铝合金和镁合金是目前使用最轻的2种金属结构材料,其中铝合金具有比强度高、塑性加工性能好等优点,镁合金则在减震性能和抗电磁屏蔽性等方面优势明显[1]。为了进一步满足结构轻量化和不同服役环境要求,经常需要将铝合金和镁合金焊接成一个整体结构。由Al-Mg二元相图[2]可知,铝合金和镁合金焊接时,Al与Mg不仅会析出多种类型的金属间化合物(intermetallic compounds,IMCs),如Al3Mg2和Al12Mg17,还可能形成2种低熔点共晶;IMCs的存在使得焊接接头严重脆化,而低熔点共晶会导致焊缝中形成液化裂纹。因此,减少IMCs和低熔点共晶的析出是实现这类异种金属有效焊接的关键,采用传统熔焊方法连接铝合金和镁合金,难以获得无冶金缺陷的铝合金/镁合金异种材料焊接接头[3~5]。

搅拌摩擦焊(friction stir weld,FSW)作为一种新型的固相连接方法,焊接温度低于母材熔点,在铝合金/镁合金等异种金属焊接领域具有明显的优势[6~9]。研究发现,采用FSW连接4 mm及以下厚度的薄板铝合金/镁合金异种材料时,接头成形质量较高[10~12];但当板厚超过6 mm时,接头局部位置会形成低熔点共晶,甚至产生孔洞缺陷,接头成形较为困难[13,14]。分析认为,FSW热量主要来源于轴肩与被焊材料之间的摩擦产热,焊缝上部温度最高[15];而接头其他区域的热量依赖于被焊材料的热传导,导致由焊缝上部向焊缝底部温度逐渐降低。对于薄板FSW而言,轴肩产生的热量能够快速传递到焊缝底部,沿板厚方向温度差异较小,可以保证接头成形所需要的温度条件;但在厚板FSW过程中,焊缝底部热量主要依赖于材料热传导,当板材越厚,焊缝底部加热越慢,有可能使得焊缝上部温度过高并形成IMCs或低熔点共晶时,底部温度仍然较低,不能形成致密的冶金结合[16,17]。尤其是当轴肩下方金属形成低熔点共晶时,轴肩与其下方金属之间的摩擦性质发生改变,由固态金属之间的摩擦转变为有低熔点共晶润滑的摩擦,摩擦系数及摩擦热量降低,传递到焊缝底部的摩擦热量突然减少,底部温度更难升高,缺陷更为严重,并有可能由于底部温度过低、对搅拌头的横向阻力增大而造成搅拌针断裂,焊接过程无法连续进行。这可由本课题组[18,19]对板厚为20 mm的5A06Al/AZ31B板材FSW接头界面反应层的组织演变规律分析得到证实。研究表明,上述接头的AZ31B侧界面沿板厚方向组织分布极不均匀,上部界面形成了较厚的共晶层组织(Mg + Al12Mg17)和IMCs层,而底部则析出较薄的IMCs层;这种差别是接头沿板厚方向存在温度差所致,而低熔点共晶、IMCs则是导致厚板铝合金/镁合金 FSW接头成形困难的主要原因。

目前,国内外众多学者采用添加中间层、超声辅助振动和外部冷却等方法减少脆性IMCs的生成。Abdollahzadeh等[20]在6061Al/AZ31Mg对接接头中加入了0.3 mm厚的Zn层,其目的是通过“替换”原有Al-Mg IMCs从而达到改善接头质量,但接头搅拌区仍发现有带状结构的Al-Mg IMCs存在。近年来,Lv等[21]和Zhao等[22]创新地将超声辅助振动施加在3 mm厚6061Al/AZ31BMg接头上,发现超声辅助振动能够有效减少界面IMCs厚度。由于超声辅助振动的作用区域较小,目前相关报道仍仅限于薄板铝合金/镁合金 FSW,其对厚板接头的影响还不清楚。Mofid等[23,24]和Zhao等[25]通过将母材置于不同冷却介质(空气、水和液氮)中焊接,发现液氮冷却时接头的峰值温度和IMCs厚度最低,这为减少Al-Mg IMCs提供了一条新途径。另外,研究[26,27]表明,Al与Mg在扩散焊时IMCs生长满足Fick第二定律,且与扩散反应温度和扩散时间紧密相关。但是,FSW本质上是一个高应变速率下发生剧烈塑性变形的过程,Fick第二定律并不能合理地解释塑性变形条件下IMCs厚度变化情况[28]。然而,目前关于FSW过程中应变速率和剧烈塑性变形对界面IMCs析出的影响仍未明晰,需要进一步研究。

综上所述,国内外关于厚板铝合金/镁合金 FSW接头成形及组织调控的基础研究仍十分欠缺,液氮作为一种能够有效降低焊接温度的冷却方法,对于改善厚板铝合金/镁合金 FSW接头成形及组织具有一定的优势。因此,本工作以厚板铝合金和镁合金为研究对象,通过FSW过程中在搅拌头后方焊缝上表面喷洒液氮,研究局部强冷作用下厚板铝合金/镁合金FSW接头成形及界面IMCs析出变化规律,分析应变速率对IMCs析出的影响。以期为厚板铝合金/镁合金接头成形及组织调控提供实验与理论指导,同时为其他异种金属焊接提供一定的参考。

