近年来,通过构建非均质Mn分布的高温奥氏体[8~10],调控淬火阶段的相变过程,改善残余奥氏体稳定性,从而优化力学性能,引起了研究学者的广泛关注。Ding等[8]首先通过临界退火,在Fe-0.18C-8.0Mn (质量分数,%,下同)合金中获得富Mn的残余奥氏体和贫Mn的铁素体;然后,结合快速奥氏体化处理,利用Mn元素缓慢扩散和奥氏体快速相变间的动力学失配,成功构建了非均质Mn分布的高温奥氏体;最后,淬火到室温获得了亚微米尺寸的富Mn块状残余奥氏体,在保证良好塑性的同时大幅提高了抗拉强度。Sun等[9]通过珠光体转变制备了富Mn渗碳体和贫Mn铁素体,再利用快速加热在高温奥氏体中保留了渗碳体与铁素体间Mn元素的非均质分布,淬火后获得了残余奥氏体片层和马氏体板条交替堆叠的鬼珠光体组织。Kim等[10]借助660℃退火24 h,在Fe-0.18C-3.5Mn-0.1Si合金中获得了富Mn碳化物、富Mn残余奥氏体和贫Mn铁素体,然后利用快速加热构造了非均质Mn分布的高温奥氏体,淬火后获得了细小富Mn残余奥氏体,实现了强度和塑性的同步提升。

然而,这些研究主要集中在构建非均质高温奥氏体,关于合金元素(Mn)的非均质程度对组织和性能影响的研究有限。本文作者[11]在前期研究中采用珠光体为初始组织结合快速淬火-配分工艺,通过构建高温奥氏体Mn元素的非均质分布,兼顾了残余奥氏体的高体积分数与以片层形貌为主,提高了试样的局部成形能力,但也未研究高温奥氏体的Mn元素不均匀程度对组织和性能的影响。因此,本工作采用以珠光体为初始组织的快速淬火-配分工艺,通过调控奥氏体化工艺的参数,构建具有不同Mn元素非均质程度的高温奥氏体,从而研究非均质Mn分布对淬火-配分钢微观组织和力学性能的影响机理。

1 实验方法

实验用钢的化学成分(质量分数,%)为:C 0.42,Si 1.45,Mn 3.71,Fe余量。首先用25 kg 真空冶炼炉冶炼铸锭,然后于Ar气保护下在1200℃均匀化处理36 h,最后在900℃热轧至7 mm。如图1所示,将热轧试样加热至800℃保温600 s后,转移至590℃的盐浴炉中保温6 h,进行珠光体转变,再进行水淬。将获得的珠光体试样通过盐浴炉快速加热(约 80℃/s)至770~790℃保温10~1200 s进行奥氏体化,然后通过110℃的油浴进行淬火60 s,再迅速转移至另一个400℃的盐浴炉中保温500 s进行配分处理,最后水淬。为方便叙述,将上述以Mn配分珠光体为初始组织的淬火-配分(partitioned pearlite-based quenching & partitioning,PPQ&P)工艺,根据奥氏体化温度(TA)和时间(tA)编号为PPQ&P TA-tA,如PPQ&P 770-10。

图1

图1

以Mn配分珠光体为初始组织的淬火-配分工艺示意图

Fig.1

Heat treatment schematic for partitioned pearlite-based quenching and partitioning (PPQ&P) process (WQ—water quench)

通过SUPRA55场发射扫描电子显微镜(SEM)观察热处理实验后试样的显微组织。采用Talos F200X透射电子显微镜(TEM)观察试样精细显微组织,并通过配套的能谱仪(TEM-EDS)分析元素分布。为避免轻质元素C对测定结果的干扰,通过计算Mn元素占置换位置的百分数(U-fraction)来表示Mn含量,即UMn = XMn / (XMn + XFe + XSi) (其中,XMn、XFe和XSi代表Mn、Fe和Si的原子分数)[9,12]。用配备NordlysNano探头的Merlin型SEM,通过透射电子束Kikuchi衍射(TKD)以15 nm的步长进一步分析TEM样品的薄区。采用D8 Advance X射线衍射仪(XRD)对试样中的残余奥氏体(retained austenite,RA)进行定量分析,所使用靶材为Cu靶,扫描速率为0.3°/min,扫描角度(2θ)为40°~120°。

