当前针对Zn及其合金的表面改性涂层包括聚合物涂层[7]、磷酸转化涂层[8]、金属氧化物涂层[9]以及有机-无机杂化涂层[10]。这些涂层能够有效减缓Zn2+的释放并改善Zn基体的腐蚀模式,同时提高其生物功能性,如促骨生成和促血管生成[11]。但是对于理想的可降解锌基骨植入体而言,除了具备腐蚀降解调控和促骨性能外,良好的抗菌抗感染性能也极为必要。有研究尝试通过ZnO/ZnP涂层[12]、SrP/CaP涂层[13]、多巴胺(PDA)涂层[14,15]改善Zn及其合金的抗菌性能,但是抗菌效果仍不够理想。因此,具有耐腐蚀性、促成骨性和抗菌活性的改性涂层对于Zn基体临床转化应用至关重要。金属-多酚表面化学涂层能够改善金属的腐蚀行为,提高生物相容性,具有潜在的抗菌功能,在金属生物材料表面改性方面具有极大的应用潜力[16,17]。此外,金属-多酚涂层能够持续释放活性物质(如金属离子、活性分子等),并且有望实现可控的药物释放功能。

单宁酸(tannic acid,TA)是一种天然多酚化合物,广泛存在于植物中,含有丰富的邻苯三酚羟基活性基团,具有很强的亲和力,能够与含有氨基或巯基的分子通过分子间作用力、H键、共价键等方式结合,还能与大约20种金属离子配位鳌合形成稳定金属-酚醛结构[18],适用于各种基材,包括各种纳米和微米尺度的材料(如Au纳米颗粒、SiO2纳米颗粒等)[19]。研究[20,21]表明,金属-多酚涂层与Ti、Mg和Fe等具有优异的结合性能,能够提高基底抗腐蚀能力和生物相容性。此外,金属-多酚网络具有潜在的载药能力,在金属离子和单宁酸配位自组装过程中引入吲哚美辛(IND),利用共价结合作用将IND接枝到单宁酸中能够实现药物控释[22]。更重要的是,金属离子不仅参与涂层的构建,改善涂层质量,而且具有促骨生成和抗菌抗感染等功能。由于配位能力和自身活性的不同,不同的金属离子对涂层的结构调控和生物功能性改善具有一定差异性。目前,国内外关于金属-多酚载药涂层的研究已有大量报道[23,24],但是对于金属-多酚载药涂层持续控制金属离子和药物释放的机制等关键问题仍需要进一步研究。

本工作利用金属离子和单宁酸化学配位,在Zn表面构建了4种金属离子(Cu2+、Fe3+、Mg2+、Sr2+)介导的金属-多酚涂层并装载二甲双胍(metformin,Met),以实现对金属离子和药物的持续控释。本工作选用的Cu2+、Fe3+、Mg2+和Sr2+与单宁酸具有较好的化学配位能力,这些金属离子也对成骨分化和抗菌抗感染有一定益处[25,26]。此外,Met是一种富含氨基的降血糖药物,能够和H键通过静电相互作用与有机分子(如TA分子)结合。Met能上调成骨相关基因COL-I和RUNX-2的表达,同时促进矿化结节的形成,诱导成骨细胞分化[27,28]。本工作通过涂层表面形貌观察和成分分析,提出涂层形成机制;采用暂态电化学测试和长期浸泡实验研究样品的腐蚀降解行为;通过体外成骨细胞培养实验研究促骨分化功能;通过细菌培养实验验证其抗菌性能。

1 实验方法

1.1 涂层制备

实验中所用挤压态纯Zn棒的纯度为99.99%。将纯Zn棒切割成直径10 mm、厚度1.8 mm的圆片,并用SiC水砂纸依次打磨至2000号。使用蒸馏水、无水乙醇超声清洗干净,放入真空干燥箱干燥备用。

ZnP预处理层的制备方法为:配制含有10.8 mg/mL NaH2PO4和6.5 mg/mL Zn3(NO3)2的混合溶液,将清洗后的样品放入混合溶液,在50℃恒温水浴下反应1 h后将样品取出并用蒸馏水清洗,得到ZnP打底层样品。放入真空干燥箱干燥备用。

金属-多酚载药涂层的制备方法为:将0.5 mg/mL的TA搅拌溶解在蒸馏水中,然后将预处理的样品浸入TA水溶液中,在50℃恒温水浴反应1 h后取出样品,清洗干燥后得到TA处理的样品。将0.1 mg/mL的Met搅拌溶解在蒸馏水中,并分别添加0.01 mol/L的CuCl2‧2H2O、FeCl3‧6H2O、MgCl2‧6H2O和SrCl2‧6H2O,然后将TA处理过的样品分别放入上述混合溶液中,在50℃恒温水浴反应1 h后取出样品并清洗干燥,得到4种不同金属离子介导的多酚载药涂层,分别命名为Cu-TA/Met、Fe-TA/Met、Mg-TA/Met、Sr-TA/Met。将TA处理的样品放入Met水溶液,得到对照组多酚载药涂层TA/Met。

1.2 样品表面表征与分析

用JSM-7401F场发射扫描电子显微镜(SEM)观察样品表面形貌。通过Nicolet 5700 Fourier变换红外光谱仪(FTIR)检测涂层表面的化学官能团。利用XSAM800 X射线光电子能谱仪(XPS)检测涂层表面化学键合状态,XPS主要实验参数为:X射线源为单色Al靶,X射线工作电压为12 kV,工作室抽真空至4 × 10-7 Pa,实验数据以C (284.8 eV)为标准峰进行荷电校正。校正后的数据用Thermo Avantage 8.4软件进行拟合。

1.3 电化学腐蚀表征

采用Zahner IM6电化学工作站对样品进行电化学测试,包括动电位极化(PDP)曲线和电化学阻抗图谱(EIS)。工作站为三电极系统,包括饱和甘汞参比电极(SCE)、Pt对电极(1.5 cm × 1.5 cm)及工作电极(测试样品,暴露面积为0.79 cm2)。测试前将样品背面用砂纸打磨后用铜导线连接,并用硅橡胶进行密封,将测试面暴露在外,选用Hank's溶液作为电解液在37℃条件下进行测试。Hank's溶液成分为:8.00 g/L NaCl、0.40 g/L KCl、0.20 g/L MgSO4·7H2O、0.19 g/L CaCl2·2H2O、0.35 g/L NaHCO3、0.12 g/L Na2HPO4·12H2O和0.06 g/L KH2PO4。对于PDP曲线测试,扫描速率为1 mV/s,利用Tafel外推法获得样品的自腐蚀电位(Ecorr)和自腐蚀电流密度(icorr)。EIS测量的扰动电位是10 mV的正弦扰动信号,测试频率为2 × 105~0.01 Hz,EIS数据用ZSimpWin软件拟合。

1.4 体外浸泡实验

样品在37℃的Hank's溶液中浸泡21 d,每3 d更换一次浸泡液。收集浸泡液,用TAS-990F原子吸收分光光度计检测不同样品的Zn2+浓度,每组4个平行样品。浸泡期间,每天用PHS-2F pH计测试pH值变化。浸泡21 d后,将样品用去离子水清洗后置于真空干燥箱干燥。采用JSM-7401F SEM和X'PertX射线衍射仪(XRD)分别表征样品的表面形貌和相结构。对于Zn基底的腐蚀情况,根据标准ASTM G1-03,将样品浸入Cr2O3 (20 mg/mL,80℃)溶液1 min去除表面涂层和腐蚀产物,并采用JSM-7401F SEM观察其形貌。为了确定Met的释放,浸泡过程中每天取样直到第14 d,采用UV-2600i紫外分光光度计测试其释放浓度。

1.5 体外细胞行为评价

1.5.1 细胞黏附、铺展行为

选用小鼠前成骨细胞MC3T3-E1 (ATCC,CRL-2594)评价细胞在材料表面的黏附、铺展行为。将样品正、反面分别在紫外辐照下灭菌0.5 h后放入24孔细胞培养板中。不锈钢(SS)样品作为阴性对照。每孔接种1 mL细胞密度为2 × 104 cell/mL的细胞悬液,之后放入含5%CO2 (体积分数)的37℃恒温孵箱。1 d后取出样品用磷酸盐缓冲液(PBS)清洗样品3次,然后每孔加入0.5 mL 2.5%C5H8O2 (质量分数)固定细胞4 h;之后用PBS溶液清洗样品3次并滴加0.5 mL稀释的C28H31ClN2O3进行染色,采用Optiphot-2倒置荧光显微镜观察细胞。

