轻质Al-Mg合金成本低、比强度高,具有优异的耐腐蚀性、可焊接性,是替代传统钢铁材料的热门候选材料[1~4]。Mg元素在Al基体中固溶度高,可显著降低铝合金层错能,抑制变形过程中的位错回复[5~7]。近年来,研究发现大变形(SPD)技术,包含等通道转角挤压(ECAP)[1,8]、高压扭转(HPT)[2,9]、累积叠轧(ARB)[10,11]和低温轧制[12,13]等,通过引入大塑性应变,可将组织细化至纳米晶和超细晶级别,显著提高Al-Mg合金的强度[9,14]。由于变形温度低,可有效抑制位错回复,提高位错密度,并促进晶粒细化,低温轧制成为制备高强铝合金的潜在方法之一。Krymskiy等[15]研究了低温轧制对2024铝合金性能的影响,发现当轧制应变量约为2.0时,合金屈服强度(YS)和抗拉强度(UTS)分别达到约590和640 MPа。Kumar等[16]通过液氮轧制结合低温时效制备了YS约488 MPa和UTS约516 MPa的高强6082铝合金。然而,目前采用低温轧制制备的高强铝合金一般塑性较低(通常< 5%),且低温轧制工艺道次多、压下量小,生产效率低。前期研究[17~23]提出一种新型短流程室温大压下量衬板控轧(HPR)方法,可将轧制过程中部分剪切应力转变为压应力,提高板材成形性;单道次HPR可实现80%~90%压下量。经单道次约80%压下量HPR变形后,Al-9Mg (质量分数,%,下同)合金UTS达到约525 MPa,断裂延伸率(δf)约14%,同时获得优异的强度和塑性[18]。

大变形技术制备的铝合金通常包含高密度位错和高体积分数的亚晶界或晶界,因此,具有较高的晶界迁移率和较低的再结晶温度[24,25]。由于缺少有效的第二相钉扎位错和晶界,大变形Al-Mg合金在热处理过程中容易发生回复、再结晶和晶粒粗化,导致组织稳定性差[26,27]。例如,Hasegawa等[28]通过ECAP制备的超细晶Al-3Mg合金在200℃退火1 h后晶粒尺寸由约300 nm长大至4~6 μm。Hayes等[29]发现通过ECAP制备的Al-3Mg合金在250℃退火1 h后,晶粒尺寸从约0.2 μm长大到约20 μm。最近,Zha等[4]报道了通过ECAP制备的混晶结构高固溶Al-7Mg合金具有较高的热稳定性,该合金在200℃退火24 h和275℃退火8 h后,仅发生位错回复。退火过程中,混晶结构中粗晶粒发生了严重回复,消耗了大部分储存能,延缓了合金的再结晶行为和纳米晶、超细晶长大过程。同时,在晶界处偏聚的Mg溶质原子以及在退火过程中析出的纳米级Al3Mg2相进一步提高了纳米晶、超细晶的热稳定性。此外,Zha等[30]发现HPR制备的混晶结构Al-9Mg合金在275℃退火24 h后以回复为主,再结晶程度较低。这主要归因于高含量固溶Mg原子稳定了(101)取向粗晶粒,促进晶内位错均匀分布,并提高了晶格转动的临界应力,抑制晶内变形带的形成。提高固溶Mg含量是改善高强Al-Mg合金热稳定性的有效手段之一,但目前关于高固溶Mg含量Al-Mg合金热稳定性的研究报道较少。

本工作开发了一种低温高应变量衬板控轧(CHR-HPR)技术,成功制备了兼具高强塑和高热稳定性的高固溶Al-9Mg合金。采用电子背散射衍射(EBSD)和透射电子显微镜(TEM)对CHR-HPR Al-1Mg、Al-5Mg和Al-9Mg合金进行了系统的微观组织表征,并对其强韧化机制进行详细讨论。同时,研究了CHR-HPR Al-Mg合金在低温、中温和高温退火过程中组织演变规律,分析了不同退火温度下组织演变机制。

1 实验方法

实验采用实验室自制的Al-1Mg、Al-5Mg和Al-9Mg合金,其实际成分见表1。实验原材料为商业纯Al和高纯Mg,经680~720℃熔炼浇铸为直径82 mm、长100 mm铸锭,随后对Al-1Mg和Al-5Mg合金铸锭进行580℃、3 h固溶处理,对Al-9Mg合金铸锭进行500℃、3 h固溶处理,并在420℃挤压,挤压比约为13。挤压Al-1Mg、Al-5Mg和Al-9Mg合金平均晶粒尺寸分别约为160、21和15 μm。将挤压板材切成尺寸为长50 mm、宽20 mm、高5 mm的块体,放在2块衬板之间,夹持固定。第1道次轧制前将衬板和样品在液氮中保温30 min,轧制压下量约为60%,第2道次轧制前将衬板和样品在液氮中保温10 min,轧制压下量约为50%,轧辊温度为室温,总压下量约为80%。

表1 Al-Mg合金化学成分 (mass fraction / %)

