近年来,研究者通过各种表面强化技术有效改善了300M钢的组织和性能。例如:Bag等[5]发现表面喷丸(SP)诱导的残余压应力有效抑制了短裂纹扩展,减缓了裂纹扩展速率,从而提高了300M钢的疲劳寿命。Zhao等[6]利用超声表面滚压(USRP)技术在300M钢表层形成表面硬化层,提高表面残余压应力的同时降低了表面粗糙度,使300M钢的微动疲劳和腐蚀疲劳性能显著提高,并分别采用电脉冲辅助超声表面纳米化(EP-UNSM)[7]和激光辅助超声表面纳米化(LA-UNSM)[8]对300M钢进行表面强化处理,试样表面形成了塑性变形层,同时位错缠结塞积形成位错墙和位错胞,使晶粒细化并产生少量孪晶,提高了材料表面硬度和耐磨性。Dang等[9,10]研究了300M钢USRP处理后的耐磨性能和抗疲劳性能,发现300M钢耐磨性和抗疲劳性能的提高得益于表层晶粒细化、加工硬化和残余压应力的形成。Wu[11]发现300M钢试样表层残余应力随着激光冲击强化(LSP)冲击次数增加而显著提高,且残余应力场分布更加均匀。Pistochini和Hill[12]对比研究了LSP和SP技术对300M钢疲劳性能的影响,发现LSP诱导形成了更深层和更高幅值的残余压应力场,显著提高了300M钢的疲劳强度和抗应力腐蚀性能。Zhang等[13]发现300M钢经LSP处理后产生高密度位错,残余压应力和显微硬度明显提高,且疲劳寿命的显著提高归功于残余压应力和表层晶粒细化。从上述研究可以看出,这些表面强化技术能够改善300M钢的使役性能,但均或多或少存在着不足。传统的SP技术获得的残余压应力场较浅,且表面粗糙度较大,表面容易形成微裂纹从而导致性能提升程度有限;USRP、UNSM和LSP技术表面纳米化效率较低,操作难度较高,且设备成本昂贵,不利于大规模生产。

因此,本工作以300M钢舰载机起落架为研究对象,采用SFPB技术对300M钢进行表面纳米化处理,系统研究SFPB工艺对300M钢在3.5%NaCl (质量分数)溶液中的腐蚀疲劳行为的影响,重点关注SFPB处理的300M钢腐蚀疲劳后的微观组织演变和残余应力松弛规律,为SFPB技术在海洋腐蚀环境中的关键承力构件上的推广应用提供重要的实验依据和技术支撑。

1 实验方法

研究材料为商用300M钢棒材,其化学成分(质量分数,%)为:C 0.42,Cr 0.85,Mn 0.82,Si 1.57,Ni 1.94,Mo 0.38,V 0.09,Cu 0.84,Fe余量。将300M钢棒材置于870℃箱式电阻炉中保温1 h,取出后油淬,然后加热至300℃回火2 h空冷(回火2次)。300M钢经热处理后具有超高的强度和优异的塑韧性[17]。

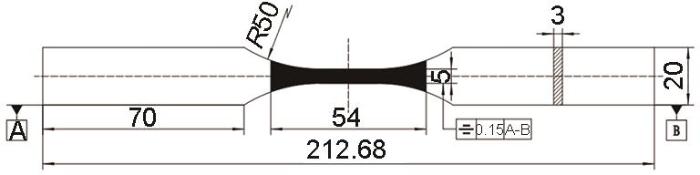

图1

分别将SFPB处理前后的300M钢板状试样在INSTRON 8802液压伺服疲劳试验机上进行腐蚀疲劳(CF)实验。将试样的标距段浸在装有3.5%NaCl中性(pH = 7)水溶液的树脂玻璃容器中,在室温下采用拉-拉方式进行,疲劳循环载荷波形为正弦波,加载频率和应力比分别为5 Hz和0.1,最大载荷(σmax)区间为400~800 MPa。一直循环加载直至试样断裂,将腐蚀疲劳后的试样断口采用超声波丙酮进行清洗,冷空气干燥,利用JSM-7800F场发射扫描电镜(SEM)观察腐蚀疲劳断口形貌。

将SFPB处理后的试样沿轴线中心剖开制备金相试样,机械抛光后用4% (质量分数)硝酸酒精进行深侵蚀,用JSM-IT200型SEM观察纵截面的微观组织形貌,电子加速电压为20 kV。分别将腐蚀疲劳前后试样用线切割方法切取约0.5 mm厚的薄片,机械减薄至40 μm左右后进行双喷电解减薄,采用JEM-2010透射电镜(TEM)分别对300M钢腐蚀疲劳前后表层和次表层微观结构进行观察,电子加速电压为200 kV。借助Nanovea HS1000P三维表面形貌仪对腐蚀疲劳后试样的表面粗糙度相关参数进行测试,并采用JSM-IT200型SEM观察试样的表面形貌。利用Nano Indenter G200 纳米压痕仪对机械抛光后的金相试样由表层至芯部的组织硬度进行检测,压头为Berkovich金刚石,最大加载载荷500 mN,加载速率5 mN/s,加载时间100 s,距离处理试样表面深度每隔10 μm进行一次测量,测量总深度150 μm。每处深度的硬度测量3组,取平均值,最终统计绘图以显示不同深度下梯度纳米结构的硬度变化规律。借助D8 ADVANCE型X射线衍射仪(XRD)测试SFPB处理300M钢腐蚀疲劳前后表层(厚度约3 μm)的物相组成,采用CuKα 射线,扫描角度范围为40°~90°,扫描步长为0.02°,管电压为40 kV,管电流为40 mA。利用X-350A X射线应力衍射仪测试SFPB试样腐蚀疲劳前后的表层残余应力(厚度0~2 μm),取距强化区域中心位置对称的2个位置测量值的平均值作为最终残余应力。应力衍射仪参数选择CuKα 射线,衍射晶面为(211)晶面,X射线管电压为27 kV,管电流为7 mA,管直径为4 mm,倾侧角选择为0°、15°、30°和45°。