1.5.2 细胞分化行为

选用小鼠前成骨细胞MC3T3-E1评价细胞在材料表面的分化行为,通过碱性磷酸酶(ALP)的染色和表达评价其分化行为。细胞接种步骤和接种密度如1.5.1所述,选用SS样品作为阴性对照。细胞接种培养1 d后用成骨诱导分化培养基替换细胞培养基,每3 d换一次液,于第14 d时吸出培养基,并用PBS溶液清洗3次。每孔加入300 μL的1.0%Triton X-100 (质量分数)试剂裂解细胞,收集细胞裂解液离心,吸取上清液30 μL至96孔板,将获得的裂解物用于ALP活性检测。使用蛋白定量(TP)测定试剂盒测定裂解物的总蛋白,并计算得出ALP活性。使用BCIP/NBT ALP试剂盒进行ALP染色:利用4% (质量分数)多聚甲醛溶液固定30 min后,用PBS溶液清洗3次加入氯化硝基蓝四唑(NBT)和5-溴-4-氯-3-吲哚磷酸盐(BCIP)染色液,在室温下孵育30 min。吸出染色液用PBS溶液清洗3次,利用Stemi 2000-C体式显微镜拍摄样品的染色情况。

1.6 体外抗菌实验

采用革兰氏阳性的金黄色葡萄球菌(S.aureus)和革兰氏阴性的大肠杆菌(E.coli)评价样品的抗菌能力。没有样品的细菌悬浮液作为阴性对照,SS样品作为参照组。将样品正、反面分别在紫外辐照下灭菌1 h后放入24孔板中,每个样品表面滴加1 mL细菌数量为106 cfu/mL的菌液。细菌在样品表面培养1 d后,收集样品组的细菌悬液,将100 μL细菌悬液转移到96孔板中,然后利用Quant酶标仪在620 nm处测试细菌悬液的吸光度[5]。同时,收集样品组的细菌悬液并稀释100倍,吸取30 μL稀释后的细菌悬液加入到琼脂固体培养基中,使用灭菌三角耙将菌液均匀地涂满整个培养基平板,并盖好培养皿,放置于5%CO2 (体积分数)的37℃恒温细菌培养箱中培养。1 d后取出固体培养基平板,然后利用Stemi 2000-C体式显微镜观察、拍摄菌落数。

2 实验结果与分析

2.1 涂层表面

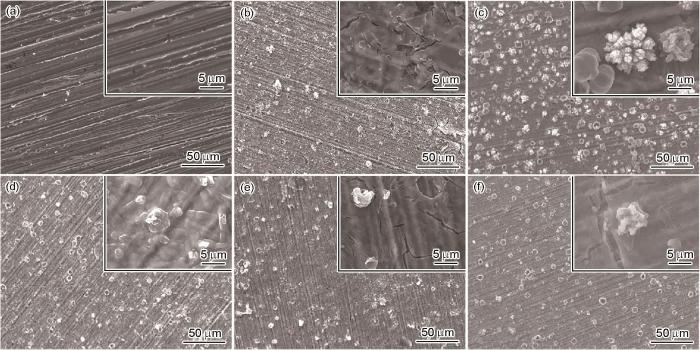

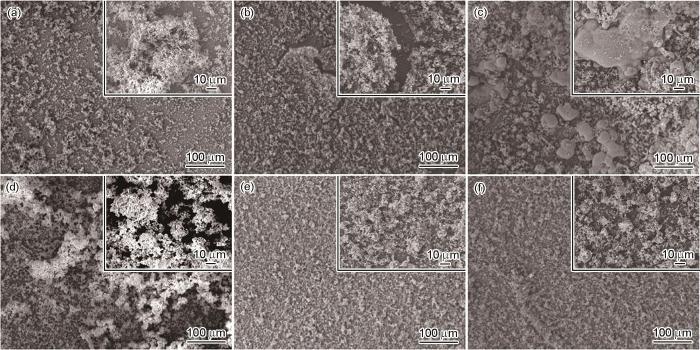

纯Zn、多酚载药涂层(TA/Met)、金属-多酚载药涂层(Cu-TA/Met、Fe-TA/Met、Mg-TA/Met、Sr-TA/Met)表面形貌的SEM像如图1所示。可以看出,纯Zn表面的打磨划痕清晰可见(图1a)。与纯Zn相比,改性后样品表面被涂层均匀且完整覆盖,表面出现了聚集性的团簇状颗粒,TA/Met表面团簇状颗粒较少(图1b);加入金属离子后的表面团簇状聚集颗粒明显增多(图1c~f),尤其Cu-TA/Met表面有大量的颗粒聚集(图1c)。这可能是因为外加的金属离子与TA配位螯合形成金属复合物,这种金属复合物会团聚堆积形成团簇物 [20,29]。注意到涂层表面均出现了一些裂纹。这主要是因为在干燥过程中金属-多酚网络中的H2O分子迅速蒸发引起的结构破坏,进而导致涂层不均匀收缩,产生裂纹[30]。

图1

图1

纯Zn、多酚载药涂层(TA/Met)、金属-多酚载药涂层(Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met)表面形貌的SEM像

Fig.1

Surface SEM images of Zn (a), polyphenol drug-loaded coating (TA/Met) (b), and metal-polyphenol drug-loaded coatings including Cu-TA/Met (c), Fe-TA/Met (d), Mg-TA/Met (e), and Sr-TA/Met (f) (Insets show the high magnified images)

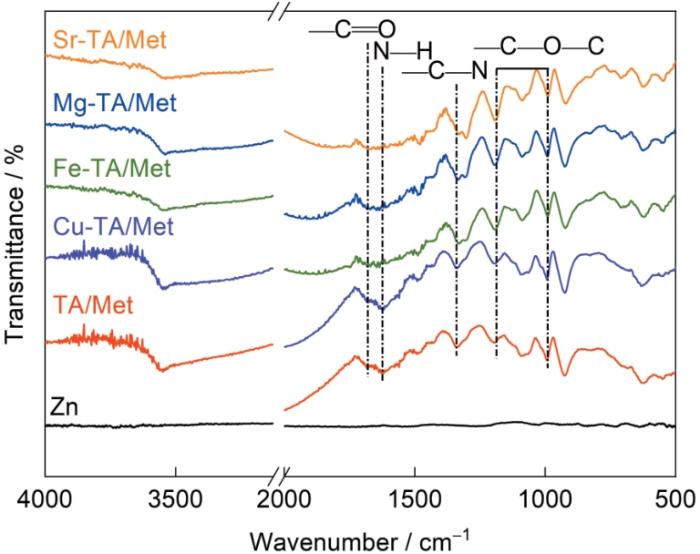

图2为TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met的FTIR。C=O (约1681.6 cm-1)和C—O—C (约1174.3和1015.0 cm-1)峰的出现表明TA的成功引入,N—H (约1626.2 cm-1)和C—N (约1340.1 cm-1)特征峰的出现表明Met被成功装载在涂层中[31]。从图2还可以看出,不同样品N—H峰的强度有差异。主要原因归结如下:Met的氨基与TA的酚羟基之间存在大量的H键作用,N—H的振动频率在H键的影响下会减小,因此TA/Met的N—H峰强度较小[32,33]。此外,加入金属离子后,与TA/Met相比,Cu-TA/Met的C—N峰形状变化不大,而Fe-TA/Met、Mg-TA/Met、Sr-TA/Met的C—N峰附近出现了一个新峰。这与在分子内H键以及金属离子与Met的氨基、TA的羟基所形成的配位键共同作用下,形成的苯并咪唑环拉伸有关[34,35]。

