Recent development in aluminium alloys for the automotive industry

1

2000

... 随着节能环保和汽车轻量化的发展,Al-Mg-Si(-Cu) (6xxx系)铝合金以低密度、中等强度、高比强度、耐蚀性好、成形性好、可回收利用、可焊性好、表面质量好等特点,被广泛运用于汽车的车身板材和发动机的零件[1 ,2 ] .传统强化方法利用时效处理,在基体中形成大量纳米亚稳析出相阻碍位错运动,可有效提高该系材料强度[3 ] .但采用热处理获得更高强度的同时,会导致合金的韧性下降[4 ,5 ] .随着应用领域与规模扩大,如何进一步改善材料性能并制备具有高强度和高韧性的合金是金属结构材料长期面临的问题.超细晶(UFG)铝合金具有高强度、足够的延展性、高应变率以及良好的冲击韧性,越来越受到研究者的关注.等通道转角挤压(ECAP)技术可用于获得三维大尺寸块体亚微米和纳米结构材料,与未变形的材料相比,材料的强度提高了200%~300%[6 ~8 ] .在ECAP后引入合适的时效处理工艺,在超细晶基体中形成弥散的纳米亚稳析出相,能够有效提高该系合金强度的同时保证足够的韧性.此外,析出相的析出序列、尺寸、种类和分布,对材料的最终性能有至关重要的影响.如何合理调控析出相的种类、尺寸、分布、以及与晶粒尺寸和位错密度之间的关系,是制备高强高韧的铝合金的热点[9 ~11 ] .Cerri和Leo[12 ] 研究了ECAP后时效处理对6082铝合金硬度的影响,结果表明,高温后时效会降低材料的硬度;而100℃或者更低的低温后时效,析出相强化的贡献将远超过回复或者晶粒粗化所带来的负面影响.此外,Kim等[13 ] 还对一种超细晶铝合金进行了后时效处理,结果表明,低温后时效后基体中高密度的位错得以很好的保留,并在基体中出现了尺寸更小的时效析出相,在纳米析出相与位错的交互作用下,材料的强度显著增加.目前关于未变形6000系铝合金析出行为的研究较多,但关于超细晶6061铝合金在不同后时效温度下的析出演变以及析出强化机制的研究较少.本工作通过透射电子显微镜(TEM)、高分辨透射电镜(HRTEM)、X射线衍射(XRD)和力学性能测试等手段对不同后时效条件下超细晶6061铝合金的微观组织和力学性能进行对比研究,讨论和解释了后时效合金中时效析出相的演变规律以及后时效析出相对其强韧性的影响. ...

Microstructure, mechanical properties and wear resistance of an Al-Mg-Si alloy produced by equal channel angular pressing

1

2020

... 随着节能环保和汽车轻量化的发展,Al-Mg-Si(-Cu) (6xxx系)铝合金以低密度、中等强度、高比强度、耐蚀性好、成形性好、可回收利用、可焊性好、表面质量好等特点,被广泛运用于汽车的车身板材和发动机的零件[1 ,2 ] .传统强化方法利用时效处理,在基体中形成大量纳米亚稳析出相阻碍位错运动,可有效提高该系材料强度[3 ] .但采用热处理获得更高强度的同时,会导致合金的韧性下降[4 ,5 ] .随着应用领域与规模扩大,如何进一步改善材料性能并制备具有高强度和高韧性的合金是金属结构材料长期面临的问题.超细晶(UFG)铝合金具有高强度、足够的延展性、高应变率以及良好的冲击韧性,越来越受到研究者的关注.等通道转角挤压(ECAP)技术可用于获得三维大尺寸块体亚微米和纳米结构材料,与未变形的材料相比,材料的强度提高了200%~300%[6 ~8 ] .在ECAP后引入合适的时效处理工艺,在超细晶基体中形成弥散的纳米亚稳析出相,能够有效提高该系合金强度的同时保证足够的韧性.此外,析出相的析出序列、尺寸、种类和分布,对材料的最终性能有至关重要的影响.如何合理调控析出相的种类、尺寸、分布、以及与晶粒尺寸和位错密度之间的关系,是制备高强高韧的铝合金的热点[9 ~11 ] .Cerri和Leo[12 ] 研究了ECAP后时效处理对6082铝合金硬度的影响,结果表明,高温后时效会降低材料的硬度;而100℃或者更低的低温后时效,析出相强化的贡献将远超过回复或者晶粒粗化所带来的负面影响.此外,Kim等[13 ] 还对一种超细晶铝合金进行了后时效处理,结果表明,低温后时效后基体中高密度的位错得以很好的保留,并在基体中出现了尺寸更小的时效析出相,在纳米析出相与位错的交互作用下,材料的强度显著增加.目前关于未变形6000系铝合金析出行为的研究较多,但关于超细晶6061铝合金在不同后时效温度下的析出演变以及析出强化机制的研究较少.本工作通过透射电子显微镜(TEM)、高分辨透射电镜(HRTEM)、X射线衍射(XRD)和力学性能测试等手段对不同后时效条件下超细晶6061铝合金的微观组织和力学性能进行对比研究,讨论和解释了后时效合金中时效析出相的演变规律以及后时效析出相对其强韧性的影响. ...

The structural and compositional evolution of precipitates in Al-Mg-Si-Cu alloy

1

2018

... 随着节能环保和汽车轻量化的发展,Al-Mg-Si(-Cu) (6xxx系)铝合金以低密度、中等强度、高比强度、耐蚀性好、成形性好、可回收利用、可焊性好、表面质量好等特点,被广泛运用于汽车的车身板材和发动机的零件[1 ,2 ] .传统强化方法利用时效处理,在基体中形成大量纳米亚稳析出相阻碍位错运动,可有效提高该系材料强度[3 ] .但采用热处理获得更高强度的同时,会导致合金的韧性下降[4 ,5 ] .随着应用领域与规模扩大,如何进一步改善材料性能并制备具有高强度和高韧性的合金是金属结构材料长期面临的问题.超细晶(UFG)铝合金具有高强度、足够的延展性、高应变率以及良好的冲击韧性,越来越受到研究者的关注.等通道转角挤压(ECAP)技术可用于获得三维大尺寸块体亚微米和纳米结构材料,与未变形的材料相比,材料的强度提高了200%~300%[6 ~8 ] .在ECAP后引入合适的时效处理工艺,在超细晶基体中形成弥散的纳米亚稳析出相,能够有效提高该系合金强度的同时保证足够的韧性.此外,析出相的析出序列、尺寸、种类和分布,对材料的最终性能有至关重要的影响.如何合理调控析出相的种类、尺寸、分布、以及与晶粒尺寸和位错密度之间的关系,是制备高强高韧的铝合金的热点[9 ~11 ] .Cerri和Leo[12 ] 研究了ECAP后时效处理对6082铝合金硬度的影响,结果表明,高温后时效会降低材料的硬度;而100℃或者更低的低温后时效,析出相强化的贡献将远超过回复或者晶粒粗化所带来的负面影响.此外,Kim等[13 ] 还对一种超细晶铝合金进行了后时效处理,结果表明,低温后时效后基体中高密度的位错得以很好的保留,并在基体中出现了尺寸更小的时效析出相,在纳米析出相与位错的交互作用下,材料的强度显著增加.目前关于未变形6000系铝合金析出行为的研究较多,但关于超细晶6061铝合金在不同后时效温度下的析出演变以及析出强化机制的研究较少.本工作通过透射电子显微镜(TEM)、高分辨透射电镜(HRTEM)、X射线衍射(XRD)和力学性能测试等手段对不同后时效条件下超细晶6061铝合金的微观组织和力学性能进行对比研究,讨论和解释了后时效合金中时效析出相的演变规律以及后时效析出相对其强韧性的影响. ...

