Al-Mg-Si合金因质量轻、导热、导电性优异且力学性能、成型性和焊接性优良等,被广泛应用于生产和生活各个领域[1,2]。作为一种时效强化型铝合金,Al-Mg-Si合金被广泛认同的析出序列为[3~9]:过饱和固溶体→原子团簇/Guinier-Preston (GP)区→β″→β′、B′、U1、U2→β,其中β″相通常在早期和峰值时效阶段形成,它被认为是Al-Mg-Si合金所有析出相中硬化效果最好的析出相[3~5]。β′、B′、U1和U2相一般在过时效阶段形成。然而近期研究[10,11]发现,Al-Mg-Si合金的析出序列实际依赖于合金成分和热处理工艺。例如,低合金含量的Al-Mg-Si合金在180℃时效时,β′相可以在时效早期直接形成,不需要由β″相转变而成[10]。

微合金化是改善铝合金性能的主要方法之一。研究[12~22]表明,Cu、Zn、Ge、Ag和Sn等微合金化元素可以有效改善Al-Mg-Si合金的性能。稀土元素作为工业维生素,也可以有效改善Al及铝合金的性能。大量研究[23~26]表明,稀土元素对合金性能和微结构的影响与其添加量有关,通常存在最佳添加量。例如,当Er添加量在0.4% (质量分数,下同)以内时,Al-Mg-Mn-Zr合金的强度随着Er含量的增加而增加,这是因为Er诱导晶内Al3Er第二相的形成以及细化晶粒[23]。进一步增加Er添加量会造成Er过量,而过量的Er只能在晶界处形成Al3Er初生相,对强度提升无益。La作为一种储量较大且便宜的稀土元素,近年来也受到特别关注。在Al-Cu合金中添加0.3%以内的La可以细化合金的晶粒和θ′相尺寸,并形成Al11La3相,从而改善合金的强度和高温抗蠕变性能[24]。当La含量超过0.3%时,合金力学性能随La含量增加呈下降趋势,这是因为晶界处形成大量的块状Al11La3相会在变形过程中切割Al基体。在亚共晶Al-Si合金中添加0.06%以内的La时,合金塑性随La含量增加逐渐提高,这主要得益于共晶Si颗粒形貌逐渐由片状变成“蠕虫”状[25]。当La含量进一步增加时,合金中会形成粗大的脆性AlLaSi金属间化合物,这对合金的塑性不利。微合金化La还可以改善Al-Mg-Si合金的抗局部腐蚀性能[26],其原因是:La元素会富集在Mg2Si颗粒表面,延缓Mg2Si颗粒的腐蚀;同时La使得Si颗粒形貌由连续分布的片状变成不连续的短棒状,阻碍了沿晶界的腐蚀扩展。当La含量低于0.08%时,合金抗腐蚀性能随La含量增加逐渐提高;当La含量超过0.08%时,合金抗腐蚀性能又出现下降,这可能与AlLaSi颗粒的形成有关[26]。然而,La元素的添加对Al-Mg-Si合金力学性能和微观结构的影响,尤其是对其析出行为的影响仍不清楚,同时合金性能和微结构的变化与La添加量之间的关系也值得研究。

本工作利用硬度、拉伸和导电率测试系统研究了不同含量La的添加对Al-Mg-Si合金性能的影响。结合扫描电镜(SEM)、原子分辨率透射电镜(TEM)、X射线能谱(EDS)和X射线衍射(XRD)等表征分析手段,揭示了不同含量La对合金的多尺度微观结构的影响。研究结果阐明了合金性能的变化与微观结构变化的关系,并发现了La诱导的多晶相和多相复合相的形成。

1 实验方法

本工作采用4种合金进行实验,实际成分如表1所示。4种合金的Mg和Si含量接近,La的添加量依次增加,后文分别用0La、0.2La、0.4La和0.6La代表4种合金。所有合金中的Fe、Cr和Mn的含量控制在0.01%以下。合金经过热模铸造成型后,在500℃均匀化处理10 h,并随炉冷却至室温。接着将铸锭热轧至10 mm厚,轧制之前在500℃保温1 h。然后在450℃中间退火1 h,空冷至室温,并冷轧至1 mm厚。将轧制后的板材切成10 mm × 10 mm × 1 mm的试样,然后进行后续的热处理实验:在560℃下固溶30 min后水淬至室温,然后立即在180℃时效0~168 h。

表1 实验用4种合金的实际成分 (mass fraction / %)

Table 1

| Alloy | Mg | Si | La | Al |

|---|---|---|---|---|

| 0La | 0.73 | 0.76 | - | Bal. |

| 0.2La | 0.69 | 0.71 | 0.22 | Bal. |

| 0.4La | 0.72 | 0.69 | 0.42 | Bal. |

| 0.6La | 0.77 | 0.71 | 0.64 | Bal. |

硬度测试在HXD-1000T Vickers硬度仪上进行,加载力为4.9 N,加载时间为10 s。导电率测试在D60K导电率仪上进行。每种状态样品的硬度和导电率分别测试5次,然后取其平均值。单轴拉伸实验在MTS Landmark 50KN型电液伺服疲劳试验机上进行,样品尺寸规格参考ASTM standard E517-00进行设计,应变速率为1 × 10-3 s-1。为确保实验结果的可靠性,每种状态的拉伸实验重复至少9次,然后选取其代表性结果。

