镍基单晶高温合金因具有优异的高温力学性能、氧化抗力和腐蚀抗力,已广泛用于航空发动机高压涡轮叶片等热端部件[1~3]。随着发动机涡轮进口温度不断提升且服役环境日益复杂,国内外学者开始在含Re第三代单晶高温合金中添加Ru元素,相继研发出承温能力更为优异的第四代单晶高温合金[4~7]。当航空发动机在服役过程中经历启动、停机及空中加减速时,合金所承受的温度和应力(热应力及机械应力)将出现交替变化,产生严重的温度循环-应力/应变循环损伤,使构件提前进入塑性变形状态,进而发生疲劳失效[8]。然而,传统的低周疲劳模型仅考虑恒定温度下的单一损伤形式,难以准确反映出温度和应力同时循环变化时合金的变形行为[9,10]。因此,为了更好地理解合金在真实服役条件下的疲劳损伤机理,预测合金的服役寿命,采用热机械疲劳(TMF)实验来评价合金的服役行为更为合理。

在TMF过程中,合金在不同阶段均会产生不同程度的损伤,且随着循环相位的变化,合金的主要损伤形式及断裂特征会随之改变[11~14]。在对SRR99单晶合金TMF行为的研究[11]中发现,合金在不同相位及应变幅下均表现出高温半周循环软化和低温半周循环硬化的特征;当应变幅增加时,合金在同相位(IP)循环断裂后断面特征由韧窝转变成解理面,而反相位(OP)循环条件下合金的主要断裂方式并未发生变化。Moverare等[12]对CMSX-4合金的研究表明,合金中大尺寸的变形带会不断积累储能,在高温半周诱发拓扑密排(TCP)相析出及再结晶晶粒的形成,进而显著加速了合金的疲劳断裂过程。在针对高代次单晶高温合金的研究中,Zhang等[13]发现变形孪晶易于在表面氧化产物附近萌生并沿着{111}面扩展(OP循环,600~900℃),为疲劳裂纹的连续扩展提供路径。然而,在TMS-196合金的OP-TMF变形过程中,研究者[14]观察到大量细小微孪晶的存在,推断其有利于提升合金的疲劳强度。由此可见,目前有关第一代至第三代单晶高温合金的TMF研究已取得了一定进展,但是针对含Ru的第四代单晶合金的研究成果仍然十分有限[14~16],且相关研究工作主要关注于合金的OP-TMF损伤特征及变形机理。此外,尽管目前有研究[11,17,18]报道单晶高温合金在OP循环条件下,其最终断裂寿命低于IP循环寿命,然而,亦有研究[19~21]指出合金在IP条件下需要同时承受高温和高应力,更易于积累损伤并迅速断裂失效。实际上,随着高代次单晶合金服役温度的提升,合金在高温半周将更加容易发生蠕变累积和氧化损伤,因此澄清第四代单晶合金的IP-TMF行为及综合损伤机理尤为重要。

综上所述,本工作以一种国产第四代单晶高温合金作为对象,开展IP-TMF实验,深入剖析合金的疲劳行为和显微组织演化规律。着重关注高温氧化效应和再结晶等因素对合金疲劳性能的影响,旨在澄清第四代单晶高温合金的IP-TMF损伤及变形机理,为解决高代次镍基单晶高温合金的安全服役问题提供数据支撑。

1 实验方法

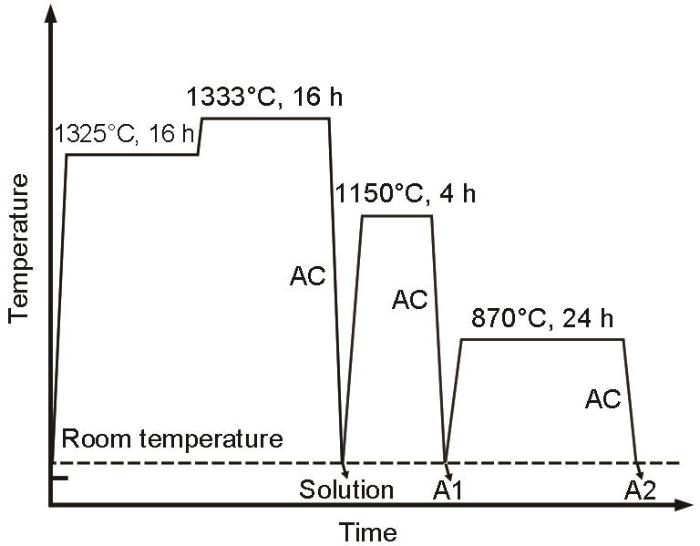

实验材料为自主研发的第四代镍基单晶高温合金DD91,其名义化学成分(质量分数,%)为:Al 5.7,Co 12,Re 5.4,Ru 3,(Cr + Mo + W + Ta) 19.2,Hf 0.15,Ni余量。采用螺旋选晶法在液态金属冷却炉中制备取向为[001]的单晶试棒,选择取向角偏差在10°以内的单晶棒进行热处理。标准热处理制度为两级连续固溶处理(1325℃、16 h + 1333℃、16 h)加两次时效热处理(1150℃、4 h,870℃、24 h),冷却方式均为空冷,如图1所示。

图1

图1

DD91合金标准热处理流程图

Fig.1

Schematic of the standard heat treatment regimens of DD91 alloy (AC—air cooling, A1—primary aging, A2—secondary aging)

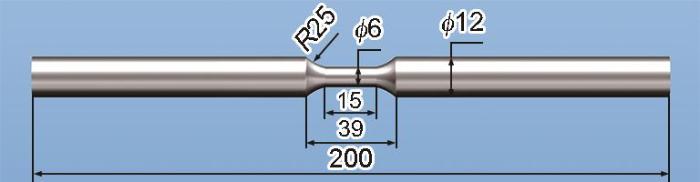

将标准热处理后的试棒加工成TMF样品,尺寸如图2所示。为了确保消除表面划痕及缺陷对疲劳性能的影响,使用2000号砂纸对机械加工后的试样进行打磨,并对标距段进行机械抛光。TMF实验在MTS Landmark 370.10型疲劳试验机上进行。采用机械应变控制的三角波形进行IP-TMF实验,应变比R = -1,循环周期为200 s。设置了0.5%、0.6%、0.8%和0.9% 4组不同机械应变幅(Δεmech / 2)的疲劳实验,实验温度范围为600~1000℃,不同测试条件下均设置一组平行实验。

图2

图2

热机械疲劳试样尺寸示意图

Fig.2

Schematic illustration of the experimental thermal-mechanical fatigue specimen (unit: mm)