Table 1

| Alloy | Mg | Fe | Mn | Si | Al |

|---|---|---|---|---|---|

| Al-1Mg | 1.05 | 0.05 | 0.002 | 0.03 | Bal. |

| Al-5Mg | 5.18 | 0.05 | 0.004 | 0.03 | Bal. |

| Al-9Mg | 9.09 | 0.05 | 0.002 | 0.04 | Bal. |

EBSD样品经砂纸研磨、机械抛光后,在5%HCl-O4 + 95%C2H5OH (体积分数)溶液中进行电解抛光,电压为20 V,时间为60 s,温度为-25℃。EBSD表征在配有EBSD探头的Sigma-500场发射扫描电镜(SEM)上进行,工作电压为20 kV,扫描步长为0.6 μm,样品倾斜角为70°。对样品的轧向(RD)-横向(TD)截面进行EBSD表征。使用Nano Measurer 1.2软件统计晶粒尺寸,每个样品统计500~800个晶粒。JEM-2100F TEM工作电压为200 kV。TEM样品减薄至约30 μm,冲压成直径为3 mm的圆片,随后在30%HNO3 + 70%CH3OH (体积分数)电解液中进行双喷减薄,电压为12 V,温度为-35℃。物相分析采用D/Max 2500PC型X射线衍射仪(XRD)。辐射源为Cu靶Kα 射线,工作参数为:电压40 kV,电流300 mA,扫描速率1°/min。拉伸实验在 AGS-X-100 kN 电动万能试验机上进行,拉伸应变速率为5 × 10-4 s-1。为保证实验结果可靠性,每种材料至少进行3次拉伸测试。采用HVS-1000A显微硬度计进行显微硬度测试,载荷为300 g,加载时间为15 s,每个样品至少测试12个点。

2 实验结果与分析

2.1 CHR-HPR Al-Mg合金微观组织演变

图1所示为挤压态和CHR-HPR Al-Mg合金的XRD谱。在所有样品中,只观察到Al相的峰,并未发现Al3Mg2和其他含Mg或含Fe相的峰。随着Mg含量增加,衍射峰逐渐向低角度偏移,这是由于Mg原子半径比Al原子半径大,随着Mg原子固溶量增加,Al基体晶格发生畸变,晶格参数增大(表2)。与挤压态样品相比,CHR-HPR样品晶格参数稍有减小,仅相差0.00020~0.00035 nm,表明CHR-HPR后大部分Mg原子仍固溶在基体中。Al-Mg合金中每增加1%Mg (原子分数)可以使晶格常数增大0.0046 nm[18],由此可以计算CHR-HPR Al-1Mg、Al-5Mg和Al-9Mg合金的固溶Mg含量分别减少了0.48%、0.68%和0.38% (质量分数)。少量的固溶Mg原子损失可能归因于晶界处原子团簇的形成[1,4,9]。

图1

图1

挤压态和低温高应变量衬板控轧(CHR-HPR) Al-Mg合金的XRD谱

Fig.1

XRD spectra of the as-extruded and cryogenic high-reduction hard-plate rolling (CHR-HPR) Al-Mg alloys (Dotted vertical lines represent the theoretical diffraction peaks of pure Al)

表2 纯Al[8]、挤压态和CHR-HPR Al-Mg合金晶格参数和Mg减少量

Table 2

| Material | State | a nm | Δa nm | ΔMg mass fraction / % |

|---|---|---|---|---|

| Pure Al[8] | 0.40413 | |||

| Al-1Mg | As-extruded | 0.40567 ± 0.00006 | 0.00025 | 0.48 |

| CHR-HPR | 0.40542 ± 0.00001 | |||

| Al-5Mg | As-extruded | 0.40776 ± 0.00007 | 0.00035 | 0.68 |

| CHR-HPR | 0.40741 ± 0.00001 | |||

| Al-9Mg | As-extruded | 0.40988 ± 0.00005 | 0.00020 | 0.38 |

| CHR-HPR | 0.40968 ± 0.00001 |

图2所示为CHR-HPR Al-1Mg、Al-5Mg和Al-9Mg合金微观组织的EBSD分析。Al-1Mg合金以(001)取向晶粒为主(图2a),粗大的晶粒受剪切而破碎严重,晶粒内部存在大量(101)取向变形带和亚晶粒。Al-5Mg和Al-9Mg合金中(101)取向晶粒晶界清晰,且晶粒内变形带较少,在晶界变形带或三叉晶界处存在少量细小等轴晶(图2b和c)。通过对比可以发现,(001)和(111)取向晶粒内形成了取向各异的亚晶结构,晶粒破碎细化,这表明(001)和(111)取向晶粒变形程度较高,且应变分布不均匀。Jin等[31]研究了动态塑性变形(DPD) Al-7Mg合金的组织演变,发现(101)取向晶粒在塑性变形过程中可以同时激活(111)[01

图2

图2

CHR-HPR Al-Mg合金微观组织的EBSD分析

Fig.2

EBSD analyses of CHR-HPR Al-1Mg (a, d), CHR-HPR Al-5Mg (b, e), and CHR-HPR Al-9Mg (c, f) alloys (High-angle grain boundaries (HAGBs) are defined by misorientation angle (θ) > 15°, and low-angle grain boundaries (LAGBs) are defined by 2° < θ < 15°, respectively. TD—transverse direction, RD—rolling direction) (a-c) inverse pole figure maps (d-f) kernel average misorientation (KAM) images

