明确Ni-Co-Cr-Fe-Al系共晶高熵合金在增材制造过程中的快速凝固行为,是深入理解其组织调控及性能优化的关键。在增材制造快速凝固条件下,金属的凝固行为有别于铸态时的凝固情况。Alamoudit和Wiezorek[16]发现,铸态Al-10Cu合金由α-Al枝晶和α-θ共晶组成,经表层激光熔化后形成Cu的过饱和胞状α-Al及胞间共晶。Wang等[17]发现,增材制造316L不锈钢中存在大量胞状结构、小角度晶界以及位错等异质结构。Zhang等[18]通过改变扫描速率调控凝固速率,发现降低扫描速率可以减少大角度晶界、减小应力集中并粗化胞状结构。大量研究[19,20]表明,增材制造合金中独特的位错胞结构是其重要的强化手段。Ni-Co-Cr-Fe-Al系共晶高熵合金在增材制造过程中形成的fcc-B2-位错胞结构具有独特的变形机制,极大地优化了合金的强度、塑性及断裂韧性[21,22]。

为此,本工作采用铜模铸造以及选区激光熔化(selective laser melting,SLM) 2种方法制备了共晶高熵合金,研究其在不同凝固条件下的组织特征和力学性能,分析了共晶高熵合金快速凝固行为和SLM组织调控方法,以期为组织调控提供理论支持。

1 实验方法

本工作采用Ni43.5Co19Cr10Fe10Al15Ti2Mo0.5 (原子分数,%)的预合金粉末制备SLM试样。SLM设备为BLT-S200金属3D打印机,采用单向变速刮刀,最大成形尺寸为105 mm × 105 mm × 200 mm。该设备配备YLR-SM系列激光器,标称输出功率为500 W,激光波长范围为1060~1080 nm。打印前先将基板预热至200 ℃。为防止打印过程中材料发生高温氧化,整个成形室中充满Ar气,使O含量低于100 × 10-6 (100 ppm)。打印过程中,控制层厚(h)和光斑直径(d)分别设置为30和80 µm。本工作通过改变激光功率(P)、扫描速率(V)以及道间距(H),实现SLM组织的调控。打印过程的激光扫描策略是将成形平面上的待扫描区域分割为若干条带,每层的条带方向相对上一层旋转67°,激光沿着条带进行逐层扫描。经大量工艺参数摸索,最佳成形参数为P = 150 W、V = 900 mm/s、H = 65 µm,此时试样的致密度最高,达到99.92%,且晶粒形态为柱状晶,下文中简称SLM-C试样。采用P = 250 W、V = 500 mm/s、H = 80 µm参数获得由等轴晶组成的试样,下文中简称SLM-E试样。

采用WK-Ⅱ非自耗电极真空电弧熔炼炉进行铸态试样制备,使用钨电极发射电弧作为热源熔化金属。为防止熔炼过程中的氧化,在熔炼合金原料前,先使用分子泵将电弧炉腔抽至真空,再充入高纯度Ar气。经过再次抽真空以及通Ar气后,熔炼纯Ti金属锭以除尽舱内剩余O2。合金原料经5次反复熔炼,每次熔炼后均要将锭料翻面,以保证成分均匀。熔炼使用的铜坩埚以及铜制模具均采用循环水冷却,去除冒口后得到尺寸为90 mm × 12 mm × 8 mm的金属锭料。

对打印和铸造试样进行电火花加工以得到金相试样,采用LHM-3000型全自动金相镶嵌机镶嵌后,用砂纸打磨,再经金刚石和SiO2悬浮液抛光制得金相试样,部分金相试样使用氯化铜腐蚀液(100 mL HCl + 100 mL C2H5OH + 5 g CuCl2)进行腐蚀。采用D8 Discover X射线衍射仪(XRD)进行物相分析,采用OLS5100激光共焦显微镜、配有能谱仪(EDS)探头的MIRA3扫描电子显微镜(SEM)进行显微组织观察,采用C-Nano电子背散射衍射(EBSD)系统进行相鉴定、晶粒形貌及各相取向关系分析,采用F200X透射电子显微镜(TEM)观察共晶高熵合金的晶体结构和成分分布。TEM样品先经砂纸打磨至50 µm,然后使用Fischione Model 1030型电解双喷减薄仪减薄至满足观察要求。采用TSMT EM6.504万能材料试验机进行拉伸性能测试,在室温下进行应变速率为1 × 10-3 s-1的单轴拉伸,拉伸试样标距段尺寸约为12.5 mm × 1.2 mm × 3 mm。