2 实验结果

2.1 腐蚀疲劳前的微观组织

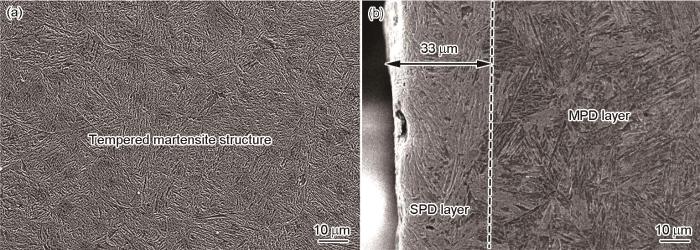

图2为SFPB处理前后300M钢腐蚀疲劳前微观组织形貌的SEM像。未强化试样不同层深处均为相互交错的针状回火马氏体,如图2a所示。SFPB处理过程中,300M钢试样表层受到高能轰击而产生超高应变速率变形[18],表层晶粒细化至纳米级,形成约33 μm厚的严重塑性变形(SPD)层,如图2b所示。随着层深的增加,冲击能量逐渐被吸收而降低,导致300M钢塑性变形和晶粒细化程度逐渐降低,形成次表面微变形(MPD)层。经SFPB处理后300M钢表层形成梯度纳米结构,从试样表层到芯部由SPD层、MPD层和芯部基体组成。同样地,在SFPB处理后的低碳钢中也观察到了类似的组织结构[19]。表层纳米晶能够有效增加位错运动阻力,阻碍300M钢腐蚀疲劳过程中的位错滑移,降低裂纹扩展速率,从而能够有效提高300M钢的抗腐蚀疲劳性能。

图2

图2

超音速微粒轰击(SFPB)处理前后300M钢腐蚀疲劳前微观组织形貌的SEM像

Fig.2

SEM images of 300M steel without (a) and with (b) supersonic fine particle bombardment (SFPB) treatment before corrosion fatigue (SPD—severe plastic deformation, MPD—minor plastic deformation)

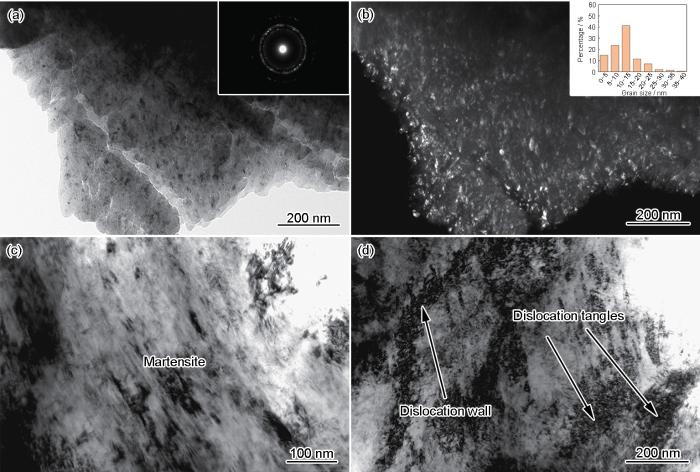

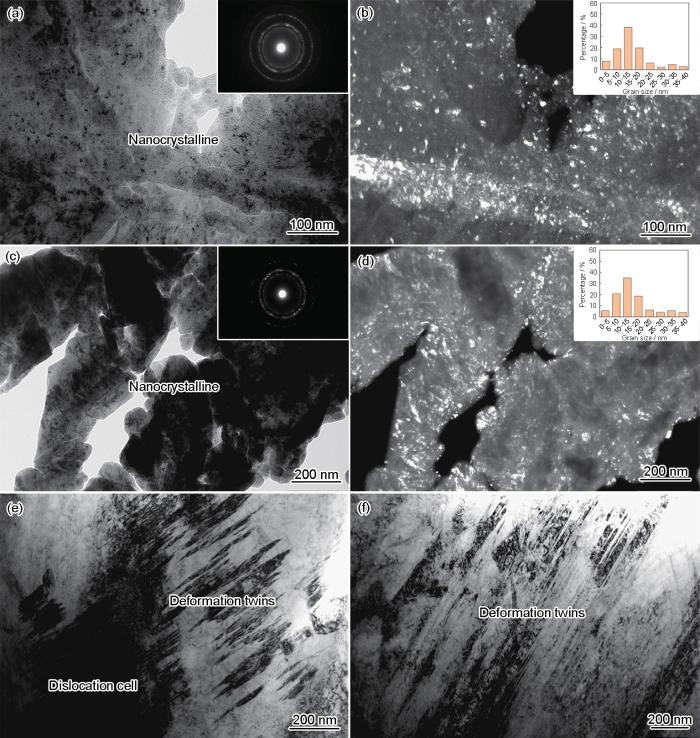

图3a和b为SFPB处理的300M钢腐蚀疲劳前表层微观结构的TEM像。300M钢经SFPB处理后表层形成高密度位错缠结,晶粒明显细化,相应的选区电子衍射(SAED)花样呈现连续环状,表明晶粒细化至纳米级,且晶粒取向随机分布,如图3a所示。通过Nano Measurer软件[20]测量平均晶粒尺寸约为14.5 nm (图3b中插图)。图3c和d为SFPB处理300M钢腐蚀疲劳前的次表层(距表层100 μm)微观组织形貌的TEM像。可以看出,300M钢经SFPB处理后次表层中针状回火马氏体仅发生弯曲断裂,如图3c所示,但次表层由于塑性变形而位错大量增殖,高密度位错不断发生交互作用,相互缠结形成位错墙,如图3d所示。在SFPB处理过程中轰击能量随着层深增加逐渐降低,仅能使300M钢次表层针状回火马氏体发生弯曲断裂,晶粒细化程度明显低于表层,表明300M钢经SFPB处理后从表层纳米晶到芯部粗晶呈现梯度变化。

