金属材料在制备过程中,往往要经历至少一次凝固过程。在传统制备过程中,由于冷速较慢,凝固组织通常较为粗大,力学性能较低,同时容易出现宏观偏析,导致材料不均匀。在凝固过程中实现晶粒细化不仅能够提高材料力学性能,还能够有效减少金属材料的铸造缺陷。晶粒细化主要分为化学法与物理法。化学方法主要是向金属熔体中添加细化剂[1~4]。早在20世纪四五十年代就开始对于化学细化法进行了研究,经过几十年的发展已经实现工业化应用[5]。但是,目前细化剂主要用于铝合金,且细化剂会引入其他元素从而对于金属洁净度造成影响。物理法主要有脉冲电磁场[6~13]、电磁搅拌[14~16]、超声波[17~19]、快速凝固[20~22]等,其中脉冲磁场细晶技术[23~30]由于其能耗低、效果显著、施加方便、普适性强,同时又能保证金属洁净度,因此逐渐受到人们的关注。

早在2000年左右,訾炳涛等[31]首次将强脉冲磁场作用于铝合金凝固过程,发现脉冲磁场可以细化金属凝固组织。Zhang等[32]在K4169高温合金定向凝固过程中施加低压脉冲磁场(LVMF),实现了凝固组织由柱状晶到等轴晶的转变。Wang等[33]研究了脉冲磁场对于AZ31镁合金凝固组织的影响,研究表明当脉冲磁场作用于AZ31镁合金时,凝固组织明显细化。Zhou等[34]在Al-4.5%Cu (质量分数,下同)合金凝固过程中施加低压脉冲磁场,发现随着脉冲电压增加,合金的晶粒尺寸逐渐减小,凝固组织从枝晶逐渐呈玫瑰状或球形。翟启杰课题组[35~37]在以工业纯Al为研究对象进行脉冲电流凝固细晶研究的基础上提出了脉冲磁致振荡(pulsed magneto-oscillation,PMO)凝固细晶技术。Gong等[38]在纯Al的凝固过程中施加PMO,实验结果表明PMO能够有效细化纯Al凝固组织。徐智帅等[39]在Al-4.5%Cu合金凝固过程中施加PMO,发现PMO能够有效抑制初生α-Al相长大,且随着PMO放电频率增加,抑制效果越好。程勇等[40]在研究了PMO对连铸GCr15轴承钢的影响,发现PMO处理可以有效增大GCr15轴承钢连铸坯等轴晶区并改善碳偏析。Sun等[41]对PMO作用下长方形65Mn钢锭凝固过程进行了研究,实验结果表明PMO能够减小晶粒尺寸,促进柱状晶向等轴晶转变(CET),并且提高了试样平均抗拉强度。

在研究脉冲磁场细晶技术的同时,有学者开始研究脉冲磁场和其他类型磁场共同作用形成的复合磁场对金属凝固过程的影响。Hua等[42]在Sn-Pb凝固过程中同时施加脉冲磁场和静磁场的组合脉冲磁场,与单一脉冲磁场相比,组合脉冲磁场可以得到更加细小的晶粒组织。谭水淋等[43]对比研究了未处理、直流磁场处理、脉冲磁场处理及直流-脉冲复合磁场处理对Mg97Y2Cu1合金的细化效果,发现复合磁场对合金凝固组织的处理效果要好于单一的直流磁场或脉冲磁场处理。胡世平等[44]研究了无磁场、施加脉冲磁场、交流磁场、脉冲-交流复合磁场4种处理工艺对AZ31镁合金凝固组织的影响,发现与交流磁场或脉冲磁场相比,复合磁场处理效果更好。占维等[45]使用脉冲磁场与稳恒磁场组成的复合磁场处理Mg93Zn6Y1合金,结果表明复合磁场对合金的细化效果比单一磁场更加显著。

目前对于复合磁场的研究主要集中于复合磁场对于合金凝固组织的影响,而对于复合磁场作用下熔体内电磁效应以及流动研究较少。本工作主要研究脉冲磁致振荡-静磁场复合磁场(下文记为CMF)对熔体电磁效应、流动形式以及对Al-7Si合金晶粒尺寸的影响。首先通过实验测量的方式来验证数值模拟,然后通过数值模拟分析磁场作用下熔体内电磁效应及流型,在此基础上分析了CMF对于Al-7%Si合金晶粒尺寸的影响机制。

1 实验方法

1.1 磁场和流场测量

式中,α和ω是与tp有关的函数。

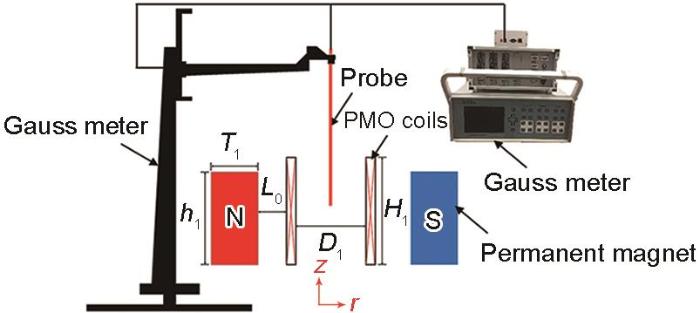

图1

图1

磁场测量示意图

Fig.1

Schematic of magnetic field measurement setup (h1 and T1 are the height and width of the magnet, respectively; L0is the distance from the magnet to the outer diameter of the coil; H1 and D1 are the height and diameter of the coil, respectively; PMO—pulsed magneto-oscillation)

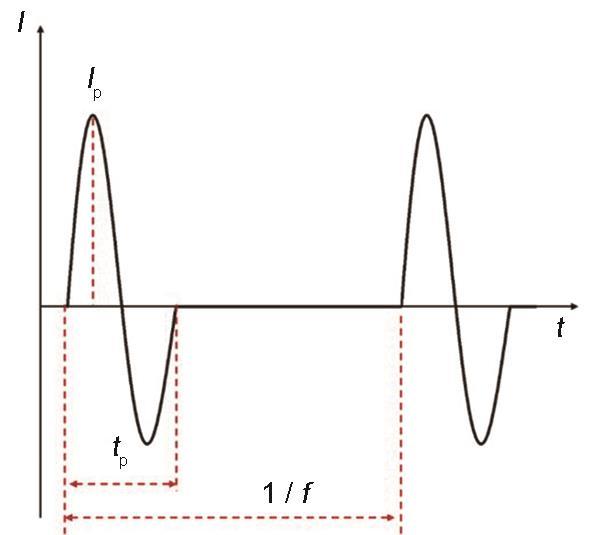

图2

图2

脉冲磁致振荡(PMO)电流波形

Fig.2

Waveform of employed PMO (Ip, tp, and f are the peak current, pulse width, and frequency of PMO current, respectively; I—current density; t—time)

静磁场由2块长100 mm (h1)、宽100 mm (T1)、厚50 mm的AlNiCo合金永磁铁产生。如图1所示,磁铁平行放置在PMO线圈的两侧,距离线圈边缘20 mm (L0),面心相距155 mm。由于磁铁尺寸和线圈尺寸较小,因此采用0.5 mm的空间分辨率对磁场进行测量,以保证精确获得线圈内部的磁场分布情况。在磁场测量的过程中,PMO磁场和静磁场分别测量,可以获得线圈中PMO磁场和静磁场的分布情况,便于后续的模拟。只测量空气中磁场分布而不测量Ga-20%In-12%Sn液态合金中磁场分布的主要原因有2点:(1) 在PMO作用下,熔体由于受到Lorentz力作用会产生流动,这种流动会导致Gauss计产生晃动,进而影响磁场的测量精度。(2) Gauss计探头最佳测量温度为20~50℃,最高限制温度为70℃,而PMO引起的Joule热效应可以使Ga-20%In-12%Sn熔体升温,因此在磁场测量持续时间较长的情况下,熔体温度过高会导致Gauss计探头测量精度下降甚至损伤Gauss计探头。