2 实验结果

2.1 铸态试样组织

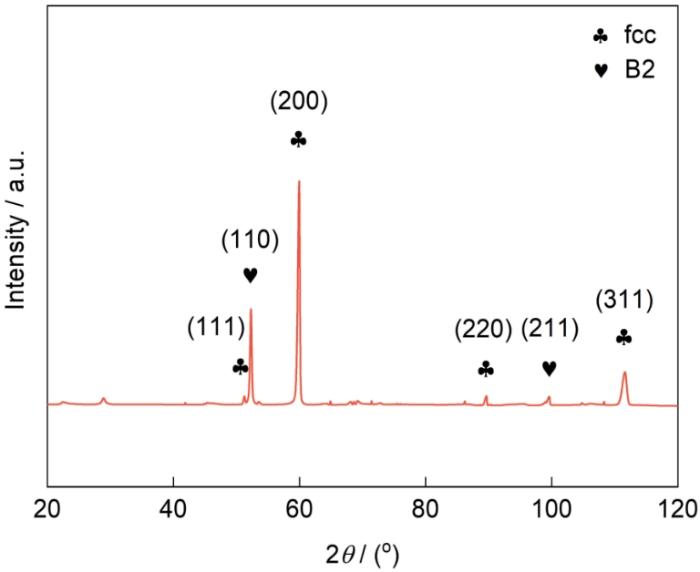

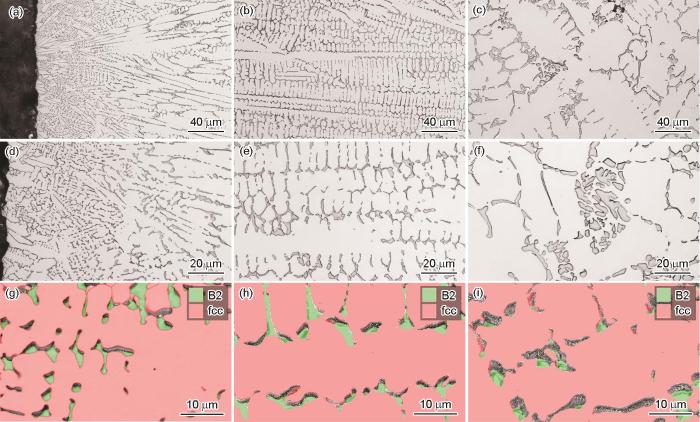

图1为铸态试样的XRD谱,其显微组织由fcc相和B2相组成。图2为铸态试样截面不同区域的OM及EBSD像(其中,图2a、d、g为铸锭表层区域,图2b、e、h为铸锭表层与心部间的区域,图2c、f、i为铸锭心部区域)。对比可见,铸态试样显微组织呈现出典型的3个区域:表层细晶区、柱状晶区以及心部等轴晶区。由于凝固条件差异,枝晶在各个区域中呈现不同的组织特征。表层细晶区中的凝固组织尺度最细,由生长方向杂乱的较细领先相枝晶以及间隙上的第二相构成,第二相面积分数达到23.0% (图2a)。柱状晶区由垂直于铸锭表面方向生长的较为粗大的枝晶构成,第二相面积分数为18.0% (图2b)。心部等轴晶区的组织最为粗大,第二相面积分数为16.9%,具有典型的“交叉十字”形等轴枝晶特征(图2c)。第二相在二次枝晶臂间隙中主要以条状或块状形态存在,具有典型的离异共晶组织特征。而在一次枝晶臂间隙中,第二相则表现出更为明显的团块状共晶组织特征。图2g~i中的相分布图显示,铸态试样由fcc相和B2相组成,其中fcc相为领先相,B2相为第二相并以共晶形态分布于枝晶间隙。

图1

图2

图2

铸态试样截面不同区域的OM像及EBSD像

Fig.2

Low (a-c) and high (d-f) magnified OM images and EBSD phase distribution (PD) images (g-i) of different regions on as-cast specimen cross-section

(a, d, g) chill crystal zones (b, e, h) columnar zones (c, f, i) equiaxed grain zones

共晶高熵合金中的元素分布与2相的面积分数密切相关。Ni-Co-Cr-Fe-Al系共晶高熵合金中,2相面积分数主要受Al元素浓度分布的影响。分析Ni-Co-Cr-Fe-Al系高熵合金铸锭各区域中2相的Al元素浓度,有助于理解其在不同冷却速率下的凝固行为。图3为铸态试样各个区域的SEM像及EDS分析。在各个区域中,B2相均为富Ni、Al、Ti相,且Al含量基本一致,约为23.2% (原子分数,下同)。表层细晶区中fcc相的Al元素浓度为13.1%,柱状晶区为13.5%,心部等轴晶区为13.7%。结果表明,随着冷却速率增大,fcc领先相中的Al元素浓度逐渐减小。

图3

图3

铸态试样各个区域的SEM像及EDS分析

Fig.3

SEM images (a, d, g) and EDS analyses (b, c, e, f, h, i) of different crystal zones of the as-cast specimen (Arrows in Fig.3a, b, d, e, g, and h show the EDS line scanming directions)

(a, b, c) chill crystal zones (d, e, f) columnar zones (g, h, i) equiaxed grain zones

2.2 SLM试样组织

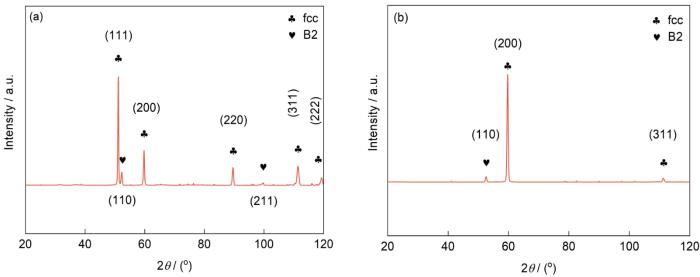

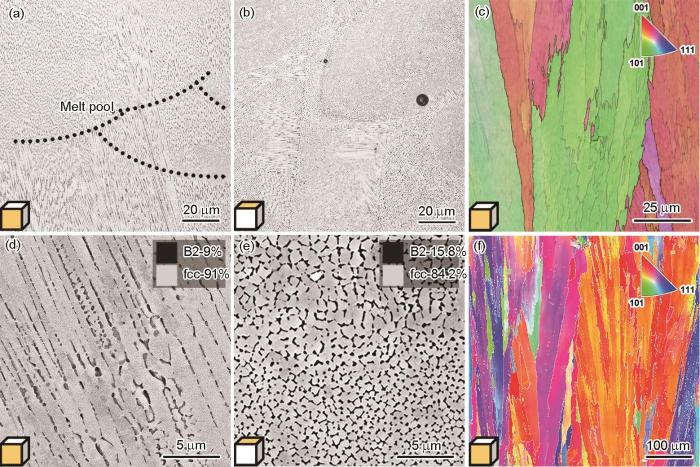

图4为粉末原料和打印态SLM-C试样的XRD谱,该粉末及成形试样均由fcc和B2相构成。试样成形期间较高的温度梯度使得晶粒倾向于沿增材方向生长形成织构,从而导致部分衍射峰减弱或消失。图5a和b为打印态SLM-C试样沿增材方向和垂直于增材方向截面的OM像,图5d和e为对应的SEM像。与铸态试样不同,由于冷却速率更快,打印态试样中未观察到二次枝晶臂,且其组织相比铸态试样表层细晶区更加细小。其中,各个柱状晶粒内部由沿着增材方向生长的胞状结构构成,B2相分布于胞壁,胞内为fcc相。打印态试样沿增材方向的反极图(inverse pole figure,IPF)如图5c和f所示,由于增材制造过程的快速凝固以及自下而上的特定成形方向,柱状晶可在上一层的基础上不断外延生长,从而穿过熔池并形成沿增材方向高达数百微米的柱状晶。

