40CrNi3MoV钢是典型的压力容器用钢,经淬火和高温回火后,具有较高的强度和优良的韧性,广泛应用于压力容器、大型锻件等领域[1],其主要的强化手段为碳化物析出强化[2]。为了满足应用领域对40CrNi3MoV钢性能提升的需求,有研究[3]报道通过调整碳化物形成元素Mo、V的含量来提高钢的强度,可将40CrNi3MoV钢调质后的屈服强度提高到1300 MPa级[4],但是采用增加碳化物的强化方法需要热处理固溶温度较高,容易引起材料开裂与变形,目前常用的热处理工艺参数控制范围和热处理设备条件不能满足稳定热处理的要求。为了进一步提高压力容器用钢的强度,同时考虑到材料工艺性等问题,需要探索其他强化手段。

近期关于复合析出强化在钢中的强化作用逐渐成为研究热点[5,6],相比目前广泛应用的碳化物析出强化,含有不同类型的析出相的复合析出强化可利用不同成分和不同晶体结构的纳米析出相的相互协同作用,获得超过单一类型纳米析出相产生的强化效果,目前这种方法主要是利用碳化物和与钢基体共格的金属间化合物共同强化[7],如B2-NiAl、L21-Ni2AlTi等。研究[8~18]发现,在这些与基体共格的析出相中,纳米级NiAl相和富Cu相的强化效果最为明显。Kapoor等[19]通过匹配合适Ni、Al、Cu等元素的原子比,利用NiAl和Cu的复合析出强度,获得了屈服强度达到1600 MPa的高强度铁素体钢。Wang等[20]在研究中不仅进一步证实了Kapoor等[19]的研究结果,同时还在其研究结果中指出,NiAl和Cu的复合沉淀在时效的早期以亚稳溶质团簇存在,随着时效时间的延长,这种亚稳团簇最终会长大分离。Jiao等[21]通过计算,利用纳米NiAl和Cu粒子共沉淀强化的效果,开发出抗拉强度达到1.9 GPa的超高强低碳合金钢,同时还保持了较为良好的塑韧性,并指出NiAl和Cu颗粒与碳化物(NbC)的交互作用对提升钢的强度有重要贡献。最近有相关研究指出,NiAl和Cu的复合析出强化不仅可以利用在低碳沉淀强化钢中,在其他的组织类型钢中也可以实现明显的强化,如Xu等[22]通过NiAl和Cu的复合析出强化,研发出抗拉强度超过1400 MPa的奥氏体-马氏体双相钢。上述研究证明了碳化物+ NiAl、Cu析出的复合强化方法在低碳马氏体钢(C含量 ≤ 0.2%,质量分数)、双相钢以及奥氏体不锈钢中具有明显的强化效果,然而对于其在中高碳的马氏体钢中的作用研究较少,40CrNi3MoV钢C含量较报道的几类钢增加了一倍以上,且多采用淬火+高温回火的热处理方式,C含量和热处理制度的不同会影响2类析出相的析出行为,因此本工作以添加Al和Cu的40CrNi3MoV钢为研究对象,利用扫描电镜(SEM)、透射电镜(TEM)、三维原子探针(3DAP)等表征手段揭示富Cu相和NiAl相在钢中的析出特点及其对力学性能的影响规律,为研制高性能的压力容器用钢提供设计思路和基础理论支撑。

1 实验方法

表1 3种实验用钢的化学成分 (mass fraction / %)

Table 1

| Steel | C | Mn | Cr | Ni | Mo | V | Al | Cu | Fe |

|---|---|---|---|---|---|---|---|---|---|

| P-Mo | 0.41 | 1.00 | 0.99 | 3.02 | 1.02 | 0.20 | - | - | Bal. |

| P-Al | 0.42 | 1.09 | 1.06 | 3.09 | 1.02 | 0.21 | 1.09 | - | Bal. |

| P-Al + Cu | 0.40 | 1.01 | 1.04 | 3.05 | 0.96 | 0.21 | 1.08 | 1.52 | Bal. |

实验用钢的热处理制度为:先在900℃保温30 min后油淬,然后在500℃回火保温2 h后水冷至室温。热处理后对拉伸毛坯进行精加工。拉伸实验按GB/T 228.1—2010 《金属材料拉伸试验第1部分:室温试验方法》在WE-300型万能试验机上进行,试样标距25 mm,应变速率0.01 s-1。在Quanta 650FEG场发射SEM下观察拉伸断口形貌,并借助X-Max50型X射线衍射仪(XRD)对断口附近的析出相成分进行表征。从回火处理后的金相试样上取直径3 mm的圆片,采用机械研磨的方法减薄到0.5 mm,再用电解双喷法制备TEM薄膜试样,利用Talos F200X TEM观察NiAl-Cu析出相并分析其晶体结构,同时借助XFlash Detector 5030型能量色散X射线仪(EDS)对析出相的成分进行表征。