图2

图2

纯Zn、TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met的FTIR谱

Fig.2

FTIR spectra of Zn, TA/Met, Cu-TA/Met, Fe-TA/Met, Mg-TA/Met, and Sr-TA/Met

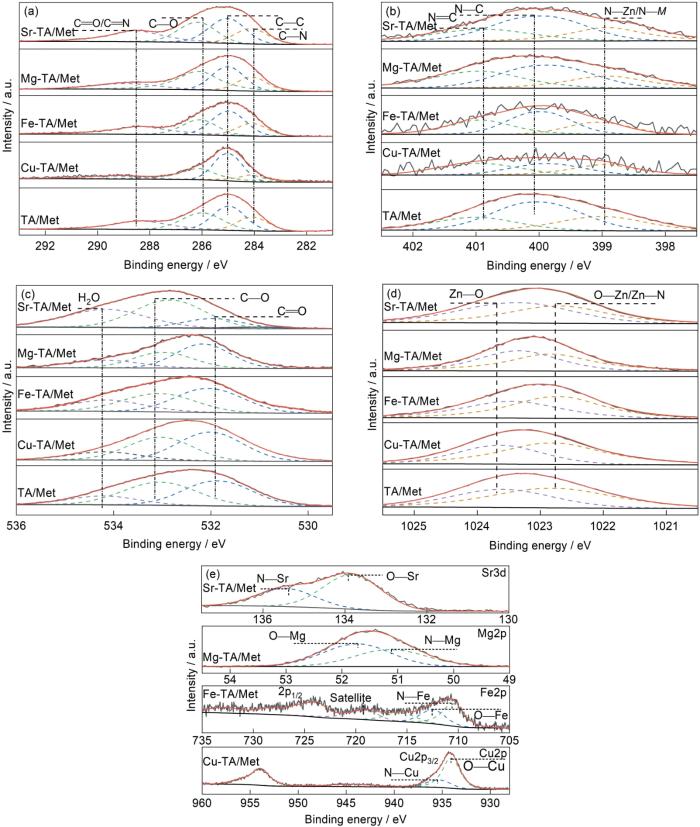

TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met的XPS如图3所示。图3a是C1s的高分辨谱,C—N特征峰的存在进一步证明Met成功装载到涂层表面,注意到Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met样品的C—N特征峰强度依次增强,可能是因为不同金属离子介导的多酚涂层装载Met的能力不同。图3b是N1s的高分辨谱,N1s可以分成3个峰:位于约400.8 eV的N=C键,约400.1 eV处的N—C键,约398.9 eV处的N—M (Cu、Fe、Mg、Sr)配位键。其中Cu-TA/Met的N峰强度最低,再次表明其药物装载量最少。N—M配位键的出现,表明金属离子与Met分子中的氨基发生了配位作用[36]。值得注意的是,对应的金属离子高分辨谱也都出现了N—M配位键,验证了金属离子和Met的配位作用。图3c是O1s高分辨谱,注意到所有样品都出现了H2O (约534.1 eV)、C—O (约533.1 eV)和C=O (约531.9 eV)的特征峰,H2O峰的出现可能是因为涂层制备过程中金属酚胺网络会吸附大量游离H2O分子[20]。从图3d中可以看出,所有样品都出现了Zn—O (约1023.7 eV)和O—Zn/N—Zn (约1022.6 eV)特征峰,Zn—O峰的出现是因为涂层制备是在碱性条件下,可能会有ZnO的形成[37]。O—Zn/N—Zn峰的出现可以归因于TA和Met分子中的O/N元素与基底释放的Zn2+配位形成。图3e是Sr2+、Mg2+、Fe3+和Cu2+的高分辨谱,Sr3d可以分为N—Sr (约135.3 eV)和O—Sr (约134.0 eV)特征峰,可以归因于Sr2+与O/N元素的配位螯合作用[38,39]。Mg2p、Cu2p和Fe3d同样可以分成O—M和N—M特征峰。注意到金属-多酚载药涂层4种样品中与O配位峰的强度均高于与N配位峰,这可能是因为金属离子与TA分子的配位螯合能力强于Met。样品表面元素的含量如表1所示。可见,金属-多酚涂层样品中检测到对应的金属元素,但是各种金属元素的含量不同,这可能是由于不同金属离子与TA和Met的螯合能力不同导致的。这些结果表明金属离子能够同时与TA和Met分子发生配位螯合作用进而成功构建金属-多酚载药涂层。

图3

图3

TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met的高分辨XPS

Fig.3

High-resolution XPS of C1s (a), N1s (b), O1s (c), Zn2p (d), Cu2p, Fe2p, Mg2p, and Sr3d (e) of TA/Met, Cu-TA/Met, Fe-TA/Met, Mg-TA/Met, and Sr-TA/Met

表1 样品表面元素含量 (atomic fraction / %)

Table 1

| Sample | C | N | O | Zn | M |

|---|---|---|---|---|---|

| Zn | 7.11 | 0.19 | 19.54 | 73.16 | - |

| TA/Met | 51.15 | 5.68 | 34.31 | 8.86 | - |

| Cu-TA/Met | 48.77 | 1.94 | 36.53 | 11.48 | 1.28 |

| Fe-TA/Met | 52.12 | 2.32 | 30.94 | 10.55 | 4.07 |

| Mg-TA/Met | 44.28 | 2.68 | 33.74 | 14.07 | 5.23 |

| Sr-TA/Met | 38.25 | 3.13 | 47.35 | 7.89 | 3.38 |

2.2 电化学腐蚀

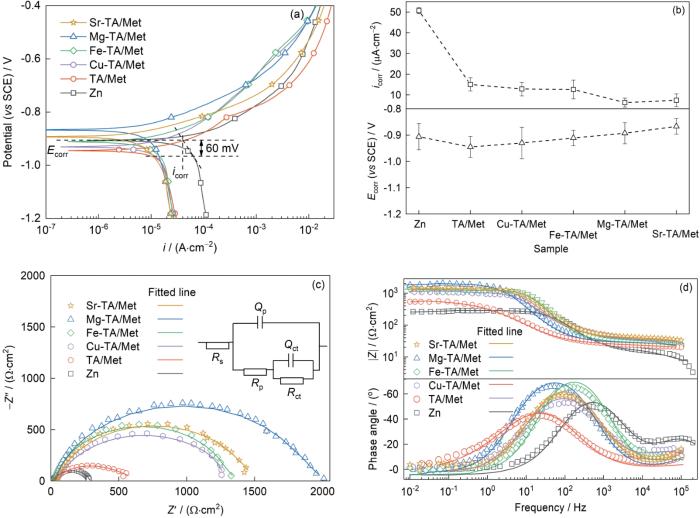

Zn、TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met的暂态电化学测试结果如图4所示。从PDP曲线(图4a)、Ecorr和icorr结果(图4b)可以看出,相比于纯Zn,改性后的样品阴极曲线分支明显左移,同时通过Tafel外推法计算得到的icorr也表明改性的样品相比于纯Zn有更小的icorr,这表明涂层显著提高了Zn基体的抗腐蚀能力。从图4b可以看出,与TA/Met样品相比,Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met样品具有更低的icorr,其中Mg-TA/Met样品的icorr最低。从图4c可以看出,相比于纯Zn和TA/Met样品,M-TA/Met样品的阻抗环更大,其中Mg-TA/Met样品具有最高的阻抗环,表明其抗腐蚀能力更高。图4d也出现类似的趋势。为了进一步分析其腐蚀行为,利用等效电路图Rs(Qp(RP(QctRct)))对EIS数据进行拟合,其中,Rs代表溶液电阻,Qp和Rp分别表示样品表面涂层的电容和电阻,Qct和Rct分别代表界面电荷转移反应的双电层电容和电阻。一般来说,Rct反映电荷从基体/电解液界面进行转移的难易程度,因此其大小通常与样品的抗腐蚀能力对应。从拟合结果(表2)可以看出,相比于纯Zn和TA/Met样品,改性样品的Rct明显提高,表明其抗腐蚀能力增强。其中Mg-TA/Met的Rct最大,Sr-TA/Met、Fe-TA/Met和Cu-TA/Met的Rct依次降低。上述结果表明金属离子介导的多酚载药涂层相比于纯Zn和TA/Met组具有更好的抗腐蚀能力,其中4种金属离子介导的多酚载药涂层的抗腐蚀能力强弱依次为Mg-TA/Met > Sr-TA/Met > Fe-TA/Met > Cu-TA/Met。

图4

图4

Zn、TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met样品在(37 ± 0.5)℃下Hank's溶液中的动电位极化曲线,自腐蚀电位和自腐蚀电流密度,Nyquist和拟合等效电路图,及Bode-阻抗和Bode-相位角图

Fig.4

Potentiodynamic polarization curves (a), the obtained self corrosion potential (Ecorr) and self corrosion current density (icorr) (b), Nyquist plots and equivalent electrical circuit (inset) (c), Bode-impedance and Bode-phase angle (d) diagrams of the Zn, TA/Met, Cu-TA/Met, Fe-TA/Met, Mg-TA/Met, and Sr-TA/Met in Hank's solution at (37 ± 0.5)oC (i—gal-vanic current density, Z″—imaginary part of impedance, Z′—real part of impedance, |Z|—impedance modulus, Rs—resistance of electrolyte, Qp—capacitance of the corrosion products layer, Rp—resistance of the coating, Qct—double-layer capacitance, Rct—resistance of the interfacial charge transfer reaction)

