为实现汽车轻量化并提高汽车的碰撞安全性,热成形钢因其高强度和易成形性而在汽车中得到广泛应用。热成形钢的生产工艺流程是将冷轧退火板放进900~950℃的加热炉中保温3~5 min进行奥氏体化,然后通过机械手将板料转移到模具中进行保压成型。带有水冷循环系统的模具使零件快速冷却至马氏体相变结束温度以下,使其组织由奥氏体转变为全马氏体,从而获得超高强度的零件[1,2]。但传统热成形钢生产使用的辊道炉占地面积大、加热时间长、能耗和排放均很高。为提高生产效率并降低能耗,加热速率最高达1000℃/s的电阻加热和感应加热等闪速加热方法日益受到重视[3]。闪速加热工艺最初应用于钢的表面硬化处理,后逐步在冷轧薄板中展开研究,其特征为快热快冷中间尽可能不经历保温。就研究对象而言,该工艺最早应用于奥氏体不锈钢中,后在先进高强钢中的应用和研究日益增多。闪速加热工艺不仅大幅减少了奥氏体化所需时间,提高了效率、降低了能耗,还具备改善汽车用钢力学性能的潜力[4]。目前,许多学者研究了闪速加热对相变诱导塑性(TRIP)钢[5]、中锰钢[6,7]、无间隙原子(IF)钢[8]以及淬火和配分(Q&P)钢[9]的影响,结果表明,加热速率会影响钢的晶粒尺寸、相变动力学、微观结构等,进而对最终产品的强度和塑韧性产生显著影响[5~7]。

目前广泛应用的热成形钢钢种为22MnB5,其抗拉强度约为1500 MPa,但延伸率较差,强塑积仅为5~15 GPa·% [10,11],已无法满足汽车行业日益发展的车身轻量化和高碰撞安全性要求,因此需要在22MnB5钢的基础上进一步提高汽车用钢的强度和强塑积,因而2000 MPa级热成形钢的研发受到广泛重视[3,12,13]。然而,目前所开发的2000 MPa级热成形钢普遍存在塑性较低的问题[2,3,14],且相关研究集中在成分、加热温度及保温时间等对力学性能的影响[2,15~17],而很少关注加热过程。闪速加热作为一种新兴的热处理手段,具有简单高效的工艺优势和显著的强化效果,本工作将闪速加热工艺引入到热成形钢的热处理过程中,研究了该工艺对新型2000 MPa级热成形钢显微组织和力学性能的影响,通过闪速加热工艺进一步提升其强度和塑性,并与传统加热工艺进行对比,阐述了影响2000 MPa级热成形钢力学性能的关键组织与工艺因素。

1 实验方法

实验用热成形钢化学成分(质量分数,%)为:C 0.37,Si 1.58,Mn 1.47,Cr 0.6,Nb 0.06,Al 0.05,Fe余量。经感应炉熔炼并浇铸成铸坯,加热至1200℃后热锻至截面尺寸为100 mm × 60 mm的板坯。将该板坯加热至1200℃并保温1 h,然后热轧至厚度4 mm,终轧温度不低于850℃且每道次压下量不大于30%,热轧后空冷到室温。热轧板在700℃下进行1.5 h的软化退火后空冷至室温,酸洗后冷轧至厚度1.7 mm。一部分冷轧板使用Gleeble 1500热模拟机进行闪速加热,以150℃/s的加热速率分别加热至850、900和950℃并保温5 s之后水淬,然后在150℃下回火20 min (样品分别记为FH850、FH900和FH950);另一部分冷轧板采用常规加热,即在马弗炉(平均加热速率约为10℃/s)中加热至相同温度并保温3 min后水淬,之后同样在150℃下回火20 min (样品分别记为CH850、CH900和CH950),样品制备和模拟热成形工艺示意图如图1a所示。

图1

图1

热成形钢制备工艺及闪速加热(FH)和常规加热(CH)模拟热成形工艺流程示意图以及热成形钢加热和冷却时的膨胀曲线

Fig.1

Schematic of the manufacturing processes of hot stamping steel, including flash heating (FH) and conventional heating (CH) processes (a), and the dilatation curves of hot stamping steel during the heating and cooling process (b) (Ac1 and Ac3 are the temperatures for austenite transformation to start and finish during heating, respectively; Ms and Mf are the temperatures for martensite transformation to start and finish during cooling, respectively)

通过Thermo-Calc热力学软件计算得出该钢的相变下临界点温度(Ae1)和上临界点温度(Ae3)分别为720和806℃。通过DIL805A/D型热膨胀相变仪(DIL)测得该钢在5℃/s加热速率下的奥氏体转变开始温度(Ac1)和奥氏体转变结束温度(Ac3)分别为735和835℃,加热至900℃保温5 min后再以40℃/s的速率冷却时,测得马氏体相变开始温度(Ms)和结束温度(Mf)分别为315和165℃,如图1b所示。热处理后的冷轧板沿轧制方向加工出标距为10 mm的拉伸试样,以0.4 mm/s的拉伸速率在WDW-200C型拉伸机上进行室温拉伸实验。通过JSM-6701F型场发射扫描电子显微镜(SEM)和电子背散射衍射仪(EBSD)以及Auger探针、JEM-2200FS型透射电子显微镜(TEM)和能谱仪(EDS)、D8 DISCOVER A25型X射线衍射仪(XRD)等对样品组织进行表征,其中SEM样品经过标准磨抛后在4% (体积分数)硝酸酒精中侵蚀;XRD和EBSD样品经过标准磨抛后在15% (体积分数)高氯酸酒精溶液中以20 V电压进行电解抛光;TEM样品首先机械减薄至厚度50 μm、然后冲出直径为3 mm的薄圆片,之后在-20℃的5% (体积分数)高氯酸酒精溶液中进行电解双喷减薄。

