近日,Li等[10]报道轻稀土元素Ce可提升基面滑移和非基面滑移的临界分切应力值,同时降低非基面滑移和基面滑移临界分切应力比,从而实现<c + a>型位错高比例开动,<c + a>型位错参与形成小角度晶界,进而实现镁合金晶粒细化。Ca是一种低成本的碱土元素,在镁合金中具有与稀土元素类似的晶粒细化效果。近期的研究[11]表明,挤压态Mg-Ca二元合金的晶粒尺寸可强烈细化至1 μm以下。据此,人们发展出了一系列以Ca作为主添加元素的Mg-Ca系合金,包括Mg-Ca-Al[12]、Mg-Ca-Zn[13]、Mg-Ca-Sn-(Mn)[14]及Mg-Ca-Al-Zn-(Mn)[15]等。譬如,Pan等[16]报道的Mg-1.0Ca-1.0Al-0.2Zn-0.1Mn合金的屈服强度可达约425 MPa,延伸率达11%,表现出优良的强塑性匹配。然而,目前开发镁合金的Ca含量依然较高,这会对合金的诸多性能产生不利影响。首先,高Ca含量的镁合金出现热裂纹的倾向严重,因此大尺寸锭坯的铸造和热处理成本大幅增加[17]。此外,高Ca镁合金在挤压过程中由于共晶温度较低,容易在样品表面产生微裂纹,无法满足疲劳力学性能、二次成形加工等的服役要求[18]。研究[19]表明,Ca在镁合金中作用和轻稀土元素Ce类似,包括但不限于细化组织和形成“稀土织构”组分等,但是2者对合金力学性能影响的关联性和叠加效应还缺乏系统研究。基于此,本工作拟添加少量Ce元素,并将Ca含量降至约0.2% (质量分数),设计制备新型低合金化的Mg-0.2Ce-0.2Ca (质量分数,%,下同)合金,以期阐明Ce和Ca元素共添加对镁合金组织演变与力学性能的影响。

1 实验方法

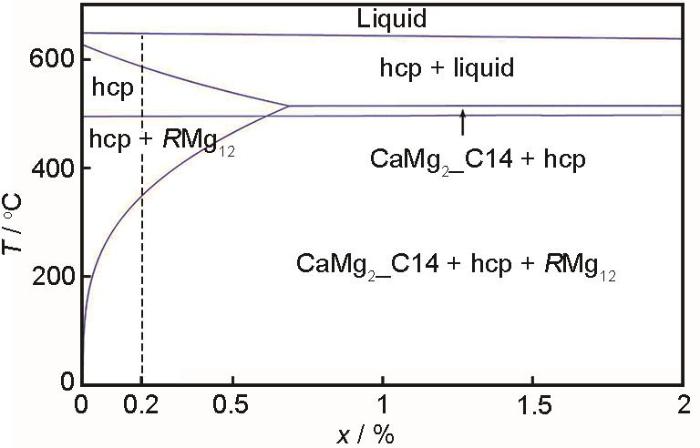

依据PanMg2017数据库通过Pandat相图计算软件得到Mg-Ce-Ca三元合金的垂直截面计算相图,如图1所示,据此设计成分为Mg-0.2Ce-0.2Ca的镁合金。实验所需的合金铸锭是在750℃下进行真空熔炼获得,得到直径45 mm、长80 mm圆柱试样,铸锭经530℃保温12 h固溶处理后获得单相固溶体组织。随后在800T立式反挤压机上挤压得到直径10 mm圆棒,挤压温度280℃,挤压速率0.4 mm/s。

图1

图1

Pandat计算Mg-0.2Ce-xCa合金的纵截面相图

Fig.1

Vertical sectional phase diagram of Mg-0.2Ce-xCa alloy calculated by Pandat software (x—mass fraction of Ca (0~2%), T—temperature)

采用AG-X Plus电子万能材料试验机测试Mg-Ce-Ca合金的力学性能,拉伸方向平行于挤压方向(ED),应变速率为0.001 s-1;采用苦味酸酒精溶液对镁合金腐蚀后,利用GX71光学显微镜(OM)观察显微组织;采用机械抛光+氩离子刻蚀(GATAN Ilion II 697)结合制备背散射电子衍射(EBSD)样品,并在配备HKL Nordlys EBSD探头的Crossbeam 550场发射扫描电子显微镜(SEM)上进行EBSD数据采集与分析(Aztec crystal 2.1),以获取晶粒尺寸、取向、晶界类型以及位错密度等微观结构参量。为系统研究镁合金在挤压过程中的微观组织演变规律,采用JEM-2100F透射电子显微镜(TEM)对距离挤压出口处不同距离的样品观察微观组织,操作电压200 kV,并结合弱束暗场像分析技术(WBDF)以及 g · b = 0位错不可见判别准则,对挤压过程中启动的孪晶/位错类型、组态与分布等进行系统表征。