图4

图4

粉末原料和打印态SLM-C试样的XRD谱

Fig.4

XRD spectra of the powder raw material (a) and SLM-C as-print specimen (b)

图5

图5

打印态SLM-C试样的OM像、SEM像及反极图(IPF)

Fig.5

OM (a, b) and SEM (d, e) images and inverse pole figures (IPFs) (c, f) of the SLM-C as-print specimen (Orange areas in the cubes indicate the observation plane, the same below)

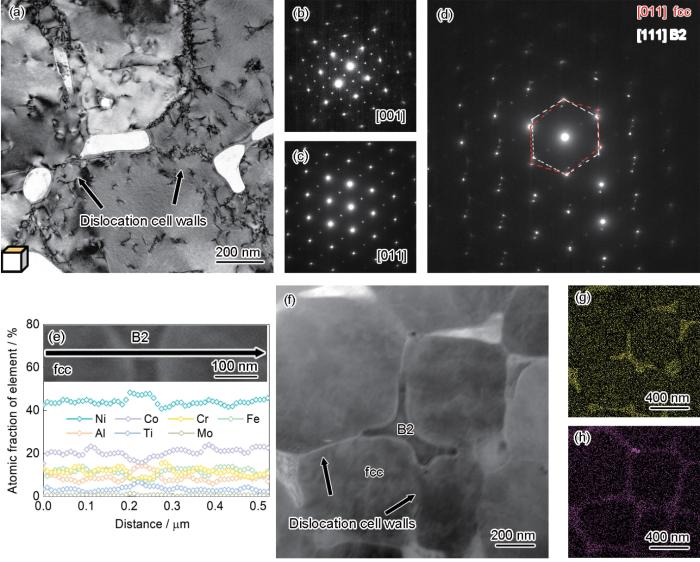

图6a为打印态SLM-C试样沿垂直于增材方向的TEM像,可观察到由高密度位错组成的位错胞壁。与单相增材制造合金不同,该试样中的胞状组织壁上并未形成完整的环状位错墙,而是形成由高密度位错桥及块状B2相交替组成的B2相-位错环。柱状晶间隙上的位错墙由高密度位错组成,B2相与fcc相界面附近位错密度较小,剩余部分离散位错分布在胞内的fcc相中。图6b和c为fcc相区域沿[001]轴和[011]轴方向的选区电子衍射(selected area electron diffraction,SAED)花样,根据图中的超衍射斑可知,打印态试样的fcc相内部有γ′相析出。但由于打印过程中的循环热输入量较低,γ′相的析出较为缓慢,沉淀相尺寸极小,在高分辨像中也未能观察到该相。图6d为打印态试样中的2相组织沿fcc相[011]轴的SAED花样,图中fcc相的[011]轴平行于B2相的[111]轴,因此fcc相与B2相保持Kurdjumov-Sachs (K-S)关系。

图6

图6

打印态SLM-C试样垂直于增材方向截面的TEM像、选区电子衍射(SAED)花样及EDS分析

Fig.6

TEM images (a, f), selected area electron diffraction (SAED) patterns (b-d), and EDS analyses (e, g, h) of the as-print SLM-C specimen along the cross-section perpendicular to the additive direction

(d) Kurdjumov-Sachs (K-S) relation between B2 and fcc phases

(e) EDS line scanning result (g, h) EDS mappings of Al (g) and Ti (h)

