现如今在航空航天、能源行业、汽车工业、生物医学等众多领域,复杂使役条件使得对多功能耦合、多性能复合新型金属材料的需求愈发迫切,如涡轮叶片需同时满足热阻、高温抗氧化以及低温强韧性等要求[1],汽车结构件需在保证良好强塑性的同时实现车身轻量化[2,3],人造关节、骨骼等生物医学植入物需要具备良好的综合性能以及生物相容性[4]等。与传统的单一材料相比,异种材料将具备不同功能与特性的材料相结合,有效提升了构件的复杂性、功能性和经济性,可通过调控材料类型与合金成分适应各种复杂工况下的性能需求,具有十分广阔的发展前景[5~7]。然而由于不同材料的物性差异与组织差异、元素互扩散、冷速过快引发热应力等原因,异种材料界面处往往容易出现脆性金属间化合物层和局部应力集中过高等问题,导致界面结合强度显著降低,最终引发界面开裂[8,9]。因此,明确异种材料的界面相容性机制,进而设计具有良好组织相容性和晶体学相容性的界面,对促进高性能异种材料的研发与应用至关重要。

中/高熵合金(MEA/HEA)分别指在原子占位无序条件下满足混合熵1R ≤ ΔSmix ≤ 1.5R和ΔSmix > 1.5R (R为气体常数)的多组元合金,由于其独特的高熵效应、晶格畸变效应、缓慢扩散效应以及鸡尾酒效应,MEA/HEA展现出良好的耐腐蚀性能、抗疲劳性能、断裂韧性、屈服强度等[10~13],成为近年来的研究热点之一。不锈钢作为相对成熟的商业合金,具备优异的抗腐蚀能力、强韧性、焊接性能以及经济性,被广泛应用于众多工业领域。MEA/HEA与不锈钢异种材料有望兼顾复合性能和成本优势,有助于进一步扩大MEA/HEA的应用领域。截至目前已有一些学者开展了相关研究,李娟等[14]研究了扩散温度对CoCrFeNiCu HEA与304不锈钢真空扩散焊的影响,异种材料接头为全固溶态亚结构和再结晶组织,无金属间化合物生成,抗拉强度分布在400~500 MPa,拉伸试样均断裂于HEA母材处。Sokkalingam等[15]利用钨极惰性气体保护焊实现Al0.1CoCrFeNi HEA与304不锈钢的异种材料连接,显微组织由界面处的柱状枝晶逐步向焊接中心的等轴枝晶转变,HEA热影响区存在明显晶粒粗化,焊接接头抗拉强度为590 MPa,断裂应变为38%。Kim等[16]借助热轧黏合法制备了V10Cr10Fe50Co30 HEA与304不锈钢的异种材料,利用HEA和不锈钢中逐步发生的相变诱导塑性(TRIP)效应以及异种材料界面附近的应变梯度调节,实现了室温803 MPa的超高抗拉强度以及44%的良好延伸率。Oliveira等[17,18]利用激光焊接法连接轧态CoCrFeMnNi HEA与316不锈钢并获得无缺陷接口,熔池区组织为fcc单相结构,焊接试样极限抗拉强度约为450 MPa,延伸率约为5%,试样断裂于熔池区;使用退火态CoCrFeMnNi HEA可使断裂应变提升至10%,而抗拉强度基本保持不变。Adomako等[19]在CoCrFeMnNi HEA与双相不锈钢异种材料体系的激光焊接中也获得了相似结论。Yan等[20]则对CrCoNi MEA与301L不锈钢进行激光焊接并获得482 MPa抗拉强度和46%断裂应变的异种材料试样。上述研究主要围绕MEA/HEA与不锈钢异种材料的连接工艺、界面形态以及组织-性能规律展开研究,但异种材料界面的相容性机制尚未得到系统性论述。

与铸造、压力加工、焊接、粉末冶金、化学气相沉积等传统加工方法相比,激光熔化沉积(LMD),又称激光熔覆或激光金属沉积,是一种利用高能激光分层熔化金属粉末或金属丝原料实现材料逐层累积的增材制造技术,在表面改性以及多材料、多结构、多功能的复杂零件制备领域具备独特优势[21~23]。激光熔化沉积可形成微小熔池,更利于实现异种材料界面成分、组织与性能的精准调控,同时与激光粉末床熔融相比更易于实现粉末更换、气氛保护以及大尺寸部件制备。因此,本工作通过在316L奥氏体不锈钢基板表面激光熔化沉积CoCrNiCu MEA制备异种材料,着重研究异种材料界面的组织相容性和晶体学相容性规律,进而为异种材料合金体系设计以及组织、性能优化提供参考。

1 实验方法

图1

图1

异种材料激光熔化沉积加工示意图和样品宏观形貌

Fig.1

Schematic of laser melting deposition for dissimilar materials (a) and specimen macroscopic morphology of deposition layers with total scanning length of 18 cm (b) (MEA—medium-entropy alloy)

激光熔化沉积异种材料试样的宏观形貌如图1b所示。借助电火花线切割机,沿垂直于异种材料界面方向切割,并在界面位置取样。采用SU5000扫描电子显微镜(SEM)和EDAX-TSL电子背散射衍射仪(EBSD)对异种材料试样的组织和界面特征进行表征,同时借助X-MAX 20能谱仪(EDS)对界面不同区域的化学成分进行线扫描、面扫描以及定量分析。SEM和EBSD试样经砂纸研磨后进行机械抛光处理,为保证组织完整性均未进行化学腐蚀。借助Crossbeam 540聚焦离子束扫描电镜(FIB-SEM)在异种材料界面处切取面积约为10.0 μm × 6.0 μm的特征区域,再利用离子减薄制得扫描透射电子显微镜(STEM)样品。利用F200X STEM拍摄异种材料界面处的明场(BF)像、暗场(DF)像、高角环形暗场(HAADF)像以及高分辨TEM像,分析异种材料界面晶体学特征。为分析316L不锈钢界面侧的组织结构转变,利用配备Symmetry探测器的EBSD系统进行同轴透射Kikuchi衍射(TKD)分析,加速电压为30 kV,工作距离为6 mm,并使用HKL-Channel 5软件完成数据处理。采用ABAQUS软件模拟激光熔化沉积过程异种材料试样的温度场以及残余热应力分布情况。

采用Hysitron TI 950纳米压痕仪(NHT)测量异种材料界面处的显微硬度分布,Vikers硬度压头直径为20 μm,加压和卸载速率为2000 mN/min,最大加载1000 mN,保持时间10 s,纳米压痕试样测试前需进行打磨抛光处理。采用DNS-100电子万能试验机测定CoCrNiCu MEA激光熔化沉积试样以及316L不锈钢铸态基板的拉伸力学性能,实验遵循GB/T 228.1—2010标准,拉伸试样标距段尺寸为20 mm × 2 mm × 1 mm,拉伸速率为1 mm/min,最大载荷为300 kN。采用DNS-100电子万能试验机测定异种材料界面的剪切强度,实验遵循GB/T 6396—2008标准,剪切试样底面尺寸为65 mm × 25 mm,异种材料复材总厚度为12 mm,剪切速率为0.5 mm/min。

2 实验结果

2.1 异种材料显微组织

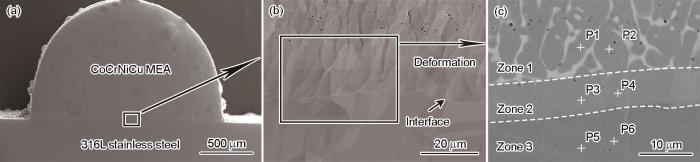

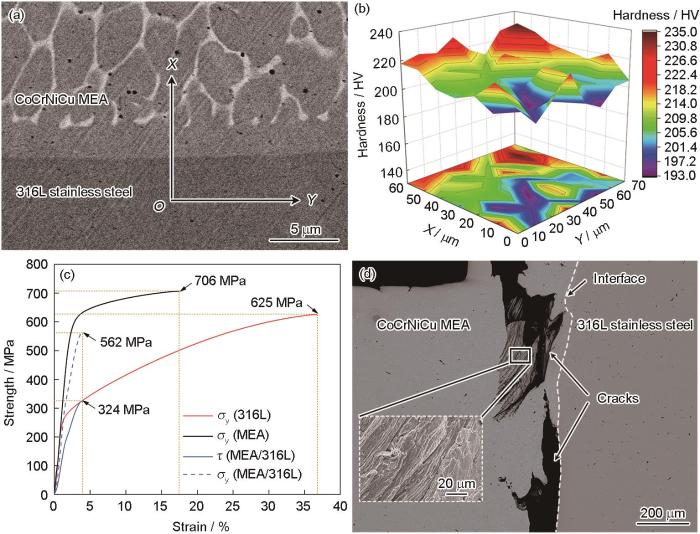

图2为CoCrNiCu MEA与316L不锈钢异种材料激光熔化沉积试样的SEM像。从图2a和b的二次电子(SE)像可见,CoCrNiCu MEA单道截面呈规则半圆状,无明显宏观缺陷,异种材料界面结合良好(图2a),熔池凝固边界呈现波纹状,且熔池区附近显微组织发生轻微浮凸(图2b),表明存在一定应力变形,这与异种材料的物性差异以及激光熔化沉积过程快速冷却引发的热应力有关。与SE像相比,图2c的背散射(BSE)像由于对大原子序数元素能够呈现更高衬度,因而可更清晰地显示异种材料界面处的组织形态。如图2c所示,异种材料界面处显微组织可分为3个区域:CoCrNiCu MEA的典型组织特征区域(Zone 1),即MEA固溶体基体中分布有网状富Cu相[25];8.0~15.0 μm宽的带状过渡区(Zone 2),该区域基体BSE像衬度与Zone 1接近,但未观察到网状第二相;316L不锈钢区域(Zone 3),BSE像衬度显著增加,表明合金成分发生明显变化,而衬度差异主要源于CoCrNiCu MEA与316L不锈钢的Cu含量不同。