利用Helios NanoLab 600i双束扫描电镜定位到样品的晶界,采用聚焦等离子束(FIB)制备含有晶界的针尖样品,利用LEAP 5000XR 3DAP分析针尖样品中元素在三维空间的分布、偏聚情况以及在晶界处的元素分布,获取的实验数据利用IVAS 3.8.10软件进行三维重构,并对元素的成分和分布进行分析。

2 实验结果

2.1 力学性能

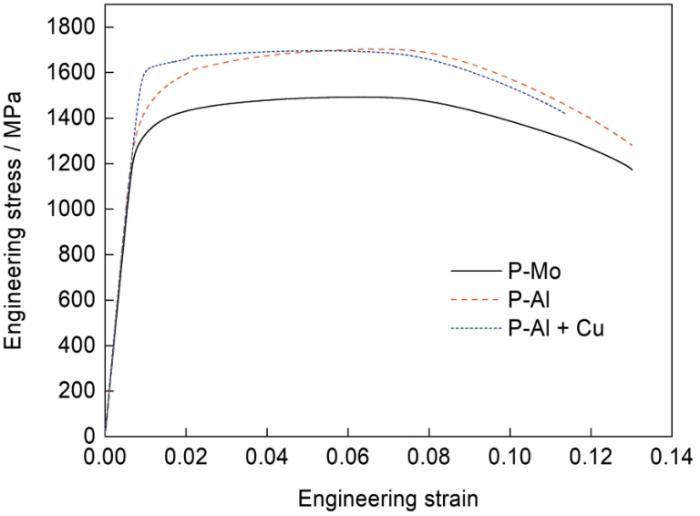

经过500℃回火后实验用钢的室温拉伸曲线如图1所示。可以看出,经回火处理后含有NiAl析出相的P-Al钢的抗拉强度相较于基础钢P-Mo有明显提高,增幅为200 MPa;进一步添加Cu后,P-Al + Cu钢的抗拉强度没有明显提高,但其屈服强度有明显的增加,和P-Al钢相比提升了150 MPa,和P-Mo钢相比提升了200 MPa。同时还可以看出,3种实验用钢的应变有所不同,P-Al钢由于抗拉强度的升高,其工程应变略小于基础钢,而添加Cu元素的P-Al + Cu钢在升高屈服强度的情况下,应变明显减小。