2 实验结果

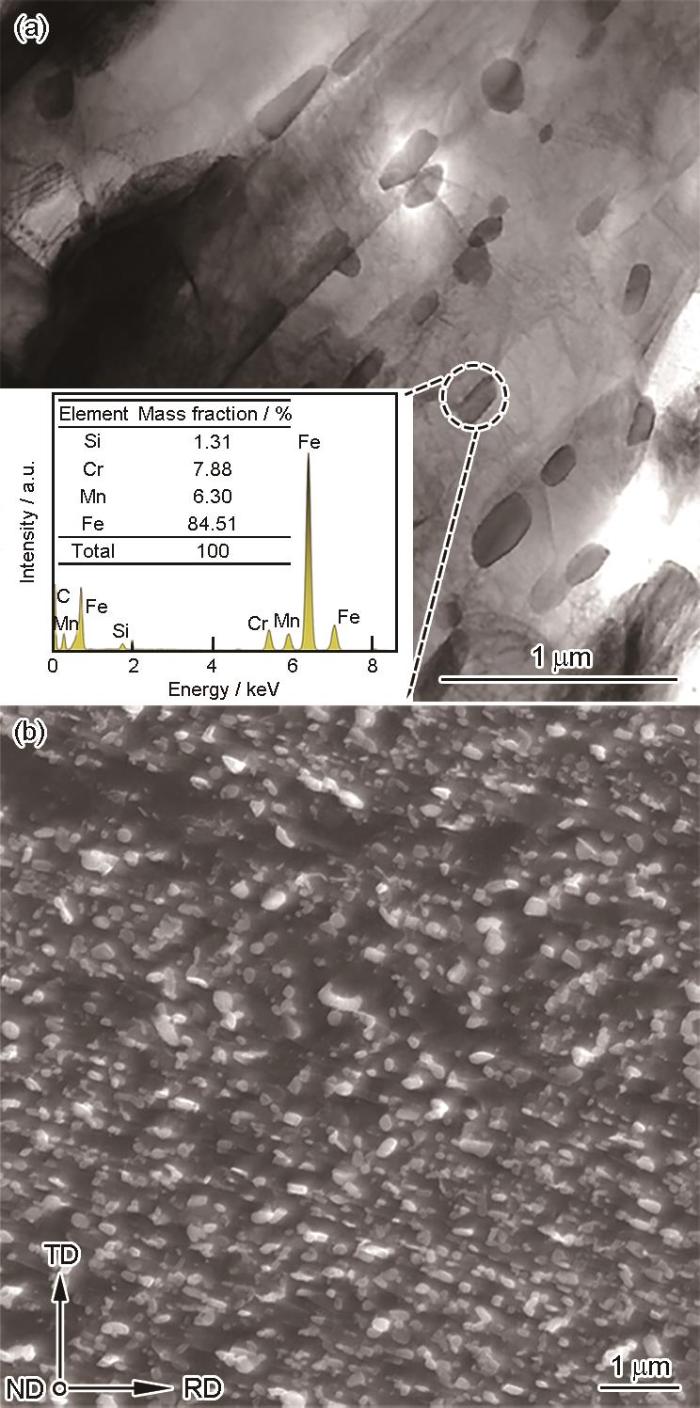

图2

图2

热轧退火板的TEM像和渗碳体EDS分析及冷轧板的SEM像

Fig.2

TEM image of the hot-rolled and annealed steel (Inset shows the EDS compositional analysis of cementite) (a) and SEM image of the cementite in the cold-rolled state (TD—transverse direction, RD—rolling direction, ND—normal direction) (b)

2.1 力学性能

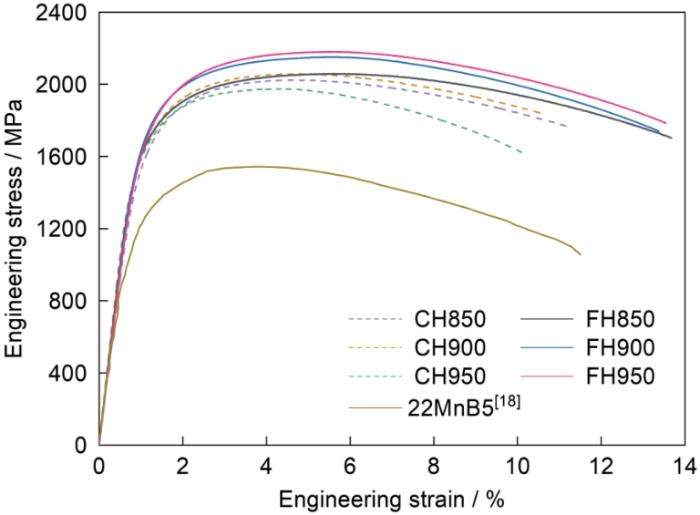

图3给出了热成形钢以不同速率加热至不同温度淬火后得到的工程应力-应变曲线,并与文献[18]中在相同标距下22MnB5钢的应力-应变曲线进行对比。可见,闪速加热工艺下热成形钢拉伸性能明显优于常规加热工艺,且均显著优于常规加热的22MnB5钢。各工艺下热成形钢和22MnB5钢[18]的力学性能如表1所示。可见,在相同加热温度下,闪速加热样品的抗拉强度(UTS)、屈服强度(YS)和总延伸率(TE)均显著高于常规加热样品,实现了强度、塑性的同步改善。常规加热样品的UTS和YS随加热温度的升高先略有增加后显著减小,而闪速加热样品的UTS和YS随着温度的升高而显著增加,导致2种工艺下强度差随着加热温度的升高而增加。常规加热样品的延伸率随加热温度的升高持续减小,而闪速加热样品的延伸率则基本不变。常规加热样品的强塑积随温度的升高逐渐降低,而闪速加热则呈相反趋势。当加热温度为950℃时,闪速加热样品获得最佳的力学性能,其UTS、YS和TE分别达到了2180 MPa、1675 MPa和13.7%;较常规加热样品分别提升了205 MPa、190 MPa和3.6%;而与22MnB5钢相比,则分别提高了610 MPa、545 MPa和2.2%。