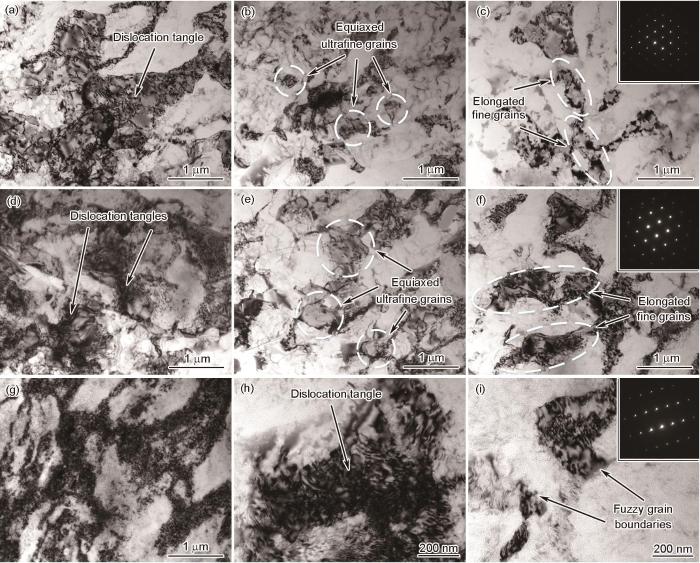

图3为CHR-HPR Al-Mg合金微观组织的TEM像。Al-1Mg和Al-5Mg合金中含有大量尺寸为300~900 nm的亚晶和1~2 μm的细晶,其中,Al-5Mg合金晶内位错缠结明显,表明位错密度较高。随着Mg含量的进一步增加,Al-9Mg合金中位错缠结数量和程度显著提高,形成了致密的三维位错网络结构(图3g)。Al-9Mg合金中亚晶或超细晶数量减少,晶粒尺寸为150~500 nm。在超细晶或亚晶粒中观察到模糊的晶界和稠密的位错缠结,表明晶内存在高局部应变和高密度位错。此外,从TEM像和选区电子衍射斑点上均未发现Al3Mg2或其他杂质相,与XRD结果相符(图1)。固溶Mg原子对Al-Mg合金的再结晶行为有2方面影响:首先,固溶Mg原子有利于提高位错密度,从而提供更高的再结晶驱动力[32];其次,固溶Mg原子可降低铝合金层错能,抑制交滑移,同时钉扎位错,阻碍位错重排,有效地抑制回复和动态再结晶[8]。Al-Mg合金塑性加工过程中的微观组织演变取决于固溶Mg原子对位错增殖的促进作用和对位错回复的抑制作用之间的动态竞争。在本工作中,Al-9Mg合金中高含量固溶Mg原子可有效抑制位错回复,从而形成大量稠密位错缠结,延缓再结晶行为。然而,在Al-1Mg合金中,由于位错增殖速率慢、动态回复快,很难形成致密的三维位错网络结构。同时,通过位错交滑移或攀移在局部形成了一些动态再结晶晶粒[18]。

图3

图3

CHR-HPR Al-Mg合金微观组织的TEM像

Fig.3

TEM images of the CHR-HPR Al-1Mg (a-c), CHR-HPR Al-5Mg (d-f), and CHR-HPR Al-9Mg (g-i) alloys (Insets in Figs.3c, f, and i are the corresponding selected area electron diffraction patterns of the matrix)

2.2 CHR-HPR Al-Mg合金力学性能及强塑性机制

图4a为CHR-HPR Al-Mg合金室温拉伸工程应力-应变曲线。随固溶Mg含量增加,CHR-HPR Al-Mg合金强度和塑性同时提升,由Al-1Mg合金YS约254 MPa,UTS约256 MPa,δf 约3.7%提高到Al-5Mg合金YS约427 MPa,UTS约454 MPa,δf 约4.2%,进一步提升至Al-9Mg合金YS约527 MPa,UTS约597 MPa,δf约7.7%。如图4c所示,Al-1Mg合金的加工硬化率较小,并且随应变增大急剧减小,直至断裂。相比之下,Al-5Mg和Al-9Mg合金出现加工硬化率平台,加工硬化率下降速率减缓,有利于稳定塑性变形。但是,Al-5Mg合金加工硬化率应变平台区间较短(0.018~0.022)。当Mg含量增加至9% (质量分数)时,加工硬化率应变平台区间扩大(0.024~0.064),表明加工硬化能力增强。随Mg含量增加,Mg原子与位错交互作用增强,促进位错增殖;同时,高含量Mg原子钉扎位错,抑制位错动态回复,2者协同作用提高加工硬化,促进合金的强度和塑性同时提高[14]。此外,在Al-5Mg和Al-9Mg合金中观察到明显的动态应变时效(DSA)现象。DSA效应反映了可动位错和迁移的溶质原子之间的相互作用[33,34]。高含量固溶Mg一方面提高了可扩散Mg溶质原子的数量,另一方面通过拖拽效应抑制位错湮灭而提高了位错密度。高密度位错导致位错滑移的平均自由程减小,移动速率降低,造成Mg原子钉扎位错的频率增大,因此Al-5Mg和Al-9Mg合金中DSA效应增强。Zha等[8]认为DSA效应可以有效地减缓位错运动,抑制位错湮灭,提高合金的加工硬化能力。因而,Al-9Mg合金的高加工硬化能力除了源于高含量固溶Mg原子外,还归因于较强的DSA效应。但是Al-Mg合金中Mg含量过高,易导致位错严重塞积,局部位错密度显著提高,从而降低塑性,甚至发生提前断裂。据Jobba等[35]推测,当局部位错密度达到临界值时,材料会形成严重应力集中,导致裂纹过早形成,进而降低合金塑性。Jang等[5]研究了冷轧Al-Mg合金的力学性能,发现当Mg含量≤ 10% (质量分数)时,随着Mg含量增加,冷轧合金的强度和塑性逐渐提高;但是当Mg含量增加到13% (质量分数)时,合金强度提高,塑性降低。

图4

图4

CHR-HPR Al-Mg合金室温拉伸性能

Fig.4

Tensile properties of CHR-HPR Al-Mg alloys

(a) engineering stress-strain curves

(b) true stress-strain curves (Inset in Fig.4b shows the locally magnified section)

(c) work hardening rate as a function of true strain

CHR-HPR Al-9Mg合金的高抗拉强度来自于其高屈服强度与强加工硬化能力。而高屈服强度可归因于3种强化机制,即溶质Mg引起的固溶强化、晶粒细化提供的晶界强化以及高密度位错产生的位错强化。Al-Mg合金中溶质原子与位错交互作用引起的固溶强化(ΔσSS)可根据下式计算[8]:

式中,H和n是与材料相关的常数(H = 13.8 MPa/%,n = 1.14),C是溶质浓度(质量分数,%)。通过

位错强化(ΔσD)计算公式如下[36]:

式中,θ为晶粒内部取向差角(弧度),μ为EBSD扫描步长。可计算出CHR-HPR Al-9Mg合金的位错密度约为2.1 × 1014 m-2。根据

针对本工作中非均匀的晶粒结构组织,采用Hansen[38]提出的修正Taylor公式分别考虑小角度晶界(LAGBs)和高角度晶界(HAGBs)对强度的贡献(σLAGB和σHAGB),其和为ΔσGB,计算公式如下:

式中,ky为完全再结晶Al-Mg合金的Hall-Petch常数,取值为105 MPa∙m1/2;dHAGB为由HAGBs包围的晶粒平均尺寸,取值为30.1 μm;SV为单位体积内总晶界面积,取值为2.1;

合金的屈服强度(σYS)可以通过下式计算得到:

式中,σ0为纯Al中晶格对位错运动的摩擦阻力,取值约为10 MPa[39]。CHR-HPR Al-9Mg合金的理论屈服强度为508 MPa,略小于实验结果527 MPa。CHR-HPR导致基体中固溶Mg含量减少,这可归因于团簇的形成。原子团簇本身也具有不可忽视的强化效果[40],弥补了理论强度与实验结果的差值。Zha等[18]分析了室温HPR Al-9Mg合金的强化机制,其位错强化和晶界强化共提供强化增量约224 MPa。在本工作中,CHR-HPR Al-9Mg合金位错强化和晶界强化共约336 MPa,明显高于室温HPR Al-9Mg合金。由此可见,CHR-HPR显著促进了高固溶Mg含量Al-9Mg合金中高密度位错和LAGBs形成,大幅提高了合金屈服强度。

2.3 CHR-HPR Al-Mg合金组织热稳定性

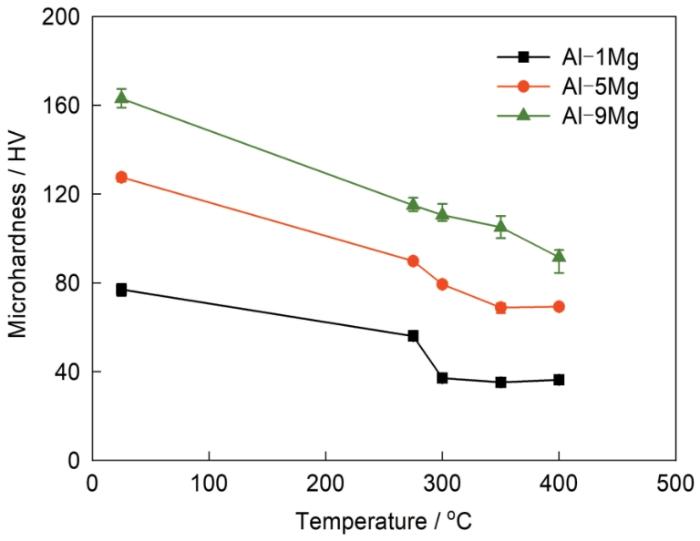

CHR-HPR Al-Mg合金经不同温度退火30 min后的硬度演变如图5所示。当退火温度从275℃提高到300℃,Al-1Mg合金硬度迅速下降;当退火温度超过300℃时,硬度基本不变,表明Al-1Mg合金在300℃退火30 min发生完全再结晶。Al-5Mg合金在275~350℃退火时,硬度缓慢下降;当退火温度超过 350℃时,硬度达到稳定,表明Al-5Mg合金完全再结晶温度为350℃。Al-9Mg合金在275~350℃退火时硬度缓慢下降,当退火温提高至400℃时,合金硬度迅速下降。

图5

图5

CHR-HPR Al-Mg合金经不同温度退火30 min后的硬度变化曲线

Fig.5

Microhardness evolution of CHR-HPR Al-Mg alloys annealed at different temperatures for 30 min

CHR-HPR Al-Mg合金经275~400℃退火30 min后的室温拉伸性能如图6所示。275℃退火30 min后,合金强度和塑性随Mg含量的提高而提高。其中Al-9Mg合金抗拉强度和塑性最高,分别约为500 MPa和15.7%。这是由于高固溶Mg含量显著抑制了位错回复。在300和350℃退火30 min后,Al-1Mg和Al-5Mg合金塑性提高,强度显著下降。而Al-9Mg合金在300和350℃退火时强度有所下降,但塑性变化不大。400℃退火30 min后,3种合金发生完全再结晶,强度均大幅降低,同时塑性显著提高。

图6

图6

CHR-HPR Al-Mg合金经不同温度退火30 min后的室温拉伸性能

Fig.6

Engineering stress-strain curves of CHR-HPR Al-Mg alloys annealed at 275oC (a), 300oC (b), 350oC (c), and 400oC (d) for 30 min