采用配备EDS和电子背散射衍射(EBSD)探头的Quanta 200 型SEM进行样品的晶粒和第二相微观形貌和成分分析。第二相物相分析在D5000全自动XRD上进行,采用CuKα 射线(波长λ = 0.15406 nm),管电压为40 kV,管电流为40 mA,测量范围2θ = 20°~100°,扫描速率为2°/min。XRD样品经过机械打磨抛光后用酒精清洗干净,烘干后进行扫描。TEM的表征在Tecnai F20 TEM上进行,工作电压为200 kV。高角环形暗场扫描透射电镜(HAADF-STEM)观察在球差矫正电镜Thermo Scientific, Themis Z(3.2)上进行,工作电压为300 kV。样品进行TEM观察之前在Gatan 950型等离子清洗仪上进行清洗以去除样品表面的非晶。所有TEM观察均沿着<100>Al方向进行。TEM样品首先经过机械减薄,然后经过电解双喷减薄,电解液为25%硝酸+75%甲醇(体积分数),工作电压为15 V,温度为-30~-25℃。差示扫描量热分析(DSC)在DSC 204 F1 Phoenix热分析仪上进行,扫描速率为20℃/min。

2 实验结果

2.1 力学性能及导电性能测试

图1为4种合金在180℃下硬度和导电率随时效时间的变化曲线。4种合金硬度和导电率的变化趋势均一致。如图1a所示,随着时效时间延长,4种合金的硬度首先逐渐升高,在时效4 h后达到最大值(峰值时效,PA)。0La和0.2La合金的峰值硬度相近。当La添加量高于0.2%时,峰值硬度随La添加量提高逐渐降低。时效12 h后,4种合金的硬度开始下降,即发生过时效。由图1b可知,随着时效时间延长,4种合金的导电率逐渐升高。据报道[27],传统时效态导电率的相对变化(定义为(C - CA) / CA× 100%,其中C代表时效态的导电率,CA代表淬火(AQ)态导电率)可以反映析出相的体积分数。在早期和峰值时效阶段,导电率升高是由于析出相的形成逐渐消耗基体中的溶质原子。而在过时效阶段,导电率升高主要是由析出相的粗化造成的。对于AQ态,0.2La合金的导电率略低于0La合金,但0.4La和0.6La合金的导电率明显高于0La合金。对于时效态,4种合金导电率的相对趋势与AQ态大致相同。按La添加量由低到高,4种合金PA态导电率的相对变化分别为5.19%、5.87%、4.66%和4.42%,这表明析出相的体积分数随着La添加量升高呈先增大后减小的趋势,0.2La合金的析出相体积分数最高。

图1

图1

4种合金在180℃人工时效过程中硬度和导电率的变化曲线

Fig.1

Variations of hardness (a) and electrical conduc-tivity (b) of the four alloys aging at 180oC (AQ—as-quenched, PA—peak-aging)

图2为4种合金AQ和PA态样品的工程应力-应变曲线。AQ态4种合金均呈现良好的塑性,时效至PA态后,合金的强度显著提高,但塑性显著下降。表2为4种合金关键拉伸性能,包括屈服强度(YS)、抗拉强度(UTS)和断后延伸率(El)的统计结果。随着La添加量的提高,合金的YS和UTS均呈现先上升后下降的趋势,其中0.4La合金的YS和UTS最大。而合金的El随着La添加量的提高逐渐升高,可见La添加量越高合金塑性越好。为更好地比较合金的综合力学性能,表2也给出了各状态的塑性和强度的综合因子(Q = UTS + 150lg(El)[28,29]),Q越大,合金的综合力学性能越好。0.4La合金的Q在4种合金中最大,说明其综合力学性能最佳。

图2

图2

4种合金淬火(AQ)态和峰值时效(PA)态的工程应力-应变曲线

Fig.2

Engineering strain-stress curves of the four alloys under the AQ and PA conditions