2 实验结果

2.1 挤压态合金的微观组织和力学性能

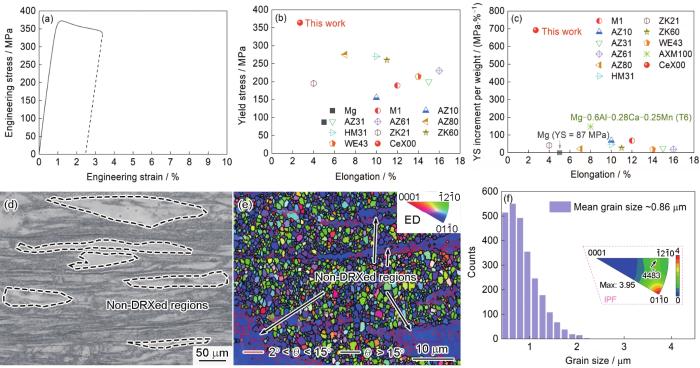

图2a示出了挤压态Mg-0.2Ce-0.2Ca合金的工程应力-应变曲线,合金的屈服强度为364 MPa,抗拉强度为374 MPa,延伸率约2.5%。表1[20,21]总结了典型商用挤压镁合金与新型Mg-Ce-Ca合金的力学性能。屈服强度和延伸率的关联分布结果如图2b所示。可以看出,新型Mg-0.2Ce-0.2Ca合金的屈服强度水平最优,较AZ系商用镁合金合金高100~170 MPa,较WE43稀土镁合金高出约150 MPa,即实现了高强度、低合金化(仅约0.4%),如表1[20,21]所示。图2c给出了单位溶质含量下屈服强度相较纯Mg提高值(屈服强度提高率)与延伸率关联分布结果,Mg-Ce-Ca合金高达约700 MPa/%,而商用镁合金的“屈服强度提高率”普遍低于150 MPa/%,表现出了显著的低合金化优势。

图2

图2

挤压态Mg-0.2Ce-0.2Ca合金力学性能和微观组织

Fig.2

Mechanical properties and microstructure of as-extruded Mg-0.2Ce-0.2Ca alloy (DRX—dynamic recrystallization, ED—extrusion direction, IPF—inverse pole figure)

(a) engineering stress-strain curve of as-extruded Mg-0.2Ce-0.2Ca alloy

(b, c) distribution maps of yield stress (YS) (b) and YS increment per weight (c) vs elongation of Mg alloys based on diverse alloy system[20,21]

(d) OM image (e) EBSD IPF map

(f) mean DRXed grain size distribution of Mg-0.2Ce-0.2Ca alloy (Inset shows the IPF of DRXed grains) (The color strip represents intensity represented as multiple of random distribution, the same in Figures below)

表1 典型挤压商用镁合金与新型Mg-0.2Ce-0.2Ca合金力学性能[20,21]

Table 1

| Alloy | Composition / (mass fraction, %) | State* | σuts / MPa | Elongation / % | |

|---|---|---|---|---|---|

| Mg | Pure Mg | F | 87 | 185 | 5 |

| M1 | Mg-1.5Mn | F | 189 | 255 | 12 |

| AZ10 | Mg-1.5Al-0.2Zn-0.2Mn | F | 155 | 240 | 10 |

| AZ31 | Mg-3Al-1Zn-0.6Mn | F | 200 | 260 | 15 |

| AZ61 | Mg-6Al-1Zn-0.6Mn | F | 230 | 310 | 16 |

| AZ80 | Mg-8Al-0.5Zn-0.1Mn | T5 | 275 | 380 | 7 |

| ZK21 | Mg-2Zn-0.6Zr | F | 195 | 260 | 4 |

| ZK60 | Mg-6Zn-0.5Zr | F | 260 | 340 | 11 |

| WE43 | Mg-4Y-3RE | F | 214 | 296 | 14 |

| AXM100 | Mg-0.6Al-0.28Ca-0.25Mn | T6 | 253 | 277 | 8 |

| MgCeCa | Mg-0.2Ce-0.2Ca | F | 364 | 374 | 2.5 (this work) |

图2d~f示出了挤压态Mg-0.2Ce-0.2Ca合金的微观组织。图2d表明,挤压态合金包含双组态的晶粒结构,由细小的动态再结晶晶粒和沿ED方向拉长的未再结晶晶粒组成,再结晶比例约83%。图2e给出了挤压态合金的EBSD取向成像图(IPF模式),其中未再结晶区晶粒的取向较为一致,表现出典型的<10

2.2 挤压过程中的微观组织演变行为

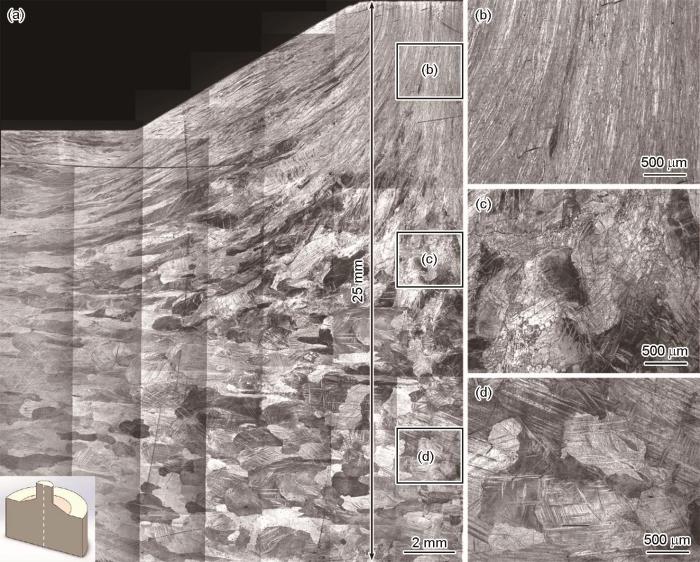

图3

图3

Mg-0.2Ce-0.2Ca合金挤压过程组织演变OM像

Fig.3

OM images of the interrupted extrusion sample of Mg-0.2Ce-0.2Ca alloy

(a) low magnified microstructure near the die exit (Inset shows the view surface diagram)