采用Tescan MIRA4型扫描电子显微镜(SEM)分析TMF样品变形组织、裂纹扩展与断裂特征以及表面氧化产物。金相样品经抛光后,使用(20 g CuSO4 + 100 mL HCl + 5 mL H2SO4 + 80 mL H2O)腐蚀剂进行化学腐蚀,时间为5 s。使用Symmetry S2型背散射衍射(EBSD)探头检测断口表面以及疲劳裂纹附近位置的再结晶晶粒形成情况,采用Channel 5软件对EBSD数据进行分析处理。另外,使用X-MaxN型能谱仪(EDS)对断裂后试样的外表面氧化产物类型进行元素分析(点扫描及面扫描)。最后,采用Talos F200X型透射电子显微镜(TEM)观察合金的微观变形组织及缺陷演化特征。TEM样品从断面以下2~3 mm位置切取,经机械研磨后进行电解双喷减薄,电解液为10%HClO4 + 90%C2H5OH (体积分数),减薄参数为电压21 V,温度-25~20℃。

2 实验结果及分析

2.1 热机械疲劳行为

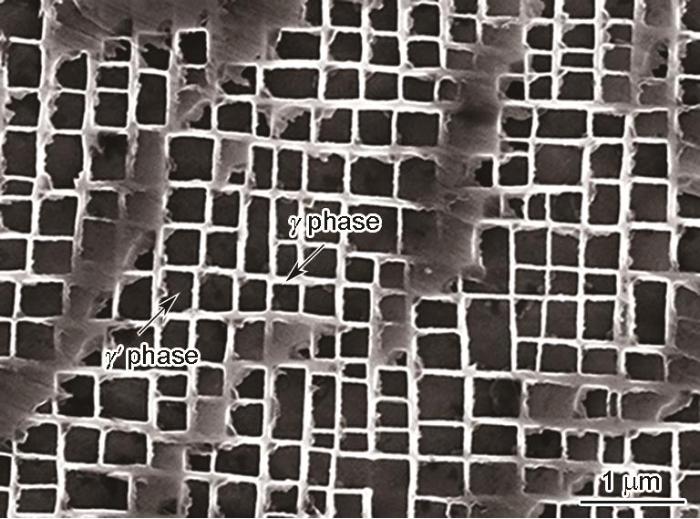

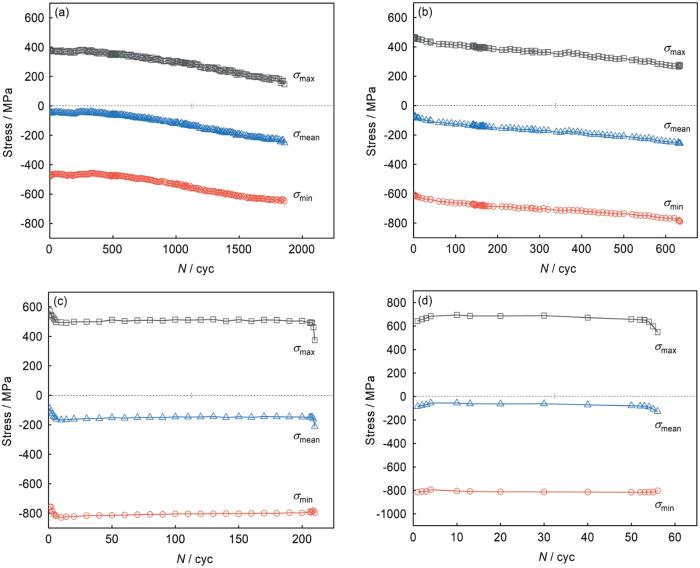

DD91合金在完全热处理后所得的γ /γ'两相组织如图3所示,其中γ'相分布均匀,呈规则立方状,体积分数约为68.7%。DD91合金在不同应变幅下的IP-TMF循环应力响应曲线如图4所示。由图可见,当应变幅从0.5%增加至0.9%,合金的TMF寿命降低约97.3%。不同应变幅下的响应曲线均表现出拉、压应力的不对称性。由于合金的弹性模量随着温度的升高而降低[8,19],合金在高温半周所受的最大拉应力会低于在低温半周所受的最大压应力,导致试样受平均压应力作用。通过对比分析,归纳出不同曲线的特征如下:(1) 随着应变幅不断升高,试样在循环初期所受的拉、压应力不断提高,初始拉应力由374 MPa增加至643 MPa,初始压应力由470 MPa升高至815 MPa。(2) 在较低的应变幅(图4a和b)下,试样在高温半周主要表现出循环软化特征,而在低温半周合金所受的压缩应力逐渐硬化。另外,在疲劳断裂之前合金所受的最大拉、压应力均未发生明显突变,这表明在低应变幅条件下,疲劳裂纹萌生后,其扩展速率变化相对稳定。(3) 当应变幅较高时(图4c和d),循环应力曲线中均出现了3个不同的阶段。在循环初期,当应变幅为0.8%时,最大拉应力降低而最大压应力有所提高;相反在应变幅为0.9%时,拉应力出现了轻微硬化而压应力略有降低。在循环应力重新分布之后,曲线均进入了相对稳定的循环变形阶段,直至断裂之前的十几个周次,疲劳裂纹相互连接并失稳扩展,导致最大拉应力显著降低。

图3

图3

DD91合金标准热处理后的γ /γ'两相组织

Fig.3

γ /γ' structure of the DD91 alloy after standard heat treatment

图4

图4

DD91合金在不同应变幅下的同相位热机械疲劳(IP-TMF)循环应力响应曲线

Fig.4

Cyclic stress response curves of the DD91 alloy during in-phase thermomechanical fatigue (IP-TMF) at strain amplitudes of 0.5% (a), 0.6% (b), 0.8% (c), and 0.9% (d) (N—cycle number, σmax—maximum stress, σmean—mean stress, σmin—minimum stress)