Effect of annealing treatment on microstructure and fatigue crack growth behavior of Al-Zn-Mg-Sc-Zr alloy

1

2018

... 随着节能环保和汽车轻量化的发展,Al-Mg-Si(-Cu) (6xxx系)铝合金以低密度、中等强度、高比强度、耐蚀性好、成形性好、可回收利用、可焊性好、表面质量好等特点,被广泛运用于汽车的车身板材和发动机的零件[1 ,2 ] .传统强化方法利用时效处理,在基体中形成大量纳米亚稳析出相阻碍位错运动,可有效提高该系材料强度[3 ] .但采用热处理获得更高强度的同时,会导致合金的韧性下降[4 ,5 ] .随着应用领域与规模扩大,如何进一步改善材料性能并制备具有高强度和高韧性的合金是金属结构材料长期面临的问题.超细晶(UFG)铝合金具有高强度、足够的延展性、高应变率以及良好的冲击韧性,越来越受到研究者的关注.等通道转角挤压(ECAP)技术可用于获得三维大尺寸块体亚微米和纳米结构材料,与未变形的材料相比,材料的强度提高了200%~300%[6 ~8 ] .在ECAP后引入合适的时效处理工艺,在超细晶基体中形成弥散的纳米亚稳析出相,能够有效提高该系合金强度的同时保证足够的韧性.此外,析出相的析出序列、尺寸、种类和分布,对材料的最终性能有至关重要的影响.如何合理调控析出相的种类、尺寸、分布、以及与晶粒尺寸和位错密度之间的关系,是制备高强高韧的铝合金的热点[9 ~11 ] .Cerri和Leo[12 ] 研究了ECAP后时效处理对6082铝合金硬度的影响,结果表明,高温后时效会降低材料的硬度;而100℃或者更低的低温后时效,析出相强化的贡献将远超过回复或者晶粒粗化所带来的负面影响.此外,Kim等[13 ] 还对一种超细晶铝合金进行了后时效处理,结果表明,低温后时效后基体中高密度的位错得以很好的保留,并在基体中出现了尺寸更小的时效析出相,在纳米析出相与位错的交互作用下,材料的强度显著增加.目前关于未变形6000系铝合金析出行为的研究较多,但关于超细晶6061铝合金在不同后时效温度下的析出演变以及析出强化机制的研究较少.本工作通过透射电子显微镜(TEM)、高分辨透射电镜(HRTEM)、X射线衍射(XRD)和力学性能测试等手段对不同后时效条件下超细晶6061铝合金的微观组织和力学性能进行对比研究,讨论和解释了后时效合金中时效析出相的演变规律以及后时效析出相对其强韧性的影响. ...

Through-thickness inhomogeneity of localized corrosion in 7050-T7451 Al alloy thick plate

1

2015

... 随着节能环保和汽车轻量化的发展,Al-Mg-Si(-Cu) (6xxx系)铝合金以低密度、中等强度、高比强度、耐蚀性好、成形性好、可回收利用、可焊性好、表面质量好等特点,被广泛运用于汽车的车身板材和发动机的零件[1 ,2 ] .传统强化方法利用时效处理,在基体中形成大量纳米亚稳析出相阻碍位错运动,可有效提高该系材料强度[3 ] .但采用热处理获得更高强度的同时,会导致合金的韧性下降[4 ,5 ] .随着应用领域与规模扩大,如何进一步改善材料性能并制备具有高强度和高韧性的合金是金属结构材料长期面临的问题.超细晶(UFG)铝合金具有高强度、足够的延展性、高应变率以及良好的冲击韧性,越来越受到研究者的关注.等通道转角挤压(ECAP)技术可用于获得三维大尺寸块体亚微米和纳米结构材料,与未变形的材料相比,材料的强度提高了200%~300%[6 ~8 ] .在ECAP后引入合适的时效处理工艺,在超细晶基体中形成弥散的纳米亚稳析出相,能够有效提高该系合金强度的同时保证足够的韧性.此外,析出相的析出序列、尺寸、种类和分布,对材料的最终性能有至关重要的影响.如何合理调控析出相的种类、尺寸、分布、以及与晶粒尺寸和位错密度之间的关系,是制备高强高韧的铝合金的热点[9 ~11 ] .Cerri和Leo[12 ] 研究了ECAP后时效处理对6082铝合金硬度的影响,结果表明,高温后时效会降低材料的硬度;而100℃或者更低的低温后时效,析出相强化的贡献将远超过回复或者晶粒粗化所带来的负面影响.此外,Kim等[13 ] 还对一种超细晶铝合金进行了后时效处理,结果表明,低温后时效后基体中高密度的位错得以很好的保留,并在基体中出现了尺寸更小的时效析出相,在纳米析出相与位错的交互作用下,材料的强度显著增加.目前关于未变形6000系铝合金析出行为的研究较多,但关于超细晶6061铝合金在不同后时效温度下的析出演变以及析出强化机制的研究较少.本工作通过透射电子显微镜(TEM)、高分辨透射电镜(HRTEM)、X射线衍射(XRD)和力学性能测试等手段对不同后时效条件下超细晶6061铝合金的微观组织和力学性能进行对比研究,讨论和解释了后时效合金中时效析出相的演变规律以及后时效析出相对其强韧性的影响. ...

DSC analyses of static and dynamic precipitation of an Al-Mg-Si-Cu aluminum alloy

2

2015

... 随着节能环保和汽车轻量化的发展,Al-Mg-Si(-Cu) (6xxx系)铝合金以低密度、中等强度、高比强度、耐蚀性好、成形性好、可回收利用、可焊性好、表面质量好等特点,被广泛运用于汽车的车身板材和发动机的零件[1 ,2 ] .传统强化方法利用时效处理,在基体中形成大量纳米亚稳析出相阻碍位错运动,可有效提高该系材料强度[3 ] .但采用热处理获得更高强度的同时,会导致合金的韧性下降[4 ,5 ] .随着应用领域与规模扩大,如何进一步改善材料性能并制备具有高强度和高韧性的合金是金属结构材料长期面临的问题.超细晶(UFG)铝合金具有高强度、足够的延展性、高应变率以及良好的冲击韧性,越来越受到研究者的关注.等通道转角挤压(ECAP)技术可用于获得三维大尺寸块体亚微米和纳米结构材料,与未变形的材料相比,材料的强度提高了200%~300%[6 ~8 ] .在ECAP后引入合适的时效处理工艺,在超细晶基体中形成弥散的纳米亚稳析出相,能够有效提高该系合金强度的同时保证足够的韧性.此外,析出相的析出序列、尺寸、种类和分布,对材料的最终性能有至关重要的影响.如何合理调控析出相的种类、尺寸、分布、以及与晶粒尺寸和位错密度之间的关系,是制备高强高韧的铝合金的热点[9 ~11 ] .Cerri和Leo[12 ] 研究了ECAP后时效处理对6082铝合金硬度的影响,结果表明,高温后时效会降低材料的硬度;而100℃或者更低的低温后时效,析出相强化的贡献将远超过回复或者晶粒粗化所带来的负面影响.此外,Kim等[13 ] 还对一种超细晶铝合金进行了后时效处理,结果表明,低温后时效后基体中高密度的位错得以很好的保留,并在基体中出现了尺寸更小的时效析出相,在纳米析出相与位错的交互作用下,材料的强度显著增加.目前关于未变形6000系铝合金析出行为的研究较多,但关于超细晶6061铝合金在不同后时效温度下的析出演变以及析出强化机制的研究较少.本工作通过透射电子显微镜(TEM)、高分辨透射电镜(HRTEM)、X射线衍射(XRD)和力学性能测试等手段对不同后时效条件下超细晶6061铝合金的微观组织和力学性能进行对比研究,讨论和解释了后时效合金中时效析出相的演变规律以及后时效析出相对其强韧性的影响. ...

... 实验材料为商用6061铝合金,合金化学成分(质量分数,%)为:Mg 0.8~1.2,Si 0.4~0.8,Cu 0.15~0.40,Cr 0.15~0.35,Mn 0.15,Fe 0.7,Zn 0.25,Ti 0.15,Al余量.材料为圆棒状挤压棒材,直径为25 mm.从圆棒中切出尺寸为19.5 mm × 19.5 mm × 100 mm的试样,在电阻炉内进行560℃、2 h的固溶处理,随后直接水淬至室温.固溶后取部分试样以Bc路线进行两道次的ECAP处理.ECAP温度控制在室温,挤压速率控制在5 mm/s.ECAP实验在MTS 810万能材料试验机进行,其模具内角Φ 为90°,外圆弧角Ψ 为20.6°.ECAP后试样分别在80、110、170℃下后时效2、5、10、20、30和180 min.为了与ECAP态和后时态试样对比,固溶处理后试样立即进行T6态峰时效处理,即在电阻炉中170℃下保温24 h.拉伸实验在计算机控制的DDL100电子万能试验机进行,拉伸应变速率10-4 s-1 .显微硬度测试在FM-ARS900型全自动显微硬度计上进行,载荷1 N,持续加载时间15 s,每项测试至少重复3次,以确保结果的准确性.采用D8 ADVANCE型XRD测定物相成分,试样尺寸为15 mm × 15 mm,将试样的一个面磨平.XRD实验电流30 mA,电压40 kV,CuKα ,实验数据使用MDI Jade 6.5软件进行处理.并由XRD谱计算平均晶粒尺寸(D XRD )、微观应变(<ε 2 >1/2 )和位错密度(ρ ).计算时,由所测各衍射峰的衍射角(θ )和半高宽(β )信息,通过Cauchy-Gaussian公式建立β 2 / tan2 θ 与β / (tanθ sinθ )的关系,得到斜率(λ / D )与截距(25ε 2 ),进而算出D XRD 和<ε 2 >1/2 .将D XRD 和<ε 2 >1/2 分别代入文献[6 ]相关公式计算得到ρ (ρ = 2 3 ε 2 1 / 2 D X R D b b 为Burgers矢量模).从上述样品上切取TEM试样薄片,用砂纸两面轻磨至厚度约0.1 mm,用冲孔器冲孔成直径3 mm的圆片,随后用Gatan手动研磨盘将圆片减薄至30~70 μm,再用Gatan凹坑仪减薄至15 μm左右,最后用Gatan 691精密离子减薄仪减薄到电子束能透明的厚度(即刚开始穿孔时).采用Tecnai G2 F20 TEM观察材料的微观形貌,工作电压200 kV. ...