(b-d) magnified microstructures right below the die exit at the locations as marked by rectangles in Fig.3a

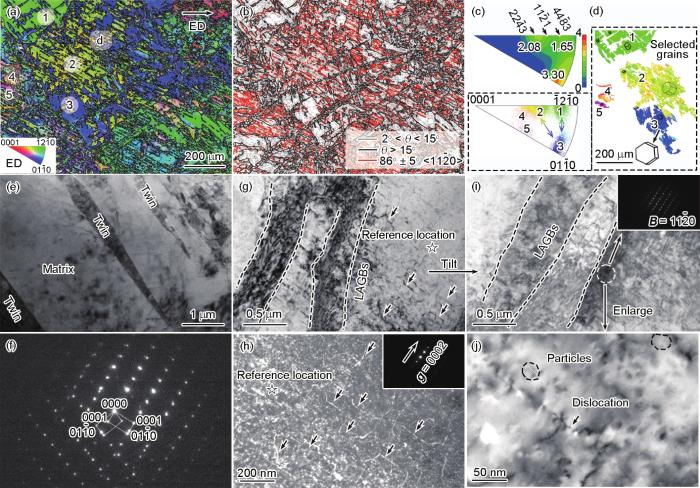

图4

图4

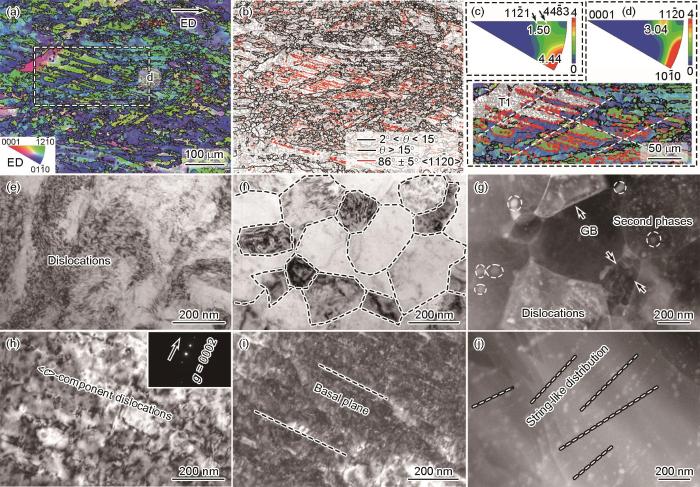

距离挤压出口17.5 mm位置处的典型EBSD和TEM像

Fig.4

Typical EBSD and TEM images at the position of 17.5 mm below extrusion die exit of Mg-0.2Ce-0.2Ca billet

(a) the IPF map

(b) grain boundary (GB) and twin boundary (TB) (θ—crystallographic misorientation angle between the two sides of the boundary)

(c) enlarged zone of Fig.4b (The schematic insert in Fig.4c illustrates characteristic position of the billet below extrusion die exit in Figs.4-7)

(d-f) existence of <a> dislocations (d) and <c + a> dislocations (e, f) (Insets in Figs.4e and f show the two-beam conditions of g = 0002 and g = 11

图5

图5

距离挤压出口12.5 mm位置处的典型EBSD和TEM像

Fig.5

Typical EBSD and TEM images at the position of 12.5 mm below extrusion die exit of Mg-0.2Ce-0.2Ca billet

(a) EBSD IPF map (b) GB and TB (c) IPF

(d) IPF map of selected grains from Fig.5a

(e-j) TEM images showing twinning (e, f), low-angle grain boundary (LAGB) (g, i), <c>-component dislocations (h), and nano second phases (j) (Arrows in Figs.5g and h represent <c>-component dislocations)

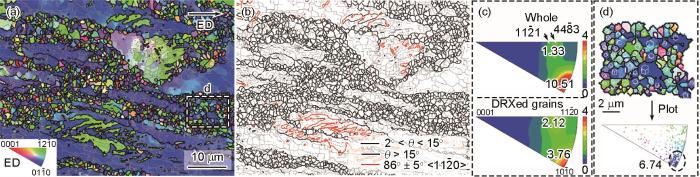

图6

图6

距离挤压出口7.5 mm 位置处的典型EBSD和TEM结果

Fig.6

Typical EBSD and TEM images at the position of 7.5 mm below extrusion die exit of Mg-0.2Ce-0.2Ca billet

(a) EBSD IPF map (b) GB and TB (c) IPF (d) selected area from Fig.6a

(e-j) TEM images showing dislocation tangles (e), DRXed grains (f), LAADF-STEM image (g), <c>-component dislocation (h, i), and HAADF-STEM image (j) (LAADF-STEM, HAADF-STEM—low and high angle annular dark-field scanning transmisson electron microscopy, respectively)

