的服役材料提出了耐腐蚀、轻量化、经济性等更高的要求。在钢筋混凝土结构中,混凝土中碱性物质在钢筋表面上形成氧化层,使钢筋处于钝化状态。然而,海水中游离的Cl-通过混凝土的孔隙或毛细管到达钢筋表面,改变钢筋的表面环境,使钢筋发生局部锈蚀。目前,延长钢筋锈蚀周期的方法包括使用实心不锈钢筋、环氧涂层钢筋、阻锈剂钢筋、不锈钢复合钢筋以及镀锌钢筋等[1]。研究[2,3]指出,考虑材料成本、维护活动以及耐腐蚀性能、力学性能等综合因素,不锈钢复合钢筋在生命周期成本中最具有吸引力,因此被广泛应用于海洋工程、核能核电、石油化工以及生物医疗等领域[4]。

鉴于此,本工作就不同压下率下复合材料近界面微观组织演变、界面夹杂物类型及元素分布特征等方面开展研究,以揭示复合界面动态再结晶机制和元素扩散行为规律,为采用热轧工艺制备性能良好的不锈钢复合材料提供理论支撑。

1 实验方法

复合坯覆层为304不锈钢无缝管,直径10 mm、壁厚3 mm;内芯为Q235碳钢棒,直径4 mm,圆柱坯料高度15 mm。在组坯之前,使用车床去除不锈钢管内壁和碳钢棒的表面污物,露出内部新鲜金属。处理后碳钢棒外径稍大于不锈钢管内径,将碳钢棒压入不锈钢管中,此时碳钢与不锈钢覆层之间有一定预紧力。复合坯主要化学成分如表1所示。

表1 不锈钢和碳钢的化学成分 (mass fraction / %)

Table 1

| Steel | C | Si | Mn | P | S | Cr | Ni | Fe |

|---|---|---|---|---|---|---|---|---|

| 304 | 0.05 | 1.00 | 2.00 | 0.022 | 0.008 | 19.1 | 8.5 | Bal. |

| Q235 | 0.17 | 0.80 | 1.00 | 0.045 | 0.040 | - | - | Bal. |

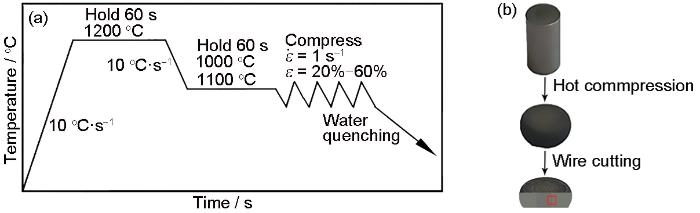

利用Gleeble-3800热模拟机进行高温压缩复合实验。压缩前在圆柱形试件侧面中心焊接热电偶,用于实时测量实验温度;在压头上涂抹机油并粘贴石墨片,以减小夹紧时试样与压头之间的摩擦力,并在温度高于900 ℃时在石墨片上粘贴Ta片。图1a为试样高温压缩实验流程图。为实现试样组织均匀化,首先将其加热至1200 ℃保温60 s,然后分别降温至1000和1100 ℃再保温60 s;之后开始高温压缩,应变速率(

图1

图1

热压缩实验流程图和压缩试样选取示意图

Fig.1

Thermal compression test flow-process diagram (a) and shematic of compression specimen selection (b) (

压缩完毕后,将试样沿径向切开,如图1b所示,打磨、抛光处理后的横截面先用4% (体积分数)的硝酸酒精溶液腐蚀10~20 s,清洗后用10%H2CrO4 (质量分数)溶液电解腐蚀120 s。采用Sigma 300场发射扫描电子显微镜(FESEM)及其附带的HKL CHANNEL5电子背散射衍射(EBSD)系统,研究复合钢筋近界面显微组织演变规律,并利用8050G场发射电子探针(EPMA)和DX-2700BH X射线衍射仪(XRD)分析界面元素扩散以及化合物析出情况。

2 实验结果与讨论

2.1 微观组织表征

2.1.1 复合近界面微观组织演变

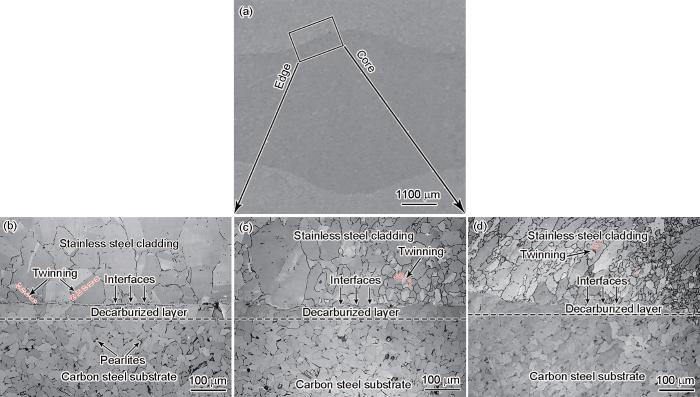

图2为不锈钢复合钢筋在变形温度1000 ℃时测量区域示意图(40%压下率)和不同压下率时复合界面显微组织的SEM像。可见,随着压下率的增大,界面形貌从薄膜(压下率20%)、不连续线(压下率40%)变为连续的球形状颗粒(压下率60%),并伴随着界面边界逐渐融入碳钢或不锈钢组织中,界面区域结合良好、趋于平滑。复合近界面微观组织可划分为3个区域:不锈钢区域、界面过渡区域、碳钢区域。界面过渡区域又划分为3层:靠近不锈钢区域的渗碳层(渗碳层边界如图中黑色虚线所示)、结合界面、靠近碳钢区域的脱碳层[12]。然而图2中界面过渡区域未观察到明显的沟状渗碳层(或者渗碳层宽度非常窄)。Liu等[13]和Jin等[14]的研究同样表明,经历高温变形的复合界面渗碳层分布不显著。这主要是由于当热变形温度超过奥氏体不锈钢的敏化温度(900 ℃)时,渗碳层内形成的脆性化合物已基本溶解;加之快速冷却效应,固溶于奥氏体中的C元素已达到过饱和状态,同时Cr元素扩散使得贫Cr区消失,即这个过程是C和Cr元素的扩散行为,而非晶界处Cr元素的贫化,有利于耐腐蚀性能和抗疲劳性能的提升。近界面脱碳层区域的晶粒尺寸明显大于碳钢基体,这是由于在冷却过程中珠光体能有效促进碳钢侧铁素体形核,在脱碳层C元素扩散充分,缺少珠光体组织,从而导致晶粒粗大。