利用线切割切取标距段长度为8 mm、宽度为2 mm、厚度为1 mm的拉伸试样,在Instron 5565型万能试验机上以4 × 10-4 s-1的初始应变速率进行单向拉伸力学性能测试。通过

式中,

2 实验结果

2.1 显微组织

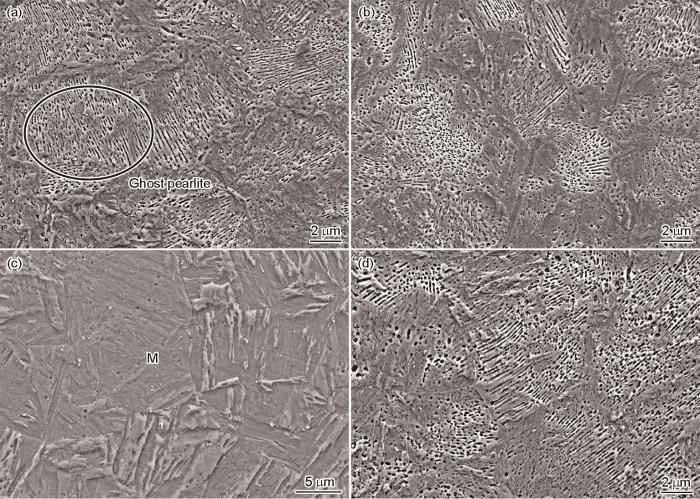

试样在590℃保温6 h后,已完全转变为由铁素体片层((128.6 ± 24.6) nm)和渗碳体片层((13.0 ± 2.8) nm)构成的珠光体组织(图2)。其中,铁素体贫Mn (UMn = (1.6 ± 0.2)%),渗碳体富Mn (UMn= (25.2 ± 2.1)%)。以该珠光体为初始组织,经不同奥氏体化时间、温度处理后的直接淬火样品的微观组织如图3所示。可见,其主要由鬼珠光体组织(ghost pearlite,GP)和正常板条马氏体(martensite,M)组织构成。鬼珠光体组织遗传了珠光体中Mn元素的非均质分布,具有类似珠光体的片层结构,是由残余奥氏体片层和板条马氏体交叠而组成的组织[9,11~14]。随奥氏体化时间的延长或温度的升高,试样中鬼珠光体组织减少,而正常板条马氏体增多,表明高温奥氏体中Mn元素扩散逐渐均匀。因此,改变奥氏体化温度与时间,能够有效调控高温奥氏体中Mn元素的非均质程度。

图2

图2

经590℃保温6 h的珠光体化处理后试样微观组织的SEM、TEM像和Mn元素分布

Fig.2

SEM (a) and TEM (b) images of partitioned pearlite obtained after holding at 590oC for 6 h following austenitization at 800oC for 600 s (Inset shows EDS line scanning, indicating Mn heterogeneity. UMn—Mn fraction at substitutional lattice site)

图3

图3

经不同奥氏体化时间、温度处理后的直接淬火试样微观组织的SEM像

Fig.3

SEM images of microstructures after directly quenching following austenitization at different temperatures and time (M—martensite)

(a) 770oC for 10 s (b) 770oC for 90 s (c) 770oC for 1200 s (d) 790oC for 10 s

以该珠光体组织为初始组织,进行快速淬火-配分处理,所获得的微观组织主要由浅灰色的残余奥氏体和深灰色的回火马氏体(tempered martensite,TM)基体构成,如图4所示。可见,残余奥氏体存在块状和片状2种形貌,马氏体形貌以细小片层为主,仅在部分样品中观测到粗大板条马氏体(图4c)。微观组织可以分为正常淬火-配分区域和鬼珠光体区域。其中,块状残余奥氏体和板条马氏体,与文献[5,15~17]报道的正常淬火-配分组织一致。当在770或790℃奥氏体化保温10 s时(图4a和d),样品中存在大量的鬼珠光体组织。随770℃奥氏体化的时间延长,样品中鬼珠光体组织减少,而正常淬火-配分组织增多(图4b)。当770℃奥氏体化保温时间增加至1200 s时,鬼珠光体组织完全消失(图4c)。