Developing processing routes for the equal-channel angular pressing of age-hardenable aluminum alloys

1

2010

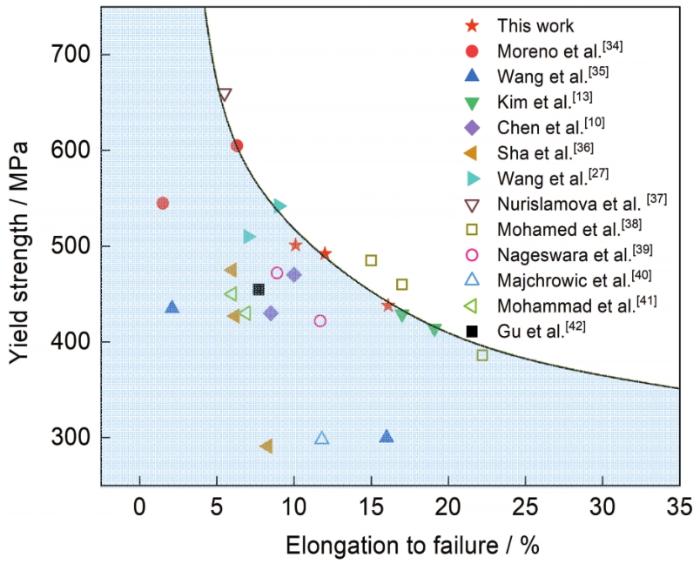

... 长期以来,超细晶纳米晶金属材料强韧性的“倒置关系”一直是制约其发展的重要瓶颈,大大限制了其工程应用[7 ,10 ,34 ,35 ] .大多数严重塑性变形超细晶纳米晶材料的低塑性主要是由于晶粒内部存储或容纳位错的能力很低,失去了使位错在晶内塞积和存储的能力,造成了应变(加工)硬化的缺失[36 ] .因此材料在拉伸过程中很容易趋于塑性失稳,造成其均匀延伸率几乎为零.如王贝贝等[35 ] 对6061铝合金进行搅拌摩擦加工,在强制冷却条件下热输入明显降低,析出相的粗化受到一定程度的抑制,屈服强度和抗拉强度分别提高至435和505 MPa,但断裂延伸率仅为2.1%.Nurislamova等[37 ] 对6061铝合金进行高压扭转,屈服强度达660 MPa,但这是以牺牲塑性为代价的,其延伸率仅有5.2%.表3 [10 ,13 ,27 ,34 ~42 ] 总结了国内外6000系铝合金的拉伸性能,并在图7 [10 ,13 ,27 ,34 ~42 ] 中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

Mechanical responses, texture and microstructural evolution of high purity aluminum deformed by equal channel angular pressing

1

2015

... 随着节能环保和汽车轻量化的发展,Al-Mg-Si(-Cu) (6xxx系)铝合金以低密度、中等强度、高比强度、耐蚀性好、成形性好、可回收利用、可焊性好、表面质量好等特点,被广泛运用于汽车的车身板材和发动机的零件[1 ,2 ] .传统强化方法利用时效处理,在基体中形成大量纳米亚稳析出相阻碍位错运动,可有效提高该系材料强度[3 ] .但采用热处理获得更高强度的同时,会导致合金的韧性下降[4 ,5 ] .随着应用领域与规模扩大,如何进一步改善材料性能并制备具有高强度和高韧性的合金是金属结构材料长期面临的问题.超细晶(UFG)铝合金具有高强度、足够的延展性、高应变率以及良好的冲击韧性,越来越受到研究者的关注.等通道转角挤压(ECAP)技术可用于获得三维大尺寸块体亚微米和纳米结构材料,与未变形的材料相比,材料的强度提高了200%~300%[6 ~8 ] .在ECAP后引入合适的时效处理工艺,在超细晶基体中形成弥散的纳米亚稳析出相,能够有效提高该系合金强度的同时保证足够的韧性.此外,析出相的析出序列、尺寸、种类和分布,对材料的最终性能有至关重要的影响.如何合理调控析出相的种类、尺寸、分布、以及与晶粒尺寸和位错密度之间的关系,是制备高强高韧的铝合金的热点[9 ~11 ] .Cerri和Leo[12 ] 研究了ECAP后时效处理对6082铝合金硬度的影响,结果表明,高温后时效会降低材料的硬度;而100℃或者更低的低温后时效,析出相强化的贡献将远超过回复或者晶粒粗化所带来的负面影响.此外,Kim等[13 ] 还对一种超细晶铝合金进行了后时效处理,结果表明,低温后时效后基体中高密度的位错得以很好的保留,并在基体中出现了尺寸更小的时效析出相,在纳米析出相与位错的交互作用下,材料的强度显著增加.目前关于未变形6000系铝合金析出行为的研究较多,但关于超细晶6061铝合金在不同后时效温度下的析出演变以及析出强化机制的研究较少.本工作通过透射电子显微镜(TEM)、高分辨透射电镜(HRTEM)、X射线衍射(XRD)和力学性能测试等手段对不同后时效条件下超细晶6061铝合金的微观组织和力学性能进行对比研究,讨论和解释了后时效合金中时效析出相的演变规律以及后时效析出相对其强韧性的影响. ...

Deformation-induced solid-state amorphization in a nanostructured Al-Mg alloy processed by high pressure torsion

1

2015

... 随着节能环保和汽车轻量化的发展,Al-Mg-Si(-Cu) (6xxx系)铝合金以低密度、中等强度、高比强度、耐蚀性好、成形性好、可回收利用、可焊性好、表面质量好等特点,被广泛运用于汽车的车身板材和发动机的零件[1 ,2 ] .传统强化方法利用时效处理,在基体中形成大量纳米亚稳析出相阻碍位错运动,可有效提高该系材料强度[3 ] .但采用热处理获得更高强度的同时,会导致合金的韧性下降[4 ,5 ] .随着应用领域与规模扩大,如何进一步改善材料性能并制备具有高强度和高韧性的合金是金属结构材料长期面临的问题.超细晶(UFG)铝合金具有高强度、足够的延展性、高应变率以及良好的冲击韧性,越来越受到研究者的关注.等通道转角挤压(ECAP)技术可用于获得三维大尺寸块体亚微米和纳米结构材料,与未变形的材料相比,材料的强度提高了200%~300%[6 ~8 ] .在ECAP后引入合适的时效处理工艺,在超细晶基体中形成弥散的纳米亚稳析出相,能够有效提高该系合金强度的同时保证足够的韧性.此外,析出相的析出序列、尺寸、种类和分布,对材料的最终性能有至关重要的影响.如何合理调控析出相的种类、尺寸、分布、以及与晶粒尺寸和位错密度之间的关系,是制备高强高韧的铝合金的热点[9 ~11 ] .Cerri和Leo[12 ] 研究了ECAP后时效处理对6082铝合金硬度的影响,结果表明,高温后时效会降低材料的硬度;而100℃或者更低的低温后时效,析出相强化的贡献将远超过回复或者晶粒粗化所带来的负面影响.此外,Kim等[13 ] 还对一种超细晶铝合金进行了后时效处理,结果表明,低温后时效后基体中高密度的位错得以很好的保留,并在基体中出现了尺寸更小的时效析出相,在纳米析出相与位错的交互作用下,材料的强度显著增加.目前关于未变形6000系铝合金析出行为的研究较多,但关于超细晶6061铝合金在不同后时效温度下的析出演变以及析出强化机制的研究较少.本工作通过透射电子显微镜(TEM)、高分辨透射电镜(HRTEM)、X射线衍射(XRD)和力学性能测试等手段对不同后时效条件下超细晶6061铝合金的微观组织和力学性能进行对比研究,讨论和解释了后时效合金中时效析出相的演变规律以及后时效析出相对其强韧性的影响. ...