表2 4种合金AQ和PA态的拉伸性能

Table 2

| Alloy | YS / MPa | UTS / MPa | El / % | Q / MPa | ||||

|---|---|---|---|---|---|---|---|---|

| AQ | PA | AQ | PA | AQ | PA | AQ | PA | |

| 0La | 97.2 | 312.2 | 172.4 | 332.0 | 21.6 | 4.7 | 372.6 | 432.8 |

| 0.2La | 98.4 | 318.8 | 172.5 | 341.4 | 24.5 | 7.4 | 378.7 | 471.1 |

| 0.4La | 111.1 | 337.3 | 203.4 | 355.8 | 26.0 | 9.1 | 415.6 | 499.7 |

| 0.6La | 100.7 | 316.3 | 191.9 | 337.7 | 28.2 | 10.2 | 409.6 | 489.0 |

2.2 SEM表征及XRD分析

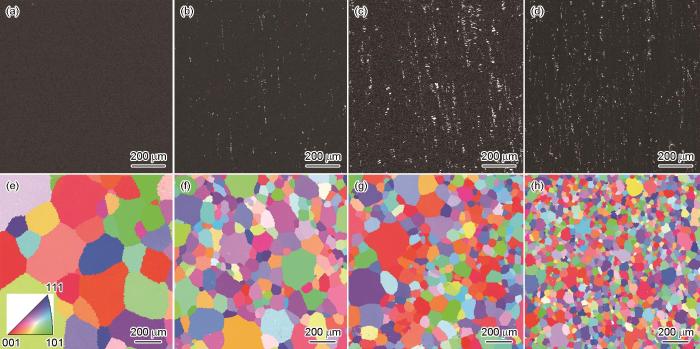

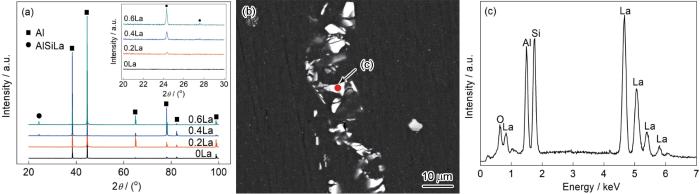

图3a~d分别为4种合金PA态背散射电子(BSE)像。0La合金中没有观察到第二相(图3a),而添加La之后,合金中形成了大量的第二相颗粒(图3b~d)。图3e~h为4种合金PA态对应的EBSD反极图。经测量,按La添加量由低到高,4种合金晶粒尺寸分别为171.2、68.8、52.7和32.6 µm。可见La添加量越高,合金晶粒细化越明显。图4a为4种合金PA态的XRD谱。可见,0La合金只有Al的衍射峰,而加La合金在24°~28°衍射角间还存在其他衍射峰,这应该是第二相的衍射峰。结合图3a~d的SEM像和图4a中XRD分析结果可得,第二相含量随着La添加量的提高逐渐增加。对0.4La合金中的第二相颗粒进行EDS分析(图4b和c),结果表明,第二相中主要含Al、Si和La元素,但具体成分尚不能确定,本工作将该第二相称为AlSiLa相。综合上述结果可以得出,La诱导形成的AlSiLa第二相含量及其晶粒细化作用随La添加量增加而增大。

图3

图3

4种合金PA态的背散射电子(BSE)像和EBSD反极图

Fig.3

Back-scattered electron (BSE) images (a-d) and EBSD inverse pole figures (IPFs) (e-h) of 0La (a, e), 0.2La (b, f), 0.4La (c, g), and 0.6La (d, h) alloys under the PA condition

图4

图4

4种合金PA态XRD谱和0.4La合金PA态BSE像及第二相EDS结果

Fig.4

XRD spectra of the four alloys under the PA condition (a), and BSE image of the 0.4La alloy (b) and EDS result of the particle marked with dot in Fig.4b (c) (Inset in Fig.4a shows the enlarged XRD spectra in the angular range 20°-30°)

图5为4种合金PA态拉伸断口形貌。其中,图5a~d为二次电子(SE)像,图5e~h为与图5a~d相同区域的BSE像。由图可见,0La合金的断口表面几乎均是解理面,是典型脆性断裂的特征(图5a)。加La合金的断口表面除解理面外还存在不同数量的韧窝,呈现脆性-韧性混合断裂的形态(图5b~d)。合金中La添加量越高,韧窝的数量越多,表明合金塑性越大,这与图2延伸率测试结果相符。细致对比BSE和SE像发现,加La合金拉伸断口的韧窝(如蓝色虚线圈所示)倾向于在第二相颗粒密集分布的区域产生(如橙色虚线圈所示),且第二相颗粒和韧窝的数量均随La添加量提高而增多。由此推断,AlSiLa相的形成是加La合金塑性提升的主要原因。第二相改善铝合金塑性的现象在Al-Li[30]和Al-Mg-Si合金[31,32]中已见报道。

图5

图5

4种合金PA态拉伸断口的二次电子(SE)像及相应BSE像

Fig.5

Secondary electron (SE) images (a-d) and corresponding BSE images (e-h) of the tensile fracture morphologies of 0La (a, e), 0.2La (b, f), 0.4La (c, g), and 0.6La (d, h) alloys under the PA condition (Arrows show the cleavage planes, blue dashed circles show the dimples, orange dashed circles show the secondary phases)

2.3 TEM及HAADF-STEM表征

图6为4种合金PA态析出相的整体形貌及析出相长度的分布图。由图可见,0La、0.2La和0.4La合金的析出相形貌无明显差异,析出相均为细小弥散的针状相(图6a、c和e)。当La添加量增至0.6%时,大部分析出相仍为针状相,但析出相尺寸发生粗化(图6g)。经统计(图6b、d、f和h),按La添加量由低到高,4种合金析出相平均长度分别为13、12、15和23 nm。相对于0La合金,0.2La合金析出相尺寸变化不明显。当La添加量继续增大,析出相平均尺寸逐渐增大,同时其尺寸分布逐渐宽化。与其他3种合金相比,0.6La合金中尽管大部分析出相的长度在20 nm以内,但还有大约30%比例的析出相的长度超过20 nm,且最长的析出相长度甚至达到了180 nm。通常,析出相尺寸粗化会导致析出硬化能力的下降,因而由析出相尺寸反映出的4种合金析出强化贡献的变化趋势是:随着La添加量增大先基本不变后逐渐下降。