图2

图2

CoCrNiCu 中熵合金(MEA)/316L不锈钢异种材料的SEM像

Fig.2

Secondary electron (SE) (a, b) and back-scattered electron (BSE) (c) SEM images of the dissimilar materials of CoCrNiCu MEA and 316L stainless steel at different magnifications

借助EDS分别测定图2c 3个区域的化学成分,每区域随机取2个测试点,结果如表1所示。表1同时列出了CoCrNiCu MEA与316L不锈钢的初始成分。可见,Zone 1中Co、Cr、Cu元素含量相较于CoCrNiCu MEA初始成分有所降低,而Ni元素含量变化较小,同时检测到16.0%~16.5% (质量分数,下同)的Fe,这表明316L不锈钢中的合金元素已部分固溶在CoCrNiCu MEA基体中;与Zone 1相比,过渡区(Zone 2)的Fe元素含量提高至24.1%~24.6%,同时Co、Cr、Ni、Cu元素含量均有不同程度下降。Zone 1与Zone 2合金成分的种类一致,仅存在含量差异,因此这2个区域均属于CoCrNiCuFe五元HEA。与316L不锈钢初始成分相比,316L不锈钢靠近异种材料界面侧(Zone 3)的Cr、Ni元素含量略有增加,Mo、Mn、Si元素含量由于稀释作用略有下降,同时检测到约0.9%的Co元素和约0.6%的Cu元素,这表明CoCrNiCu MEA中的Co、Cr、Ni、Cu元素也部分固溶在316L 不锈钢中,但固溶程度明显更小。

表1 CoCrNiCu MEA与316L不锈钢的初始成分以及CoCrNiCu MEA/316L不锈钢异种材料界面不同位置化学成分的EDS测定结果 (mass fraction / %)

Table 1

| Material | Position | Co | Cr | Ni | Cu | Fe | Mo | Mn | Si | C |

|---|---|---|---|---|---|---|---|---|---|---|

| CoCrNiCu MEA | P1 | 22.7 | 20.9 | 25.7 | 14.8 | 16.0 | - | - | - | - |

| P2 | 23.3 | 21.5 | 26.1 | 12.6 | 16.5 | - | - | - | - | |

| Transition zone | P3 | 20.5 | 20.7 | 23.6 | 10.6 | 24.6 | - | - | - | - |

| P4 | 21.1 | 20.8 | 23.5 | 10.5 | 24.1 | - | - | - | - | |

| 316L stainless steel | P5 | 0.9 | 17.3 | 10.7 | 0.6 | Bal. | 1.90 | 1.07 | 0.39 | 0.03* |

| P6 | 0.9 | 17.5 | 10.3 | 0.6 | Bal. | 2.00 | 1.02 | 0.44 | 0.03* | |

| CoCrNiCu MEA | Original | 25.3 | 22.3 | 25.2 | 27.2 | - | - | - | - | - |

| 316L stainless steel | Original | - | 16.5 | 10.2 | - | Bal. | 2.06 | 1.22 | 0.53 | 0.03 |

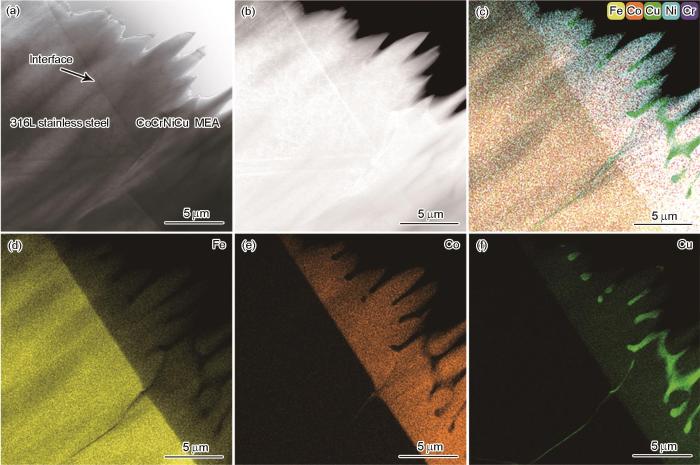

为进一步研究CoCrNiCu MEA与316L不锈钢激光熔化沉积异种材料的组织特征与成分分布规律,采用STEM对FIB试样进行形貌观察与成分分析,如图3所示。图3a和b分别为异种材料界面接头附近的BF像和HAADF像。可见,2种材料界面清晰,界面结合程度良好且未发现显微缺陷。图3c显示异种材料界面两侧存在明显合金成分差异,同时可清晰观察到图2c中总结的3类区域。其中右上方区域的网状第二相富含Cu元素,进一步验证Zone 1为CoCrNiCu MEA。Zone 2内合金元素整体分布均匀、实现良好固溶,局部区域观察到线状富Cu相由CoCrNiCu MEA向316L不锈钢中延伸生长,这可能与熔池局部偏析有关。Zone 2内未观察到大尺寸富Cu相析出,这不仅受合金元素稀释的影响,同时Fe元素固溶形成的五元HEA固溶体也强化了高熵效应,进一步提高了Cu元素的固溶度。Zone 3内除极少量富Cu相外未观察到元素富集区域,表明无异常金属间化合物形成。图3d~f对比了代表性元素Fe、Co、Cu的分布情况。可见,Fe元素形成了更为明显的成分梯度,这与表1的结果一致。结合激光熔化沉积的加工特性分析可知,Zone 1与Zone 2内合金元素的含量差异与熔池对流和界面扩散2个因素有关,部分316L不锈钢基板材料经激光熔化后在熔池对流作用下进入CoCrNiCu MEA中并发生元素稀释,同时在激光熔化沉积的高温环境下316L不锈钢中合金元素存在向CoCrNiCu MEA的界面扩散,上述2个因素促使在异种材料界面的垂直方向上形成成分梯度,最终在高熵合金的高熵效应下实现固溶态组织。相比之下,Zone 3的合金元素含量差异主要受界面扩散影响,而316L不锈钢侧元素稀释现象并不明显,这表明界面扩散作用相对有限,这与激光熔化沉积后伴随的较高冷却速率有关。

图3

图3

CoCrNiCu MEA/316L不锈钢异种材料的STEM分析

Fig.3

STEM analyses of the dissimilar materials of CoCrNiCu MEA and 316L stainless steel

