低碳马氏体不锈钢0Cr13Ni4Mo因其高强度、良好的耐腐蚀性能和抗空蚀能力以及良好的焊接性能而被广泛应用于机械行业,如制造水轮机转轮、压缩机叶轮和石油化工高压管路等关键部件[1~3]。随着油气开采等工程领域向环境恶劣地区的不断延伸,对材料的综合力学性能和耐腐蚀性能等提出了更为严苛的要求。为进一步提升钢的服役性能,通常采取添加合金元素等方法。Cu在α-Fe中固溶度非常低,易在钢中形成纳米富Cu相,产生析出强化效果,因而纳米Cu析出相强化在高强度低合金钢(HSLA钢)、沉淀硬化马氏体钢17-4PH等钢中得到广泛研究与应用[4~9]。国内外研究学者针对Cu析出相在铁素体基体中的析出过程、组织变化及析出相中成分变化等已经做了广泛研究,通常认为Cu析出相的结构先从bcc转变为亚稳态的9R结构最终转变为稳定的fcc结构的Cu,而Cu析出相成分则与其形成阶段及合金组元密切相关[10~15]。对于Cu的强化机制已有较多报道且较为完善,而关于其对合金钢耐腐蚀性能的影响仍存在争议。Luo等[16]研究发现,15-5PH钢中富Cu纳米析出相会破坏钝化膜的连续性和完整性,从而降低了材料的耐腐蚀性能。而彭新元等[17]研究结果则表明15-5PH钢在时效温度低于450℃时富Cu相的耐腐蚀性能最好,随着时效温度升高,Cu析出相长大,耐腐蚀性能变差。Jang等[18]研究了Cu对低合金钢在HCl溶液中耐腐蚀性能的影响,发现合金钢表面形成了保护性的Cu2O和Cu(OH)2层,从而降低了钢的均匀腐蚀速率,但由于不完整的保护层会产生电偶效应导致钢发生局部腐蚀。Brigham和Tozer[19]研究发现,含2%Cu (质量分数,下同)对18%Cr不锈钢的耐点蚀性能没有影响,而Lizlovs[20]研究发现,当含2%Cu和1%Mo时,17%Cr不锈钢的临界电流密度降低,但会对不锈钢钝化膜的稳定性带来不利的影响。究其原因是由于热处理过程中析出了富Cu团簇或者Cu纳米相。因此,关于Cu合金化对钢铁材料耐腐蚀性能的影响仍有待深入研究。

前期工作[21]研究了Cu含量对低碳马氏体不锈钢0Cr13Ni4Mo力学性能的影响,结果表明添加3%Cu后不锈钢的综合力学性能优异。但关于Cu合金化对该不锈钢耐腐蚀性能的影响及其作用机制尚不明确。鉴于此,本工作以含3%Cu和不含Cu低碳马氏体不锈钢0Cr13Ni4Mo为研究对象,考察了固溶处理和回火处理后的组织演变行为以及2种钢在3.5%NaCl (质量分数)溶液中的耐腐蚀性能,探讨了Cu对0Cr13Ni4Mo不锈钢耐腐蚀性能的影响,为低碳马氏体不锈钢在更为严苛的服役环境中的应用提供理论依据。

1 实验方法

以低碳马氏体不锈钢0Cr13Ni4Mo为基础,设计了不含Cu和含3%Cu的2种低碳马氏体不锈钢,分别记为0Cu钢和3Cu钢。均采用真空感应炉熔炼,浇铸成25 kg的钢锭,钢锭热锻后经1200℃保温2 h后轧制成厚度为12 mm的板材,其化学成分如表1所示。从板材上截取试样进行热处理,固溶处理温度为1050℃,保温2 h后水冷;回火处理温度分别为400和500℃,保温2 h后空冷。

表1 2种低碳马氏体不锈钢的化学成分 (mass fraction / %)

Table 1

| Steel | C | Cr | Ni | Mo | Si | Mn | Cu | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

0Cu 3Cu | 0.051 0.056 | 12.87 13.03 | 4.06 4.12 | 0.47 0.48 | 0.43 0.51 | 0.68 0.66 | 0.01 2.82 | 0.005 0.005 | 0.0041 0.0050 | Bal. Bal. |

采用D/Max2400型X射线衍射仪(XRD)定性分析试样的相组成,靶材为Cu,扫描步长为0.02°,衍射角2θ范围为40°~102°。试样经Vilella试剂(50 mL HCl + 1 g C6H3N3O7 + 100 mL C2H5OH)刻蚀后,采用JSM-6301F场发射扫描电子显微镜(SEM)观察其显微组织,工作电压为20 kV。试样经磨抛冲孔成直径为3 mm、厚为50 μm的薄片,随后在-25℃的10% (体积分数)高氯酸酒精溶液中进一步双喷减薄(电压为20 V)后,采用带能谱(EDS)的F20透射电子显微镜(TEM)观察Cu析出相。采用LEAP 5000XR原子层析探针(APT)技术从原子尺度对钢中微观不均匀区域进行化学成分分析[22,23]。其中实验激光波长为355 nm,能量为40 pJ,脉冲频率为200 kHz,每次激光脉冲的离子收集速率为1%,实验温度为-223℃。APT实验试样的制备方法为:准备尺寸为0.5 mm × 0.5 mm × 20 mm的细棒,将其4个侧面在砂纸上打磨光亮后使用两步电解抛光的方法制备APT针尖。粗抛时使用的电解液是由25%HClO4和75%CH3COOH (体积分数)组成的混合溶液,抛光电压在10~20 V区间;精抛时使用的电解液是由4%HClO4和96%C6H14O2 (体积分数)组成的混合溶液,抛光电压在10~15 V区间,具体实验方法见文献[24]。实验所得的数据利用IVAS 3.8.2 软件进行三维重构,并对元素分布、团簇及其成分进行分析[24]。分析纳米团簇或者析出相时运用的主要方法是最近邻分布(nearest neighbor distribution,NND)法、等浓度面方法(isoconcentration surface methodology,ICSM)以及Proxigram成分分析方法[25]。