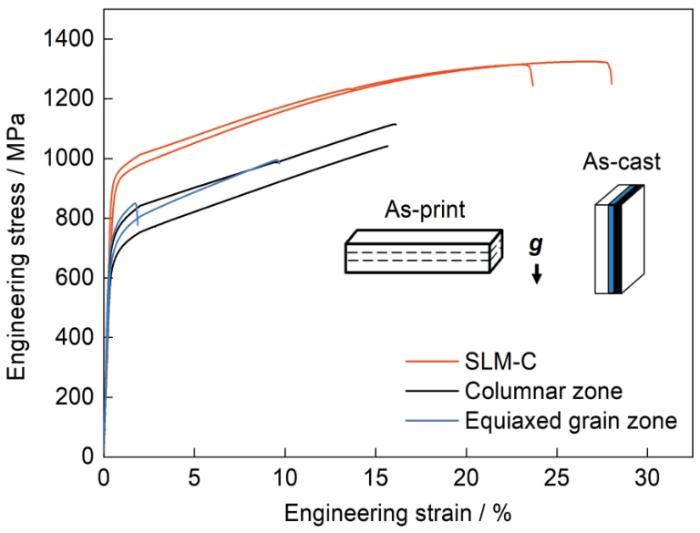

2.3 拉伸性能

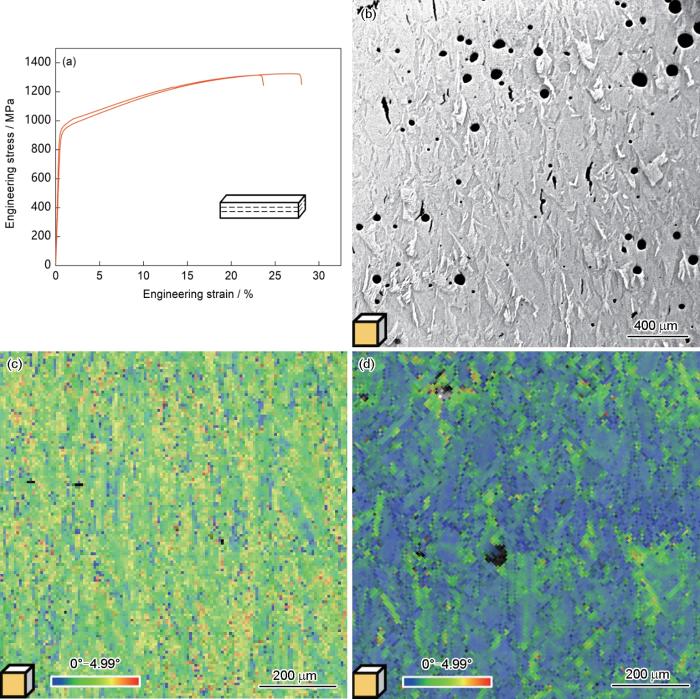

图7为铸态试样的柱状晶区、心部等轴晶区以及打印态SLM-C试样的工程应力-应变曲线和对应取样位置,相同颜色拉伸曲线重叠度越高,表明拉伸性能越稳定。其中,柱状晶区的拉伸方向垂直于柱状晶的生长方向,取自铸态试样表层1~2 mm厚的黑色区域;心部等轴晶区的拉伸试样取自铸态试样中心约1~2 mm宽的蓝色区域;打印态的拉伸试样均取自打印块体靠近上表面的2层,每层厚度约2 mm。由于表层细晶区较薄,经表面打磨可以完全去除其干扰。由图7可知,铸态试样心部等轴晶区和柱状晶区的强度较为接近,平均屈服强度分别为(708.5 ± 23.5) MPa和(687 ± 37) MPa,平均抗拉强度分别为(922.5 ± 72.5) MPa和(1078 ± 37) MPa。柱状晶区的平均延伸率更高,为(15.9 ± 0.2)%,而心部等轴晶区仅有(5.8 ± 3.9)%。SLM-C试样的平均屈服强度高达(916 ± 12) MPa,平均抗拉强度高达(1320.5 ± 4.5) MPa,平均断裂延伸率达到(25.8 ± 2.2)%。结果表明,打印态SLM-C试样的强塑性均高于铸态试样柱状晶区和心部等轴晶区。

图7

图7

打印态SLM-C试样、铸态试样柱状晶区和心部等轴晶区的工程应力-应变曲线和对应取样位置

Fig.7

Engineering strain-stress curves of the as-print SLM-C specimen and columnar and equiaxed grain zones of the as-cast specimen (g represents the direction of gravity. Insets are the sampling position schematics, where black and blue areas represent the sampling positions of the columnar and equiaxed grain zones in as-cast specimen, respectively; and two layers close to the upper surface represent the sampling position of as-print specimen)

3 分析讨论

3.1 凝固行为及组织演化规律

本工作中Ni-Co-Cr-Fe-Al系共晶高熵合金领先相为fcc相,第二相为B2相。其中,2相中的Al元素含量差异最大,fcc相贫Al而B2相富Al,通过研究Al元素的分配情况,可以分析合金在不同凝固速率下的凝固行为。在铸态试样的凝固过程中,凝固速率从心部向柱状晶区再至表层的逐渐增大,fcc领先相中Al元素浓度逐渐减小,分别为13.7%、13.5%和13.1%,而B2相中的Al元素浓度保持稳定。因此,凝固速率的影响主要表现在fcc领先相析出期间。

平衡凝固时,贫Al的fcc领先相在凝固过程中伴随着固相的扩散以及液相的完全混合。随着温度降低至共晶温度,先结晶的fcc相通过扩散从后结晶的fcc相中获得Al元素,后结晶的fcc相从液相中补充Al元素,使fcc领先相中整体Al元素浓度逐渐升高并最终到达固溶度极限,此时液相成分到达共晶点并开始发生共晶反应。然而,在非平衡的铸造过程中,fcc领先相中Al元素浓度随凝固速率增大而降低。这表明较高的凝固速率将阻碍溶质在fcc领先相中的扩散,从而使得fcc领先相中Al元素浓度低于固溶度极限。通过分析各区域中B2相的面积分数进一步验证了上述观点。随凝固速率升高,B2相的面积分数由心部到表层逐渐增大,分别为16.9%、18.0%和23.0%。这是由于凝固速率升高使fcc领先相的Al元素浓度降低且生长时间缩短,导致液相中的Al元素含量更高,到达共晶点的剩余液相体积分数更大,使共晶相的体积分数增大[30,31],B2相的体积分数也相应增大。因此,铸态条件下,Ni-Co-Cr-Fe-Al系共晶高熵合金凝固速率的增大将阻碍固相中溶质扩散,引起fcc领先相Al元素浓度降低,并降低第二相的相分数。

在SLM-C试样中,尽管凝固速率进一步增大[32],B2相在垂直于打印方向的面积分数为15.8%,沿打印方向的面积分数仅有9.0%,低于铸态试样中的各个区域。此外,与铸态试样相比,SLM-C试样中fcc领先相的Al元素浓度更高,达到14.3%。这种现象不仅源于SLM快速凝固过程中固相溶质扩散受阻,还与液相的溶质分配密切相关。研究[16,33]表明,增材制造中存在溶质截留效应,即在极高的冷却速率下,固/液界面前沿液相中的溶质来不及排出便随着凝固被保留在固相中,形成过饱和fcc领先相。因此,快速凝固期间大量的Al元素将被固定在fcc领先相中,只向液相中排出少量的Al元素,剩余的液相需要在析出更多的领先相后才能达到共晶成分,故只能在fcc领先相间隙形成极少量共晶相,导致B2相面积分数大幅减少。综上所述,铸态条件下凝固速率变化主要改变领先固相中溶质的扩散能力,而增材制造中快速凝固的影响则主要体现在限制液相的溶质分配。