(a) bright field (BF) image (b) high-angle annular dark field (HAADF) image

(c) EDS diagram (d) Fe mapping (e) Co mapping (f) Cu mapping

2.2 异种材料界面特征

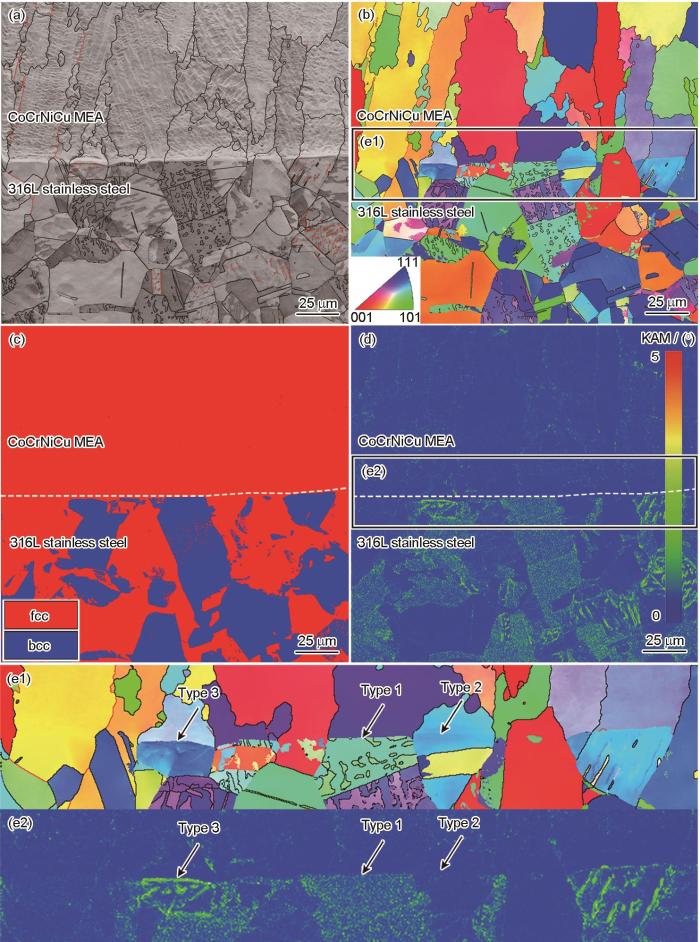

CoCrNiCu MEA与316L不锈钢异种材料界面特征的EBSD分析结果如图4所示。图4a为Kikuchi带衬度(BC)图,其中大角度晶界(取向差> 15°)和小角度晶界(取向差在2°~15°范围)分别用黑色和红色线标出。CoCrNiCu MEA与316L不锈钢的晶粒尺寸接近,不过铸态316L不锈钢多为等轴晶,而激光熔化沉积态CoCrNiCu MEA则呈垂直于异种材料界面方向生长的柱状晶。部分316L不锈钢晶粒内出现大量亚结构,且小角度晶界数量显著增多。图4b和c分别为异种材料界面的反极图(IPF)与相分布(PD)图,CoCrNiCu MEA的晶粒取向相对随机,且CoCrNiCu MEA基体与过渡层均为fcc结构;在316L不锈钢奥氏体基体(fcc结构)中发现部分晶粒出现向bcc结构的转变,结合IPF可判断发生了马氏体转变,形成马氏体板条束、板条块等亚结构。值得注意的是,图2c中归纳的Zone 1与Zone 2共属于同一个晶粒,图4c进一步说明两区域无结构转变发生,这表明Zone 2是CoCrNiCu MEA基体固溶以Fe为主的不锈钢合金元素而形成的稀释区。考虑到Zone 1与Zone 2仅存在成分差异、无明显物理界面和组织结构转变,下文中“异种材料界面”均指代Zone 2/Zone 3界面。图4d为内核平均取向差(KAM)图,可表征晶粒之间或晶粒内部的局部取向差,从而反映材料内部的应变分布状态。由图可知,CoCrNiCu MEA侧的应变整体较低,主要集中在晶界附近;而316L不锈钢侧马氏体组织区域的应变程度显著升高,尤其是小角度晶界密集分布的区域。由于几何必需位错密度与局部取向差呈正相关[26],因而激光熔化沉积实验可明显提高316L不锈钢侧局部晶粒的几何必需位错密度。为进一步研究异种材料界面的取向差规律,取图4b和d中方框区域进行局部放大对比分析,分别如图4e1和e2所示,CoCrNiCu MEA与316L不锈钢异种材料界面可归纳成3种主要类型:(1) 界面两侧晶粒取向差较大,此时316L不锈钢侧为完全马氏体组织(Type 1);(2) 界面两侧晶粒无明显取向差且共属于同一个晶粒,此时界面处未发生fcc→bcc转变(Type 2);(3) 界面两侧晶粒取向差相对较小,此时316L不锈钢侧已发生fcc→bcc转变,但尚未出现马氏体亚结构,即处于未完全马氏体转变状态(Type 3)。结合界面处的KAM图分析可知,3种界面的应变程度遵从如下规律:Type 3 > Type 1 > Type 2。

图4

图4

CoCrNiCu MEA/316L不锈钢异种材料的EBSD分析

Fig.4

EBSD analyses of the dissimilar materials of CoCrNiCu MEA and 316L stainless steel

(a) bond contrast (BC) image (The high-angle boundaries with misorientation angle >15° and low-angle boundaries with misorientation angle at 2°~15° are marked with black and red lines, respectively)

(b) inverse pole figure (IPF)

(c) phase distribution (PD) figure

(d) kernel average misorientation (KAM) map

(e1, e2) comparisons of the IPF (e1) and KAM map (e2) for the local magnification area of dissimilar material interface in Figs.4b and d, respectively (Types 1, 2, and 3 represent the interfaces with complete martensitic transformation, without martensitic transformation, and with incomplete martensitic transformation, respectively)

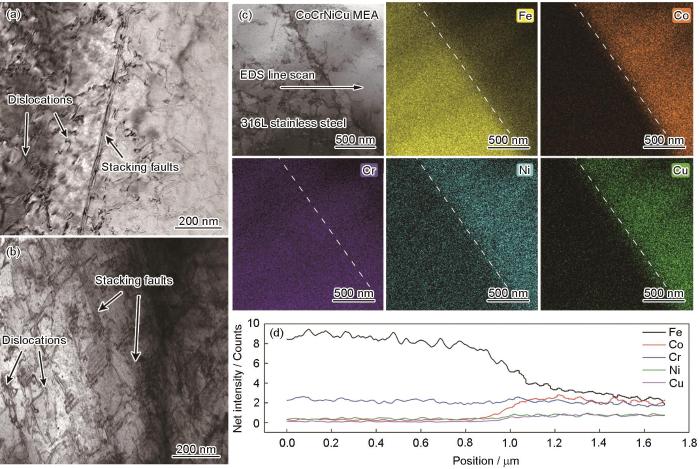

结合STEM进一步分析CoCrNiCu MEA与316L不锈钢异种材料界面处的显微组织与元素配分规律,如图5所示。图5a和b分别为316L不锈钢和CoCrNiCu MEA显微组织的TEM像。在316L不锈钢基体中可观察到大量位错线、位错网以及少量层错,而CoCrNiCu MEA组织则由CoCrNi固溶体基体、富Cu相、位错以及层错构成,其中位错与层错的数量密度明显增加。一方面,由于激光熔化沉积态CoCrNiCu MEA需承受更大的热应力,这有助于激发更多的位错与层错开动,纳米尺寸富Cu相的钉扎作用可提升材料的加工硬化能力;另一方面,研究[27]表明提高Cu含量会导致层错能(SFE)升高,在稳定γ-fcc相的同时增加界面的类型及数量,促进长度更短、宽度更窄的层错出现。本团队前期工作[25]研究了Cu含量对CoCrNiCu MEA显微组织与力学性能的影响,结果表明,由于Cu与基体元素较大的正混合焓,Cu元素更易于偏聚并以富Cu相形式存在,基体相与富Cu相界面处的错配位错有助于提升界面的协调变形能力,此外较硬基体相和较软富Cu相的交错分布可综合提升MEA的强塑性。借助EDS对异种材料界面的元素配分规律进行面扫描和线扫描分析,结果分别如图5c和d所示。在异种材料界面两侧形成了明显的Fe、Co元素成分梯度,Cu、Ni元素的成分梯度相对较小,而Cr元素在界面两侧浓度较为接近。除了上文所述激光熔化沉积过程中熔池对流的影响外,界面两侧较大的浓度差也为Fe、Co元素的界面扩散提供了更大的驱动力。

图5

图5

CoCrNiCu MEA/316L不锈钢异种材料显微组织的TEM像与界面元素配分

Fig.5

TEM images and interfacial element partitioning of the dissimilar materials of CoCrNiCu MEA and 316L stainless steel

(a) TEM image of 316L stainless steel (b) TEM image of CoCrNiCu MEA

(c) EDS element mapping near the interface (d) EDS line scan profile across the interface

2.3 异种材料力学性能

为评估CoCrNiCu MEA与316L不锈钢异种材料的力学性能,在界面附近沿X、Y轴分别等距取点测定显微硬度,如图6a和b所示。可见,沿Y轴方向(即平行于异种材料界面方向)硬度分布较为均匀,沿X轴方向由316L不锈钢至CoCrNiCu MEA硬度逐渐升高,不过2种材料硬度差异较小。图6c为铸态316L不锈钢基板、激光熔化沉积态CoCrNiCu MEA以及316L不锈钢基板表面激光熔化沉积CoCrNiCu MEA异种材料的强度性能对比。基于Mises屈服准则[28],在纯剪切情况下抗拉强度(σy)与剪切强度(τ)近似遵循

图6

图6

CoCrNiCu MEA/316L不锈钢异种材料的显微硬度、强度和断口形貌

Fig.6

Microhardness, strength, and fracture morphology for the dissimilar materials of CoCrNiCu MEA and 316L stainless steel

(a) sampling location for microhardness

(b) microhardness distribution

(c) strength profile (σy—yield strength, τ—shear strength)

(d) fracture morphology of dissimilar materials (Inset shows the locally enlarged image)

3 分析讨论

3.1 CoCrNiCu MEA/316L不锈钢异种材料界面固溶体形成机理

式中,δ为原子半径差;n为多组元合金体系的组元数;i为元素序数;