图2

图2

不锈钢复合钢筋在1000 ℃时测量区域示意图(40%压下率)和不同压下率时复合界面显微组织的SEM像

Fig.2

Schematic of the measurement zone (a) and SEM images of the composite interface of composite stainless steel rebar with reduction rates of 20% (b), 40% (c), and 60% (d) at 1000 oC (Black dash lines in Figs.2b-d show the boundaries of carburized layer, and red dash lines show twin boundaries. The schematic of the measurement zone is illustrated by an example with reduction rate of 40%)

从图2可以看出,当压下率较小(20%)时,不锈钢侧大部分组织为粗大等轴晶粒,出现少量孪晶(孪晶界如图中红色虚线所示),无再结晶晶粒产生。随着压下率增大(40%),不锈钢侧部分组织呈现拉长趋势,原始大角度晶界呈锯齿状,大量动态再结晶晶粒通过应变诱导机制沿着晶界优先产生[15];少量孪晶呈细小状分布在晶体内部,孪晶的产生与奥氏体不锈钢的低层错能相关,层错能越低,孪生所需临界切应力越小,当压下率达到一定程度,内应力增至孪生临界切应力,孪生机制被激活而产生孪晶[16]。随着压下率继续增大(60%),晶粒垂直于压缩方向层状分布愈加明显,晶粒进一步细化,孪晶数量仍保持较低水平,此时位错、形变带等易于成为形核位置的缺陷增多,晶界数量也增多,再结晶晶粒数量显著增加,但尚未达到完全再结晶状态。这与Yanushkevich等[17]研究结果相符,奥氏体不锈钢晶粒细化形核机制通常为经典位错滑移控制的不连续动态再结晶。

此外,不同压下率时,碳钢侧晶粒均发生动态再结晶,晶粒细化均匀。相对于不锈钢侧,碳钢侧晶粒优先发生动态再结晶,这主要是由于复合材料异种金属力学性能差异造成应变配分不均匀,进而导致界面两侧晶粒动态再结晶的异步性[18]。另一方面,Mirzadeh等[19]研究发现,由于粗晶效应和溶质拖曳效应,不锈钢侧溶质原子在晶界处的偏聚对晶界的弓出施加拖曳力,从而延缓了动态再结晶的进程。这一现象可以通过适当提高变形温度得到缓解[20]。需要注意的是,不锈钢侧近界面沿界面方向动态再结晶程度不均匀(以40%压下率为例展示测量区域示意图2a),尤其是高压下率(40%、60%)近界面心部(图2c和d右侧区域)为大变形区域,动态再结晶晶粒优先随局部应变的增大而不断形核生长,并伴随小角度晶界吸收位错,使位错密度降低,进而发生小角度晶界向再结晶晶粒晶界(大角度晶界)的转化,导致近界面心部动态再结晶程度明显大于近界面边缘(图2c和d左侧)[21]。综上,不锈钢/碳钢复合材料的整体动态再结晶过程为:具有更高应变配分的碳钢侧率先发生动态再结晶,处于畸变能储存阶段的不锈钢侧累积变形达到临界值才开始进行动态再结晶;而对于不锈钢侧,近界面心部优先达到临界应变而出现动态再结晶晶粒,近界面边缘需不断产生位错塞积并积累足够的储存应变能才开始有动态再结晶晶粒产生,随后2者同时进行动态再结晶。

2.1.2 复合近界面动态再结晶机制

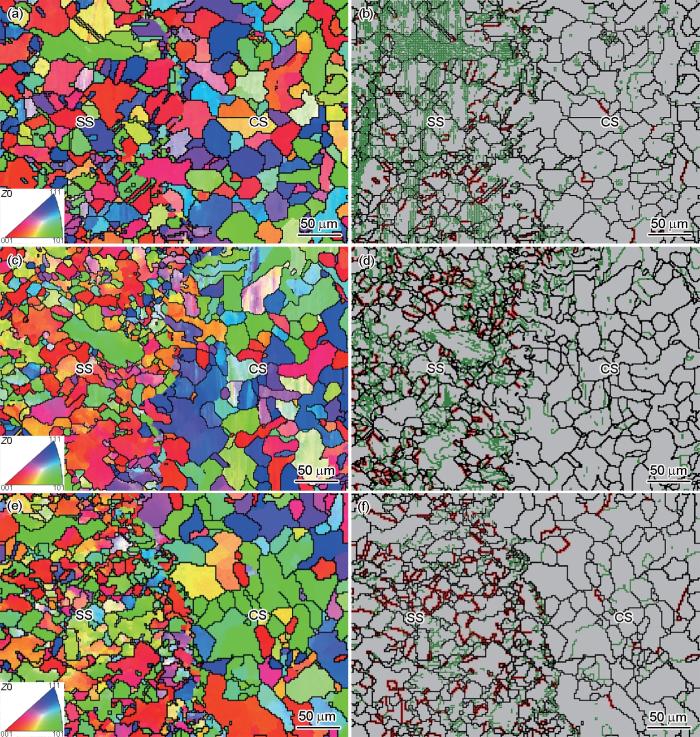

为进一步明确高应变速率下孪晶对动态再结晶机制的影响,采用EBSD对不同压下率的不锈钢复合钢筋试样进行分析。图3为304/Q235复合材料在变形温度1100 ℃不同压下率时复合界面的反极图和晶界图。晶界图(图3b、d和f)中绿色线代表小角度晶界(LAGBs,晶界取向差2°~15°),黑色线代表大角度晶界(HAGBs,晶界取向差≥15°),红色线代表Σ3孪晶界([111]/60°)。压下率为20%时,不锈钢侧少量的细小再结晶晶粒已表现出项链状形核特征,然而由于初始晶粒尺寸较大,使变形激活能增加,作为形核点的边界数量减少,导致较低的应变能不足以刺激大量再结晶晶粒产生,动态再结晶体积分数较低;小角度晶界聚集在大角度晶界附近密集分布,这是由于塑性变形迫使大角度晶界内部位错缠结,分割出高密度亚晶界,其取向差随晶粒的持续变形不断增大而转变成小角度晶界,如图3a和b所示。压下率增至40%时,再结晶晶粒继续形成,并开始不断消耗变形的亚结构,导致小角度晶界体积分数明显减少,再结晶晶粒数量增加,如图3c和d所示。压下率继续增至60%时,大角度晶界由于持久应变引起的边界迁移呈现愈加明显的锯齿状,而锯齿状晶界是通过膨胀机制成核的潜在位点[25],最终导致动态再结晶晶粒数量显著增加;但再结晶晶粒平均尺寸相较于低压下率并无明显变化,且残余未结晶区存在的小角度晶界分布稀疏,如图3e和f所示。此外,Σ3孪晶数量随压下率的增加而增加,且大部分Σ3孪晶是在再结晶区产生。