表2 EIS拟合结果

Table 2

| Sample | Rs Ω·cm2 | Qp 10-6 S n ·Ω-1·cm-2 | Rp Ω·cm2 | Qct 10-6 S n ·Ω-1·cm-2 | Rct Ω·cm2 |

|---|---|---|---|---|---|

| Zn | 12.81 | 18.73 | 205.11 | 0.21 | 56.42 |

| TA/Met | 35.60 | 13.58 | 302.12 | 4.81 | 218.21 |

| Cu-TA/Met | 36.68 | 9.12 | 545.43 | 24.53 | 487.23 |

| Fe-TA/Met | 33.07 | 10.08 | 698.12 | 6.91 | 521.21 |

| Mg-TA/Met | 34.21 | 3.84 | 1221.24 | 23.11 | 825.23 |

| Sr-TA/Met | 36.58 | 3.48 | 843.25 | 23.14 | 731.12 |

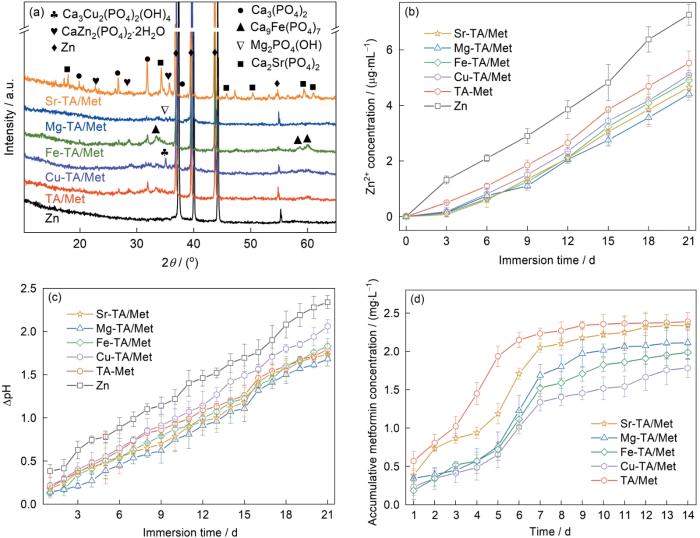

2.3 长期腐蚀浸泡

图5是Zn、TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met在Hank's溶液中浸泡21 d后表面形貌的SEM像。所有样品表面都出现了颗粒状的腐蚀产物。纯Zn表面腐蚀产物分布不均匀,有明显的裂缝状不连续区域。相比于纯Zn和TA/Met样品,金属-多酚载药涂层样品表面的腐蚀产物覆盖更完整,不连续区域更少,尤其是Mg-TA/Met和Sr-TA/Met表面腐蚀产物更均匀。相比于金属-多酚载药涂层,TA/Met涂层主要是通过TA和Met之间的H键和静电吸附作用力形成,稳定性和结合力较差,浸泡期间无法有效抑制腐蚀液扩散到Zn基体表面,而且可能会脱落,因此表面的腐蚀产物分布不均匀[22,40]。金属-多酚载药涂层中除了H键和静电吸附作用外,金属离子能够与TA和Met中的活性基团配位,使得涂层更加稳定,能够更有效地阻碍电解液的扩散。此外,表面暴露的活性基团(如氨基、羧基、羟基等)和金属离子作为腐蚀产物的形核位点,形成更均匀的腐蚀产物层[41]。

图5

图5

Zn、TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met在(37 ± 0.5)℃下Hank's溶液中浸泡21 d后表面形貌的SEM像

Fig.5

Surface SEM images of Zn (a), TA/Met (b), Cu-TA/Met (c), Fe-TA/Met (d), Mg-TA/Met (e), and Sr-TA/Met (f) immersed in Hank's solution at (37 ± 0.5)oC for 21 d (Insets show the high magnified images)

图6a为Zn、TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met浸泡21 d后表面腐蚀产物的XRD谱。纯Zn样品中的腐蚀产物峰强度较低,主要是因为Zn表面形成的腐蚀产物是无定形的复合物,结晶性差。改性后样品表面都检测到了CaZn2(PO4)2‧2H2O和Ca3(PO4)2特征峰。此外,Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met的XRD谱中分别出现了Ca3Cu2(PO4)2(OH4)、Ca9Fe(PO4)7、Mg2PO4(OH)、Ca2Sr(PO4)2特征峰,可以归因于浸泡过程中释放的金属离子与溶液中阴离子(PO

图6

图6

纯Zn、TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met在(37 ± 0.5)℃下Hank's溶液中浸泡21 d后的XRD谱、Zn2+累计释放量、pH累计变化量和二甲双胍累计释放量

Fig.6

XRD spectra (a), the accumulated Zn2+ concentrations (b), pH value changed with immersion time (c), and metformin concentration (d) of Zn, TA/Met, Cu-TA/Met, Fe-TA/Met, Mg-TA/Met, and Sr-TA/Met immersed in Hank's solution at (37 ± 0.5)oC for 21 d

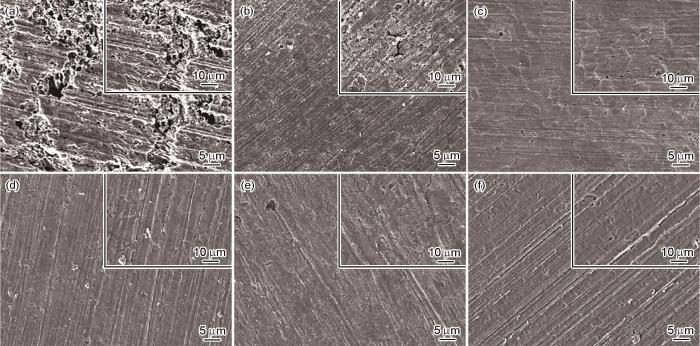

图7是Zn、TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met在Hank's溶液中浸泡21 d后去除腐蚀产物后表面形貌的SEM像。纯Zn表面出现了明显的局部小孔腐蚀,且腐蚀坑相互贯穿连接。TA/Met样品表面也存在少量的腐蚀坑。与纯Zn和TA/Met样品相比,金属-多酚载药涂层改性后的样品表面没有明显的腐蚀坑,且腐蚀较为均匀,表现出更优异的长期腐蚀保护效果。

图7

图7

Zn、TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met在(37 ± 0.5)℃下Hank's溶液中浸泡21 d去除腐蚀产物后表面形貌的SEM像

Fig.7

Surface SEM images of Zn (a), TA/Met (b), Cu-TA/Met (c), Fe-TA/Met (d), Mg-TA/Met (e), and Sr-TA/Met (f) immersed in Hank's solution at (37 ± 0.5)oC for 21 d after removal of corrosion products (Insets show the high magnified images)

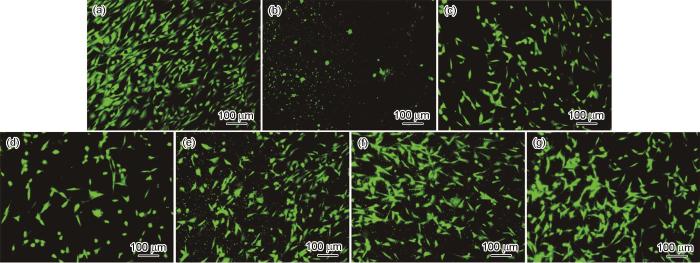

2.4 体外细胞行为评价

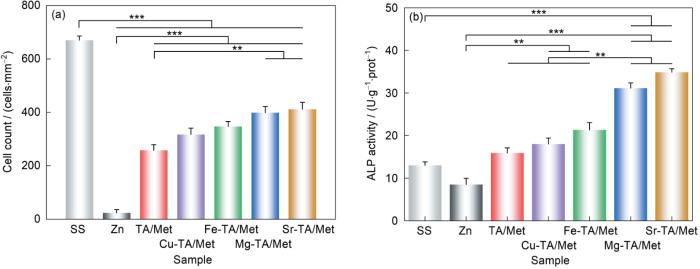

为评估涂层的体外成骨相容性,将成骨细胞MC3T3-E1直接在SS、Zn、TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met样品表面培养,观察细胞黏附和铺展,结果如图8所示。SS表面的细胞形态自然,铺展良好。纯Zn表面的成骨细胞呈现皱缩球形。相比于纯Zn,改性后的样品表面细胞形态自然,铺展较好。尤其是Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met样品表面的成骨细胞相比于纯Zn和TA/Met样品细胞形态更好,黏附数量更多。细胞黏附数量统计如图9a所示。可见,与纯Zn相比,TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met组的细胞黏附数量均明显增加,Sr-TA/Met样品表现出最高的细胞黏附数量。以上结果表明,金属-多酚载药涂层能有效提高成骨细胞的黏附和增殖。

图8

图8

MC3T3-E1在不锈钢(SS)、Zn、TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met样品表面培养1 d后的荧光图像

Fig.8

Fluorescence microscopy images of MC3T3-E1 cultured on stainless steel (SS) (a), Zn (b), TA/Met (c), Cu-TA/Met (d), Fe-TA/Met (e), Mg-TA/Met (f), and Sr-TA/Met (g) for 1 d

图9

图9

MC3T3-E1在SS、Zn、TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met样品表面培养1 d后的细胞黏附数量和碱性磷酸酶(ALP)活性定量结果