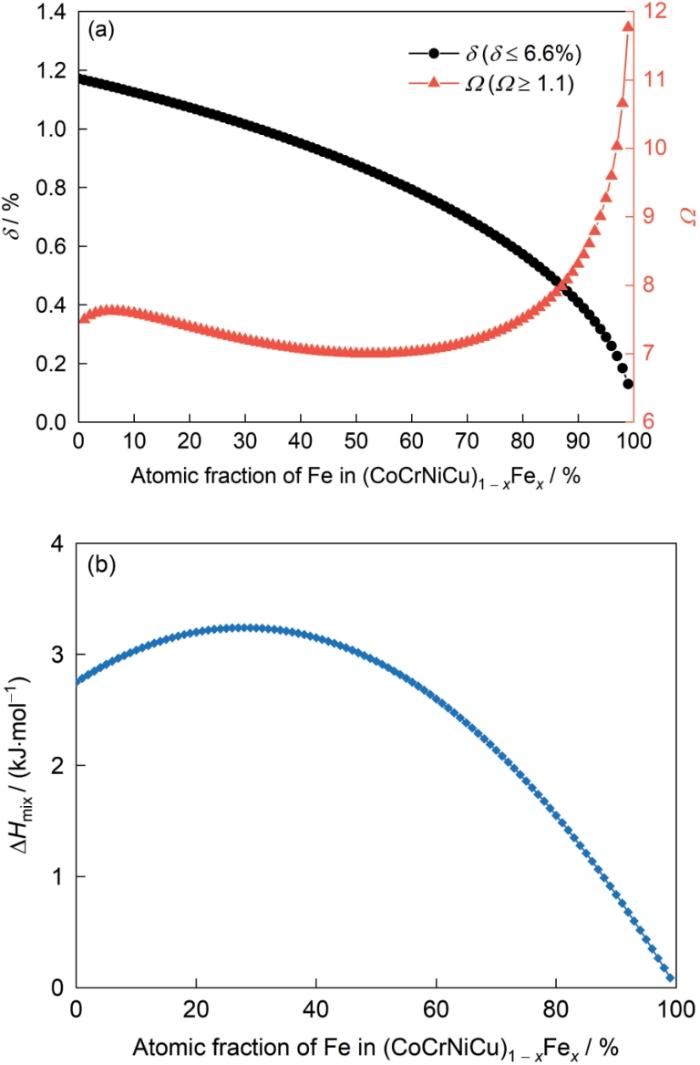

表1和图5均表明,CoCrNiCu MEA/316L不锈钢异种材料界面两侧Fe元素的浓度梯度最为显著。因此以CoCrNiCu MEA作为基体,计算固溶不同原子分数Fe所对应CoCrNiCu1 - x Fe xHEA固溶体的判据数值。通常来说,形成固溶体需满足Ω ≥ 1.1,δ ≤ 6.6%以及-10 kJ/mol ≤ ΔHmix ≤ 5 kJ/mol[30,31]。如图7所示,随着Fe原子分数由0增加至100%,多组元合金体系的Ω值在7.0~11.7范围内波动,δ值由1.2%逐步降低至0.1%,ΔHmix数值分布在0.1~3.2 kJ/mol,均符合固溶体形成判据,这说明理论上CoCrNiCu MEA可以无限固溶Fe元素。此前已有一些学者[14~18,20,29,32~34]针对不同成分体系HEA或MEA与不锈钢焊接接头的显微组织与力学性能展开研究,在2种材料界面处均未发现金属间化合物。异种材料焊接与激光熔化沉积过程均存在非稳态温度场与应力场、元素扩散配分等共性问题,因而2者的金属间化合物形成机理存在相似性。固溶体判据计算结果从理论上解释了HEA/MEA与不锈钢异种材料界面实现固溶的内在原因,同时说明HEA/MEA与不锈钢是相当理想的异种材料体系。

图7

图7

CoCrNiCu MEA/316L不锈钢异种材料的固溶体判据计算结果

Fig.7

Calculation results of solid solution criterions for the dissimilar materials of CoCrNiCu MEA and 316L stainless steel

(a) Ω-δ criterion (Ω—ratio parameter, δ—atomic size difference)

(b) mixing enthalpy (ΔHmix) criterion

3.2 CoCrNiCu MEA/316L不锈钢异种材料界面马氏体相变机理

图4显示在316L不锈钢靠近异种材料界面处的部分奥氏体晶粒发生了马氏体相变,该现象在奥氏体不锈钢与MEA/HEA异种材料的焊接以及激光增材制造领域尚未得到系统性报道,因此下面重点分析其形成机理。马氏体相变主要受化学成分与形变诱导2个因素影响,其相变机理与化学驱动力足够大使得奥氏体可以在没有外加应力的作用下发生马氏体相变的最高温度(Ms)和在塑性变形条件下能够发生马氏体相变的最高温度(Md)紧密相关[35]。理论上超过Md无法发生形变诱导马氏体相变。Olson和Cohen[36]引入临界温度(Msσ )进一步区分应力诱导和应变诱导2种马氏体相变方式,当温度位于Ms~Msσ 区间内,马氏体在外加应力的作用下才可以形核,此时局部应力低于奥氏体屈服强度,即处于弹性变形区间内,属于应力诱导马氏体相变;当温度达到Msσ 时,局部应力恰好等于奥氏体屈服强度,此时塑性变形产生,开始进入应变诱导马氏体相变阶段;当温度位于Msσ ~Md区间内,温度持续升高将导致化学驱动力逐渐下降,因此需要更大的额外变形以满足马氏体相变需要。由于化学成分与形变诱导2个因素在激光熔化沉积过程中同时存在,现逐一进行论证。

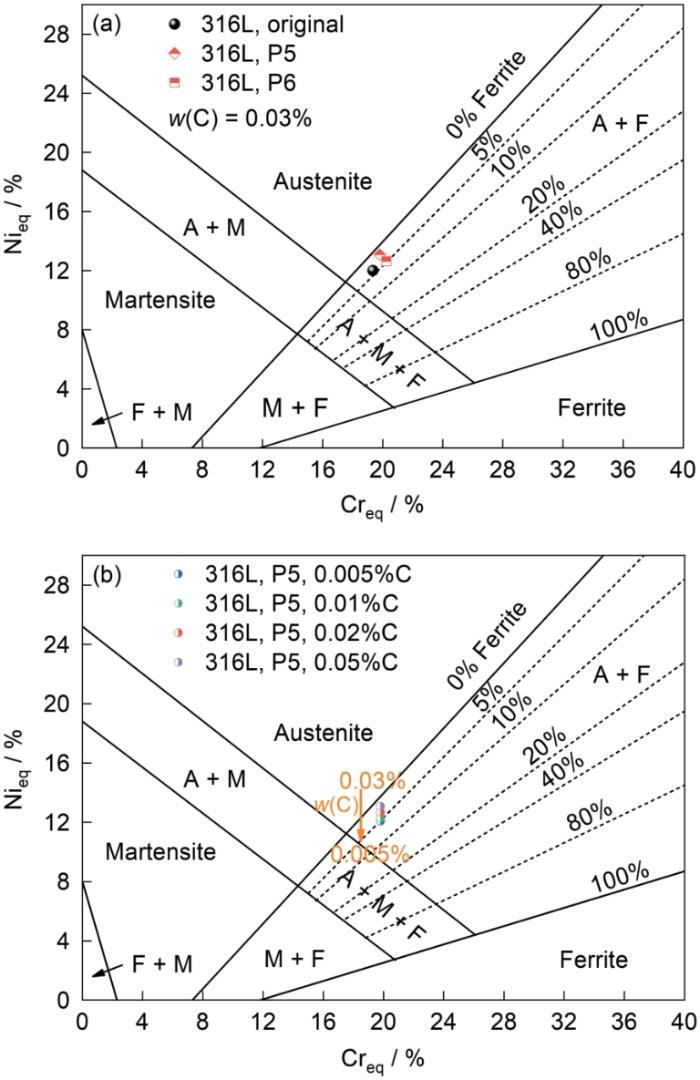

首先考虑化学成分因素影响。316L不锈钢为典型的奥氏体不锈钢,通常难以出现马氏体组织,因而需考虑界面元素配分对化学成分的作用。表1和图5均表明CoCrNiCu MEA中的Co、Cr、Ni、Cu等置换型元素不同程度地向316L不锈钢扩散。Lee等[37]借助电子探针显微分析(EPMA)对V10Cr10Fe45Co30Ni5 HEA和高锰钢异种材料的界面成分进行分析,结果表明,在高锰钢侧距离2种材料界面越近,C含量越低,同时在HEA侧检测到C元素,表明间隙型元素C在成分梯度作用下也将发生扩散。本工作借助Schaeffler图[38]分别衡量置换型元素(Co、Cr、Ni、Cu)以及间隙型元素(C)的界面配分行为对显微组织的影响,其中置换型元素含量取自316L不锈钢初始成分以及316L不锈钢靠近异种材料界面侧的实测成分(图2c,P5、P6点),由于EDS对间隙型元素含量的精准定量误差较大,因此本工作选取0.005%、0.01%、0.02%和0.03% (质量分数,下同) 4个梯度成分进行对比分析。Schaeffler图将合金元素分为铁素体形成元素和奥氏体形成元素2类,通过构建Ni当量(Nieq)和Cr当量(Creq)与不同合金元素含量的关系式[38],被广泛用于预测奥氏体不锈钢经焊接或激光融化沉积后的显微组织。置换型元素与间隙型元素C发生界面配分前后对应的Nieq、Creq以及显微组织如表2和图8所示。可知,316L不锈钢初始成分的预测结果为奥氏体和铁素体的双相组织(A + F),其中铁素体体积分数约为5%~10%。经置换型元素界面配分后,316L不锈钢显微组织趋于向远离马氏体区方向移动,同时铁素体平衡含量波动较小,这表明置换型元素界面配分对马氏体相变有抑制作用,这主要因为Cr、Ni元素含量增加均有利于提高奥氏体稳定性。由于P5、P6点成分较为接近,图8b选取P5点成分为基体计算间隙型元素C含量的贡献,随着C含量从0.03%逐步降低至0.005%,Nieq持续下降,Creq则不受影响,这使得标记点沿纵轴负方向逐步下移,铁素体体积分数逐渐增加,但显微组织预测结果仍处于A + F区域,这表明C元素的界面配分会导致奥氏体稳定性降低,但不足以导致马氏体相变。由Eichelman等[39]模型可知,间隙型元素C、N是影响Ms的最主要因素,计算结果表明,C含量为0.001%、0.005%、0.01%以及0.03%时316L不锈钢的Ms分别为-67.0、-73.6、-82.0和-115.3℃,均远低于实验温度。上述结果进一步证明仅靠界面元素配分提供的化学驱动力不足以激活马氏体相变。