图3

表1 经不同工艺制备的热成形钢和22MnB5钢[18]力学性能总结

Table 1

| Specimen | YS / MPa | UTS / MPa | TE / % | Product of UTS and TE / (GPa·%) |

|---|---|---|---|---|

| 22MnB5[18] | 1130 | 1570 | 11.5 | 13.0 |

| CH850 | 1540 ± 20 | 2025 ± 30 | 11.1 ± 0.2 | 22.4 |

| CH900 | 1555 ± 22 | 2050 ± 35 | 10.6 ± 0.3 | 21.7 |

| CH950 | 1485 ± 28 | 1975 ± 25 | 10.1 ± 0.3 | 19.9 |

| FH850 | 1590 ± 26 | 2070 ± 30 | 13.7 ± 0.2 | 28.4 |

| FH900 | 1655 ± 21 | 2155 ± 20 | 13.4 ± 0.2 | 28.9 |

| FH950 | 1675 ± 25 | 2180 ± 25 | 13.7 ± 0.4 | 29.9 |

2.2 微观组织

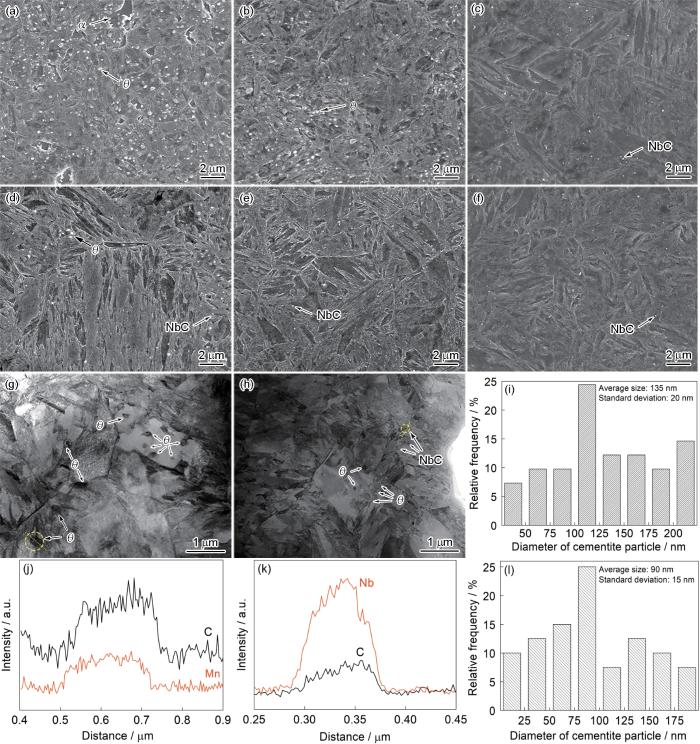

图4a~f为不同热成形工艺下热成形钢微观组织的SEM像。当加热温度为850℃时,闪速加热样品的微观组织主要由马氏体基体及其上大量弥散分布的渗碳体颗粒(θ)以及少量铁素体晶粒(α)组成(图4a),通过TEM像(图4g)统计渗碳体平均尺寸为(135 ± 20) nm,尺寸分布如图4i示;由于冷轧和热成形工艺后保留的渗碳体是直接由热轧退火板中继承而来,因此渗碳体中Mn含量(质量分数,下同)仍为6%~7% (图2a),显著高于基体中Mn含量。而常规加热样品中马氏体基体上所分布的渗碳体数量明显较少,且可观察到细小的NbC粒子,平均尺寸为(90 ± 15) nm (图4d)。加热温度为900℃时,从图4b可见,闪速加热样品基体组织依然为马氏体,铁素体组织消失,渗碳体颗粒数量较850℃样品明显减少,且平均尺寸减小至(90 ± 15) nm (图4h),其尺寸分布如图4l所示,而常规加热样品为全马氏体组织,其上分布着细小的NbC (图4e);加热温度为950℃时,闪速和常规加热样品的组织均为全马氏体,渗碳体均消失(图4c和f),但在闪速加热样品中可观察到更多平均尺寸为(65 ± 10) nm的NbC (图4c)。渗碳体、NbC均是在热轧板软化退火过程中析出的,由于闪速加热保温时间远短于常规加热,部分渗碳体来不及固溶而被保留下来,而NbC的固溶温度为1300℃,在图4g和h黄色圆圈中渗碳体和NbC的EDS线扫描结果分别如图4j和k所示。FH850样品上分布一定量的铁素体是因为高加热速率会提高材料的Ac3[7,19],且保温时间短,少量的铁素体来不及逆相变而保留下来,而大量未溶的渗碳体也导致马氏体硬度下降,这些均导致FH850样品强度较低。

图4

图4

热成形钢闪速加热和常规加热至不同温度后形成的组织与析出相

Fig.4

Microstructures and precipitates formed in the hot stamping steels subjected to both the flash heating and conventional heating to 850, 900, and 950oC

(a-c) SEM images of FH850 (a), FH900 (b), and FH950 (c) specimens (α and θ represent ferrite and cementite, respectively)

(d-f) SEM images of CH850 (d), CH900 (e), and CH950 (f) specimens

(g-i, l) TEM images (g, h) and statistical size distributions of cementite particles (i, l) in FH850 (g, i) and FH900 (h, l) specimens

(j, k) EDS linear composition measurements on cementite in FH850 (j) and NbC in FH900 (k) indicated by yellow circles in Figs.4g and h, respectively

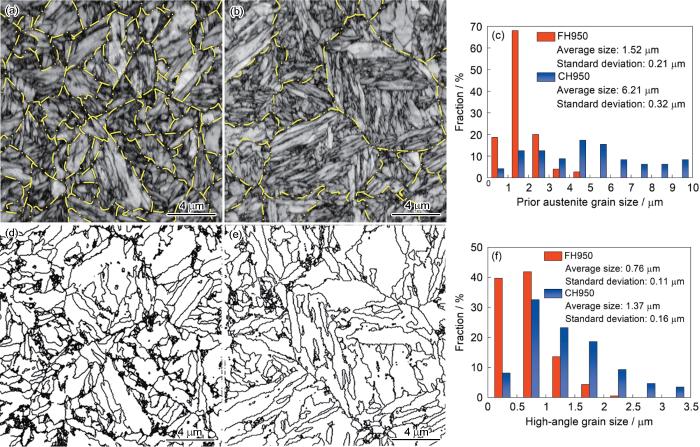

图5a和b分别为FH950和CH950样品组织的EBSD质量图与原奥氏体晶界的叠加图,其中将取向差为20°~50°的晶界定义为原奥氏体晶界[18]。可见,闪速加热样品的原奥氏体晶粒尺寸明显更小。图5d和e分别为FH950和CH950样品中取向差> 15°的大角度晶界EBSD像(包括原奥氏体晶界、马氏体束界和马氏体块界)。大角度晶界可对位错滑移运动起到阻碍作用并导致位错塞积,因此将原奥氏体晶界和马氏体束/块界等大角度晶界均考虑进去后所得到的由大角度晶界构成的晶粒尺寸才符合Hall-Petch晶粒细化强化机制[20,21]。图5c和f分别是采用线截距法测得的FH950和CH950样品的原奥氏体晶粒和大角度晶粒尺寸统计分布图。FH950样品的平均原奥氏体晶粒和大角度晶粒尺寸分别为(1.52 ± 0.21)和(0.76 ± 0.11) μm,而CH950样品则分别为(6.21 ± 0.32)和(1.37 ± 0.16) μm。不同热成形工艺样品的平均原奥氏体晶粒和大角度晶粒尺寸统计结果列于表2。可以看出,闪速加热样品的原奥氏体晶粒和大角度晶粒尺寸均显著小于常规加热样品,且随着温度的升高,常规加热样品的原奥氏体晶粒尺寸显著增加,而闪速加热样品几乎没有变化,这是因为闪速加热下奥氏体晶粒尺寸主要由形核数量决定[4,6],而闪速加热大幅增加了奥氏体形核率,导致晶粒显著细化。