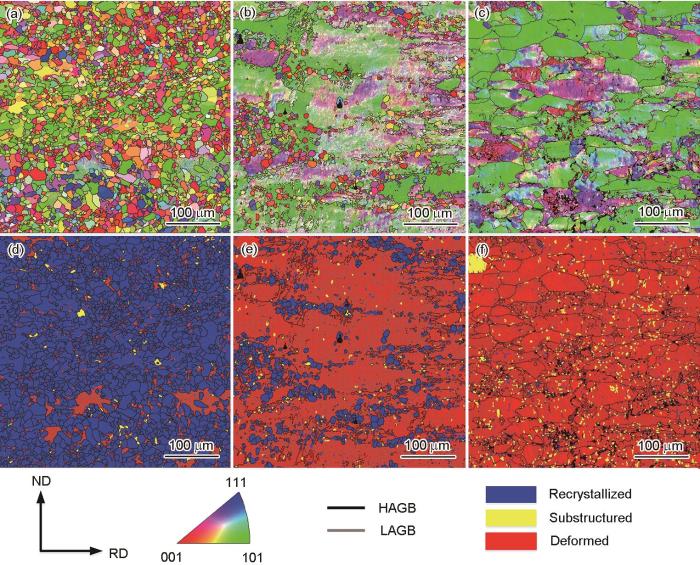

CHR-HPR Al-Mg合金经275和300℃退火30 min后的微观组织的EBSD分析分别如图7和8所示。在275℃退火30 min后,Al-1Mg合金开始发生再结晶,再结晶体积分数约为11.7%;而Al-5Mg和Al-9Mg合金主要发生位错回复(图7)。当退火温度提高至300℃,Al-1Mg合金接近完全再结晶,再结晶体积分数约为90.0% (图8a和d);Al-5Mg合金发生部分再结晶,再结晶体积分数约为18.2% (图8b和e);而Al-9Mg合金仍以位错回复为主(图8c和f)。在300℃退火30 min后,Al-5Mg合金中残留变形晶粒以(101)取向为主,这是由于(101)取向晶粒具有较高的热稳定性,在300℃退火时主要发生位错回复[30]。

图7

图7

CHR-HPR Al-Mg合金经275℃退火30 min后微观组织的EBSD分析

Fig.7

EBSD analyses of CHR-HPR Al-1Mg (a, d), Al-5Mg (b, e), and Al-9Mg (c, f) alloys annealed at 275oC for 30 min (ND—normal direction) (a-c) inverse pole figure maps (d-f) different types of grains

图8

图8

CHR-HPR Al-Mg合金经300℃退火30 min后微观组织的EBSD分析

Fig.8

EBSD analyses of CHR-HPR Al-1Mg (a, d), Al-5Mg (b, e), and Al-9Mg (c, f) alloys annealed at 300oC for 30 min (a-c) inverse pole figure maps (d-f) different types of grains

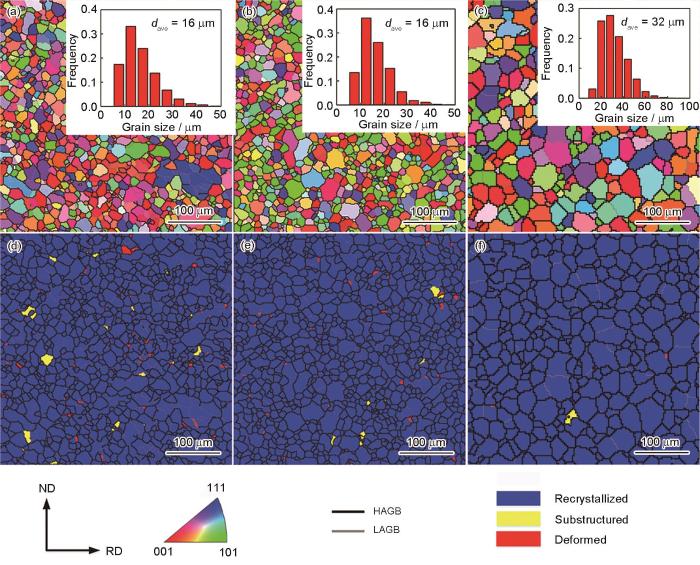

图9为CHR-HPR Al-Mg合金经350℃退火30 min后的微观组织EBSD分析。在350℃退火30 min后,Al-1Mg和Al-5Mg合金发生完全再结晶,再结晶体积分数分别达96.3%和97.5%,再结晶晶粒尺寸均约为14 μm (图9a和b中插图所示)。Al-9Mg合金仅在晶界和变形带处发生较低程度的再结晶,再结晶体积分数约为6.3%。根据文献报道,ECAP Al-7Mg合金在300℃退火5 min后,发生了完全再结晶[4];室温HPR Al-9Mg合金在300℃退火4 min后,剪切带处出现了大量再结晶晶粒,组织发生部分再结晶[30]。而在本工作中,CHR-HPR Al-9Mg合金组织热稳定性显著提高,这主要是由于低温变形促进位错积累,在退火过程中高密度位错发生回复形成亚晶界,消耗了大量变形储存能,延缓了再结晶的发生,而晶界附近的亚晶粒为了协调变形发生转动,优先发生了再结晶[41]。

图9

图9

CHR-HPR Al-Mg合金经350℃退火30 min后微观组织的EBSD分析

Fig.9

EBSD analyses of CHR-HPR Al-1Mg (a, d), Al-5Mg (b, e), and Al-9Mg (c, f) alloys annealed at 350oC for 30 min (a-c) inverse pole figure maps (Insets in Figs.9a and b are the corresponding grain size distribution charts. dave— average grain size) (d-f) different types of grains

图10

图10

CHR-HPR Al-Mg合金经400℃退火30 min后微观组织的EBSD分析

Fig.10

EBSD analyses of CHR-HPR Al-1Mg (a, d), Al-5Mg (b, e), and Al-9Mg (c, f) alloys annealed at 400oC for 30 min (a-c) inverse pole figure maps (Insets in Figs.10a-c are the corresponding grain size distribution charts) (d-f) different types of grains

图11为CHR-HPR Al-Mg合金不同温度退火前后组织演变的示意图。在较低温度退火时,如275℃,Al-1Mg合金晶粒内部发生位错回复和重排,优先在晶界和变形带处发生再结晶行为。随固溶Mg含量的增加,位错回复和再结晶受到抑制,Al-5Mg和Al-9Mg合金仅发生不同程度回复。在中高温度退火时,如300℃,Al-1Mg合金绝大部分完全再结晶,仅存在少量变形晶粒。对于Al-5Mg合金,固溶Mg原子对再结晶的抑制效果较弱,在晶界和变形带交错处发生再结晶行为。随退火温度升高到350℃,Al-1Mg和Al-5Mg合金均发生完全再结晶;而Al-9Mg合金组织虽然回复程度加剧,仅发生少量再结晶,表现出较高的组织热稳定性。在400℃退火后,Al-9Mg合金发生完全再结晶且晶粒粗化。上述分析表明随固溶Mg含量增加,CHR-HPR Al-Mg合金再结晶温度从300℃提高至400℃,CHR-HPR Al-9Mg合金的热稳定性明显高于CHR-HPR Al-1Mg和Al-5Mg合金。