图3

图3

不锈钢复合钢筋在1100 ℃不同压下率时复合界面的反极图和晶界图

Fig.3

Inverse pole figures (IPFs) (a, c, e) and grain boundary diagrams (b, d, f) of the composite interface of composite stainless steel rebar with reduction rates of 20% (a, b), 40% (c, d), and 60% (e, f) at 1100 oC (The green, black, and red lines in Figs.3b, d, and f represent boundaries with 2° ≤ θ < 15°, θ ≥ 15°, and Ʃ3 twin boundaries, respectively. θ is misorientation angle of the boundary. SS—stainless steel, CS—carbon steel)

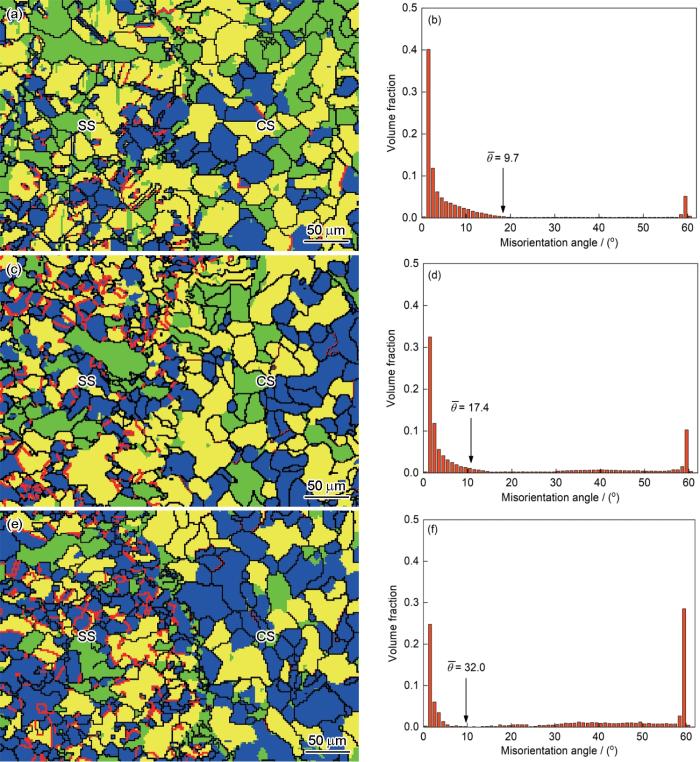

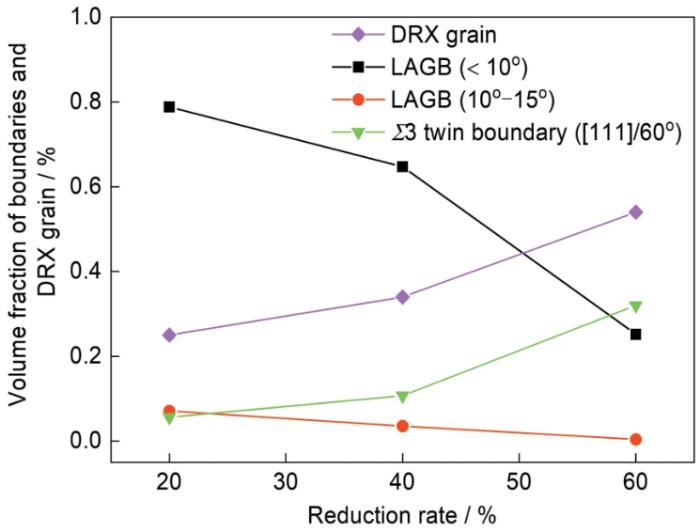

图4a、c和e为不锈钢复合钢筋在变形温度1100 ℃不同压下率时复合界面再结晶分布图。蓝色区域代表再结晶晶粒,黄色区域为亚晶粒,绿色区域表示变形晶粒,黑色线代表HAGBs,红色线代表Σ3孪晶界。可见,随着压下率从20%增加至60%,近界面不锈钢侧蓝色的再结晶区域不断增加,再结晶晶粒体积分数从25%增加到54%;绿色的变形区域和黄色的亚晶粒区域不断减少,相应的体积分数分别从29%、46%降低至14%、32%。这表明在持续变形过程中,绿色变形晶粒和黄色亚晶粒会逐渐向再结晶晶粒转变。

图4

图4

不锈钢复合钢筋在1100 ℃不同压下率时复合界面再结晶晶粒分布图和不锈钢侧晶界取向差分布直方图

Fig.4

Distributions of dynamic recrystallized grains (a, c, e) and corresponding stainless steel side grain boundary orientation distribution maps (b, d, f) of the composite interface of composite stainless steel rebar with reduction rates of 20% (a, b), 40% (c, d), and 60% (e, f) at 1100 oC (The green, yellow, and blue regions in Figs.4a, c, and e represent deformed, substructure, and recrystallized grains, respectively. The black and red lines in Figs.4a, c, and e represent boundaries with θ ≥ 15° and Ʃ3 twin boundaries, respectively.

如图4b、d和f为不锈钢复合钢筋在变形温度1100 ℃不同压下率时不锈钢侧晶界取向差分布直方图。可见,随压下率增大,小角度晶界体积分数逐渐减少,大角度晶界体积分数缓慢增加,但一阶共格Σ3孪晶体积分数显著增加,这充分说明Σ3孪晶界主要是由孪生产生,而非由小角度晶界转变。这种现象揭示了晶界取向差的不连续转变,与位错机制明显不同。当压下率增至60%时尤为明显,Σ3孪晶体积分数达到最大值(31.1%),低角度晶界体积分数为34.2%,主要集中在2°~5°。这是因为晶界迁移往往伴随着孪生,而孪生导致晶粒细化、晶界数量增加,这又是动态再结晶形核的有利场所。此外,伴随大角度晶界,尤其是Σ3孪晶界体积分数的增加,平均晶界取向差(

图5

图5

1100 ℃下不锈钢复合钢筋中不同角度晶界和动态再结晶晶粒体积分数随压下率的变化

Fig.5

Changes of the volume fractions of different grain boundaries and dynamically recystallized (DRX) grain with reduction rates at 1100 oC

因此,与变形温度为1000 ℃的复合界面微观组织相比,在1100 ℃、1 s-1的高应变速率和60%的高压下率条件下,较高的应变能和热能产生较高的晶界迁移驱动力,且大量Σ3孪晶可减小再结晶晶粒的边界能,增加晶界的迁移率,加速再结晶晶粒的形核和生长,最终形成均匀化程度较高的再结晶组织,界面两侧动态再结晶的异步性得到明显改善,复合界面表现出良好的变形协调性和结合性能。