图3

图3

SFPB处理的300M钢腐蚀疲劳前表层和次表层微观组织形貌的TEM像

Fig.3

TEM images of SFPB-treated 300M steel before corrosion fatigue

(a, b) uppermost surface layers (Inset in Fig.4a shows the selected area electron diffraction (SAED) pattern, and inset in Fig.4b shows the grain size distribution histogram calculated by Nano Measurer software)

(c, d) subsurface layers

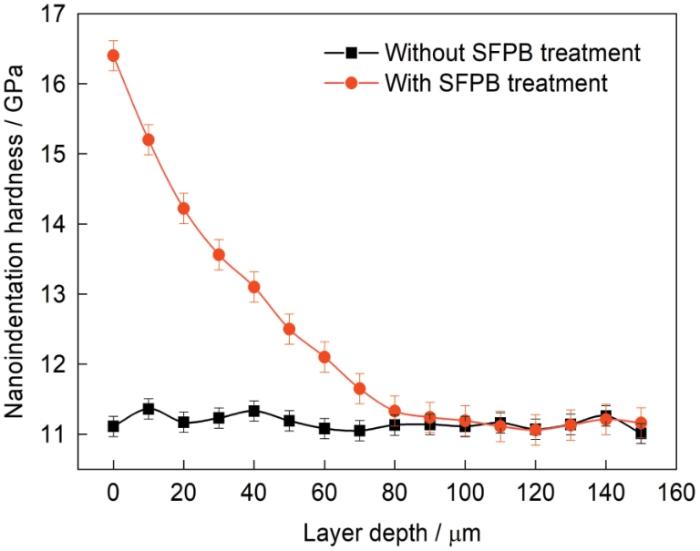

2.2 腐蚀疲劳前的纳米压痕硬度

图4为SFPB处理前后300M钢腐蚀疲劳前的纳米压痕硬度。可以看出,未强化试样从表层到芯部硬度没有明显变化,均为11.2 GPa左右。经SFPB处理后,300M钢表面硬度显著提高,试样表面纳米压痕硬度约为16.4 GPa,较未强化试样提升46%,硬化区域深度可达110 μm左右。在SFPB过程中,300M钢表面由于高密度位错的产生及位错之间交互作用的加剧,导致材料出现明显的加工硬化;同时300M钢表层晶粒破碎严重形成纳米晶,产生细晶强化效果[21],如图3所示。因此,在加工硬化和细晶强化共同作用下300M钢表层硬度显著提高。然而,随着层深的增加300M钢纳米压痕硬度逐渐降低,这是由于SFPB形成的高能轰击能量在材料内部传播过程中逐渐衰减,塑性变形程度逐渐降低,晶粒尺寸相应增大,导致加工硬化和细晶强化效果逐渐减弱,从而使其硬度呈现梯度变化特征。这与图3中300M钢腐蚀疲劳前的梯度纳米结构的微观组织变化趋势相一致。

图4

图4

SFPB处理前后300M钢腐蚀疲劳前的纳米压痕硬度

Fig.4

Nanoindentation hardnesses of 300M steel without and with SFPB treatment before corrosion fatigue

2.3 腐蚀疲劳行为

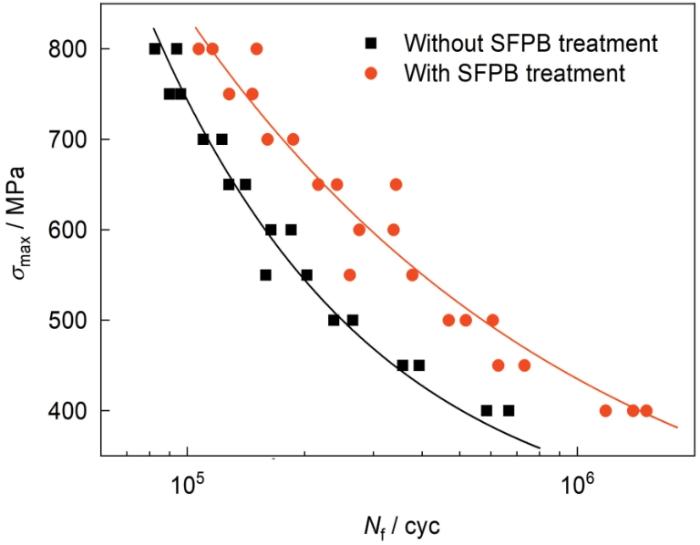

图5为SFPB处理前后300M钢的腐蚀疲劳应力-寿命(S-N)曲线。在相同加载载荷下,经SFPB处理后300M钢的腐蚀疲劳寿命明显高于未强化试样。当σmax为400 MPa时,未强化试样平均腐蚀疲劳寿命为6.06 × 105 cyc,SFPB试样的平均腐蚀疲劳寿命增至1.31 × 106 cyc,提高了约1.16倍。300M钢腐蚀疲劳寿命的显著提高与阻止裂纹萌生的表面梯度纳米结构(图2b)和可以抑制疲劳裂纹扩展的残余压应力[22]的共同作用有关。另外还可以看出,随着加载应力水平的增加,SFPB处理对300M钢腐蚀疲劳性能的增强效果不断弱化。这主要是由于循环载荷增加使试样表面钝化膜遭到严重破坏,进而使腐蚀溶液与裂纹尖端充分接触,腐蚀程度增加,试样表面裂纹萌生区域增大,且试样表层残余压应力松弛速率加快[23],从而导致SFPB强化引入的有益效应急剧减少,强化效果降低。

图5

图5

SFPB处理前后300M钢腐蚀疲劳应力-寿命(S-N)曲线

Fig.5

Corrosion fatigue stress-life (S-N) curves of 300M steel without and with SFPB treatment (Nf—cycle to failure, σmax—maximum stress)