图4

图4

经不同奥氏体化时间、温度处理后的淬火-配分试样微观组织的SEM像

Fig.4

SEM images of microstructures of PPQ&P samples after austenitization at different temperatures and time (RA—retained austenite)

(a) 770oC for 10 s (b) 770oC for 90 s (c) 770oC for 1200 s (d) 790oC for 10 s

图5为不同奥氏体化时间、温度处理后的淬火-配分试样的XRD谱。由图可见,快速淬火-配分处理后试样的(111) γ 、(200) γ 、(220) γ 和(311) γ 峰值明显,随770℃奥氏体化时间延长和温度升高,残余奥氏体含量基本不变(约30%,体积分数,下同)。

图5

图5

经不同奥氏体化时间、温度处理后的淬火-配分试样的XRD谱

Fig.5

XRD spectra of PPQ&P samples after austenitization at different temperatures and time

通过Photoshop软件统计不同奥氏体化工艺的淬火-配分试样SEM像,获得了各相含量及晶粒尺寸变化,如图6所示。由图6a可见,当在770℃奥氏体化的时间由10 s延长至1200 s时,鬼珠光体的含量由(81.3 ± 2.7)%迅速降低至(4.1 ± 0.9)%,粗大马氏体的含量从(1.7 ± 0.7)%增加至(17.6 ± 1.9)%,块状残余奥氏体的含量从(9.5 ± 1.3)%增加至(20.2 ± 1.4)%,而残余奥氏体总体积分数仅在 29%~35%之间小幅波动。同时,随保温时间的增加,残余奥氏体和马氏体形貌发生明显的改变,其中块状残余奥氏体的等效圆直径(equivalent circle diameter,ECD)从(0.9 ± 0.3) μm大幅增长至(1.8 ± 0.6) μm,而粗大马氏体的ECD从(1.3 ± 0.4) μm显著增大到(2.2 ± 0.7) μm (图6b)。特别地,在770℃保温1200 s时,部分粗大马氏体的ECD尺寸高达5.1 μm。随着奥氏体化温度从770℃升高到790℃,同样使得鬼珠光体含量降低、块状残余奥氏体增加且尺寸增大、粗大马氏体增多且尺寸增大。

图6

图6

不同奥氏体化时间、温度处理后淬火-配分试样中各相含量及晶粒尺寸变化

Fig.6

Evolution of phase faction (a) and grain size (b) in PPQ&P samples with austenitization temperature and time (ECD—equivalent circle diameter)

图7为通过TEM和TKD技术对PPQ&P 770-10试样中不同区域微观组织及元素分布的精细表征。如图7a所示,鬼珠光体组织由交替堆叠的片状残余奥氏体((58.3 ± 6.3) nm)和马氏体板条((110.9 ± 19.9) nm)组成,残余奥氏体和马氏体板条之间呈Kurdjumov-Sachs取向关系({110} α //{111} γ 、<111> α //<101> γ )。值得注意的是,片状残余奥氏体与马氏体板条之间存在强烈的Mn梯度,见图7a右下角插图,其中片状残余奥氏体富集Mn元素(UMn = (8.7 ± 1.1)%),马氏体板条贫Mn元素(UMn = (2.8 ± 0.3)%)。图7b所示的TKD像进一步证实了鬼珠光体组织是由交替堆叠的片状残余奥氏体和马氏体板条组成的,部分片状残余奥氏体聚结为块状残余奥氏体。另外,图7c和d的TEM像与插图选区电子衍射(SAED)花样表明,正常淬火-配分区域中存在块状残余奥氏体(图7c)和马氏体板条间的片状残余奥氏体(图7d),2者与板条马氏体之间的Mn元素呈均匀分布。