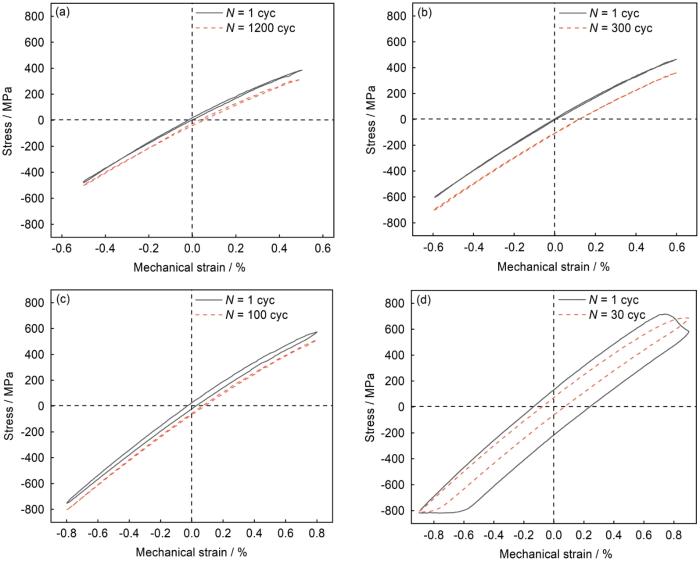

DD91合金IP-TMF第1 cyc及循环稳定时的迟滞回线如图5所示。当应变幅为0.5%和0.6%时,由于合金的塑性变形程度较低,迟滞回线基本闭合(图5a和b)。随着疲劳过程的进行,半寿命左右的滞回环已明显垂直向下平移,有趣的是在0.6%应变幅下,迟滞回线的平移范围更大,表明合金在此条件下的拉应力软化和压应力硬化行为更加明显。当应变幅为0.8%时,循环1 cyc的迟滞回线轻微张开,而半寿命时的滞回环再次趋于闭合(图5c),表明疲劳过程中,尤其是半寿命以前,合金内部累积的塑性变形量不断升高。而当应变幅进一步提高至0.9%时,迟滞回线完全张开,合金表现出明显的循环塑性。在高温半周,拉伸应力在蠕变变形过程中得到松弛,因此在应变量达到最大值时拉应力已有所降低;而在低温半周,当循环应力达到一定水平时,合金提前屈服并开始塑性变形,在迟滞回线中能观察到明显的屈服平台。而且,合金在高温半周的应力松弛及低温半周的塑性变形都随循环次数的增加而减缓,因此与第1 cyc相比,循环稳定时的迟滞回线已明显收缩(图5d)。

图5

图5

DD91合金在不同应变幅IP-TMF过程第1 cyc及循环稳定时的迟滞回线

Fig.5

Typical hysteresis loops of first cycle and steady stage of the DD91 alloy during IP-TMF at mechanical strain amplitudes of 0.5% (a), 0.6% (b), 0.8% (c), and 0.9% (d)

2.2 微观组织演化

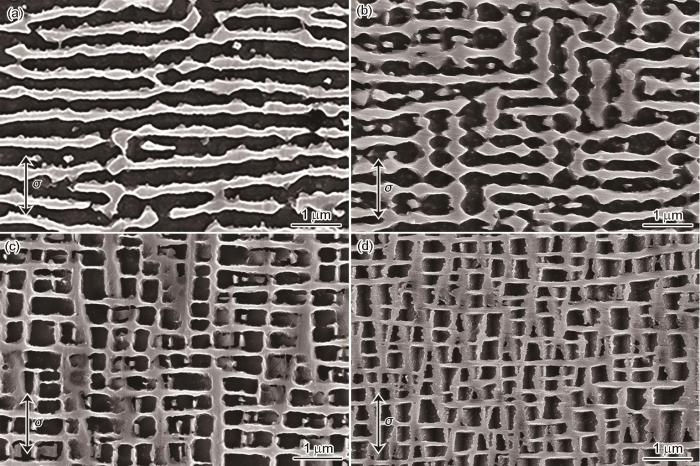

DD91合金在IP-TMF断裂后纵截面((011)面)的SEM像如图6所示。由图可见,合金在不同应变幅下断裂后,γ'强化相出现了不同程度的粗化及筏化。应变幅为0.5%时,合金内部形成了完整且连贯的N型筏状组织,且相比于热处理态,γ基体已显著宽化(图6a)。当应变幅提高至0.6%时,γ'相已明显球化并大部分连接成筏,但特征筏状组织的连续性较0.5%应变幅已明显下降(图6b)。当应变幅达到0.8%时,合金在200 cyc左右就已发生疲劳断裂失效,合金中的γ'相基本保留了立方形态,只有部分强化相在垂直于应力的方向相互连接,形成了短小的筏形组织(图6c)。当应变幅继续升高至0.9%时,γ /γ'两相仅在一定程度上粗化长大,并未观察到处于消失过程中的岛状γ基体,这主要是由于合金在高温半周停留的时间短(总疲劳寿命低),原子扩散不充分所导致的。因此,尽管高温半周的拉应力进一步提高,γ /γ'组织也很难形筏。此外,由于应力水平过高,合金在TMF循环过程中发生明显塑性变形,致使部分γ'相的边界出现了一定程度扭转变形,形态变得不规则(图6d)。

图6

图6

DD91合金在不同应变幅IP-TMF断裂后纵截面((011)面)的SEM像

Fig.6

SEM images in (011) plane of the DD91 alloy after IP-TMF fracture at mechanical strain amplitudes of 0.5% (a), 0.6% (b), 0.8% (c), and 0.9% (d) (σ—cyclic stress)

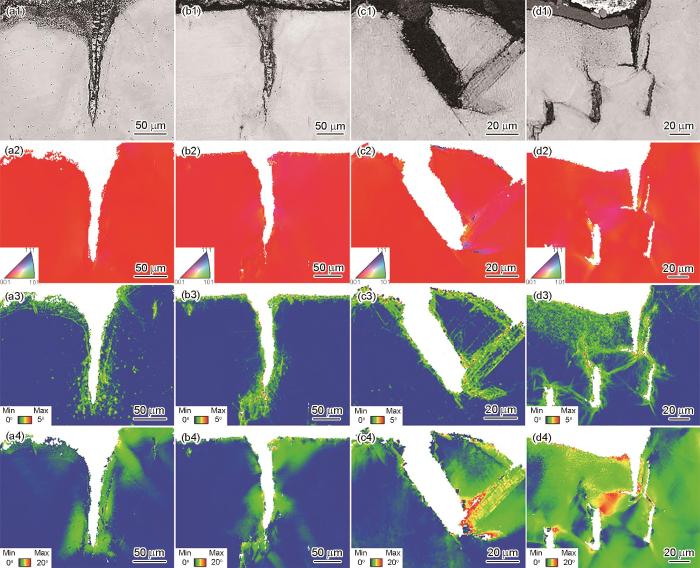

图7为DD91合金在不同应变幅下失效断裂后的表面裂纹形貌及对应的反极图(IPF)、局部取向差(KAM)和晶内参考取向差(GROD)图(对于低应变幅和高应变幅条件下的试样分别选择外表面和断裂表面的特征裂纹进行放大观察)。由图7a1和b1可见,合金在0.5%和0.6%应变幅循环断裂后,外表面的主裂纹尺寸分别超过了200和150 μm,通过对比IPF和KAM图(图7a2、b2、a3、b3),可以看出尽管合金中的裂纹边界处存在一定程度的应力集中,但是其能量储存不足以诱发再结晶晶粒的形成。在IPF中只观察到了<001>取向单晶体(图7a2和b2),对应的GROD图中也未出现明显的局部晶格转向(图7a4和b4)。另外,由于主裂纹尖端所存储的位错密度较高,不同条件下的裂纹尖端均有细小二次裂纹萌生。0.8%应变幅下,在裂纹附近能够观察到平行的滑移迹线(图7c1),且这些滑移线所在位置的KAM和GROD较高(图7c3和c4),表明这些位置存在更为明显的变形和晶格转动。当应变幅升高至0.9%时,在合金断面以下出现了大尺寸裂纹(图7d1),整个试样表面呈现非常高的GROD (图7d4),代表着合金内部发生了严重的塑性变形和晶体转动。特别是在裂纹与裂纹之间的位置,在IPF中已经出现了轻微的晶格取向偏转(图7d3)。但值得注意的是,在高应变幅下断裂后,合金表面仍未出现典型的再结晶晶粒或变形孪晶,因此可以推测,在整个IP-TMF过程中,合金内部的局部能量储存及晶体旋转程度可能不足以诱发再结晶及孪晶的形成。