Fig.9

Adherent cell amounts (a) and quantification of alkaline phosphatase (ALP) activities (b) of MC3T3-E1 cultured on SS, Zn, TA/Met, Cu-TA/Met, Fe-TA/Met, Mg-TA/Met, and Sr-TA/Met for 1 d (Null hypothesis value of p < 0.05 was labeled as *, p < 0.01 as **, and p < 0.001 as ***)

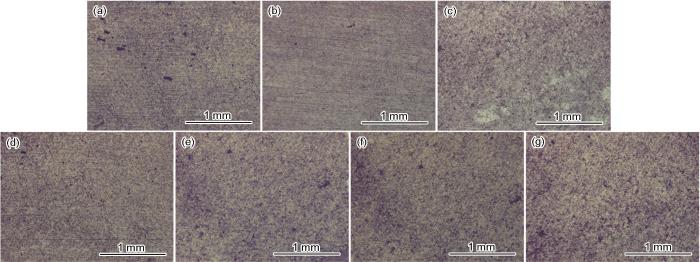

MC3T3-E1在SS、Zn、TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met样品表面培养14 d后的ALP定量结果如图9b所示。相比于纯Zn组和TA/Met组,金属-多酚载药涂层组表现出更高的ALP活性,其中Sr-TA/Met的活性最高。ALP染色结果如图10所示,表现出与定量结果类似的趋势,纯Zn表面只有少量紫色区域,改性涂层组中出现更多的紫色区域。4种金属-多酚载药涂层Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met组中的颜色深度和面积相比于TA/Met组有明显提高,其中Sr-TA/Met染色效果最为明显,表明金属-多酚涂层有效提升了碱性磷酸酶的表达。

图10

图10

MC3T3-E1在SS、Zn、TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met样品表面培养14 d后的ALP染色结果

Fig.10

ALP staining images of MC3T3-E1 cultured on SS (a), Zn (b), TA/Met (c), Cu-TA/Met (d), Fe-TA/Met (e), Mg-TA/Met (f), and Sr-TA/Met (g) for 14 d

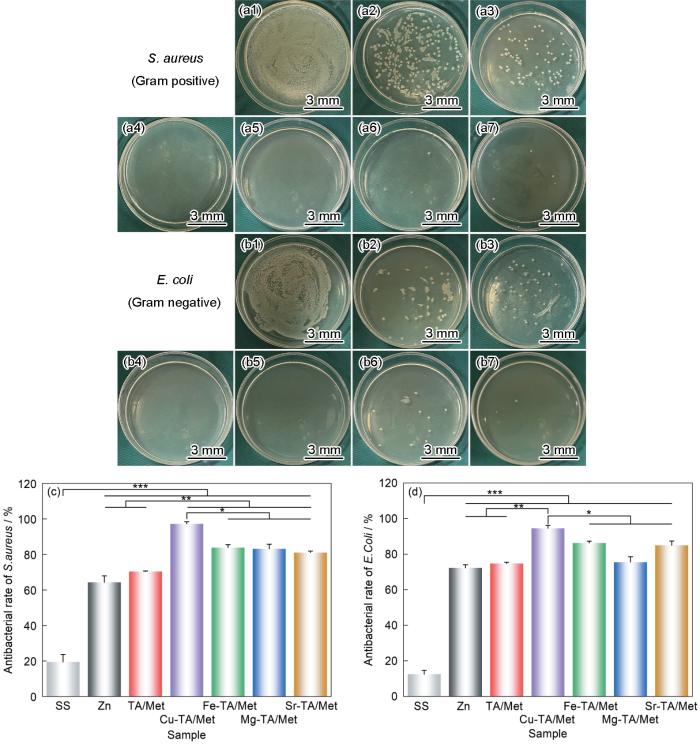

2.5 体外抗菌性能评价

图11是在样品表面培养1 d后金黄色葡萄球菌和大肠杆菌的平板涂附结果和抗菌率。SS样品表面铺满了菌落,纯Zn和TA/Met的平板表面菌落数量相比于SS有所减少。与纯Zn和TA/Met相比,Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met的菌落数明显减少。抗菌率和铺板结果趋势类似。Cu-TA/Met对金黄色葡萄球菌和大肠杆菌分别显示出约97%和95%的抗菌率,抗菌效果最好。这得益于TA分子和金属离子本身的抗菌特性以及2者的协同作用。

图11

图11

金黄色葡萄球菌(S.aureus)和大肠杆菌(E.coli)在SS、Zn、TA/Met、Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met表面孵育1 d的菌落数和抗菌率

Fig.11

Photos of colony numbers (a1-a7, b1-b7) and antibacterial rates (c, d) of S.aureus (a1-a7, c) and E.coli (b1-b7, d) cultured on SS (a1, b1), Zn (a2, b2), TA/Met (a3, b3), Cu-TA/Met (a4, b4), Fe-TA/Met (a5, b5), Mg-TA/Met (a6, b6), and Sr-TA/Met (a7, b7) for 1 d

3 分析讨论

3.1 金属-多酚载药涂层形成机制

不同金属离子介导的多酚-载药涂层构建机理如图12所示。金属-多酚载药涂层的构建过程分为TA和Met分子的共价结合、TA/Met在Zn表面的化学沉积以及金属离子的介导。首先,TA和Met分子在水溶液中通过共价作用进行自组装形成混合物。除了共价作用外,2者可能还会发生静电吸附和H键作用。随后,TA和Met化学沉积到Zn表面,Zn表面原位释放的Zn2+会与TA和Met分子中的活性官能团(羟基、氨基等)化学配位,将TA和Met分子固定到Zn表面。在金属离子与Met混合溶液中,TA涂层上的酚羟基会吸引Met中带正电荷的氨基,通过H键、静电吸引的作用,形成TA/Met复合物。同时还有一部分酚羟基与金属离子螯合形成配位键[42]。因此在配位键、H键、静电吸附的共同作用下,金属离子和Met自组装沉积在TA涂层上。此外,Met中的氨基也能参与到与金属离子的配位作用中。一般来说,高价态的Fe3+对TA的配位能力要比二价金属离子强[43]。而二价离子配位能力Cu2+ > Mg2+ ≈ Sr2+。正如Cu-TA/Met的形貌(图1c)所示,配位能力强的离子在与TA配位时会形成过多的团聚状颗粒,导致涂层不均匀。而Fe-TA/Met涂层由于Fe3+配位能力过强,大量的Fe3+在溶液中会与Met和TA配位形成络合物颗粒,没有参与到涂层的形成过程,因此涂层中的Fe3+含量较少,并且表面颗粒也相应减少。配位能力弱的离子无法有效增强涂层稳定性,而配位能力适中的Mg2+和Sr2+可以兼顾涂层生长和稳定性增强,因此能形成致密均匀且稳定性高的Mg-TA/Met和Sr-TA/Met涂层。

图12

图12

金属-多酚载药涂层的构建机制

Fig.12

Schematic of the formation mechanism of metal-polyphenol drug-loaded coating

3.2 金属-多酚载药涂层的腐蚀调控和生物性能改善

电化学测试和长期浸泡实验结果均表明,在Zn表面沉积多酚载药涂层(TA/Met)和金属-多酚载药涂层(Cu-TA/Met、Fe-TA/Met、Mg-TA/Met和Sr-TA/Met)后,显著提高了纯Zn的抗腐蚀能力。相比较而言,TA/Met涂层的结构较不稳定,在长期浸泡过程中,对基体的保护不足。电解液易通过涂层中裂缝和孔隙形成的通道,渗透至Zn基体,经Cl-的攻击,引起Zn基体发生局部腐蚀。而金属-多酚载药涂层由于具有更稳定的化学键合,能够更有效地阻隔电解液的扩散,进而减缓Zn基体的腐蚀,起到长效的保护作用[44]。其中Mg-TA/Met和Sr-TA/Met由于涂层更为均匀,质量更好,其抗腐蚀性能相对Cu-TA/Met和Fe-TA/Met更好。此外,与TA/Met相比,金属-多酚载药涂层上形成的腐蚀产物更加均匀致密。一方面,复杂涂层对基体的有效保护为无机腐蚀产物的生长提供了稳定的平台,导致腐蚀产物均匀沉积;另一方面,活性官能团和金属离子可以为腐蚀产物提供成核位点并促进其沉积。均匀的腐蚀产物层还会反过来阻隔基体的腐蚀,并为样品表面提供潜在的骨相容性功能[11,45]。从药物释放结果来看,金属离子的加入减少了Met的装载量。这主要是因为金属离子、Met在与TA作用时,金属离子占据了Met的结合位点[46]。其中Fe-TA/Met由于Fe3+配位能力过强,在溶液中形成了大量Fe3+和Met的络合物颗粒,未参与涂层的构建,因此涂层中Fe3+和Met含量较少。而Cu-TA/Met由于Cu2+配位能力较强,并且主要与TA的酚羟基配位,占据了Met的结合位点,因此Met分子的装载量减少。而Mg2+和Sr2+由于配位能力适中,对Met分子结合位点占用较少,故Mg-TA/Met和Sr-TA/Met中Met的装载量较Cu-TA/Met和Fe-TA/Met多。