表2 基于Schaeffler图计算的Ni当量(Nieq)、Cr当量(Creq)以及显微组织预测结果

Table 2

| Material | Position | Nieq | Creq | PM |

|---|---|---|---|---|

| 316L | Original | 19.4 | 12.0 | A + F |

| 316L | P5 | 19.8 | 13.1 | A + F |

| 316L | P6 | 20.3 | 12.6 | A + F |

| 316L, 0.005%C | P5 | 12.1 | 19.2 | A + F |

| 316L, 0.01%C | P5 | 12.3 | 19.2 | A + F |

| 316L, 0.02%C | P5 | 12.7 | 19.2 | A + F |

| 316L, 0.05%C | P5 | 13.1 | 19.2 | A + F |

图8

图8

置换型元素与间隙型元素C的界面配分对316L不锈钢Schaeffler图显微组织的影响

Fig.8

Effects of interfacial partitioning of substitu-tional elements (w(C)—mass fraction of C) (a) and interstitial element C (b) on the predicted microstructures of 316L stainless steel based on the Schaeffler diagram

式中,d代表奥氏体的ASTM晶粒度,通常

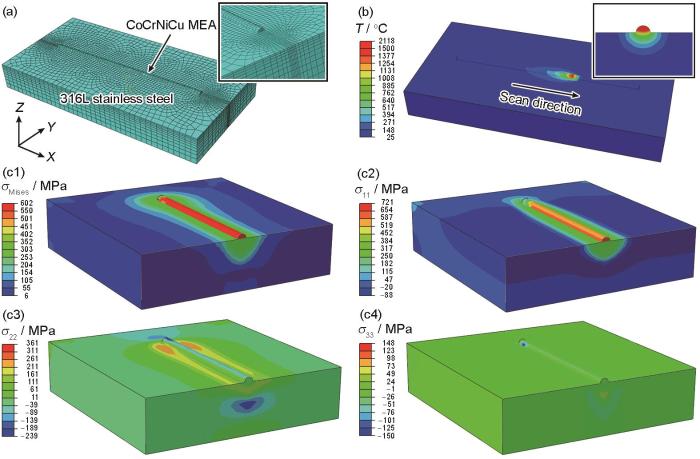

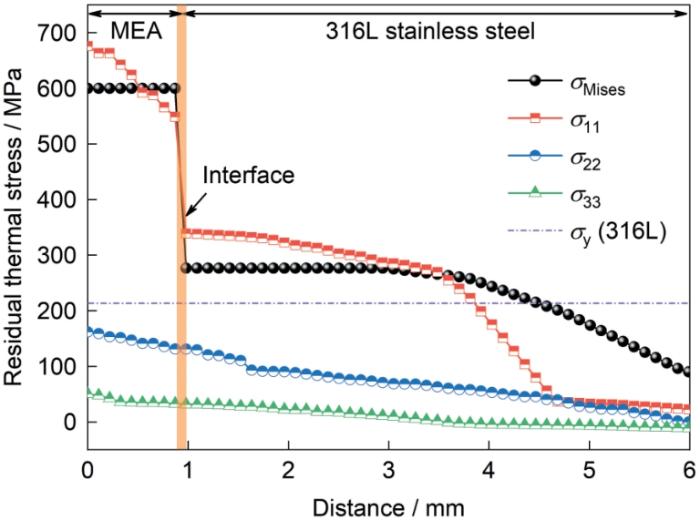

结合有限元分析方法对表面激光熔化沉积试样界面附近的温度场与残余热应力进行模拟。图9a为316L不锈钢基体上单层单道激光熔化沉积CoCrNiCu MEA的有限元建模及网格划分情况。模型根据实际样品等比例构建,将316L不锈钢基板设置为80 mm × 40 mm × 10 mm (长×宽×高)尺寸的长方体,CoCrNiCu MEA熔覆层设置为直径1.8 mm、长度60 mm的半圆柱体。采用环形热源三维模型,热源方程及边界条件详见文献[24]。弹性模量、Poisson比等材料参数取自参考文献[47,48]以及Jmatpro热力学软件模拟结果,经对比2种来源的数据偏差可忽略不计。图9b为激光熔化沉积过程中的温度场分布。熔池中心温度可达2118℃,剖面图(图9b中插图)显示高温区域主要集中在CoCrNiCu MEA以及异种材料界面处,向316L不锈钢基体侧温度逐渐降低。基于Mises屈服准则判断残余热应力是否足以使奥氏体发生塑性变形,图9c1~c4为Mises等效应力以及沿X、Y、Z 3个方向应力分量的模拟结果。由图可知Mises等效应力最高值出现在CoCrNiCu MEA中,且向316L不锈钢方向逐渐降低,CoCrNiCu MEA以X方向拉应力(σ11)为主,而Y方向拉应力(σ22)主要集中在2种材料界面附近,Z方向分应力(σ33)则整体分布相对均匀且数值较低。为进一步明晰316L不锈钢靠近异种材料界面处的马氏体相变机理,沿垂直于异种材料界面方向提取残余热应力演变数据,如图10所示。CoCrNiCu MEA侧等效Mises应力平稳维持在602 MPa左右,而316L不锈钢在靠近界面处达到Mises等效应力最大值(276.5 MPa),随着与异种材料界面距离的增加应力持续降低,异种材料界面处形成326.5 MPa的局部应力差。需要指出,除残余热应力外,2种材料物理性质的差异还会导致界面处产生额外的组织应力,结合图6c可确定316L不锈钢的屈服强度为213.3 MPa,因此异种材料界面处的总残余应力足以让奥氏体发生塑性变形,因此应属于应变诱导马氏体相变。此外,图4中只有离散分布的部分奥氏体晶粒发生了马氏体相变,这也可说明界面元素配分对马氏体相变不起决定作用,因为元素扩散会在一整片区域形成成分梯度。马氏体组织的离散分布与不同晶粒的Schmid因子存在差异有关,处于软取向晶粒的滑移系更容易开动,因而更容易发生马氏体相变。

图9

图9

316L不锈钢基体上单层单道激光熔化沉积CoCrNiCu MEA的有限元建模及网格划分情况,表面激光熔化沉积试样界面附近温度场与残余热应力的有限元模拟结果

Fig.9

Finite element model creating and mesh generation for the single-layer single-pass laser melting deposition of CoCrNiCu MEA on 316L stainless steel surface (Inset shows the mesh details near the interfaces of dissimilar materials) (a); simulation results of temperature field (Inset shows the temperature distribution on the cross section perpendicular to the scanning direction, T—temperature) (b); and simulation results of residual thermal stress including the equivalent Mises stress (σMises) (c1) and corresponding components along X (σ11) (c2), Y (σ22) (c3), and Z (σ33) (c4) directions

图10

图10

垂直于CoCrNiCu MEA/316L不锈钢异种材料界面方向残余热应力的演变

Fig.10

Evolutions of residual thermal stress perpendicular to the interface of dissimilar materials of CoCrNiCu MEA and 316L stainless steel

目前有关增材制造过程中奥氏体不锈钢的马氏体相变研究较少,但轧制过程形变诱导马氏体相变的机理研究可提供理论参考,大体可分为2种转变模式[49~51]:(1) 奥氏体(fcc)→ε-马氏体(hcp)→α'-马氏体(bcc);(2) 奥氏体(fcc)→α'-马氏体(bcc)。部分奥氏体的马氏体相变将有助于在提高应变硬化速率的同时达到强度与塑性的综合提升,即引发TRIP效应。部分研究[16,52]通过制备V10Cr10Fe50Co30或V10Cr10Fe45Co30-Ni5 HEA与304奥氏体不锈钢的多层板材并开展室温变形实验,结果表明10%应变时主要发生高熵合金TRIP效应;应变达到30%时高熵合金的TRIP效应已基本完成,此时304不锈钢TRIP效应开始发动;当应变达到72%时,高熵合金与304不锈钢TRIP效应均已完成。有趣的是,本工作中未发现CoCrNiCu MEA的TRIP效应,这表明316L不锈钢的TRIP效应优先发生。这一方面由于本工作316L不锈钢采用铸件基板,而CoCrNiCu MEA采用激光熔化沉积,快冷引发的高应力可促进材料加工硬化,致使其变形能力相应降低;另一方面,Cu元素的添加可提高fcc中熵合金的稳定性,有效推迟TRIP转变发生[27,53],最终导致CoCrNiCu MEA的力学稳定性超过316L不锈钢。由图4可知,完全马氏体相变晶粒的残余应变程度相较于未完全马氏体相变的晶粒更低,这表明马氏体转变有助于消耗部分应变能从而降低系统总自由能,TRIP效应有助于改善异种材料界面附近的应力集中,优化异种材料界面强塑性从而提高界面结合强度,这为异种材料制备提供了新思路。