图7

图7

DD91合金在不同应变幅下IP-TMF失效断裂后的表面裂纹形貌及对应的反极图(IPF)、局部取向差(KAM)和晶内参考取向差(GROD)图

Fig.7

Surface crack morphologies (a1-d1) and corresponding inverse pole figures (IPFs) (a2-d2), kernel average misorientation (KAM) maps (a3-d3), and grain reference orientation deviation (GROD) maps (a4-d4) of DD91 alloy after IP-TMF fracture at strain amplitudes of 0.5% (a1-a4), 0.6% (b1-b4), 0.8% (c1-c4), and 0.9% (d1-d4)

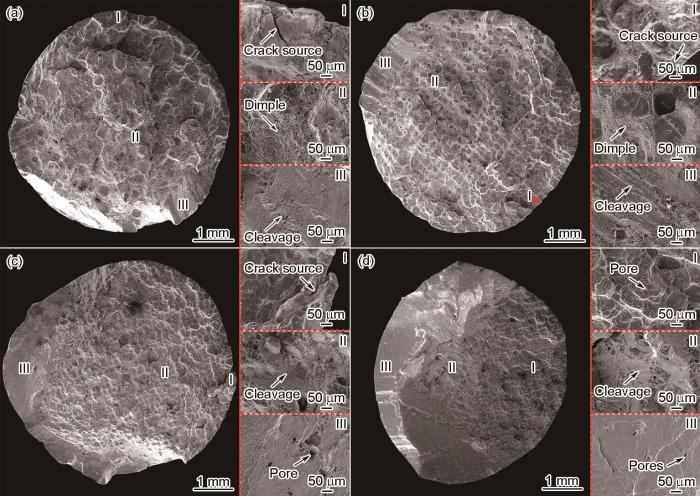

2.3 疲劳断裂特征

DD91合金IP-TMF断裂后的断口形貌如图8所示,其中右侧插图为细节特征放大。整体看来,合金在IP-TMF循环至断裂后,宏观断口主要呈现以韧窝为主导的韧性断裂特征,仅在最终瞬断区等少量位置观察到解理或纯剪切断裂特征。通过对比不同应变幅下的断裂特征可以看出,当应变幅从0.5%升高至0.9%后,韧窝区的面积分数由81.3%下降至39.2%。在应变幅为0.5%时,裂纹源区已完全被氧化层覆盖,说明表面裂纹的萌生及初始扩展速率较慢。裂纹扩展区的形貌与某些单晶高温合金高温蠕变断裂后的特征相似度较高[22,23],在高温半周的拉应力作用下,合金内部微孔处易萌生裂纹并扩展形成小平台。这些平台主要以撕裂棱为边界,且平台之间存在细小韧窝结构,而最终瞬断区出现了少量解理平台(图8a中区域III所示)。0.6%应变幅条件下,裂纹扩展区内小平面的数量大幅提升,韧窝变得更加细密且尺寸分布更加均匀,同时瞬断区内的解理台阶也变得更加密集,如图8b所示。随着应变幅进一步提升至0.8%,裂纹源区的韧窝表面仍然发生了严重的氧化,并且解理台阶已经开始在裂纹扩展区出现,与韧窝共同组成混合断裂特征(图8c)。另外,当裂纹延伸至瞬断区后将会沿{111}面出现失稳扩展,光滑平坦的剪切平面对裂纹的快速扩展没有任何阻碍作用,导致合金在几个循环周次内就发生纯剪切断裂。当应变幅继续增大至0.9%时,宏观上能观察到3个不同的区域,分别为韧窝区(I)、解理区(II)和剪切唇区(III)。同时在剪切唇区(III)观察到不同晶面的分界线,由此可以推断试样最终沿不同{111}平面发生断裂。综上所述,IP-TMF裂纹萌生及扩展区的主要特征并未随应变幅的升高而改变(始终为韧窝特征),但少量解理平台出现的位置由低应变幅下的瞬断区提前至高应变幅下的裂纹缓慢扩展区。

图8

图8

DD91合金在不同应变幅下IP-TMF失效断裂后的断口形貌

Fig.8

SEM images of fracture characteristics of DD91 alloy after IP-TMF fracture failure at mechanical strain amplitudes of 0.5% (a), 0.6% (b), 0.8 (c), and 0.9% (d) (Insets show the typical magnified fracture features at each condition)

2.4 表面氧化产物演化特征

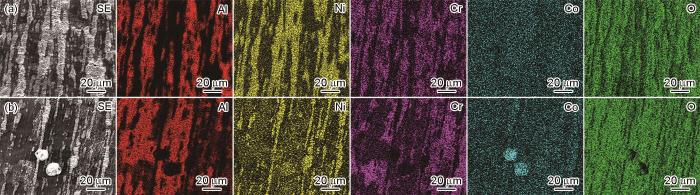

DD91合金在不同应变幅下IP-TMF循环至断裂后的外表面形貌及氧化产物演化特征如图9所示。当应变幅为0.9%时(疲劳寿命56 cyc),合金表面出现富Ni和Co的氧化物及富Al氧化层(图9g),而在高水平的循环应力作用下,它们会局部脱落并在其原来的位置形成大量微裂纹。另外,在试样表面还观察到了NiO颗粒连续堆积而形成的氧化丘(图9h),大尺寸裂纹能够沿着其内部空隙快速扩展,同时引起二次裂纹的萌生。在TMF总寿命提升至210 cyc (应变幅为0.8%)时,合金外表面的NiO堆积现象更加明显,主裂纹在氧化丘处萌生并不断向合金内部扩展,通过高倍SEM观察发现NiO晶粒具有疏松多孔的特征(图9e和f)。在远离氧化丘(NiO)的区域对表面氧化产物进行EDS面扫描分析,结果如图10所示,在此阶段合金表面已形成致密Al2O3层和富Cr氧化层(图10b),以及少量零散分布的富Co氧化球。连续的Al2O3层具有阻碍O2向合金内部扩散的能力[24],表面氧化损伤在一定程度上得到缓解,裂纹的萌生及扩展主要集中在NiO颗粒聚集区。

图9

图9

DD91合金IP-TMF断口外表面形貌及表面氧化产物分布特征

Fig.9

Characteristics of the outer fracture surfaces (a, c, e, g) and surface oxidations (b, d, f, h) in DD91 alloy after IP-TMF fracture at strain amplitudes of 0.5% (a, b), 0.6% (c, d), 0.8% (e, f), and 0.9% (g, h) (Insets show magnified images of oxides)