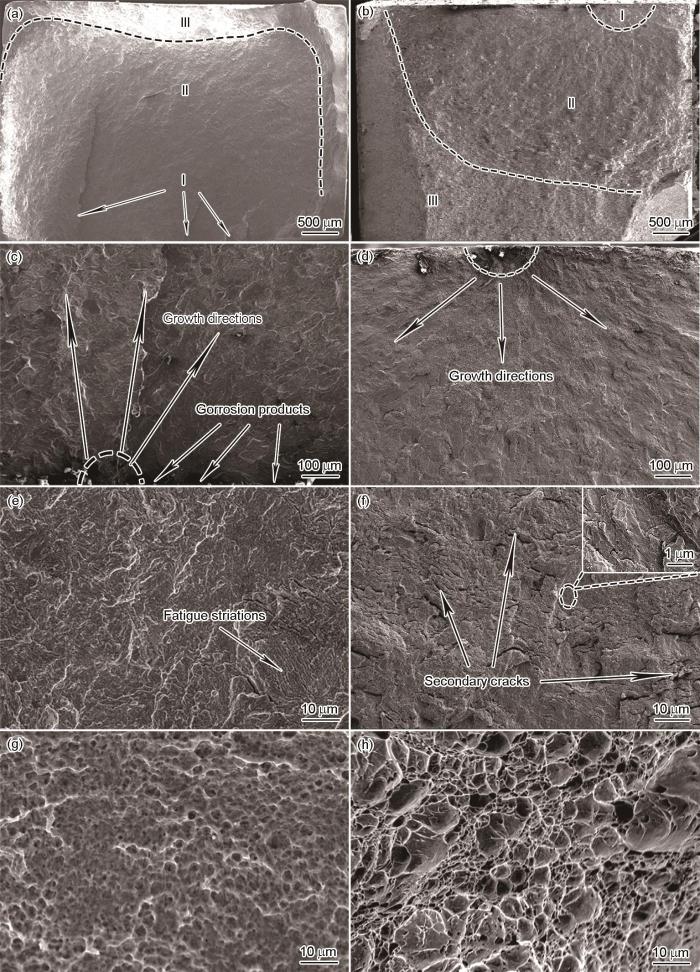

图6为SFPB处理前后300M钢腐蚀疲劳断口形貌的SEM像(σmax = 400 MPa,未处理试样腐蚀疲劳寿命N = 6.67 × 105 cyc,SFPB处理试样腐蚀疲劳寿命N' = 1.18 × 106 cyc,下同)。300M钢SFPB处理前后的腐蚀疲劳断口均具有3个不同的区域,即疲劳源区(I)、裂纹扩展区(II)和瞬断区(III)。区域I周围分布着大量散射状条纹,裂纹以疲劳源为中心,向试样芯部不断扩展,形成了具有方向性的腐蚀疲劳损伤,如图6a和b所示。从区域I的放大图(图6c和d)可以看出,未强化试样疲劳源处较为粗糙,存在多个腐蚀疲劳源,疲劳裂纹形成于疲劳源处,且存在较多的腐蚀产物。经SFPB处理后的300M钢的疲劳源处形貌光滑,疲劳裂纹源数量明显减少的同时腐蚀产物减少,这主要归功于SFPB诱导的表面纳米化、残余压应力和加工硬化[24]。300M钢经SFPB处理后表层纳米晶原子活性增强,使表层更易发生腐蚀而促进致密钝化膜的形成[25],从而有效抑制了NaCl溶液对材料的腐蚀作用,进而抑制表面腐蚀疲劳裂纹的形核,使腐蚀疲劳源数量明显减少。同时,高幅值残余压应力则抑制了局部塑性变形,从而降低疲劳载荷下的原子活性,并且抑制裂纹尖端处的原子活性,有效延缓腐蚀疲劳裂纹向试样内部扩展。

图6

图6

SFPB处理前后300M钢腐蚀疲劳断口形貌的SEM像(最大载荷σmax = 400 MPa,未处理试样腐蚀疲劳寿命N = 6.67 × 105 cyc,SFPB处理试样腐蚀疲劳寿命N' = 1.18 × 106 cyc,下同)

Fig.6

Corrosion fatigue fracture SEM images of 300M steel without (a, c, e, g) and with (b, d, f, h) SFPB treatment (σmax = 400 MPa, the life of samples without SFPB N = 6.67 × 105 cyc, the life of samples with SFPB N' = 1.18 × 106 cyc, the same below)

(a) overall morphology before SFPB (b) overall morphology after SFPB

(c) enlarged view of area I in Fig.6a (d) enlarged view of area I in Fig.6b

(e) enlarged view of area II in Fig.6a (f) enlarged view of area II in Fig.6b (Inset shows the locally enlarged view)

(g) enlarged view of area III in Fig.6a (h) enlarged view of area III in Fig.6b

随着腐蚀疲劳循环次数增加,当裂纹达到裂纹扩展门槛值后裂纹开始以疲劳源为中心呈放射状扩展,形成裂纹扩展区(图6e和f)。300M钢未强化试样裂纹扩展区存在数量较少的二次裂纹,裂纹扩展较为容易,并且存在较多的疲劳辉纹。SFPB处理试样裂纹扩展区出现了少量解离台阶并汇合形成河流花样,二次裂纹数量明显增多,主裂纹的扩展路径更加曲折,有效降低了主裂纹扩展的驱动力,分散了裂纹尖端应力集中的作用,使裂纹尖端变钝,减缓了裂纹扩展速率[26]。另外,从图6f中的局部放大图可以看出,SFPB处理试样腐蚀疲劳后的裂纹扩展区存在少量的疲劳辉纹。根据文献[27]中疲劳辉纹宽度的测量方法,从图6e和f中测量计算得到未强化试样和SFPB处理试样的疲劳辉纹宽度分别约为0.80和0.20 μm,表明SFPB处理有效降低了300M钢的腐蚀疲劳裂纹扩展速率,从而提高300M钢的腐蚀疲劳寿命。当裂纹扩展到临界尺寸时试样发生断裂,从而形成瞬断区(图6g和h)。未强化试样瞬断区(图6g)的韧窝密集细小且较浅,SFPB处理试样的瞬断区韧窝尺寸和深度均有明显增加(图6h)。这可能与SFPB处理诱导的300M钢试样表层晶粒细化有关。