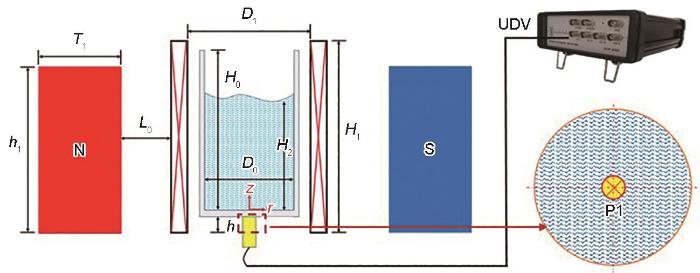

对于流场测量,采用DOP4000超声Doppler测速仪测量Ga-20%In-12%Sn熔体的流场。如图3所示,PMO线圈和2个永久磁铁的相对位置与磁场测量装置(图1)相同。盛放Ga-20%In-12%Sn液态金属的圆柱形容器由亚克力玻璃制成,其高度(H0)为100 mm、内径(D0)为54 mm,放置于距离线圈底部垂直高度(h) 10 mm处。为了测量PMO和CMF作用下金属熔体的流动,在亚克力圆柱形熔体中加入高度(H2)为75 mm的Ga-20%In-12%Sn金属熔体。在容器底部垂直放置1个8-MHz超声传感器(型号TR0805L,直径5 mm),其径向位置位于容器底部中心位置,在图3中对应位置为P1。传感器可以对轴向流动进行测量,速度分辨率为0.15 mm/s,在轴向的空间分辨率为0.235 mm。

图3

图3

流场测量示意图

Fig.3

Schematic of melt flow measurement setup (H0 and D0 are the height and diameter of the cylindrical container respectively; H2 is the melt height; h is the distance between the bottom of the container and the bottom of the coil; UDV—ultrasound Doppler velocimetry; P1 is the position of the probe at the bottom of the container)

1.2 数值模拟

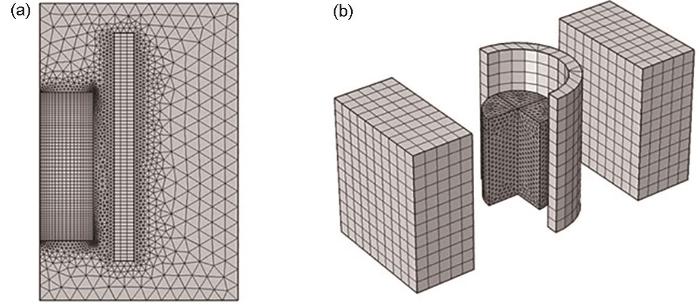

本工作采用COMSOL Multiphysics 5.4 (以下简称COMSOL)对PMO和CMF引起的电磁效应和流动分布进行数值模拟,Ga-20%In-12%Sn和Al-7%Si熔体物性参数如表1[7]所示。图4a和b分别为PMO模型与CMF模型,在PMO模型中,采用的是二维轴对称模型,熔体的截面为长方形,在此种条件下四边形网格能够贴合长方形结构,而且能够在保证计算精度的条件下减少网格数量。在CMF模型中,熔体域为一个圆柱,边界是弧形,此时如果采用四边形网格就会造成网格在某些位置产生畸变,从而出现质量较低网格,质量较低网格会导致计算结果收敛性差,因此采用四面体网格。为实现对该模型的求解,对该几何模型进行如下假设与简化:(1) 假设电流在线圈中均匀分布,忽略电流在线圈中的趋肤效应;(2) 假设熔体为不可压缩Newton流体;(3) 忽略Joule热对熔体物性参数的影响;(4) 忽略自由液面波动对流动的影响。先通过COMSOL软件中磁场模块计算PMO与CMF作用下熔体内电磁效应,然后再利用k-ε湍流模块计算流场(k为湍动能,ε为湍动能耗散率),其中电磁力以体积力的方式添加入模型。静磁场是先通过Gauss计测量CMF作用下线圈内的磁场分布,然后将数据导入COMSOL软件中,使用软件中的函数将数据拟合为线性函数,从而模拟CMF作用下线圈内磁场分布。如图5所示,在2块永磁铁作用下,磁场强度主要沿x方向,最大磁场强度可达200 mT,磁场强度在y方向和z方向较小。

表1 Ga-20%In-12%Sn和Al-7%Si熔体物性参数[7]

Table 1

| Thermophysical property | Al-7%Si | Ga-20%In-12%Sn | Unit |

|---|---|---|---|

| Liquidus TL | 615 | 10.5 | oC |

| Density ρ | 2422 | 6360 | kg·m-3 |

| Viscosity υ | 0.5 × 10-6 | 0.34 × 10-6 | m2·s-1 |

| Electrical conductivity σ | 3.74 × 106 | 3.27 × 106 | S·m-1 |

| Relative permeability μr | 1 | 1 | - |

| Relative permittivity εr | 1 | 1 | - |

图4

图4

PMO模型及CMF模型示意图

Fig.4

Numerical simulation geometries of PMO (a) and CMF (b) (CMF—combined magnetic field)

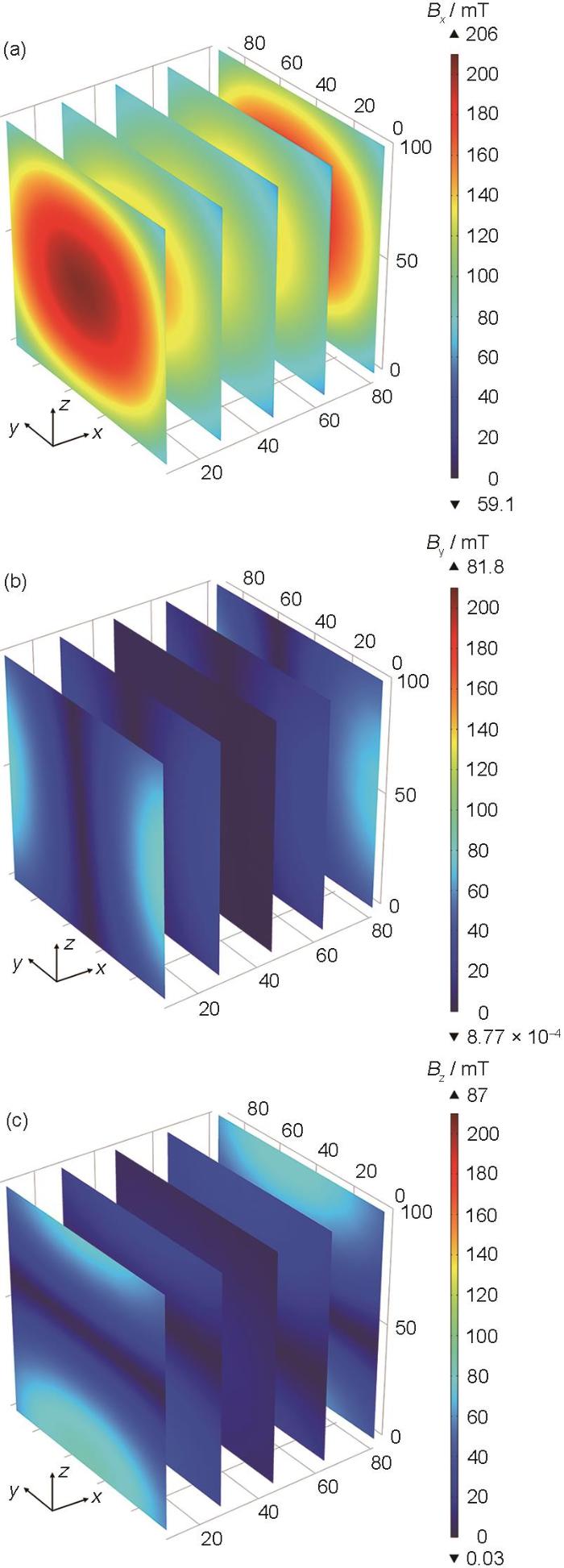

图5

图5

静磁场分布测量结果

(a) magnetic field strength in x-direction(Bx )