图1

图1

3种实验用钢500℃回火后的工程应力-应变曲线

Fig.1

Engineering stress-strain curves of three tested steels after tempering at 500oC

2.2 TEM分析

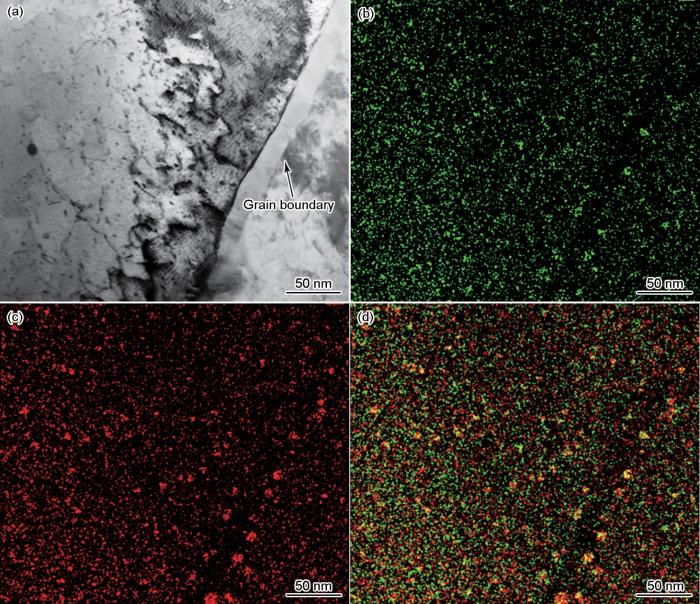

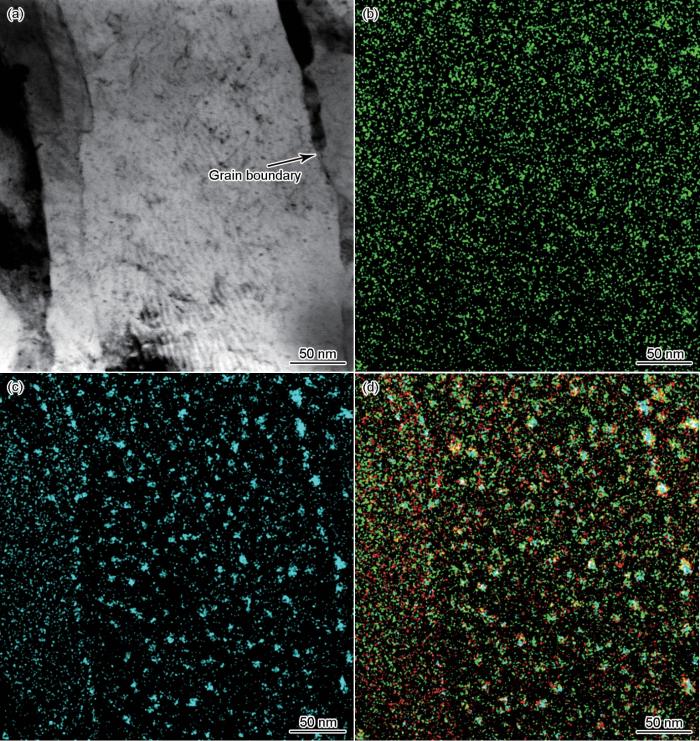

对经过500℃回火后的P-Al钢和P-Al + Cu钢进行了TEM分析,结果如图2和3所示。从图2a中可以看到,添加Al元素的P-Al钢中有球形析出相分布在基体中的位错处和晶界处,考虑到实验用钢中的NiAl析出相尺寸过于细小(< 5 nm),通过EDS来确定析出相的成分和析出位置,其中,绿色代表Al元素,红色代表Ni元素。从图2b和c可以看到有Al元素和Ni元素在相同的位置发生偏聚,其中在晶界的偏聚较为明显。为了更加直观地观察NiAl相的析出,将2种元素叠加后的EDS如图2d所示。根据能量的映射强弱可以看出,NiAl相在晶界处析出相较于在基体内部析出更加明显,说明纳米级NiAl相主要在晶界处析出。进一步添加Cu后的P-Al + Cu钢TEM像如图3所示。从图3a中可以观察到有大量的球形和椭球形析出相分布在基体中的位错处和晶界处,EDS表明有NiAl和Cu的析出,可知实验用纲中的Ni除了与Al形成析出相外,还会有一部分固溶在基体中形成偏聚,所以选用Al元素来代表NiAl相,其中新添加的Cu用蓝色来表示。图3b显示基体中Al没有在晶界处发生明显的偏聚,而图3c显示Cu在基体中有明显的偏聚,且在晶界处和基体内部析出没有明显差异。观察Al、Ni和Cu 3种元素叠加后的图像(图3d)可以看出,富Cu相和NiAl相的析出位置几乎相同,且两相主要是单独析出。

图2

图2

500℃回火后的P-Al钢TEM像和EDS元素分布图

Fig.2

TEM image of the matrix with grain boundaries (a) and EDS element maps showing the distributions of Al element (green) (b), Ni element (red) (c), Ni and Al elements (d) of P-Al steel tempered at 500oC

图3

图3

500℃回火后的P-Al + Cu钢的TEM像和EDS元素分布图

Fig.3

TEM image of the matrix with grain boundaries (a) and EDS element maps showing the distributions of Al element (green) (b), Cu element (blue) (c), and Ni, Al and Cu elements (Ni is red) (d) of P-Al + Cu steel tempered at 500oC

值得注意的是,相较于P-Al钢中的NiAl析出相,P-Al + Cu钢中的Al元素在更多位置发生了偏聚,这说明添加Cu后,不仅使得NiAl相的析出行为由主要在晶界析出转变为在晶内析出,还促进了NiAl相的析出,提高了其析出密度。