2.2 界面化合物类型及元素分布表征

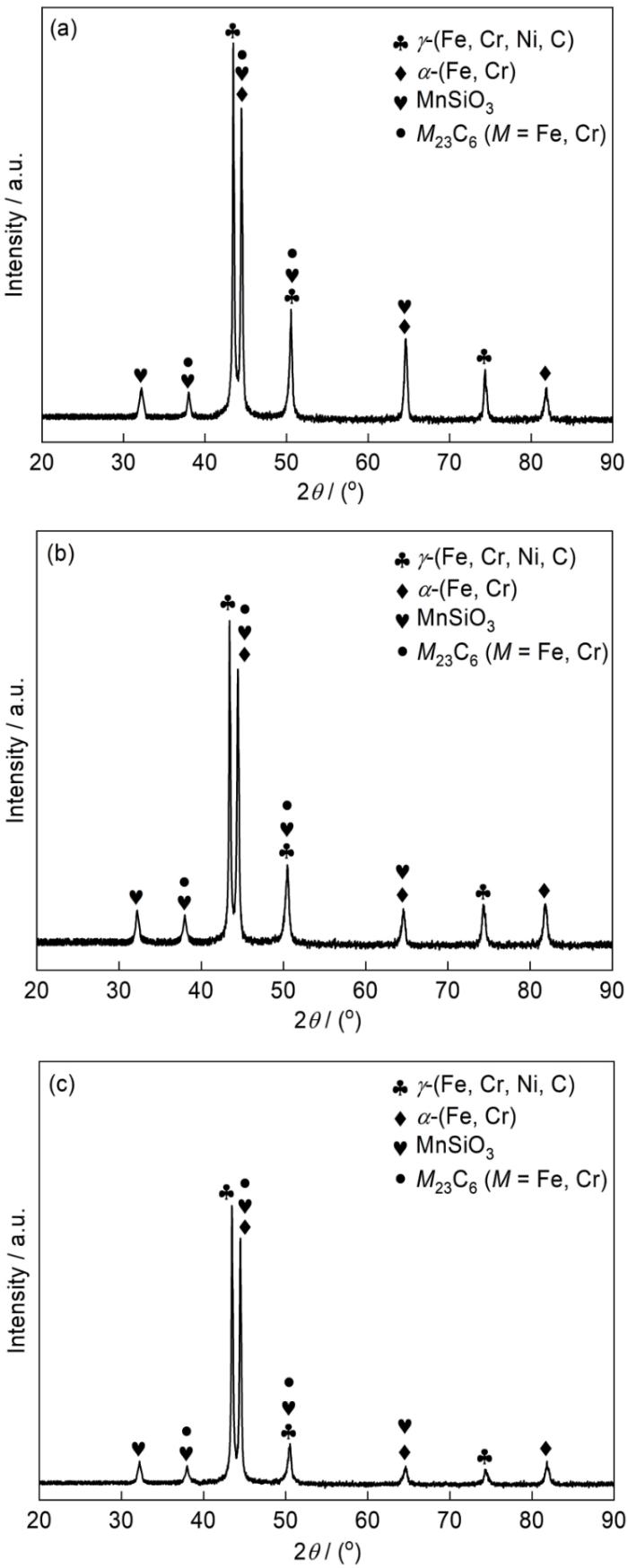

2.2.1 复合近界面化合物分析

图6为复合界面XRD谱。可见,不同压下率的衍射峰峰位基本一致且无明显偏移,说明晶体结构并未发生变化。但随压下率增大衍射峰峰值有所减弱,这是由于平均晶粒尺寸随压下率增大而减小,导致晶体择优取向较弱。界面处存在大量奥氏体相γ-(Fe, Cr, Ni, C)和铁素体相α-(Fe, Cr),还发现MnSiO3氧化夹杂物以及晶界析出相M23C6 (M = Fe, Cr)碳化物。李龙等[31]研究表明,根据金属氧化反应的ΔG-T关系曲线(ΔG为金属标准Gibbs自由能,T为热力学温度),1100 ℃下ΔG均表现出共同特征:ΔG(Al2O3) < ΔG(SiO2) < ΔG(MnO) < ΔG(Cr2O3) < ΔG(FeO) < ΔG(Fe3O4) < ΔG(NiO) < ΔG(Fe2O3) < 0,ΔG越小氧化反应越容易自发进行。MnSiO3氧化物的生成也可以归因于选择性氧化理论;Si元素具有最强的亲和力,其首先与O元素结合形成SiO2,之后与Mn元素结合形成MnSiO3。Liu等[32]研究同样表明近界面不锈钢侧存在M23C6碳化物,且残余应力区M23C6导致的晶间微孔极易形成晶间裂纹,这将会降低不锈钢侧的晶间抗腐蚀性能。

图6

图6

不锈钢复合钢筋在1100 ℃不同压下率时复合界面的XRD谱

Fig.6

XRD spectra of the composite interface of composite stainless steel rebar with reduction rates of 20% (a), 40% (b), and 60% (c) at 1100 oC