(b) magnetic field strength in y-direction(By )

(c) magnetic field strength in z-direction(Bz )

Fig.5

Measured static magnetic field distributions (The two numbers adjacent the up and down arrows in the label are the maximum and minimum values, respectively, the same below)

磁场模块控制方程为[46]:

式中, B 为磁场强度,μ为磁导率, J 为电流密度, E 为电场强度, A 为磁矢,σ为电导率。通过上述方程便可计算出PMO和CMF作用下熔体产生的磁场与感应电流,则Lorentz力( F )为:

流体控制方程和k-ε湍流控制方程为[46]:

上述方程中,

1.3 凝固实验

凝固实验采用Al-7%Si合金为研究对象。Al-7%Si合金制备方法如下:首先按照比例称取纯Al (99.99 %)和纯Si (99.9999 %),然后将纯Al和纯Si放入石墨黏土坩埚,其中纯Si置于坩埚底部。将石墨黏土坩埚放入马弗炉升温至750℃后,保温2 h。其中保温1 h后,每隔15 min中使用石墨棒对熔体进行搅拌,共搅拌3次,使Si充分熔于Al中。保温结束之后,将制备好的Al-7%Si合金熔体浇入准备好的石墨坩埚之中。

将称重好的416 g Al-7%Si合金放入内径54 mm、高100 mm的刚玉坩埚中。然后将坩埚放入马弗炉中加热熔化,待炉温升至700℃后保温1 h。开启PMO电源,设置PMO频率为30 Hz,脉宽为3 ms,电流峰值分别为2000和2500 A。待电流波形稳定之后将坩埚放入线圈中,分别采用单独施加PMO与PMO + 静磁场(CMF) 2种形式电磁场对其进行处理直至样品完全凝固。

将试样从中间沿纵截面切开取中心样品,将样品打磨抛光。然后,使用2%HBF4对样品进行电解腐蚀,电压20 V,腐蚀时间50 s。最后,将腐蚀后的样品在Axio Imager A2m光学显微镜(OM)偏光模式下观察显微组织,并使用截线法统计晶粒尺寸。

2 实验结果

2.1 磁场

为验证数值模拟磁场的准确性,对比PMO (Ip= 1500 A,f = 30 Hz,tp= 3 ms)作用下磁场测量结果与数值模拟结果。图6a展示了PMO作用下线圈几何中心磁场测量结果。可以看出,中心处磁场强度主要沿z方向,而x和y方向上的磁场分量远小于z分量。因此,验证模拟可靠性主要对比z方向上的磁场强度。PMO作用下线圈几何中心磁场z分量的测量结果与模拟结果对比如图6b所示。可以看出,模拟与实测结果吻合度较高。为进一步验证磁场模拟的准确性,测量线圈中心轴线上的磁场强度,2点之间测量间距为5 mm。由于PMO产生的磁场是一个脉冲磁场,且该磁场具有波峰(最大值)与波谷(最小值),因此对中心轴线上波峰与波谷值进行对比。如图7所示,模拟结果与实测结果趋势基本吻合,在靠近线圈顶部时误差有所增大。这是因为模拟时线圈为完美的几何对称图形,而实际使用铜管绕线而成的线圈与数值模拟有一定差距。同时在实验中仪器平整度保持在0.05°以内,但是Gauss计长度较长,移动过程中会出现一定偏差,也可能导致实测与模拟在线圈顶部有一定偏差。通过对线圈中心与线圈轴线上测量磁场与模拟磁场数值进行对比,可以认为磁场模拟结果是可靠的。

图6

图6

PMO (峰值电流强度Ip = 1500 A,脉冲频率f = 30 Hz,脉冲宽度tp = 3 ms)作用下线圈中心处x、y和z方向上磁场强度(Bx 、By 和Bz )测量结果,及线圈中心处z方向上磁场强度实测和模拟结果对比

Fig.6

Measured Bx, By,and Bz (a) and comparison of measured and simulated magnetic field strength along the z direction (b) at the center of the coil under the application of PMO (Ip = 1500A, f = 30 Hz, tp = 3 ms)

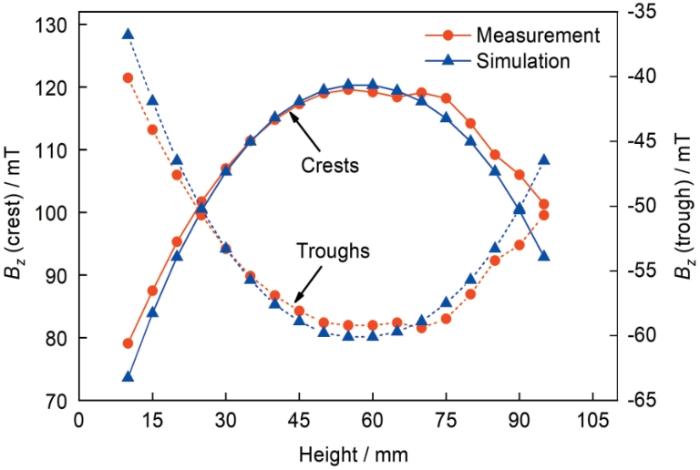

图7

图7

PMO (Ip = 1500A,f = 30 Hz,tp= 3 ms)作用下线圈中心轴线上Bz 波峰波谷实测和模拟结果对比

Fig.7

Comparison of measured and simulated results of the crests and troughs of Bz along the center axis of the coil under the application of PMO (Ip= 1500A, f = 30 Hz, tp= 3 ms)

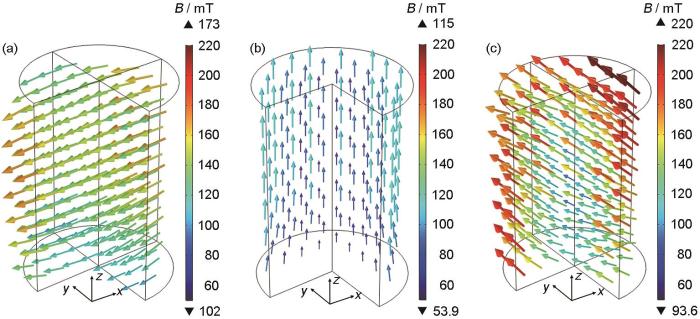

在数值模拟可靠性验证之后,分别模拟了静磁场、PMO (Ip= 1500 A,f = 30 Hz,tp= 3 ms)和CMF作用下Ga-20%In-12%Sn熔体内磁场分布。图8为不同磁场作用下,在0.25tp时刻熔体内的磁场分布。可以看出,在静磁场作用下熔体内磁场主要沿x负方向;在PMO作用下熔体内磁场主要沿z轴方向;而在CMF作用下,静磁场与PMO磁场经过矢量叠加之后方向发生转变,与z方向和x负方向形成一定夹角。同时,相比于静磁场与PMO单独作用,复合之后磁场强度更大。

图8

图8

不同磁场作用下0.25tp时刻熔体内磁场分布

(a) static magnetic field (b) PMO (c) CMF

Fig.8

Magnetic field distributions in the melt at 0.25tpunder the application of different magnetic fields

2.2 CMF作用下金属熔体流动

将电磁力导入几何模型,再通过k-ε湍流模型控制方程(式(

图9

图9

PMO作用下Ga-20%In-12%Sn熔体流动分布状态

(a) schematic of the melt yz center plane

(b) melt flow direction in three dimensions (U—flow velocity)

(c) z-component of flow velocity (Uz ) in the yz center plane

(d) contour of measured flow along the center axis

Fig.9

Melt flow of Ga-20%In-12%Sn under the impact of PMO (Ip= 1500 A,f = 30 Hz,tp= 3 ms)