式中,G为界面处的温度梯度,K/m;n和a为金属常数;Vg为生长速率,m/s;Cst为计算判据所用代数符号;ΔT0为平衡液、固相线间的温度区间,K;N0为形核密度,m-3。

在冷却速率最大的打印态SLM-C试样中,可观察到沿增材方向生长不含二次枝晶臂的极细柱状晶,这一特征表明该参数下的打印过程伴随着较大的温度梯度。研究[40]表明,不同打印层高处以及同一层的不同区域中,由于凝固条件差异,可能形成不同形态的晶粒。首先,由于基板的散热能力较强,打印层与基板间的距离越小,冷却速率越大,使得首层容易形成等轴晶,而在随后的层中逐渐转变为柱状晶。其次,由于温度梯度不同,熔池的各个区域会形成不同形貌的晶粒。熔池底部与固相接触,温度梯度较大,晶粒倾向于在上一层的基础上外延生长,形成柱状晶;熔池顶部的温度梯度较小,冷却速率与熔池底部相比更快,倾向于形成等轴晶[28]。在本工作中,由于打印过程温度梯度较大,且随着打印层与基板的距离变大,冷却速率逐渐降低,形成了完全的柱状晶。

此外,增材制造试样中位错胞壁与fcc胞状晶间隙基本重合但并不完整,位错胞壁的部分位置被B2相占据,且在fcc相与B2相界面上位错密度较低。该fcc-B2-位错胞结构的形成一方面是由于fcc领先相胞状生长,并在间隙上形成成分偏析以及B2相,使位错在随后的应力循环中被间隙上的溶质和B2相钉扎;另一方面是由于fcc相与B2相之间形成非共格界面,持续吸纳位错,降低2相界面附近的位错密度,最终形成围绕fcc柱状晶的B2相-位错胞壁。

综上所述,通过选择合适的打印参数,可改变增材制造凝固过程中的温度梯度和冷却速率,进而实现晶粒形态的调控。其中,激光功率和扫描速率是影响凝固过程的主要参数。一方面,提高激光功率、降低扫描速率可以增大热输入,提高平均温度进而降低温度梯度;另一方面,减小激光功率,增大扫描速率可以提高凝固速率。上述方法均可以促进等轴晶的形成。

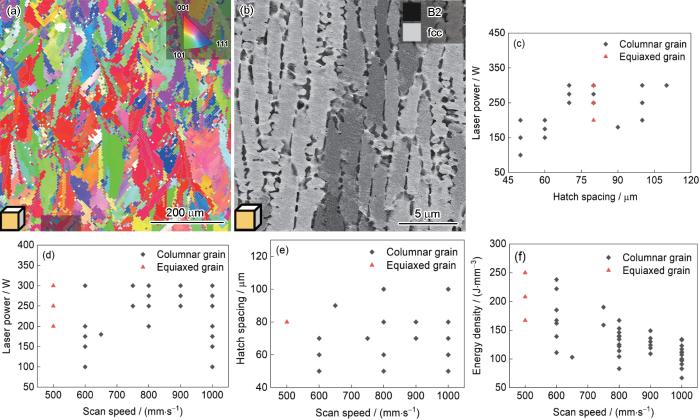

3.2 SLM晶粒形态调控及柱状晶-等轴晶转变

上述共晶高熵合金凝固行为与组织形貌的强关联为组织调控提供了方向,本工作以对晶粒形态的调控为例进行验证。在SLM-C试样中,由于扫描速率较快,能量密度较低,因此冷却速率较快且热量累积较小,熔池中的温度梯度较大。此时,若通过进一步增大扫描速率并减小激光功率以提高冷却速率来调控晶粒形态,容易出现熔合不良的问题。因此,采用增大热输入、减小温度梯度的方式,通过将激光功率提高至250 W,扫描速率降低为500 mm/s,并将道间距增大至80 µm,获得了由等轴晶组成的SLM-E试样。

图8

图8

SLM-E试样的IPF和SEM像及打印态等轴晶、柱状晶试样的激光功率、扫描速率、道间距和能量密度的关系

Fig.8

IPF (a) and SEM image (b) of the SLM-E as print specimen and relationships between the columnar to equiaxed transition (CET) and the printing parameters in SLM-E as-print specimens (c-f)

通过分析打印参数摸索实验中各参数成形试样的晶粒形态,可以得到SLM中对晶粒形态起决定性作用的参数。图8c~f为SLM-E试样的晶粒形态与激光功率、扫描速率、道间距以及体能量密度(

3.3 拉伸性能分析

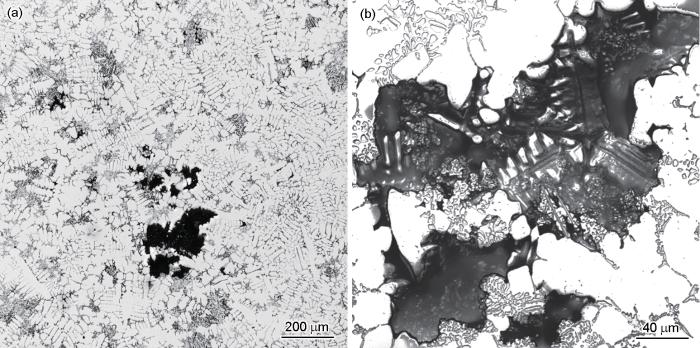

图9

图9

铸态试样心部缩孔的OM像

Fig.9

Low (a) and high (b) magnified OM images of shrinkage cavity in the middle of the as-cast specimen