图6

图6

4种合金PA态TEM明场像及析出相长度分布图

Fig.6

Typical TEM bright field images (a, c, e, g) and precipitate length distributions (b, d, f, h) of 0La (a, b), 0.2La (c, d), 0.4La (e, f), and 0.6La (g, h) alloys under the PA condition

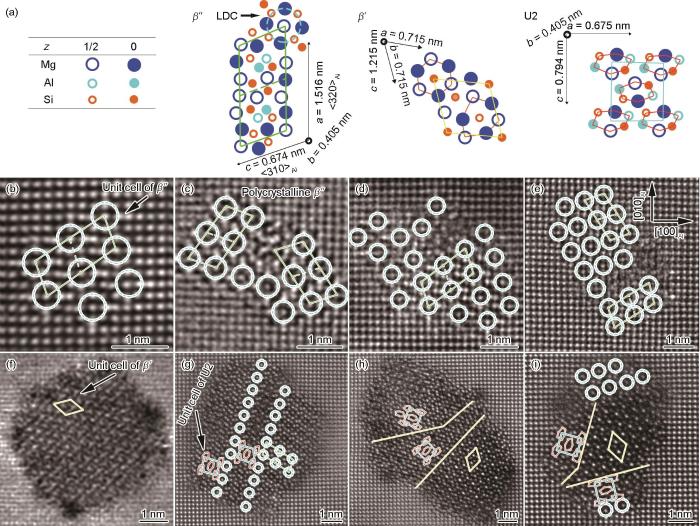

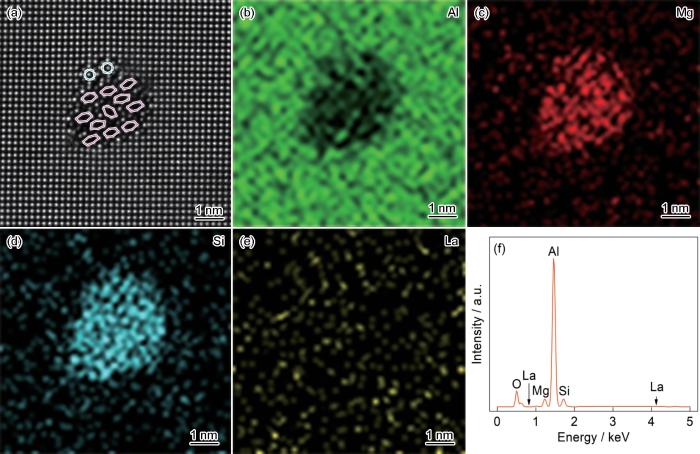

为研究La的添加对析出相结构的影响,对4种合金PA态和过时效态样品进行原子分辨率HAADF-STEM表征。HAADF-STEM像是Z (原子序数)衬度像,衬度大小与Z1.7~2.0成正比[33]。图7a给出了本表征结果中涉及到的3种已知析出相的单胞示意图。其中,β″、β′和U2相的亚结构单元分别用青色圆圈、橙色六边形和红色六边形标识。β″相的“眼睛”状的亚结构单元也被称为低密度圆柱体(LDC)。本工作经过大量表征发现,La的添加改变了Al-Mg-Si合金时效态析出相的类型,且La添加量只影响各种类型析出相的相对比例。选取0La和0.4La合金中典型析出相的原子尺度的HAADF-STEM像进行展示,如图7b~i所示。由图可见,0La合金PA态典型析出相主要为β″相(图7b)。0.4La合金PA态除β″相外,还析出了大量的多晶β″相(图7c~e)。每一个多晶β″相中都存在2种或2种以上等效取向的β″相,这些取向与过去报道[34]的β″相取向相同。研究[11]表明,小变形位错可以诱导析出多晶U2相。本工作在经传统热处理的加La合金中观察到多晶β″相,这必然与La的添加有关。值得注意的是,HAADF-STEM像中的Z衬度表明,多晶β″相中没有明显的La原子信号。时效96 h后,0La合金基体内主要析出β′相(图7f)。而0.4La合金基体内主要析出了β″/U2 (图7g)、β′/U2 (图7h)和β′/U2/β″ (图7i) 3种类型的多相复合相。与多晶β″相一样,这些复合相的HAADF-STEM像也表明其没有明显的La原子占据。为进一步确认复合相中否含有La,对其进行STEM-EDS分析。结果表明,所有复合相中La元素都不明显,这与HAADF-STEM表征所得信息一致。图8展示了其中一类典型复合相β″/U2的EDS分析结果。图8a为原子分辨率的HAADF-STEM像,图8b~f分别为相应的EDS元素面分布和EDS点分析结果。可见,该析出相中富Mg和Si,但是La元素的信号不明显。据文献[11,17,21]报道,小变形位错和其他某些微合金化元素会诱导复合相的形成。在Zn、Ag和Sc微合金元素诱导的情况下,Zn、Ag和Sc明显进入了析出相中[17~19,21]。因此,微合金化La的添加是以一种与已报道的情况不同的机制诱导复合相的形成。鉴于La原子半径(0.187 nm)明显大于Mg、Al和Si原子半径(分别为0.160、0.143和0.117 nm),猜测La非常少量地掺杂在析出相与Al基体界面处,造成界面的弹性应变增大。在这种情况下,多晶相和复合相的形成相比单晶相更有利于降低系统总能。要充分理解La诱导的多晶β″相和复合相的形成机制,需要结合定量电子显微学和系统的能量计算进行进一步研究。