图7

图7

距离挤压出口2.5 mm位置处的典型EBSD结果

Fig.7

Typical EBSD results at the position of 2.5 mm below extrusion die exit of Mg-0.2Ce-0.2Ca billet, showing the IPF map (a), GB and TB (b), IPF (c), and selected area in Fig.7a (d)

图4a和b分别对应约17.5 mm处的EBSD IPF模式取向成像图和晶界分布图。该阶段已有高密度、较大片层厚度的孪晶被激活,且缺陷类型可判断为{10

图5a和b分别示出了约12.5 mm处的IPF模式取向成像图与晶界分布图。随着挤压的进行,该阶段样品晶粒开始逐渐形成<10

图5e~j示出了12.5 mm位置处的TEM结果,包含典型的拉伸孪晶片层组织(图5e和f)以及晶粒内部动态形成的小角度晶界(图5g和i中虚线),与EBSD结果保持一致。同时,该阶段镁合金样品的累计应变量较大,启动了高密度位错。图5g和h为临近区域,其中星号标注的位置可作为参考,满足 g = 0002双光束条件的图5h表明该区域含有大量含<c>组分的位错,即<c + a>位错;与17.5 mm位置处不同,该阶段样品中的<c + a>位错线大部分平行于基面,伴随有少量的位错线与基面成一定夹角,即出现了大量<c + a>刃型位错以及少量的<c + a>混合型位错,启动的高密度位错逐渐演变为亚晶片层组织。Wang等[22,23]报道在镁合金的孪晶过程中会发生位错与孪晶界的交互作用,即在运动中的孪晶界面处会形成<c + a>刃型位错和/或I1型层错。因此,本阶段的高密度<c + a>刃型位错可能与大量孪晶界面的迁移有关。图5i示出该阶段镁合金的基体中析出高密度球状第二相(尺寸10~20 nm),结合相图可知形成的第二相主要为Mg12Ce和Mg2Ca相。

图6示出了距离挤压出口7.5 mm位置处的显微组织。该阶段样品的孪晶界和小角度晶界被大量消耗,大角度晶界明显增多(图6a和b),表明动态再结晶已大量启动;从图6b中选定区域的放大图(图6d)中可以看出,动态再结晶晶粒主要是在2组孪晶变体的交割区域形核长大,且对应的织构类型表现为典型的<10

3 分析讨论

3.1 动态再结晶机制

镁合金变形过程中的微观组织演变行为与基体的滑移、孪生等变形机制的启动密切相关。本工作涉及的是一种Mg-0.2Ce-0.2Ca三元合金,因此Ce、Ca 2种元素对Mg基体中各变形机制临界剪切应力(CRSS)的调控作用均会对挤压组织演变产生影响。Li等[10]近期研究了Mg-0.2Ce二元合金的挤压组织演变规律,发现Ce元素的单独添加对镁合金基体中孪生行为的调控作用有限,即孪晶在挤压变形的早期阶段即可快速完成,Ce元素主要是通过改变非基面<c + a>、基面<a>、柱面<a>等滑移的CRSS,从而将主导变形机制由纯Mg的基面/柱面<a>滑移转变成了Mg-0.2Ce二元合金的<c + a>滑移,进而提升由<c + a>位错组成的位错墙热稳定性。这一结果同Ye等[26]报道的Mg-Ce二元合金纳米柱压缩实验结果一致,即Ce元素的添加对Mg基体孪生的CRSS影响较小(与纯Mg相当),因此启动后的孪晶界面可迅速扩展进而吞并整个原始晶粒,孪晶变体少。另一方面,Ca元素对镁合金基体孪生变形CRSS的影响显著。Wang等[27]最近报道了0.2%Ca的添加即可强烈提升镁合金基体孪晶生长的CRSS至约40 MPa,较纯Mg的孪晶生长CRSS (约12 MPa)提升了近4倍。这一实测结果很好佐证了本工作中出现的高密度孪晶片层组织,即由于Ca的添加导致Mg-0.2Ce-0.2Ca三元合金的孪晶生长强烈受阻,在整个挤压过程中表现出好的孪晶片层组织稳定性,且需不断启动新的孪晶变体以协调变形,因此孪晶片层的厚度较小(3~5 μm),如图4~6所示。