从细胞响应行为来看,金属-多酚载药涂层具有比TA/Met涂层更优异的成骨性能。这可能是金属离子和药物的持续释放,以及表面微纳结构的综合作用。研究[27]表明,Met浓度在0~200 µmol/L范围内能够促进成骨细胞碱性磷酸酶活性、I型胶原合成、骨钙素表达增加,进而促进成骨细胞的增殖和分化,浓度超过 200 µmol/L 时,对细胞增殖起到抑制作用。虽然金属-多酚涂层中Met的释放浓度相比于TA/Met有轻微下降,但TA-Met和金属-多酚载药涂层的Met释放量均在此浓度范围内。此外,TA-Met和金属-多酚涂层中的Zn2+释放量没有明显差异,均在成骨细胞耐受浓度范围(低于80 µmol/L)内[4]。更重要的是,金属-多酚载药涂层中的金属离子也能够持续释放,本工作中使用的Cu2+、Fe3+、Mg2+和Sr2+均有利于成骨细胞的黏附增殖和分化[25,26]。因此,与TA/Met相比,金属-多酚载药涂层具有更好的成骨性能。Sr-TA/Met表现出最好的促骨生成性,这得益于Sr2+的释放。研究[47,48]表明,与Cu2+、Fe3+和Mg2+相比,Sr2+能够更快速地诱导CaP的沉积,进而刺激新骨生成。此外,Sr2+作为钙敏感受体的调节剂有助于成骨细胞的增殖、分化和矿化。研究[11,49]表明,涂层微/纳米表面结构也会影响细胞行为,细胞的黏附和增殖与涂层形貌密切相关,具有微/纳米结构的涂层,如球粒状,有利于支持细胞的黏附。金属-多酚载药涂层的抗菌性能优于TA-Met涂层,这可能得益于外加的金属离子和TA分子的协同作用。金属离子或金属螯合物能与细菌细胞膜结构相互作用,破坏其通透性,导致细菌蛋白质功能障碍,进而抑制细菌的增殖[21,22]。值得一提的是,ZnP预处理层对于成骨细胞的增殖黏附以及抗菌性能也有益。已有研究[4]表明,纯Zn表面ZnP涂层能够促进成骨细胞黏附[4,10]。ZnP涂层对大肠杆菌的抗菌率约为75%。与ZnP涂层相比,本工作中的金属-多酚涂层成骨和抗菌性能更优异,这可能得益于金属离子和Met的持续释放。从抗腐蚀性能和生物性能来看,Sr-TA/Met涂层表现出最优效果,有望应用到锌基植入体的表面改性中。

本工作对金属-多酚载药涂层的体外腐蚀行为、体外促成骨性能和抗菌性能进行了研究,但更深入的促成骨细胞的分子生物学机制以及体内动物实验的验证仍需进一步研究;此外,利用其他类似于Met的药物治疗性小分子如唑来膦酸、阿仑膦酸等构建金属-多酚载药涂层,也是未来研究的一个重要方向。

4 结论

(1) 在可降解纯Zn表面通过不同金属离子(Cu2+、Fe3+、Mg2+、Sr2+)与单宁酸、二甲双胍配位,制备了结构均匀致密的各金属-多酚载药涂层。

(2) 金属-多酚载药涂层改性纯Zn的抗腐蚀和降解行为较未改性纯Zn显著提高。相对来说,Mg-TA/Met和Sr-TA/Met涂层具有最强的抗腐蚀效果。

(3) 体外细胞评价证实金属-多酚载药涂层具有良好的成骨活性和抗菌能力,这主要得益于功能改性涂层的活性金属离子和Met组分及其特殊的形貌结构。其中,Sr-TA/Met对成骨细胞的黏附、生长和分化表现出显著的促进作用并具有优异的抗菌性能,有望应用于骨科植入体表面改性。

参考文献

Revolutionizing metallic biomaterials

[J].Entering 21st century, the metallic biomaterials are revolutionizing. New kinds of metallic biomaterials represented by biodegradable metals, nacocrystalline metals and alloys, and bulk metallic glasses, had been explored as implantable biomaterials, and correspondingly the nature of metallic biomaterials are shifting from the bio-inert (with stainless steel, Co-based alloys and Ti alloys) to bio-active and multi-biofunctional (anti-bacterial, anti-proliferation, anti-cancer, etc.). The newly-emerging 3D printing technology and thin film technology had been applied to the advancing manufacture and intelligence of the medical devices made of metallic biomaterials. In this paper, the current research status of the revolutionizing metallic biomaterials had been reviewed, and the future research and development tendencies for newly-developed metallic biomaterials towards bio-functionalization, composite and intelligence are also proposed.

处在变革中的医用金属材料

[J].进入21世纪,医用金属材料正在发生变革。以可降解金属、纳米晶金属、大块非晶合金为代表的新型医用金属材料被尝试作为植入材料,材料属性正在从生物惰性向生物活性和生物功能化(抗菌、抗增生、抗肿瘤)方向发展,同时3D打印技术和薄膜技术也在被尝试用于金属植入器械的先进制造以及智能化。本文综合评述了处于变革中的医用金属材料研究现状,展望了新型医用金属材料功能化、复合化、智能化的未来发展趋势。

Design biodegradable Zn alloys: Second phases and their significant influences on alloy properties

[J].Alloying combined with plastic deformation processing is widely used to improve mechanical properties of pure Zn. As-cast Zn and its alloys are brittle. Beside plastic deformation processing, no effective method has yet been found to eliminate the brittleness and even endow room temperature super-ductility. Second phase, induced by alloying, not only largely determines the ability of plastic deformation, but also influences strength, corrosion rate and cytotoxicity. Controlling second phase is important for designing biodegradable Zn alloys. In this review, knowledge related to second phases in biodegradable Zn alloys has been analyzed and summarized, including characteristics of binary phase diagrams, volume fraction of second phase in function of atomic percentage of an alloying element, and so on. Controversies about second phases in Zn-Li, Zn-Cu and Zn-Fe systems have been settled down, which benefits future studies. The effects of alloying elements and second phases on microstructure, strength, ductility, corrosion rate and cytotoxicity have been neatly summarized. Mg, Mn, Li, Cu and Ag are recommended as the major alloying elements, owing to their prominent beneficial effects on at least one of the above properties. In future, synergistic effects of these elements should be more thoroughly investigated. For other nutritional elements, such as Fe and Ca, refining second phase is a matter of vital concern.© 2020 Production and hosting by Elsevier B.V. on behalf of KeAi Communications Co., Ltd.

High-efficient vacuum ultraviolet-ozone assist-deposited polydopamine for poly (lactic-co-glycolic acid)-coated pure Zn toward biodegradable cardiovascular stent applications

[J].

Enhanced cytocompatibility and antibacterial property of zinc phosphate coating on biodegradable zinc materials

[J].Zinc (Zn) has recently emerged as a promising biodegradable metal thanks to its critical physiological roles and promising degradation behavior. However, cytocompatibility and antibacterial property of Zn is still suboptimal, in part, due to the excessive Zn ions released during degradation. Inspired by the calcium phosphate-based minerals in natural bone tissue, zinc phosphate (ZnP) coatings were prepared on pure Zn using a chemical conversion method in this study. The coating morphology was then optimized through controlling the pH of coating solution, resulting in a homogeneous micro-/nano-ZnP coating structure. The ZnP coating significantly increased the cell viability, adhesion, and differentiation of pre-osteoblasts and vascular endothelial cells, while significantly reduced the adhesion of the platelets and E. coli. Additionally, ZnP coating significantly reduced the Zn ion release from the bulk material during degradation process, resulting in a much lower Zn concentration and pH change in the surrounding environment. The improved hemocompatibility, cytocompatibility and antibacterial performance of ZnP coated Zn biomaterials could be mainly attributed to the controlled Zn ion release and micro-/nano-scaled coating structure. Taken together, ZnP coating on Zn-based biomaterial appears to be a viable approach to enhance its biocompatibility and antibacterial property as well as to control its degradation rate. Statement of Significance Zn and its alloys are promising biodegradable implant materials for orthopedic and cardiovascular applications. However, notable cytotoxicity has been reported due to degradation products accumulated in the local environment, largely overdosed Zn. Thus, controlling burst Zn release is the key to minimize the toxicity of Zn implants. To achieve this goal, we prepared a homogenous ZnP coating on Zn metals thanks to its easy synthesis, stable chemical property, and good biocompatibility. Results showed that ZnP not only improved the cell viability, adhesion and proliferation, but also significantly reduced the attachment of platelet and bacterial. Therefore, ZnP could be a promising approach to improve the functional performance of Zn-based implants, and potentially be applied to many other medical implants.Copyright © 2019. Published by Elsevier Ltd.