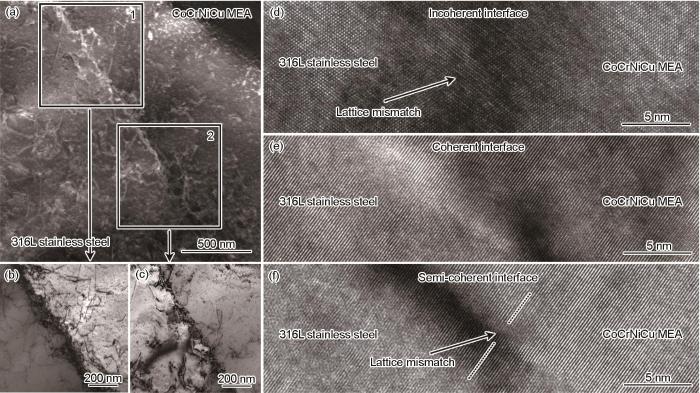

3.3 CoCrNiCu MEA/316L不锈钢异种材料界面晶体学分析

借助TEM对CoCrNiCu MEA/316L不锈钢异种材料界面晶体学展开分析,图11a为异种材料界面处TEM暗场(DF)像,可清晰表征界面形态以及位错、层错等晶体学缺陷。从图11a可观察到由左上方至右下方有一倾斜界面,其中左上段界面的衬度较大,表明晶格错配度更高,右下段界面衬度则明显减小。界面左右两侧分别对应316L不锈钢和CoCrNiCu MEA,两侧基体均存在大量缺陷。图11b和c为2类异种材料界面的TEM明场像对比,其中图11b异种材料界面两侧存在明显衬度差,界面存在大量位错堆积且界面宽度更大;图11c中异种材料界面两侧衬度较为接近,界面位错堆积明显减少。为进一步研究异种材料界面的匹配规律,对比了异种材料界面不同位置的TEM高分辨晶格衍衬像,如图11d~f所示,存在3种匹配类型:(1) 部分晶界原子排布十分混乱,存在大量晶格错配,形成非共格界面(图11d);(2) 部分晶界原子排布规整,界面两侧晶格衍衬像完美衔接,形成共格界面(图11e);(3) 部分晶界处可观察到刃位错等晶格缺陷交替出现,即形成半共格界面(图11f)。由于CoCrNiCu MEA与316L不锈钢基体均为fcc晶格结构,且晶格常数十分接近,在理想情况下可实现完全共格,但激光熔化沉积过程中热应力、组织应力引起的局部应力集中以及塑性变形会增加异种材料界面处的晶格错配,使界面匹配方式从共格向半共格甚至非共格转变,造成界面匹配度下降。

图11

图11

CoCrNiCu MEA/316L不锈钢异种材料界面匹配机制的TEM分析

Fig.11

TEM analyses of matching mechanism of the heterogeneous interface between CoCrNiCu MEA and 316L stainless steel

(a) dark field (DF) image

(b, c) locally enlarged BF images of square areas of 1 (b) and 2 (c) in Fig.11a

(d-f) high resolution TEM images of the heterogeneous interface show the incoherent interface (d), coherent interface (e), and semi-coherent interface (f)

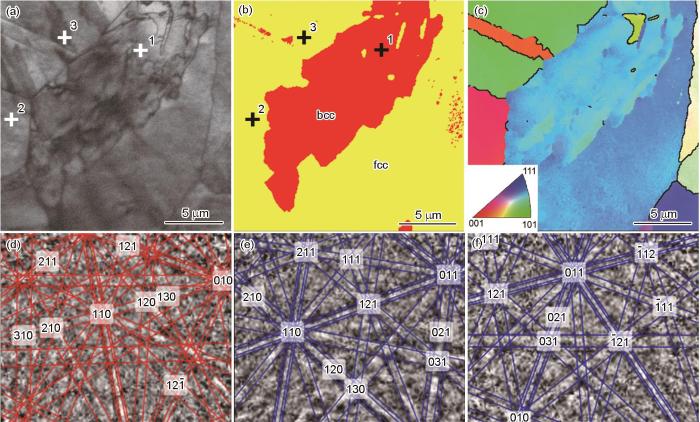

为阐明CoCrNiCu MEA/316L不锈钢异种材料界面的形变诱导马氏体相变对晶体学匹配方式的影响,对部分发生马氏体相变的奥氏体晶粒进行TKD分析,如图12所示。图12a~c分别为马氏体相变区域的SE像、PD图以及IPF。对比可知,图12b中央奥氏体晶粒的左上部分区域(红色)已由fcc结构转变为bcc结构,SE像(图12a)显示该区域亚组织显著增多且存在表面浮凸,符合马氏体组织的基本特征,而中央奥氏体晶粒的右下部分依然保持奥氏体组织。Tian等[54]研究表明,形变诱导α'-马氏体与原奥氏体晶粒保持Kurdjumov-Sachs (K-S)位相关系,而ε-马氏体与原奥氏体晶粒保持Shoji-Nishiyama (S-N)位相关系。Wang等[55]则系统研究了奥氏体不锈钢形变诱导马氏体的变体选择规律以及晶体学特征,结果表明,α'-马氏体在薄滑移带处形核时,由于可以自由生长协调变形从而形成单一变体,而当α'-马氏体在宽滑移带处形核时,自由生长的单一变体以及限制生长导致的多个变体均会出现。此外,对比了形变诱导马氏体与周围奥氏体的Kikuchi花样,如图12d~f所示。结果表明,因TRIP效应产生的马氏体与相邻晶粒未发现存在明确位相关系,这表明局部马氏体相变与所在奥氏体晶粒的匹配度较好,但可能导致与其余奥氏体晶粒的匹配能力下降。图4e1和e2观察到未发生马氏体相变的晶界应变程度最小,其次是完全马氏体相变的晶界,未完全马氏体相变的晶界应变程度最大,这说明马氏体相变会增加异种材料界面处的晶格错配,从而影响界面匹配度。

图12

图12

316L不锈钢马氏体转变组织的透射Kikuchi衍射(TKD)分析

Fig.12

Transmission Kikuchi diffraction (TKD) analyses of martensitic transformation microstructure in 316L stainless steel

(a) SEM-SE image (b) PD figure (c) IPF

(d-f) Kikuchi band patterns of positions 1 (d), 2 (e), and 3 (f) in Fig.12a

3.4 异种材料界面相容性设计策略

异种材料的组织相容性与晶体学相容性均会影响界面结合程度,从而影响异种材料的综合力学性能,因此在实际设计过程中需综合考虑2种因素。2种材料形成无限或者有限固溶体通常是较为理想的异种材料设计策略,由于Fe元素可与CoCrNiCu等MEA/HEA形成无限固溶体,因此奥氏体不锈钢与MEA/HEA是极佳的异种材料合金体系。在316L不锈钢表面激光熔化沉积CoCrNiCu MEA的过程中,C元素的界面配分有助于提高奥氏体不锈钢的Md30和Ms、降低SFE,从而引起奥氏体晶粒的力学稳定性下降,最终在热应力和组织应力的共同作用下发生形变诱导马氏体相变。这在吸收应变能的同时可促进TRIP效应,有助于改善异种材料界面的应力集中,综合提高异种材料强塑性;但从晶体学角度,马氏体相变会导致异种材料界面以及马氏体与周围奥氏体晶粒的匹配度下降。

基于本工作研究结果,进一步提出改善异种材料界面相容性的设计策略:对于晶体结构相同、晶格常数接近、物性差异较小的异种材料,如fcc结构的MEA/HEA与奥氏体不锈钢,理论上可实现全共格界面,此时应尽可能降低残余应力引发的塑性变形,从而抑制晶格错配,提升界面晶体学相容性;对于晶体结构和晶格常数存在一定差异、物性差异较大的异种材料,如bcc结构的MEA/HEA与奥氏体不锈钢,此时残余应力较高,界面晶格错配较大,可考虑通过调控奥氏体稳定元素界面配分以及形变诱导马氏体的TRIP效应,在异种材料界面处设计bcc + fcc双相结构,调控应变梯度,从而提升异种材料的协调变形能力。此外,还可借助优化热输入参数和冷却方式、引入预热处理和后热处理等手段,改善异种材料界面的温度场与应力场,从而实现最佳的组织相容性与晶体学相容性。该设计策略不只局限于激光熔化沉积,对异种材料的熔化焊接以及增材制造均有一定参考意义。

4 结论

(1) 在铸态316L不锈钢基板上激光熔化沉积CoCrNiCu中熵合金,获得了无宏观缺陷、无金属间化合物层、剪切强度为324 MPa的异种材料界面。界面处形成CoCrNiCuFe五元高熵合金全固溶过渡区,Ω-δ和混合焓判据计算表明CoCrNiCu可无限固溶Fe元素。

(2) 316L不锈钢靠近异种材料界面处出现部分离散马氏体组织,Schaeffler图和Ms计算结果表明置换型元素(Co、Cr、Ni、Cu)以及间隙型元素(C)的界面配分无法为马氏体相变提供足够的化学驱动力。残余热应力有限元模拟结果显示在316L不锈钢靠近界面处的Mises应力超过其屈服强度,因而属于应变诱导马氏体相变,其中C元素界面配分会降低奥氏体的力学稳定性。

(3) CoCrNiCu中熵合金/316L不锈钢异种材料界面同时存在共格、半共格和非共格3种匹配形式。应变诱导马氏体相变有助于促进TRIP效应,但同时会导致界面匹配程度降低,因此需协调设计异种材料的组织相容性与晶体学相容性。当异种材料物性差异较小时,应保持相同晶体结构的单相匹配,通过促进界面晶格匹配改善界面结合强度;当异种材料物性差异较大时,可借助TRIP效应设计bcc + fcc双相结构以提高协调变形能力。

参考文献

Research progress on additive manufacturing of metallic heterogeneous materials

[J].New requirements for the functionality of materials are raised on the conditions of extremely complex working conditions. Compared with traditional manufacturing technology, additive manufacturing technology of metal heterogeneous materials has greater advantages in the manufacture of heterogeneous material parts. It has broad application prospects in many areas, such as aerospace, biomedical and automotive industries, and can meet these areas’ demand for high performance and multifunctionality of components. Based on the research progress of metal heterogeneous material additive manufacturing technology in recent years, the research status and technical characteristics of arc, electron beam and laser additive manufacturing technology on heterogeneous materials are reviewed. In addition, based on the team’s research on heterogeneous material metal additive manufacturing equipment, material technology and interface defects, the key problems and applications of metal heterogeneous material additive manufacturing technology are summarized, and its development trend are prospected.