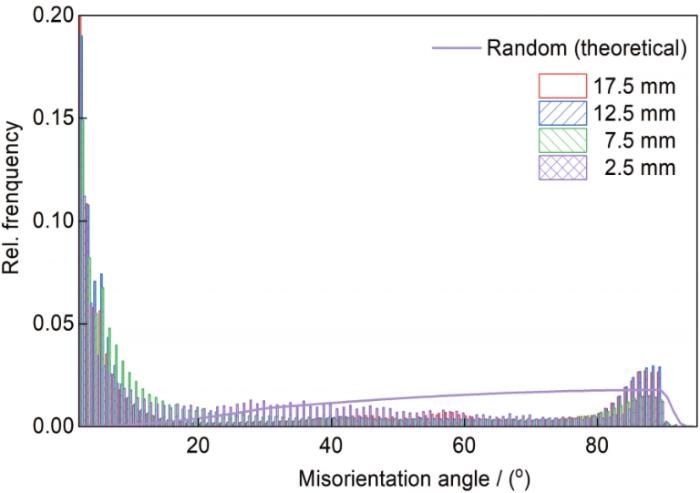

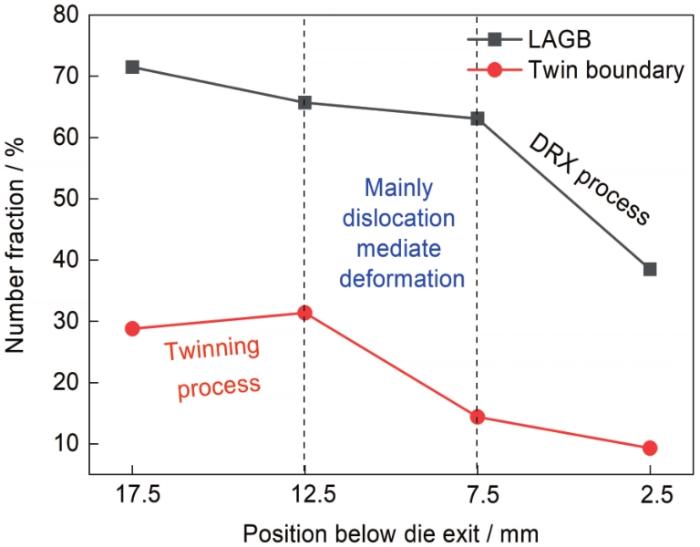

图8和9分别示出了挤压过程不同阶段的晶界取向差分布以及小角度晶界和孪晶界占比分布图。首先,在挤压的整个阶段均有孪晶的存在,证实了Mg-Ce-Ca合金中孪晶迁移的高阻力,随着挤压进行至中后期阶段(7.5~2.5 mm),部分动态再结晶晶粒沿着孪晶变体交割区域形核才导致孪晶界面比例的显著降低,这说明孪晶诱导形核是该体系合金的一个重要再结晶形核机制,如图6a~d所示。其次,小角度晶界的比例代表的是存储位错密度含量,在挤压中前期(17.5~7.5 mm)的比例一直维持在较高的水平,各阶段未再结晶区内的双束衍射TEM结果也表明了位错含量较高,如图3~6所示。在挤压后期(7.5~2.5 mm),形成的小角度晶界吸收新的位错并逐渐演变成为大角度晶界,完成了存储应力的释放,并因此导致小角度晶界含量显著减少。因此,在除了孪晶诱导形核的其他大部分未再结晶区域,位错主导的回复机制对镁合金基体中的动态再结晶行为起到了关键作用,并且同已报道的Mg-Ce二元合金的结果[10]一致,Mg-Ce-Ca三元合金中启动的同样是高比例的<c+a>位错,因此回复再结晶行为相对滞后,直至挤压变形的后期才得以发生。图7和9均示出了2.5 mm位置的位错/小角度晶界的数密度大幅度降低,并逐渐演化为图2d和e中所示的挤压态合金的双组态晶粒组织。

图8

图8

距离挤压出口不同位置处取向差角分布图

Fig.8

Distribution diagram of misorientation angle at different positions from extrusion die exit

图9

图9

距离挤压出口不同位置处小角度晶界和孪晶界占比分布

Fig.9

Proportion distribution of low angle grain boundary and twin boundary at different positions from extrusion die exit

3.2 强化机制

图10

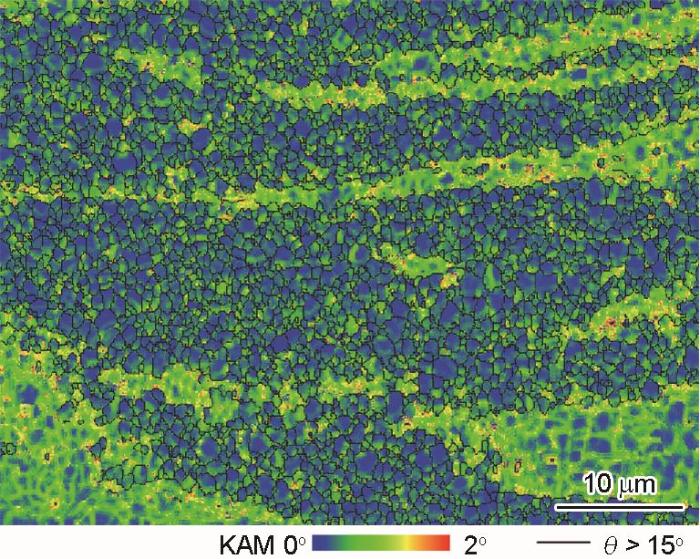

图10

挤压态Mg-Ce-Ca合金的局部取向差和晶界叠加处理图

Fig.10

KAM + GB overlapped map for as-extruded Mg-Ce-Ca alloy (KAM—kernel average misorientation)

式中,μ为EBSD扫描步长(111.3 nm);b为Burgers矢量模(0.321 nm);