A tuning nano-precipitation approach for achieving enhanced strength and good ductility in Al alloys

8

2014

... 长期以来,超细晶纳米晶金属材料强韧性的“倒置关系”一直是制约其发展的重要瓶颈,大大限制了其工程应用[7 ,10 ,34 ,35 ] .大多数严重塑性变形超细晶纳米晶材料的低塑性主要是由于晶粒内部存储或容纳位错的能力很低,失去了使位错在晶内塞积和存储的能力,造成了应变(加工)硬化的缺失[36 ] .因此材料在拉伸过程中很容易趋于塑性失稳,造成其均匀延伸率几乎为零.如王贝贝等[35 ] 对6061铝合金进行搅拌摩擦加工,在强制冷却条件下热输入明显降低,析出相的粗化受到一定程度的抑制,屈服强度和抗拉强度分别提高至435和505 MPa,但断裂延伸率仅为2.1%.Nurislamova等[37 ] 对6061铝合金进行高压扭转,屈服强度达660 MPa,但这是以牺牲塑性为代价的,其延伸率仅有5.2%.表3 [10 ,13 ,27 ,34 ~42 ] 总结了国内外6000系铝合金的拉伸性能,并在图7 [10 ,13 ,27 ,34 ~42 ] 中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... [10 ,13 ,27 ,34 ~42 ]总结了国内外6000系铝合金的拉伸性能,并在图7 [10 ,13 ,27 ,34 ~42 ] 中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... [10 ,13 ,27 ,34 ~42 ]中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... 国内外超细晶纳米晶6000系时效铝合金的强韧性对比[10 ,13 ,27 ,34 ~42 ] ...

... Comprehensive comparisons of tensile properties of 6000 series Al alloys[10 ,13 ,27 ,34 -42 ] ...

... [

10 ]

6061 ECAP at RT + post-aging 411 450 17.8 [13 ] 6061 under-aging + coldrolling + re-aging 542 560 8.5 [27 ] 6061 HPT at RT 605 705 6.3 [34 ] 6061 Friction stir processing 435 505 2.1 [35 ] AA6060 HPT at RT 475 525 6.0 [36 ] 6061 HPT at RT 660 690 5.5 [37 ] 6061 HPT at RT + post-aging 455 485 15.0 [38 ] 6061 multi directional forging + aging 409 472 8.9 [39 ] 6101 hydrostatic extrusion + aging 345 354 5.5 [40 ] 6061 accumulative roll bonding + aging 450 - 6.5 [41 ] Al-Mg-Si-Cu pre-deformation + aging 435 450 7.1 [42 ] Note: UTS—ultimate tensile strength, E f —elongation to failure, HPT—high-pressure torsion ...

...

Note: UTS—ultimate tensile strength,

E f —elongation to failure, HPT—high-pressure torsion

图7 国内外Al-Mg-Si铝合金屈服强度-延伸率综合对比<sup>[<xref ref-type="bibr" rid="R10">10</xref>,<xref ref-type="bibr" rid="R13">13</xref>,<xref ref-type="bibr" rid="R27">27</xref>,<xref ref-type="bibr" rid="R34">34</xref>~<xref ref-type="bibr" rid="R42">42</xref>]</sup> Comprehensive comparisons of yield strength and uniform elongation of Al-Mg-Si alloys<sup>[<xref ref-type="bibr" rid="R10">10</xref>,<xref ref-type="bibr" rid="R13">13</xref>,<xref ref-type="bibr" rid="R27">27</xref>,<xref ref-type="bibr" rid="R34">34</xref>-<xref ref-type="bibr" rid="R42">42</xref>]</sup> Color online ...

... [

10 ,

13 ,

27 ,

34 -

42 ]

Color online ...

Atomistic structure of Cu-containing β'' precipitates in an Al-Mg-Si-Cu alloy

1

2014

... 随着节能环保和汽车轻量化的发展,Al-Mg-Si(-Cu) (6xxx系)铝合金以低密度、中等强度、高比强度、耐蚀性好、成形性好、可回收利用、可焊性好、表面质量好等特点,被广泛运用于汽车的车身板材和发动机的零件[1 ,2 ] .传统强化方法利用时效处理,在基体中形成大量纳米亚稳析出相阻碍位错运动,可有效提高该系材料强度[3 ] .但采用热处理获得更高强度的同时,会导致合金的韧性下降[4 ,5 ] .随着应用领域与规模扩大,如何进一步改善材料性能并制备具有高强度和高韧性的合金是金属结构材料长期面临的问题.超细晶(UFG)铝合金具有高强度、足够的延展性、高应变率以及良好的冲击韧性,越来越受到研究者的关注.等通道转角挤压(ECAP)技术可用于获得三维大尺寸块体亚微米和纳米结构材料,与未变形的材料相比,材料的强度提高了200%~300%[6 ~8 ] .在ECAP后引入合适的时效处理工艺,在超细晶基体中形成弥散的纳米亚稳析出相,能够有效提高该系合金强度的同时保证足够的韧性.此外,析出相的析出序列、尺寸、种类和分布,对材料的最终性能有至关重要的影响.如何合理调控析出相的种类、尺寸、分布、以及与晶粒尺寸和位错密度之间的关系,是制备高强高韧的铝合金的热点[9 ~11 ] .Cerri和Leo[12 ] 研究了ECAP后时效处理对6082铝合金硬度的影响,结果表明,高温后时效会降低材料的硬度;而100℃或者更低的低温后时效,析出相强化的贡献将远超过回复或者晶粒粗化所带来的负面影响.此外,Kim等[13 ] 还对一种超细晶铝合金进行了后时效处理,结果表明,低温后时效后基体中高密度的位错得以很好的保留,并在基体中出现了尺寸更小的时效析出相,在纳米析出相与位错的交互作用下,材料的强度显著增加.目前关于未变形6000系铝合金析出行为的研究较多,但关于超细晶6061铝合金在不同后时效温度下的析出演变以及析出强化机制的研究较少.本工作通过透射电子显微镜(TEM)、高分辨透射电镜(HRTEM)、X射线衍射(XRD)和力学性能测试等手段对不同后时效条件下超细晶6061铝合金的微观组织和力学性能进行对比研究,讨论和解释了后时效合金中时效析出相的演变规律以及后时效析出相对其强韧性的影响. ...

Influence of severe plastic deformation on aging of Al-Mg-Si alloys

1

2005

... 随着节能环保和汽车轻量化的发展,Al-Mg-Si(-Cu) (6xxx系)铝合金以低密度、中等强度、高比强度、耐蚀性好、成形性好、可回收利用、可焊性好、表面质量好等特点,被广泛运用于汽车的车身板材和发动机的零件[1 ,2 ] .传统强化方法利用时效处理,在基体中形成大量纳米亚稳析出相阻碍位错运动,可有效提高该系材料强度[3 ] .但采用热处理获得更高强度的同时,会导致合金的韧性下降[4 ,5 ] .随着应用领域与规模扩大,如何进一步改善材料性能并制备具有高强度和高韧性的合金是金属结构材料长期面临的问题.超细晶(UFG)铝合金具有高强度、足够的延展性、高应变率以及良好的冲击韧性,越来越受到研究者的关注.等通道转角挤压(ECAP)技术可用于获得三维大尺寸块体亚微米和纳米结构材料,与未变形的材料相比,材料的强度提高了200%~300%[6 ~8 ] .在ECAP后引入合适的时效处理工艺,在超细晶基体中形成弥散的纳米亚稳析出相,能够有效提高该系合金强度的同时保证足够的韧性.此外,析出相的析出序列、尺寸、种类和分布,对材料的最终性能有至关重要的影响.如何合理调控析出相的种类、尺寸、分布、以及与晶粒尺寸和位错密度之间的关系,是制备高强高韧的铝合金的热点[9 ~11 ] .Cerri和Leo[12 ] 研究了ECAP后时效处理对6082铝合金硬度的影响,结果表明,高温后时效会降低材料的硬度;而100℃或者更低的低温后时效,析出相强化的贡献将远超过回复或者晶粒粗化所带来的负面影响.此外,Kim等[13 ] 还对一种超细晶铝合金进行了后时效处理,结果表明,低温后时效后基体中高密度的位错得以很好的保留,并在基体中出现了尺寸更小的时效析出相,在纳米析出相与位错的交互作用下,材料的强度显著增加.目前关于未变形6000系铝合金析出行为的研究较多,但关于超细晶6061铝合金在不同后时效温度下的析出演变以及析出强化机制的研究较少.本工作通过透射电子显微镜(TEM)、高分辨透射电镜(HRTEM)、X射线衍射(XRD)和力学性能测试等手段对不同后时效条件下超细晶6061铝合金的微观组织和力学性能进行对比研究,讨论和解释了后时效合金中时效析出相的演变规律以及后时效析出相对其强韧性的影响. ...