图7

图7

Al-Mg-Si合金中3种析出相结构示意图及有无La添加的合金2种时效状态典型析出相的HAADF-STEM像

Fig.7

Schematics of the unit cell of β", β', and U2 (a), and HAADF-STEM images of 0La (b, f) and 0.4La alloys (c-e, g-i) peak-aged (b-e) and 96 h-aged (f-i) at 180oC (Cyan circle, orange and red hexagons depict the sub-unit(s) of β", β', and U2, respectively; z—fractional coordinate of atoms along precipitates' longest dimension; LDC—low density cylinder; a, b, c—lattice parameters)

图8

图8

β″/U2复合相原子分辨率HAADF-STEM像和EDS分析

Fig.8

Atomic-resolution HAADF-STEM image (a) and the corresponding EDS analyses (b-f) of the β″/U2 composite precipitate

3 分析讨论

铝合金的强度(σ)主要来源于Al基体本征强度(σAl)、位错强化(Δσdislo)、晶界强化(ΔσGB)、固溶强化(Δσss)和析出(包括第二相,其强化用Δσsp表示)强化(Δσprecip)[35]:

传统热处理工艺下,可以认为4种合金Δσdislo相同。下面从ΔσGB、Δσss、Δσsp和Δσprecip的差异出发,讨论不同含量La的添加对Al-Mg-Si合金强度的影响。同一合金AQ和PA态的ΔσGB和Δσsp几乎相同,先从无纳米析出相的AQ态开始讨论。根据Hall-Petch关系,ΔσGB可以描述为[36]:

式中,kGB为Hall-Petch系数,d为平均晶粒尺寸。对于铝合金而言,kGB = 68 MPa·μm0.5 [35]。4种合金晶粒尺寸分别为171.2、68.8、52.7和32.6 µm,则其ΔσGB分别为5.2、8.2、9.4和11.9 MPa。因此,晶粒细化对3种加La合金的强度提升贡献分别约为3.0、4.2和6.7 MPa。由Al-La相图[37]可知,室温下La在Al中的溶解度非常低,因此La对固溶强化的影响可以忽略不计。AlSiLa第二相的形成使得合金的Δσss降低,且La添加量越高,Δσss降低得越明显(因为La添加量越高,AlSiLa第二相含量越高(图4a)),但同时Δσsp会越来越高。AQ态合金YS的差异由ΔσGB、Δσss和Δσsp共同决定。0.2La、0.4La和0.6La合金YS分别比0La合金高1.2、13.9和3.5 MPa (表2)。综合3种强化机制的变化趋势并考虑实验误差,将La添加量对AQ态合金强度的影响理解如下:当添加0.2%La时,合金形成少量AlSiLa第二相,其本身产生轻微的第二相强化并由此带来轻微的细晶强化,同时固溶强化略微降低,合金总体强度变化不明显;当添加0.4%La时,AlSiLa第二相含量增加,细晶强化贡献相对0.2%La时增加不明显(约1 MPa),但第二相强化明显增加,且其增加的水平大于固溶强化进一步降低的水平,合金总体强度明显提升;当La添加量进一步提高到0.6%,AlSiLa第二相含量又进一步增加,尽管第二相和细晶强化都再增加,但此时固溶强化降低的水平明显大于第二相和细晶强化增加的水平,造成总体强度提升低于添加0.4%La的情况。虽然加La合金中溶质原子浓度的降低对合金的强度造成了负面影响,但其对合金的导电率提升有利,这是0.4La和0.6La合金导电率高于0La合金的原因。但是0.2La合金的导电率反而略低于0La合金,这是因为添加0.2%La时第二相所消耗的溶质原子数量少,此时合金导电率的变化主要取决于晶粒细化的影响。