1 实验方法

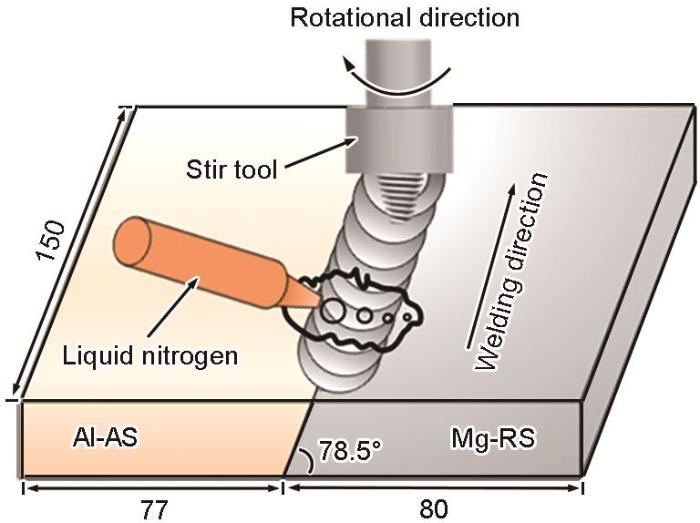

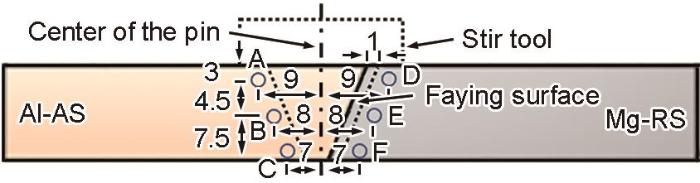

实验材料为15 mm厚的5A06-H112铝合金和AZ31B-O镁合金板材,其化学成分如表1所示。搅拌头轴肩选用凹形,轴肩直径为40 mm;采用表面带有螺纹的锥形搅拌针,根部直径为14 mm,端部直径为8 mm,针长为14.6 mm。5A06-H112/AZ31B-O FSW试样设计成斜对接形式,对接面的倾斜角度与搅拌针的锥度一致,即对接面与搅拌针母线平行,如图1所示,其目的是易于控制焊缝厚度方向Al与Mg的相对含量,减少IMCs和低熔点共晶的形成[29]。基于前期工作[18,19],选取FSW焊接工艺参数为:搅拌头旋转速率375 r/min,焊接速率23.5 mm/min,且铝合金置于前进侧(advancing side,AS),镁合金置于返回侧(retreating side,RS),搅拌针切入镁合金1 mm。5A06-H112/AZ31B-O FSW空冷实验是将焊缝表面暴露于空气中,而液氮冷却实验采用DPL550型自增压液氮罐实现,液氮排液软管出口置于搅拌头后方10 mm处,其流量控制在200 mL/min。空冷和表面液氮冷却条件下的接头界面处的焊接热循环曲线通过自主搭建的温度采集系统获得,图2示意给出了接头界面沿板厚方向的热电偶放置位置,其中编号A、B和C分别对应AS界面上部、中部和底部,编号D、E和F分别对应RS界面上部、中部和底部。

表1 5A06-H112铝合金和AZ31B-O镁合金的化学成分 (mass fraction / %)

Table 1

| Material | Al | Zn | Mn | Si | Cu | Fe | Ni | Mg |

|---|---|---|---|---|---|---|---|---|

| 5A06-H112 | Bal. | ≤ 0.2 | 0.6 | 0.4 | 0.1 | ≤ 0.4 | 0.1 | 6.2 |

| AZ31B-O | 3.0 | 1.2 | 0.2-1 | ≤ 0.1 | ≤ 0.05 | ≤ 0.005 | ≤ 0.005 | Bal. |

图1

图1

表面液氮冷却条件下5A06-H112 /AZ31B-O搅拌摩擦焊(FSW)示意图

Fig.1

Schematic of 5A06-H112/AZ31B-O friction stir weld (FSW) under liquid nitrogen cooling (unit: mm. AS—advancing side, RS—retreating side)

图2

图2

5A06-H112/AZ31B-O FSW接头界面附近热电偶放置位置示意图

Fig.2

Schematic of thermocouple position near the interface of 5A06-H112/AZ31B-O FSW joint (unit: mm. A-C represent the upper, middle, and bottom near the interface of AS, respectively; D-F represent the upper, middle, and bottom near the interface of RS, respectively)

5A06-H112 /AZ31B-O FSW接头界面电子背散射衍射(EBSD)样品采用Gatan 685氩离子截面抛光仪制备,由配有EBSD探头的S8000场发射扫描电子显微镜(SEM)进行样品花样、取向差角和物相分布(phase distribution,PD)等数据的采集,扫描步长为0.2 μm;利用AztecCrystal2.1软件测量相邻扫描点之间晶粒局部的取向差角,获取晶粒尺寸分布和大(小)角度晶界分布,由此统计平均晶粒尺寸和大(小)角度晶界占比;其中,小角度晶界(low angle grain boundary,LAGB)定义为2°~15°,而大角度晶界(high angle grain boundary,HAGB)则为> 15°[30]。同时,利用AztecCrystal2.1获得的晶粒取向散布(grain orientation spread,GOS)图中的数据,判断该晶粒是否发生再结晶,当GOS ≤ 2°时定义为晶粒已发生再结晶,GOS > 2°时则判定为变形晶粒[31]。接头界面处透射电镜(TEM)样品利用Thermo Scientific Scios 2聚焦离子束(focused ion beam,FIB)显微镜制备,采用Talos F200X TEM获取界面IMCs的高角度环形暗场(high-angle annular dark field,HADDF)像、元素分布和选区电子衍射(SAED)花样等信息。