Enhancement of strength and superplasticity in a 6061 Al alloy processed by equal-channel-angular-pressing

8

2002

... 随着节能环保和汽车轻量化的发展,Al-Mg-Si(-Cu) (6xxx系)铝合金以低密度、中等强度、高比强度、耐蚀性好、成形性好、可回收利用、可焊性好、表面质量好等特点,被广泛运用于汽车的车身板材和发动机的零件[1 ,2 ] .传统强化方法利用时效处理,在基体中形成大量纳米亚稳析出相阻碍位错运动,可有效提高该系材料强度[3 ] .但采用热处理获得更高强度的同时,会导致合金的韧性下降[4 ,5 ] .随着应用领域与规模扩大,如何进一步改善材料性能并制备具有高强度和高韧性的合金是金属结构材料长期面临的问题.超细晶(UFG)铝合金具有高强度、足够的延展性、高应变率以及良好的冲击韧性,越来越受到研究者的关注.等通道转角挤压(ECAP)技术可用于获得三维大尺寸块体亚微米和纳米结构材料,与未变形的材料相比,材料的强度提高了200%~300%[6 ~8 ] .在ECAP后引入合适的时效处理工艺,在超细晶基体中形成弥散的纳米亚稳析出相,能够有效提高该系合金强度的同时保证足够的韧性.此外,析出相的析出序列、尺寸、种类和分布,对材料的最终性能有至关重要的影响.如何合理调控析出相的种类、尺寸、分布、以及与晶粒尺寸和位错密度之间的关系,是制备高强高韧的铝合金的热点[9 ~11 ] .Cerri和Leo[12 ] 研究了ECAP后时效处理对6082铝合金硬度的影响,结果表明,高温后时效会降低材料的硬度;而100℃或者更低的低温后时效,析出相强化的贡献将远超过回复或者晶粒粗化所带来的负面影响.此外,Kim等[13 ] 还对一种超细晶铝合金进行了后时效处理,结果表明,低温后时效后基体中高密度的位错得以很好的保留,并在基体中出现了尺寸更小的时效析出相,在纳米析出相与位错的交互作用下,材料的强度显著增加.目前关于未变形6000系铝合金析出行为的研究较多,但关于超细晶6061铝合金在不同后时效温度下的析出演变以及析出强化机制的研究较少.本工作通过透射电子显微镜(TEM)、高分辨透射电镜(HRTEM)、X射线衍射(XRD)和力学性能测试等手段对不同后时效条件下超细晶6061铝合金的微观组织和力学性能进行对比研究,讨论和解释了后时效合金中时效析出相的演变规律以及后时效析出相对其强韧性的影响. ...

... 长期以来,超细晶纳米晶金属材料强韧性的“倒置关系”一直是制约其发展的重要瓶颈,大大限制了其工程应用[7 ,10 ,34 ,35 ] .大多数严重塑性变形超细晶纳米晶材料的低塑性主要是由于晶粒内部存储或容纳位错的能力很低,失去了使位错在晶内塞积和存储的能力,造成了应变(加工)硬化的缺失[36 ] .因此材料在拉伸过程中很容易趋于塑性失稳,造成其均匀延伸率几乎为零.如王贝贝等[35 ] 对6061铝合金进行搅拌摩擦加工,在强制冷却条件下热输入明显降低,析出相的粗化受到一定程度的抑制,屈服强度和抗拉强度分别提高至435和505 MPa,但断裂延伸率仅为2.1%.Nurislamova等[37 ] 对6061铝合金进行高压扭转,屈服强度达660 MPa,但这是以牺牲塑性为代价的,其延伸率仅有5.2%.表3 [10 ,13 ,27 ,34 ~42 ] 总结了国内外6000系铝合金的拉伸性能,并在图7 [10 ,13 ,27 ,34 ~42 ] 中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... ,13 ,27 ,34 ~42 ]中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... 国内外超细晶纳米晶6000系时效铝合金的强韧性对比[10 ,13 ,27 ,34 ~42 ] ...

... Comprehensive comparisons of tensile properties of 6000 series Al alloys[10 ,13 ,27 ,34 -42 ] ...

... [

13 ]

6061 under-aging + coldrolling + re-aging 542 560 8.5 [27 ] 6061 HPT at RT 605 705 6.3 [34 ] 6061 Friction stir processing 435 505 2.1 [35 ] AA6060 HPT at RT 475 525 6.0 [36 ] 6061 HPT at RT 660 690 5.5 [37 ] 6061 HPT at RT + post-aging 455 485 15.0 [38 ] 6061 multi directional forging + aging 409 472 8.9 [39 ] 6101 hydrostatic extrusion + aging 345 354 5.5 [40 ] 6061 accumulative roll bonding + aging 450 - 6.5 [41 ] Al-Mg-Si-Cu pre-deformation + aging 435 450 7.1 [42 ] Note: UTS—ultimate tensile strength, E f —elongation to failure, HPT—high-pressure torsion ...

...

Note: UTS—ultimate tensile strength,

E f —elongation to failure, HPT—high-pressure torsion

图7 国内外Al-Mg-Si铝合金屈服强度-延伸率综合对比<sup>[<xref ref-type="bibr" rid="R10">10</xref>,<xref ref-type="bibr" rid="R13">13</xref>,<xref ref-type="bibr" rid="R27">27</xref>,<xref ref-type="bibr" rid="R34">34</xref>~<xref ref-type="bibr" rid="R42">42</xref>]</sup> Comprehensive comparisons of yield strength and uniform elongation of Al-Mg-Si alloys<sup>[<xref ref-type="bibr" rid="R10">10</xref>,<xref ref-type="bibr" rid="R13">13</xref>,<xref ref-type="bibr" rid="R27">27</xref>,<xref ref-type="bibr" rid="R34">34</xref>-<xref ref-type="bibr" rid="R42">42</xref>]</sup> Color online ...

... ,

13 ,

27 ,

34 -

42 ]

Color online ...

Improvement of strength and ductility for a 6056 aluminum alloy achieved by a combination of equal-channel angular pressing and aging treatment