与铸态试样相比,打印态SLM-C试样不仅强度更高且塑性更好。结合SLM-C试样的微观组织可知,在SLM过程中析出的γ′相以及形成的独特位错胞结构[41]是其具有高屈服强度的原因,而快速冷却产生的细晶则使SLM-C试样具有远超铸态试样的塑性。

打印态试样中,晶粒形态也会对力学性能产生影响。图10a为打印态SLM-E试样的工程应力-应变曲线,拉伸试样均取自打印块体靠近上表面的2层,每层厚度约2 mm。SLM-E试样的平均屈服强度为(784.5 ± 17.5) MPa,平均抗拉强度为(972 ± 20) MPa,平均断裂延伸率仅为(5.4 ± 1.2)%。与SLM-C相比,SLM-E试样不仅强度更低,而且塑性更差。

图10

图10

SLM-E试样的应力-应变曲线、OM像以及SLM-C和SLM-E试样的局部平均取向差(KAM)图

Fig.10

Engineering strain-stress curves (a) and OM image (b) of SLM-E as-print specimen and kernel average misorientation (KAM) images of SLM-C (c) and SLM-E (d) as-print specimens (Inset in Fig.10a is the sampling position schematic of SLM-E, where two layers close to the upper surface represent the sampling position)

增材制造高熵合金的强度主要由细晶强化、位错强化以及第二相强化决定。EBSD结果表明,SLM-C试样的平均晶粒尺寸为386 µm,而SLM-E试样仅为193 µm,故SLM-E试样的细晶强化效果更大。如图10c和d所示,SLM-C试样的位错密度高于SLM-E,且位错分布更均匀,位错强化效果更明显。SLM-E试样中,沿增材方向截面的B2相面积分数为17.1%,而SLM-C试样中该数值仅为9.0%,故SLM-E试样中B2相对位错运动的阻碍作用更强。同时,由于SLM-E试样的激光功率更高、扫描速率更低,其成形期间的热量累积较大,平均温度比SLM-C更高,更有利于γ′相析出,故其沉淀强化效果更强。然而,SLM-C试样的强度高于SLM-E试样,因此在该增材制造高熵合金中,与细晶强化和第二相强化相比,位错强化机制占主导地位。此外,如图10b所示,SLM-E试样中存在大量的匙孔和裂纹,但SLM-C试样中缺陷极少,故SLM-C试样表现出更好的塑性。

结合力学性能和微观组织可知,位错密度增大可以有效提高增材制造共晶高熵合金的强度,而匙孔的出现则会引起塑性的大幅下降。在增材制造过程中,激光使金属汽化后,金属蒸汽在熔池的液态金属内形成空腔,并伴随快速凝固成为孔洞[42~44]。匙孔的产生与线能量密度(El)密切相关,计算方法为

4 结论

(1) 铸态试样中,领先相以枝晶形式生长,自铸锭表层至心部,冷却速率下降,B2相面积分数从23.0%降低至16.9%,且Al元素浓度保持23.2%不变,fcc领先相中Al元素浓度由13.1%上升至13.7%。选区激光熔化中,领先相以柱状晶形式生长,由于溶质截留效应,fcc领先相形成饱和固溶体,Al元素浓度为14.3%,并使B2相面积分数减小至15.8%,Al元素浓度降低至16.5%。

(2) 较高的冷却速率和较低的温度梯度有利于产生柱状晶-等轴晶转变,其中扫描速率是CET转变的敏感参数。当扫描速率低于500 mm/s时,较大的能量输入使温度梯度降低,促进CET转变的发生。但由于等轴晶试样中缺陷较多,位错密度较低,其强度和塑性均低于柱状晶组织。

(3) 由于组织更细,且存在γ′强化相及位错胞,SLM-C打印态试样的强度和塑性均远超铸态试样。其平均屈服强度高达(916 ± 12) MPa,平均抗拉强度高达(1320.5 ± 4.5) MPa,平均断裂延伸率达到(25.8 ± 2.2)%,实现了强度和塑性的良好匹配。

参考文献

Microstructural development in equiatomic multicomponent alloys

[J].

A critical review of high entropy alloys and related concepts

[J].

Phase-selective recrystallization makes eutectic high-entropy alloys ultra-ductile

[J].Excellent ductility is crucial not only for shaping but also for strengthening metals and alloys. The ever most widely used eutectic alloys are suffering from the limited ductility and losing competitiveness among advanced structural materials. Here we report a distinctive concept of phase-selective recrystallization to overcome this challenge for eutectic alloys by triggering the strain hardening capacity of the duplex phases completely. We manipulate the strain partitioning behavior of the two phases in a eutectic high-entropy alloy (EHEA) to obtain the phase-selectively recrystallized microstructure with a fully recrystallized soft phase embedded in the skeleton of a hard phase. The resulting microstructure fully releases the strain hardening capacity in EHEA by eliminating the weak boundaries. Our phase-selectively recrystallized EHEA achieves a high ductility of ∼35% uniform elongation with true stress of ∼2 GPa. This concept is universal for various duplex alloys with soft and hard phases and opens new frontiers for traditional eutectic alloys as high-strength metallic materials.© 2022. The Author(s).