图10为CMF作用下熔体流动分布以及测量结果,采用的PMO电流参数为Ip= 1500 A,f = 30 Hz,tp= 3 ms。图10b为熔体整体流动方向,x方向为静磁场方向。图10c和d分别为yz中心平面和xz中心平面流速z分量Uz 分布。结合图10b~d可以看出,熔体流型与单独施加PMO双环流流型不同,CMF作用下流型在xz平面上主要为一个大环流并且流动强度较强,在yz平面上主要为双环流且流动强度较弱。同时可以看出,在中心轴线上,熔体下部Uz 方向朝下,而熔体上部Uz 流速向上,与实测结果(图10d)相似,因此可以说明CMF作用下熔体流场模拟流型基本可靠。通过对比PMO与CMF作用下的熔体流场可以看出,静磁场加入流场主要有2点变化:一是静磁场方向的流型发生改变,由双环流改变为单环流;二是增强了熔体流动,单独施加PMO时,熔体最大流速为94.2 mm/s,平均流速为45.7 mm/s,加入静磁场后,熔体最大流速为275 mm/s,平均流速为103.5 mm/s。

图10

图10

CMF作用下熔体流动分布状态

(a) schematic of yz center plane S1, xz center plane S2, and the direction of the static magnetic field

(b) melt flow direction in three dimensions

(c) Uz in S1 plane

(d) Uz in S2 plane

(e) contour of measured flow along the central axis

Fig.10

Melt flow under the application of CMF

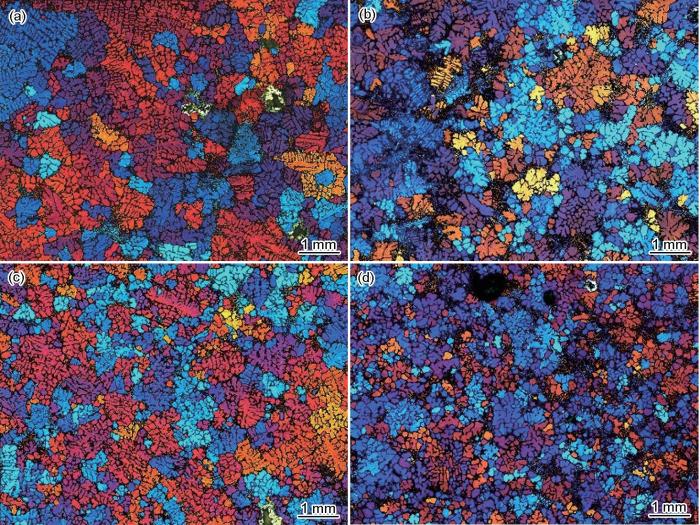

2.3 CMF作用下Al-7%Si合金凝固组织

在Al-7%Si凝固过程中分别采用PMO和CMF处理,其凝固组织如图11所示。当电流峰值为2000 A时,PMO处理和CMF处理后凝固组织如图11a和c所示。可以看出,当峰值电流相同的情况下,相比于PMO单独处理,CMF处理后的凝固组织更加细小。单独施加PMO的凝固组织平均晶粒尺寸约为469 μm,而CMF处理后凝固组织平均晶粒尺寸为378 μm。当电流峰值增加至2500 A时,PMO处理和CMF处理后凝固组织如图11b和d所示。单独施加PMO时,凝固组织平均晶粒尺寸约为417 μm,CMF处理之后凝固组织平均晶粒尺寸约为340 μm。在PMO电磁参数相同条件下,静磁场的加入更有利于凝固组织细化。对比分析PMO峰值电流2000和2500 A的凝固组织可以看出,提高脉冲电流之后,凝固组织中黑色区域增加,这是因为提高峰值电流之后,熔体受到的电磁力过大,磁压力会导致熔体液面严重凸起,而当液面遇冷凝固之后,就会形成一个拱形坯壳,而中心区域最后凝固时就会形成较多缩孔,因此会导致凝固组织中黑色区域增加,这与文献[30]中提到的沙化现象有一定类似。

图11

图11

不同电流峰值的PMO和CMF处理后Al-7Si合金凝固组织

Fig.11

Solidification microstructures of Al-7Si alloy treated by PMO (a, b) and CMF (c, d) with different current peaks (a, c) 2000 A (b, d) 2500 A

3 分析和讨论

3.1 熔体流型形成机制

通过对比PMO和CMF作用下GaInSn熔体流场模拟结果发现:在PMO作用下,熔体流型为双环流;而在CMF作用下,与静磁场平行方向,熔体流型为一个大环流,流动速度较强,与静磁场垂直方向,熔体流型为双环流,且该双环流相比于单独施加PMO而言,流速较弱。

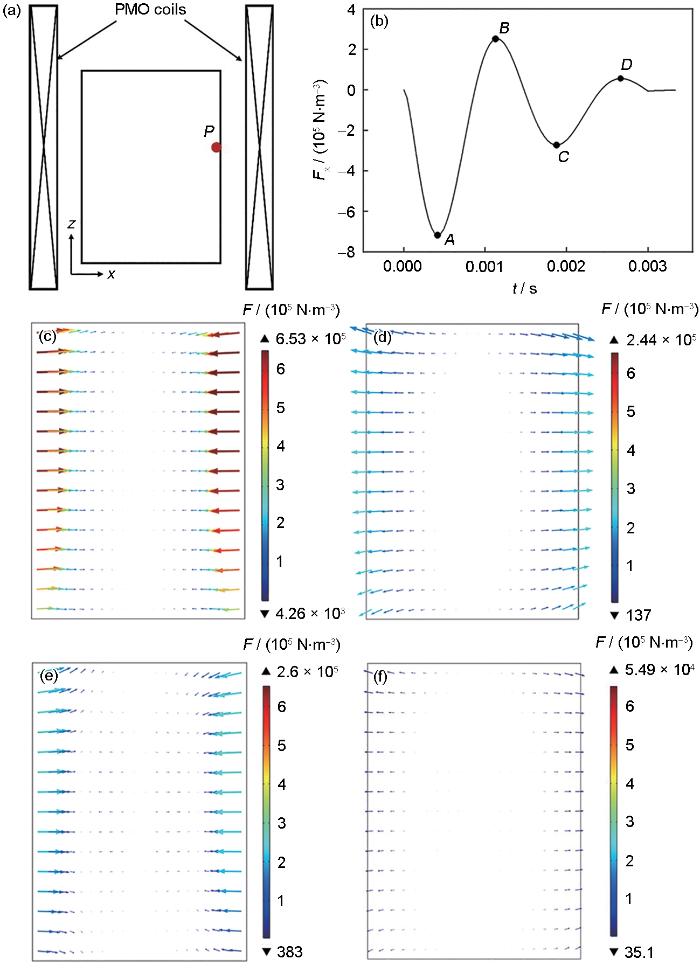

根据磁流体力学理论,熔体受到Lorentz力而产生流动,因此熔体内Lorentz力分布对于分析熔体流型具有重要作用。图12为PMO (Ip= 1500 A,f = 30 Hz,tp= 3 ms)作用下Lorentz力在一个脉宽时间内的分布规律。在线圈半高位置,取熔体xz中心平面边缘P点(图12a),该点Lorentz力在一个脉宽时间内方向变化3次(图12b)。当P点处Lorentz力达到极值时(图12b中A、B、C和D所对应时刻),xz中心平面上Lorentz力分布如图12c~f所示。可以看出,由于趋肤效应,Lorentz力主要集中于熔体表面,方向主要沿x轴方向。而且,在一个脉宽时间内,Lorentz力首先朝向熔体内部并在A时刻达到最大值(图12c);随后Lorentz力逐渐减小至0后,方向改变为朝向熔体外部并在B时刻达到极值(图12d);然后Lorentz力逐渐减小,方向又一次改变指向熔体内部并在C时刻达到极值(图12e);最后Lorentz力数值减小,方向改变为朝向熔体外部,经过小幅度上涨在D时刻达到极值(图12f)之后逐渐减小并消失。同时,Lorentz力在边缘沿着z方向分布不均匀,这是由于螺线管线圈产生的磁场不均匀导致,在线圈半高位置磁场强度最大,随时间变化率最大,因此此处Lorentz力较大。在PMO作用下,熔体侧壁受到不均匀Lorentz力作用,从而导致熔体由Lorentz力较大区域向熔体中心流动,到中心交汇之后向熔体中心上部以及下部流动,然后到达边界之后向四周流动,从边缘再汇集至Lorentz力较大位置从而形成上、下2个环流[47]。