Appropriately adapted properties of hot-extruded Zn-0.5Cu-xFe alloys aimed for biodegradable guided bone regeneration membrane application

[J].Appropriately adapted comprehensive mechanical properties, degradation behavior and biocompatibility are prerequisites for the application of Zn-based biodegradable implants. In this study, hot-extruded Zn-0.5Cu-xFe (x = 0.1, 0.2 and 0.4 wt%) alloys were fabricated as candidates for biodegradable materials for guided bone regeneration (GBR) membranes. The hot-extrusion process and Cu alloying were expected mostly to enhance the mechanical properties, and the Fe alloying was added mainly for regulating the degradation. The microstructure, mechanical properties and degradation behavior were systematically investigated. The ZnCuFe alloys were composed of a Zn matrix and FeZn phase. With increasing Fe content, a higher FeZn phase precipitation with larger particles was observed. Since elongation declined significantly until fracture with increasing Fe content up to 0.4 wt%, the ZnCuFe (0.2 wt%) alloy achieved a good balance between mechanical strength and ductility, with an ultimate tensile strength of 202.3 MPa and elongation at fracture of 41.2%. Moreover, the addition of Fe successfully accelerated the degradation of ZnCuFe alloys. The ZnCuFe (0.2 wt%) alloy showed relatively uniform corrosion in the long-term degradation test. Furthermore, extracts of the ZnCuFe (0.2 wt%) alloy showed no apparent cytotoxic effects against L929 fibroblasts, Saos-2 osteoblasts or TAg periosteal cells. The ZnCuFe (0.2 wt%) alloy exhibited the potential to inhibit bacterial adhesion of and mixed oral bacteria. Our study provides evidence that the ZnCuFe (0.2 wt%) alloy can represent a promising material for the application as a suitable GBR membrane.© 2020 [The Author/The Authors].

Current status and outlook on the clinical translation of biodegradable metals

[J].

Development and in vitro biodegradation of biomimetic zwitterionic phosphorylcholine chitosan coating on Zn1Mg alloy

[J].

Interfacial zinc phosphate is the key to controlling biocompatibility of metallic zinc implants

[J].

In vitro corrosion and in vivo response to zinc implants with electropolished and anodized surfaces

[J].

Corrosion and degradation decelerating alendronate embedded zinc phosphate hybrid coating on biodegradable Zn biomaterials

[J].

Osteogenic and angiogenic bioactive collagen entrapped calcium/zinc phosphates coating on biodegradable Zn for orthopedic implant applications

[J].

Zinc phosphate, zinc oxide, and their dual-phase coatings on pure Zn foam with good corrosion resistance, cytocompatibility, and antibacterial ability for potential biodegradable bone-implant applications

[J].

Electrodeposited dopamine/strontium-doped hydroxyapatite composite coating on pure zinc for anti-corrosion, antimicrobial and osteogenesis

[J].

Improved biocompatibility and antibacterial property of zinc alloy fabricated with γ-polyglutamic acid-g-dopamine/copper coatings for orthopedic implants

[J].

Facile fabrication of biodegradable endothelium-mimicking coatings on bioabsorbable zinc-alloy stents by one-step electrophoretic deposition

[J].

Medical applications based on supramolecular self-assembled materials from tannic acid

[J].

Advances in tannic acid-incorporated biomaterials: Infection treatment, regenerative medicine, cancer therapy, and biosensing

[J].

Plant-inspired adhesive and tough hydrogel based on Ag-Lignin nanoparticles-triggered dynamic redox catechol chemistry

[J].Adhesive hydrogels have gained popularity in biomedical applications, however, traditional adhesive hydrogels often exhibit short-term adhesiveness, poor mechanical properties and lack of antibacterial ability. Here, a plant-inspired adhesive hydrogel has been developed based on Ag-Lignin nanoparticles (NPs)triggered dynamic redox catechol chemistry. Ag-Lignin NPs construct the dynamic catechol redox system, which creates long-lasting reductive-oxidative environment inner hydrogel networks. This redox system, generating catechol groups continuously, endows the hydrogel with long-term and repeatable adhesiveness. Furthermore, Ag-Lignin NPs generate free radicals and trigger self-gelation of the hydrogel under ambient environment. This hydrogel presents high toughness for the existence of covalent and non-covalent interaction in the hydrogel networks. The hydrogel also possesses good cell affinity and high antibacterial activity due to the catechol groups and bactericidal ability of Ag-Lignin NPs. This study proposes a strategy to design tough and adhesive hydrogels based on dynamic plant catechol chemistry.

Tannic acid with antiviral and antibacterial activity as a promising component of biomaterials—A minireview

[J].

An environmental-friendly tannic acid/Zn conversion film with a good corrosion protection for iron

[J].

Mg-phenolic network strategy for enhancing corrosion resistance and osteocompatibility of degradable magnesium alloys

[J].Magnesium-based alloys are the most widely used materials for degradable metallic implants and have considerable potential for bone applications owing to their excellent stimulating effect on osteogenesis. However, their high corrosion rate limits their structural stability and causes oxygen deficiency and an excessive increase in the pH around the defect area during bone healing. Magnesium oxides, which are the main corrosion products of Mg, are nontoxic materials with useful effects on new bone formation and pH neutralization. Metal-phenolic networks were introduced recently as a cost-effective and efficient surface modifier and were fabricated by deposition of nanosized metal oxides on different types of substrates using the chemical reaction between phenolic groups and metallic ions. In this study, magnesium oxide films were formed successfully on a Mg-based substrate using Mg-phenolic networks. The effects of various coating parameters on the surface morphology, corrosion resistance, degradation behavior, wettability, and osteocompatibility of degradable metallic materials after surface modification with Mg-phenolic networks were thoroughly investigated for the first time. The results showed that the initial concentration of Mg ions was the main parameter affecting the corrosion resistance, which was almost as much as 3 times that of uncoated samples. Additionally, cytotoxicity and viability assessment and observation of the morphological changes in bonelike cells showed that the in vitro osteocompatibility was significantly enhanced by coatings with Mg concentrations of 2.4-3.6 mg mL. Finally, in vivo animal studies using the rat calvarial defect model confirmed that the proposed coating method mitigated the formation of gas cavities around the implantation area by reducing the corrosion rate of the Mg-based implant. The nanosized metal oxides produced by the Mg-phenolic network significantly improved the biodegradability and osteocompatibility of Mg alloys, suggesting a potential approach to advancing the clinical application of Mg alloys.Copyright © 2019 American Chemical Society.

A novel coating with universal adhesion and inflammation-responsive drug release functions to manipulate the osteoimmunomodulation of implants

[J].

High foliar retention tannic acid/Fe3+ functionalized Ti-pillared montmorillonite pesticide formulation with pH-responsibility and high UV stability

[J].

Development of sodium alginate/glycerol/tannic acid coated cotton as antimicrobial system

[J].Present study aims at developing antimicrobial cotton gauze by dip coating of sodium alginate (SA), glycerol (Gly) and tannic acid (TA) blend. SA blends were prepared with varying concentration of glycerol in the range of 10-40 %. Blended films were fabricated and characterized by Fourier transform-infrared (FTIR) spectroscopy, X-ray diffraction (XRD), tensile studies, and contact angle analysis. The mechanical behavior of films indicated significant decrease in the tensile strength and modulus with the increase in the glycerol content due to the plasticization effect. The hydrophilicity of the blend films increased with increase in the glycerol content. TA was added to the blend as an antimicrobial agent. These blends were coated on the cotton gauze by dip coating method and their characterizations were carried out by the scanning electron microscopy (SEM) which revealed a smooth coating of SA:Gly:TA blend on cotton gauze. Antimicrobial analysis of TA coated gauzes was carried out which showed >95 % viable colony reduction against E. coli and S. aureus. Cytocompatibility studies indicated excellent cell-compatible activity. These results implicated that such coated gauzes are promising candidate that hold the great potential to be utilized as infection-resistant material in the health care sector.Copyright © 2022. Published by Elsevier B.V.

The roles of ions on bone regeneration

[J].Bone scientists are actively investigating a range of methods to promote skeletal tissue regeneration. A review of recent literature has revealed that several ions are uniquely capable of inducing stem cell differentiation down desired lineages. There exists enormous promise for these ions to be used in bone regenerative medicine. Given that these ions can be released from biodegradable polymeric materials, their long-term delivery can be achieved through a variety of controlled-release strategies compared with the relatively few options available for expensive and fragile polypeptide-based growth factors. In this review, we highlight the developments in using ions in conjunction with biomaterials for bone regeneration.Copyright © 2018 Elsevier Ltd. All rights reserved.