图11

图11

CHR-HPR Al-Mg合金不同温度退火前后组织演变示意图

Fig.11

Microstructure evolution models of CHR-HPR Al-1Mg (ai-ei), Al-5Mg (aii-eii), and Al-9Mg (aiii-eiii) alloys before (ai-aiii) and after annealing at 275oC (bi-biii), 300oC (ci-ciii), 350oC (di-diii), and 400oC (ei-eiii) (Red lines represent deformation bands and green hexagons represent recrystallized grains, while black and gray curve lines represent HAGBs and LAGBs, respectively)

3 结论

(1) 通过CHR-HPR新方法实现了难变形高固溶Mg含量Al-9Mg合金短流程大压下量变形,2道次总压下量约80%。

(2) CHR-HPR Al-9Mg合金兼具高强度和高塑性,其屈服强度、抗拉强度和延伸率分别约为527 MPa、597 MPa和7.7%。高强度归因于高密度位错、高密度LAGBs和高含量固溶Mg原子。高塑性归因于高含量固溶Mg原子以及DSA效应共同提高了加工硬化能力。

(3) 高含量固溶Mg原子显著抑制了CHR-HPR Al-Mg合金的再结晶行为,其中CHR-HPR Al-9Mg合金在≤ 350℃温度下退火表现出优异的组织热稳定性;其再结晶温度提升至400℃,远高于低固溶Mg含量CHR-HPR Al-Mg合金。这主要归因于高含量固溶Mg原子钉扎晶界并抑制位错滑移,延缓回复与再结晶的发生。此外,CHR-HPR Al-9Mg合金具有高密度位错,在退火过程中优先发生回复,降低了再结晶驱动力。

参考文献

Prominent role of multi-scale microstructural heterogeneities on superplastic deformation of a high solid solution Al-7Mg alloy

[J].

Concurrent strengthening of ultrafine-grained age-hardenable Al-Mg alloy by means of high-pressure torsion and spinodal decomposition

[J].

Mechanism of grain refinement of pulse current assisted plasma arc welded Al-Mg alloy

[J].During welding, the vibration effect of applying a pulse current on the molten pool can effectively improve weld formation and refine grains. The effect of pulse current on grain refinement and its mechanism were studied for Al-Mg alloy welds fabricated by conventional plasma welding (PAW), PAW with conventional pulse current, and PAW with composite pulse current. The grain size produced by conventional PAW was 78.2 μm, whereas the average grain size was reduced from 78.2 μm to 53.3 μm with increasing conventional pulse current frequency from 0 Hz to 100 Hz; in addition, the degree of grain refinement increased by about 30%. However, the minimum grain size was 48.2 μm, and the grain refinement effect can reach nearly 40% by combining low-frequency pulse current with conventional pulse current. The proportion of small grains and high-angle grain boundaries increased significantly after applying the composite pulse current. The additional oscillation effect of the composite pulse current can effectively eliminate coarse grains during the solidification of the weld pool. The main mechanism of grain refinement is dendrite fragmentation, which is discussed through thermodynamics and composition.

脉冲电流辅助等离子弧焊Al-Mg合金晶粒细化机理

[J].

Stabilizing a severely deformed Al-7Mg alloy with a multimodal grain structure via Mg solute segregation

[J].Single-phase Al-Mg alloys processed by severe plastic deformation (SPD) usually suffer from unsatisfactory thermal stability at moderate to high temperatures with recrystallization occurring and obvious grain coarsening. In the present work, an Al-7Mg alloy prepared by equal-channel angular pressing (ECAP) possessed markedly enhanced thermal stability upon annealing at moderate to high temperatures (200-275 ℃), compared with those ultrafine-grained dilute Al-Mg alloys with a uniform microstructure. The enhanced thermal stability is due primarily to the multimodal grain structure consisting of nano-, ultrafine- and micron-sized grains, strong segregation and/or clusters of Mg solute along grain boundaries (GBs), and Al3Mg2 precipitates formed during annealing. First, extensive recovery predominates over recrystallization and consumes most of the stored energy in the ECAPed Al-7Mg alloy annealed at ≤ 275 ℃, leading to the recrystallization and growth of nano/ultrafine grains being retarded or postponed. Moreover, Mg solute segregation and/or clusters along GBs of nano/ultrafine grains could further suppress grain growth via diminishing GB energy and dragging GBs efficiently. In addition, Al3Mg2 precipitates formed with increasing annealing time could inhibit grain growth by pinning GBs. The present multimodal-grained Al-7Mg alloy with enhanced thermal stability is believed to be particularly attractive in potential engineering applications at moderate to high temperatures.

Significant strengthening in superlight Al-Mg alloy with an exceptionally large amount of Mg (13 wt%) after cold rolling

[J].

Effect of Mg content on the minimum grain size of Al-Mg alloys obtained by friction stir processing

[J].