图10

图10

DD91合金在0.5%和0.8%应变幅IP-TMF疲劳断裂后表面EDS分析

Fig.10

EDS analyses of the oxidized DD91 alloy surfaces after IP-TMF fracture at strain amplitudes of 0.5% (a) and 0.8% (b)

当循环周次达630 cyc (应变幅为0.6%),试样宏观表面开始变得凹凸不平,氧化产物明显堆积,此时NiO颗粒已由疏松多孔结构转为复杂多边形结构,如图9d中插图所示。另一方面,由于合金同时承受循环机械应力和热应力,当内应力积累至一定程度时,微裂纹开始在致密的Al2O3层萌生,并迅速沿{111}<110>系滑移迹线扩展,最终导致Al2O3层从合金表面不断剥落,如图9c和d所示。值得注意的是,不同应变幅试样的表面滑移迹线与<001>方向的夹角基本一致,因此初步判断合金在IP-TMF过程中所开动的主要滑移系并未随应变幅的升高而改变,只是在高应变幅下同一方向上的滑移带分布得更加密集(图9d和h),即合金的变形不均匀程度有所提高。Al2O3层的剥落导致合金基体再一次裸露于空气中,合金进入氧化加速阶段[24],超过1800 cyc后(应变幅为0.5%),合金外表面的粗糙程度明显提升,已基本被NiO层所覆盖(图9a和b)。由于循环时间足够长,NiO晶粒已完全球化,颗粒之间的边界清晰可见。此外,在合金表面不再出现富Co氧化球,仅在局部少量区域观察到了Al2O3层及富Cr氧化层,如图10a所示。

2.5 位错组态演化特征

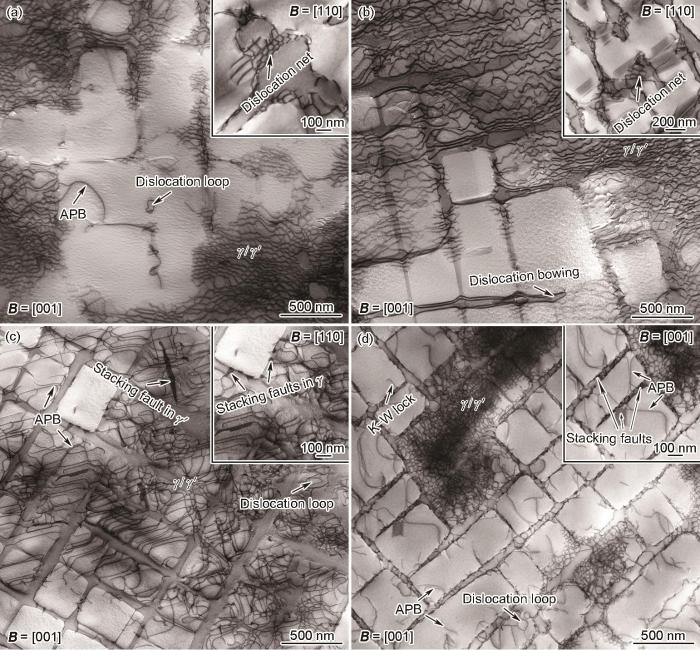

DD91合金在不同应变幅下IP-TMF断裂失效后的特征位错组态如图11所示。可见,当应变幅为0.5%时,γ /γ'界面处已沉积了致密且分布均匀的位错网,尚未消失的基体通道内亦存在一定程度的位错塞积,只有极少量超位错最终切入了γ'相内部,如图11a所示。当应变幅升高至0.6%时,从[001]晶带轴能够观察到立方状γ'相,γ /γ'界面处的位错网络仍然处于演化过程,除少量平直网格线外,大部分位错线呈现锯齿状且分布间距较大[21,25](图11b)。图11a和b插图中进一步放大了2种应变幅下合金[110]面的位错网组态,可以看出随着循环周次的提高,界面位错网已由不规则四边形逐渐转变为六边形形貌。当应变幅进入高水平范围时,最显著的特征是γ'相内部开始出现层错和超位错对(图11c)。应变幅的提升导致基体内大量位错迅速开动并发生反应,然而由于循环寿命较短,合金中界面位错的分布十分离散且形态不规则。另外,合金中γ基体内出现了大量呈60°或90°转向的位错线以及少量的层错,变形组织整体呈典型波状滑移特征。令人意外的是,合金在0.9%应变幅下的微观变形组织相比0.8%应变幅具有明显差异。首先,合金中基体通道及界面位置的位错塞积程度显著提高,而且γ'强化相中层错的出现频率大幅降低;相反,在γ'相中,夹着反相畴界(APB)的位错对的数量明显提升(图11d),表明在此条件下超位错切割γ'相的机制完全占据主导。此外,在不同应变幅IP-TMF循环失效后,合金中出现了特殊的位错环结构,如图11a、c和d所示。这些位错环的形成方式各不相同,分别是在γ基体完全连接、位错网演化以及超位错切割γ'相的过程中形成[10,25,26],而它们对合金剩余疲劳寿命的影响有待进一步的研究。

图11

图11

DD91合金在不同应变幅下IP-TMF断裂后的特征位错组态

Fig.11

Typical dislocation configurations of the DD91 alloy after IP-TMF fracture at strain amplitudes of 0.5% (a), 0.6% (b), 0.8% (c), and 0.9% (d) (Insets show magnified images of special configurations. APB—anti-phase boundary, K-W—Kear-Wilsdorf)

3 分析讨论

3.1 变形组织与IP-TMF行为

在IP-TMF实验中,合金的循环应力响应行为与微观组织及位错组态的演化密切相关。在循环初期,基体位错首先在高温半周开动并不断滑移/交滑移,具有不同Burgers矢量的位错线于γ /γ'界面不断沉积并相遇后,发生复杂位错反应,开始形成位错网并松弛错配应力,导致位错在基体中弓出和运动所需的应力降低[27,28]。因此,当应变幅在0.5%~0.8%范围内时(图4a~c),合金在变形初始阶段都表现出不同程度的拉应力松弛。然而,当应变幅达到0.9%后(图4d),合金所受的最大拉应力接近该温度下合金的屈服强度,γ基体中出现了严重的位错塞积,对位错的滑移和攀移过程起到明显阻碍作用,因此最大拉应力在循环初期反而表现出轻微的加工硬化。而且,在高温及高循环应力的共同作用下,a / 2<101>位错能够交滑移至{100}平面,形成Kear-Wilsdorf锁来进一步抑制剩余位错在{111}滑移面上的运动(图11d所示),这种机制也会对合金的初始循环硬化有一定的贡献[29]。当合金进入低温半周循环时,由于热激活程度降低,位错的开动会在一定程度上受到限制,且在高温半周形成的位错网格能够与低温半周位错发生相互反应并缠结,进而阻碍其滑移过程,最终导致最大压应力不断升高。而且,a / 2<101>基体位错在低温半周难以通过攀移或交滑移的方式运动,这也进一步促进了循环硬化过程。比较特殊的是在0.9%应变幅下,压应力在应变幅达到最大值之前已进入屈服平台,此时高温半周形成的界面位错不足以限制低温半周位错在基体通道内的运动(图11d中γ基体内出现许多单根位错线),因此在响应曲线中并未观察到最大压应力的硬化现象。