图5

图5

FH950和CH950样品的EBSD质量图和原奥晶界叠加图、大角度晶界EBSD像及原奥氏体晶粒和大角度晶粒尺寸统计分布图

Fig.5

EBSD quality map overlapped with outlined prior austenite grain boundaries with the misorientation between 20° and 50° (yellow lines) (a, b) and images on all the high angle grain boundaries with the misorientation > 15° (d, e) in FH950 (a, d) and CH950 (b, e) specimens; the distributions of prior austenite grain size (c) and high-angle grain size (f) derived from Figs.5d and e, respectively, in which high-angle grain size was defined by all the high angle grain boundaries and consistent with the Hall-Petch strengthening mechanism

表2 不同工艺样品中原奥氏体晶粒及大角度晶粒尺寸 (μm)

Table 2

| Specimen | Prior austenite grain size | High-angle grain size |

|---|---|---|

| CH850 | 3.71 ± 0.36 | 0.94 ± 0.12 |

| CH900 | 4.88 ± 0.28 | 1.26 ± 0.18 |

| CH950 | 6.21 ± 0.32 | 1.37 ± 0.16 |

| FH850 | 1.42 ± 0.19 | 0.62 ± 0.16 |

| FH900 | 1.46 ± 0.23 | 0.71 ± 0.15 |

| FH950 | 1.52 ± 0.21 | 0.76 ± 0.11 |

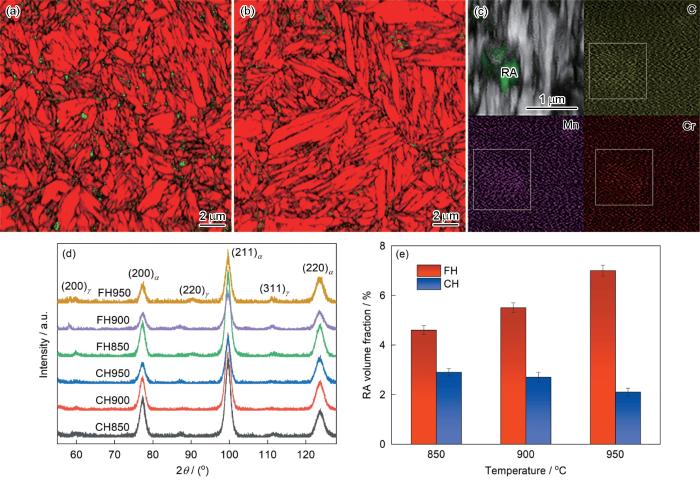

图6a和b分别为FH950和CH950样品中残余奥氏体的EBSD像。可见,闪速加热样品中的残余奥氏体数量明显多于常规加热样品;图6d的XRD谱揭示了同样的规律。闪速加热至850~950℃样品中残余奥氏体体积分数为5%~7%,而常规加热至同样温度区间的样品中残余奥氏体体积分数只有2%~3%,如图6e所示。这是因为闪速加热导致部分渗碳体逆转变为奥氏体后,由于保温时间短而无法均匀化导致奥氏体中存在C/Mn/Cr元素富集,其中C、Mn和Cr浓度足够高的区域在淬火后可成为残余奥氏体,图6c为FH950样品的Auger电子能谱结果,也揭示了残余奥氏体中有C、Mn和Cr富集的现象。另外,常规加热样品的残余奥氏体体积分数随着温度升高逐渐降低,而闪速加热样品则正好相反,这可能与渗碳体的逆转变有关,这将在后续内容中通过模拟计算进行讨论。

图6

图6

FH950和CH950样品的EBSD质量图和相分布叠加图、FH950样品Auger能谱、不同热成形工艺样品的XRD谱及残余奥氏体体积分数

Fig.6

EBSD image quality map overlapped with phase distribution on the microstructures of FH950 (a) and CH950 (b) specimens; Auger mapping of C, Mn, and Cr distributions in retained austenite (RA, green regions) in FH950 specimen (c); XRD spectra (d) and RA volume fractions (e) of the specimens subjected to both the conventional and flash heating processes