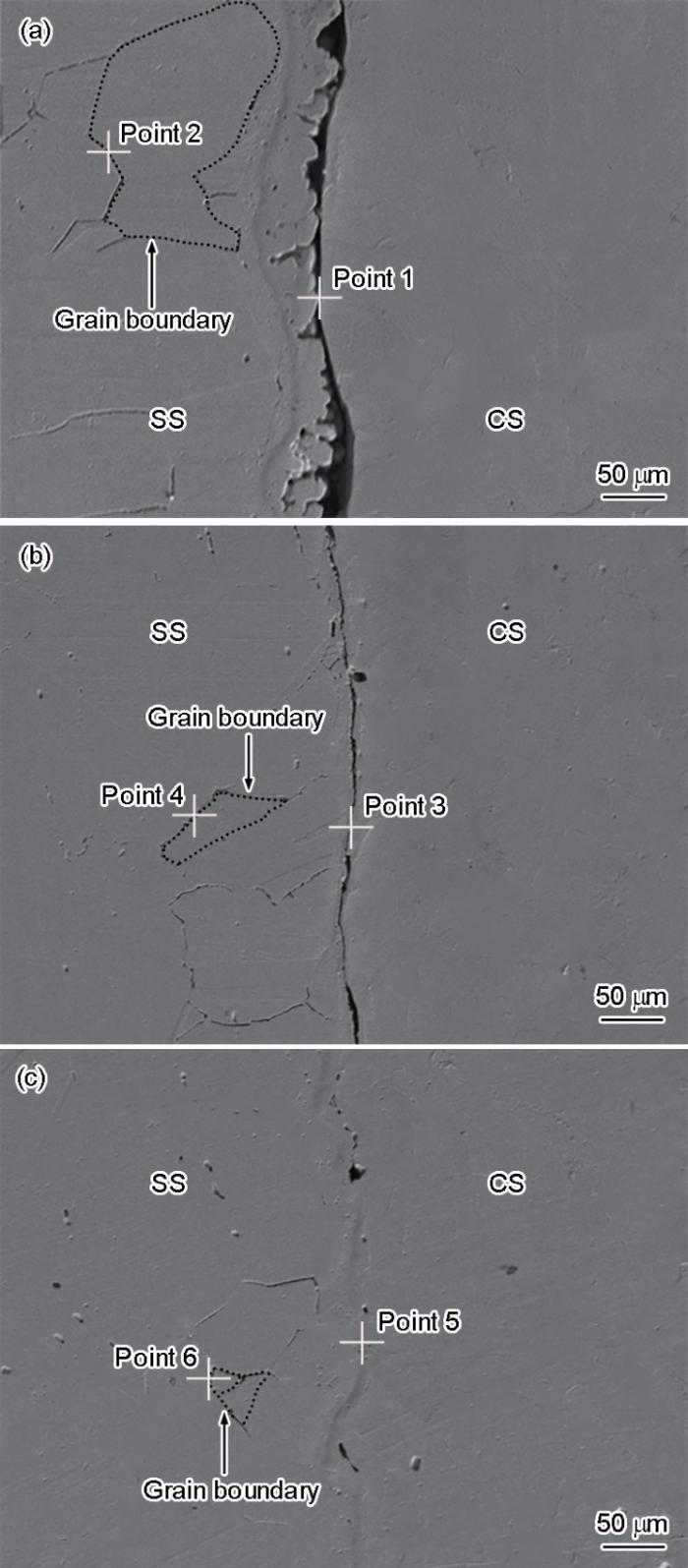

图7

图7

不锈钢复合钢筋在1100 ℃不同压下率时复合界面微观形貌的EPMA像

Fig.7

EPMA images showing the interface microstruc-tures with reduction rates of 20% (a), 40% (b), and 60% (c) at 1100 oC

表2 图7中点1~6的EDS分析结果

Table 2

| Reduction rate | Point | Mass fraction of element / % | Ratio | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Si | Mn | O | Fe | Cr | C | Mn∶Si∶O | M∶C | ||

| 20% | 1 | 20.2 | 20.8 | 59.9 | - | - | - | 1∶1.03∶2.97 | - |

| 2 | - | - | - | 33.6 | 45.3 | 21.1 | - | 22.4∶6 | |

| 40% | 3 | 20.0 | 19.5 | 60.5 | - | - | - | 1∶0.98∶3.03 | - |

| 4 | - | - | - | 26.8 | 52.5 | 20.7 | - | 22.9∶6 | |

| 60% | 5 | 20.6 | 20.9 | 59.5 | - | - | - | 1∶1.01∶2.89 | - |

| 6 | - | - | - | 29.1 | 50.7 | 20.2 | - | 23.7∶6 | |

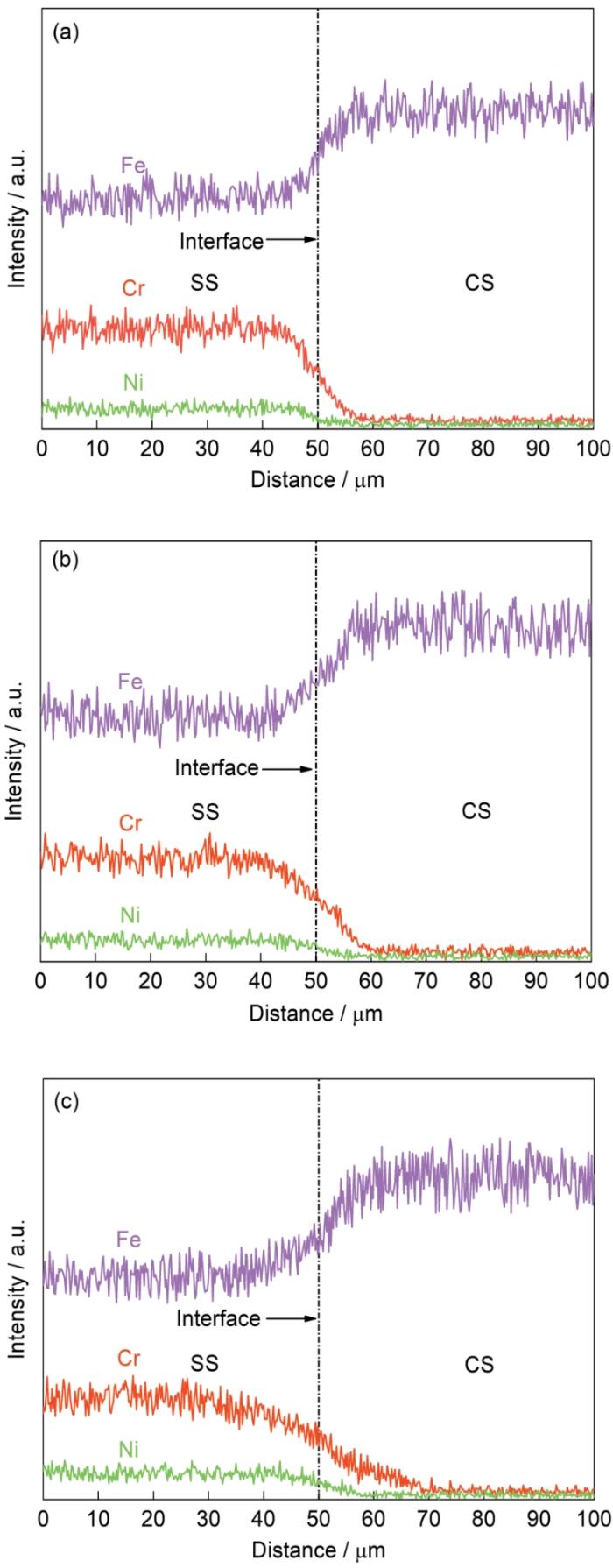

2.2.2 复合近界面元素扩散分析

图8

图8

不锈钢复合钢筋在1100 ℃不同压下率时复合界面的EPMA线扫谱

Fig.8

EPMA line scan spectra near the composite interface of composite stainless steel rebar with reduction rates of 20% (a), 40% (b), and 60% (c) at 1100 oC