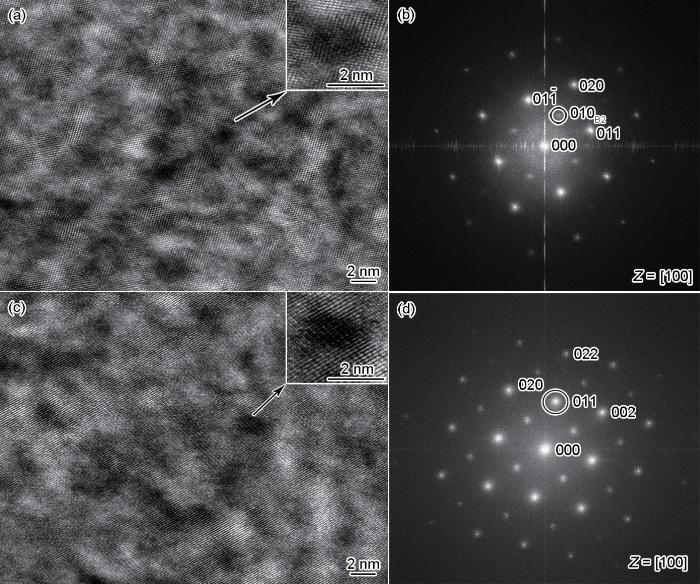

选取上述2种钢的析出相能谱映射较为强烈的区域,通过高分辨率透射电镜(HRTEM)分析实验用钢中的析出相和基体的晶体结构关系。图4为2种实验用钢的高分辨TEM (HRTEM)像和经快速Fourier变换(FFT)衍射花样,其中电子束沿着<100>方向入射。可以看出基体为bcc结构。对P-Al钢中析出相进行分析,如图4a和b,可观察到球形NiAl析出相,FFT显示有明显的超点阵衍射斑,经分析为B2结构,表明NiAl相与基体呈共格关系。对P-Al + Cu钢进行相同的分析,如图4c和d,可以发现椭球形的析出相,标定后发现衍射斑点间距和排列规律相同(图4d),表明富Cu相为与基体共格的bcc结构。同时在图中也发现了明显的超点阵衍射,证明富Cu相和NiAl相是单独析出且析出位置相同,且Cu对NiAl相晶体结构没有明显影响。

图4

图4

500℃回火后P-Al钢和P-Al + Cu钢中析出相的HRTEM像和FFT衍射图

Fig.4

HRTEM images (a, c) and Fourier fast transform (FFT) diffraction patterns (b, d) of precipitates in P-Al experimental steel (a, b) and P-Al + Cu experimental steel (c, d) after tempering at 500oC (Insets are partial enlarged views of the precipitated phase)

2.3 3DAP分析

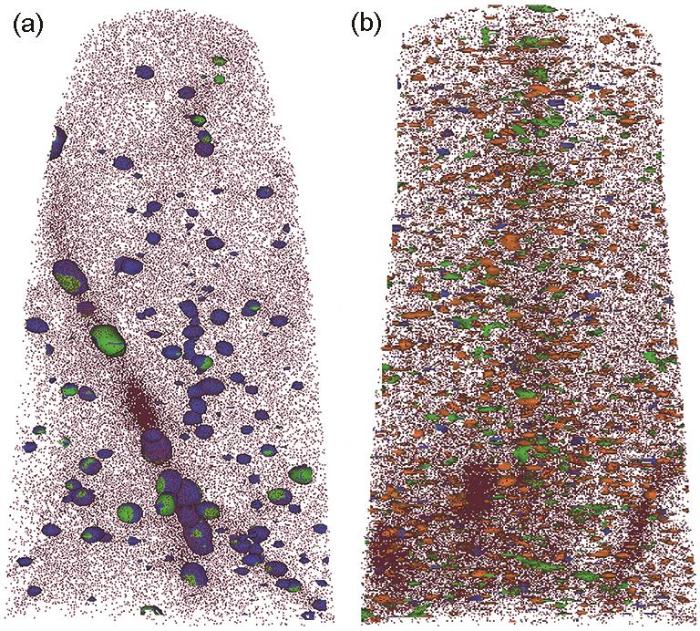

添加Al、Cu元素后,TEM分析证明了实验用钢在回火过程中会析出细小的纳米级NiAl析出相和富Cu相,为了更加深入地表征NiAl析出相和富Cu相的析出特征和统计纳米析出相的尺寸和密度,利用3DAP分别对500℃回火处理后P-Al和P-Al + Cu钢的元素分布进行表征,结果如图5和6所示。图5为P-Al钢中主要元素的原子空间分布,其中包含一条晶界,可以看出金属间化合物形成元素(Ni、Al)的偏聚位置相同,且主要偏聚在晶界处。添加Cu元素的P-Al + Cu钢的原子空间分布图(图6)中同样包含一条晶界,经观察发现,富Cu相在测试区域内主要呈现出弥散分布,在基体内部和晶界处没有明显的浓度差异;同时可看出,由于Cu的添加,纳米级NiAl析出相在晶界处没有发生明显的偏聚,由之前在晶界处大量偏聚转变为在晶内均匀分布。

图5

图5

500℃回火后P-Al钢的原子三维空间分布图

Fig.5

Three dimensional spatial distributions of atoms in P-Al experimental steel tempered at 500oC

图6

图6

500℃回火后的P-Al + Cu钢的原子三维空间分布图

Fig.6

Three dimensional spatial distributions of atoms in P-Al + Cu steel tempered at 500oC

3DAP分析结果表明,只添加Al元素,NiAl析出相更容易在晶界处形成,进一步添加Cu后,不仅弥散析出了富Cu相,同时使得NiAl相的析出特点发生了改变,降低了NiAl相晶界析出的概率。这与上述TEM结果相吻合。