3 分析与讨论

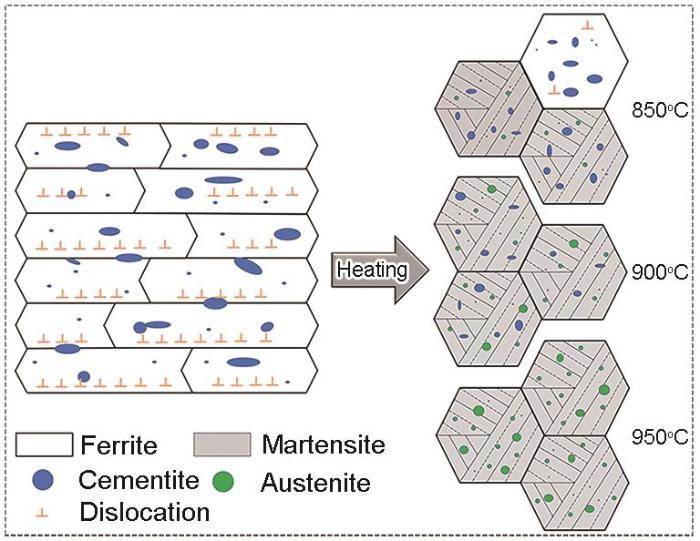

3.1 闪速加热过程中的组织演变及其对强度的影响

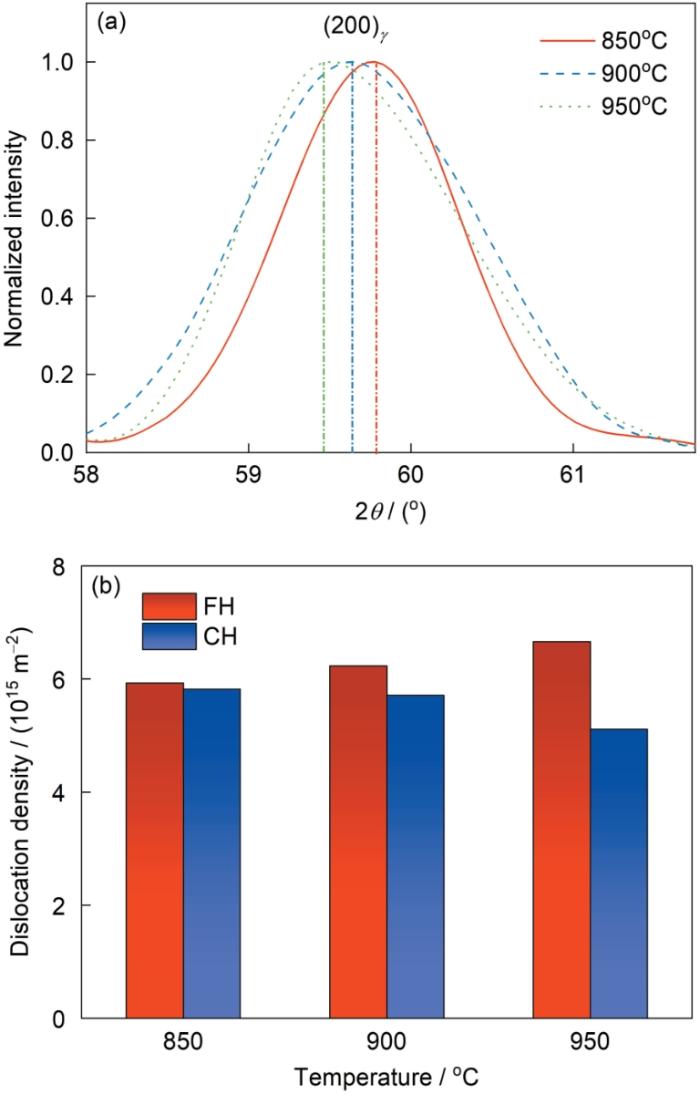

冷轧板闪速加热工艺下的微观组织演变示意图如图7所示。初始冷轧组织是沿轧制方向变形拉长的铁素体晶粒及其上分布的大量棒状渗碳体颗粒(图2b),当闪速加热至850℃时,大部分变形铁素体晶粒和部分渗碳体在闪速加热和保温过程中逆转变为奥氏体,而少部分变形铁素体晶粒发生再结晶后来不及逆转变为奥氏体从而保留下来[5],导致淬火后形成马氏体基体、未固溶渗碳体和少量的铁素体晶粒(图4a)。渗碳体的溶解伴随着C/Mn/Cr原子配分至相邻奥氏体中,与常规加热相比,闪速加热的爆发式形核使得原奥氏体晶粒更为细小,且奥氏体中原渗碳体或临近渗碳体区域中C/Mn/Cr浓度更高[6,22],这2者均使得原奥氏体的稳定性增强,导致残余奥氏体数量更多(图6e);当闪速加热至900℃时,冷轧基体完全转变为奥氏体,渗碳体颗粒进一步回溶但没有完全溶解,随后淬火后的组织由马氏体基体、少量的渗碳体和更多的残余奥氏体组成,后者由于更多的渗碳体固溶因而所形成的奥氏体中C/Mn/Cr浓度更高(图6c);闪速加热至950℃时,渗碳体完全回溶,富集Mn和Cr的碳化物释放出更多的C/Mn/Cr原子配分至奥氏体中,奥氏体稳定性进一步增加,因此残余奥氏体数量继续增多。图8a的XRD谱也证实了随着闪速加热温度的升高,(200) γ 峰的衍射角逐渐减小,即奥氏体的晶格常数随着C含量增加而不断增大,因此其稳定性是逐渐增加的。

图7

图7

冷轧板在850、900和950℃闪速加热5 s后的微观组织演变示意图

Fig.7

Schematic of the microstructural evolutions of cold-rolled steel during the flash heating at 850, 900, and 950oC for 5 s

图8

图8

热成形钢在闪速加热至不同温度的(200) γ 晶面衍射峰强度与不同热成形工艺样品的位错密度

Fig.8

(200) γ diffraction peak intensities of hot stamping steel after the flash heating to the diff-erent temperatures (a) and dislocation densities of the specimens subjected to both the conven-tional and flash heating processes (b)

位错强化增量(σd)可以用下式表示[26]:

式中,M为Taylor因子,取值为3;α为常数,取值为0.25;G为剪切模量,为80 GPa;b为Burgers矢量模,取值0.248 nm;ρ为位错密度。通过计算得出FH950和CH950样品的σd分别为1214和1064 MPa,前者高于后者150 MPa。

细晶强化增量(σg)可以用Hall-Petch公式来计算[27]:

综上,FH950和CH950样品通过计算得出的σg和σd叠加的强度差值为209 MPa,这与拉伸实验得到的数值(190 MPa)非常接近。说明FH950与CH950样品屈服强度的差异主要是位错强化和细晶强化共同作用的结果。当温度降至900和850℃时,2种加热工艺下组织发生变化,例如碳化物的析出。合金元素(C、Mn、Cr)固溶量的不同和铁素体的出现,使得量化2种加热工艺所导致屈服强度差异的因素变得极为复杂,但可以定性解释这2者的差异随加热温度降低而减小的原因。

3.2 闪速加热下残余奥氏体的形成及其对塑性的影响

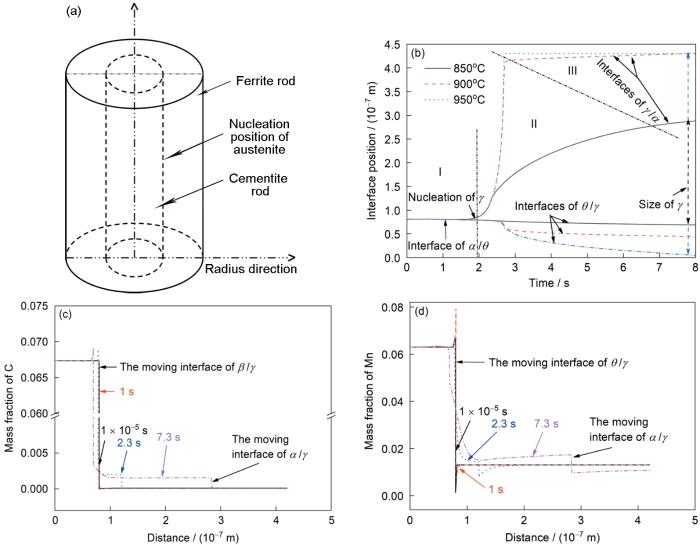

图9

图9

奥氏体逆转变动力学计算模型示意图,热成形钢在不同温度下闪速加热5 s时渗碳体、铁素体和奥氏体之间的界面移动,以及850℃下界面边界随时间发展的浓度分布

Fig.9

Schematic of the reverse austenitization kinetic simulation (a), the moving interfaces between cementite, ferrite, and austenite in the hot stamping steel during the flash heating to different temperatures and the isothermal holding for 5 s (b); the calculated C concentration (c) and Mn concentration (d) profiles developed near the interface boundaries time during the process of flash heating to 850oC