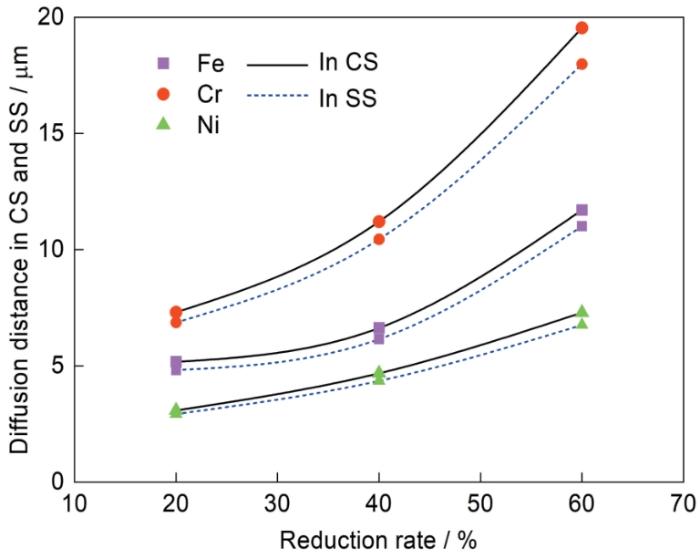

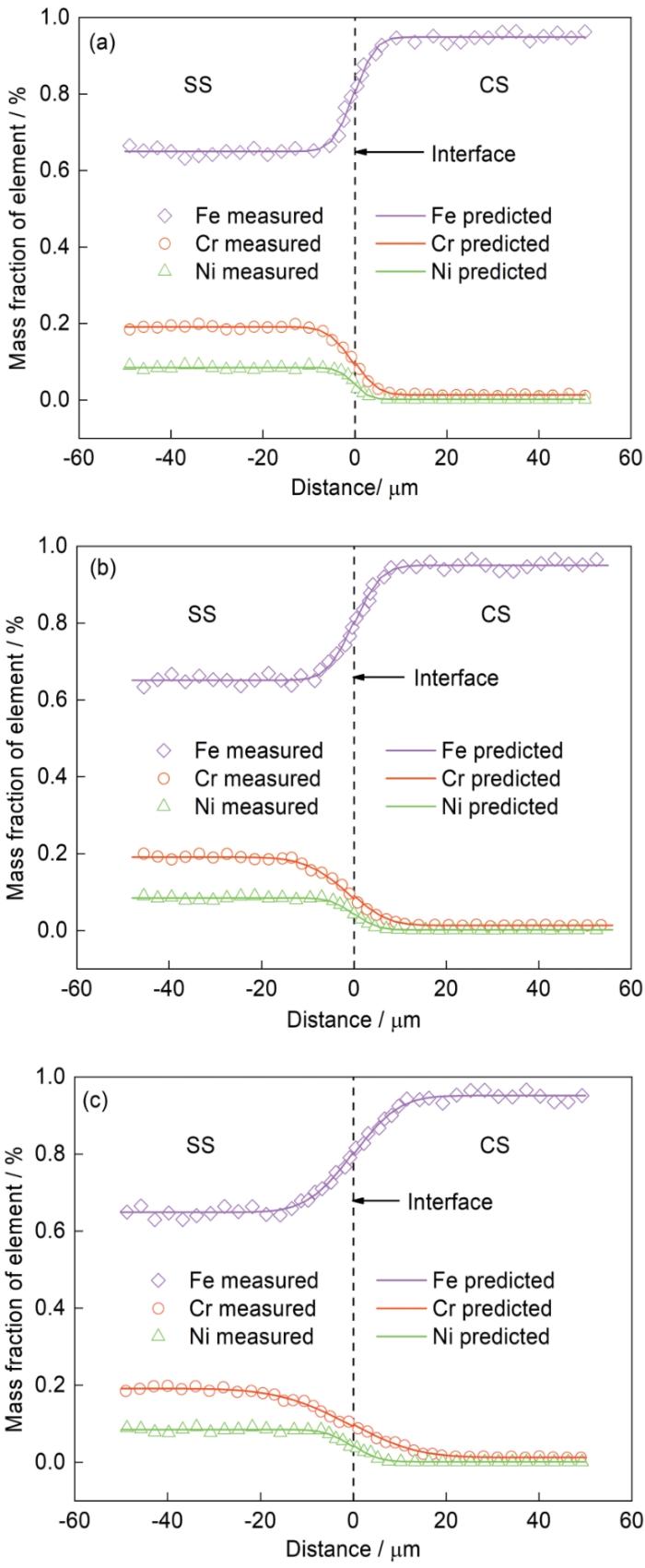

碳钢侧Fe元素跨越界面不断向不锈钢侧扩散,而Cr、Ni元素呈现相反的扩散方向;不同压下率时Ni元素浓度在界面两侧变化较小,而Fe、Cr元素浓度变化明显,这是界面两侧材料自身元素含量差异造成的元素非稳态下坡扩散。同时,近界面浓度曲线呈现差异明显的坡度,但不同压下率时3种元素均发生不同程度扩散,说明该工艺条件可为近界面原子提供足够的能量,越过能量势垒进行长程运动而产生原子扩散;随着压下率增大,近界面元素过渡区域浓度变化趋于平缓且无明显折线突变[36,37]。由于C元素定量检测困难且误差较大,故在EPMA线扫谱中未显示。此外,Cr、Ni元素的扩散对强化界面结合起着重要作用,扩散距离越大,熔覆界面结合越强[38],60%的压下率时Cr元素达到良好的扩散速率和扩散距离,形成约40 μm厚的富Cr、Ni元素的界面过渡层,从而保证了复合材料良好的界面结合强度。

图9

图9

1100 ℃下压下率对元素扩散距离的影响

Fig.9

Effects of reduction rate on the diffusion distance at 1100 oC

2.3 复合近界面元素扩散动力学

为研究热变形过程中压下率对界面附近元素扩散行为的影响,基于非稳态条件单向流动的Fick第二定律,提出考虑压下率和变形时间的元素扩散模型,预测双金属变形过程中过渡区域元素的浓度,揭示界面元素扩散规律以及扩散层形成机制。

2.3.1 模型构建原理

式中,C为元素浓度,D为扩散系数,ε为压下率,ε0为有效参考压下率,γ为压下率影响指数,x为扩散距离,t为变形时间。

采用Boltzmann变换使偏微分方程变为常微分方程,设中间变量

式中,A为复合材料中心界面元素浓度,B为相应元素浓度变化幅值。

结合界面扩散元素浓度的初始条件和边界条件,确定扩散方程的解。

初始条件:

边界条件:

式中,C1和C2分别为不锈钢和碳钢侧某元素初始浓度值。

结合误差函数的性质和定义,复合材料界面过渡区域元素扩散模型的浓度分布方程为:

式中,CSS和CCS分别为不锈钢和碳钢侧某元素浓度值,B1和B2分别为不锈钢和碳钢侧某元素浓度变化幅值,D1和D2分别为不锈钢和碳钢侧某元素扩散系数,α和β分别为不锈钢和碳钢侧某元素压下率影响指数。