3.2 不同应变幅IP-TMF变形及损伤机制

合金在低应变幅下的疲劳变形机理相对单一,在0.5%应变幅下,基体位错难以克服γ'强化相以及界面位错网的阻碍作用,位错主要在基体中运动,在循环后期以Orowan绕越机制通过γ'相。当应变幅小幅提升后,由于总疲劳寿命降低导致界面位错网格未能充分演化,大部分呈现锯齿状形态(图11b)。考虑到合金在高温半周受拉应力作用,可以认为这些锯齿状位错线主要是在高温蠕变过程中,由互相垂直的a / 2<110>位错在界面沉积并发生位错反应形成,且优先形成的60°界面位错会进一步发生滑移-攀移运动,演变为可动性较差的90°界面位错[32]。另外,在0.6%应变幅下,位错线能够更容易地在γ通道内不断弓出(图11b),但γ'相中的缺陷数量仍然十分有限,说明合金的变形机制仍然为{111}<110>系位错在基体中开动并滑移,并以绕过或者攀移的方式通过强化相。可以发现,在低应变幅下,在γ'相被破坏之前合金就已经在热应变和机械应变导致的其他损伤作用下出现了断裂失效。不同于低应变幅条件,合金在高应变幅下断裂失效后γ'相内的缺陷数量大幅提高,表明强化相抵抗塑性变形的能力已显著降低,合金的疲劳失效过程不断加速。在0.9%应变幅下,合金中超位错对的数量明显提升,主要是由于在应变幅升高后,合金在高温半周承受的最大拉应力提升约180 MPa,而平均压应力未发生明显变化。在等同的压应力下,更高的拉应力使得低温半周分解出的a / 3<112>不全位错更倾向于束集成a / 2<110>位错而不是切入γ'相中,致使大量a / 2<110>位错在γ /γ'界面结合成a<110>超位错对并切入强化相中[33,34],即超位错切割机制完全占据主导。

在损伤机制方面,DD91合金在不同应变幅下疲劳断裂后的外表面最长裂纹尺寸及内部裂纹(距离断面1 mm以内区域)数量如表1所示。当应变幅为0.5%和0.6%时,合金外表面最长裂纹尺寸均超过150 μm,主要是由于IP-TMF循环过程中,NiO晶粒在试样表面迅速形核并不断演化,但NiO层的整体致密度不足,外界O2可以通过NiO晶界之间的缝隙不断向合金内部扩散,导致裂纹在样品表面不断萌生[35]。虽然裂纹尖端在压应力的作用下会趋于闭合,但在下一个循环的高温拉应力的作用下,处于愈合过程的裂纹又会重新张开,并不断向合金内部扩展[36]。因此,即使合金表面形成致密的Al2O3层对新裂纹的萌生有一定的抵抗作用,也无法有效抑制已有裂纹的不断氧化与扩展。随着疲劳周次的延长,Al2O3层在循环应力作用下开始发生剥落,无法有效阻碍O2的内扩散,使得O2进一步接触到未被氧化的合金基体,从而加速氧化裂纹的扩展并加剧合金所承受的氧化损伤[24,37]。另外,在合金内部同时也出现了一定数量的裂纹(表1),结合合金断口形貌特征(图8a和b),可以认为它们是在高温蠕变过程中由微孔聚集而形成的。当应变幅升高至0.8%和0.9%后,合金中外表面的最长裂纹尺寸大幅下降至50 μm以下(表1),即合金所承受的高温氧化损伤减轻。相反,高应变幅条件下,在合金内部由塑性变形引起的疲劳裂纹启裂数量较低应变幅条件明显提升,表明合金开始承受相当的塑性变形损伤。综上所述,在低应变幅条件下,合金中疲劳裂纹的主要启裂形式为氧化产物开裂致裂纹萌生,合金主要承受氧化损伤并伴随一定程度的蠕变损伤;而在较高应变幅下,裂纹的主要启裂形式转变为塑性变形致裂纹萌生,合金外表面最长裂纹尺寸大幅下降,塑性变形损伤逐渐占据主导而氧化损伤程度有所减轻。

表1 DD91合金在不同应变幅下IP-TMF断裂后的外表面最长裂纹尺寸及内部裂纹数量

Table 1

| Strain amplitude % | Maximum crack size on outer surface / μm | Number of internal crack (Within 1 mm from crack surface) |

|---|---|---|

| 0.5 | 210.92 | 32 ± 3 |

| 0.6 | 151.42 | 35 ± 4 |

| 0.8 | 27.29 | 58 ± 5 |

| 0.9 | 49.10 | 88 ± 7 |

4 结论

(1) 应变幅为0.5%和0.6%时,DD91合金在高温半周和低温半周分别展现出拉应力循环软化和压应力循环硬化,当应变幅升高至0.8%和0.9%时,循环应力响应行为呈现以循环稳定为主导的特征。随应变幅的升高,合金IP-TMF寿命大幅下降,迟滞回线明显张开。

(2) 合金IP-TMF断口整体呈韧性断裂特征,且随应变幅的提高,韧窝区的面积分数不断下降,解理平台出现的位置由瞬断区提前至裂纹缓慢扩展区。在低应变幅条件下,疲劳裂纹的主要启裂形式为表面氧化产物开裂致裂纹萌生;而在较高应变幅下,疲劳裂纹的主要启裂形式转变为塑性变形致裂纹萌生,并伴随少量小尺寸的表面氧化裂纹萌生。

(3) 随应变幅的升高,IP-TMF主要变形机制由Orowan绕越γ'相,逐渐转变为a / 2<110>界面位错以生成SF或APB的形式切割γ'相。在等同压应力作用下,合金在0.9%应变幅下所受的平均拉应力较0.8%应变幅明显升高,促进了a / 3<112>不全位错束集成a / 2<110>全位错,超位错切割γ'相的变形机制完全占据主导。

(4) 在0.5%~0.9%应变幅下疲劳断裂失效后,合金内部均未出现特征再结晶晶粒和变形孪晶。

参考文献

Effects of sand blasting on surface integrity and high cycle fatigue properties of DD6 single crystal superalloy