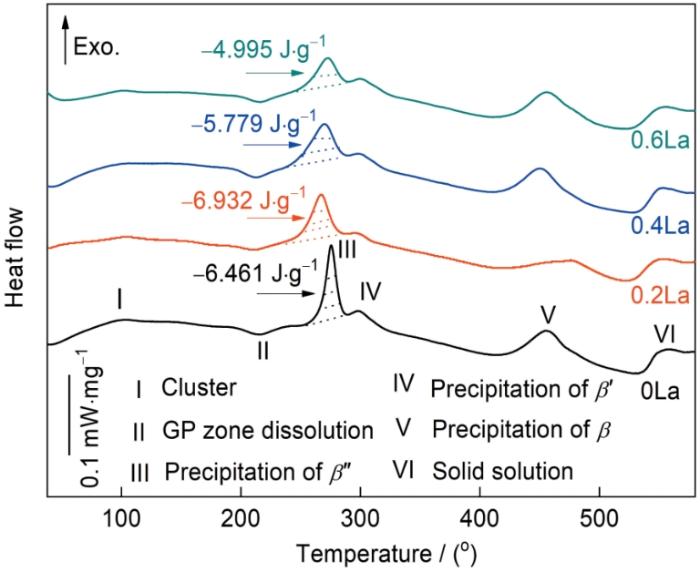

时效态合金强度的变化主要受Δσss和Δσprecip影响。随着时效时间延长直至PA态,Δσprecip逐渐提升而Δσss逐渐降低。原子分辨率HAADF-STEM观察(图7b~e)已表明,加La前后,合金PA态的析出相结构(即β″相结构)相似。另外,除0.6La合金的析出相尺寸粗化较为明显外,其他3种合金析出相尺寸差异较小(图6),表明4种PA态合金Δσprecip的差异主要与析出相体积分数的差异有关。图1b表明了,0.2%La的添加略微提高了PA态合金析出相的体积分数,当La添加量超过0.4%后,析出相体积分数随La添加量提高而降低。为了检验PA态合金析出相体积分数的变化,对4种AQ态合金进行DSC分析,结果如图9所示。根据Chang和Banhart[38]的研究可知,峰III为β″相的析出峰,且峰面积越大代表析出相体积分数越大。4种合金峰III所对应的面积分别为-6.461、-6.932、-5.779和-4.995 J/g,其中负号代表放热。这与导电率相对变化所反映的析出相体积分数的变化趋势是一致的。4种合金PA态析出相体积分数的差异与其基体中溶质原子的浓度有关。如前文所分析,随着La添加量增加,AlSiLa第二相消耗的Si原子逐渐增多,时效过程中可利用的Si原子逐渐减少,这是造成0.4La和0.6La合金析出相体积分数减小的原因。然而,0.2La合金析出相体积分数反而略高于0La合金,这是因为此时AlSiLa第二相对Si原子消耗很少,同时少量La掺杂到析出相中对析出相析出起到略微的促进作用。根据析出相体积分数的变化趋势,推得4种合金PA态Δσprecip的变化趋势为:0.2La合金 > 0La合金 > 0.4La合金 > 0.6La合金。Δσprecip的不同会造成不同的Δσss变化,但Δσprecip的变化量远高于Δσss的变化量。因此,基于4种合金AQ态强度变化趋势,并考虑Δσprecip的影响,可以将3种加La合金PA态强度相对0La合金的差异大致理解如下:当添加0.2%La时,合金AQ态强度变化不明显,由于PA处理获得的Δσprecip相对无La添加时略微增加,因此PA态强度有略微提升;当添加0.4%La时,AQ态强度明显提升,PA处理获得的Δσprecip轻微下降,最终PA态强度仍然有明显提升;当La添加量为0.6%时,AQ态强度轻微提升,PA处理获得的Δσprecip下降更加明显,最终PA态强度提升有限。

图9

铝合金硬度的微观结构来源与强度相同,但是本工作中的硬度测量值受晶粒尺寸和第二相影响不明显,主要受Δσss和Δσprecip的影响。根据前文的分析,当La添加量较少时,0.2La合金AQ和PA态硬度与0La合金相近,这是因为少量AlSiLa第二相的形成对AQ态Δσss影响小,而PA态Δσprecip变化不明显。当La添加量进一步提高时,AQ态Δσss和PA态Δσprecip均逐渐降低,合金的硬度也逐渐降低。

4 结论

(1) 微合金化La改变了Al-Mg-Si合金时效析出相的类型。峰值时效态,除β″相外,加La合金中还析出了大量的多晶β″相。过时效状态,加La合金中主要析出了β″/U2、β′/U2和β′/U2/β″复合相。

(2) 峰值时效态析出相的体积分数随La添加量的提高先轻微增大后逐渐减小,造成析出强化作用先小幅度提高后逐渐降低。

(3) 随着La添加量的提高,La诱导形成的AlSiLa第二相含量逐渐增大,由此引起合金性能发生改变:一是合金的塑性因第二相的形成而逐渐提升;二是第二相所消耗的溶质原子数量逐渐增加,因而合金的导电率逐渐提升;三是第二相自身的强化作用及其细化晶粒作用逐渐增大,但其造成固溶强化作用逐渐降低。第二相强化、晶界强化和固溶强化对合金强度贡献的总和随着La添加量的提高先上升后下降,当La的添加量为0.4%时,合金的强度最高。

参考文献

Progress in structural materials for aerospace systems

[J].

Assessment of the ability of conventional and advanced wrought aluminum alloys for mechanical performance in light-weight applications

[J].

Structure determination of Mg5Si6 particles in Al by dynamic electron diffraction studies

[J].Precipitation hardening, in which small particles inhibit the movement of dislocations to strengthen a metal, has long been used to improve mechanical strength, especially of aluminum alloys. The small size of precipitates and the many possible variants of the orientation relation have made their structural determination difficult. Small precipitates in commercial aluminum-magnesium-silicon alloys play a crucial role in increasing the mechanical strength of these alloys. The composition and structure of the β” phase in an aluminum-magnesium-silicon alloy, which occur as precipitates (typically 4 nanometers by 4 nanometers by 50 nanometers) and are associated with a particularly strong increase in mechanical strength, were determined. Element analysis indicates that the composition is Mg5Si6. A rough structure model was obtained from exit waves reconstructed from high-resolution electron microscopy images. The structure was refined with electron nanodiffraction data (overallRvalue of 3.1 percent) with the use of a recently developed least squares refinement procedure in which dynamic diffraction is fully taken into account.