采用Reference 600P-43085电化学工作站对试样进行电化学阻抗谱(EIS)以及动电位极化曲线测试,实验介质为未除氧的3.5%NaCl溶液。采用标准的三电极体系,其中测试样品为工作电极,饱和甘汞电极(SCE)为参比电极,Pt片为对电极,实验均在室温下进行。将样品切割成尺寸为10 mm × 10 mm × 3 mm的试片,用环氧导电胶将试片与Cu导线粘连,非工作面采用环氧树脂密封,使工作电极的暴露面积为10 mm × 10 mm。试样经SiC水砂纸逐级打磨至2000号,并分别用去离子水、无水乙醇、去离子水清洗及冷风吹干后待用;在电化学测量开始前,将试样于-800 mV (vs OCP (开路电位))电位下阴极极化480 s以去除试样表面的氧化膜;随后等待3600 s后,进行开路电位下的EIS和动电位极化曲线测试。其中,EIS测量的交流电振幅10 mV,频率范围为10-2~105 Hz,测试后的数据采用ZSimpWin软件进行等效电路拟合;动电位极化曲线测试时的扫描速率为0.33 mV/s,并采用电化学工作站自带软件进行Tafel拟合分析。

2 实验结果

2.1 微观组织

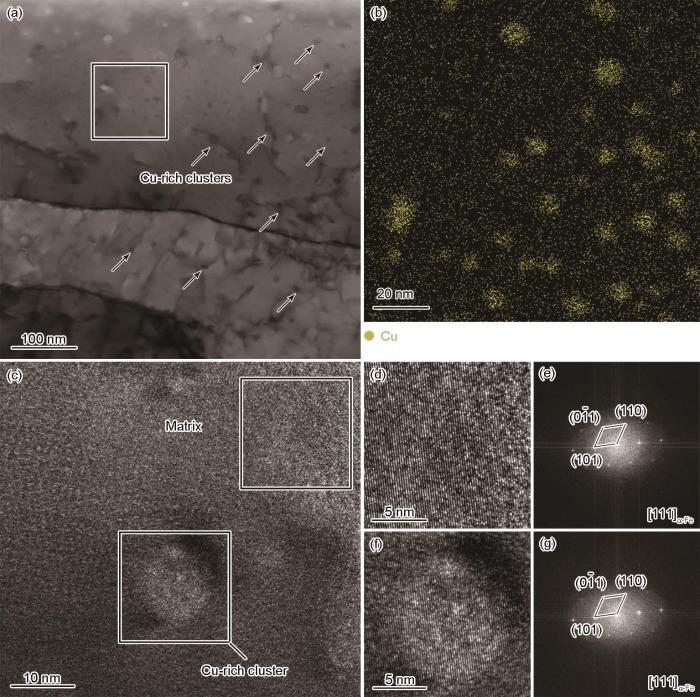

图1为0Cu钢和3Cu钢分别经过不同热处理工艺后基体组织的SEM像。可以看出,2种不锈钢经过固溶处理、400和500℃回火处理后的组织均为单一的板条状马氏体,未见明显的析出相。根据板条取向分析原始奥氏体的晶界后发现,2种不锈钢回火处理后的原始奥氏体晶粒尺寸与固溶处理后接近,约为50 μm,没有明显的差异。为进一步确定微观组织,利用XRD对2种钢的相组成进行定性分析。鉴于前期研究[21]发现,550℃以下回火处理后低碳马氏体不锈钢0Cr13Ni4Mo的基体组织均为板条状马氏体,XRD谱结果无差异,因此本工作只给出了2种不锈钢的固溶态和500℃回火处理态的XRD谱,如图2所示。可见,0Cu钢和3Cu钢的XRD谱均显示为单一的马氏体衍射峰,未检测到其他相的衍射峰,证实了0Cu钢和3Cu钢经过固溶处理和500℃回火处理后的基体组织均为板条马氏体组织。利用TEM观察3Cu钢经500℃回火处理后的显微组织,可以发现有大量析出相的存在,如图3a中箭头所示。相应的EDS结果(图3b)显示为富Cu析出相。图3c为基体和富Cu析出相的HRTEM像。经快速Fourier变换(FFT)得出的衍射斑点可知,富Cu析出相与基体处于共格关系,均为bcc结构,如图3e和g所示。此外,由图3b还可以看出,富Cu析出相以接近于球形的形式析出并分布在马氏体基体上,直径约为10 nm。

图1

图1

不同热处理工艺下0Cu钢和3Cu钢基体组织的SEM像

Fig.1

SEM images of 0Cu (a-c) and 3Cu (d-f) steels after different heat treatments (a, d) solution treated at 1050oC (b, e) tempered at 400oC (c, f) tempered at 500oC

图2

图2

0Cu钢和3Cu钢经不同热处理后的XRD谱

Fig.2

XRD spectra of 0Cu and 3Cu steels after different heat treatments

图3

图3

3Cu不锈钢经过500℃回火2 h后的TEM分析

Fig.3

TEM analyses of the 3Cu steel tempered at 500oC for 2 h

(a) bright field TEM image

(b) corresponding EDS mapping of square area in Fig.3a of Cu

(c) HRTEM image of the matrix and Cu-rich precipitate

(d, f) enlarged HRTEM images of the matrix (d) and Cu-rich precipitate (f) in Fig.3c, respectively

(e, g) corresponding fast Fourier transformation (FFT) patterns of Figs.3d (e) and f (g), respectively