2 实验结果

2.1 接头界面峰值温度及高温停留时间

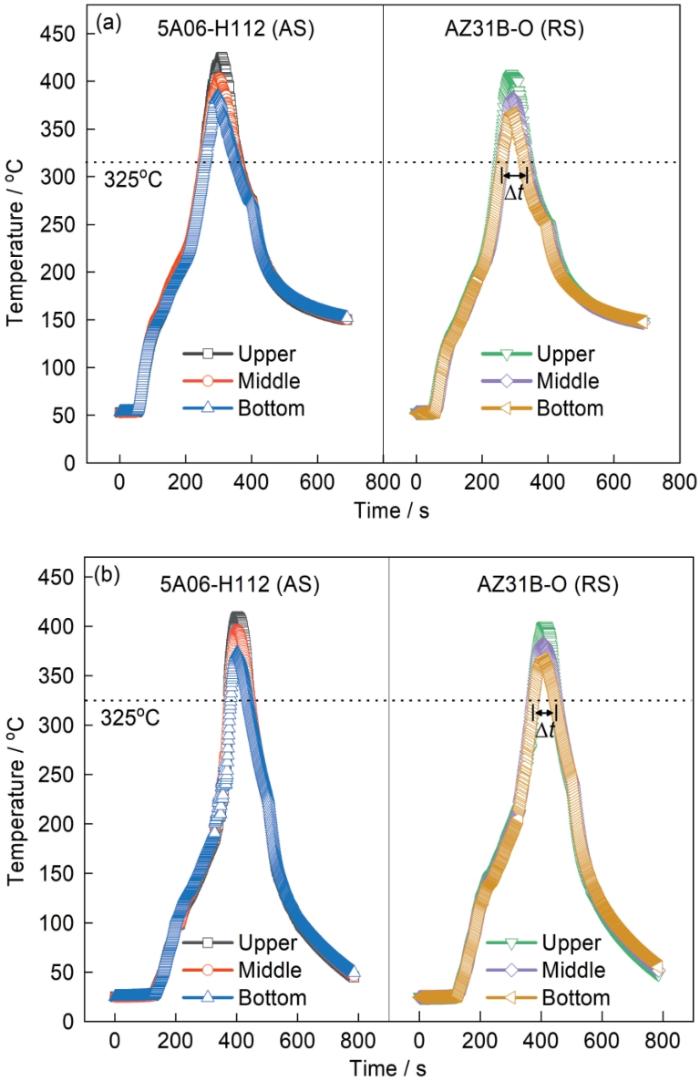

图3a和b分别为在空冷和试样上表面液氮冷却时,5A06-H112/AZ31B-O FSW接头两侧界面附近沿板厚方向各点的温度变化。由图3a可知,空冷时接头5A06-H112铝合金侧界面上部、中部和底部的峰值温度分别为425.5、403.6和384.6℃,上、下部温差为40.9℃;AZ31B-O镁合金侧界面上部、中部和底部的峰值温度分别为420.2、394.3和380.6℃,上、下部温差为39.6℃。由图3b可知,在表面液氮冷却时,接头5A06-H112铝合金侧界面沿板厚方向的峰值温度有所下降,上部、中部和底部分别降至409.8、396.8和377.8℃,上、下部温差为32.0℃;对于AZ31B-O镁合金侧界面,上部、中部和底部分别为401.9、382.1和372.4℃,上、下部温差降至29.5℃。

图3

图3

空冷和表面液氮冷却时5A06-H112/AZ31B-O FSW接头界面附近热循环曲线

Fig.3

Thermal cycle curves near the interface of 5A06-H112/AZ31B-O FSW joints under air (a) and liquid nitrogen (b) cooling (Δt—dwell time above 325oC)

据Yu等[34]报道,当应变ε和应变速率

表2 空冷和表面液氮冷却时AZ31B-O镁合金侧界面上部和底部峰值温度和高温停留时间

Table 2

| Cooling medium | Upper | Bottom | ||

|---|---|---|---|---|

| Tp / oC | Δt / s | Tp / oC | Δt / s | |

| Air | 420.2 | 88 | 380.6 | 72 |

| Liquid nitrogen | 401.9 | 76 | 372.4 | 70 |

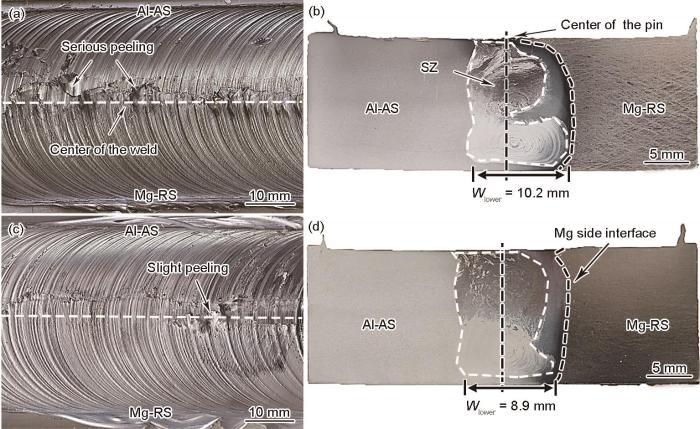

2.2 接头宏观成形

图4

图4

空冷和表面液氮冷却时5A06-H112/AZ31B-O FSW接头的宏观形貌

Fig.4

Surface (a, c) and cross-sectional (b, d) morphologies of 5A06-H112/AZ31B-O FSW joints under air (a, b) and liquid nitrogen (c, d) cooling (SZ—stir zone, Wlower—width of lower stir zone)

采用不同的冷却介质时,5A06-H112/AZ31B-O FSW接头横截面形貌也发生了明显的变化。空冷时FSW接头搅拌区(stir zone,SZ)“上窄下宽”,而液氮冷却时FSW接头SZ宽度沿厚度方向较为一致(图4b和d)。测量表明,空冷时SZ底部宽度约为10.2 mm,SZ面积达到171.2 mm2;表面液氮冷却时,所获得的SZ底部宽度和SZ面积都略有减小,分别约为8.9 mm和170.4 mm2。以上结果表明,在5A06-H112/AZ31B-O FSW时,表面施加液氮冷却能够有效改善焊缝表面成形,同时减小热力耦合对SZ金属流动的影响。