3

2010

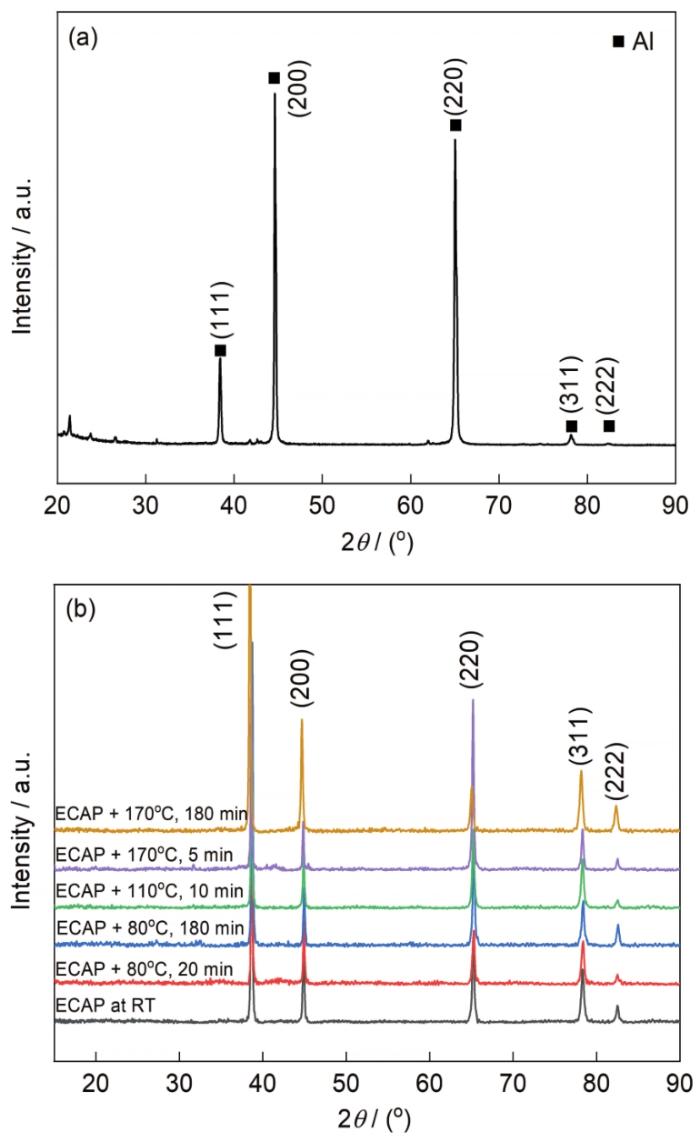

... 图1 和表1 分别是6061铝合金不同状态下的XRD谱及定量分析.对比图1a (T6态)和1b (ECAP态和ECAP后时效态)可见,由于ECAP变形合金的晶粒尺寸急剧细化并且在晶粒内部引入了晶格畸变,ECAP处理后XRD衍射峰宽化,峰强减弱.随着在80℃下后时效时间从20 min增加到180 min,D XRD 从211 nm大幅度增加到488 nm,相应的<ε 2 >1/2 从0.15%减少到0.11%.在170℃下后时效时间从5 min增加到180 min后,D XRD 从395 nm增加到770 nm,<ε 2 >1/2 从0.14%减少到0.08%.对于等通道转角挤压材料而言,位错密度与微观应变成正比,与晶粒尺寸成反比.从表1 可以看出,80℃、20 min后时效后微观参数变化最小.造成这种现象的原因是,在低温短时后时效时,由于原子活动能力较弱,材料能积累大量的晶体缺陷,且这些晶体缺陷可长时间保留.高密度位错有利于细化晶粒,因此低温短时时效的位错密度最高且晶粒尺寸最小.另一方面,ECAP在基体中引入的大量位错也利于时效析出相的形核,从而加速后时效过程中的析出动力学[14 ] .值得注意的是,对超细晶纳米晶材料,TEM测得的平均晶粒尺寸通常大于XRD测定结果[15 ] . ...

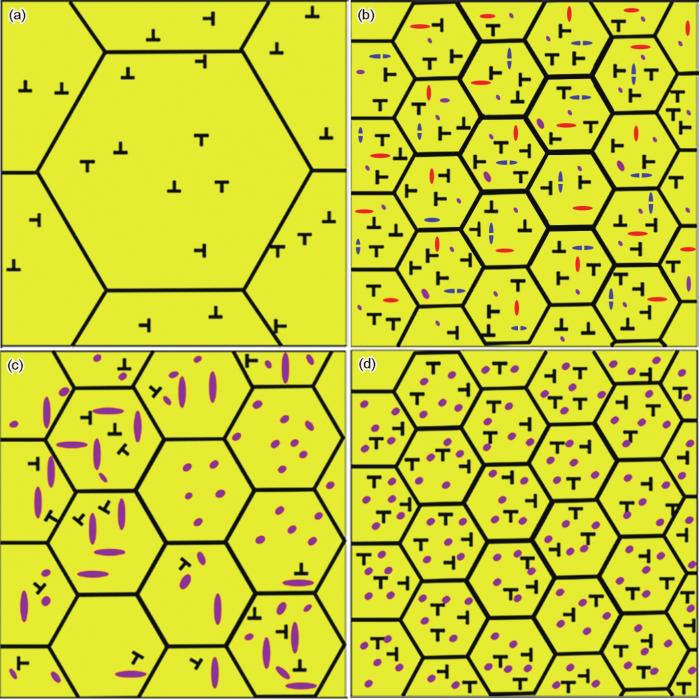

... 依据上述实验结果分析,得到合金不同状态微观结构和时效析出相的演变示意图.如图6a 所示,固溶态时合金中第二相几乎全部融入基体内,且合金中位错密度很低.与固溶态相比(图6a ),ECAP后合金中位错密度迅速增加(见表1 、图5a 和b ),晶粒尺寸明显减小(见表1 和图3a~c ).合金在ECAP过程中同时存在3种时效析出相:(1) 由ECAP动态时效作用[14 ,15 ] 而析出的动态时效相(见图6b 中红色析出相);(2) 动态时效相在ECAP的作用下发生破碎[15 ] 而形成的析出相(见图6b 中蓝色析出相),部分破碎的时效析出相重新融入基体形成新的过饱和固溶体[14 ,15 ,26 ] ;(3) 因时效析出相重新融入基体形成的新的过饱和固溶体在ECAP过程中将再次析出,即产生再析出相(见图6b 中粉红色析出相).图6c 为合金ECAP后高温时效微观结构示意图.与ECAP态相比(图6b ),高温时效态合金中位错密度迅速减少,晶粒尺寸有所长大(见表1 );上述过饱和固溶体在高温时效过程中析出较细小的时效析出相(见图6b 中细小粉红色析出相),同时,ECAP态中存在的时效析出相经高温时效后继续长大形成较粗大的时效析出相(见图6b 中粗大粉红色析出相),即ECAP高温时效后合金中既有粗大时效析出相又有细小时效析出相(图5d ).图6d 为合金ECAP后低温时效微观结构示意图.与ECAP态相比(图6b ),低温时效态合金中位错密度和晶粒尺寸基本不变(见表1 和图3 );在低温时效过程中,上述过饱和固溶体同样会析出较细小的析出相,而原ECAP态可能存在的上述3种时效析出相的尺寸则基本保持不变,即ECAP后低温时效不会引起原ECAP态存在的时效析出相明显长大(见图4b~e 和图5c ),ECAP低温时效后合金中的时效析出相均为较细小的时效析出相(见图6d 中细小粉红色析出相). ...

... [14 ,15 ,26 ];(3) 因时效析出相重新融入基体形成的新的过饱和固溶体在ECAP过程中将再次析出,即产生再析出相(见图6b 中粉红色析出相).图6c 为合金ECAP后高温时效微观结构示意图.与ECAP态相比(图6b ),高温时效态合金中位错密度迅速减少,晶粒尺寸有所长大(见表1 );上述过饱和固溶体在高温时效过程中析出较细小的时效析出相(见图6b 中细小粉红色析出相),同时,ECAP态中存在的时效析出相经高温时效后继续长大形成较粗大的时效析出相(见图6b 中粗大粉红色析出相),即ECAP高温时效后合金中既有粗大时效析出相又有细小时效析出相(图5d ).图6d 为合金ECAP后低温时效微观结构示意图.与ECAP态相比(图6b ),低温时效态合金中位错密度和晶粒尺寸基本不变(见表1 和图3 );在低温时效过程中,上述过饱和固溶体同样会析出较细小的析出相,而原ECAP态可能存在的上述3种时效析出相的尺寸则基本保持不变,即ECAP后低温时效不会引起原ECAP态存在的时效析出相明显长大(见图4b~e 和图5c ),ECAP低温时效后合金中的时效析出相均为较细小的时效析出相(见图6d 中细小粉红色析出相). ...

Dynamic precipitation during severe plastic deformation of an Al-Mg-Si aluminium alloy

5

2008

... 图1 和表1 分别是6061铝合金不同状态下的XRD谱及定量分析.对比图1a (T6态)和1b (ECAP态和ECAP后时效态)可见,由于ECAP变形合金的晶粒尺寸急剧细化并且在晶粒内部引入了晶格畸变,ECAP处理后XRD衍射峰宽化,峰强减弱.随着在80℃下后时效时间从20 min增加到180 min,D XRD 从211 nm大幅度增加到488 nm,相应的<ε 2 >1/2 从0.15%减少到0.11%.在170℃下后时效时间从5 min增加到180 min后,D XRD 从395 nm增加到770 nm,<ε 2 >1/2 从0.14%减少到0.08%.对于等通道转角挤压材料而言,位错密度与微观应变成正比,与晶粒尺寸成反比.从表1 可以看出,80℃、20 min后时效后微观参数变化最小.造成这种现象的原因是,在低温短时后时效时,由于原子活动能力较弱,材料能积累大量的晶体缺陷,且这些晶体缺陷可长时间保留.高密度位错有利于细化晶粒,因此低温短时时效的位错密度最高且晶粒尺寸最小.另一方面,ECAP在基体中引入的大量位错也利于时效析出相的形核,从而加速后时效过程中的析出动力学[14 ] .值得注意的是,对超细晶纳米晶材料,TEM测得的平均晶粒尺寸通常大于XRD测定结果[15 ] . ...