[J].DD6 is a second generation single crystal superalloy independently developed in China, which offers advantages such as high-temperature strength, stable structure, and satisfactory casting process performance. Currently, it is being widely used in development of aviation engine turbine blades. Sand blasting can be performed for surface cleaning and adjusting surface roughness of single crystal turbine blades and is an essential process in manufacturing of single crystal blades. Although sand blasting has been widely used in the manufacturing process of DD6 alloy turbine blades, only few reports studied the impact of sand blasting on the surface integrity and fatigue performance of DD6 alloy. Therefore, research is required to provide a theoretical basis for the safe service of DD6 alloy turbine blades. In this work, several specimens after a standard heat treatment are blasted with white corundum sand with 150, 124, and 100 μm diameters at 0.5 MPa to study the effect of sand blasting on the surface integrity of DD6 alloy; the rotary bending high cycle fatigue properties of the specimens without and with sand blasting (blasting with white corundum sand with 150 μm diameter) were tested at 760 and 980oC, respectively, to study the effect of sand blasting on the alloy's fatigue property. The results show that sand blasting destroys the surface integrity of the single crystal superalloy, resulting in irregular pits on the surface caused by the cutting by sand particles while changing the surface morphology as well; the surface roughness and microhardness increase with sand particle size increase; after sand blasting, many dislocations slip in the γ phase, and the dislocation density near the surface is high. Additionally, many dislocations shear the γ′ phase, forming antiphase domain boundaries and stacking faults; sand blasting results in deformation strengthening and residual stress; blasting with 150 μm diameter sand at 0.5 MPa has a small effect on the rotary bending high cycle fatigue properties of DD6 alloy at 760oC, but it considerably reduces the alloy's fatigue properties at 980oC in the low stress amplitude region, decreasing the fatigue strength of the alloy by 7.3%. The combined action of the notch effect, oxidation damage, deformation strengthening, and residual compressive stress leads to the changes in fatigue life without and with sand blasting.

吹砂对DD6单晶高温合金表面完整性和高周疲劳强度的影响

[J].将标准热处理的试样分别采用粒径为150、124和100 μm白刚玉砂在0.5 MPa压力下吹砂,研究吹砂对第二代单晶高温合金DD6表面完整性的影响;对未吹砂和粒径150 μm吹砂试样分别进行760和980℃旋转弯曲高周疲劳性能测试,研究吹砂对DD6合金疲劳性能的影响。结果表明:吹砂会破坏单晶高温合金的表面完整性,使表面出现砂粒切削造成的不规则凹坑,改变表面形貌;砂粒粒径增加,表面粗糙度和显微硬度均增大;吹砂使大量位错在γ相通道中滑移,靠近表面区域位错密度较大;并且,大量位错剪切γ'相,形成反相畴界和层错;吹砂造成形变强化、引入残余应力;150 μm、0.5 MPa吹砂对DD6合金760℃旋转弯曲疲劳性能基本无影响,但会降低合金980℃疲劳性能,对低应力幅区疲劳寿命影响较大,使疲劳强度下降约7.3%。缺口效应、氧化损伤、形变强化和残余压应力的耦合作用导致吹砂与不吹砂试样疲劳寿命产生差异。

Recent progress in research and development of nickel-based single crystal superalloys

[J].Single crystal Ni-based superalloys are key materials used in the hot section of aeroengines and industrial gas turbines. In service, single crystal blades face harsh environments, including high temperatures, complex stresses, oxidation and hot corrosion. Therefore, they must meet strict technical specifications, such as impurity, defects and dimensional control. Single crystal components should be manufactured using complex technologies within a highly narrow processing window. The present paper reviews recent progress in the research and development of alloy design, microstructure and property evolution and characterization, evaluation in near-service conditions, and single crystal manufacture. Further, the development of “next generation” high-temperature structural materials, such as refractory high-entropy alloys, is briefly discussed.

镍基单晶高温合金的研发进展

[J].

Thermal-stress coupling effect on microstructure evolution of a fourth-generation nickel-based single-crystal superalloy at 1100oC

[J].

热力耦合对一种第四代镍基单晶高温合金1100℃蠕变组织演变的影响

[J].

In situ SANS investigation of the kinetics of rafting of γ′ precipitates in a fourth-generation single-crystal nickel-based superalloy

[J].

Slip geometry of dislocations related to cutting of the γ′ phase in a new generation single-crystal superalloy

[J].

The effect of Re and Ru on γ /γ′ microstructure, γ-solid solution strengthening and creep strength in nickel-base superalloys

[J].

Recrystallization during thermo-mechanical fatigue of two high-generation Ni-based single crystal superalloys

[J].Ni-based single crystal superalloys are widely used for turbine engine blades because of their excellent high-temperature mechanical properties. Thermo-mechanical fatigue (TMF) is a complex deformation process that combines strain and temperature effects. This process is also considered as a deformation method related to the working conditions of aviation turbine blades. Therefore, understanding the deformation mechanism of materials undergoing TMF is important for extending the service life of aviation turbine blades. Here, third-generation and fourth-generation single crystal superalloys that experienced TMF deformation are investigated by SEM and TEM, including aberration-corrected STEM. The results show the formation of deformation twins on different {111} planes of the single crystal superalloys. In addition, a large number of recrystallized grains are found in parallel twin lamellae or around the intersection of twin lamellae. The grain boundary of recrystallized grains is primarily composed of twin boundaries, low-angle grain boundaries, and large-angle grain boundaries generated by twin intersections. Furthermore, the twinning boundaries after deformation are analyzed using aberration-corrected TEM. Consequently, the process of twinning-induced dynamic recrystallization is comprehensively understood, which improved the TMF fracture mechanism of single crystal high-temperature alloys. These results improve the understanding of the deformation mechanism of single crystal superalloys under service conditions.

两种高代次镍基单晶高温合金热机械疲劳中的再结晶行为

[J].

Investigation on low cycle fatigue behaviors of the [001] and [011] oriental single crystal superalloy at 760oC

[J].

Influences of Re on low-cycle fatigue behaviors of single crystal superalloys at intermediate temperature

[J].Low-cycle fatigue behaviors of Ni-base single crystal superalloys containing different Re contents have been investigated at 760 °C. During heat treatment, Re retards γ′ phases coarsening and equalizes the distribution of γ′ phases. As Re content increases, fatigue life increases and slip bands distribute more inhomogeneously. Moreover, adding Re not only reduces stacking fault energy of the matrix, but also promotes the element segregation to increase the lattice misfit. However, the larger lattice misfit does not lead to the formation of dislocation networks, but which activates dislocation movement and promotes dislocations cross-slip and climbing movement under high temperature and applied stress. On the other hand, with the addition of Re, cyclic deformation behaviors change from cyclic hardening to cyclic stability, mainly depending on a transformation of deformation mechanisms from slip bands cutting through γ and γ′ phases to stacking faults shearing.

Thermo-mechanical fatigue behavior of a single crystal nickel-based superalloy

[J].

Deformation and damage mechanisms during thermal-mechanical fatigue of a single-crystal superalloy

[J].

Deformation twins and failure due to thermo-mechanical cycling in TMS-75 superalloy

[J].

Significant thinning of deformation twins and its effect on thermomechanical fatigue fracture in nickel base single crystal superalloys

[J].

Deformation twinning and twinning-related fracture in nickel-base single-crystal superalloys during thermomechanical fatigue cycling

[J].

Influence of Ru on the thermomechanical fatigue deformation behavior of a single crystal superalloy

[J].

Experiment on thermomechanical fatigue in nickel based single crystal superalloy DD6

[J].