2.2 电化学测试

2.2.1 动电位极化曲线

图4为不同热处理后0Cu钢和3Cu钢在3.5%NaCl溶液中的动电位极化曲线。可以看出,经不同热处理后2种钢的动电位极化曲线具有相似的演化规律,即:阴极反应区主要由析氢反应过程控制[26];阳极反应区主要由电化学动力学控制,当外加电位低于点蚀电位(Eb)时,虽然阳极电流密度随着外加电位的增加缓慢上升但仍维持在nA/cm2量级,此时动电位极化曲线上阳极电流密度的波动对应于不锈钢表面亚稳态点蚀坑的发展与消亡[27];随着外加电位的进一步正移,阳极电流密度急剧增大,表明不锈钢表面的钝化膜被击穿,发生稳态点蚀。此外,当外加电位低于Eb时,阳极反应动力学过程呈现明显的线性区,因此可以通过Tafel外推法得到腐蚀电位(Ecorr)和腐蚀电流密度(icorr)等电化学参数。表2所示为拟合得到的Ecorr、icorr和Eb等电化学参数。其中,根据国家标准GB/T17899—1999和国际惯例,将阳极电流密度急剧增大时对应的最正电位定义为Eb。

图4

图4

不同热处理工艺下0Cu钢和3Cu钢在3.5%NaCl溶液中的动电位极化曲线

Fig.4

Potentiodynamic polarization curves of 0Cu and 3Cu steels after different heat treatments in 3.5%NaCl solution (E—potential, i—current density)

表2 不同热处理工艺下0Cu钢和3Cu钢在3.5%NaCl溶液中的动电位极化曲线特征值

Table 2

| Steel | Heat treatment | Ecorr / VSCE | icorr / (nA·cm-2) | Eb / VSCE |

|---|---|---|---|---|

| 0Cu | Solution treated | -0.173 | 62.1 | -0.019 |

| 0Cu | 400oC tempered | -0.161 | 66.6 | 0.069 |

| 0Cu | 500oC tempered | -0.181 | 65.7 | 0.097 |

| 3Cu | Solution treated | -0.162 | 64.0 | 0.080 |

| 3Cu | 400oC tempered | -0.144 | 57.5 | 0.051 |

| 3Cu | 500oC tempered | -0.147 | 42.3 | 0.109 |

由表2可知,3Cu钢的Ecorr总体要正于0Cu钢,说明添加3%Cu可以提高不锈钢的抗阳极溶解能力[28]。经固溶处理后,0Cu钢和3Cu钢的icorr接近,分别为62.1和64.0 nA/cm2,说明固溶态时,添加3%Cu对不锈钢的耐腐蚀性能影响不明显,但此时0Cu钢的Eb明显低于3Cu钢,说明3Cu钢表面钝化膜更致密,稳定性更好;而回火态3Cu钢的icorr均小于0Cu钢,说明回火处理后,3Cu钢的耐腐蚀性能均优于0Cu钢。此外,经500℃回火处理后,3Cu钢具有最正的Eb和最小的icorr以及更少的亚稳态点蚀电流峰,说明此时3Cu钢的抗点蚀能力和抗均匀腐蚀能力更好。然而,经400℃回火处理后3Cu钢的亚稳态点蚀电流峰多于0Cu钢,且Eb也低于0Cu钢,这可能是由于3Cu钢在400℃回火时碳化物与Cu析出相开始形核, C和Cu原子产生了偏聚,从而使得400℃回火处理后的3Cu钢表面钝化膜均匀性和稳定性降低,点蚀倾向性增大。再者,经500℃回火处理后3Cu钢的Eb高于0Cu钢,说明500℃回火处理后3Cu钢的抗点蚀能力也更好。由此证明,经500℃回火处理之后,3Cu钢表面更容易形成稳定的钝化膜,膜层耐腐蚀性能更好,具有更好的抗点蚀性能和更小的腐蚀速率。

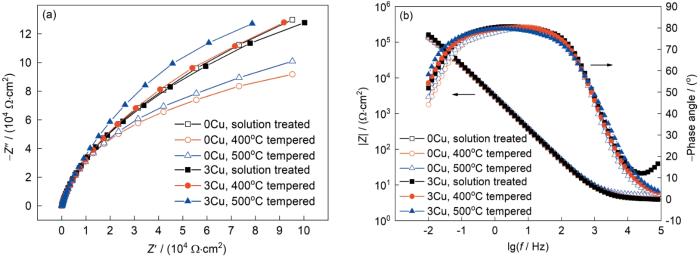

2.2.2 EIS

图5为不同热处理后0Cu钢和3Cu钢在3.5%NaCl溶液中开路电位下的EIS谱,其中图5a为Nyquist图,图5b为Bode图。由图5a可见,不同热处理状态下2种不锈钢的Nyquist图高频均呈现不完整的单容抗弧特征,容抗弧半径的大小可以反映不锈钢电极的阻抗模值,半径越大代表阻抗值越大,说明钝化膜的耐腐蚀性能越好。比较发现,经固溶处理后,0Cu钢和3Cu钢的容抗弧半径基本重合,说明固溶态时,添加3%Cu对不锈钢的耐腐蚀性能影响不明显;经400和500℃回火处理后,3Cu钢的容抗弧半径均大于0Cu钢,说明回火处理后3Cu钢的抗均匀腐蚀性能均优于0Cu钢,这均与表2所示icorr演化结果一致。图5b显示不同热处理后2种不锈钢的相位角呈现2个时间常数特征,表明电极表面钝化膜对电极过程的影响不可忽略,同时,相位角在中低频区呈现恒定值,即出现常相位角元件(CPE)特征,此外,图5b还显示中低频区阻抗模值的斜率大于-1,也说明存在CPE特征。这可能是由不锈钢电极表面钝化膜成分和结构的不均匀所致。其次,电极表面不同区域的电荷转移电阻和界面电容不同也是导致出现CPE特征的重要原因[29]。

图5

图5

不同热处理工艺下0Cu钢和3Cu钢在3.5%NaCl溶液中的EIS

Fig.5

Nyquist (a) and Bode (b) plots of 0Cu and 3Cu steels after different heat treatments in 3.5%NaCl solution (Z—impedance, Z'—real part of impedance, Z''—imaginary part of impedance, f—frequency)