式中,σ0为晶格摩擦应力,也是Hall-Petch公式中的截距;ky为Hall-Petch斜率,2者一般为实验测量和统计值,该值与镁合金合金体系和织构有关;d为晶粒尺寸;σdislo.和σOrowan分别是位错和第二相对屈服强度的贡献。镁合金中Hall-Petch系数受添加合金元素种类和工艺影响,因为2者会影响变形机制(<a>位错、<c + a>位错、孪晶)的开动比例、织构,以及各滑移系的CRSS。Wen等[31]的研究表明,含有稀土织构组分的挤压态Mg-2.22Gd的σ0和ky分别为5 MPa和285 MPa·μm0.5。本工作制备的Mg-0.2Ce-0.2Ca合金具有类似的稀土织构组分,参考该值计算可得当d = 0.86 μm时,晶界强化对屈服强度的贡献为250.1 MPa。根据Pan等[15]的研究结果,位错对强度的贡献可通过下式计算:

式中,α为常数(0.2),M为Taylor因子(本工作取值2.5),G为剪切模量(17 GPa)。代入前文估算得到的ρGND值,可得位错强化对屈服强度的贡献为63.3 MPa。根据Wang等[32]的计算结果,σOrowan可通过下式计算:

式中,G = 17 GPa,b = 0.321 nm,λ为颗粒间间距,ν为Poisson比(取0.35),dp为平均等效直径,r0为位错核半径(0.32 nm)。根据图6g和j以及TEM照片的统计结果,可以得出dp = 28 nm,λ = 75 nm,从而计算出Orowan强化贡献的屈服强度提高值为31.4 MPa。因此,可以看出,挤压合金主要的强化机制是细晶强化。由计算得到的晶格摩擦阻力、晶界和挤压态组织中残余几何必需位错对挤压态组织屈服强度的预测值为344.8 MPa,而实验测得的屈服强度为364 MPa。本工作制备的挤压态Mg-Ce-Ca合金是混晶组织,计算值比实测值低约20 MPa可能来自于粗晶的织构强化和组织的异构强化[33]。

4 结论

(1) 挤压态Mg-0.2Ce-0.2Ca合金的屈服强度、抗拉强度和延伸率分别为364 MPa、374 MPa和2.5%,强度水平均优于传统的商用镁合金,并实现了高强度和低合金化。

(2) 组织演变结果表明,孪晶存在于挤压的整个阶段,即表现出了高的孪晶运动阻力,这主要是与Ca元素的添加导致孪晶的临界运动阻力增大有关;高密度的孪晶变体交割并诱导了部分动态再结晶晶粒在约7.5 mm挤压位置处开始形核。

(3) Mg-0.2Ce-0.2Ca合金在挤压变形的早期阶段即存储了大量<c + a>位错,但是锥面位错的运动阻力较大,导致位错回复主导的再结晶机制直至挤压变形的后期才开始大量启动,回复再结晶的迟滞效应直接导致了细小再结晶晶粒的形成(约0.86 μm)以及高的屈服强度(约364 MPa)。

参考文献

Research advances of magnesium and magnesium alloys worldwide in 2021

[J].

The effects of orientation control via tension-compression on microstructural evolution and mechanical behavior of AZ31 Mg alloy sheet

[J].

Thermodynamics and kinetics of phase transformation in rare earth-magnesium alloys: A critical review

[J].Magnesium and its alloys are significant superior metallic materials for structural components in automobile and aerospace industries due to their excellent physicomechanical properties. The Mg-rare earth (RE) systems have attracted great interests because RE additions can improve both the deformability and the strength of Mg alloys through solid solution strengthening and precipitation hardening mechanisms. This paper focuses on the interface stability, together with thermodynamics and kinetics of nucleation and growth of the key phases and matrix phases in Mg-RE alloys. In this paper, the theory and recent advances on Mg-RE alloys, especially for the interface stability, thermodynamics and kinetics of nucleation and growth of the key phases and matrix phases, together with their relationships with micro-structures, and macroscopic properties, are reviewed. By combining the thermodynamics/kinetics integrated simulations with various advanced experimental techniques, “reverse” design of Mg-RE alloys starting from the target service performance is put forward as a kind of scientific paradigm with rational design.

Experimental study and thermodynamic evaluation of Mg-La-Zn system

[J].

Development and application of plastic processing technologies of magnesium alloys

[J].China has the most abundant magnesium resources in the world. Magnesium and its alloys have the advantages of low density, high specific strength, good damping property, and exceptional electromagnetic-shielding and energy-storage characteristics. They are one of the most promising lightweight materials. The enhanced applications of magnesium alloys can save energy and reduce emissions and are significant to the new Chinese energy strategy. However, magnesium alloys have a hexagonal close-packed structure and exhibit relatively low ductility. A bottleneck in expanding the application of magnesium alloys is improving the ductility of magnesium alloys. For more than ten years, efforts have been made to improve the ductility and plastic deformation ability. Progress has been made in plastic-processing technologies of magnesium alloys. The novel alloy design theory “solid solution strengthening and ductilizing” and advanced preparation technologies such as “melt self-purification through varying temperature” have been established. Series of new magnesium alloys with good ductility and corresponding alloy grades have been developed, where the impurity content of iron can be reduced to below 10 × 10-6; the elongation was more than 60% for ultrahigh plasticity magnesium alloys and is above 10% for the ultrahigh-strength magnesium alloys (UTS > 550 MPa). New plastic-processing technologies, such as asymmetric extrusion, asymmetric rolling, asymmetric modification, cyclical multipass upsetting and squeezing, expansion control large ratio forging, and extrusion and forging composite forming, have been developed. These newly developed magnesium alloys and processing technologies weaken the basal texture in wrought magnesium alloys, improving the formability of sheets, tubes, profiles, and forgings and their product quality and reducing their product cost. These technologies have been successfully applied in the processing of magnesium sheets, pipe profiles, and forgings.