A promising new class of high-temperature alloys: Eutectic high-entropy alloys

[J].High-entropy alloys (HEAs) can have either high strength or high ductility, and a simultaneous achievement of both still constitutes a tough challenge. The inferior castability and compositional segregation of HEAs are also obstacles for their technological applications. To tackle these problems, here we proposed a novel strategy to design HEAs using the eutectic alloy concept, i.e. to achieve a microstructure composed of alternating soft fcc and hard bcc phases. As a manifestation of this concept, an AlCoCrFeNi2.1 (atomic portion) eutectic high-entropy alloy (EHEA) was designed. The as-cast EHEA possessed a fine lamellar fcc/B2 microstructure, and showed an unprecedented combination of high tensile ductility and high fracture strength at room temperature. The excellent mechanical properties could be kept up to 700 degrees C. This new alloy design strategy can be readily adapted to large-scale industrial production of HEAs with simultaneous high fracture strength and high ductility.

Promising properties and future trend of eutectic high entropy alloys

[J].

Enhancing the yield strength of Ni-Co-Cr-Fe-Al as-cast hypoeutectic high-entropy alloys by introducing γ′ precipitation

[J].

A casting eutectic high entropy alloy with superior strength-ductility combination

[J].

Directly cast bulk eutectic and near-eutectic high entropy alloys with balanced strength and ductility in a wide temperature range

[J].

Microstructure and mechanical properties of a high entropy alloy with a eutectic composition (AlCoCrFeNi2.1) synthesized by mechanical alloying and spark plasma sintering

[J].

Additive manufacturing of metallic components—Process, structure and properties

[J].

Additive manufacturing of metals

[J].

Additive manufacturing of metals: A brief review of the characteristic microstructures and properties of steels, Ti-6Al-4V and high-entropy alloys

[J].

Effect of Al/Ni ratio, heat treatment on phase transformations and microstructure of Al x FeCoCrNi2 - x (x = 0.3, 1) high entropy alloys

[J].

Deformation behaviors of an additive-manufactured Ni32Co30Cr10Fe10Al18 eutectic high entropy alloy at ambient and elevated temperatures

[J].

Remelting induced fully-equiaxed microstructures with anomalous eutectics in the additive manufactured Ni32Co30Cr10Fe10Al18 eutectic high-entropy alloy

[J].

Probing effects of solute trapping on the mechanical properties of α-Al in rapidly solidified hypoeutectic Al-10at.%Cu after surface laser melting

[J].

Additively manufactured hierarchical stainless steels with high strength and ductility

[J].Many traditional approaches for strengthening steels typically come at the expense of useful ductility, a dilemma known as strength-ductility trade-off. New metallurgical processing might offer the possibility of overcoming this. Here we report that austenitic 316L stainless steels additively manufactured via a laser powder-bed-fusion technique exhibit a combination of yield strength and tensile ductility that surpasses that of conventional 316L steels. High strength is attributed to solidification-enabled cellular structures, low-angle grain boundaries, and dislocations formed during manufacturing, while high uniform elongation correlates to a steady and progressive work-hardening mechanism regulated by a hierarchically heterogeneous microstructure, with length scales spanning nearly six orders of magnitude. In addition, solute segregation along cellular walls and low-angle grain boundaries can enhance dislocation pinning and promote twinning. This work demonstrates the potential of additive manufacturing to create alloys with unique microstructures and high performance for structural applications.

On the microstructure evolution and strengthening mechanism of GH4099 Ni-based superalloy fabricated by laser powder bed fusion

[J].

Effects of cell network structure on the strength of additively manufactured stainless steels

[J].

Role of the solidification cells on the yield strength of the Al-Si-Mg alloy manufactured using laser powder bed fusion: A micropillar compression study

[J].

High strength Al0.7CoCrFeNi2.4 hypereutectic high entropy alloy fabricated by laser powder bed fusion via triple-nanoprecipitation

[J].

A strong fracture-resistant high-entropy alloy with nano-bridged honeycomb microstructure intrinsically toughened by 3D-printing

[J].Strengthening materials via conventional "top-down" processes generally involves restricting dislocation movement by precipitation or grain refinement, which invariably restricts the movement of dislocations away from, or towards, a crack tip, thereby severely compromising their fracture resistance. In the present study, a high-entropy alloy AlCrCoFeNi is produced by the laser powder-bed fusion process, a "bottom-up" additive manufacturing process similar to how nature builds structures, with the microstructure resembling a nano-bridged honeycomb structure consisting of a face-centered cubic (fcc) matrix and an interwoven hexagonal net of an ordered body-centered cubic B2 phase. While the B2 phase, combined with high-dislocation density and solid-solution strengthening, provides strength to the material, the nano-bridges of dislocations connecting the fcc cells, i.e., the channels between the B2 phase on the cell boundaries, provide highways for dislocation movement away from the crack tip. Consequently, the nature-inspired microstructure imparts the material with an excellent combination of strength and toughness.© 2024. This is a U.S. Government work and not under copyright protection in the US; foreign copyright protection may apply.

Theory of eutectic growth under rapid solidification conditions

[J].

Rapid solidification of Al-Cu eutectic alloy by laser remelting

[J].

Understanding grain refinement in aluminium welding: Henry Granjon Prize 2015 winner category B: Materials behaviour and weldability

[J].

Laser powder bed fusion of a near-eutectic Al-Fe binary alloy: Processing and microstructure

[J].

Estimation of cooling rates in suction casting and copper-mould casting processes

[J].

Multi-scale simulation of columnar-to-equiaxed transition during laser selective melting of rare earth magnesium alloy

[J].A model of coupling macro finite volume method (FVM) and cellular automata (CA) is proposed in this paper to explore the columnar-to-equiaxed transition (CET) during selective laser melting (SLM) of rare earth magnesium alloy. Taking into account the impact of recoil pressure and Marangoni convection on the molten pool temperature field, the grain structure is simulated. As suggested by the simulation results, with the undissolved Zr serving as heterogeneous nucleation sites, the liquid undercooled layer under the combined action of forced cooling, the temperature gradient and the liquid solute concentration gradient leads to CET. While considering the dissolution of Zr in magnesium matrix, the results demonstrate that the dissolution of element Zr is effective in significantly inhibiting the growth of columnar crystals and ensuring the sufficient constitutional supercooling (CS) required for nucleation. In addition, to raise the preheating temperature contributes to enhancing the outcome of nucleation and incresing the grain size. Invoking the interdependence model (IM), with the cooling rate gradually increasing in the SLM process of magnesium alloy, the nucleation-free zone (NFZ) reduces by decreasing the solute diffusion layer in the front of the solid/liquid (SL) interface and the temperature gradient. The reduction in temperature gradient can promote undercooling for nucleation and facilitate the development of equiaxed crystals. The simulation results are qualitatively verified as highly consistent through experimentation.