3 分析讨论

3.1 NiAl和Cu在40CrNi3MoV钢中的析出特点

从图5中可以看到Ni和Al元素有明显的偏聚,为了更加直观地观察析出相的形貌,对NiAl析出相(10%Ni,5%Al[11~14,20~23])进行三维原子重构,结果如图7a所示。可以明显观察到纳米级NiAl析出相为球形,且晶界处是NiAl相析出的主要位置,同时可以看出在晶界处析出的NiAl相尺寸大于晶内析出相。这种现象的产生可以从2个方面进行解释:一方面是晶界处的特性决定了Ni原子和Al原子会在晶界处发生偏聚。由于晶界处存在较大的空隙,疏松的结构使得晶界成为溶质原子快速扩散的通道,同时晶界处相较于晶内具有更高的弹性畸变能,使得Ni原子和Al原子更容易偏聚在晶界处。另一方面是由于钢中的一些合金元素会促进偏聚在晶界处的Ni原子和Al原子的形核和长大。相关研究[25~27]表明,钢中的Mn会促进偏聚在晶界处的Ni原子Al原子发生形核,进而促进晶界处的NiAl相析出。这是由于Mn元素本身也会偏聚在晶界处(图5),同时Mn在NiAl相中的溶解度要远大于在Fe基体中的溶解度,从热力学的角度上可以理解为在元素偏聚的过程中Mn会向NiAl纳米粒子优先分配,从而导致Mn在NiAl纳米粒子中的富集,这就使得在形核的过程中,Mn优先分配到NiAl纳米粒子上,进而减小了纳米粒子与基体之间的晶格失配,这样不仅增加了形核的化学驱动力,同时降低了NiAl相的形核功,从而显著降低了钢中NiAl纳米粒子形成的临界能量,使得纳米级NiAl相更容易达到形核的临界半径,促进其在晶界处形核长大。

图7

图7

实验用钢中NiAl和Cu经三维原子重构的空间分布图

Fig.7

Spatial distributions of NiAl and Cu in P-Al steel (a) and P-Al + Cu steel (b) reconstructed by three-dimensional atoms (The green color repre-sents Ni, blue for Al, and orange for Cu)

在实验用钢中进一步添加Cu后,可以看出NiAl相的析出行为发生了改变(图5),NiAl相由在晶界处的大尺寸析出转变为在晶内的均匀析出,相应的三维原子重构图(图7b,10%Ni,5%Al,2%Cu)显示析出的NiAl相的形貌除了球形以外,还有部分为椭球形。Cu的添加使得NiAl相的析出特征发生改变的原因主要有2个。一个原因是Cu的添加降低了NiAl相大尺寸析出的化学驱动力。有研究表明,Ni、Al和Cu的质量比影响基体中NiAl相和富Cu相的析出顺序[23],在Fe-Cu-Mn-Ni-Al体系中[19,21],当Ni/Cu和Al/Cu的比值分别为1.6和0.4时,强化相的析出序列为Cu→NiAl + Cu;而当比值分别为3.33和1.33时,强化相的析出序列为 NiAl→Cu + NiAl。在本工作中,P-Al + Cu钢的Ni/Cu和Al/Cu的比值分别为2.0和0.71,该比值对于富Cu相的优先析出提供了较高的化学驱动,因此析出相的析出顺序更倾向于Cu→Cu + NiAl。这种析出顺序从微观上可以理解为富Cu相首先从过饱和固溶体中析出,然后Ni和Al不断偏聚在富Cu团簇和基体之间的界面上,最终形成NiAl相析出。而优先析出的富Cu相快速降低了基体中的过饱和度,降低了基体中纳米粒子大尺寸析出的化学驱动,进而降低了晶界处大尺寸NiAl相析出的成核率,抑制了NiAl相在晶界处的析出。

此外,偏析在晶界处的Cu降低了晶界能。元素在晶界处偏聚引起的晶界能量变化公式[28]为:

以上2种原因导致了添加Cu后的实验用钢中NiAl相的析出行为发生了改变,从而获得了在晶内均匀分布的NiAl纳米析出相,增加了NiAl析出相密度的同时也细化了析出相的尺寸。

3.2 NiAl和Cu析出对力学性能的影响

式中,ε为裂纹萌生的宏观应变,R为第二相平均半径,b为Burgers矢量模,σc为基体与第二相分离的临界应力,σm为外加应力,G为弹性模量。

图8

图8

500℃回火后P-Al钢和P-Al + Cu钢的拉伸断口形貌和XRD谱

Fig.8

Tensile fracture morphologies (a, c) and XRD spectra (b, d) of P-Al experimental steel (a, b) and P-Al + Cu experi-mental steel (c, d) after tempering at 500oC

针对本工作中添加1.5%Cu的P-Al + Cu钢,采用Russell-Brown强化模型[8]计算富Cu相对屈服强度的强化贡献(σp):

式中,M为Taylor参数,M = 3;基体的b = 0.25 nm;G = 80 GPa;L为滑移平面上析出相平均距离,由析出相的平均半径R和数密度N决定[18]:

Ep为析出相中位错线能量;Em为基体中位错线能量;Ep / Em的值取决于析出相的平均半径[8]:

式中,r为位错内截止半径,r = 2.5b;r0为位错外截止半径,r0 = 1000r;

本工作中,P-Al + Cu钢中富Cu析出相的R为1.4 nm,N为1.2 × 1024 m-3,计算得到富Cu相对强度的贡献为152.25 MPa,与文献[39]报道的Cu强化效果一致,表明富Cu析出相是P-Al + Cu钢屈服强度提高的主要原因。此外,P-Al + Cu钢中的NiAl相由于尺寸和数密度的变化也会带来强度变化,计算其强化增量为15.93 MPa。

4 结论

(1) 添加Al元素的40CrNi3MoV钢经过淬火和高温回火后,在基体析出大量纳米级B2结构的NiAl相,在晶界处的NiAl析出相尺寸较大。进一步添加Cu元素后,析出的富Cu相不仅抑制了NiAl相在晶界处的大尺寸析出,还促进了NiAl相的析出数量,同时细化了NiAl析出相的尺寸。

(2) B2结构的NiAl析出相与bcc结构的基体α-Fe晶体点阵错配度相对较小,获得了明显的共格析出强化效果,可将40CrNi3MoV钢的强度提高约200 MPa。添加Cu后,均匀分布细小的富Cu相和细化的NiAl相增加了对位错的阻碍作用,进一步提高了屈服强度,然而由于大量细小、高密度的NiAl和Cu析出相,降低了拉伸过程产生裂纹的临界应变,因此并未提高抗拉强度。

参考文献

Study of high strength and high toughness homogenizing Cr-Ni-Mo-V series steels

[D].

高强高韧均质化Cr-Ni-Mo-V系钢的研究

[D].

Effect of tempering process on Microstructure and mechanical properties of Cr-Ni-Mo-V high strength steel

[J].

回火工艺对Cr-Ni-Mo-V高强钢组织和力学性能的影响

[J].

Effects of tempering temperature on microstructure and mechanical properties of 40CrNi3MoV steel

[J].

回火温度对40CrNi3MoV钢组织和力学性能的影响

[J].

Study on Microstructure and mechanical properties of 1350 MPa high strength martensitic steel

[D].

1350 MPa级高强度马氏体钢组织与力学性能的研究

[D].

Research and development of advanced nano-precipitate strengthened ultra-high strength steels

[J].

新型纳米强化超高强度钢的研究与进展

[J].

Progress and perspective of ultra-high strength steels having high toughness

[J].

超高强高韧化钢的研究进展和展望

[J].

M2C precipitates in isothermal tempering of high Co-Ni secondary hardening steel

[J].

Tempering process of Cu-NiAl nano co-precipitation strengthened steel

[J].

Cu-NiAl纳米复合析出强化钢回火工艺

[J].

Strengthening of Ni-Mn-Cu-Al-Co steel by nanoscale Cu and β-NiAl co-precipitated couples

[J].

Co-precipitation mechanisms research of Cu-rich and Ni-Al phases in steel

[D].

钢中富Cu相和NiAl相复合析出机制的研究

[D].

Effects of co-addition of Ni and Al on precipitation evolution and mechanical properties of Fe-Cu alloy

[J].

Effects of welding and post-weld heat treatments on nanoscale precipitation and mechanical properties of an ultra-high strength steel hardened by NiAl and Cu nanoparticles

[J].

Effects of increased alloying element content on NiAl-type precipitate formation, loading rate sensitivity, and ductility of Cu- and NiAl-precipitation-strengthened ferritic steels

[J].

Mechanism research of nanaoscale composite precipitates in Fe-Cu-Ni-Al-Mn steel

[D].

Fe-Cu-Ni-Al-Mn钢中强化相复合析出机制的研究

[D].

Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation

[J].

Precipitation characterization of NiAl and Cu-rich phases in dual-phase region of precipitation strengthening steel

[J].Precipitation strengthening plays an important role on improving the mechanical properties of steels, NiAl and Cu-rich phases are two kinds of common precipitates. This work aims to reveal the precipitation characteristics of these two phases in martensite and retained austenite in precipitation strengthening steel by atom probe tomography (APT). The hot rolled samples were aged at 500 ℃ for 1 h after solution treatment at 900 ℃ for 2 h, followed by microstructure analysis. The results show that NiAl and Cu-rich phases form in martensite phase as well as at martensite/austenite phase boundaries, while no precipitate develops in retained austenite. Precipitation was not observed near the phase boundaries in martensite. Equivalent radius, spacing and concentration of the strengthening phases at phase boundary are larger than that inside martensite. In addition, NiAl phase tend to separate from Cu-rich phase, and the separated tendency becomes stronger at phase boundaries than in martensite. Besides, the growth of NiAl and Cu-rich phases at phase boundary differs from that within martensite, which should be induced by the defect density difference between them.