2.4 腐蚀疲劳后的表面完整性

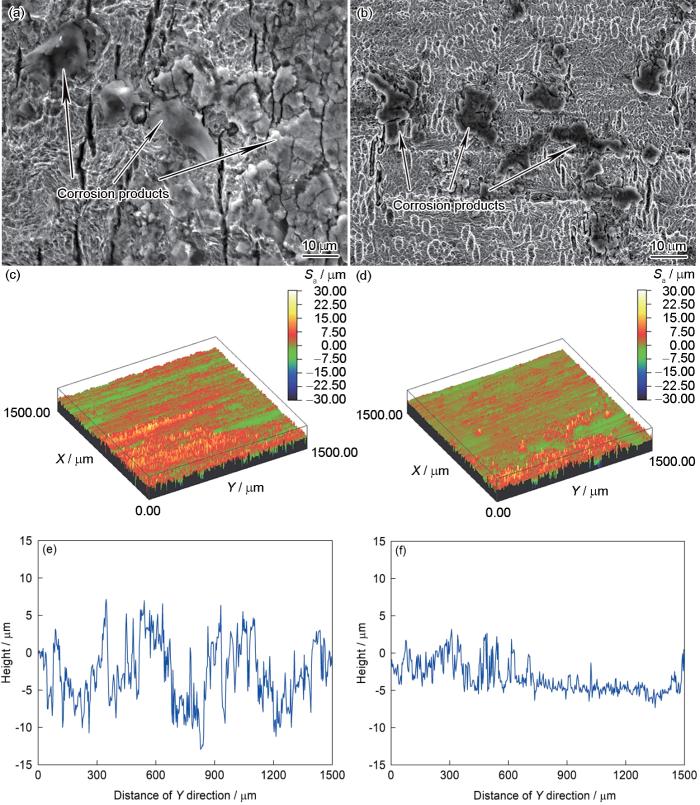

图7为SFPB处理前后的300M钢腐蚀疲劳后的表面形貌、表面粗糙度以及三维轮廓图(σmax = 400 MPa)。未强化试样腐蚀疲劳后表面出现大量裂纹,且相互连接形成长裂纹,裂纹尖端存在较多的腐蚀产物,如图7a所示,其相应的表面粗糙度Sa为4.53 μm (图7c),表面峰谷值(PV)为19.95 μm (图7e)。SFPB处理试样腐蚀疲劳后表面未出现明显的微裂纹,仅存在少量腐蚀产物和腐蚀坑,如图7b所示,相应的Sa和PV分别减小至4.32 和10.50 μm,如图7d和f所示。表明SFPB有效改善了300M钢的表面质量,这是由于SFPB处理试样表面的梯度纳米结构能够有效促进表面钝化膜的形成[28],有助于降低由腐蚀缺陷引起的裂纹萌生概率,同时,试样表面形成的高幅值残余压应力有效抑制了裂纹萌生和扩展,从而使300M钢腐蚀疲劳后表面裂纹和腐蚀产物数量明显减少,表面粗糙度降低,能够有效提高300M钢的抗腐蚀疲劳性能。

图7

图7

SFPB处理前后300M钢腐蚀疲劳后的表面形貌、表面粗糙度以及三维轮廓图(σmax = 400 MPa)

Fig.7

Surface morphologies (a, b), roughnesses Sa (c, d), and three-dimensional contour maps (e, f) of 300M steel without (a, c, e) and with (b, d, f) SFPB treatment after corrosion fatigue (σmax = 400 MPa)

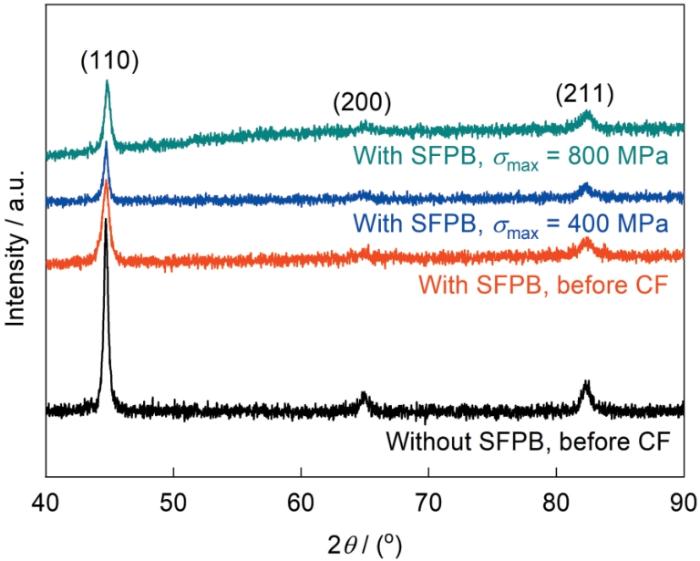

2.5 腐蚀疲劳后的XRD谱

图8

图8

SFPB处理前后300M钢腐蚀疲劳前后的XRD谱

Fig.8

XRD spectra of 300M steel without and with SFPB treatment before and after corrosion fatigue