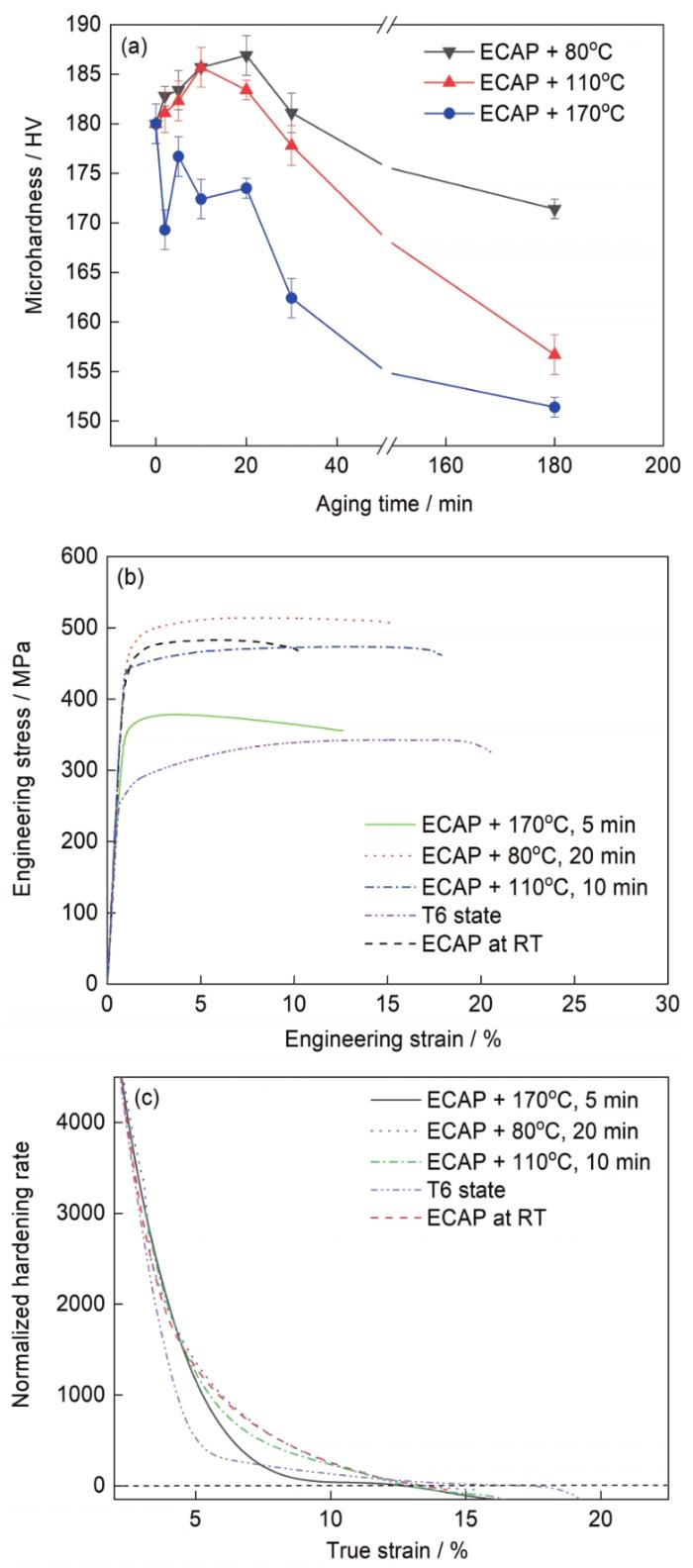

... 图2a 为6061铝合金ECAP后80、110、170℃后时效的硬度曲线.随着时效时间的延长,硬度迅速增加到最大值,而后缓慢降低.与作者之前工作[15 ] 中未变形的铝合金相比,ECAP后的合金在后时效后具有更高的硬度,并且达到峰值硬度的时间更短.显然,ECAP可以增强Al-Mg-Si-Cu合金的析出动力学,合金达到峰值时效的时间大大缩减,温度越高达到峰值时效的时间越短.如图2a 所示,80℃下后时效峰值硬度达到187 HV.Hockauf等[16 ] 认为铝合金的时效温度对合金的最大硬度有影响,通常通过长时间低温时效来达到最高峰值硬度,在较低温度下时效时,合金的析出相会更加细小,并且更加弥散. ...

... 依据上述实验结果分析,得到合金不同状态微观结构和时效析出相的演变示意图.如图6a 所示,固溶态时合金中第二相几乎全部融入基体内,且合金中位错密度很低.与固溶态相比(图6a ),ECAP后合金中位错密度迅速增加(见表1 、图5a 和b ),晶粒尺寸明显减小(见表1 和图3a~c ).合金在ECAP过程中同时存在3种时效析出相:(1) 由ECAP动态时效作用[14 ,15 ] 而析出的动态时效相(见图6b 中红色析出相);(2) 动态时效相在ECAP的作用下发生破碎[15 ] 而形成的析出相(见图6b 中蓝色析出相),部分破碎的时效析出相重新融入基体形成新的过饱和固溶体[14 ,15 ,26 ] ;(3) 因时效析出相重新融入基体形成的新的过饱和固溶体在ECAP过程中将再次析出,即产生再析出相(见图6b 中粉红色析出相).图6c 为合金ECAP后高温时效微观结构示意图.与ECAP态相比(图6b ),高温时效态合金中位错密度迅速减少,晶粒尺寸有所长大(见表1 );上述过饱和固溶体在高温时效过程中析出较细小的时效析出相(见图6b 中细小粉红色析出相),同时,ECAP态中存在的时效析出相经高温时效后继续长大形成较粗大的时效析出相(见图6b 中粗大粉红色析出相),即ECAP高温时效后合金中既有粗大时效析出相又有细小时效析出相(图5d ).图6d 为合金ECAP后低温时效微观结构示意图.与ECAP态相比(图6b ),低温时效态合金中位错密度和晶粒尺寸基本不变(见表1 和图3 );在低温时效过程中,上述过饱和固溶体同样会析出较细小的析出相,而原ECAP态可能存在的上述3种时效析出相的尺寸则基本保持不变,即ECAP后低温时效不会引起原ECAP态存在的时效析出相明显长大(见图4b~e 和图5c ),ECAP低温时效后合金中的时效析出相均为较细小的时效析出相(见图6d 中细小粉红色析出相). ...

... [15 ]而形成的析出相(见图6b 中蓝色析出相),部分破碎的时效析出相重新融入基体形成新的过饱和固溶体[14 ,15 ,26 ] ;(3) 因时效析出相重新融入基体形成的新的过饱和固溶体在ECAP过程中将再次析出,即产生再析出相(见图6b 中粉红色析出相).图6c 为合金ECAP后高温时效微观结构示意图.与ECAP态相比(图6b ),高温时效态合金中位错密度迅速减少,晶粒尺寸有所长大(见表1 );上述过饱和固溶体在高温时效过程中析出较细小的时效析出相(见图6b 中细小粉红色析出相),同时,ECAP态中存在的时效析出相经高温时效后继续长大形成较粗大的时效析出相(见图6b 中粗大粉红色析出相),即ECAP高温时效后合金中既有粗大时效析出相又有细小时效析出相(图5d ).图6d 为合金ECAP后低温时效微观结构示意图.与ECAP态相比(图6b ),低温时效态合金中位错密度和晶粒尺寸基本不变(见表1 和图3 );在低温时效过程中,上述过饱和固溶体同样会析出较细小的析出相,而原ECAP态可能存在的上述3种时效析出相的尺寸则基本保持不变,即ECAP后低温时效不会引起原ECAP态存在的时效析出相明显长大(见图4b~e 和图5c ),ECAP低温时效后合金中的时效析出相均为较细小的时效析出相(见图6d 中细小粉红色析出相). ...

... ,15 ,26 ];(3) 因时效析出相重新融入基体形成的新的过饱和固溶体在ECAP过程中将再次析出,即产生再析出相(见图6b 中粉红色析出相).图6c 为合金ECAP后高温时效微观结构示意图.与ECAP态相比(图6b ),高温时效态合金中位错密度迅速减少,晶粒尺寸有所长大(见表1 );上述过饱和固溶体在高温时效过程中析出较细小的时效析出相(见图6b 中细小粉红色析出相),同时,ECAP态中存在的时效析出相经高温时效后继续长大形成较粗大的时效析出相(见图6b 中粗大粉红色析出相),即ECAP高温时效后合金中既有粗大时效析出相又有细小时效析出相(图5d ).图6d 为合金ECAP后低温时效微观结构示意图.与ECAP态相比(图6b ),低温时效态合金中位错密度和晶粒尺寸基本不变(见表1 和图3 );在低温时效过程中,上述过饱和固溶体同样会析出较细小的析出相,而原ECAP态可能存在的上述3种时效析出相的尺寸则基本保持不变,即ECAP后低温时效不会引起原ECAP态存在的时效析出相明显长大(见图4b~e 和图5c ),ECAP低温时效后合金中的时效析出相均为较细小的时效析出相(见图6d 中细小粉红色析出相). ...