Microstructure and mechanical properties of 5356 aluminum alloy fabricated by TIG arc additive manufacturing

[J].5356 aluminum alloy has been widely applied in transportation, aerospace and other fields owing to its low density, excellent fatigue property, and superior corrosion resistance. Aluminum alloy is widely manufactured by the arc additive technique that operates at a fast manufacturing speed with simple equipment and high material utilization. The property of 5356 aluminum alloy is closely related to its microstructure. To better control the property of this alloy for the additive manufacturing of forming parts, it is necessary to study the evolution of its microstructure. In this work, 5356 aluminum alloy forming parts were produced by tungsten inert gas welding (TIG) arc additive manufacturing, and their microstructures and mechanical properties were analyzed. The 5356 aluminum alloy formed by TIG additive manufacturing was composed of α-Al matrix and β(Al3Mg2) phase. As the deposition height increased, the layer microstructure transformed from equiaxed grains to columnar grains and tended to stabilize at thermal equilibrium. The top layer exhibited a dendritic microstructure with serious segregation of the Mg element. The middle and lower microstructures were varied and included equiaxed grains, columnar grains, and a mixture of these, with improved Mg-element segregation. As the deposition height increased, the microhardness in the layer first decreased and then stabilized. The microhardness was larger in the interlayers than in the deposition layers. The pores gathered in the interlayers might explain the lower yield strength of the thin-walled parts than the theoretically calculated value. The tensile strength, yield strength, and elongation were all anisotropic, and the tensile property was better in the transverse than in the longitudinal direction. This result was attributable to pore accumulation between the layers of the thin-walled parts and to the uneven microstructure.

5356铝合金TIG电弧增材制造组织与力学性能

[J].采用钨极惰性气体保护焊(TIG)电弧增材制造工艺制备5356铝合金成形件,并对成形件的组织和力学性能进行研究。结果表明,5356铝合金增材制造的相组成为α-Al基体和β(Al3Mg2)相;随沉积高度增加,沉积层显微组织由等轴晶向柱状晶转变,达到热平衡状态后趋于稳定,这是因为增材制造具有热积累效应;最顶层组织呈现树枝状,且Mg元素偏析严重;中下部组织形态多样,包括等轴晶组织、柱状晶组织及其混合组织,同时Mg元素偏析得到改善。力学性能测试结果显示,随沉积高度的增加,层内显微硬度先降低后趋于稳定,这是因为沉积层组织在增材制造过程中经历逐渐粗化的过程,导致显微硬度下降,达到热平衡状态后显微组织相对稳定,显微硬度也趋于稳定。沉积层层间位置的硬度大于层内,这是因为层间结合处为细小的等轴晶组织。聚集在层间的气孔可能是导致薄壁件屈服强度低于理论计算值的原因。抗拉强度、屈服强度以及伸长率都表现了各向异性,横向拉伸性能优于纵向,这是因为薄壁件层间气孔聚集以及显微组织不均匀。

Microstructure evolution and mechanical behavior of a binary Al-7Mg alloy processed by equal-channel angular pressing

[J].

Effect of Mg on microstructure and mechanical properties of Al-Mg alloys produced by high pressure torsion

[J].

Global and local strain rate sensitivity of bimodal Al-laminates produced by accumulative roll bonding

[J].

Transitions in mechanical behavior and in deformation mechanisms enhance the strength and ductility of Mg-3Gd

[J].

Microstructural response of pure copper to cryogenic rolling

[J].

High tensile ductility in a nanostructured metal

[J].

High ductility bulk nanostructured Al-Mg binary alloy processed by equal channel angular pressing and inter-pass annealing

[J].

2024 aluminum alloy ultrahigh-strength sheet due to two-level nanostructuring under cryorolling and heat treatment

[J].

Investigation of tensile behaviour of cryorolled and room temperature rolled 6082 Al alloy

[J].

Influences of the Al3Sc particle content on the evolution of bimodal grain structure and mechanical properties of Al-Mg-Sc alloys processed by hard-plate rolling

[J].

High strength and ductile high solid solution Al-Mg alloy processed by a novel hard-plate rolling route

[J].

Spheroiding and refining of coarse CaMgSn phase in Mg-Al-Sn-Ca alloys for simultaneously improved strength and ductility via sub-rapid solidification and controlled rolling

[J].

Tailoring bimodal grain structure of Mg-9Al-1Zn alloy for strength-ductility synergy: Co-regulating effect from coarse Al2Y and submicron Mg17Al12 particles

[J].

Effect of large thickness-reduction on microstructure evolution and tensile properties of Mg-9Al-1Zn alloy processed by hard-plate rolling

[J].

Balancing the strength and ductility of Mg-6Zn-0.2Ca alloy via sub-rapid solidification combined with hard-plate rolling

[J].

Prominent role of high-volume fraction Mg17Al12 dynamic precipitations on multimodal microstructure formation and strength-ductility synergy of Mg-Al-Zn alloys processed by hard-plate rolling (HPR)

[J].

Microstructural evolution during recovery and recrystallization of a nanocrystalline Al-Mg alloy prepared by cryogenic ball milling

[J].

Annealing behavior of aluminum after low-temperature severe plastic deformation

[J].

Insight into the microstructural evolution during cryo-severe plastic deformation and post-deformation annealing of aluminum and its alloys

[J].

Recent progress in high-temperature resistant aluminum-based alloys: Microstructural design and precipitation strategy

[J].Many load-bearing industrial settings require light-weight structural materials with adequate strength. Although commercial aluminum (Al) alloys are suitable for room-temperature applications, their strength at elevated temperatures (300-500oC) is largely reduced by coarsening of the strengthening precipitates. However, high-temperature alternatives such as titanium alloys are much heavier and more expensive than Al alloys. Creating microstructures that remain stable over 300oC is an important goal of the aluminum-manufacturing community. This article focuses on the recent development of high-temperature resistant Al-based alloys. Especially, it discusses the unique microstructural features, selection criteria of the strengthening phase, alloying effects, and microstructural stabilization of aluminum. The strategies summarized in this review are expected to realize the new microstructural architectures of light-weight alloys, which are currently limited to low-temperature service.