Pre-precipitate clusters and precipitation processes in Al-Mg-Si alloys

[J].

Atomic pillar-based nanoprecipitates strengthen AlMgSi alloys

[J].Atomic-resolution electron microscopy reveals that pillarlike silicon double columns exist in the hardening nanoprecipitates of AlMgSi alloys, which vary in structure and composition. Upon annealing, the Si2 pillars provide the skeleton for the nanoparticles to evolve in composition, structure, and morphology. We show that they begin as tiny nuclei with a composition close to Mg2Si2Al7 and a minimal mismatch with the aluminum matrix. They subsequently undergo a one-dimensional growth in association with compositional change, becoming elongated particles. During the evolution toward the final Mg5Si6 particles, the compositional change is accompanied by a characteristic structural change. Our study explains the nanoscopic reasons that the alloys make excellent automotive materials.

The crystal structure of the β' phase in Al-Mg-Si alloys

[J].

Atomic scale investigation of the crystal structure and interfaces of the B' precipitate in Al-Mg-Si alloys

[J].

The structural relation between precipitates in Al-Mg-Si alloys, the Al-matrix and diamond silicon, with emphasis on the trigonal phase U1-MgAl2Si2

[J].

Crystal structure of the orthorhombic U2-Al4Mg4Si4 precipitate in the Al-Mg-Si alloy system and its relation to the β' and β" phases

[J].

Low-alloy-correlated reversal of the precipitation sequence in Al-Mg-Si alloys

[J].

Structures and formation mechanisms of dislocation-induced precipitates in relation to the age-hardening responses of Al-Mg-Si alloys

[J].In the slightly deformed Al-Mg-Si alloys, dislocation-induced precipitates are frequently observed, and they usually line up, forming sophisticated precipitation microstructures. Using atomic-resolution electron microscopy in association with hardness measurements, we systematically investigated these precipitates in relation to the age-hardening responses of the alloys. Our study reveals that the majority of dislocation-induced complex precipitates are actually short-range ordered while long-range disordered polycrystalline precipitates and multiphase composite precipitates, including polycrystalline U2 precipitates, B'/U2, B'-2/U2, B'/B'-2/U2 and β'/U2 composite precipitates. It is suggested that the formation of these complex precipitates is mainly owing to a high nucleation rate and rapid growth of different precipitate phases parallel to the associated dislocation lines. Since dislocation-induced precipitates consume more Mg than Si from the matrix and have a high formation kinetics, they will have different impacts on the matrix precipitation in different types of Al-Mg-Si alloys. Our results further demonstrate that for the “normally-β"-hardened” alloy, their formation leads to a coarser precipitate microstructure in the matrix, whereas for the “normally-β'-hardened” alloy, their formation reverses the precipitation pathway in the matrix, resulting in a reduced age-hardening potential of the former alloy and an improved age-hardening potential of the latter alloy.

Effects of Si on the aging behaviour and formability of aluminium alloys based on AA6016

[J].

The effects of Cu addition on the microstructure and thermal stability of an Al-Mg-Si alloy

[J].

Effect of Cu content on precipitation and age-hardening behavior in Al-Mg-Si-xCu alloys

[J].

The effect of Zn on precipitation in Al-Mg-Si alloys

[J].

HAADF-STEM and DFT investigations of the Zn-containing β" phase in Al-Mg-Si alloys

[J].

Atomic-scale roles of Zn element in age-hardened AlMgSiZn alloys

[J].Adding alloying elements to improve the performances or the manufacturing processes of Al-Mg-Si alloys has long been a serious issue in developing advanced automotive aluminum materials. The Zn element, among those promising ones, has demonstrated positive alloying effects on Al-Mg-Si alloys. However, the atomic-scale roles of Zn in an age-hardened Al-Mg-Si-Zn alloy have not been adequately understood. Using atomic-resolution electron microscopy, here we report the precise locations of Zn elements in all hardening precipitates involved and their alloying mechanism at the atomic scale when alloying the alloy. Our results show that Zn atoms enter all the major hardening phases to occupy specific featured atomic sites of the original elements, e.g. the Si1 and Mg2 sites in the β'-2 phase, and modify their crystal structures, interfacial structures and morphologies in characteristic manners. It is revealed that for the β'-phase, Zn atoms occupy unique atomic sites, whereas for other phases, they demonstrate similar behaviors as other additive alloying elements such as Ag and Cu do.

Effects of germanium, copper, and silver substitutions on hardness and microstructure in lean Al-Mg-Si alloys

[J].

Atomistic details of precipitates in lean Al-Mg-Si alloys with trace additions of Ag and Ge studied by HAADF-STEM and DFT

[J].

The effects and behaviour of Li and Cu alloying agents in lean Al-Mg-Si alloys

[J].

Formation of β"-related composite precipitates in relation to enhanced thermal stability of Sc-alloyed Al-Mg-Si alloys

[J].