镍基单晶高温合金DD6热机械疲劳试验

[J].

In- and out-of-phase thermomechanical fatigue of a Ni-based single-crystal superalloy

[A].

Thermo-mechanical fatigue behaviours of DD8 single crystal nickel base superalloy

[J].

DD8单晶镍基高温合金的热机械疲劳

[J].对DD8合金进行了同位相(IP)与反位相(DP)热疲劳(TMF)实验.结果表明:当以机械应变幅作为参量时,在高应变幅下,IP疲劳寿命均低于OP的寿命;随着应变幅的降低,IP疲劳寿命有向OP寿命靠近的趋势.扫描电镜观察表明,IP和OP TMF 试样的断口形貌有明显的不同.在IP实验中,裂纹萌生于试样内的铸造孔洞,垂直于加载轴方向扩展;而OP裂纹则是萌生于试样的自由表面,沿着{111}晶面扩展.不同的裂纹萌生和扩展机制是导致IP和OP TMF 寿命差异的主要原因.

A study on thermo mechanical fatigue life prediction of Ni-base superalloy

[J].

High temperature thermo-mechanical and low cycle fatigue behaviors of DD32 single crystal superalloy

[J].

The effect of thickness on the creep properties of a single-crystal nickel-based superalloy

[J].

Microstructure of recrystallization and their effects on stress rupture property of single crystal superalloy DD6

[J].The specimens of single crystal superalloy DD6 were grit blasted and heat treated at 1100, 1200, and 1300 ℃ for 4 h at vacuum atmosphere respectively, then the microstructure of recrystallized DD6 alloy and their effects on the stress rupture performance were investigated. The results showed that cellular recrystallization nucleated in grit blasted samples heat treated at 1100 ℃ for 4 h, the dislocation tangles were found in the front of cellular recrystallization grain boundary in DD6 alloy, equiaxed recrystallization grains nucleated in grit blasted samples heat treated at 1300 ℃ for 4 h, and the carbides precipitate at the equiaxed recrystallization grain boundary, while the coexistence of equiaxed recrystallization grains and cellular recrystallization, defined as mixed recrystallization, occurred in the grit blasted samples heat treated at 1200 ℃ for 4 h. The cellular recrystallization reduced the stress rupture lives of DD6 alloy slightly, and the equiaxed recrystallization reduced stress rupture lives seriously, while the reduction degree of the stress rupture lives of the mixed recrystallization was between cellular recrystallization and equiaxed recrystallization. Besides this, with increase of depth of recrystallization and stress, the stresses rupture life decreased. It was also found that the fracture surface configuration was belonging to intergranular fracture with equiaxed recrystallization samples. The characteristic of the fracture surface changed to dimple fracture with cellular recrystallization samples, at all these condition the crack nucleated on the recrystallization grain boundaries of specimens during stress rupture process.

单晶高温合金DD6再结晶组织及其对持久性能的影响

[J].对单晶高温合金DD6进行表面吹砂处理, 然后分别在1100, 1200和1300 ℃保温4 h, 研究了不同加热条件下DD6合金的再结晶组织及其对持久性能的影响. 结果表明, DD6合金吹砂试样1100 ℃加热4 h形成胞状再结晶组织, 胞状再结晶晶界前沿的基体中存在大量的位错缠结, 合金的持久寿命略微降低; 1200 ℃加热4 h形成胞状再结晶与等轴再结晶同时存在的混合型再结晶组织, 合金的持久寿命降低; 1300 ℃加热4 h形成等轴再结晶组织, 等轴再结晶晶界上发现碳化物析出, 合金的持久寿命严重降低. 带有等轴再结晶组织的持久试样的断口形貌为沿晶断口, 带有胞状再结晶组织的持久试样的断口形貌为韧窝断口, 带有再结晶组织的试样裂纹起源于再结晶晶界.

Oxidation behavior of a novel nickel-based single crystal superalloy at elevated temperature

[J].

Influence of the γ′ fraction on the γ /γ′ topological inversion during high temperature creep of single crystal superalloys

[A].

Investigations on the thermo-mechanical fatigue of two Ni-based single-crystal superalloys

[J].

Interfacial dislocation motion and interactions in single-crystal superalloys

[J].

Calculation of the internal stresses at the γ /γ′ interface of DD8 single crystal nickel base superalloy after thermomechanical fatigue

[J].

DD8单晶镍基高温合金热机械疲劳后γ /γ′界面位错网产生内应力的计算

[J].

Temperature dependence of compressive behavior and deformation microstructure of Ni-based single crystal superalloy with low stacking fault energy

[J].

Dependence of stacking faults in gamma matrix on low-cycle fatigue behavior of a Ni-based single-crystal superalloy at elevated temperature

[J].

Effect of ruthenium on compressive creep of Ni-based single-crystal superalloy

[J].

SEM investigation of interfacial dislocations in nickel-base superalloys

[J].

Tension/compression asymmetry in yield and creep strengths of Ni-based superalloys

[A].

Localized microtwin formation and failure during out-of-phase thermomechanical fatigue of a single crystal nickel-based superalloy

[J].

Effect of rhenium addition on isothermal oxidation behavior of single-crystal Ni-based superalloy

[J].

Oxidation assisted thermomechanical fatigue failure of polycrystalline superalloys

[J].Thermomechnical fatigue (TMF) failure of Nimonic 90, a polycrystalline superalloy, has been investigated under out of phase (OP), in phase (IP) and counterclockwise (CCD) tests. The tests have been carried out in a temperature range of 400–850°C and mechanical strain range of ±0·4%. One IP test has been carried out at a lower strain range of ±0·3%. The TMF lives are greatly affected by the TMF cycle profiles. The shortest TMF life was recorded for the IP test, whereas the longest was recorded for the OP test at the same strain level. Detailed investigation of the micromechanisms of deformation highlighted that γ′ coarsening rate during the IP test was much higher than the other tests and that this was consistent with a faster stress drop during the course of the TMF test. In addition the γ′ coarsening rate was greater for both tests than that occurring during simple thermal cycling of the alloy over the same temperature range but without load. However the more important factor determining the shorter life of the IP test compared with the OP test is related to the initiation and propagation of the failure crack in the two samples. The IP samples showed both initiation and propagation at grain boundaries while the OP test revealed grain boundary initiation followed by an intragranular propagation mode. Measurements conducted on the microcrack size revealed a much higher microcrack growth rate during the IP test. It is likely that the tensile strain during the high temperature part of the IP cycle accelerates oxygen diffusion and thus increases grain boundary oxidation at the tips of microcracks, shortening IP life.

Oxidation behavior of a single-crystal Ni-base superalloy between 900 and 1000oC in air

[J].

Thermal-mechanical fatigue behaviour of a new single crystal superalloy: Effects of Si and Re alloying

[J].

Deformation and damage mechanisms during thermomechanical fatigue of a single-crystal superalloy in the <001> and <011> directions

[A].