耐热铝基合金研究进展: 微观组织设计与析出策略

[J].工业选材在满足强度要求以保证结构安全之余,通常也需要尽可能兼顾轻量化以使机械结构更加轻盈。当仅仅考虑室温服役性能时,大量的商用铝合金材料因其优异的室温力学性能可供备选,并通常能很好地契合“轻质-高强”这一目标。然而,对于需要在300~500℃中温区间服役的构件,铝合金的上述优势则荡然无存。其主要原因在于传统高强铝合金赖以强化的析出相在200℃以上便将发生快速失稳粗化,导致材料丧失强化效果并快速软化失效。而若以更耐热的钛合金、高温合金等作为替代,则随之带来的结构增重与成本提高又令设计者甚觉“重材轻用”。目前,在>300℃温度区间难以实现安全服役仍是轻质铝基材料开发的难点所在,而其关键的解决方案在于如何寻求微观组织的高温稳定化。本文从耐热铝合金中特异性的微观组织特点出发,综述近期业界在耐热铝基合金开发过程中关于强化相选择、合金化策略以及微观组织热稳定化的进展与内在构建机理,以期能够提供一些耐热轻质合金材料微观组织设计过程的普适性基本理论依据。

Thermal stability of ultrafine-grained aluminum in the presence of Mg and Zr additions

[J].

Effect of grain size on tensile behaviour of a submicron grained Al-3wt%-Mg alloy produced by severe deformation

[J].

Enhancing thermal stability of binary Al-Mg alloys by tailoring grain orientations using a high solute Mg content

[J].

Deformation of an Al-7Mg alloy with extensive structural micro-segregations during dynamic plastic deformation

[J].

Effect of pre-deformation on microstructure and mechanical properties of ultra-high strength Al-Zn-Mg-Cu alloy after ageing treatment

[J].Ultra-high strength Al-Zn-Mg-Cu alloy is a promising lightweight structural material, and there is still room to improve its mechanical property. As a typical precipitation strengthening material, controlling the size and distribution of precipitate is an effective way to enhance the mechanical properties of the ultra-high strength Al-Zn-Mg-Cu alloy. The influence of pre-deformation on the microstructures and properties of the ultra-high strength Al-Zn-Mg-Cu alloy after ageing treatment was studied by TEM, XRD, SEM, DSC and tensile tests. The microstructures and the tensile mechanical properties of Al-Zn-Mg-Cu alloy without pre-deformation and with 3% and 4% pre-deformation were compared. It is found that the pre-deformation can promote the ageing precipitation rate and enhance the precipitate density in the Al-Zn-Mg-Cu alloy, and the pre-deformation ratio of 3% can promote the dispersion of the precipitate phase in the grain interiors, but the pre-deformation ratio of 4% may result in coarsening of precipitate. The size of precipitate along the grain boundaries and the width of precipitation free zones decreased in the pre-deformation treated ultra-high strength Al-Zn-Mg-Cu alloys. The tensile strength and yield strength of the pre-deformation treated ultra-high strength Al-Zn-Mg-Cu alloys increased, and the elongation also increased slightly, in which the tensile strength and elongation of 3% pre-deformation alloy combined with 80 ℃ for 12 h and 120 ℃ for 8 h ageing were (813±4) MPa and 10.10%±0.77%, respectively. The results show that the dislocations produced by pre-deformation may provide more heterogeneous nucleation sites for the precipitate formation, and improve the precipitate's distribution.

预变形对超高强Al-Zn-Mg-Cu合金时效组织与力学性能的影响

[J].利用TEM、XRD、SEM、DSC以及室温拉伸等方法,研究了预变形对超高强Al-Zn-Mg-Cu合金组织与性能的影响。通过对比未经预变形和预变形量为3%及4%的Al-Zn-Mg-Cu合金时效态微观组织与拉伸力学性能,发现:预变形可以提高铝合金时效析出速率和密度,变形量为3%时可促进析出相在晶内弥散分布,但增加到4%会导致析出相粗化;经预变形处理后晶间析出相尺寸减小,晶界无析出带宽度降低;抗拉强度和屈服强度提高,伸长率略微提高,经3%预变形以及80 ℃、12 h和120 ℃、8 h时效后的抗拉强度可达到(813±4) MPa,伸长率为10.10%±0.77%。分析认为,预变形产生的位错为析出相形核提供了异质形核的质点,改善了其在晶内与晶间的分布状态。

State parameter-based constitutive modelling of stress strain curves in Al-Mg solid solutions

[J].

Two mechanisms for the normal and inverse behaviors of the critical strain for the Portevin-Le Chatelier effect

[J].

Flow stress and work-hardening behaviour of Al-Mg binary alloys

[J].

Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy

[J].

Mechanistic investigation of a low-alloy Mg-Ca-based extrusion alloy with high strength-ductility synergy

[J].

Hall-Petch relation and boundary strengthening

[J].

On the origin of the extremely high strength of ultrafine-grained Al alloys produced by severe plastic deformation

[J].

Aluminum alloys: Solute atom clusters and their strengthening

[J].Benefiting from the rapid development in advanced characterization technologies, solute atom clusters in metal materials can now be quantitatively characterized in a high temporal and spatial resolution. This greatly promotes in-depth investigations on solute atom clustering. As for the widely-used Al alloys, solute atom clusters are attracting increasing attention not only as precursors for the precipitates during the aging process but also as a novel approach to strengthen and toughen the Al alloys. Experimental evidence has proved that solute atom clusters can simultaneously afford high strength and great ductility, indicating potential tailoring freedom to achieve an excellent strength-ductility combination. In this paper, the recent progress in solute atom clustering associated with Al alloys are summarized, including comprehensive characterization, thermodynamics and kinetics of formation, influencing factors, strengthening and toughening, and an application example. Ultimately, from the author's point of view, possible key directions for further studies of solute atom clusters are also proposed.

铝合金中的溶质原子团簇及其强韧化

[J].