2.3 微观组织分析

2.3.1 铝合金侧界面IMCs沿板厚方向的分布

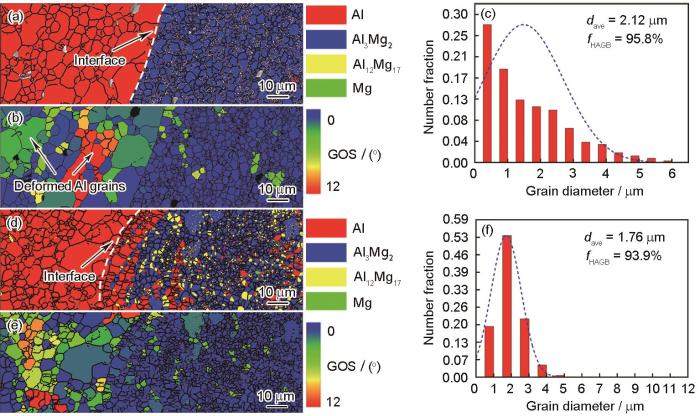

图5为空冷和表面液氮冷却时5A06-H112/AZ31B-O FSW接头铝合金侧界面上部的物相分布(PD)、晶粒取向散布(GOS)及右侧SZ晶粒尺寸分布。由图5a可见,在空冷条件下,前进侧热力影响区中的铝合金(界面左侧)中没有第二相形成,界面右侧SZ中则主要为细小的Al3Mg2相,并有少量的Al12Mg17相和铝合金颗粒。由于界面右侧SZ中Al12Mg17相和铝合金相数量较少,不具备统计学意义,因此下文仅统计界面右侧SZ的Al3Mg2相晶粒尺寸。结合图5b和c可知,界面左侧铝合金晶粒呈尺寸不均匀的等轴晶,各晶粒内部变形量差别明显,大部分晶粒变形量较小(图5b中蓝色区域),但仍有部分晶粒内部存在有较大的变形(图5b中红色区域),表明热力影响区部分铝合金晶粒发生了再结晶;界面右侧的SZ中Al3Mg2晶粒的平均直径约为2.12 μm,HAGB占比达到95.8%,仅有少量Al3Mg2晶粒内存在较小的变形,表明在铝合金侧与界面邻近的SZ发生了比较完全的连续动态再结晶(continuous dynamic recrystallization,CDRX)[35]。

图5

图5

空冷和表面液氮冷却时5A06-H112/AZ31B-O FSW接头铝合金侧界面上部物相分布(PD)、晶粒取向散布(GOS)和右侧SZ晶粒尺寸分布

Fig.5

Phase distributions (PDs) (a, d), grain orientation spreads (GOSs) (b, e), and size distributions of the right SZ (c, f) at the upper of Al alloy side interface of 5A06-H112/AZ31B-O FSW joints under air (a-c) and liquid nitrogen (d-f) cooling (dave—average diameter of the right SZ, fHAGB—fraction of high angle grain boundary (HAGB))

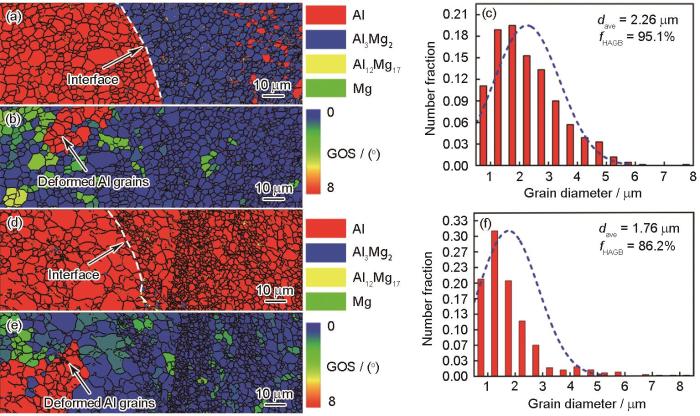

图6为空冷和表面液氮冷却时5A06-H112/AZ31B-O FSW接头铝合金侧界面中部PD、GOS及右侧SZ晶粒尺寸分布。由图6a可知,当采用空冷FSW时,铝合金侧界面中部附近SZ中形成了大量Al3Mg2相;相较于上部,在Al3Mg2相的中间还夹杂着较多的铝合金相和较少的Al12Mg17相。结合图6b和c分析可知,这些位于界面右侧SZ的Al3Mg2相平均直径为2.26 μm,且右侧SZ的HAGBs占比达到95.1%,仅少数晶粒存在较小的变形,这表明绝大部分的Al3Mg2相已发生了动态再结晶。当施加液氮冷却时(图6d~f),铝合金侧中部界面附近SZ中几乎都为铝合金相,仅有少量Al3Mg2相和Al12Mg17相析出;统计分析表明,液氮冷却时界面右侧铝合金相平均直径仅为1.76 μm,明显小于空冷界面右侧SZ的Al3Mg2相晶粒尺寸;热力影响区中细小的铝合金晶粒中有部分晶粒呈现出变形特征(如图6e中箭头指示),从GOS图看,界面右侧SZ中HAGB比例为86.2%,大部分组织发生了动态再结晶,但再结晶程度较空冷时要低。

图6

图6

空冷和表面液氮冷却时5A06-H112 /AZ31B-O FSW接头铝合金侧界面中部PD、GOS和右侧SZ晶粒尺寸分布

Fig.6

PDs (a, d), GOSs (b, e), and size distributions of the right SZ (c, f) at the middle of Al alloy side interface of 5A06-H112/AZ31B-O FSW joints under air (a-c) and liquid nitrogen (d-f) cooling

图7

图7

空冷和液氮冷却时5A06-H112/AZ31B-O FSW接头铝合金侧界面底部PD、GOS和右侧SZ晶粒尺寸分布

Fig.7

PDs (a, d), GOSs (b, e), and size distributions of the right SZ (c, f) at the bottom of Al alloy side interface of 5A06-H112/AZ31B-O FSW joints under air (a-c) and liquid nitrogen (d-f) cooling