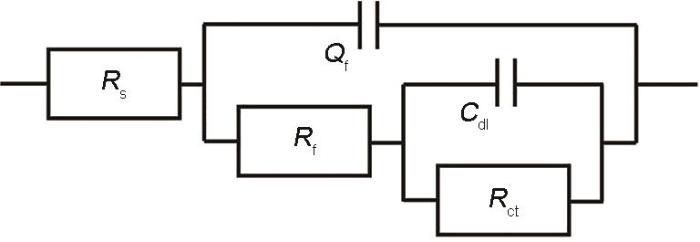

为进一步分析添加3%Cu对0Cr13Ni4Mo低碳马氏体不锈钢耐均匀腐蚀性能和表面钝化膜耐腐蚀性能的影响,利用图6所示等效电路模型对开路电位下测量得到的图5所示EIS数据进行拟合,其中Rs为溶液电阻,Rf为表面钝化膜电阻,Rct为双电层电荷转移电阻,Qf和Cdl分别为表面钝化膜电容和双电层电容,具体拟合参数如表3所示。可知,经固溶处理后,0Cu钢和3Cu钢的Rct相当,说明固溶态时,添加3%Cu对不锈钢基体的耐腐蚀性能影响不明显,但此时3Cu钢的Rf却小于0Cu钢,说明固溶态时3Cu钢表面钝化膜不均匀。经400和500℃回火处理后,3Cu钢的Rct和Rf均大于0Cu钢,尤其是500℃回火处理后,3Cu钢的Rct是0Cu钢的2倍多,Rf是0Cu钢的近4倍,说明500℃回火处理后3Cu钢基体的耐腐蚀性能较0Cu钢显著提高,表面钝化膜的耐腐蚀性能也显著增强,这均与表2所示icorr的演化结果一致。可见,添加3%Cu后,经500℃回火处理可以显著提高0Cr13Ni4Mo低碳马氏体不锈钢耐均匀腐蚀性能和表面钝化膜耐腐蚀性能。这可能是因为固溶态时Cu原子弥散分布于钢基体中,经500℃回火后,Cu原子开始析出长大,且在此过程中碳化物也随之析出长大,Cu原子的析出长大在一定程度上弥补了碳化物对钝化膜的不利影响。

图6

图6

不同热处理工艺下0Cu钢和3Cu钢在3.5%NaCl溶液中的等效电路图

Fig.6

Equivalent circuit diagram of 0Cu and 3Cu stainless steels in 3.5%NaCl solution (Rs—solution resistance, Rf—surface passivation film resistance, Qf—surface passivation film capacitance, Rct—double layer charge transfer resistance, Cdl—double layer capacitance)

表3 不同热处理工艺下0Cu钢和3Cu钢在3.5%NaCl溶液中EIS的等效电路拟合参数

Table 3

| Steel | Heat treatment | Rs Ω·cm2 | Rf kΩ·cm2 | Qf 10-5 Ω-1·cm-2·s-1 | nf | Rct Ω·cm2 | Cdl 10-5 Ω-1·cm-2·s-1 |

|---|---|---|---|---|---|---|---|

| 0Cu | Solution treated | 4.008 | 38.89 | 5.912 | 0.8852 | 320.6 | 67.02 |

| 0Cu | 400oC tempered | 4.124 | 24.33 | 5.838 | 0.8811 | 194.6 | 71.53 |

| 0Cu | 500oC tempered | 4.766 | 13.74 | 6.402 | 0.8659 | 211.3 | 57.93 |

| 3Cu | Solution treated | 3.880 | 11.56 | 5.293 | 0.8712 | 322.0 | 99.60 |

| 3Cu | 400oC tempered | 4.129 | 26.16 | 5.866 | 0.8792 | 331.6 | 72.57 |

| 3Cu | 500oC tempered | 3.954 | 48.35 | 5.834 | 0.8643 | 447.2 | 74.91 |

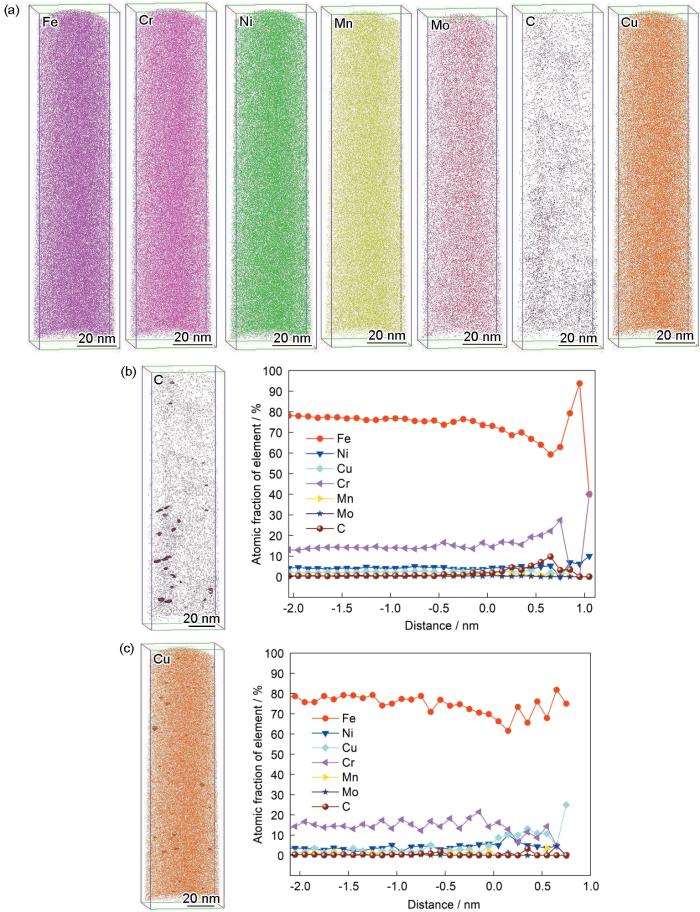

2.3 APT分析

图7

图7

3Cu钢经过1050℃固溶2 h后Fe、Cr、Ni、Mn、Mo、C和Cu原子的三维空间分布图及Cu原子最近邻分布曲线

Fig.7

Atom distribution maps of Fe, Cr, Ni, Mn, Mo, C, and Cu in 3Cu steel solution treated at 1050oC for 2 h (a) and the nearest neighbor count distributions of Cu (b) (d-pair—distance between two atoms)