表1 SFPB处理前后300M钢腐蚀疲劳前后的表层位错密度和微观应变

Table 1

| Treatment | ρ 1014 m-2 | ε 10-4 |

|---|---|---|

| Without SFPB, before CF | 2.08 | 6.0 |

| With SFPB, before CF | 9.06 | 55.8 |

| With SFPB, σmax = 400 MPa | 8.76 | 43.6 |

| With SFPB, σmax = 800 MPa | 7.81 | 30.9 |

式中,D为晶粒尺寸,b为Burgers矢量模,ε为微观应变,<ε2>1/2为平均微观应变。

经SFPB处理后300M钢位错密度明显增加。然而,在低应力循环载荷下,SFPB处理的300M钢发生塑性变形,试样内原有位错发生滑移使异号位错相消湮灭,同时材料变形产生可动位错,使位错重排形成位错缠结,从而导致位错密度略有降低后并逐渐趋于稳定。随着加载应力水平增加,SFPB处理试样在高应力载荷下腐蚀疲劳后表层位错密度明显减小,这可能是由于较高的加载载荷提供了更高的位错滑移驱动力,使 SFPB处理试样在循环加载过程中高密度位错缠结被破坏,导致试样表层位错密度降低,这使得阻碍裂纹萌生抗力减弱,导致 SFPB处理试样在高应力载荷下腐蚀疲劳寿命减弱。

对SFPB处理的300M钢腐蚀疲劳前后断口附近表层残余应力测试结果表明,300M钢经SFPB处理后表层形成了高幅值残余压应力-938 MPa。这主要是由于300M钢表层受到Al2O3微粒的轰击作用,使表层发生晶格畸变,产生高密度位错,部分变形能以位错的形式存储在材料内部[32],因此材料表面形成了高幅值压应力。SFPB处理试样腐蚀疲劳后表面残余压应力均发生不同程度的松弛,在σmax为400 MPa下腐蚀疲劳后,试样表层残余应力松弛为-490 MPa,松弛量为47.76%,随着加载载荷增加,σmax为800 MPa下残余应力松弛为-212 MPa,松弛量达到77.40%。SFPB试样在腐蚀疲劳过程中受到拉压循环载荷作用,表层储存的变形能逐渐释放,导致表面残余应力发生松弛[33]。随着加载载荷增加,表面裂纹数量增多,且高应力载荷促进了位错运动[34],导致残余应力松弛程度增加,使SFPB处理试样在高应力水平下腐蚀疲劳寿命明显降低,这与图5中腐蚀疲劳寿命变化相一致。

2.6 腐蚀疲劳后的微观组织

图9为SFPB处理300M钢不同载荷下腐蚀疲劳后微观组织的TEM像。从图9a插图的SAED花样可以看出,SFPB处理的300M钢在腐蚀疲劳后SAED花样呈现出连续环状且形状完整,表明SFPB处理试样腐蚀疲劳后表层晶粒尺寸仍处于纳米量级,且晶粒取向随机分布。通过Nano Measurer软件测得平均晶粒尺寸约为14.6 nm,如图9b插图所示。随着加载载荷增加,SFPB处理试样表层平均晶粒尺寸约为14.8 nm,如图9c和d所示,表明SFPB处理300M钢的表层纳米晶具有良好的组织稳定性。图9e和f所示为SFPB处理的300M钢在不同载荷下腐蚀疲劳后的次表层微观组织的TEM像(距表层100 μm)。SFPB处理300M钢腐蚀疲劳后次表层高密度位错不断缠绕塞积,位错和位错之间发生交互作用而形成位错胞等亚结构缺陷,同时形成形变孪晶以协调塑性变形,如图9e所示。随着加载载荷的增加,次表层形变孪晶数量增多,如图9f所示,这主要是由于高应力载荷导致试样内部应力集中加剧,内应力更易达到临界孪晶应力,从而形成更多的形变孪晶以协调塑性变形。

图9

图9

SFPB处理300M钢不同载荷下腐蚀疲劳后微观组织的TEM像

Fig.9

TEM images of SFPB-treated 300M steel after corrosion fatigue at different loads

(a, b) topmost surface, σmax = 400 MPa

(c, d) topmost surface, σmax = 800 MPa (Insets of Figs.9a and c show the SAED patterns, and insets in Figs.9b and d present the grain size distribution histograms calculated by Nano Measurer software)

(e) subsurface, σmax = 400 MPa

(f) subsurface, σmax = 800 MPa

3 分析与讨论

本工作通过SFPB技术诱导表面纳米化有效提高了300M钢在NaCl溶液中的腐蚀疲劳性能。300M钢经SFPB处理后表面晶粒细化至纳米级,表面纳米晶层强度明显提升,提供了较大的塑性应变阻力,能够有效减少应力集中和抑制裂纹形核,增强了300M钢的抗点蚀性能,抑制了试样的腐蚀进程,从而提高了300M钢在NaCl溶液中的抗腐蚀性能[35]。同时,细化的晶粒可以增强材料的滑移变形抗力,加强腐蚀疲劳裂纹的扩展阻力,在腐蚀疲劳裂纹扩展过程中,由于晶粒细化而晶界增多,位错移动受阻,裂纹的扩展需要穿过更多晶界,因此消耗的能量更多,从而使腐蚀疲劳裂纹的扩展受到抑制[36],显著提高了300M钢的腐蚀疲劳寿命(图5)。理论上,材料强度可以通过下式来评估[37]:

式中,σf为强度,σ0为摩擦应力,k为Hall-Petch常数,dfp为位错平均自由程,α为常数,G为剪切模量。从

300M钢经SFPB处理后高幅值残余压应力有效抑制了裂纹形核和扩展。在裂纹萌生阶段,残余压应力可以抵消部分载荷,降低有效拉应力,从而抑制表面裂纹的萌生。在裂纹扩展阶段,根据叠加模型[39],腐蚀疲劳裂纹扩展速率(da / dN)可以表示为:

式中,da / dNmec为机械疲劳裂纹扩展速率,da / dNenv为金属材料裂纹尖端腐蚀环境引起的裂纹扩展速率。

da / dNmec可以由Paris 定律表达:

式中,f为载荷频率,CP和m是材料常数,ΔK为应力强度因子范围。

da / dNenv可以由Faraday方程描述[40]:

式中,icor为裂纹尖端腐蚀电流密度,F为Faraday常数,M和z分别为金属材料的原子量和氧化数。

式中,σ(e, local)是局部疲劳强度,σ(r, local)是局部残余压应力(负值),σe是未强化试样的疲劳强度,σu是材料的抗拉强度。从

4 结论

(1) 采用SFPB技术在300M钢表层制备出晶粒尺寸约为14.5 nm、厚度约为33 μm的梯度纳米组织,且腐蚀疲劳后的表层纳米晶具有良好的组织稳定性,次表层形成大量位错缠结和形变孪晶,且随着载荷增加形变孪晶数量增加。

(2) 300M钢经SFPB处理后腐蚀疲劳源明显减少,疲劳辉纹宽度明显减小。在相同载荷下300M钢经SFPB处理后腐蚀疲劳寿命显著提高,且随着加载应力水平增加SFPB对300M钢抗腐蚀疲劳性能的强化效果逐渐弱化。

(3) 300M钢经SFPB处理后表层形成约-938 MPa的高幅值残余压应力,腐蚀疲劳后表层残余应力发生松弛,且随着加载应力水平的增加残余应力松弛程度明显增加。

致谢

感谢中国科学院金属研究所王吉强研究员在超音速微粒轰击实验中提供的支持与帮助!

参考文献

The growth behavior of austenite grain in the heating process of 300M steel

[J].

Properties of direct-quenched aircraft forged component made of ultrahigh-strength steel 300M

[J].

Corrosion damage failure law analysis and corrosion control for naval aircraft in servicing

[J].

海军现役飞机的腐蚀损伤失效分析及腐蚀防护

[J].

Nitriding effect on corrosion fatigue strength of low alloy steel in 1% HCl aqueous solution

[J].

Effect of shot peening on short crack propagation in 300M steel

[J].

Improving the fretting and corrosion fatigue performance of 300M ultra-high strength steel using the ultrasonic surface rolling process

[J].

The effect of electropulsing-assisted ultrasonic nanocrystal surface modification on the microstructure and properties of 300M steel

[J].

The effects of laser-assisted ultrasonic nanocrystal surface modification on the microstructure and mechanical properties of 300M steel

[J].

Surface integrity and wear behavior of 300M steel subjected to ultrasonic surface rolling process

[J].

Surface modification and its effect on the tensile and fatigue properties of 300M steel subjected to ultrasonic surface rolling process

[J].

Strengthen experimental study of high strength steel 40CrNi2Si2MoVA based on laser shock processing

[J].

Effect of laser peening on fatigue performance in 300M steel

[J].

Microstructural evolution, mechanical behaviors and strengthening mechanism of 300M steel subjected to multi-pass laser shock peening

[J].

Supersonic fine particles bombarding: A novel surface nanocrystallization technology

[J].

超音速微粒轰击金属表面纳米化新技术

[J].

Research progress in nanocrystalline microstructure, mechanical properties and nanocrystallization mechanism of titanium alloys via surface mechanical treatment

[J].

钛合金表层机械处理的纳米化组织、力学性能与机理研究进展

[J].

Effect of surface nano-crystallization induced by supersonic fine particles bombarding on microstructure and mechanical properties of 300M steel

[J].

Microstructure evolution and properties of gradient nanostructures subjected to laser shock processing in 300M ultrahigh-strength steel

[J].

Research on mechanism of surface nanocrystalline layer in 2219 Al alloy induced by supersonic fine particles bombarding

[J].

Electrochemical corrosion properties of the surface layer produced by supersonic fine-particles bombarding on low-carbon steel

[J].

Effect of Ce addition on modifying the microstructure and achieving a high elongation with a relatively high strength of as-extruded AZ80 magnesium alloy

[J].Forming magnesium alloys with rare earth elements (La, Gd, Nd, Y, Ce) is a routine method for modifying their microstructure and properties. In the present work, the effect of Ce addition on the microstructure evolution and the mechanical properties of as-extruded Mg-8Al-0.5Zn (AZ80) alloy was investigated. All of the extruded AZ80-xCe (x = 0, 0.2, 0.8 and 1.4 wt %) alloys exhibited equiaxed grains formed by fully dynamic recrystallization, and the grain size of the extruded AZ80 alloy was remarkably reduced by ~56.7% with the addition of 1.4 wt % Ce. Furthermore, the bulk-shaped Al4Ce phase formed when Ce was first added, with the Ce content rising to 0.8 wt % or higher, and Al4Ce particles in both the nano- and micron sizees were well distributed in the primary α-Mg matrix. The area fraction of the Al4Ce particles expanded with increasing Ce content, providing more nuclei for dynamic recrystallization, which could contribute to the grain refinement. The results of the tensile tests in this study showed that Ce addition effectively improved the room temperature formability of the as-extruded AZ80 alloy, without sacrificing strength. The significantly improved mechanical properties were ascribed to excellent grain refinement, weakened texture strength, an increased Schmid factor, and a reduced area fraction of low-angle grain boundaries, all resulting from Ce addition to the as-extruded AZ80 alloy. The contribution of the nano-Al4Ce precipitates on improving the mechanical properties was also discussed in this paper.

Effect of stress shot peening on the residual stress field and microstructure of nanostructured Mg-8Gd-3Y alloy

[J].