2.3.2 镁合金侧界面IMCs沿板厚方向的分布

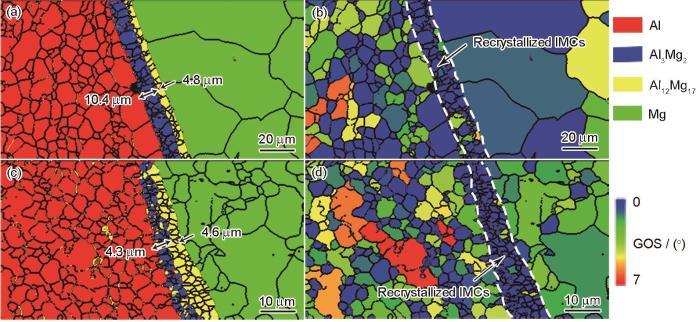

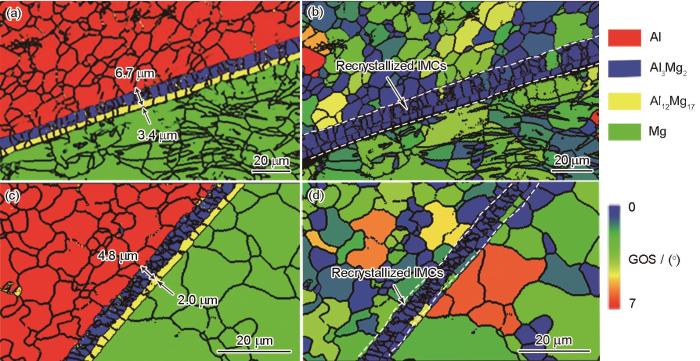

图8给出了空冷和表面液氮冷却时5A06-H112/AZ31B-O FSW接头镁合金侧界面上部PD和GOS图。由图8a可知,空冷条件下焊接时,镁合金侧界面上部由粗大Al12Mg17相和“镶嵌”在Al12Mg17相内部的细小镁合金固溶体组成,表明镁合金侧界面上部已经发生了局部液化,形成了Mg与IMCs组成的共晶层,其平均厚度约为66.1 μm。另外,在界面共晶层和SZ内部铝固溶体之间存在连续的Al3Mg2层,其平均厚度约4.1 μm。结合图8b的GOS图,共晶组织中的Al12Mg17相呈现出一定程度的变形特征,而与SZ内部铝固溶体相邻的Al3Mg2层未呈现变形特征,内部呈细小的等轴晶,即呈完全再结晶状态。

图8

图8

空冷和表面液氮冷却时5A06-H112 /AZ31B-O FSW接头镁合金侧界面上部PD和GOS

Fig.8

PDs (a, c) and GOSs (b, d) at the upper of Mg alloy side interface of 5A06-H112/AZ31B-O FSW joints under air (a, b) and liquid nitrogen (c, d) cooling

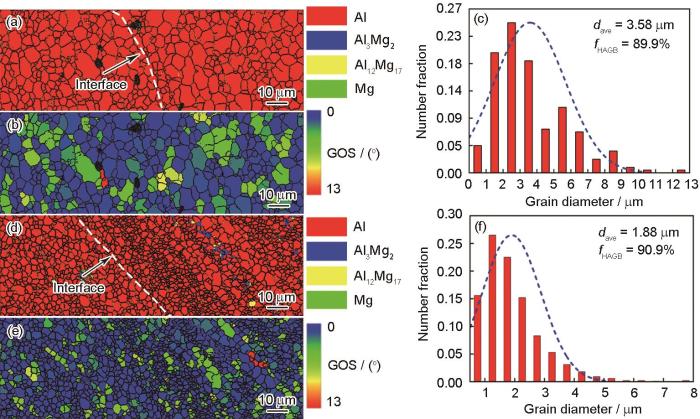

图9为空冷和表面液氮冷却时5A06-H112/AZ31B-O FSW接头镁合金侧界面中部PD和GOS图。由图9a和b可知,靠近SZ内部的铝合金和母材镁合金之间析出了界线分明、由Al3Mg2层和Al12Mg17层组成的IMCs叠层,平均厚度为15.2 μm。叠层中Al3Mg2层厚度达到10.4 μm,明显大于Al12Mg17层的厚度。根据界面GOS图分析,叠层内IMCs变形量较低,2种IMCs都呈细小的等轴晶。当施加液氮冷却时,镁合金侧界面中部IMCs叠层厚度减小,仅为8.9 μm,Al3Mg2相和Al12Mg17相的平均厚度分别降至4.3和4.6 μm,如图9c所示,表明温度对2种类型的IMCs析出的影响程度有明显差异,温度由394℃降低到382℃时,Al12Mg17层厚度变化不大,而Al3Mg2层厚度则减少了近60%。从图9d还可以看出,在IMCs层内部变形量较低,SZ和镁合金热力影响区内部分晶粒还存在较大变形,表明IMCs在界面处形核并长大,这个过程完全消耗了该区域的变形能。

图9

图9

空冷和表面液氮冷却时5A06-H112 /AZ31B-O FSW接头镁合金侧界面中部PD和GOS

Fig.9

PDs (a, c) and GOSs (b, d) at the middle of Mg alloy side interface of 5A06-H112/AZ31B-O FSW joints under air (a, b) and liquid nitrogen (c, d) cooling