奥氏体在α/θ界面形核后闪速加热至不同温度过程中各相界迁移的计算结果如图9b所示,图9c和d为加热至850℃过程中在各相界附近形成的C和Mn的浓度梯度。闪速加热下奥氏体逆转变动力学可分为3个阶段,如图9b所示,在第I阶段,样品加热时间大约为2 s,为奥氏体形核酝酿期。在第II阶段,奥氏体(γ)爆发式形核,且γ相向α和θ相两侧迁移和长大,但γ/α界面迁移速率远高于γ/θ界面;且随着加热温度的升高,2个相界的迁移速率均增加。在这个阶段,当加热时间在2.3~7.3 s区间时,由于固溶渗碳体颗粒尺寸缩小约10 nm (θ/γ相界面位置实际上对应着渗碳体颗粒的尺寸),而铁素体区域的尺寸则相应缩小约200 nm (图9c),这是因为θ固溶所提供的C在高温下快速扩散至γ/α界面导致了该相界迅速向α扩展,渗碳体的固溶和C在奥氏体中的扩散决定了该阶段的逆相变动力学,同时Mn在三相间进行短程的配分(图9d)。在第III阶段,由于Mn的扩散速率远低于C,在θ/γ相界γ侧Mn浓度累积得越来越高,导致渗碳体的固溶越来越慢,因此奥氏体逆转变也变得极缓慢。图9b的动力学计算结果也表明,闪速加热至850℃时并未完成完全的奥氏体化;加热至900℃时,α相完全转变为γ,但仍保留部分θ相;加热至950℃时,θ相完全溶解,完全转变为奥氏体,这与图4a~c的实验结果一致。

4 结论

(1) 与常规加热相比,闪速加热后冷轧组织马氏体基体中存在更多渗碳体和残余奥氏体,且淬火后的马氏体组织得到显著细化。而且随着闪速加热温度升高,渗碳体不断固溶,更多C/Mn被继承和配分到奥氏体中,奥氏体稳定性增强,导致得到更多残余奥氏体。

(2) 与常规加热相比,在同样工艺条件下,闪速加热可以同时提高所研发的2000 MPa级别热成形钢的强度和塑性。当闪速加热至950℃时,拉伸力学性能最佳,其UTS、YS和TE分别为2180 MPa、1675 MPa和13.7%,相较于同样温度下常规加热样品分别提高了205 MPa、190 MPa和3.6%。强化机制主要来源于位错强化和细晶强化;而塑性改善除了由于晶粒细化以外,闪速加热可以获得更多残余奥氏体,通过TRIP效应改善了塑性。

(3) 针对闪速加热中的奥氏体逆转变动力学的数值模拟表明,该逆相变可分为3个阶段:第I阶段为C、Mn配分的奥氏体形核的酝酿阶段;第II阶段是奥氏体爆发式形核和快速长大,逆相变动力学主要由渗碳体的固溶和C在奥氏体中的扩散所控制,且奥氏体向铁素体中的长大远快于向渗碳体中的长大;在第III阶段,由于渗碳体前期固溶所释放的Mn在奥氏体中扩散缓慢,导致γ/θ界面奥氏体侧累积了高Mn浓度,因而渗碳体溶解缓慢,奥氏体生长速率大幅降低。

参考文献

Inferring the specific heat of an ultra high strength steel during the heating stage of hot forming die quenching, through inverse analysis

[J].

A review of current state and prospect of the manufacturing and application of advanced hot stamping automobile steels

[J].<p>Ultrahigh strength steels are highly competitive materials for vehicles to concurrently meet the increasing demand of the weight reduction and passenger safety. Hot stamping is the key forming technology to manufacture automobile components with high strength. Hot stamping steel and its manufacturing technology experienced a fast development in the past decade. This paper reviewed the state of the art of the manufacturing and applications of hot stamping steels/components in the following aspects: (1) hot stamping steels (from traditional MnB steels to recently newly developed hot stamping steels); (2) forming technologies (from traditional hot stamping process to industry 4.0 intelligent production); (3) novel hot stamping + quenching & partitioning (Q&P) process and fundamentals of deformation assisted heat treatments; (4) simulation techniques for hot stamping process (modeling of the temperature-stress field, microstructure field and simulation of the manufacturing process); (5) the assessments of in-service performance of hot stamped components. Finally, the trends of the development of hot stamping steels and related forming technologies in the future will be discussed.</p>

先进热成形汽车钢制造与使用的研究现状与展望

[J].汽车采用超高强钢是实现轻量化兼顾安全性的必由之路,热冲压成形是高强汽车零件成形的关键工艺。近10年来,热成形钢及其零件制造技术迅速发展。本文从以下几方面对热成形钢/零件制造与使用现状进行了综述:(1) 热成形钢材料(从传统MnB钢到最近新发布的一些热成形新钢种);(2) 工艺(热成形传统工艺到工业4.0智能化生产);(3) 热成形淬火配分(Q&P)创新工艺研究现状及形变热处理基本原理;(4) 热成形过程的仿真模拟(热/力场、组织场、工艺等的模拟);(5) 热成形零件的使用服役评价。并对今后热成形汽车钢制造与使用前景作出展望。

A review on hot stamping

[J].

Application of flash processing in advanced high strength steels

[J].Steel industries are always trying to manufacture advanced high strength steel (AHSS) product with higher efficiency and better mechanical properties. Over the past decades, replacing batch annealing by continuous annealing led to much improved production efficiency but not as much in the improvement of mechanical properties. Recently, a novel flash processing (FP), also termed as ultrafast heating (UFH) process, under which steel is heated at a rate over 100℃/s to a peak temperature and instantly cooled, has attracted more attentions due to its unprecedented high efficiency. The FP can significantly shorten the heat treatment duration to avoid grain growth, thus bringing significant strengthening effect without deteriorating ductility and toughness. The mechanical properties of typical AHSS grades subjected to FPs were summarized. The influence of process parameters, including initial microstructure, preheating, heating rate were analyzed. Moreover, the accurate microstructure tailoring via the ultrafast heating to an intercritical temperature was also briefly discussed. Finally, the industrial application of current FP technology was prospected.

闪速加热工艺在先进高强钢领域的应用

[J].对于先进高强钢而言,实现热处理工艺的简化与高效,并保证良好的力学性能一直为从业者所追求。过去数十年间,罩式退火发展到连续退火,虽然一定程度上提升了生产效率,但效果仍然有限。近年来,一种新型的闪速加热工艺(超快速加热工艺)因其极高的工艺效率而逐渐为业内所熟知,该工艺典型特点为以高于100℃/s的热速加热至目标温度并快速冷却。该技术的突出优势在于大幅缩短热处理周期、提升效率的同时,能够抑制晶粒的长大,从而获得显著的强化效果并能保证塑韧性。总结了多种先进高强钢经超快速加热工艺处理后的力学性能,并分析讨论了一些关键影响因素,如起始组织、预热温度、加热速率等的作用机制;同时,对该工艺下的精准组织调控进行了分析讨论,并对其工业化应用前景进行了展望。

Cold rolling and intercritical annealing of C-Mn steel sheets with different initial microstructures

[J].