2.3.2 模型参数确定与验证

引入非线性最小二乘法——Levenber-Marquardt,对不同压下率元素浓度进行拟合,运用1stOpt软件求解模型参数。

式中,x0为Matano面位置,c为界面过渡区元素浓度,C3、C4分别为x = -∞和x =+∞,t'为任意常数时不锈钢和碳钢侧某元素浓度。

以Matano面作为中心面,使用一维无限长非稳态扩散模型,界面过渡区域的元素浓度分布方程可简化为:

D1、D2、A以及B1、B2可通过拟合304不锈钢和Q235碳钢两侧的浓度曲线得到;α和β可通过拟合

表3 1100 ℃元素扩散模型拟合参数

Table 3

| Reduction rate | Element | A | B1 | B2 | α | β | D1 | D2 |

|---|---|---|---|---|---|---|---|---|

| 20% | Fe | 0.808 | 0.161 | 0.145 | 0.328 | 1.921 | 2.171 | 2.000 |

| Cr | 0.094 | -0.102 | -0.086 | 0.591 | 1.050 | 3.150 | 2.452 | |

| Ni | 0.041 | -0.043 | -0.039 | -2.304 | 2.444 | 1.353 | 0.905 | |

| 40% | Fe | 0.801 | 0.153 | 0.154 | 1.014 | 1.386 | 1.509 | 1.204 |

| Cr | 0.087 | -0.109 | -0.077 | 1.185 | 1.554 | 4.085 | 1.679 | |

| Ni | 0.043 | -0.042 | -0.042 | -0.252 | -1.445 | 2.827 | 6.530 | |

| 60% | Fe | 0.801 | 0.156 | 0.153 | 1.308 | 0.862 | 2.005 | 3.193 |

| Cr | 0.096 | -0.099 | -0.085 | 2.952 | 1.443 | 0.859 | 3.311 | |

| Ni | 0.042 | -0.045 | -0.042 | 0.790 | -0.321 | 1.268 | 3.816 |

为验证元素扩散模型的准确性,对不同压下率时界面过渡区域元素浓度的实验值和理论值进行比较,结果如图10所示。Fe、Cr和Ni元素模型的平均相对误差分别为1.03%、5.64%和6.63%。实验数据点沿着元素浓度预测曲线有规律地分布,且无异常点存在,表明模型误差较小,能以较高的精度预测过渡区的元素浓度分布和扩散距离。某些区域元素浓度相对理论浓度有一定偏离,可能是由于材料本身的缺陷对元素扩散行为的影响以及元素浓度测量值存在一定误差。

图10

图10

不锈钢复合钢筋在1100 ℃不同压下率时界面过渡区域元素浓度分布曲线

Fig.10

Distribution curves of element concentration in interface transition zone of composite stainless steel rebar with reduction rates of 20% (a), 40% (b), and 60% (c) at 1100 oC

3 结论

(1) 变形温度1000 ℃时,不锈钢复合钢筋界面两侧晶粒动态再结晶比例不协调,碳钢侧晶粒发生完全动态再结晶,不锈钢侧晶粒细化形核机制为经典位错滑移控制的不连续动态再结晶。变形温度为1100 ℃时,不锈钢侧动态再结晶由孪生机制主导控制;且动态再结晶体积分数与Σ3孪晶界体积分数存在线性关系。

(2) 随着压下率增加,不锈钢侧位错分割的高密度亚晶界不断被消耗,小角度晶界分布愈加稀疏,位错滑移受到明显抑制;变形晶粒和亚晶粒不断向再结晶晶粒转变,再结晶体积分数从25%增至54%,Σ3孪晶的体积分数相应增加,并对动态再结晶引起的晶粒细化进程起加速作用,导致作为扩散通道的晶界数量增多,提高了元素扩散效率。

(3) 随着压下率增加,部分氧化膜和线状夹杂物被压碎成细小颗粒,均匀分布在结合界面,夹杂物含量逐渐降低,对元素扩散行为的抑制效果明显减弱;界面空洞闭合程度增加,复合界面结合更加致密紧实,元素扩散路径随之缩短;最终导致近界面元素扩散距离明显提高,过渡区域元素浓度变化更加平缓。

(4) 基于非稳态条件单向流动的Fick第二定律,研究了压下率对复合近界面元素扩散行为的影响,建立引入压下率和变形时间的复合材料界面过渡区域元素扩散模型,预测双金属变形过程中过渡区域元素的浓度,误差分析表明模型具有较高的预测精度,Fe、Cr和Ni元素的平均相对误差分别为1.03%、5.64%和6.63%。

刊载于《金属学报》2024年第60卷第8期1141—1149页,题为《C包覆Ni磁性载体负载Pt催化硝基苯加氢性能》的文章,由于作者的疏忽,导致作者署名单位信息不完整,现做如下勘误。

文章中第一页,原作者署名单位信息如下:

武 逸1 司 阳1 黄彦民2 刁江勇1 孟繁敬2 刘 增2 刘洪阳1

1 中国科学院金属研究所 沈阳材料科学国家研究中心 沈阳 110016

2 沧州大化股份有限公司 河北省改性异氰酸酯技术创新中心 沧州 061000

更正后作者署名单位信息如下:

武 逸1,2 司 阳2 黄彦民3 刁江勇2 孟繁敬3 刘 增3 刘洪阳1,2

参考文献

Research advances of stainless-clad bimetallic steel structures

[J].

不锈钢复合钢材钢结构研究进展

[J].

Development and application prospect of hot rolled stainless steel-carbon steel composite rebar

[J].

热轧不锈钢-碳钢复合钢筋的开发和应用前景

[J].

Effect of micro-tension on interfacial composite quality and atomic diffusion of stainless/carbon steel

[J].

微张力对不锈钢/碳钢界面复合质量及原子扩散的影响

[J].

Heat-treatment of clad steel plate for application of hull structure

[J].

Influence of hot clad rolling process parameters on life cycle of reinforced bar of stainless steel carbon steel bars

[J].

Composite plate rolling technology of 304/Q345R based on a corrugated interface

[J].

Thicker steel plate shape-changing law and control method during the snake rolling process

[J].

Effect of carbon content of substrate on the microstructure changes and tensile behavior of clad layer of stainless steel composites

[J].

Hot deformation behavior and microstructure evolution of stainless steel/carbon steel laminated composites

[J].

Diffusion bonding of 9Cr ODS ferritic/martensitic steel with a phase transformation

[J].

Hot pressing diffusion bonding of a titanium alloy to a stainless steel with an aluminum alloy interlayer

[J].

The effect of Ni interlayer on the hot-rolled and quenched stainless steel clad plate

[J].

Microstructure and mechanical properties of hot rolled stainless steel clad plate by heat treatment

[J].

Numerical simulation and experimental study on the interface bonding of stainless steel clad plate

[J].

Static recrystallization kinetics of 304 stainless steels

[J].