Improving fatigue performance of Ti-6Al-4V alloy via ultrasonic surface rolling process

[J].The effect of a gradient nanostructured (GNS) surface layer obtained by ultrasonic surface rolling process (USRP) on the fatigue behavior of Ti-6Al-4 V alloy has been studied in this paper. Microstructure, surface topography, surface roughness and residual stress measurements were performed to characterize the surface under different conditions. Rotating bending fatigue tests were carried out to evaluate the fatigue behavior of different treatments. The results present a remarkable fatigue performance enhancement for the Ti-6Al-4 V alloy with a GNS surface layer obtained by application of USRP with respect to the untreated condition, notwithstanding its considerable surface roughness due to severe ultrasonic impacts and extrusions. Mechanical surface polishing treatment further enhances the beneficial effects of USRP on the fatigue performance. The significantly improved fatigue performance can mainly be ascribed to the compressive residual stress. Simultaneously, the GNS surface layer and surface work hardening have a synergistic effect that accompanies the effect of compressive residual stress.

Residual stress relaxation and low- and high-cycle fatigue behavior of shot-peened medium-carbon steel

[J].

Mechanical and corrosion fatigue behaviors of gradient structured 7B50-T7751 aluminum alloy processed via ultrasonic surface rolling

[J].In this work, ultrasonic surface rolling process (USRP) was utilized to produce a gradient structured layer on 7B50-T7751 aluminum alloy, and the mechanical properties and corrosion fatigue behavior of treated samples were studied. These results reveal that underwent USRP, a 425 μm thick gradient structure and a 700 μm deep compressive residual stress field are created, aluminum grain size become fine(~ 67 nm), and the corrosion rate of treated surface reduces by 60.08% owing to the combined effect of compressive residual stress and surface nanocrystallization. The corrosion fatigue strength is enhanced to 117% of that of 7B50 Al alloys by means of USRP due to the introduced compressive residual stress, which is considered as the major favorable factor in suppressing the initiation and early propagation of corrosion fatigue cracks. Besides, the gradient structure is an important factor in providing a significant synergistic contribution to the improvement of corrosion fatigue performance.

Formation of a gradient nanostructured surface layer on a martensitic stainless steel and its effects on the electrochemical corrosion behavior

[J].

马氏体不锈钢上梯度纳米结构表层的形成及其对电化学腐蚀行为的影响

[J].采用表面机械滚压处理(SMRT)在Z5CND16-4马氏体不锈钢上制备出梯度纳米结构(GNS)表层. 利用SEM和TEM研究了GNS表层的组织特点. 结果表明: 晶粒尺寸随深度的增大由最表层的25 nm逐渐增加到基体的原始尺寸, 整个组织细化层的厚度约为150 mm. 对比研究了SMRT样品与原始样品在3.5%NaCl (质量分数)水溶液中的电化学腐蚀行为, 发现点蚀击破电位由原始样品的0.179 V提高到0.313 V, 自腐蚀电位也有所提高. 分析表明, GNS表层中晶粒尺寸纳米化、组织均匀性提高、残余压应力的产生以及表面光洁度的提高有利于其耐点蚀能力的提高.

Effect of microstructure on high cycle fatigue behavior of Ti-20Zr-6.5Al-4V alloy

[J].

Fatigue fracture analysis of TC11 titanium alloy at different temperatures

[J].

TC11钛合金在不同温度下的疲劳断裂分析

[J].

Influence of ultrasonic shot peening on corrosion behavior of 7075 aluminum alloy

[J].

Williamson-Hall anisotropy in nanocrystalline metals: X-ray diffraction experiments and atomistic simulations

[J].

Validating grain size analysis from X-ray line broadening: A virtual experiment

[J].

Effect of supersonic fine particle bombardment on microstructure and fatigue properties of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy at different temperatures

[J].

Effect of laser shock peening on microstructure and properties of TC11 titanium alloy with lamellar microstructure

[J].

激光冲击强化对片层TC11钛合金组织和性能的影响

[J].

Influence of carburization followed by shot peening on fatigue property of 20CrMnTi steel

[J].

Residual stress relaxation and re-shot-peening process of wet shot-peened titanium alloy during tensile fatigue load

[J].

拉-拉疲劳载荷下钛合金湿喷丸的残余应力松弛及再次喷丸工艺

[J].采用湿法喷丸强化工艺(wet shot-peening)对TC4钛合金表面进行处理,研究高、低周的拉-拉疲劳过程中合金残余应力松弛规律,探讨再次喷丸工艺(re-shot-peening,RSP)对疲劳寿命的影响。结果表明:在拉应力载荷状态下,残余压应力依然发生松弛现象。疲劳载荷水平对喷丸TC4钛合金残余压应力场(CRSF)的松弛速率、松弛程度和松弛范围具有重要影响。高周疲劳(HCF)过程中残余应力松弛主要发生在近表层0~30 μm,松弛速率较慢。低周疲劳(LCF)过程中残余应力松弛发生在0~80 μm,范围更大,速率更快。RSP周期对于TC4钛合金的疲劳寿命也具有较大影响。在25%和50%初始喷丸疲劳寿命进行RSP处理会显著提高疲劳寿命,而在75%初始喷丸疲劳寿命处进行RSP处理对于疲劳寿命基本没有影响。此外,RSP的强化效果与疲劳载荷水平相关,对于高周疲劳寿命提高明显。

Laser shock peening without coating induced residual stress distribution, wettability characteristics and enhanced pitting corrosion resistance of austenitic stainless steel

[J].

Effects of laser shock peening on corrosion fatigue behavior of 2Cr13 stainless steel

[J].

Surface nanocrystallization of 17-4 precipitation-hardening stainless steel subjected to ultrasonic surface rolling process

[J].

Fatigue behaviors of AISI 316L stainless steel with a gradient nanostructured surface layer

[J].

Theoretical considerations on corrosion fatigue crack initiation

[J].

The influence of crack face contact on the prediction of fatigue crack propagation in residual stress fields

[J].

Corrosion behaviour of AISI 304 stainless steel subjected to massive laser shock peening impacts with different pulse energies

[J].

Subsurface crack initiation during fatigue as a result of residual stresses

[J].

Effect of surface nanocrystallization on fatigue properties of Ti-6Al-4V alloys with bimodal and lamellar structure

[J].