A strong and ductile medium Mn steel manufactured via ultrafast heating process

[J].Ultrafast heating (UFH) at the rates of 10-300 °C/s was employed as a new strategy to anneal a cold-rolled 7wt% Mn steel, followed by the immediate cooling. Severely deformed strain-induced martensite and lightly-deformed thermal martensite, both had been already enriched with C and Mn before, transformed to fine and coarse austenite grains during the UFH, leading to the bimodal size distribution. Compared with the long intercritical annealing (IA) process, the UFH processes produced larger fraction of RA grains (up to 37%) with a high density of dislocation, leading to the significant increase in yield strength by 270 MPa and the product of strength and elongation up to 55 GPa% due to the enormous work hardening capacity. Such a significant strengthening is first attributed to high density dislocations preserved after UFH and then to the microstructural refinement and the precipitation strengthening; whilst the sustainable work hardening is attributed to the successive TRIP effect during deformation, resulting from the large fraction of RA instantly formed with the bimodal size distribution during UFH. Moreover, the results on the microstructural characterization, thermodynamics calculation on the reverse transformation temperature and the kinetic simulations on the reverse transformation all suggest that the austenitization during UFH is displacive and involves the diffusion and partition of C. Therefore, we propose that it is a bainite-like transformation.

Flash annealing yields a strong and ductile medium Mn steel with heterogeneous microstructure

[J].

Effect of flash processing on recrystallization behavior and mechanical performance of cold-rolled IF steel

[J].

On the role of chemical heterogeneity in phase transformations and mechanical behavior of flash annealed quenching & partitioning steels

[J].

Hot stamping of ultra-high strength steel parts

[J].

On the ferrite and bainite transformation in isothermally deformed 22MnB5 steels

[J].

Strength, ductility and fracture strain of press-hardening steels

[J].

热冲压成形钢的强度与塑性及断裂应变

[J].轻量化是支撑汽车电动化和智能化的重要赋能技术之一。抗拉强度为1500 MPa的热冲压成形用硼钢(22MnB5)是目前最经济有效的车身轻量化技术解决方案,而汽车工业对轻量化需求的日益提高正引领热冲压成形钢向着更高强度、更高塑性及更高断裂应变的方向发展。本文首先分析了车身轻量化对碰撞过程中构件变形抗力和断裂抗力的要求,解释了强度与塑性及断裂应变等材料的力学性能参量对碰撞变形抗力和断裂抗力的影响,然后介绍了作者及其他研究人员在研究开发更高强度、更高延伸率、更高断裂应变的新一代热冲压成形钢的最新进展:(1) 提出了一种新的强韧化方法,在热冲压成形钢的马氏体基体组织内引入大量纳米级的VC析出物,从而在获得2000 MPa强度的同时保持了与常规1500 MPa热冲压钢22MnB5相当的延伸率和断裂应变。(2) 在热冲压成形钢的微观组织中引入残余奥氏体,利用相变诱导塑性效应显著提升热冲压成形钢的延伸率;具体的工艺实施途径包括模具外淬火-配分工艺、淬火-闪配分工艺、淬火-回火配分工艺等。(3) 介绍了热冲压成形钢的新一代Al-Si镀层技术以及Al-Si镀层板断裂应变改善方面的最新研究进展;通过降低Al-Si镀层与钢板基体之间的合金化扩散来减少界面C富集,从而达到显著提高Al-Si镀层热冲压成形钢断裂应变的目的。

Effect of Si and Mn contents on the microstructure and mechanical properties of ultra-high strength press hardening steel

[J].<p>It is very important to find out the mechanism of composition in steel. Many efforts have been put on the study of the effect of Si and Mn elements on the microstructure and mechanical properties of middle Mn steel, transformation induced plasticity (TRIP) steel and quenching and partitioning (Q&P) steel. But fewer studies were focused on the mechanism of Si and Mn contents in a press hardening steel. In this work, the microstructures after hot rolled and the fine martensite structure after hot stamping in ultra-high strength press hardening steel (PHS) with different Si and Mn contents were studied by OM, SEM, EBSD and TEM. The results showed that there are a great influence of Si and Mn contents on the microstructure and mechanical properties of PHS after hot rolled. The yield strength of the PHS increases from 552 MPa to 751 MPa, the ultimate tensile strength (UTS) increases from 757 MPa to 1124 MPa, and the microstructures are different with the Mn content rose from 0.57% to 1.21% and the other components remained the same. The UTS of the steels goes up as the Si content goes up from 0.25% to 0.38%, and the yield strength and the elongation show a fluctuation trend. After simulating hot stamping process at 950 ℃ and holding 5 min, the microstructure of the steels with different compositions is martensite, but it is different in the fine martensite structure and the average size of sub-grain; after hot stamping process, the comprehensive mechanical properties of the steel B with 0.30%C, 0.34%Si and 1.21%Mn are the most outstanding, the yield strength is 1161 MPa, the UTS is 1758 MPa, and the elongation is 6.5%; after hot stamping process, the microstructure of the steel B is fine lath martensite, and there is a large amount of dislocation in the martensite lath, and precipitates a small number of carbide. The mechanical properties of the ultra-high strength press hardening steels designed in this work is not obvious correlation before and after hot stamping process, and it is just a slight difference in martensite fine structure which is beneficial to controlling the performance stability of the mass industrial production.</p>

Si和Mn含量对超高强度热成形钢组织和性能的影响

[J].采用OM、SEM、EBSD和TEM等技术,研究了Si、Mn含量对超高强度热成形钢在相同的轧制和模拟热冲压成形工艺处理后的组织和性能的影响。结果表明,Si、Mn含量对热成形前轧制态钢的组织和性能有较大影响,在其它成分相同的情况下,随着Mn含量(质量分数)由0.57%增加到1.21%,实验用钢的屈服强度由552 MPa提高到751 MPa,抗拉强度由757 MPa提高到1124 MPa,组织由贝氏体+铁素体+珠光体转变为马氏体+贝氏体。随着Si含量由0.25%增加到0.38%,实验用钢的抗拉强度逐渐升高,屈服强度和伸长率呈波动趋势。在950 ℃保温5 min相同的工艺条件下模拟热冲压淬火实验后,4种钢的组织均为马氏体,但马氏体的精细结构各不相同,平均亚晶粒尺寸大小不一;含0.34%Si和1.21%Mn的钢B的综合力学性能最优,其屈服强度为1161 MPa,抗拉强度为1758 MPa,伸长率为6.5%,且热冲压成形后的组织为细小的板条马氏体,马氏体板条上有大量的位错,且只有少量的碳化物析出。基于本研究成分设计的超高强度热成形钢,其热冲压成形前的组织和性能与热成形后的力学性能无明显相关性,只是最终的马氏体精细结构略有差别,有利于工业化批量试制零件的性能稳定性控制。

A 2000 MPa grade Nb bearing hot stamping steel with ultra-high yield strength

[J].

Analysis of microstructure and mechanical properties of different high strength carbon steels after hot stamping

[J].

New generation ultrahigh strength boron steel for automotive hot stamping technologies

[J].