图7

图7

PPQ&P 770-10试样中的RA形貌、Mn元素分布、选区电子衍射(SAED)花样和TKD像

Fig.7

Morphologies, Mn distributions along the red lines (insets at the bottom), SAED patterns of the green circles (insets at the top), and TKD phase map of RA in PPQ&P 770-10 sample

(a) ghost pearlite within the conventional martensite matrix (TM—tempered martensite)

(b) TKD phase map corresponding to the rectangle in Fig.7a

(c) blocky RA within the conventional martensite matrix

(d) film RA within the conventional martensite matrix

2.2 力学性能

以珠光体为初始组织的淬火-配分试样,在770℃保温不同时间的工程应力-工程应变曲线如图8a所示,所有试样均呈现连续屈服,力学性能汇总于表1。可见,随着保温的时间由10 s增加至1200 s,抗拉强度(ultimate tensile strength,UTS)变化较小(约1700 MPa),断裂总延伸率(total elongation,TEL)呈小幅波动(约20%),而屈服强度(yield strength,YS)从(1499 ± 9) MPa快速降低至(1247 ± 12) MPa,均匀延伸率(uniform elongation,UEL)从(13.8 ± 1.0)%大幅增加至(16.5 ± 0.2)%,同时颈缩后延伸率从6.9%降低至5.3%。

图8

图8

在770℃保温不同时间的淬火-配分试样的工程应力-工程应变曲线及应变硬化指数曲线

Fig.8

Engineering stress-engineering strain curves (a) and strain hardening exponent (b) of PPQ&P samples after austenitization at 770oC for different time (n—strain hardening exponent, ε—true strain)

表1 在770℃保温不同时间的淬火-配分试样的力学性能

Table 1

Time s | YS MPa | UTS MPa | TEL % | UEL % | TEL - UEL % |

|---|---|---|---|---|---|

| 10 | 1499 ± 9 | 1719 ± 6 | 20.7 ± 1.8 | 13.8 ± 1.0 | 6.9 |

| 90 | 1430 ± 4 | 1677 ± 21 | 20.1 ± 1.4 | 15.0 ± 1.5 | 5.1 |

| 1200 | 1247 ± 12 | 1697 ± 2 | 21.8 ± 0.4 | 16.5 ± 0.2 | 5.3 |

图9

图9

在770℃保温不同时间的淬火-配分试样拉伸断口的SEM像

Fig.9

SEM images of fracture surfaces after austenitization at 770oC for 10 s (a), 90 s (b), and 1200 s (c)

3 分析讨论

3.1 奥氏体化工艺对微观组织的影响

式中,D为扩散系数,m2/s;t为保温时间,s。高温奥氏体中的Mn原子的D可表示为[24]:

式中,Q为扩散激活能,对于体扩散(volume diffusion)和管扩散(pipe diffusion,沿位错的短路扩散)分别为264000和192720 J/mol[1,24,25];T为奥氏体化温度,K;R为摩尔气体常数,取8.314 J/(mol·K)。根据

图10

图10

在770℃保温不同时间的Mn原子扩散距离及淬火-配分工艺组织演变示意图

Fig.10

Diffusion distance of Mn when austenitization at 770℃ for different time (a) and schematics of microstructure evolution with austenitization during PPQ&P process (b) (tA—austenitization time)

进一步地,通过图11所示热膨胀曲线分析非均质Mn分布高温奥氏体对马氏体转变的影响。由杠杆定律(图11a)结合一阶求导(图11b),将马氏体转变过程分为快速转变(fast transformation)和慢速转变(slow transformation) 2个阶段[26]。当保温时间较短时(770℃保温10 s),非均质高温奥氏体的贫Mn区域稳定性低,在淬火过程中迅速转变为马氏体;同时,均质高温奥氏体转变为粗大马氏体。因此,快速转变阶段开始温度高(201℃),且温度区间窄(21℃),转变速度快(一阶导数的绝对值大)。随着鬼珠光体和粗大马氏体的增多,剩余高温奥氏体晶粒得到细化,同时马氏体转变引入位错和静水压,阻碍了马氏体片层的生长,从而生成细小的板条马氏体,对应马氏体转变曲线一阶导数的斜率降低(图11b),进入了宽广的慢速转变温度区间[27]。随保温时间延长至1200 s,Mn元素扩散距离增加,使得贫Mn高温奥氏体的Mn含量升高,导致快速转变阶段开始温度降低(174℃)。同时,高温奥氏体中Mn含量更加分散[28],使得快速转变温度区间拓宽(32℃)。此外,富Mn高温奥氏体的Mn含量下降,对粗大马氏体生长的阻碍效果降低,使得粗大马氏体含量升高(图6a)。