Parametric analysis of thermal behavior during selective laser melting additive manufacturing of aluminum alloy powder

[J].

Influence of cooling speed on the microstructure and wear behaviour of hypereutectic Fe-Cr-C hardfacings

[J].

The effect of cooling rate on the microstructure and physical properties of hypereutectic Al-Ce alloys

[J].

Simulations of microstructure coupling with moving molten pool by selective laser melting using a cellular automaton

[J].

Solute trapping and solute drag during non-equilibrium solidification of Fe-Cr alloys

[J].

Epitaxial laser metal forming: Analysis of microstructure formation

[J].

Columnar to equiaxed transition in Al-Mg(-Sc)-Zr alloys produced by selective laser melting

[J].

Columnar to equiaxed transition in additively manufactured CoCrFeMnNi high entropy alloy

[J].

Promoting the columnar to equiaxed transition and grain refinement of titanium alloys during additive manufacturing

[J].Preventing columnar grain formation during additive manufacturing has become a significant challenge. Columnar grains are generally regarded as unfavourable as their presence can impart solidification defects and mechanical property anisotropy, however, the thermal conditions experienced during additive manufacturing make columnar grains difficult to avoid. In this work the thermal conditions during solidification (cooling rate, temperature gradients) are characterised during wire based additive manufacturing. For the selection of deposition conditions that favour equiaxed grain formation, the role of alloy constitution is explored in three classical alloy design regimes: an alloy containing no grain refiners (Ti-6Al-4V); an alloy only containing grain refining solutes (Ti-3Al-8V-6Cr-4Mo-4Zr); and an alloy containing both grain refining solute and nucleant particles (Ti-3Al-8V-6Cr-4Mo-4Zr + La2O3). Substantial refinement and equiaxed grain formation is achieved in the latter case which is attributed to beta-Ti nucleation on La2O3. However, the thermal environment is dynamic during additive manufacturing and equiaxed grain formation is only achievable when temperature gradients decrease sufficiently to permit constitutional supercooling. (C) 2019 Acta Materialia Inc. Published by Elsevier Ltd.

Columnar to equiaxed transition in solidification processing

[J].

In-situ grain structure control in directed energy deposition of Ti6Al4V

[J].

Graded microstructure and mechanical properties of additive manufactured Ti-6Al-4V via electron beam melting

[J].

Additive manufacturing of metals: Microstructure evolution and multistage control

[J].As a revolutionary industrial technology, additive manufacturing creates objects by adding materials layer by layer and hence can fabricate customized components with an unprecedented degree of freedom. For metallic materials, unique hierarchical microstructures are constructed during additive manufacturing, which endow them with numerous excellent properties. To take full advantage of additive manufacturing, an in-depth understanding of the microstructure evolution mechanism is required. To this end, this review explores the fundamental procedures of additive manufacturing, that is, the formation and binding of melt pools. A comprehensive processing map is proposed that integrates melt pool energy- and geometry-related process parameters together. Based on it, additively manufactured microstructures are developed during and after the solidification of constituent melt pool. The solidification structures are composed of primary columnar grains and fine secondary phases that form along the grain boundaries. The post-solidification structures include submicron scale dislocation cells stemming from internal residual stress and nanoscale precipitates induced by intrinsic heat treatment during cyclic heating of adjacent melt pool. Based on solidification and dislocation theories, the formation mechanisms of the multistage microstructures are thoroughly analyzed, and accordingly, multistage control methods are proposed. In addition, the underlying atomic scale structural features are briefly discussed. Furthermore, microstructure design for additive manufacturing through adjustment of process parameters and alloy composition is addressed to fulfill the great potential of the technique. This review not only builds a solid microstructural framework for metallic materials produced by additive manufacturing but also provides a promising guideline to adjust their mechanical properties.

Keyhole fluctuation and pore formation mechanisms during laser powder bed fusion additive manufacturing

[J].Keyhole porosity is a key concern in laser powder-bed fusion (LPBF), potentially impacting component fatigue life. However, some keyhole porosity formation mechanisms, e.g., keyhole fluctuation, collapse and bubble growth and shrinkage, remain unclear. Using synchrotron X-ray imaging we reveal keyhole and bubble behaviour, quantifying their formation dynamics. The findings support the hypotheses that: (i) keyhole porosity can initiate not only in unstable, but also in the transition keyhole regimes created by high laser power-velocity conditions, causing fast radial keyhole fluctuations (2.5-10 kHz); (ii) transition regime collapse tends to occur part way up the rear-wall; and (iii) immediately after keyhole collapse, bubbles undergo rapid growth due to pressure equilibration, then shrink due to metal-vapour condensation. Concurrent with condensation, hydrogen diffusion into the bubble slows the shrinkage and stabilises the bubble size. The keyhole fluctuation and bubble evolution mechanisms revealed here may guide the development of control systems for minimising porosity.© 2022. The Author(s).

Mechanism of keyhole pore formation in metal additive manufacturing

[J].

Metal vaporization and its influence during laser powder bed fusion process

[J].

Understanding keyhole induced-porosities in laser powder bed fusion of aluminum and elimination strategy

[J].