镁合金塑性加工技术发展及应用

[J].我国是世界上镁资源最为丰富的国家,镁及镁合金具有质轻、比强度高、阻尼减振、电磁屏蔽性能优良、储能特性好等优点,是最有潜力的轻量化材料之一,其推广应用对节能减排和能源转型战略具有重要意义。但镁合金具有密排六方晶体结构,塑性变形能力较差。如何改善镁合金的塑性变形能力是扩大镁合金应用的瓶颈问题之一。本文综述了10多年来,世界各国在改善镁合金塑性、提升镁合金塑性变形能力等方面所做的大量工作,及在镁合金塑性加工技术等方面取得的重要进展。发展了“固溶强化增塑”新型镁合金设计理论和“熔体变温自纯化”等关键制备技术,形成了一批高塑性变形镁合金材料和牌号,其中杂质Fe含量可降到10 × 10<sup>-6</sup>以下,超高塑性镁合金延伸率可达到60%以上,超高强度(抗拉强度大于550 MPa)镁合金延伸率可以达到10%以上;开发了非对称挤压、非对称轧制、非对称改性、往复循环多道次镦挤开坯技术、扩收控制大比率锻造技术、挤锻复合成形技术等一批镁合金新型塑性加工技术。这些合金和技术使变形镁合金基面织构显著弱化,明显提高了变形镁合金板材、管型材和锻件的塑性成形能力和制品质量,产品成本大幅度降低,在板材、管型材和锻件制备加工中实现了成功应用。

Advancement in research of rolled magnesium alloys with high performance

[J].

高性能轧制镁合金研究进展

[J].

Quasi-in-situ observing the rare earth texture evolution in an extruded Mg-Zn-Gd alloy with bimodal microstructure

[J].

Grain refinement of as-cast Mg-RE alloys: Research progress and future prospect

[J].Magnesium rare-earth (Mg-RE) alloy castings with a large size and complex structure exhibit versatile prospects in critical aircraft, aerospace, and defense fields owing to their ultralow density, excellent specific strength, and high-temperature resistance. The grain refinement of cast Mg-RE alloys can significantly improve their strength, plasticity, toughness, and casting performance, which are critical for expanding their applications. In this work, the grain refinement mechanism of Mg alloys by introducing RE elements and heterogeneous particles is first discussed based on the classical theory of constitutional supercooling and heterogeneous nucleation. Various grain refinement technologies for Mg-RE alloy casting using chemical and physical methods are comprehensively summarized. Further, the influence of grain refinement on the casting performance, mechanical properties, and corrosion properties of Mg-RE cast alloys is thoroughly discussed. Finally, the deficiencies and development trends of the current grain refinement of Mg-RE alloys are discussed from the point of actual application requirements.

铸造Mg-RE合金晶粒细化行为研究现状与展望

[J].轻质高强耐热的镁稀土(Mg-RE)合金大型复杂铸件在航空航天、国防军工装备轻量化等方面展现出独特的优势。对铸造Mg-RE合金进行晶粒细化处理能够显著改善合金的强度、塑韧性以及铸造工艺性能,对拓宽其应用领域意义重大。本文首先基于成分过冷和异质形核,探讨了稀土元素及外加颗粒对镁合金晶粒细化的影响。归纳了适用于铸造Mg-RE合金的化学、物理细化方法及其作用机制,并系统论述了晶粒细化对铸造Mg-RE合金铸造工艺性能、力学性能及腐蚀性能的影响。最后面向Mg-RE合金的实际应用需求,对其细化处理方面存在的不足和发展趋势进行了探讨。

Research progress on composite refinement strengthening of magnesium alloy

[J].

镁合金复合细晶强化研究进展

[J].

Mechanistic investigation on Ce addition in tuning recrystallization behavior and mechanical property of Mg alloy