图11

图11

热膨胀曲线推导出的淬火阶段马氏体的转变曲线及一阶导数曲线

Fig.11

Evolution of martensite fraction with quenching temperature deduced from the dilatation curves based on lever rule (a) and first order derivation of the transformation curves in Fig.9a (b) (QT—quenching temperature)

3.2 鬼珠光体对力学性能的影响

式中,

当在770℃奥氏体化处理的时间由10 s延长至1200 s时,鬼珠光体由(81.3 ± 2.7)%降低至(4.1 ± 1.9)% (图6a),相应的正常淬火-配分组织增加。残余奥氏体尺寸由(58.3 ± 6.3) nm增加至(1.8 ± 0.6) μm,马氏体板条宽度由(110.9 ± 19.9) nm增加至(303.0 ± 25.1) nm,导致残余奥氏体和马氏体的屈服强度分别降低49.4和424.1 MPa;当考虑2者体积分数时,屈服强度分别降低16.9和274.0 MPa。因此,鬼珠光体组织向正常淬火-配分组织的演变,使得屈服强度共降低290.9 MPa。与表1中实验所得的屈服强度降低252 MPa,具有较好的一致性。由此可见,奥氏体化时间的延长造成鬼珠光体含量的降低,引发了残余奥氏体和马氏体的粗化,是导致屈服强度降低的主要原因。随奥氏体化时间的延长,均匀延伸率大幅增加(表1),这主要与残余奥氏体的TRIP效应有关。TRIP效应主要取决于残余奥氏体的稳定性,受化学成分、晶粒尺寸、形貌以及相邻相等的影响[1~4]。

如图12所示,通过间断拉伸实验来观察残余奥氏体的转变。在200℃回火2 h后,间断拉伸样品中残余奥氏体表面保持光滑(图12a箭头所示),而由残余奥氏体转变的新生马氏体(fresh martensite,FM)表面明显粗糙[39,40] (图12b箭头所示)。当应变较低(≤ 6.9%)时,仅有较大尺寸的块状残余奥氏体发生转变(图12b);当应变增加至13.8%后,所有的块状残余奥氏体都转变为了新生马氏体,而鬼珠光体内的片状残余奥氏体未见转变(图12c)。由此可见,块状残余奥氏体是颈缩前应变硬化的主要来源。随奥氏体化时间的延长,块状残余奥氏体数量增多、尺寸增大(图6a和b),促使更多的残余奥氏体在颈缩前发生转变,引发更强烈的TRIP效应,使得应变硬化指数曲线的第2阶段显著提高(图8b),从而导致均匀延伸率增加。

图12

图12

PPQ&P 770-10试样在不同应变下的显微组织

Fig.12

Microstructures of PPQ&P 770-10 sample when the uniaxial tension is interrupted at the strains of 0 (a), 6.9% (b), 13.8% (c), and about 20% (fractured) (d)(FM—fresh martensite. Inset in Fig.12d shows the FM transformed from ghost pearlite)

4 结论

(1) 通过以珠光体为初始组织的快速淬火-配分工艺,能够获得片层残余奥氏体((58.3 ± 6.3) nm)与马氏体板条((110.9 ± 19.9) nm)相间组成的鬼珠光体组织。奥氏体保温时间延长和温度升高,使得高温奥氏体的Mn分布更加均匀,导致鬼珠光体的含量减少。

(2) 随770℃保温时间的延长,鬼珠光体减少而正常淬火-配分组织增多,使得残余奥氏体和板条马氏体的尺寸增大,细晶强化效果减弱,导致屈服强度降低。

(3) 随770℃保温时间的延长,块状残余奥氏体增多,在变形过程中容易转变,使得加工硬化能力升高,导致均匀延伸率的增加;同时,块状残余奥氏体转变生成的新生块状马氏体为硬脆相,会加速颈缩后裂纹的形成和扩展,导致颈缩后延伸率的降低。