沉淀强化钢中两相区NiAl相和富Cu相的析出特点

[J].沉淀强化钢在900 ℃固溶2 h后水淬, 500 ℃时效1 h, 利用原子探针层析技术(APT)研究了残余奥氏体和马氏体两相区强化相的析出特点. 结果表明, 残余奥氏体中没有析出相, 马氏体和马氏体/残余奥氏体界面处均有强化相析出, 马氏体中靠近界面处有一层析出贫化区. 界面处强化相的等效半径和间距均大于马氏体中的强化相, 界面处富Cu相和NiAl相中Cu, Ni和Al的含量均大于马氏体中的富Cu相和NiAl相, 而且界面处富Cu相和NiAl相的分离趋势要大于马氏体, 这是因为界面处存在大量缺陷, 促进了强化相的长大, 使得界面处和马氏体中的强化相处于长大的不同阶段.

Second phase strengthening in advanced metal materials

[J].

先进金属材料的第二相强化

[J].

Synergistic effects of Cu and Ni on nanoscale precipitation and mechanical properties of high-strength steels

[J].

Aging characteristics and mechanical properties of 1600 MPa body-centered cubic Cu and B2-NiAl precipitation-strengthened ferritic steel

[J].

Age-hardening effect and formation of nanoscale composite precipitates in a NiAlMnCu-containing steel

[J].

Precipitation mechanism and mechanical properties of an ultra-high strength steel hardened by nanoscale NiAl and Cu particles

[J].

Mechanical properties and deformation mechanisms of a novel austenite-martensite dual phase steel

[J].

Precipitation reactions in a Cu-Ni-Al medium carbon alloyed dual hardening steel

[J].

Characterization of precipitates NiAl and Cu in 10Ni3MnCuAl steel during aging by three-dimensional atomic probe

[J].

三维原子探针表征10Ni3MnCuAl钢时效过程中析出相NiAl和Cu的变化规律

[J].

Effects of Mn partitioning on nanoscale precipitation and mechanical properties of ferritic steels strengthened by NiAl nanoparticles

[J].

Designing Heusler nanoprecipitates by elastic misfit stabilization in Fe-Mn maraging steels

[J].

Precipitation kinetics and mechanical properties of nanostructured steels with Mo additions

[J].

Alloy effects in nanostructures

[J].

Mechanisms for suppressing discontinuous precipitation and improving mechanical properties of NiAl-strengthened steels through nanoscale Cu partitioning

[J].

Grain boundary energies in body-centered cubic metals

[J].

An identification scheme of grain boundaries and construction of a grain boundary energy database

[J].

High-strength steels hardened mainly by nanoscale NiAl precipitates

[J].

Nanoscale co-precipitation and mechanical properties of a high-strength low-carbon steel

[J].

In situ TEM/HRTEM investigations on deformation mechanisms in metals

[J].

透射电镜原位拉伸研究金属材料形变机制

[J].

Plastic deformation behavior and fracture mechanism of rare earth H13 steel based on in situ TEM tensile study

[J].Fatigue failure caused by crack propagation is one of the main failure modes of H13 die steel. Because H13 die steel is mainly used under operational conditions involving high-pressure cycling or high friction, its crack initiation and propagation behavior play a critical role in fatigue failure. However, to the best of the authors' knowledge, few reports on the direct observation of deformation and crack propagation behavior of H13 die steel exist, which limits the understanding of the fracture mechanism of H13 die steel. In this work, an in situ TEM tensile study combined with post-mortem EBSD analysis was employed to investigate the microstructure evolution and crack propagation behavior of rare earth (RE) H13 steel. Results indicate that the stress concentration at the grain boundaries and coarse granular inclusions in the tensile specimen were the main sources of crack initiation. After crack initiation and during the tensile process, many cracks converged into the main crack. The main crack propagated along the direction perpendicular to the tensile direction, exhibiting zigzag-shaped features. The stress distribution in the area near a crack in a specimen was heterogeneous; the length fraction of V1/V2 inter-variant boundaries in the relatively high-stress area increased from 56.5% to 58.8% compared with the relatively low-stress area, and the length fraction of V1/V3&V5 inter-variant boundaries increased from 16.3% to 21.6%. The increase in the length fraction of V1/V2 inter-variant boundaries indicated an increase in the twin martensite fraction, which effectively relieved the stress concentration at the grain boundaries and reduced crack initiation. During the tensile process, the austenite retained at the grain boundaries underwent stress-induced phase transformation and was partially transformed into V1/V2 and V1/V3&V5 variant pairs. The dislocation propagation in martensite contributed to dislocation pile-up at high-angle grain boundaries and carbide precipitation. Moreover, the dislocation pile-up at the high-angle grain boundaries promoted the stress-induced phase transformation of the retained austenite.