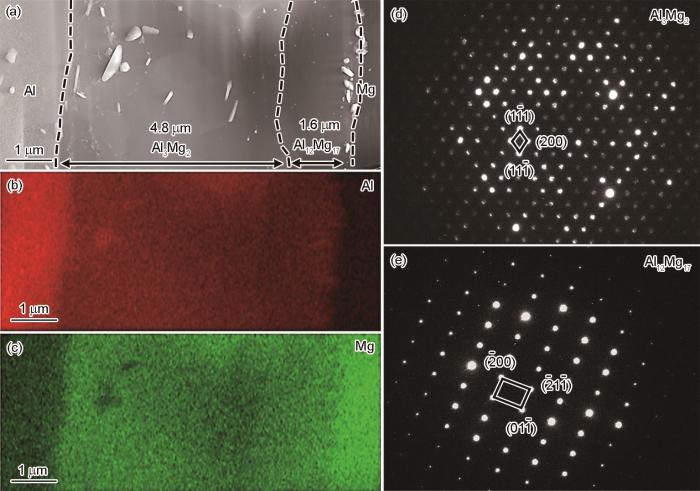

图10为空冷和表面液氮冷却时5A06-H112/AZ31B-O FSW接头镁合金侧界面底部PD和GOS图。由图10a和b可知,空冷FSW接头镁合金侧界面底部存在连续的IMCs叠层,平均厚度约为10.1 μm,其中Al3Mg2层厚度约为6.7 μm,Al12Mg17层厚度约为3.4 μm;另外,从GOS图可以看到,界面反应层中晶粒变形量很低,而其两侧的铝合金和镁合金晶粒仍存在一定程度的变形,表明反应层中的IMCs已经发生再结晶,形成了细小的等轴晶组织。当施加液氮冷却时,镁合金侧界面底部IMCs叠层厚度由空冷时的10.1 μm减小到6.8 μm,整个界面层形成了细小的IMCs晶粒,如图10c和d所示;液氮冷却时IMCs叠层厚度下降幅度小于中部界面处,主要是因为2种冷却状态下,底部温度仅相差8℃,而高温停留时间差别不大。此外,图11给出了液氮冷却时镁合金侧界面底部IMCs层的HADDF像、元素分布和SAED花样。进一步表明,镁合金侧界面底部存在2种IMCs,靠近SZ铝合金侧的是富Al层,平均厚度为4.8 μm,而靠近镁合金热力影响区的是富Mg层,其厚度仅为1.6 μm;通过对SAED进行标定再次证实,富Al层为Al3Mg2相,富Mg层为Al12Mg17相,这与图10c和d中的EBSD结果相符。

图10

图10

空冷和表面液氮冷却时5A06-H112/AZ31B-O FSW接头镁合金侧界面底部PD和GOS

Fig.10

PDs (a, c) and GOSs (b, d) at the bottom of Mg alloy side interface of 5A06-H112/AZ31B-O FSW joints under air (a, b) and liquid nitrogen (c, d) cooling

图11

图11

表面液氮冷却时5A06-H112/AZ31B-O FSW接头镁合金侧界面底部IMCs层的HADDF像、元素分布和SAED花样

Fig.11

HADDF image (a), element distributions (b, c), and SAED patterns (d, e) of IMCs layer at the bottom of Mg alloy side interface of 5A06-H112/AZ31B-O FSW joint under liquid nitrogen cooling

3 分析讨论

3.1 铝合金侧界面IMCs析出行为

由图5~7可知,2种冷却条件下铝合金侧界面附近物相类型及尺寸沿板厚方向呈现出一定的差异性。其中,在空冷作用下,铝合金侧界面上部和中部附近的SZ中析出了大量细小的Al3Mg2相,底部则为细小的等轴铝合金晶粒;当在焊缝表面施加液氮冷却时,铝合金侧界面上部附近SZ中除了Al3Mg2相外,还有少部分的铝合金晶粒和Al12Mg17相,而界面中部和底部SZ中均为等轴状的铝合金晶粒;2种冷却条件下,铝合金侧界面附近SZ中的变形量都较低,表面界面附近SZ材料由于受到剧烈塑性变形及高温作用,IMCs和铝合金晶粒都发生了动态再结晶,呈现出细小的等轴晶,晶粒大小与材料的变形温度和应变速率有关,其相关关系可用Zener-Hollomon参数(Z)来表示[36]:

式中,Q为扩散激活能(kJ/mol),R为气体常数(8.314 × 10-3 kJ/(mol·℃)),T为变形温度(℃),

式中,ω为搅拌头旋转速率(r/min),re和Le分别简化为SZ的有效半径(mm)和有效深度(mm)。

而Watanabe等[37]提出了晶粒尺寸与Z参数之间的关系:

式中,Dnugget为SZ晶粒尺寸(μm),Dinitial为母材晶粒尺寸(μm)。

表3 空冷和表面液氮冷却时5A06-H112/AZ31B-O FSW接头铝合金侧界面沿板厚方向的应变速率和峰值温度

Table 3

| Cooling medium | Position | re mm | Le mm | s-1 | Tp oC |

|---|---|---|---|---|---|

| Air | Upper | 4.7 | 3.0 | 30.7 | 425.5 |

| Middle | 4.6 | 7.5 | 12.0 | 403.6 | |

| Bottom | 3.9 | 15.0 | 5.1 | 384.6 | |

| Liquid nitrogen | Upper | 5.4 | 3.0 | 35.3 | 409.8 |

| Middle | 5.1 | 7.5 | 13.3 | 396.8 | |

| Bottom | 4.0 | 15.0 | 5.2 | 377.8 |

另外,在空冷和液氮冷却条件下,铝合金侧界面附近SZ中的IMCs平均直径沿板厚方向呈现依次增大的趋势,这表明Z参数沿板厚方向依次减小。进一步地,从表3分析可知,从界面上部到界面底部,