(4) 以珠光体为初始组织的快速淬火-配分工艺,由于残余奥氏体和马氏体的含量不随奥氏体化工艺发生改变,使得抗拉强度和断裂总延伸率也不变;通过改变奥氏体化的工艺参数,能够在保证高抗拉强度(约1700 MPa)和高断裂总延伸率(约20%)的基础上,实现对屈服强度和均匀延伸率的进一步调控。

参考文献

Site-specific atomic-scale characterisation of retained austenite in a strip cast TRIP steel

[J].

The effect of morphology on the stability of retained austenite in a quenched and partitioned steel

[J].

Review: Relations between metastable austenite and fatigue behavior of steels

[J].With the deepening and improvement of the research on the conventional mechanical properties of metallic materials, the long-term service properties, such as fatigue and creep, showed more and more critical influence on the development of metallic materials. As one of the most important engineering structural materials, in order to clarify the fatigue failure mechanism, the research of steels on the relationship between microstructure and fatigue properties has been a hot and difficult problem for a long time. With the rapid development of smelting technology for steels, the research on the influencing factors of fatigue gradually changes from inclusions to microstructures as metastable austenite, precipitates, etc. Therefore, in order to further analyze the feasible direction of the research on the influence of microstructure on fatigue, this paper summarizes the influence and mechanism of metastable austenite on the fatigue property of advanced steel materials. The influence mechanism of metastable austenite on fatigue property by relevant scholars under different service conditions such as low cycle fatigue and high cycle fatigue was reviewed. Based on the experimental results, the relationship between metastable austenite and fatigue properties was quantitatively evaluated by machine learning. The quantitative relationship between the content/stability of metastable austenite and fatigue life was established, which could provide the basis direction for the further study of the mechanism of fatigue for steels.

综述: 钢中亚稳奥氏体组织与疲劳性能关系

[J].

Effect of ausforming on the microstructures and mechanical properties of an ultra-high strength bainitic steel

[J].Ultra-high-strength bainitic steels with excellent combinations of strength and ductility may be the new generation of metallurgical interest. However, there still exist some production problems, such as long transformation times due to low-temperature processing and difficulty in tailoring the elongation. In this work, both ausforming and austempering were used to investigate the effects of deformation on the transformation and microstructure in a medium-carbon bainitic steel. The Gleeble 3500 simulator, SEM, TEM, XRD, and tensile tests were used to analyze the effects of ausforming on retained austenite, the strength and plasticity of bainitic steel. The results show that ausforming at 300oC with a strain of 0.2 not only accelerates the kinetics of isothermal transformation, but also refines the bainitic microstructure and optimizes the retained austenite and its stability. The stability of the retained austenite is affected by the carbon content and dislocation density, and the carbon content can be increased by prolonging the duration of the isothermal stage. The volume fraction of retained austenite is increased by ausforming because of the enhanced dislocation density, which leads to ultra-high-strength bainitic steel with excellent properties of a tensile strength of 1733 MPa and ductility of 15.7%.

变形对超高强贝氏体钢组织和力学性能的影响

[J].

Carbon partitioning into austenite after martensite transformation

[J].

Very strong bainite

[J].

Experimental and numerical analysis on formation of stable austenite during the intercritical annealing of 5Mn steel

[J].

Chemical boundary engineering: A new route toward lean, ultrastrong yet ductile steels

[J].Chemical boundary engineering expands the dimensionality of alloy design.

Advanced high strength steel (AHSS) development through chemical patterning of austenite

[J].

Microstructure and tensile properties of chemically heterogeneous steel consisting of martensite and austenite

[J].

Heterogeneous quenching and partitioning from manganese-partitioned pearlite: Retained austenite modification and formability improvement

[J].

Effect of tempering time on microstructures and mechanical properties of an Fe-0.39C-3.69Mn medium Mn steel

[J].