经400℃回火处理后的3Cu钢微观组织特征的APT分析如图8所示。图8a为400℃回火处理后的3Cu钢中Fe、Cr、Ni、Mn、Mo、C和Cu原子的三维空间分布图,图8b和c分别为1.3%C原子和4%Cu原子(原子分数,下同)的等浓度面分布图以及相应团簇的成分分布。可以清晰地看出,C原子和Cu原子以团簇的形式从基体中析出。其中,横坐标0点对应于析出相界面,即所选择的等浓度面,负数代表析出相以外区域,正数代表析出相内部区域[30]。1.3%C原子团簇的直径在1 nm左右,团簇中主要富Fe和Cr。4%Cu原子团簇的直径比C原子团簇略微小一些,团簇中主要偏聚大量的Fe原子,占比可达80% (原子分数)。

图8

图8

3Cu钢经过400℃保温2 h回火后Fe、Cr、Ni、Mn、Mo、C和Cu原子的三维空间分布图,1.3%C和4%Cu原子的等浓度面分布图以及相应团簇的成分分布

Fig.8

Atom distribution maps of Fe, Cr, Ni, Mn, Mo, C, and Cu in 3Cu steel 400oC tempered for 2 h (a), isoconcentration surface distribution of 1.3%C (atomic fraction) and corresponding C clusters distribution (b), and isoconcentration surface distribution of 4%Cu (atomic fraction) and corresponding Cu cluster distribution (c)

经500℃回火处理后3Cu钢微观组织特征的APT分析如图9所示。从图9a可以看出,C和Cu原子的偏聚更加显著,已形成明显的析出相。由图9b可知,3%C原子团簇的直径为5~15 nm之间,且C团簇内部明显富Cr并向外排Fe,可以推断是形成了富Cr的碳化物。由图9c可知,富Cu析出相直径在5~10 nm之间;值得注意的是,由图9c还可以发现,Cu团簇析出长大的同时会向外排出Fe、Cr、Ni等原子,析出相中Cu的含量达到90%以上。因此,APT分析认为,3Cu钢经过500℃回火后表现出优异耐腐蚀性能的原因可能是富Cu析出相长大过程中伴随着向周边基体排出了Cr原子,减少了由富Cr碳化物造成的贫Cr区,从而降低了3Cu低碳马氏体不锈钢的腐蚀敏感性。

图9

图9

3Cu钢经过500℃保温2 h回火后Fe、Cr、Ni、Mn、Mo、C和Cu原子的三维空间分布图,3%C原子和15%Cu原子的等浓度面分布图以及相应团簇的成分分布

Fig.9

Atom distribution maps of Fe, Cr, Ni, Mn, Mo, C, and Cu in 3Cu stainless steel 500oC tempered for 2 h (a), isoconcentration surface distribution of 3%C (atomic fraction) and corresponding C clusters distribution (b), and isoconcentration surface distribution of 15%Cu (atomic fraction) and corresponding Cu cluster distribution (c)

3 分析讨论

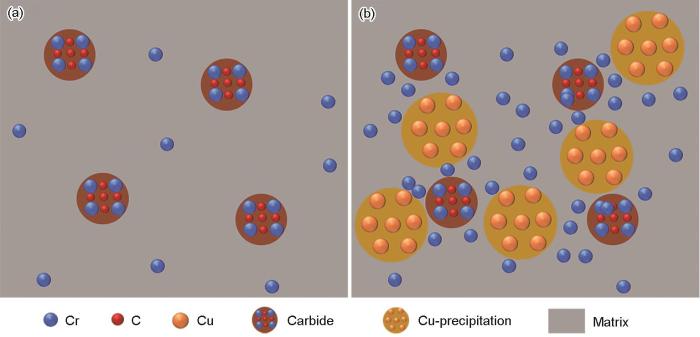

本工作实验结果表明,0Cu钢和3Cu钢的基体组织类似,均为淬火板条状马氏体组织,原始奥氏体晶粒尺寸也没有明显差异。Cu均匀弥散地分布在马氏体基体中。对于0Cu钢来说,EIS测试表明,经400和500℃回火处理后容抗弧直径相比较固溶处理后的试样要小,Rf和Rct降低,说明回火温度上升会破坏0Cu钢表面钝化膜对基体的保护作用。在回火过程中,伴随着碳化物的析出,APT结果显示最初形成的碳化物团簇里主要是Fe,随着回火温度的升高,碳化物会长大,并且其中的合金元素成分也随着发生了变化,Cr会富集在碳化物中,形成了富Cr的碳化物。由于Cr的消耗,在碳化物析出长大时,会在析出相附近产生贫Cr区,从而破坏不锈钢钝化膜的连续性[31,32],导致周围的耐腐蚀性能下降[33,34]。

而对于3Cu钢而言,回火过程中,不仅有碳化物的形成,还有富Cu相的析出。APT结果显示最初富Cu相的核心主要是Fe原子,随着回火温度的升高,析出相逐渐长大。一般认为,Cu析出相会形成核壳结构,核心处是Cu,外壳为富Ni和Mn层,将Fe、Cr等原子排斥到基体中[6]。并且3Cu钢中富Cu析出相的体积分数大于碳化物,因此能够弥补富Cr碳化物周围所形成的贫Cr区。另外,TEM观察也发现所形成的富Cu析出相与马氏体基体成共格关系。共格的原子团簇与基体的点位相差甚小,产生腐蚀微电池的倾向也小,同时在钝化膜下易形成Cu的富集层,可以阻止不锈钢的腐蚀氧化向基体内部扩展[17]。因此富Cu相的析出有利于低碳马氏体不锈钢0Cr13Ni4Mo耐腐蚀性能的提高。

显然,在阳极溶解过程中Cu首先被氧化成Cu+,接着Cu+与溶液中的Cl-生成微溶于水的CuCl多孔薄膜,薄膜附着在不锈钢的表面会在一定程度上抑制不锈钢基体的阳极溶解,随后CuCl会再与Cl-进一步生成可溶性的