3.2 镁合金侧界面IMCs析出行为

式中,K为扩散系数(m2/s),K0为频率因子(m2/s),t为扩散时间(s),d为反应层厚度(μm)。

取平衡态下Al3Mg2相和Al12Mg17相的激活能分别为53.54和125.65 kJ/mol,频率因子参数分别为1.53 × 10-8和2.24 × 10-3 m2/s[39]。铝合金/镁合金FSW接头界面扩散时间和反应温度难以准确获取,这里简化为接头界面峰值温度Tp和高温停留时间Δt进行分析。利用表2给出的空冷和液氮冷却条件下接头界面峰值温度和高温停留时间,由

分析认为,界面附近的应变速率也是影响IMCs厚度的重要因素之一[40],在5A06-H112/AZ31B-O FSW过程中,搅拌区和搅拌针附近的镁合金热力影响区材料经历了高应变速率下的严重塑性变形。以镁合金侧界面上部为例,结合图4d中横截面形貌轮廓,可测出镁合金侧界面上部的有效半径re和有效深度Le分别为7.0和3.0 mm,代入

4 结论

(1) 5A06-H112/AZ31B-O FSW过程中表面液氮冷却,能降低接头沿板厚方向的峰值温度和高温停留时间,有利于抑制IMCs的析出和低熔点共晶的形成。接头铝合金侧主要析出Al3Mg2相;而镁合金侧主要析出Al12Mg17相,当局部温度较高时会与Mg形成低熔点共晶。在液氮冷却作用下,镁合金侧界面上部和底部的峰值温度分别降至401.9和372.4℃,上部共晶层的平均厚度减少至47.1 μm;而底部界面处靠近SZ内部的铝合金和母材镁合金之间析出了界线分明、由Al3Mg2层和Al12Mg17层组成的IMCs叠层,叠层总厚度约为6.8 μm。

(2) 在空冷和表面液氮冷却条件下,铝合金侧界面IMCs析出沿板厚方向呈现一定的差异。在空冷时,铝合金侧界面上部和中部附近的SZ中析出了大量的细小Al3Mg2相,底部则为细小的等轴铝合金晶粒;当在焊缝表面施加液氮冷却时,铝合金侧界面上部附近SZ中除了Al3Mg2相外,还有少部分Al12Mg17相和铝合金晶粒,而界面中部和底部SZ中均为等轴状的铝合金晶粒。

(3) 在空冷和表面液氮冷却条件下,5A06-H112/AZ31B-O FSW接头界面附近的应变速率对IMCs的析出有显著影响。对于铝合金侧界面而言,从界面上部至底部,应变速率依次减小,界面附近的IMCs晶粒尺寸逐渐增大;在镁合金侧界面,应变速率沿板厚方向的减小会降低界面原子扩散速率,导致界面反应层厚度减薄。

参考文献

Relationship between grain size and Zener-Holloman parameter during friction stir processing in AZ31 Mg alloys

[J].

Thermodynamic calculation of the Al-Mg phase diagram

[J].

Microstructure characteristics in TIG welded joint of Mg/Al dissimilar materials

[J].

The effect of the adhesive on the microcracks in the laser welded bonding Mg to Al joint

[J].

Aluminum element effect for electron beam welding of similar and dissimilar magnesium-aluminum-zinc alloys

[J].

Friction stir welding-recent developments in tool and process technologies

[J].

Investigation of the microstructure, mechanical properties and fracture mechanisms of dissimilar friction stir welded aluminium/titanium joints

[J].

Joining of AZ91 Mg alloy and Al6063 alloy sheets by friction stir welding

[J].

Interfacial microstructure and mechanical property in friction stir welded Mg/Al joints under low rotation speed

[J].

Dissimilar friction stir welding between magnesium and aluminum alloys

[J].

Friction stir welding process of dissimilar metals of 6061-T6 aluminum alloy to AZ31B magnesium alloy

[J].

Intermetallic compounds in the banded structure and their effect on mechanical properties of Al/Mg dissimilar friction stir welding joints

[J].Dissimilar friction stir welding (FSW) between aluminum and magnesium alloy was performed, using various tool rotational speed (TRS) at a fixed travel speed, with tool offset to aluminum to investigate the formation of intermetallic compounds (IMCs) in the banded structure (BS) zone and their effect on mechanical properties. Large quantities of IMCs, in the form of alternating bands of particles or lamellae, were found in the BS zone, where drastic material intermixing occurred during FSW. The BS microstructural characters in terms of the morphology of the bands and the quantity and distribution of IMC particles varied with TRS. All welds exhibited brittle fracture mode with their fracture paths propagating mainly in/along the IMCs in the BS. It is shown that these BS microstructural characters have significant effect on the mechanical properties of the joints. Suggestions on tailoring the BS microstructure were proposed for improving the strength of the BS zone and the final mechanical properties of the Al/Mg FSW joints.

Constitutional liquation during dissimilar friction stir welding of Al and Mg alloys

[J].

Mg/Al reaction and mechanical properties of Al alloy/Mg alloy friction stir welding joints

[J].<p>Mg alloys are increasingly used in aerospace, aircraft and automotives structures due to the low density and good damping properties, especially, the welding of Mg alloy to Al alloys is of practical importance for widening the application of Mg alloys. Although friction stir welding (FSW) has been used to join Mg and Al alloys, defect free joints are achieved only in the thin plate (less than 4 mm). In this paper, three ways of FSW of 6 mm thick 6061--T651 Al alloy and AZ31 Mg alloy plates, offsetting the pin to the seam between the two plates (M4A4), to the Mg alloy side 2 mm (M6A2) and to the Al alloy side 2 mm (A6M2), were studied. The aim is to examine the effects of the relative position between tool and plate on the microstructure and mechanical properties of FSW Mg/Al alloys joint. SEM and XRD analyses revealed the formations of intermetallics Mg<sub>17</sub>Al<sub>12</sub> and voids in the interface between Mg and Al alloy plates in the three FSW samples. The voids are resulted from the melting and subsequent solidification of eutectic. In the M4A4 and M6A2 samples, some Al are stirred into the Mg alloy side during FSW, forming the Mg<sub>17</sub>Al<sub>12</sub>, whereas in the A6M2 sample, some Mg stirred into the Al alloy side are also transformed to the Mg<sub>17</sub>Al<sub>12</sub>. Some fine pores are observed around the Mg<sub>17</sub>Al<sub>12</sub>. The hardness of the nugget zone exhibits a slight increase due to the formation of a small amount of Mg<sub>17</sub>Al<sub>12</sub>. The intermetallics and pores at the jointed interface decrease the strength of the joints significantly.</p>

铝合金/镁合金搅拌摩擦焊接界面处Mg/Al反应及接头力学性能

[J].