The influence of cold rolling deformation on tensile properties and microstructures of Mn18Cr18N austenitic stainless steel

[J].

Microstructural evolution of a 304-type austenitic stainless steel during rolling at temperatures of 773-1273 K

[J].

Recrystallization in AISI 304 austenitic stainless steel during and after hot deformation

[J].

Hot deformation behavior of a medium carbon microalloyed steel

[J].

Effect of deformation temperature and strain rate on dynamic recrystallized grain size of a powder metallurgical nickel-based superalloy

[J].

Interfacial microstructure and strengthening mechanism of stainless steel/carbon steel laminated composite fabricated by liquid-solid bonding and hot rolling

[J].

Proportion of recovery and recrystallization during interpass times at high temperatures on a Nb-and N-bearing austenitic stainless steel biomaterial

[J].

Dynamic recrystallization behavior of a superaustenitic stainless steel containing 16%Cr and 25%Ni

[J].

Effect of initial grain size on dynamic recrystallization in high purity austenitic stainless steels

[J].

EBSD study of a hot deformed nickel-based superalloy

[J].

Effects of deformation microbands and twins on microstructure evolution of as-cast Mn18Cr18N austenitic stainless steel

[J].

Discontinuous dynamic recrystallization mechanism and twinning evolution during hot deformation of Incoloy 825

[J].

Meso and microscale clad interface characteristics of hot-rolled stainless steel clad plate

[J].Stainless steel clad plate containing corrosion-resistant 304 stainless steel cladding and Q235 carbon steel substrate has been successfully fabricated by vacuum hot rolling at 1150 degrees C. The interface characteristics, microstructure, alloy element distribution and precipitation phases of clad plate were investigated by SEM, EPMA and TEM analysis in detail. Due to the carbon element diffusion, a decarburized layer (60-80 mu m) and a carburized layer (20-40 mu m) were formed at the carbon steel substrate and stainless steel cladding beside the interface, respectively. The uphill diffusion and interface peak value of carbon element are attributed to the differences in the diffusion velocity and solubility of carbon element in the substrate and cladding. Concentration gradient and diffusion coefficient between Cr and Ni elements are different, leading to different diffusion distances. Meanwhile, the grain boundaries of carburized layer were surrounded by Cr23C6 particles. The interface with a thickness of 300-400 nm contains refined grains accompanying with many Cr23C6 and MnSi2O4, SiO2 particles. The sufficient alloy element diffusion behavior and interface oxides, precipitation phases lead to a high interface bonding shear strength (389 MPa).

NiCoCrAlY coating of in-situ synthesis by vacuum diffusion and its oxidation resistance

[J].

真空扩散原位合成NiCoCrAlY涂层及其抗氧化性能

[J].

The evolution behavior and constitution characteristics of interfacial oxides in the hot-rolled stainless steel clad plate

[J].

Formation mechanism of oxide inclusion on the interface of hot-rolled stainless steel clad plates

[J].The inclusions on the bonded interface were analyzed by optical microscopy (OA) and scanning electron microscopy (SEM), and the formation mechanism of oxide inclusions was investigated and discussed. The results show that the inclusions are mainly made of oxides. The chemical composition of oxide inclusions can also be related to vacuum degree inside the clad metal slab, in which silicon dominated at the vacuum degree of 15Pa or higher and the aluminum did at the vacuum degree of 0.1Pa or lower. It can be considered that the oxide inclusions were formed due to the oxidation of aluminum, silicon, manganese elements diffusing from the inside to interfaces to be bonded of metals. The experimental results also indicate that oxidation also become more evident with the reduction in vacuum degree, and the proportion of oxide inclusions increases to 50% from 15% with the decrease of vacuum degree from 0.1Pa to near 15Pa.

热轧不锈钢复合板界面氧化物夹杂的形成机制

[J].

The tensile behaviors and fracture characteristics of stainless steel clad plates with different interfacial status

[J].

Evolution of interfacial characteristics and mechanical properties for 316LN stainless steel joints manufactured by hot-compression bonding

[J].

Microstructure, mechanical properties and interface bonding mechanism of hot-rolled stainless steel clad plates at different rolling reduction ratios

[J].

Ab initio molecular dynamics simulation on interfacial reaction behavior of Fe-Cr-Ni stainless steel in high temperature water

[J].

Inter-diffusion behavior of Ni/Fe/Ni laminated composite for magnetic and electromagnetic interference shielding

[J].

Influence of high-current pulsed electron beam irradiation on element diffusion behavior and mechanical properties of TC4/304 stainless steel diffusion bonded joints

[J].

Tensile shear sample design and interfacial shear strength of stainless steel clad plate

[J].

Microstructure and mechanical properties of diffusion bonded SiC/steel joint using W/Ni interlayer

[J].

Effect of grain size on grain boundary diffusion process and properties of sintered NdFeB

[D].

晶粒尺寸对烧结钕铁硼晶界扩散行为及性能的影响

[D].

Microstructure evolution and element migration (diffusion) behavior of a Ni-based alloy processed by surface mechanical rolling treatment

[D].

表面机械滚压处理镍基合金结构演化和元素迁移与扩散行为的研究

[D].

Interface characteristics and fracture behavior of hot rolled stainless steel clad plates with different vacuum degrees

[J].In order to investigate the effect of vacuum degree on the interface microstructure and mechanical properties of stainless steel clad plate, series of 316L/Q235 clad plates were successfully fabricated by hot rolling with different vacuum degrees of 10(5) Pa, 400 Pa, 10 Pa, 10(-1) Pa and 10(-2) Pa. Interestingly, with the increase of vacuum degree, the interface oxides distribution changed from continuous wall/film to dispersed refined particles, and the thicknesses of martensite layer, decarburized layer and carburized layer were gradually increased. Meanwhile, the interface bonding strength of clad plates can be effectively enhanced by improving the vacuum degree. Due to thin decarburized and carburized layers, the stainless steel clad plate with a low vacuum degree of 10(5) Pa reveals superior yield strength and ultimate strength, while a low fracture elongation was obtained due to severe interface delamination. However, the stainless steel clad plate with a high vacuum degree can obtain a superior tensile ductility, which is attributed to the strong interface and localized necking delaying effect.

On the mechanism of diffusion-induced recrystallization: Comparison between experiment and molecular dynamics simulations

[J].

Low temperature diffusion bonding of Ti-6Al-4V and duplex stainless steel

[J].

Interfacial characteristics and mechanical properties of duplex stainless steel bimetal composite by heat treatment

[J].

Sluggish diffusion in Co-Cr-Fe-Mn-Ni high-entropy alloys

[J].

Extracting interdiffusion coefficients from binary diffusion couples using traditional methods and a forward-simulation method

[J].