Sn-induced modification of the precipitation pathways upon high-temperature ageing in an Al-Mg-Si alloy

[J].The 6xxx series aluminum alloys (Al-Mg-Si(-Cu) alloys) are widely used for the industrial applications in the lightweight construction, automotive and architecture because of their light weight, medium to high strength, excellent formability and good corrosion resistance. It has been reported that trace Sn addition can accelerate ageing kinetics and increase peak hardness of Al-Mg-Si alloys when ageing at high temperatures (>210 ℃). However, the mechanism about it has not been investigated comprehensively yet. For Mg-excess Al-Mg-Si alloys, when aged at 250 ℃, the alloys are hardened by the β'-precipitates. While after applying natural ageing prior to artificial ageing, the β"-precipitates will be formed, with the percentage of which increasing with natural ageing time, and eventually become the main hardening precipitates. In this work, the effect of Sn on natural ageing and subsequent artificial ageing at 250 ℃ in a Mg-rich Al-Mg-Si alloy was investigated by Vickers microhardness measurements and TEM. The results show that adding a small amount (0.2%, mass fraction) of Sn in the Mg-rich Al-Mg-Si alloy can modify the precipitation pathways upon 250 ℃-ageing: when the alloy is directly artificially aged, the β"-precipitates are dominant, whereas when the alloy is subjected to "natural ageing+artificial ageing" treatment, upon prolonged natural ageing time, the percentage of β"-precipitates would not increase but decrease and that of β'-precipitates would not decrease but increase, but ultimately the β"-precipitates are still dominant over the β'-precipitates. The Sn-induced modification of the precipitation pathways can significantly enhance the age-hardening potential of the alloy upon high-temperature artificial ageing. The addition of Sn increases the effective Si-concentration in the matrix, and consequently changes the precipitation pathways in the Sn-free alloy, which is different from the explanation proposed in literatures.

微合金化元素Sn对Al-Mg-Si合金高温时效强化相析出路径的改变

[J].研究了Sn (0.2%,质量分数)的添加对一种富Mg的Al-Mg-Si合金经历不同时间的自然时效后在250 ℃下人工时效过程中的时效硬化行为的影响,并利用TEM观察揭示了其微观机理。结果表明,在Al-Mg-Si合金中添加微量Sn (0.2%)可以改变合金250 ℃人工时效的强化相析出路径:当直接进行人工时效时,析出相主要为β"相;当进行自然时效+人工时效处理时,随着自然时效时间的延长,β"相的比例不增反降,而β'相的比例不降反增,但最终β"相的比例仍高于β'相的比例。Sn对强化相析出路径的改变,可以明显提高合金高温人工时效的硬化能力。Sn的添加提高了基体中有效的Si浓度,从而改变了不含Sn合金的强化相析出路径。

The effect of erbium on the microstructure and mechanical properties of Al-Mg-Mn-Zr alloy

[J].

Effects of La addition on the elevated temperature properties of the casting Al-Cu alloy

[J].

Effect mechanisms of micro-alloying element La on microstructure and mechanical properties of hypoeutectic Al-Si alloys

[J].The rare earth influence on the as-cast microstructures and mechanical properties of aluminum alloys attracted great attentions in the last decades. But up to date no reports can be found on the effect of micro-alloying element La (La addition is below 0.1 wt.%) on the solidification of hypoeutectic Al-Si alloys. This study carried out solidification experiments with Al-6Si alloys micro-alloyed by element La. The α-Al grain refinement, the eutectic Si modification and the tensile properties improvement caused by micro-alloying element La were investigated. The effect mechanisms of La were discussed. It is demonstrated that the addition of La as low as 100 ppm can deprave the more effective heterogeneous nucleation conditions for the eutectic Si caused by the impurity P. The addition of 0.06 wt.% La is sufficient to achieve an ideal α-Al grain refinement, eutectic Si modification and ductility improvement of the alloys. LaAlSi phase forms in the Al-Si alloy with the additive amount of La higher than 0.06 wt.%. It has a tetragonal structure. Micro-alloying element La refines the α-Al grains by working as a surfactant and modifies the eutectic Si by promoting the formation of the significant multiple Si twins.

Effect of micro-alloying element La on corrosion behavior of Al-Mg-Si alloys

[J].

Impact of Cu/Mg ratio on thermal stability of hot extrusion of Al-4.6 pct Cu-Mg-Ag alloys

[J].

The bimodal effect of La on the microstructures and mechanical properties of in-situ A356-TiB2 composites

[J].

Effect of minor lanthanum on the microstructures, tensile and electrical properties of Al-Fe alloys

[J].

Effects of second-phase dispersoids on deformation behavior of Al-Li alloys

[J].

The influences of multiscale-sized second-phase particles on ductility of aged aluminum alloys

[J].

Heat treatment-modulated coupling effect of multi-scale second-phase particles on the ductile fracture of aged aluminum alloys

[J].

The principles and interpretation of annular dark-field Z-contrast imaging

[J].

The diffraction patterns from β" precipitates in 12 orientations in Al-Mg-Si alloy

[J].

Optimization of electrical conductivity and strength combination by structure design at the nanoscale in Al-Mg-Si alloys

[J].

Nanomechanics of Hall-Petch relationship in nanocrystalline materials

[J].

Phase equilibria and thermodynamic limits for partitionless crystallization in the Al-La binary system

[J].

Low-temperature differential scanning calorimetry of an Al-Mg-Si alloy

[J].

Effect of grain size on the superplastic behavior of a 7475 aluminum alloy

[J].

Influence of friction stir welding parameters on grain size and formability in 5083 aluminum alloy

[J].