Construction and application of therapeutic metal-polyphenol capsule for peripheral artery disease

[J].

Metformin enhances the osteogenesis and angiogenesis of human umbilical cord mesenchymal stem cells for tissue regeneration engineering

[J].

Metformin facilitates the proliferation, migration, and osteogenic differentiation of periodontal ligament stem cells in vitro

[J].

Hydroxyapatite/tannic acid composite coating formation based on Ti modified by TiO2 nanotubes

[J].

Epigallocatechin gallate (EGCG) induced chemical conversion coatings for corrosion protection of biomedical MgZnMn alloys

[J].

Phenolic-amine chemistry mediated synergistic modification with polyphenols and thrombin inhibitor for combating the thrombosis and inflammation of cardiovascular stents

[J].

Synthesis, spectroscopic, and thermal investigation of transition and non-transition complexes of metformin as potential insulin-mimetic agents

[J].

Synthesis, spectroscopic and antimicrobial studies of La(III), Ce(III), Sm(III) and Y(III) Metformin HCl chelates

[J].

Vanadium compounds as insulin mimics

[J].

An infrared and Raman spectroscopic study of polyanilines co-doped with metal ions and H+

[J].

Green synthesis of amino-functionalized carbon nanotube-graphene hybrid aerogels for high performance heavy metal ions removal

[J].

Recent advancements to mitigate zinc oxide formation in zinc-air batteries: A technical review

[J].

Green tea polyphenol induced Mg2+-rich multilayer conversion coating: Toward enhanced corrosion resistance and promoted in situ endothelialization of AZ31 for potential cardiovascular applications

[J].

Metal-phenolic networks as a promising platform for pH-controlled release of bioactive divalent metal ions

[J].

A homogenous microstructural Mg-based matrix model for orthopedic application with generating uniform and smooth corrosion product layer in Ringer's solution: Study on biodegradable behavior of Mg-Zn alloys prepared by powder metallurgy as a case

[J].

Mg ions incorporated phytic acid (PA) and zoledronic acid (ZA) of metal-organic complex coating on biodegradable magnesium for orthopedic implants application

[J].

Comprehensive study of the electrochemical growth and physicochemical properties of polycatecholamines and polycatechol

[J].

Properties and applications of flavonoid metal complexes

[J].

Comparison of corrosion resistance of phenylalanine, methionine, and asparagine-induced Ca-P coatings on AZ31 magnesium alloys

[J].Ca-P coating not only enhances the corrosion resistance of biodegradable magnesium alloys but also contributes to the formation of new bones and promotes bone integration around implants. However, the Ca-P coatings may have defects like porosity, low adhesion, and coarse grains, which lead to prefailure in the early stage and then the coatings cannot meet the requirements of long-term clinical service. Amino acids can induce the formation of calcium-bearing phosphates on biodegradable magnesium alloy. To clarify the influence of amino acid groups on film formation, Phenylalanine (Phe), Methionine (Met), and Asparagine (Asn) were used to regulate the degradation rate of magnesium alloy. Three amino acid-induced Ca-P (Ca-PPhe, Ca-PMet, and Ca-PAsn) coatings were prepared on AZ31 magnesium alloy via a constant temperature water bath method at a temperature of 60oC. Additionally, the morphology of the coatings, composition distributions, and phase structures were observed and analyzed via SEM, EDS, XRD, FTIR, and XPS. The corrosion resistance of the coating in simulated body fluid (Hank's solution) was investigated through electrochemical polarization, AC impedance, and hydrogen evolution tests. The formation mechanisms of amino acid additive-induced Ca-P (Ca-PPhe, Ca-PMet, and Ca-PAsn) coatings on AZ31 magnesium alloy were probed. Results showed that the thicknesses of Ca-P, Ca-PPhe, Ca-PMet, and Ca-PAsn coatings were about (3.47 ± 0.47), (6.06 ± 0.77), (7.63 ± 1.70), and (8.23 ± 1.37) μm, respectively. The main constituents of the amino acid-induced Ca-P coatings were CaHPO4 and Ca10(PO4)6(OH)2 (HA). The results of electrochemical polarization curves, EIS, and hydrogen evolution tests demonstrated that the addition of amino acids enhanced the corrosion resistance of the Ca-P coatings, which was ascribed to the inhibition and adsorption of amino acid molecules on AZ31 magnesium alloy. The adsorption of the amino group was mainly achieved through the coupling of the lone pair electrons of nitrogen atoms with the surface, whereas the carboxyl group combined with Mg2+ via their oxygen atoms. Additionally, heteroatoms in amino acids could share their lone pair electrons with the vacant molecular orbitals of the magnesium alloy. A formation mechanism of amino acid-induced Ca-P coating was proposed.

AZ31镁合金表面苯丙氨酸、甲硫氨酸和天冬酰胺诱导Ca-P涂层耐蚀性能比较

[J].为澄清氨基酸基团对成膜的影响,采用苯丙氨酸(Phenylalanine,Phe)、甲硫氨酸(Methionine,Met)和天冬酰胺(Asparagine,Asn) 3种氨基酸调控AZ31镁合金的降解速率,采用恒温水浴法(60℃)在其表面制备了3种氨基酸Ca-P涂层(Ca-P<sub>Phe</sub>、Ca-P<sub>Met</sub>和Ca-P<sub>Asn</sub>),并使用SEM、EDS 、XRD、FTIR及 XPS对涂层的形貌、成分分布和物相结构进行分析,利用电化学极化和交流阻抗及析氢腐蚀实验对涂层在模拟人体体液(Hank's)中的耐蚀性能进行研究。探讨了氨基酸添加剂在AZ31镁合金表面诱导Ca-P涂层成膜的作用机制。Ca-P、Ca-P<sub>Phe</sub>、Ca-P<sub>Met</sub>和Ca-P<sub>Asn</sub>涂层的厚度分别为(3.47 ± 0.47)、(6.06 ± 0.77)、(7.63 ± 1.70)和(8.23 ± 1.37) μm。涂层主要组成物相为CaHPO<sub>4</sub>及Ca<sub>10</sub>(PO<sub>4</sub>)<sub>6</sub>(OH)<sub>2 </sub>(HA)。电化学和析氢实验结果表明,氨基酸提高了Ca-P涂层耐蚀性能。这主要归因于氨基酸分子的缓蚀作用,并在AZ31镁合金表面发生化学吸附。氨基酸中的氨基吸附主要是通过N原子的孤对电子与镁合金表面耦合来实现的;羧基是通过羰基中的O原子与Mg<sup>2+</sup>结合。此外,氨基酸中的杂原子亦能与镁合金的空位分子轨道共享其孤对电子。最后,提出了氨基酸诱导Ca-P涂层的成膜机理。

Corrosion resistance of superhydrophobic Mg(OH)2/calcium myristate composite coating on magnesium alloy AZ31

[J].

A facile metal-phenolic-amine strategy for dual-functionalization of blood-contacting devices with antibacterial and anticoagulant properties

[J].

Ionic substitutions in calcium phosphates synthesized at low temperature

[J].Ionic substitutions have been proposed as a tool to improve the biological performance of calcium phosphate based materials. This review provides an overview of the recent results achieved on ion-substituted calcium phosphates prepared at low temperature, i.e. by direct synthesis in aqueous medium or through hydrolysis of more soluble calcium phosphates. Particular attention is focused on several ions, including Si, Sr, Mg, Zn and Mn, which are attracting increasing interest for their possible biological role, and on the recent trends and developments in the applications of ion-substituted calcium phosphates in the biomedical field.Copyright 2009 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Nucleation of strontium-substituted apatite

[J].

The effect of mineral coating morphology on mesenchymal stem cell attachment and expansion

[J].Previous studies have demonstrated the influence of calcium phosphate (CaP) mineral coating characteristics on cell attachment, proliferation, and differentiation. However, the wide range of mineral properties that can potentially influence cell behavior calls for an efficient platform to screen for the effects of specific mineral properties. To address this need, we have developed an efficient well-plate format to probe for the effects of mineral coating properties on stem cell behavior. Specifically, here we systematically controlled mineral coating morphology by modulating ion concentrations in modified simulated body fluids (mSBF) during mineral nucleation and growth. We found that mineral micro-morphology could be gradually changed from spherulitic, to plate-like, to net-like depending on [Ca] and [PO] in mSBF solutions, while other mineral properties (Ca/P ratio, crystallinity, dissolution rate) remained constant. Differences in mineral morphology resulted in significant differences in stem cell attachment and expansion. These findings suggest that an enhanced throughput mineral coating format may be useful to identify mineral coating properties for optimal stem cell attachment and expansion, which may ultimately permit efficient intraoperative seeding of patient derived stem cells.