回火时间对Fe-0.39C-3.69Mn中锰钢的组织和力学性能的影响

[J].

Effects of induction hardening and prior cold work on a microalloyed medium carbon steel

[J].

Evolution of microstructures and mechanical properties with tempering temperature of a pearlitic quenched and tempered steel

[J].

Microstructural development during the quenching and partitioning process in a newly designed low-carbon steel

[J].

Study on the martensite in low carbon CrNi3Si2MoV steel treated by Q&P process

[J].

Q&P工艺处理低碳CrNi3Si2MoV钢中马氏体的研究

[J].

Prediction and evaluation of optimum quenching temperature and microstructure in a 1300 MPa ultra-high-strength Q&P steel

[J].

Characterization and control of the compromise between tensile properties and fracture toughness in a quenched and partitioned steel

[J].

Enhanced work-hardening behavior and mechanical properties in ultrafine-grained steels with large-fractioned metastable austenite

[J].

Tailoring the metastable reversed austenite from metastable Mn-rich carbides

[J].

Transition between alloy-element partitioned and non-partitioned growth of austenite from a ferrite and cementite mixture in a high-carbon low-alloy steel

[J].

Study of partition to non-partition transition of austenite growth along pearlite lamellae in near-eutectoid Fe-C-Mn alloy

[J].

Tracer diffusion of 63Ni in nano-γ-FeNi produced by powder metallurgical method: Systematic investigations in the C, B, and A diffusion regimes

[J].

On the mechanism of Mn partitioning during intercritical annealing in medium Mn steels

[J].

Influence of austenite deformation on ferrite growth in a Fe-C-Mn alloy

[J].

Optimum properties of quenching and partitioning steels achieved by balancing fraction and stability of retained austenite

[J].

Heterogeneous nucleation of the martensite transformation

[J].

A new insight into annealing parameters in tailoring the mechanical properties of a medium Mn steel

[J].

Correlation between microstructure and yield strength of as-quenched and Q&P steels with different carbon content (0.06-0.42 wt% C)

[J].

Analysis of the mechanical behavior of a 0.3C-1.6Si-3.5Mn (wt%) quenching and partitioning steel

[J].

Microstructure-based model for the static mechanical behaviour of multiphase steels

[J].

The influence of rolling variables on the strengthening mechanisms operating in niobium steels

[J].

Martensite in steel: Strength and structure

[J].

Unified formulation to predict the tensile curves of steels with different microstructures

[J].

Clustering, nano-scale precipitation and strengthening of steels

[J].

Influence of structural parameters on the yield strength of tempered martensite and lower bainite

[J].

The mechanism of plastic deformation of crystals. Part I.—Theoretical

[J].

Metallographic methods for revealing the multiphase microstructure of TRIP-assisted steels

[J].

Ductile and intergranular brittle fracture in a two-step quenching and partitioning steel

[J].

A new effect of retained austenite on ductility enhancement of low carbon Q-P-T steel

[J].A low carbon Fe-0.25C-1.48Mn-1.20Si-1.51Ni-0.05Nb (mass fraction, %) steel exhibits the combination of high tensile strength and good elongation after treated by a novel quenching-partitioning-tempering (Q-P-T) process. The variation in volume fraction of retained austenite in this steel with strain is measured by XRD, and the deformed twin-type martensite plates are also observed by TEM, from which the transformation induced plasticity (TRIP) effect in this steel is confirmed. Based on the measurement of average dislocation densities in both martensite and retained austenite combined with TEM observation, the effect of dislocation absorption by retained austenite (DARA) is found in the low carbon steel, similar to that in the medium carbon steel proposed recently, from which the generation conditions of DARA effect is proposed, and the mechanism of retained austenite on ductility enhancement of high strength steel is clarified.

残余奥氏体增强低碳Q-P-T钢塑性的新效应

[J].

Crack closure and fatigue crack growth near threshold of a metastable austenitic stainless steel

[J].

Influence of deformation-induced martensite on fatigue crack propagation in 304-type steels

[J].

Fatigue crack growth—Microstructure relationships in a high-manganese austenitic TWIP steel

[J].