图12

图12

PMO作用下xz平面上Lorentz力(F)分布

(a) schematic of the position of point P

(b) variation of x-component of Lorentz force (Fx ) at point P with time

(c-f) Lorentz force distributions in the xz-plane corresponding to points A-D shown in Fig.12b, respectively

Fig.12

Lorentz force (F) distributions in the xz-plane under the application of PMO

在PMO作用过程中加入x方向静磁场复合之后,复合磁场方向与PMO单独作用时会发生变化,因此感应电流和Lorentz力方向也会发生变化。在线圈半高位置,取熔体xz中心平面边缘P点(图13a),该点Lorentz力z分量(Fz )变化规律如图13b所示,在一个脉宽时间内,Lorentz力方向变化2次。从该曲线上取A~Z 9个点,对应时刻分别为1/40tp、1/8tp、1/4tp、3/8tp、1/2tp、5/8tp、3/4tp、7/8tp、tp,这些时刻对应熔体xz中心平面上Lorentz力分布分别如图13c~k所示。随着PMO施加,平面对角首先出现Lorentz力(图13c),方向指向中心。随着时间增加,Lorentz力逐渐增强并在1/8tp时刻达到最大值(图13d)。从1/8tp时刻至1/4tp时刻(B点至C点),Lorentz力开始减小(图13e)。从1/4tp时刻至3/8tp时刻(C点至D点),Lorentz力减小至0以后改变方向(图13f)。从3/8tp时刻至1/2tp时刻(D点至E点),Lorentz力逐渐增加并且达到最大值(图13g)。从1/2tp时刻至3/4tp时刻,Lorentz力开始逐渐减小(图13h和i)。从3/4tp时刻至7/8tp时刻,Lorentz力减小至0并且再次改变方向(图13j)。从7/8tp时刻至tp时刻,Lorentz力逐渐增加达到最大值,虽然此时PMO电流已经为0,但是由于静磁场存在,Lorentz力会继续存在并逐渐减小。

图13

图13

CMF作用下xz平面上Lorentz力分布

(a) schematic of the point P and the line L

(b) variation of the z-component of Lorentz force (Fz) at point P with time

(c-k) Lorentz force distributions in the xz-plane corresponding to points A-I shown in Fig.13b

Fig.13

Lorentz force distributions in the xz-plane under the application of CMF

由于趋肤效应影响,Lorentz力主要集中于熔体表面,取熔体边缘一条曲线L (图13a),先对该曲线上 Fz 进行积分,然后对时间进行积分,以判断该曲线上Lorentz力的累积效应(冲量):

式中, I 代表冲量。采用上式对0~0.004 s积分,结果为3.28 × 105 N·s/m2,说明在该曲线上Lorentz力产生的累积效应主要朝z轴正方向。结合图13b~k,可以看出,xz中心平面上的逆时针环流主要由D~G时刻Lorentz力分布导致,而A到C时刻和H到I时刻Lorentz力作用时间较短,产生的累积效应较小。因此,中心平面上左侧Lorentz力主要方向朝下,右侧Lorentz力主要方向朝上,从而带动熔体流动,形成逆时针环流。

图14

图14

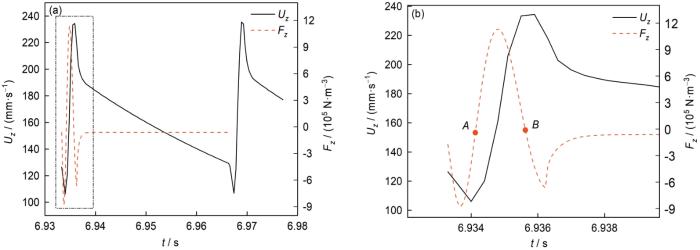

熔体平均流速(

Fig.14

Variations of melt average flow velocity (

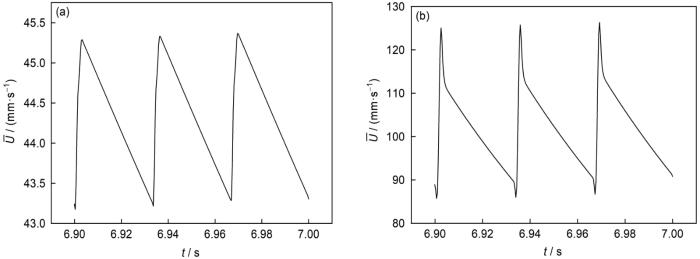

图15为CMF作用下熔体P点流速与Lorentz力随时间变化关系。从图15a中可进一步得知振荡周期与PMO频率有关。在PMO电流存在时,熔体流速变化剧烈,当PMO处于间歇期时,熔体流速由于静磁场的抑制作用以及自身粘滞阻力影响,速度逐渐减缓。为进一步了解Lorentz力与熔体流速变化关系,将图15a中方框区域放大,结果如图15b所示,在图中A和B时刻时Lorentz力为0,可以看出从零时刻到A时刻时,Lorentz力与流动速度相反,因此流动速度迅速减小,到A时刻时达到极小值;在A至B时刻,Lorentz力方向改变,因此流动速度迅速增加,B时刻时达到流速极大值;在B时刻之后,Lorentz力方向改变,因此流速迅速减小,随着Lorentz力逐渐减小,流速减小趋势逐渐变缓,直至Lorentz力不变时,流速减小趋势保持一致。

图15

图15

CMF作用下P点流速Uz 与Fz 的关系

Fig.15

Relationship between the flow velocity Uz and Fz at point P under the application of CMF (a) and its enlarged view of the dotted box in Fig.15a (b)

通过PMO和CMF作用下熔体内Lorentz力的变化规律可以看出,在PMO和CMF作用下,由于趋肤效应影响,熔体Lorentz力主要集中于表面,而熔体中心Lorentz力很小。同时PMO作用下的Lorentz力分布与CMF作用下Lorentz力分布有明显区别。但是从图11中的凝固组织可以看出,这种Lorentz力分布不均对于凝固组织没有造成明显影响。这可能是因为金属熔体强制流动使晶核分布更加均匀,从而使最终凝固组织并未出现晶粒尺寸分布不均的情况。

3.2 PMO与CMF作用下金属凝固细晶机制

由2.3节可知,在相同峰值电流条件下,经过CMF处理后Al-7%Si合金凝固组织更加细小。PMO与CMF作用于金属熔体时,内部会产生感应电流,从而产生Lorentz力,熔体在Lorentz力作用下产生强制流动。因此PMO与CMF对于Al-7%Si合金细化差异可能是由多种原因导致。

秦荣山等[48]给出了短脉冲作用下金属形核率公式:

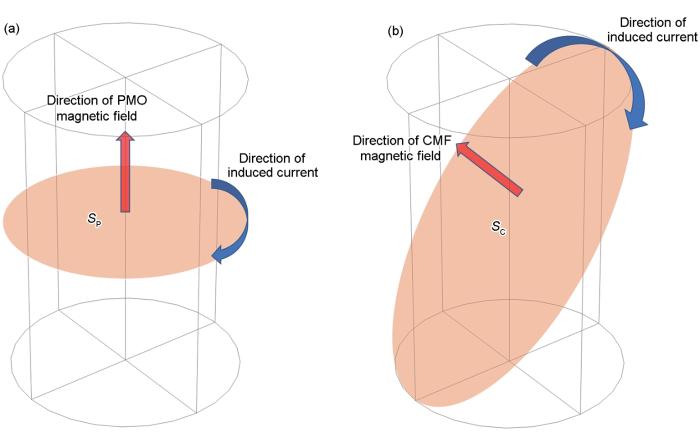

式中,N为形核率,

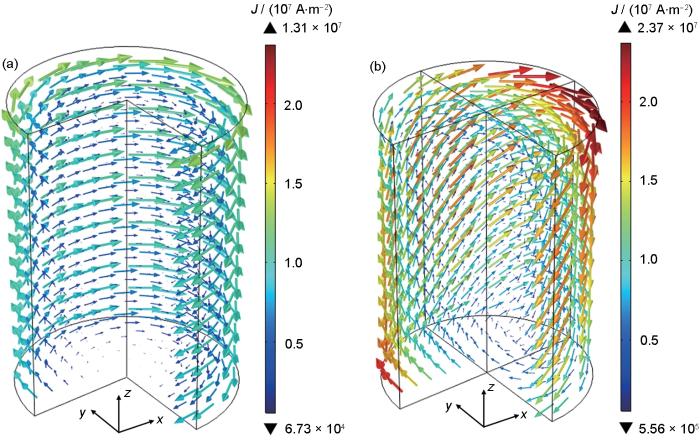

式中, V 为感应电动势,S为感应电流环路回路围绕面积(磁场正对面积)。可以看出正对面积越大,感应电流越大。由计算得知CMF正对面积SC与PMO正对面积SP比值约为1.7,这与感应电流最大值比值近似,认为CMF作用下磁场方向改变导致正对面积增大是引起感应电流增大的主要原因。因此根据

图16

图16

电流峰值为2500 A时熔体内感应电流分布

Fig.16

Induced electric current (J) distributions in the melt under the application of PMO (a) and CMF (b) with current peak of 2500 A

图17

图17

磁场方向、感应电流方向和感应电流环路面积示意图

(a) PMO (b) CMF

Fig.17

Schematics of magnetic field direction, induced electric current direction, and induced electric current loop area (SP and SC are the areas of the induced current loop under the application of PMO and CMF, respectively )

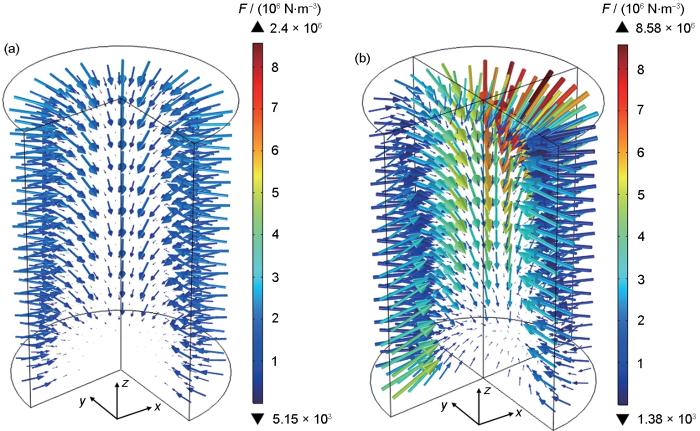

图18为电流峰值为2500 A时,PMO与CMF作用下熔体内Lorentz力分布。可以看出,PMO作用下熔体内产生Lorentz力最大值为2.4 × 106 N/m3,CMF作用下熔体内Lorentz力最大值为8.58 × 106 N/m3,约为PMO产生Lorentz力最大值的3.6倍。因此,较大的Lorentz力更容易导致型壁上晶核脱落,也更容易导致枝晶臂断裂[31]。由于Lorentz力作用,熔体产生强制流动,在电流峰值为2500 A时,PMO作用下熔体平均流速为141 mm/s,CMF作用下熔体平均流速为206 mm/s,更强的流动既有利于脱落的晶核更容易被带入熔体内部,也有利于温度场更加均匀从而提升晶核存活率[49]。

图18

图18

电流峰值为2500 A时熔体内Lorentz力分布

Fig.18

Lorentz force distributions in the melt under the application of PMO (a) and CMF (b) with current peak of 2500 A

4 结论

(1) 通过对PMO和CMF作用下熔体内电磁场及流场进行模拟,发现PMO作用下熔体流型结构为双环流,CMF作用下平行于静磁场方向熔体流型为单环流结构,垂直于静磁场方向熔体流型为双环流。同时相对于单独施加PMO而言,在CMF作用下熔体流速振荡幅度更大。

(2) 以Al-7%Si为实验材料,研究了在相同电流峰值条件下PMO和CMF对凝固组织的影响。相比于单独施加PMO,CMF对于Al-7%Si合金凝固组织细化效果更好。

(3) 通过对PMO和CMF作用下金属熔体内Lorentz力分析,发现PMO作用下熔体侧壁受到Lorentz力在线圈中心位置较大,在顶部和底部较小,从而产生双环流运动。而CMF作用下,沿静磁场方向,中心平面熔体左侧主要受到向下Lorentz力,右侧主要受到向上Lorentz力影响,从而产生逆时针单环流流动。

(4) 通过对Al-7%Si凝固细晶机制及模拟结果综合分析,认为相对于单独施加PMO而言,CMF对于Al-7%Si合金细化效果更好的原因可能是CMF能够提供更大感应电流、Lorentz力以及流动速度。

参考文献

Effects of Al-Al4C3 refiner and ultrasonic field on microstructures of pure Mg

[J].

Al-Al4C3细化剂和超声场对纯Mg组织的影响

[J].在不同Al-Al<sub>4</sub>C<sub>3</sub>细化剂添加量条件下, 对纯Mg熔体进行孕育处理. 当添加质量分数为1.0%Al-Al<sub>4</sub>C<sub>3</sub>细化剂时细化效果最佳, α-Mg晶粒平均尺寸由毫米级降至106 μm. 在纯Mg熔体中施加不同功率超声场, 当施振功率为600 W时细化效果最好. 研究表明, 空化泡破碎产生的过冷对形核具有促进作用, 空化泡的破裂及声流对熔体的搅动使得细小枝晶破碎, 形成新的结晶核心, 这一过程对形核起主要作用. 功率超声与Al-Al<sub>4</sub>C<sub>3</sub>细化剂共同作用于纯Mg熔体过程, 可以显著细化晶粒. 其机理为超声对杂质的“活化”作用.

Effects of foundry variables and refiners on cast structures of superalloy K4169 I. Grain structures and grain refinement mechanisms

[J].

铸造工艺参数和细化剂对K4169高温合金铸态组织的影响 Ⅰ. 晶粒组织及晶粒细化机理

[J].

研究了K4169高温合金在各种工艺条件下及向熔体中加入复合细化剂时的晶粒组织.结果表明.降低浇注温度和加入复合细化剂可以明显细化冷凝后基体的晶粒和提高铸件断面等轴晶的比例在通常的浇注温度1400℃下加入复合细化剂.对合金熔体进行或不进行过热处理时.可使圆柱锭的晶粒分别细化至ASTM 1.7级和ASTM 3.2级:断面等轴晶的比例分别达96%和99%以上.当浇注温度为1420 ℃、加入复合细化剂并对合金熔体进行过热处理时,可使圆柱锭晶粒细化至ASTM M10.5级.断面等轴晶的比例达90%以上.提出了晶粒细化的机理并对晶粒细化后断面等轴晶比例增大的现象进行了分析.

Influence of thermo-mechanical treatment of Al-5Ti master alloy on its grain refining performance on aluminium

[J].