金属异质材料增材制造研究进展

[J].

Research progress of microstructure control and strengthening mechanism of QPT process advanced steel with high strength and toughness

[J].Advanced high-strength steels have undergone rapid development from the first to third generation, which has considerably contributed to the continuous improvement of lightweight materials and safety in the automotive industry. The third generation representative steels, including quenching-partitioning (QP) and quenching-partitioning-tempering (QPT) steels have rapidly developed in the past 10 years. This article summarizes the preparation process as well as the strengthening and toughening mechanisms of QP and QPT steels from the following perspectives: (1) process design development and principles from QP to QPT, (2) carbon distribution and microstructure evolution during the partitioning process, (3) stability of metastable austenite and its influence on transformation-induced plasticity, (4) microstructure and heat-treatment process design of nanoprecipitation-strengthened QPT steel, (5) the integrated process of hot-forming QPT steel, and (6) the strengthening and toughening mechanisms and the service performance of QP and QPT steels. Finally, future prospects for manufacturing and using QP and QPT steels are discussed.

高强韧QPT工艺的先进钢组织调控和强韧化研究进展

[J].

M3 microstructure control theory and technology of the third-generation automotive steels with high strength and high ductility

[J].

高强度高塑性第三代汽车钢的M3组织调控理论与技术

[J].高强度、高塑性是汽车钢的重要发展方向,本文综述了高强度高塑性第三代汽车钢的“多相(multiphase)、亚稳(metastable)和多尺度(multiscale)” M<sup>3</sup>组织性能调控理论和技术,以及面临的新挑战。M<sup>3</sup>组织与性能调控理论为高强度高塑性钢提供了理论支持,亚稳奥氏体的相变诱发塑性(TRIP)效应能够提高加工硬化率并推迟颈缩的发生,从而提高了钢的强度与塑性,同时产生了剪切边裂纹敏感性提高,氢致延迟断裂性能下降,循环载荷下亚稳奥氏体的转变行为复杂等新的问题和挑战。当前,含亚稳奥氏体高强度高塑性钢的质量一致性和应用基础研究缺乏,而汽车钢作为量大面广的产品,需要从它的成分设计和组织调控-冲裁切割-成形制造-连接涂装-服役评价等全链条环节中开展组织演变和性能评估,充分考虑产品的技术适用性和成本,进而为组织调控理论和技术的完善提供依据。

Multiple material additive manufacturing- Part 1: A review

[J].

Microstructure and local properties of a domestic safe-end dissimilar metal weld joint by using hot-wire GTAW

[J].Dissimilar metal weld joints (DMWJ) widely exist in the nuclear power plants to join the different parts which are made of different structural materials. Among these DMWJs, safe-end DMWJ has attracted much attention of researchers and operating enterprises, as premature failures, mainly stress corrosion cracking failures, have occurred in these kinds of joints. However, DMWJ with 52M as filler metal in the nuclear power plants has no in-service experience. To ensure the structural integrity of the weld joint and the safe operation of the future plants, the microstructure and local properties of a domestic safe-end DMWJ by using hot-wire gas tungsten arc welding (GTAW) technology was studied in detail by OM, SEM, micro-hardness testing, local mechanical tensile testing and slow strain rate tests. The tensile tests were performed at room temperature with the tensile speed of 5 μm/s while the slow strain rate tests were conducted in simulated primary water containing 1500 mg/L B as H3BO3 and 2.3 mg/L Li as LiOH with 2 mg/L dissolved oxygen at 325 ℃. A large amount of type I boundaries and type II boundaries which are susceptible to stress corrosion cracking (SCC) exist in 52Mb near the SA508/52Mb interface and result in the highest SCC susceptibility of this interface. Microstructure transition was found in the SA508 heat affected zone (HAZ). In 316LN HAZ, increasing the distance from the fusion boundary, the number fraction of CSL boundaries increase while the residual strain decreases, resulting in the second-highest SCC susceptibility of 316LN HAZ. In 52M, residual strain distributes randomly but not uniformly, the residual strain is prone to accumulate at the grain boundaries. Dramatic changes of mechanical properties are observed across the joint, especially at the SA508/52M interface. The differences of the local microstructure and chemical composition lead to the differences of the local properties of the weld joint.

国产核电安全端异种金属焊接件的微观结构及局部性能研究

[J].

Review of heterogeneous material objects modeling in additive manufacturing

[J].

Heterogeneous materials design in additive manufacturing: Model calibration and uncertainty-guided model selection

[J].Multi-material additive manufacturing enables high-performance heterogeneous design at the mesoscale, through which bulk parts can be engineered to adapt to complex loading conditions. The optimization of multi-material parts relies on accurate forward prediction, which is challenging to achieve owing to the complex processing conditions in additive manufacturing and the resultant uncertainties in material properties. To address these limitations, here we present a new model calibration and model selection framework based on the high dimensional, local-scale deformation data. By matching the pixel-level deformation data from digital image correlation experiments and constitutive modeling, the presented framework enables more accurate prediction and significant reduction of the prediction uncertainties, as compared to the single material calibration approach that is widely used in additive manufacturing. In turn, this enables quantitative comparison of the candidate models, so the most accurate and computationally efficient constitutive model can be selected for forward prediction in heterogeneous material design. The advantages of the framework are demonstrated using a multi-polymer system manufactured by dual-extrusion additive manufacturing, which consists of two constituent materials with dramatically different deformation behaviors.

A short review on laser welding/brazing of aluminum alloy to steel

[J].

Laser techniques for dissimilar joining of aluminum alloys to steels: A critical review

[J].

A critical review of high entropy alloys and related concepts

[J].

High entropy alloys: A focused review of mechanical properties and deformation mechanisms

[J].

Multicomponent high-entropy Cantor alloys

[J].

Research and development of welding methods and welding mechanism of high-entropy alloys: A review

[J].

Diffusion bonding of CoCrFeNiCu high-entropy alloy to 304 stainless steel

[J].During fusion welding of the Cu-containing high-entropy alloy (HEA) of CoCrFeNiCu, Cu precipitates at the grain boundary and reduces the welding quality and mechanical properties. Solid-phase diffusion welding is connected with the diffusion of elements, which reduces the segregation of Cu and solves this problem well. In the present work, the study of diffusion welding of CoCrFeNiCu HEA with 304 stainless steel (304SS) was carried by SEM, EBSD, TEM, and XRD. The properties of the microstructure and crystal type were obtained. The results show that element diffusion can achieve high-quality connection between the two metals. As the temperature increases, the diffusion capacity increases. The pores at the interface disappear. The thickness of the diffusion layer is between 10-31 μm, without forming intermetallic compound, which shows that a solid solution microstructure is formed after diffusion. According to the XRD, this microstructure is mainly as CoCrFeNiCuMn, that leads to an improvement in the mechanical properties. The hardness of the CoCrFeNiCu HEA-diffusion layer-304SS shows a gradient increase. The crystal structure type is mainly as substructured and recrystallized structure. The proportion of low-angle grain boundaries is 93% in the diffusion layer. The EBSD test results show that the grain orientation of the welded joint (diffusion layer) has changed, mostly concentrated on the (111) plane. This also causes anisotropy of the mechanical properties. Tensile performance test showed that the material fractured in the CoCrFeNiCu HEA base material area. These show that diffusion welding achieves a high-quality connection of the two materials.

CoCrFeNiCu高熵合金与304不锈钢真空扩散焊

[J].

Dissimilar welding of Al0.1CoCrFeNi high-entropy alloy and AISI304 stainless steel

[J].

Excellent strength-ductility combination of multi-layered sheets composed of high-strength V10Cr10Fe50Co30 high entropy alloy and 304 austenitic stainless steel

[J].

Dissimilar laser welding of a CoCrFeMnNi high entropy alloy to 316 stainless steel

[J].

Improving the ductility in laser welded joints of CoCrFeMnNi high entropy alloy to 316 stainless steel

[J].