图10

图10

经500℃回火处理后0Cu钢与3Cu钢的腐蚀机制示意图

Fig.10

Schematics of the corrosion mechanism of 0Cu (a) and 3Cu (b) steels tempered at 500oC

4 结论

(1) 含3%Cu低碳马氏体不锈钢0Cr13Ni4Mo经固溶处理后,Cu在基体中均匀分布;经400和500℃回火处理后的不锈钢基体组织均由板条状马氏体、碳化物和Cu析出相组成。其中,Cu首先以团簇的形式从基体组织中析出,且与基体处于共格关系;在长大过程中向外排出Fe、Cr等原子,形成Cu析出相。碳化物则由主要偏聚Fe的纳米团簇生长为富Cr的析出相。

(2) 含3%Cu的低碳马氏体不锈钢0Cr13Ni4Mo经500℃回火处理之后,具有最小的电流密度、最正的点蚀电位,最大的容抗弧半径、最高的表面钝化膜等效电阻和双电层电荷转移电阻,因此具有最优的耐腐蚀性能。这可能是由于Cu析出相在长大过程中向基体中排出的Cr原子弥补了由于碳化物而形成的贫Cr区,从而提升了不锈钢的耐腐蚀性能。

参考文献

Effect of structure of martensitic stainless cast steel ZG06Cr13Ni4Mo on properties

[J].

ZG06Cr13Ni4Mo马氏体不锈铸钢组织对性能的影响

[J].

Microstructure and mechanical properties in simulated HAZ of 0Cr13Ni5Mo martensitic stainless steel

[J].

ZG0Cr13Ni5Mo马氏体不锈钢模拟焊接HAZ组织与性能

[J].

Weldability assessment of thick super-martensitic 13Cr stainless steel welds made with matching consumables

[J].

Aging behaviour in copper bearing high strength low alloy steels

[J].

Origin of copper precipitation strengthening in steel revisited

[J].

Interfacial segregation at Cu-rich precipitates in a high-strength low-carbon steel studied on a sub-nanometer scale

[J].

Phase transformation of Cu precipitates from bcc to fcc in Fe-3Si-2Cu alloy

[J].

Microstructure characterization of Cu-rich nanoprecipitates in a Fe-2.5Cu-1.5Mn-4.0Ni-1.0Al multicomponent ferritic alloy

[J].

Nano-precipitates evolution and their effects on mechanical properties of 17-4 precipitation-hardening stainless steel

[J].

An atom-probe tomographic study of the temporal evolution of the nanostructure of Fe-Cu based high-strength low-carbon steels

[J].

Effects of proton irradiation on nanocluster precipitation in ferritic steel containing fcc alloying additions

[J].

Synergistic effects of Cu and Ni on nanoscale precipitation and mechanical properties of high-strength steels

[J].

A nanoscale co-precipitation approach for property enhancement of Fe-base alloys

[J].Precipitate size and number density are two key factors for tailoring the mechanical behavior of nanoscale precipitate-hardened alloys. However, during thermal aging, the precipitate size and number density change, leading to either poor strength or high strength but significantly reduced ductility. Here we demonstrate, by producing nanoscale co-precipitates in composition-optimized multicomponent precipitation-hardened alloys, a unique approach to improve the stability of the alloy against thermal aging and hence the mechanical properties. Our study provides compelling experimental evidence that these nanoscale co-precipitates consist of a Cu-enriched bcc core partially encased by a B2-ordered Ni( Mn, Al) phase. This co-precipitate provides a more complex obstacle for dislocation movement due to atomic ordering together with interphases, resulting in a high yield strength alloy without sacrificing alloy ductility.

Co-precipitation of nanoscale particles in steels with ultra-high strength for a new era

[J].

The strengthening mechanism of Cu bearing high strength steel as-quenched and tempered and Cu precipitation behavior in steel

[J].High strength low alloy (HSLA) steels are widely used in the construction of ship structures, oil pipelines, offshore platforms and so on because of their good strength, toughness and weldability. HSLA steel is generally designed with low carbon and Cu alloying. Tempered lath bainite or martensite and nano-precipitate phase of Cu can be obtained by quenching and ageing process after rolling to ensure the excellent matching of strength, low temperature toughness and weldability of HSLA steel. At present, increasing attention has been focused on the precipitation behavior and strengthening mechanism of Cu particles in HSLA steel which was aged at the peak hardness of ageing curve. However, in practical engineering applications, overageing heat treatment is generally used to make HSLA steel achieve a good match of strength and toughness. In this work, the microstructure and nano-sized Cu precipitates of an industrial production HSLA steel plate with thickness of 35 mm were characterized by SEM, EBSD, HRTEM and APT. Meanwhile, the strengthening mechanism of the tested steel was investigated. The results show that Cu precipitates in the tested steel processed by overageing are mainly in the range of 6~50 nm, Cu particles exhibiting short rod or spherical shape within 30 nm are 9R structure, and other particles size larger than 30 nm exhibiting long rod or spherical shape are fcc structure. The segregation of trace Mn and Ni in rod particles on the interface between Cu particles and matrix is more obvious. After ageing at a higher temperature range, the yield strength of the tested steel decreases linearly with the increase of tempering temperature. The main strengthening mechanism of the HSLA steel is fine grain strengthening, followed by dislocation strengthening and precipitation strengthening. The calculated results show that every 1%Cu added in the tested steel can produce about 90 MPa precipitation strengthening increment under the condition of overageing heat treatment. The strength difference between the surface and the center of the tested steel plate is about 40 MPa, which is mainly due to the difference of grain size and dislocation density of steel.