基于原位TEM拉伸的稀土H13钢塑性形变行为和断裂机制

[J].

In-situ tension fracture of super-high Mn steel and mechanism analysis

[J].

超高锰钢原位拉伸断裂及机理分析

[J].

In situ investigation on plastic deformation and cracking of metals under TEM/SEM

[D].

金属塑性变形与断裂的TEM/SEM原位研究

[D].

The work-hardening of copper-silica v. Equilibrium plastic relaxation by secondary dislocations

[J].

Microstructure and mechanical properties of HSLA steel containing 1.4%Cu

[J].The Cu bearing high strength low alloy (HSLA) steels exhibit high-strength, high toughness and good weldability, which have been widely used in shipbuilding, offshore structures etc. Due to the extremely poor impact energy when attained peak strength, the Cu bearing HSLA steels are usually used at overaged state, which have a good combination of impact energy and strength. In order to clarify the effect of Cu on mechanical properties especially on the impact energy for HSLA steels at peak ageing state, two HSLA steels without Cu (0Cu) and with 1.4%Cu (1.4Cu), were prepared by vacuum induction melting in this study. The influence of Cu on the microstructure of HSLA steel was investigated by OM, SEM and EBSD. Meanwhile, the Cu-riched clusters were characterized by APT and the mechanical properties were measured by tensile test and impact test. The results show that the Cu is completely solid-solutioned into the matrix after quenching, and there are a great number of Cu-riched clusters precipitated in the matrix and boundaries after tempering. Cu element has no obvious effect on the prior austenite grain size, microstructure and effective grain size of tempered HSLA steel, but has significant influence on the strength and impact energy for tempered HSLA steel. After tempered at 450 ℃, the 1.4Cu steel attained the maximum yield strength (1053 MPa), higher than that of 0Cu steel. It is worth noting that the impact energy of 1.4Cu steel tempered at 450 ℃ is only 24 J at room temperature and the impact fracture is a quasi-cleavage brittle fracture mode dominated by river patterns. However, 0Cu steel exhibits a completely ductile fracture mode dominated by dimples at room temperature and the impact energy is 127 J. The APT results show that both 0Cu and 1.4Cu tempered steels have the segregation of C, Cr, Ni, Mn elements at the lath boundary. Compared with 0Cu steel, there precipitate a great number of Cu-riched clusters at the lath boundary for 1.4Cu steel, which will result in the stress concentration and then promote the crack initiation at the lath boundary. In addition, the Cu-rich clusters precipitated at the lath boundary could prevent the Mo segregated at the lath boundary, which will decrease the bonding energy and then promote the crack propagation along the lath boundary. Besides, the negative effect of strengthening due to the Cu-riched clusters at matrix will also accelerate the crack propagation in the matrix, which will decrease the impact energy of 1.4Cu steel. Therefore, the impact energy of 1.4Cu steel is much lower than that of 0Cu steel at room temperature.

含1.4%Cu的HSLA钢的组织和力学性能

[J].以不含Cu (0Cu)和含1.4%Cu (1.4Cu)的HSLA钢为研究对象,利用OM、SEM、EBSD等技术手段研究了Cu对HSLA合金钢显微组织的影响,利用APT表征了纳米富Cu团簇的析出特征,并通过拉伸和冲击实验测定了合金钢的力学性能。结果表明,淬火态Cu固溶在基体中,经回火后则以富Cu团簇的形式在基体和界面处析出。Cu对回火态HSLA合金钢的原始奥氏体晶粒尺寸、显微组织及有效晶粒尺寸均无明显影响,但对其强度和冲击功影响较大。1.4Cu钢经过450 ℃回火处理后获得最佳强化效果,其屈服强度比0Cu钢提升了143 MPa,此时1.4Cu钢的室温冲击功仅为24 J,断口以河流花样为主,其断裂方式为准解理脆性断裂;而0Cu钢的室温冲击功高达127 J,其断裂方式为韧窝的韧性断裂。APT实验结果表明,2种回火态合金钢的板条界面处均存在C、Cr、Ni、Mn元素的富集。与0Cu钢相比,1.4Cu钢的板条界面处存在大量富Cu团簇,从而导致较大的应力集中,有利于裂纹的萌生,并且板条界面处析出的富Cu团簇会排斥Mo元素,抑制了Mo元素在板条界处的偏聚,相对降低了板条界面处的结合强度,有利于裂纹沿板条界扩展。此外,富Cu团簇在强化基体的同时,也会降低基体的韧性,加快裂纹在基体内的扩展。因而,1.4Cu钢在获得最佳强化效果时其冲击性能较差。