Laser dissimilar welding of CoCrFeMnNi-high entropy alloy and duplex stainless steel

[J].High entropy alloys (HEAs) have superior mechanical properties that have enabled them to be used as structural materials in nuclear and aerospace applications. As a dissimilar joint design is required for these applications, we created a dissimilar joint between CoCrFeMnNi-HEA and duplex stainless steel (DSS) through laser beam welding; a technique capable of producing a sound joint between the two materials. Microstructure examination using SEM/EBSD/XRD analysis revealed that the weld metal (WM) exhibits an FCC phase regardless of the postweld heat treatment (PWHT) temperature (800 and 1000 °C) without forming detrimental intermetallic compounds or microsegregation. The heat-affected zone of the CoCrFeMnNi-HEA showed CrMn oxide inclusions while that of the DSS showed no inclusions. Moreover, a lower hardness was recorded by the WM compared to the base metal after welding. After PWHT, the hardness of the WM, CoCrFeMnNi-HEA, and DSS decreased with an increase in the PWHT temperature. However, the decrease in the hardness of the HEA was more significant than in the WM and DSS. The cause for this reduction in hardness was attributed to recrystallization and grain growth. In addition, a strength of 584 MPa with low ductility was recorded after welding. The obtained strength was lower than that of the BMs, but comparable to that of the welded CoCrFeMnNi-HEA. The application of PWHT resulted in over a 20% increment in ductility, with only a marginal reduction in strength. The deformation mechanism in the as-weld joint was mainly dominated by dislocation while that for the PWHT joint was twinning. We propose laser beam offset welding as a technique to improve the mechanical properties of the dissimilar joint, which will be the subject of future studies.

High strength-ductility synergy in a laser welded dissimilar joint of CrCoNi medium-entropy alloy and stainless steel

[J].

Effect of laser oscillation on the microstructure and mechanical properties of laser melting deposition titanium alloys

[J].Laser melting deposition (LMD) combines the laser cladding and rapid prototyping manufacturing technologies, and can be used for swift prototyping of complex parts with excellent comprehensive properties. However, due to its unique metallurgical conditions, it is easy to develop penetrating columnar crystals and coarse primary grains along the building direction. This remarkably reduces the mechanical properties of the alloy. The root cause of this issue can be traced back to the thermodynamic and dynamic metallurgical processes. Thus, this study proposes an oscillating laser melting deposition (OLMD) based on laser oscillating welding technology, and aims to elucidate the metallurgical structure and defects of laser melt deposition. OLMD modifies the motion trajectory of the molten pool using a laser in situ oscillation, and directly impacts the temperature gradient and solidification rate, thus improving the microstructure of titanium alloy by LMD. Furthermore, the microstructure evolution and mechanical properties of TC4 titanium alloy produced using OLMD were studied using OM, SEM, EBSD, and a Vickers hardness tester. The results indicate that the optimum process parameters of laser melting deposition without oscillation are as follows: the laser power is 1000 W, scanning rate is 8 mm/s, and powder feeding rate is 6.92 g/min. The optimum technological parameters of linear oscillation are as follows: the frequency is 200 Hz and the oscillation amplitude is 1.5 mm. Addition of linear laser oscillation considerably improved the morphology of the molten pool, and defects such as porosity and cracks were not observed. The overall number and size of columnar crystals reduced, and the grains were equiaxed. When compared to the sample without oscillation, the average grain size of Ti-6Al-4V alloy with linear oscillation decreased from 5.20 μm to 4.37 μm, while hardness increased from 418.00 HV to 428.75 HV.

激光摆动对激光熔化沉积钛合金微观组织及力学性能的影响

[J].针对激光熔化沉积冶金组织与缺陷,借鉴激光摆动焊接技术,提出一种激光摆动送粉增材制造TC4钛合金工艺,借助激光原位摆动改变熔池运动轨迹进而影响温度梯度和凝固速率,改善增材制造钛合金的微观组织。利用OM、SEM、EBSD和Vickers硬度计研究了激光摆动送粉增材制造工艺对TC4钛合金微观组织演变及力学性能的影响。结果表明,无摆动激光熔化沉积实验的最佳工艺参数为:激光功率1000 W,扫描速率8 mm/s,送粉速率6.92 g/min;直线型激光摆动的最佳工艺参数为:摆动频率200 Hz,摆动幅度1.5 mm。直线型激光摆动对熔池形貌改善显著,气孔和裂纹等缺陷较少,柱状晶数量和尺寸均有所减小,并且晶粒出现了等轴化的现象。相比无摆动样品,激光摆动后Ti-6Al-4V合金单道区域平均晶粒尺寸从5.20 μm减小到4.37 μm;硬度从418.00 HV提升到428.75 HV。

Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review

[J].

Additive manufacturing of metals

[J].

Formation mechanism of pearlite during thermal cycling in U75V steel rail repaired by laser directed energy deposition

[J].

Effect of Cu-rich phase precipitation on the microstructure and mechanical properties of CoCrNiCu x medium-entropy alloys prepared via laser directed energy deposition

[J].

The effect of microstructure evolution on the mechanical properties of martensite ferritic steel during long-term aging

[J].

Role of Cu addition in enhancing strength-ductility synergy in transforming high entropy alloy

[J].

On the relationship between uniaxial yield strength and resolved shear stress in polycrystalline materials

[J].

Post treatment of an additively manufactured composite consisting of 304L stainless steel and CoCrFe-MnNi high-entropy alloy

[J].

Prediction of high-entropy stabilized solid-solution in multi-component alloys

[J].

High-entropy alloy: Challenges and prospects

[J].

Nature of CoCrFeMnNi/Fe and CoCrFeMnNi/Al solid/solid interface

[J].

Effects of groove on the microstructure and mechanical properties of dissimilar steel welded joints by using high-entropy filler metals

[J].

Electro spark coating of AlCoCrFeNi high entropy alloy on AISI410 stainless steel

[J].

The difference in thermal and mechanical stabilities of austenite between carbon- and nitrogen-added metastable austenitic stainless steels

[J].

A mechanism for the strain-induced nucleation of martensitic transformations

[J].

Strength-ductility enhancement in multi-layered sheet with high-entropy alloy and high-Mn twinning-induced plasticity steel

[J].

Composition equivalents of stainless steels understood via gamma stabilizing efficiency

[J].The phase-type of a stainless steel is generally predicted by equivalent equations in terms of a major austenitic (γ) or ferritic (α) stabilizer Ni or Cr. The present paper attempts to understand the equivalent methods in stainless steels via the slopes of the phase boundary lines separating γ and γ + α phase zones. The prevailing equivalent coefficients are well interpreted using the slope ratios of the alloying elements divided by that of Ni or Cr, after analyzing over one hundred common stainless steels. Different from traditional composition equivalents which evaluate γ stabilizers and α stabilizers separately; the new equivalent scheme provides a unified phase stabilizing parameter for all alloying elements in stainless steels. This parameter is defined as γ stabilizing efficiency. Its negative or positive sign indicates γ stabilizer or α stabilizer, and its value represents the stabilizing efficiency.

The effect of composition on the temperature of spontaneous transformation of austenite to martensite in 18-8-type stainless steel

[J].

Evaluation of the martensitic transformations in austenitic stainless steels

[J].

Formation of martensite in austenitic stainless steels effects of deformation, temperature, and composition

[J].

Composition and grain size dependencies of strain-induced martensitic transformation in metastable austenitic stainless steels

[J].

準安定オーステナイトステンレス鋼における加工誘起マルテンサイト変態の組成および結晶粒度依存性

[J].

The effect of cold rolling regime on microstructure and mechanical properties of AISI 304L stainless steel

[J].

The effect of cold rolling on microstructure and mechanical properties of a new Cr-Mn austenitic stainless steel in comparison with AISI 316 stainless steel

[J].

Deformation induced martensite in AISI 316 stainless steel

[J].

Deformation-induced martensite in austenitic stainless steels: A review

[J].

FCC-to-HCP phase transformation in CoCrNi x medium-entropy alloys

[J].

Elastic moduli and thermal expansion coefficients of medium-entropy subsystems of the CrMnFeCoNi high-entropy alloy

[J].

Deformation microstructure and deformation-induced martensite in austenitic Fe-Cr-Ni alloys depending on stacking fault energy

[J].

Morphologies and characteristics of deformation induced martensite during tensile deformation of 304 LN stainless steel

[J].

The influence of stacking fault energy on the microstructural and strain-hardening evolution of Fe-Mn-Al-Si steels during tensile deformation

[J].

Excellent combination of cryogenic-temperature strength and ductility of high-entropy-alloy-cored multi-layered sheet

[J].

Critical assessment 19: Stacking fault energies of austenitic steels

[J].

Comparing the deformation-induced martensitic transformation with the athermal martensitic transformation in Fe-Cr-Ni alloys

[J].

EBSD investigation of the crystallographic features of deformation-induced martensite in stainless steel

[J].Variant selection during the martensitic transformation in steels may play an important role in determining the transformation kinetics and the resulting mechanical properties. In this study, the variant selection and crystallographic features of deformation-induced martensite were investigated by quasi in situ electron backscatter diffraction (EBSD) in grade SUS321 during tensile deformation. Significant differences in variant selection between austenite (γ)→hcp-martensite (ε)→bcc-martensite (α’) and γ→α’ transformation routes were observed and reported in detail, which demonstrated that ε-martensite plays an important role in the variant selection of α’. Variant selection at different deformation stages was also analysed and revealed that α’ variants with the highest priority and variant pairs were preferred at the initial and last deformation stages in the γ→ε→α’ sequence, respectively. Meanwhile, the single α’ variant nucleated at the thin slip band keeps its crystallography feature upon further deformation in the γ→α’ sequence. In addition, the strain work of the martensitic transformation for applied loads was quantitatively estimated to explain the variant selection and associated mechanism. When these calculations are compared to the experimental results it is found that they are not able to predict which α’ variant is forming preferentially during either during the γ→α’ or the ε→α’ sequences, while only accurate predictions are obtained for the γ→ε transformation which indicates that the γ→α’ variant selection is more complex.