调质态含Cu高强钢的强化机理及钢中Cu的析出行为

[J].对含Cu低合金高强度钢板淬火并经高温时效后,采用SEM、EBSD、HRTEM和APT等手段对其微观组织和纳米尺度Cu的析出相进行了表征,对其厚度截面的室温拉伸性能进行了测定,并对钢板厚度方向近表面和心部的强化机理进行了分析。结果表明,高温时效后钢中Cu的析出相尺寸在6~50 nm范围内,30 nm以内的为9R结构的短棒状或球状粒子,30 nm以上的为fcc结构的长棒状粒子,棒状粒子中微量的Mn、Ni在Cu粒子与基体界面上的偏聚更明显。在较高温度范围内进行时效后,钢的屈服强度随着时效温度的升高而呈大致线性下降趋势,钢的主要强化机制为细晶强化,其次为位错强化和析出强化,经计算,钢中每1% (质量分数)的Cu在过时效状态下能够产生约90 MPa的析出强化增量。钢板厚度截面存在强度差异,表面与心部强度相差约40 MPa,这主要是由于晶粒尺寸及位错密度差异所导致。

Influence of the aging time on the microstructure and electrochemical behaviour of a 15-5PH ultra-high strength stainless steel

[J].

Aging hardening behavior and corrosion resistance of 15-5PH stainless steel

[J].

15-5PH不锈钢的时效硬化行为及耐蚀性能

[J].

Effects of copper on the corrosion properties of low-alloy steel in an acid-chloride environment

[J].

Effect of alloying additions on the pitting resistance of 18% Cr austenitic stainless steel

[J].

Effects of Mo, Cu, Si and P on anodic behavior of 17Cr steels

[J].

Effect of Cu on the microstructure and mechanical properties of a low-carbon martensitic stainless steel

[J].

On the current role of atom probe tomography in materials characterization and materials science

[J].

Atom probe tomography for catalysis applications: A review

[J].

An atom probe tomography study of site preference and partitioning in a nickel-based superalloy

[J].

Effect of SO2 on corrosion evolution of Q235B steel in simulated coastal-industrial atmosphere

[J].

模拟工业-海岸大气中SO2对Q235B钢腐蚀行为的影响

[J].采用循环干/湿模拟腐蚀增重实验、动电位极化曲线、电化学阻抗谱和XRD方法, 研究了模拟海岸-工业大气中SO<sub>2</sub>对Q235B钢腐蚀行为的影响. 结果表明, 在腐蚀初期SO<sub>2</sub>抑制了Q235B钢的腐蚀; 在腐蚀后期, SO<sub>2</sub>促进了Q235B钢的腐蚀. 当SO<sub>2</sub>的浓度较低时, 腐蚀速率随SO<sub>2</sub>浓度的升高而增大; 当SO<sub>2</sub>的浓度较高时, 腐蚀速率随SO<sub>2</sub>浓度的升高而减小. 工业-海岸大气中的SO<sub>2</sub>组分可以抑制腐蚀产物中g -FeOOH和b<sup> </sup>-FeOOH的生成, 而促进a<sup> </sup>-FeOOH生成. 低碳钢腐蚀速率随SO<sub>2</sub>浓度变化出现的极值现象与SO<sub>2</sub>导致的锈层相组分变化密切相关.

Impact of reversed austenite on the pitting corrosion behavior of super 13Cr martensitic stainless steel

[J].

Numerical approach for atmospheric corrosion monitoring based on EIS of a weathering steel

[J].

Corrosion and cavitation erosion behavior of GLNN/Cu composite in simulated seawater

[J].Herein, three-dimensional graphene-like nanosheet network (3D-GLNN)/copper (Cu) materials were synthesized using hop-pressing (HP) and hot-rolling (HR) methods and their corrosion resistance and mechanism were investigated using polarization curves, electrochemical impedance spectroscopy (EIS), and weight loss data after a cavitation corrosion test. Microstructural characterization results revealed that the 3D-GLNN structure was intact in the bulk composites, thereby restricting the effective grain growth of the Cu matrix. Compared with pure Cu, the Vickers hardness of 3D-GLNN/Cu fabricated using the HP and HR methods improved by 8% and 46%, respectively. Polarization curve results indicated that the anodic dissolution current of 3D-GLNN/Cu was considerably lower than that of pure Cu, indicating that 3D-GLNN/Cu exhibited better corrosion resistance. EIS measurements under a corrosion potential revealed that the electrode process kinetics was complex, with both charge and mass transfer controlling it. By extending the immersion time from 1 h to 9 d, the corrosion potential first became positive and then became negative. The capacitance arc at a high-frequency EIS range first increased and then decreased, attributed to the formation and detachment of a CuCl salt film. Diffusion impedance was observed in the low-frequency EIS range, with a phase angle of 18°-23°, indicating that the mass transfer process was not attributed to a single species but controlled by anodic and cathodic reactants. The constant phase angle element (CPE) behavior of the electrochemical system was further evaluated using the ohm-corrected phase angle and impedance modulus. The high-frequency phase angle was greater than -90 °, while the slope of impedance modulus was approximately -0.9; thus, the CPE was used to model the EIS data. The CPE behavior was attributed to the surface distribution of the charge transfer resistance and interface capacitance, implying a time-constant dispersion on the surface. Weight loss data after the cavitation corrosion test indicated that pure Cu showed better cavitation resistance than 3D-GLNN/Cu fabricated using the HR and HP methods. This is because of the difference in the elastic modulus between the graphene and Cu matrix that caused deformation dissonance during cavitation erosion.