Effect of Al-Ti-C master alloy addition on microstructures and mechanical properties of cast eutectic Al-Si-Fe-Cu alloy

[J].

Development of research on grain refiners for aluminum alloys

[J].

铝合金晶粒细化剂的研究进展

[J].

Microstructure and properties of A357 aluminium alloy treated by pulsed magnetic field

[J].This study examined the effects of a pulsed magnetic field (PMF) on the solidified microstructure and properties of A357 aluminium alloy. Results showed that the solidified microstructure of the alloy treated by a PMF was refined. The treated alloy in the T6 state had superior mechanical properties, with the ultimate tensile strength, yield strength and elongation increasing by 48 MPa (18.5%), 46 MPa (16.4%) and 4.8% (142%), respectively, when compared with the untreated alloy. When testing at room temperature, with a strain amplitude of 1 × 10−4 and at a frequency of 1 Hz, the damping capacity value was 14.2 × 10−3 for the alloy subjected to a PMF treatment, which increased by nearly 170% when compared with the untreated alloy.

The relevance of melt convection to grain refinement in Al-Si alloys solidified under the impact of electric currents

[J].

Solidification of pure aluminium affected by a pulsed electrical field and electromagnetic stirring

[J].

Repairing irreversible hydrogen-induced damages using electric current pulse

[J].

Residual stress removal under pulsed electric current

[J].

Separation of electrically neutral non-metallic inclusions from molten steel by pulsed electric current

[J].Effect of a pulsed electric current on the distribution of Al2O3 inclusions in liquid steel is explored; these inclusions ranged in size from micrometres to nanometres. When no electric current was applied, the inclusions were randomly distributed in the steel. However, when an electric current was applied, the inclusions were found in highly populated regions near the various interfaces. Moreover, this process applies to a wide range of inclusion diameters, in contrast to conventional inclusion removal methods which tend to apply to larger (>20 μm) particles only. Consequently, the application of pulsed electric current provides a method of removing inclusions from the steel and thereby improving the mechanical, physical and corrosion resistance properties of the steel.

The relevance of forced melt flow to grain refinement in pure aluminum under a low-frequency alternating current pulse

[J].

Effect of medium-density direct current on dendrites of directionally solidified Pb-50Sn alloy

[J].This paper investigated the effect of coupling of direct current (DC) and pulling rate on dendrites and cooling behaviours of directionally solidified Pb–50Sn alloy. Experimental results indicated that the secondary dendritic arm spacing (SDAS) decreased and temperature gradient increased as increasing current densities. Moreover, temperature rise and SDAS under positive DC were higher than those under negative DC. It was speculated that Joule heating and electromigration were obviously induced by the present DC. The effect of DC on the microstructure and solidification parameters was weakened as the pulling rate increases. The coarsening rate reduced from tf1/3 toward a value of tf0.29 when DC of ±200 A cm–2 were applied. The refinement mechanism of SDAS was discussed.

Effect of electromagnetic stirring on microstructure and mechanical properties of TiB2 particle-reinforced steel

[J].

电磁搅拌对TiB2颗粒增强钢组织和力学性能的影响

[J].

Experimental study of macrostructure and segregation by a novel electromagnetic nozzle swirling flow combined with electromagnetic stirring in continuous casting

[J].

Controlling segregation behavior of primary Si in hypereutectic Al-Si alloy by electromagnetic stirring

[J].Controlling the segregation behavior of primary Si in the solidification process of hypereutectic Al-Si alloy is crucial for enhancing the design ability of the solidification structure. To explore the separation condition and morphological evolution of primary Si in detail, a series of experiments concerning the coupling effect of a temperature field and electromagnetic stirring on the segregation behavior of primary Si were carried out. Experimental results show that the temperature field and fluid flow in the melt are two key points for controlling the segregation behavior of primary Si. The establishment of a temperature gradient in the Al-Si melt is a precondition for realizing the separation of primary Si. On the basis of the temperature gradient, the electromagnetic stirring can further strengthen the separation effect for primary Si, forming a Si-rich layer with 65~70 wt.% Si content. The formation of the Si-rich layer is a continuous growth process of primary Si by absorbing Si atoms from Al-Si melt with the help of electromagnetic stirring. The separation technology for primary Si is proposed to realize the segregation control of primary Si, which not only broadens the application of Al-Si alloys in the functionally gradient composites but also provides a low-cost supply strategy of Si raw materials for the solar photovoltaic industry.

A synchrotron X-radiography study of the fragmentation and refinement of primary intermetallic particles in an Al-35Cu alloy induced by ultrasonic melt processing

[J].

The role of ultrasonically induced acoustic streaming in developing fine equiaxed grains during the solidification of an Al-2 Pct Cu alloy

[J].

The role of ultrasonic treatment in refining the as-cast grain structure during the solidification of an Al-2Cu alloy

[J].

Rapid solidification kinetics and mechanical property characteristics of Ni-Zr eutectic alloys processed under electromagnetic levitation state

[J].

A new thermodynamically stable Nb2Ni intermetallic compound phase revealed by peritectoid transition within binary Nb-Ni alloy system

[J].

Liquid structure and thermophysical properties of ternary Ni-Fe-Co alloys explored by molecular dynamics simulations and electrostatic levitation experiments

[J].

The influence of pulse magnetic field intensity on the morphology and electrochemical properties of NiCoS alloys

[J].

Effects of a high-voltage pulsed magnetic field on the solidification structures of biodegradable Zn-Ag alloys

[J].

Effect of pulsed magnetic field treatment on the residual stress of 20Cr2Ni4A steel

[J].To study the effect of a pulsed magnetic field on the residual stress of 20Cr2Ni4A steel, the material was treated for 120 s with a 1 T pulsed magnetic field. The microstructure of the materials was studied using residual stress measurement, transmission electron microscopy (TEM) observations, X-ray diffraction analysis, and magnetic domain observations. Experimental results revealed that the residual stress of the 1 T sample was reduced by 14.26% compared with that of the 0 T sample. The results show that the residual stress is effectively reduced by the pulsed magnetic field. The mechanism of magnetic field action involves improving the flexibility of dislocation movement, proliferating and entangling the dislocation structure, and inducing slippage. During the pulsed magnetic treatment, the labyrinth domain with larger stress changes to a lamellar domain with less stress and the residual stress decreases.

Microstructural characteristics and mechanical properties of Mg-Zn-Y alloy containing icosahedral quasicrystals phase treated by pulsed magnetic field

[J].

Revealing the mechanisms for the nucleation and formation of equiaxed grains in commercial purity aluminum by fluid-solid coupling induced by a pulsed magnetic field

[J].

Effect of rectangle aspect ratio on grain refinement of superalloy K4169 under pulsed magnetic field

[J].The researches on the grain refinement by applied pulsed magnetic field (PMF) during solidification have received much attention in recent years and lots of positive experimental results indicate that it is a potential method for controlling solidification process. Various grain refinement mechanisms under PMF are proposed and most of them are considered to be relevant to the convection of melt driven by the electromagnetic force. An obvious fact is that the forced convection caused by PMF is strongly limited by the shape of the melt. However, most of previous studies were focused on the cylindrical samples rather than rectangular ones, and actually the later one was widely used in industry. The aim of this work is to investigate the influence of PMF on the grain refinement of K4169 superalloy rectangular samples with various aspect ratios. Grain refinement of K4169 superalloy under PMF was experimentally investigated in the rectangular samples with the aspect ratios of 1.0, 2.0, 4.5 and 5.5 on the transverse section. In order to study the influence of aspect ratio on the forced convection, the distributions of the electromagnetic field, electromagnetic force and melt flow caused by PMF were numerically simulated by finite element software ANSYS. The experimental results show that the grains of the K4169 rectangular samples are coarse equaxied grains without PMF and the grain size slightly decreases with the increase of aspect ratio. Under the PMF with same excitation voltage and frequency, the grains are refined remarkably in the sample with the aspect ratio of 1.0. As the aspect ratio is increased, the grain refinement effect can still be observed but not such obvious. The numerical simulation results indicate that the periodic pushing-pulling electromagnetic force is induced by the PMF, which drives the melt to vibrate and flow circularly. Under the same PMF, the electromagnetic force and fluid rate decreases with the increase of aspect ratio. When the aspect ratio increases from 1.0 to 5.5, the average electromagnetic force and fluid rate in the melt is reduced to 40% and 60%, respectively. The strongest fluid flow and vibration occur in the sample with section aspect ratio 1.0 in the present experiment, which is beneficial for grain refinement due to detachment of the solidified nuclei from mould wall and the break of dendrite arms from dendrite trunks.