A dual-phase press-hardening steel with improved mechanical properties and superior oxidation resistance

[J].

The effect of initial microstructure on the final properties of press hardened 22MnB5 steels

[J].

The effects of the heating rate on the reverse transformation mechanism and the phase stability of reverted austenite in medium Mn steels

[J].

Influence of refined hierarchical martensitic microstructures on yield strength and impact toughness of ultra-high strength stainless steel

[J].The hierarchical martensitic features in ultra-high strength stainless steel (UHSSS), including the prior austenite grains, martensite packets, blocks and laths with the descending size, were refined to various extents by employing different thermomechanical processes and then carefully characterized. Their relation to yield strength and impact toughness was analyzed. We conclude that the refinement of martensitic structures could lead to the significant increase of yield strength, which follows the Hall-Petch relation with the effect grain size defined by high angle boundaries (HABs). Impact toughness of UHSSS depends on the frequency and capability for retained austenite (RA) grains at both HABs and martensite lath boundaries to trap the propagating cracks via strain-induced transformation, in which the film-like RA grains at lath boundaries appear to make the greater contribution.

Mechanical behavior of fresh and tempered martensite in a CrMoV-alloyed steel explained by microstructural evolution and strength modeling

[J].

Kinetic transitions and Mn partitioning during austenite growth from a mixture of partitioned cementite and ferrite: Role of heating rate

[J].Austenite formation from a ferrite-cementite mixture is a crucial step during the processing of advanced high strength steels (AHSS). The ferrite-cementite mixture is usually inhomogeneous in both structure and composition, which makes the mechanism of austenite formation very complex. In this contribution, austenite formation upon continuous heating from a designed spheroidized cementite structure in a model Fe-C-Mn alloy was investigated with an emphasis on the role of heating rate in kinetic transitions and element partitioning during austenite formation. Based on partition/non-partition local equilibrium (PLE/NPLE) assumption, austenite growth was found alternately contribute by PLE, NPLE and PLE controlled interfaces migration during slow-heating, while NPLE mode predominately controlled the austenitization by a synchronous dissolution of ferrite and cementite upon fast-heating. It was both experimentally and theoretically found that there is a long-distance diffusion of Mn within austenite of the slow-heated sample, while a sharp Mn gradient was retained within austenite of the fast-heated sample. Such a strong heterogeneous distribution of Mn within austenite cause a large difference in driving force for ferrite or martensite formation during subsequent cooling process, which could lead to various final microstructures. The current study indicates that fast-heating could lead to unique microstructures which could hardly be obtained via the conventional annealing process.

Strengthening mechanisms of Nb and V microalloying high strength hot-stamped steel

[J].

Evaluation of the dislocation density and dislocation character in cold rolled Type 304 steel determined by profile analysis of X-ray diffraction

[J].

A low-alloy high-carbon martensite steel with 2.6 GPa tensile strength and good ductility

[J].

Influence of annealing temperature on both mechanical and damping properties of Nb-alloyed high Mn steel

[J].In the engineering design of machines and vehicles, the technologies involving vibration and noise reduction receive considerable attention as they can prevent undesirable fatigue failures and offer more comfort to the users. Compared with other damping alloys, high Mn steel has been intensively studied because its high strength and excellent damp capacity can be achieved simultaneously at a low cost. Particularly, it has a strong potential of circumventing the long-existing trade-off of strength and damping capacity for more applications in the new circumstance. In this study, the microstructures and damping and mechanical properties of a novel hot-rolled Nb-alloyed high Mn steel annealed at the temperature range of 750-1050oC were investigated. Heterogeneous recrystallization occurred during hot rolling, resulting in the formation of recrystallized bands along the rolling direction, in which fine lamellar ε martensite grains were interwoven with austenite; the coarse unrecrystallized ε martensite blocks were located between the bands. The latter was reversely transformed to the coarse austenite with a single orientation, remained unrecrystallized, and transformed back to the coarse highly-dislocated ε martensite blocks during the annealing below 850oC. Conversely, the ε martensite blocks reversely transformed the austenite grains partially and completely recrystallized to form even more refined grains with multi-orientations during annealing at 950 and 1050oC, respectively. Thus, the recrystallized austenite grains transformed to fine ε lamellar martensite, and the austenite grains were retained with multi-orientations, both having a low density of dislocation. Consequently, the higher annealing temperature led to higher damping capacity but lower strength; whereas, the partial recrystallization occurring during annealing at 950oC resulted in the best combination of mechanical and damping properties. Therefore, this indicates that tailoring the extent of recrystallization via the Nb-alloying and annealing process for high Mn steel can be an effective method to achieve different combinations of strength and damping capacity.

退火温度对含Nb高锰钢力学和阻尼性能的影响

[J].

Relation between martensite morphology and volume change accompanying fcc to bcc martensitic transformation in Fe-Ni-Co alloys

[J].

A novel medium-Mn steel with superior mechanical properties and marginal oxidization after press hardening

[J].

A novel observation on cementite formed during intercritical annealing of medium Mn steel

[J].

Influence of tempering temperature on mechanical properties and microstructures of high-Al-contained medium Mn steel having δ-ferrite

[J].

回火温度对含δ铁素体高铝中锰钢力学性能和显微组织的影响

[J].研究了回火温度对含15% δ铁素体(体积分数)的热轧高铝中锰钢显微组织和力学性能的影响。结果表明,钢中长300 μm的δ铁素体经热轧再结晶可被细化分割至大量长3 μm左右竹节状晶粒,且在回火温度高达700℃时尺寸不变。400~500℃回火后,马氏体基体依然维持较高的位错密度且析出细小渗碳体和纳米级VC粒子,屈服强度最高;同时C由马氏体向奥氏体的大量配分提高了奥氏体稳定性,获得了相对持久的加工硬化,最终获得了屈服强度约1500 MPa、抗拉强度1800 MPa和断后延伸率14%的最佳力学性能组合。该钢δ铁素体相一方面由于析出强化、晶粒细化和位错强化而得到显著硬化;另一方面δ铁素体体积分数不高且呈孤岛状嵌在马氏体基体中,这些特征导致该钢屈服强度由马氏体基体而非δ铁素体所决定,因此相比于其他类似Al含量的含δ铁素体中锰钢,屈服强度大幅度提高。

Fast-heating for intercritical annealing of cold-rolled quenching and partitioning steel

[J].

Formation of ultrafine grained dual phase steels through rapid heating

[J].

Very fine structured DP steel with tempered-martensite matrix fabricated by fast heating

[J].

Effect of heating rate on microstructure and mechanical properties of TRIP-aided multiphase steel

[J].

Effect of heating rate on the austenite formation in low-carbon high-strength steels annealed in the intercritical region

[J].