[J].Constructing bimodal grain structure is a promising approach to achieve the high strength-ductility synergy in Mg alloy. Formation of bimodal grain is closely related to the dynamic and/or static recrystallization process, which has not been fully understood in the typical Mg-RE based alloy. In this work, it is claimed for the first time that the minor Ce addition (∼0.3 wt%) into Mg matrix significantly promotes the pyramidal <c+a> and non-basal <a> dislocations at the early stage of extrusion, which consequently enhances the formation of sub-grain boundaries via the movement and recovery of pyramidal II-type <c+a> dislocations. At this stage, fine sub-grain lamellae are widely observed predominantly due to the low migration rate of sub-grain boundary caused by the limited mobility of <c+a> dislocations. At the later stage, the sub-grains continuously transform into dynamic recrystallized (DRXed) grains that have $\langle 10\bar{1}0\rangle $ Taylor axis and also strong fiber texture, indicating substantial activation of pyramidal II-type <c+a> dislocation. The low mobility of <c+a> dislocations, accompanied with the solute drag from grain boundary (GB) segregation and pinning from nano-phases, cause a sluggish DRX process and thus a bimodal microstructure with ultra-fined DRXed grains, ∼0.51 µm. The resultant texture hardening and grain refinement hardening effects, originated from bimodal microstructure, result in a yield strength of ∼352 MPa, which is exceptional in Mg-Ce dilute alloy. This work clarifies the critical role of Ce addition in tuning recrystallization behavior and mechanical property of magnesium, and can also shed light on designing the other high-performance Mg alloys.

Effect of extrusion speed on microstructure and mechanical properties of the Mg-Ca binary alloy

[J].

Role of Al addition in modifying microstructure and mechanical properties of Mg-1.0wt%Ca based alloys

[J].

Role of Zn on the rapid age-hardening in Mg-Ca-Zn alloys

[J].

A new rare-earth-free Mg-Sn-Ca-Mn wrought alloy with ultra-high strength and good ductility

[J].

Realizing ultra-fine grains and ultra-high strength in conventionally extruded Mg-Ca-Al-Zn-Mn alloys: The multiple roles of Nano-precipitations

[J].

Mechanistic investigation of a low-alloy Mg-Ca-based extrusion alloy with high strength-ductility synergy

[J].

A review on hot tearing of magnesium alloys

[J].

Thermodynamic modelling of the Mg-Ca, Mg-Sr, Ca-Sr and Mg-Ca-Sr systems using the modified quasichemical model

[J].

Effect of Ca addition on the intensity of the rare earth texture component in extruded magnesium alloys

[J].

Magnesium extrusion alloys: A review of developments and prospects

[J].Magnesium (Mg) alloys have received a significant interest in the past 20 years, owing to a nonlinearly increasing demand for lightweight structural materials. Magnesium extrusions alloys to date have had lower industrial uptake than their counterpart aluminium extrusion alloys, predominantly due to lower extrudability and formability, tension-compression yield asymmetry and no clear advantage in the specific strength. Any improvement in extrusion alloy properties requires a better understanding of the effects of alloy composition and processing conditions; and how these dictate the final alloy microstructure. This review sheds insightful information on the processing-microstructure-property relationships of extruded magnesium alloys. Historical and recent progress in magnesium extrusion alloys is critically reviewed, including the advances in extrudability, mechanical properties and microstructural characterisation. The challenges associated with the 'gap' in properties between the magnesium and aluminium extrusion alloys are identified, and prospects discussed regarding the development of high performance magnesium extrusion alloys.

Rational design of a lean magnesium-based alloy with high age-hardening response

[J].

Dislocation induced twin growth and formation of basal stacking faults in {10

Dislocation transmutation by tension twinning in magnesium alloy AZ31

[J].

Unexpected partial dislocations within stacking faults in a cold deformed Mg-Bi alloy

[J].

Correlation between dynamic recrystallization and formation of rare earth texture in a Mg-Zn-Gd magnesium alloy during extrusion

[J].The trace addition of rare earth (RE) elements in Mg alloys can modify the extrusion texture, leading to the formation of RE texture and thus improved formability. The interrupted extrusion experiment as well as electron back-scatter diffraction (EBSD) characterization was conducted in Mg-1.5Zn-0.5Gd (wt.%) alloy to unveil the dominant dynamic recrystallization (DRX) mechanism and its correlation with the formation of RE texture during extrusion. The results indicate that continuous DRX (CDRX) dominated the microstructural development. Fresh DRXed grains with 30 degrees [0001] grain boundaries preferentially nucleated in unDRXed grains with [10 (1) over bar0] basal fiber orientation via CDRX, showing preferred selection of [2 (11) over bar0] basal fiber orientation rather than RE texture orientation. Consequently, CDRX contributed to the weakening of [10 (1) over bar0] basal fiber texture and had a more significant effect on the formation of [2 (11) over bar0] basal fiber component than that of RE texture component. Besides, the preferred growth of recrystallized grains with RE texture orientation was confirmed to occur during static annealing after extrusion, which is inferred as the key reason for the formation of RE texture in dilute Mg-RE alloys.

In situ TEM compression testing of Mg and Mg-0.2wt.%Ce single crystals

[J].

Deformation mechanisms of Mg-Ca-Zn alloys studied by means of micropillar compression tests

[J].

The deformation of plastically non-homogeneous materials

[J].

Geometrically necessary dislocations and strain-gradient plasticity: A few critical issues

[J].

Fabrication of exceptionally high-strength Mg-4Sm-0.6Zn-0.4Zr alloy via low-temperature extrusion

[J].

Solute atom mediated Hall-Petch relations for magnesium binary alloys

[J].

Effect of precipitate shape and orientation on Orowan strengthening of non-basal slip modes in hexagonal crystals, application to magnesium alloys

[J].

On the micromechanism of superior strength and ductility synergy in a heterostructured Mg-2.77Y alloy

[J].