三维石墨烯/Cu复合材料在模拟海水环境中的腐蚀和空蚀行为

[J].采用热压和热轧方法制备了三维石墨烯纳米片网络/Cu复合材料(3D-GLNN/Cu),组织表征结果表明,在块体复合材料中石墨烯网络结构保持完整,有效限制了Cu基体晶粒长大,热压态和热轧态3D-GLNN/Cu的硬度分别较纯Cu提高了8%和46%。采用电化学方法和空蚀失重分析研究了其在模拟海洋环境中的腐蚀和空蚀行为。极化曲线测试结果表明,3D-GLNN/Cu的阳极溶解电流与热压态纯Cu相比显著降低,热轧处理对复合材料的耐蚀性影响不大。腐蚀电位下的电化学阻抗谱(EIS)及电化学等效电路拟合分析结果表明,3D-GLNN/Cu的电极过程动力学较为复杂,主要受电荷转移和扩散过程共同控制。欧姆电阻校正后的Bode图结果表明,高频区的相位角大于-90°而阻抗模斜率约为-0.9,Cu及2种3D-GLNN/Cu复合材料在模拟海水中均存在常相位角元件(CPE)特征,这主要是因为电极表面材料结构和成分不均一性导致的局部界面电容和电荷转移电阻存在差异。随着浸泡时间延长(从1 h到9 d),EIS高频区容抗弧均是先增加后减小,主要是因为腐蚀生成的CuCl盐膜在表面的覆盖与局部脱落有关,EIS低频区出现扩散阻抗特征,且低频区相位角为18 °~23 °,说明电极过程不是单一反应物的Warburg扩散阻抗特征,而是受阴阳极传质过程共同控制。空蚀失重结果表明,热轧后的3D-GLNN/Cu与热压态的材料相比,耐空蚀性能显著下降,这主要是因为石墨烯与Cu基体的弹性模量的差异,在空蚀机械冲击力作用下形变不协调,易产生凹坑。

Study on the precipitation of γ' in a Fe-Ni base alloy during ageing by APT

[J].

Fe-Ni基合金时效过程中γ'相析出的原子探针层析技术研究

[J].将一种Fe-Ni基沉淀强化奥氏体合金在980 ℃固溶后水淬,在620 ℃经过不同时间时效。利用硬度测试及原子探针层析技术(APT)研究时效过程中γ'相的析出行为及其对材料硬度的影响。结果表明,当时效时间小于6 h时,合金硬度增加较快,由时效前的145 HV迅速增加至205 HV,随后硬度增加速率缓慢;时效120 h时,硬度为251 HV。APT结果表明,合金经固溶处理后,合金元素均匀分布在基体中。在时效最初阶段,Ti发生了较为明显的偏聚,形成含有Fe、Ni和Al等元素的富Ti纳米团簇。随着时效时间延长,富Ti纳米团簇中的Ni和Al原子的含量逐步增多,而Fe、Cr及Mo等原子的含量不断减少;当时效至120 h时,团簇中Ni与Ti+Al比值近似于3,即已完全形成γ'相,表明γ'相析出是形核-长大过程。合金硬度的变化与时效过程中γ'相的数量密度和体积分数有关。

The effect of tempering temperature on the microstructure and electrochemical properties of a 13wt.% Cr-type martensitic stainless steel

[J].

Unmasking of the temperature window and mechanism for “loss of passivation” effect of a Cr-13 type martensite stainless steel

[J].

Quantitative analysis of Cr-depleted zone morphology in low carbon martensitic stainless steel using FE-(S)TEM

[J].

Formation of M23C6-type precipitates and chromium-depleted zones in austenite stainless steel

[J].

Effect of Cr addition on the corrosion behavior of twinning-induced plasticity steel

[J].High-Mn austenitic Fe-Mn-C twinning-induced plasticity (TWIP) steels are prospective candidates in many industrial fields, owing to their excellent mechanical properties. However, these steels show poor corrosion resistance, which affects their performance and prevents their applications particularly in aqueous environment. In this study, an effective way to improve the corrosion resistant property of TWIP steels was described by understanding the corrosion behavior of TWIP steel that was alloyed with Cr. A series of Fe-25Mn-xCr-0.3C (x = 0, 3, 6, 9, and 12, mass fraction, %) TWIP steels were prepared in a vacuum arc melting furnace using high purity raw materials (≥ 99.8%). Thereafter, the resulting steels were solution treated at 1200oC for 2 h under an argon atmosphere. The effect of Cr addition on the corrosion behavior of the prepared TWIP steels was investigated using various analytical techniques including XRD, potentiodynamic polarization, electrochemical impedance spectroscopy, and XPS. XRD results showed that the TWIP steels with Cr content that ranged from 3% to 12% retained their single austenite phase. Moreover, increasing the concentration of Cr in the alloys substantially increased and decreased the corrosion potential and corrosion current density, respectively. These resulted in an improvement in the corrosion resistant property of the alloys, which was verified by the increase in the charge transfer resistance found in the Nyquist plots. Meanwhile, XPS results revealed that the prepared quasi-passive oxide film was composed of FeO, Fe2O3, FeOOH, MnO, MnO2, Cr2O3, and Cr(OH)3. Furthermore, these results showed the progressive enrichment of Cr oxides and decrease of both Fe and Mn oxides in the outermost oxide as the Cr content was increased. The improved corrosion resistance of the prepared TWIP steels was caused by the protective Cr oxide film.

Cr添加对孪生诱发塑性钢腐蚀行为的影响

[J].通过动电位极化曲线、电化学阻抗谱(EIS)测试和X射线光电子能谱(XPS)分析等研究了Cr添加对Fe-25Mn-xCr-0.3C (x = 0、3、6、9、12,质量分数,%)孪生诱发塑性(TWIP)钢腐蚀行为的影响。结果表明,TWIP钢基体中Cr含量增加导致腐蚀电位显著增加和腐蚀电流密度明显降低。耐腐蚀性能改善还通过Nyquist图中电荷转移电阻随着Cr含量的增加而增加得到证实。XPS结果表明,准钝化膜由FeO、Fe<sub>2</sub>O<sub>3</sub>、FeOOH、MnO、MnO<sub>2</sub>、Cr<sub>2</sub>O<sub>3</sub>和Cr(OH)<sub>3</sub>等组成,并且随着Cr含量增加,Cr氧化物在最外层氧化物中逐渐富集,同时Fe氧化物和Mn氧化物逐渐减少。正是这种保护性Cr氧化膜提高了TWIP钢的耐腐蚀性能。

Passive films on stainless steels—Chemistry, structure and growth

[J].

The roles of mercapto, benzene and methyl groups in the corrosion inhibition of imidazoles on copper: I. Experimental characterization

[J].