脉冲磁场作用下矩形截面宽厚比对K4169高温合金晶粒细化的影响

[J].

Simulation of the influence of pulsed magnetic field on the superalloy melt with the solid-liquid interface in directional solidification

[J].

Research progress of grain refinement and homogenization of solidified metal alloys driven by pulsed electromagnetic fields

[J].

脉冲电磁场凝固组织细化和均质化技术研究与应用进展

[J].

Effect of strong pulsed electromagnetic field on metal's solidified structure

[J].

强脉冲电磁场对金属凝固组织影响的研究

[J].

Influence of the low voltage pulsed magnetic field on the columnar-to-equiaxed transition during directional solidification of superalloy K4169

[J].The low voltage pulsed magnetic field (LVPMF) disrupts the columnar dendrite growth, and the columnar-to-equiaxed transition (CET) occurs during the directional solidification of superalloy K4169. Within the pulse voltage ranging from 100 V to 200 V, a transition from columnar to equiaxed grain was observed, and the grain size decreased as the pulse voltage rised. As the pulse frequency increased, the CET occurred, and the grains were refined. However, the grains became coarse, and the solidification structure was columnar crystal again when frequency increased to 10 Hz. The LVPMF had an optimal frequency to promote CET. The LVPMF on the CET was affected by the withdrawal speed and increasing the withdrawal speed enhances the CET. The distribution of electromagnetic force and flow field in the melt under the LVPMF were modeled and simulated to reveal the CET mechanism. It is considered that the CET should be attributed to the coupling effects of magnetic vibration and melt convection induced by the LVPMF.

Microstructure refinement of AZ31 alloy solidified with pulsed magnetic field

[J].

Effects of low-voltage pulsed magnetic field and pouring temperature on solidified structure of Al-4.5%Cu alloy

[J].

Refining mechanism of the electric current pulse on the solidification structure of pure aluminum

[J].

Research on solidification structure refinement of pure aluminum by electric current pulse with parallel electrodes

[J].

The solidification technology of pulsed magneto oscillation

[J].With the development of metallurgical technology, some requirements such as high homogenization, high purification, superfine crystallization and low consumption have been put forward for the properties of metal materials. The pulse electromagnetic field has become the development direction of the new generation of metallurgy due to its energy saving, convenient application and refinement effect. The technology of pulse electromagnetic field in solidification includes electric current pulse, pulsed magnetic field and pulsed magneto oscillation (PMO). Based on the theories of pulsed current and electromagnetic stirring, the pulse current is applied to the induction coil in PMO technique. The melt is induced by magnetic field to produce electromagnetic force, and thereby, the non-contact treatment can be achieved to avoid dirtying the melt. In this paper, PMO technique is introduced, including invention process, theoretical basis, refinement mechanism, research status and its applications.

脉冲磁致振荡凝固技术

[J].

Structure refinement of pure aluminum by pulse magneto-oscillation

[J].

Morphology of the Al-4.5wt%Cu alloy by pulse magneto oscillation treatment

[J].

脉冲磁致振荡下Al-4.5wt%Cu合金微观组织形态

[J].

Application of PMO solidification homogenization technology in continuous casting production of GCr15 bearing steel

[J].

PMO凝固均质化技术在连铸GCr15轴承钢生产中的应用

[J].

Influence of pulsed magneto-oscillation on microstructure and mechanical property of rectangular 65Mn steel ingot

[J].

Grain refinement of Sn-Pb alloy under a novel combined pulsed magnetic field during solidification

[J].

Effect of compound magnetic field on solidified structure of Mg97Y2Cu1 alloy reinforced by long period ordered structure

[J].

复合磁场对Mg97Y2Cu1合金凝固组织的影响

[J].

Effects of compound magnetic field of pulsed and alternate field on solidified structure and mechanical properties of AZ31 magnesium alloy

[J].

脉冲-交流磁场对AZ31镁合金组织及力学性能的影响

[J].采用无磁场的常规铸造处理、施加脉冲磁场、施加交流磁场、施加脉冲-交流复合磁场4种工艺处理方式对AZ31镁合金凝固组织和力学性能的影响进行了分析,另外在施加复合磁场中考察了3种不同工艺参数:脉冲电压、脉冲频率及模具温度对合金的初生相形貌和晶粒尺寸的影响。结果表明,与交流磁场处理或脉冲磁场处理相比,复合磁场处理细化效果最好。经复合磁场处理后,合金的初生相由发达的树枝晶转变为细小的等轴晶,平均晶粒尺寸从3.5 mm减小到0.93 mm,断面等轴晶的比例由55.8%提高到97%;复合磁场中随着脉冲电压(0~300 V)或脉冲频率(1~10 Hz)增加,初生相由不完整的树枝晶逐渐退化为细小的等轴晶或蔷薇状晶;随模具温度从20℃增加至600℃,复合磁场处理后合金的晶粒尺寸先增大后减小然后再增大,200℃时晶粒尺寸最小。3种磁场处理方式中,复合磁场处理对合金的力学性能提高最明显,与常规铸造相比,合金的抗拉强度与伸长率分别提高了35.8%和25.6%。

Effects of compound magnetic field on microstructure and mechanical properties of the Mg93Zn6Y1 alloy

[J].

复合磁场对Mg93Zn6Y1合金凝固组织和力学性能的影响

[J].

Fundmental research on magnetohydrodynamics in secondary cooling zone of round billet continuous casting under the application of PMO

[D].

PMO在圆坯连铸二冷区中的磁流体力学基础研究

[D].

Distributions of electromagnetic fields and forced flow and their relevance to the grain refinement in Al-Si alloy under the application of pulsed magneto-oscillation

[J].

Exploration on the fabrication of bulk nanocrystalline materials by direct nanocrystallizing method I. Nucleation in disordered metallic media by electropulsing

[J].

直接晶化法制备块状纳米材料的探索──Ⅰ 脉冲电流作用下无序金属介质的成核理论

[J].利用经典热力学和连续介质电动力学理论计算了脉冲电流作用下无序介质(包括金属熔体和非晶态金属)的成核率.结果表明:对于无序介质的晶化过程,随脉冲电流密度增加,形核率成指数增大;超短时脉冲有可能使熔体直接冷凝成大块纳米晶材料,并能限制已经形成的纳米晶粒的长大.

Structure refinement of pure Mg under pulsed magnetic field

[J].A pulsed magnetic field (PMF) was introduced into the solidification of pure Mg. Fine uniform equiaxed grains are acquired in the whole ingot from the PMF treatment, in contrast with the coarse columnar grains observed in conventional casting, and the average grain size is refined to 260 μm with a 200 V PMF treatment. Pulsed magnetic field increases melt convection during solidification, and the violent agitation causes warmer liquid to fracture the tip of columnar dendrites or to break off dendrite branches to promote the formation of an equiaxed structure, with the broken pieces transported into the bulk liquid acting as nuclei. In addition, the uniform temperature field resulting from the stirring increases the likelihood of nuclei survival. The Joule heat effect also participates in the structure refinement. The pure Mg produced with a 200 V PMF treatment exhibits improved mechanical properties, such as the ultimate compressive strength (227 MPa) and fracture strain (33·2).