Friction-stir welded defects and repairing weld process of thick aluminum plates with telescopic stir-pin

[J].

伸缩式搅拌头厚铝板搅拌摩擦焊缺陷及其补焊工艺

[J].

Materials flow and phase transformation in friction stir welding of Al 6013/Mg

[J].

Friction stir welding of magnesium alloy AZ31B to aluminium alloy 5083

[J].

Precipitation behavior of intermetallic compounds and their effect on mechanical properties of thick plate friction stir welded Al/Mg joint

[J].

Interfacial microstructure evolution of thick plate Al/Mg FSW: Effect of pin size

[J].

The effect of changing chemical composition on dissimilar Mg/Al friction stir welded butt joints using zinc interlayer

[J].

Effects of ultrasonic vibration on material flow and thermal cycles in friction stir welding of dissimilar Al/Mg alloys

[J].

Ultrasonic effect on thickness variations of intermetallic compound layers in friction stir welding of aluminium/magnesium alloys

[J].

The effect of water cooling during dissimilar friction stir welding of Al alloy to Mg alloy

[J].

Investigating the formation of intermetallic compounds during friction stir welding of magnesium alloy to aluminum alloy in air and under liquid nitrogen

[J].

Influence of cooling conditions on joint properties and microstructures of aluminum and magnesium dissimilar alloys by friction stir welding

[J].

Microstructure and properties of diffusion bonded Mg/Al joints

[J].

Effect of annealing temperature on joints of diffusion bonded Mg/Al alloys

[J].

Improvement in tensile strength of Mg/Al alloy dissimilar friction stir welding joints by reducing intermetallic compounds

[J].

Formation investigation of intermetallic compounds of thick plate Al/Mg alloys joint by friction stir welding

[J].

The effect of microstructure on the mechanical properties of friction stir welded 5A06 Al alloy

[J].

Microstructure and texture correlation of secondary heating assisted dissimilar friction stir welds of aluminum alloys

[J].

Al-to-Mg friction stir welding: Effect of material position, travel speed, and rotation speed

[J].

Heat transfer modeling of dissimilar FSW of Al 6061/AZ31 using experimentally measured thermo-physical properties

[J].

Influence of strain, temperature, and strain rate on interfacial structure and strength of AZ31BMg/6063Al formed by plastic deformation bonding

[J].

Investigation of interface microstructure and mechanical properties of rotatory friction welded dissimilar aluminum-steel joints

[J].

Friction stir welding of magnesium alloys: A review

[J].In recent years, the increasing application demand for Mg alloys in automobile, rail transport, aviation and aerospace industries brings about the growing prominence of seeking reliable techniques to join Mg alloys. As a solid state welding method, friction stir welding (FSW) exhibits unique advantages in joining Mg alloys, and thus arouses widespread research interest. This paper emphatically reviewed the research status of conventional friction stir butt-welding of Mg alloys, and highlighted the welding process, microstructure evolution, texture characteristics, mechanical behavior and their interaction mechanisms. It was indicated that the texture plays a vital role in FSW joint performance of wrought Mg alloys, which is quite different from that in the FSW Al alloy joints. The specific strong texture formed in the weld is the main factor that gives rise to the impediment to achieving equal-strength joints to base materials. At the same time, some focuses like the weldability and the factors that influence joint performance in other types of FSW like lap welding, spot welding and double-sided welding; the weldability, interface bonding mechanism, joint performance and its affecting factors and optimization methods in dissimilar FSW between Mg alloys and other materials like Mg alloys of other grades, Al alloys and steels, were summarized and discussed. Finally, the future research and development directions in FSW of Mg alloys were prospected.

镁合金搅拌摩擦焊接的研究现状与展望

[J].近年来,镁合金在汽车、轨道交通、航空航天等领域的应用需求快速增长,其可靠连接的重要性愈发突出。作为固相焊接技术,搅拌摩擦焊(FSW)对镁合金焊接具有独特优势,因此得到了广泛关注。本文重点综述了镁合金常规对接FSW的研究进展,就焊接工艺、微观组织演化、织构分布特征、接头力学性能及其之间的相互作用机制进行了详细分析与评述。研究表明,不同于铝合金,在变形镁合金FSW时,织构是影响接头性能的关键因素,焊后形成的特殊强织构分布是导致接头难以达到与母材同等强度的主要原因。同时,对其它焊接形式如搭接焊、点焊、双面焊的可焊性及接头性能的影响因素与变化规律进行了讨论,并对镁合金与其它镁合金、铝合金以及钢之间异种焊的可焊性、界面结合机制、接头性能的影响因素及调控方法进行了评述。最后,对镁合金FSW的未来研究方向进行了展望。

Grain size control of commercial wrought Mg-Al-Zn alloys utilizing dynamic recrystallization

[J].

Effect of intermetallic compound layer on tensile strength of dissimilar friction-stir weld of a high strength Mg alloy and Al alloy

[J].

Phase formation and growth in Al-Mg couple with an electromagnetic field

[J].

An innovative joint interface design for reducing intermetallic compounds and improving joint strength of thick plate friction stir welded Al/Mg joints

[J].