Simultaneous improvement of strength and ductility of Al-Mg-Si alloys by combining equal-channel angular extrusion with subsequent high-temperature short-time aging

1

2009

... 图2a 为6061铝合金ECAP后80、110、170℃后时效的硬度曲线.随着时效时间的延长,硬度迅速增加到最大值,而后缓慢降低.与作者之前工作[15 ] 中未变形的铝合金相比,ECAP后的合金在后时效后具有更高的硬度,并且达到峰值硬度的时间更短.显然,ECAP可以增强Al-Mg-Si-Cu合金的析出动力学,合金达到峰值时效的时间大大缩减,温度越高达到峰值时效的时间越短.如图2a 所示,80℃下后时效峰值硬度达到187 HV.Hockauf等[16 ] 认为铝合金的时效温度对合金的最大硬度有影响,通常通过长时间低温时效来达到最高峰值硬度,在较低温度下时效时,合金的析出相会更加细小,并且更加弥散. ...

Unique defect evolution during the plastic deformation of a metal matrix composite

1

2019

... 为了研究材料的强度和韧性,对ECAP后的试样在不同温度下进行后时效处理,得到了不同温度下的峰值强度,如图2a 所示.作为对比,一些材料固溶处理后直接在170℃下进行时效(T6态).图2b 为6061铝合金在不同处理状态下的应力-应变曲线.ECAP后合金的抗拉强度从T6态的342 MPa增加到室温ECAP态的483 MPa,并且在80℃下后时效20 min后达到514 MPa,同时均匀延伸率从20.6%分别变为10.2%和15.1%.但是,170℃、5 min短时间峰值后时效表现出较差的性能,其抗拉强度、屈服强度和均匀伸长率分别为378 MPa、366 MPa和12.5%.与170℃、5 min短时间峰值后时效相比,110℃、10 min峰值后时效的强韧性均有所提高,其抗拉强度、屈服强度和均匀伸长率分别为471 MPa、434 MPa和16.8%,但是其抗拉强度仍低于ECAP后合金的抗拉强度483 MPa.合金在80℃、20 min峰值后时效的性能为强韧性的最佳组合,其抗拉强度、屈服强度和均匀伸长率分别为514 MPa、483 MPa和15.1%.ECAP后合金中引入大量的缺陷,导致合金加工硬化和合金强度提高.然而,大塑性变形后的材料塑韧性往往较低,塑韧性低的主要原因是应变硬化能力低,位错在晶粒中积累和储存的能力丧失,导致局部塑性应变失稳(颈缩)[17 ] .本工作制备的Al-Mg-Si-Cu铝合金试样经过ECAP和时效处理后,既具有较高的强度,又具有较好的均匀伸长率.通过计算发现,该合金表现出较高的硬化速率(图2c ),从而延缓了颈缩.高硬化率的原因是后时效过程中存在大量时效析出相与位错的交互作用,增加了在晶粒内部积聚位错的能力,从而获得了较高的韧性[18 ] . ...

Design of solute clustering during thermomechanical processing of AA6016 Al-Mg-Si alloy

1

2021

... 为了研究材料的强度和韧性,对ECAP后的试样在不同温度下进行后时效处理,得到了不同温度下的峰值强度,如图2a 所示.作为对比,一些材料固溶处理后直接在170℃下进行时效(T6态).图2b 为6061铝合金在不同处理状态下的应力-应变曲线.ECAP后合金的抗拉强度从T6态的342 MPa增加到室温ECAP态的483 MPa,并且在80℃下后时效20 min后达到514 MPa,同时均匀延伸率从20.6%分别变为10.2%和15.1%.但是,170℃、5 min短时间峰值后时效表现出较差的性能,其抗拉强度、屈服强度和均匀伸长率分别为378 MPa、366 MPa和12.5%.与170℃、5 min短时间峰值后时效相比,110℃、10 min峰值后时效的强韧性均有所提高,其抗拉强度、屈服强度和均匀伸长率分别为471 MPa、434 MPa和16.8%,但是其抗拉强度仍低于ECAP后合金的抗拉强度483 MPa.合金在80℃、20 min峰值后时效的性能为强韧性的最佳组合,其抗拉强度、屈服强度和均匀伸长率分别为514 MPa、483 MPa和15.1%.ECAP后合金中引入大量的缺陷,导致合金加工硬化和合金强度提高.然而,大塑性变形后的材料塑韧性往往较低,塑韧性低的主要原因是应变硬化能力低,位错在晶粒中积累和储存的能力丧失,导致局部塑性应变失稳(颈缩)[17 ] .本工作制备的Al-Mg-Si-Cu铝合金试样经过ECAP和时效处理后,既具有较高的强度,又具有较好的均匀伸长率.通过计算发现,该合金表现出较高的硬化速率(图2c ),从而延缓了颈缩.高硬化率的原因是后时效过程中存在大量时效析出相与位错的交互作用,增加了在晶粒内部积聚位错的能力,从而获得了较高的韧性[18 ] . ...

TEM analysis of microstructure evolution process of pure tungsten under high pressure torsion

1

2019

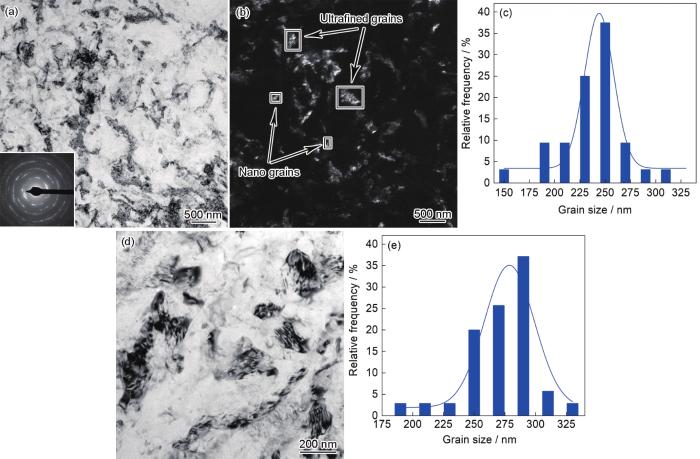

... 图3 显示了不同状态下超细晶6061铝合金的TEM像和晶粒尺寸分布.ECAP态和80℃、20 min后时效态试样中均存在大量纳米晶,并且晶粒中存在严重的晶格畸变(图3a 和d ).图3a 插图中选区电子衍射(SAED)花样呈环状,说明ECAP后试样内部晶粒显著细化.此外,较大的晶粒中晶界往往是弯曲、定义不清或者出现了一定厚度的轮廓蔓延,这说明晶粒内部存在局部高密度的位错和应力集中,正是因为晶格中极高的内应力和弹性扭曲,晶粒变得更加细小.ECAP变形后试样中引入了大量的剪切应变,以及位错密度的增加形成了非平衡晶界,这些晶粒会在进一步引入剪切应变时转化为超细晶[19 ] . ...

纯W高压扭转显微组织演化过程TEM分析

1

2019

... 图3 显示了不同状态下超细晶6061铝合金的TEM像和晶粒尺寸分布.ECAP态和80℃、20 min后时效态试样中均存在大量纳米晶,并且晶粒中存在严重的晶格畸变(图3a 和d ).图3a 插图中选区电子衍射(SAED)花样呈环状,说明ECAP后试样内部晶粒显著细化.此外,较大的晶粒中晶界往往是弯曲、定义不清或者出现了一定厚度的轮廓蔓延,这说明晶粒内部存在局部高密度的位错和应力集中,正是因为晶格中极高的内应力和弹性扭曲,晶粒变得更加细小.ECAP变形后试样中引入了大量的剪切应变,以及位错密度的增加形成了非平衡晶界,这些晶粒会在进一步引入剪切应变时转化为超细晶[19 ] . ...

Microstructure and mechanical properties of 6013 aluminium alloy processed by a combination of ECAP and preaging treatment

1

2017

... 如图3c 所示,ECAP样品的平均晶粒尺寸为243 nm,最小晶粒尺寸仅为151 nm,最大晶粒尺寸可达319 nm.图3d 和e是合金经ECAP及80℃、20 min后时效的TEM像和晶粒尺寸分布图.可以看出,经过短时间的低温时效后合金的晶粒尺寸不变,合金中依然存在较大密度的位错,晶界多为非平衡晶界.由TEM测得的平均晶粒尺寸较XRD测得的结果更大,这是因为TEM分析通常是局部定性的,而且仅能分辨出晶界清晰的大角度晶界,对于位向差较小的晶粒(如小角度晶界和亚晶界)则难以区分[20 ] .而XRD不仅可以区分大角度晶界分割晶粒和位相差很小的亚晶界,而且还能分辨出基体内部很小的晶格畸变区域,因此测得的晶粒尺寸较小.该结果也证实了大塑性变形制备的超细晶/纳米晶材料,其晶粒分布极不均匀,并且处于非平衡状态. ...

The influence of composition on the clustering and precipitation behavior of Al-Mg-Si-Cu alloys

2

2017

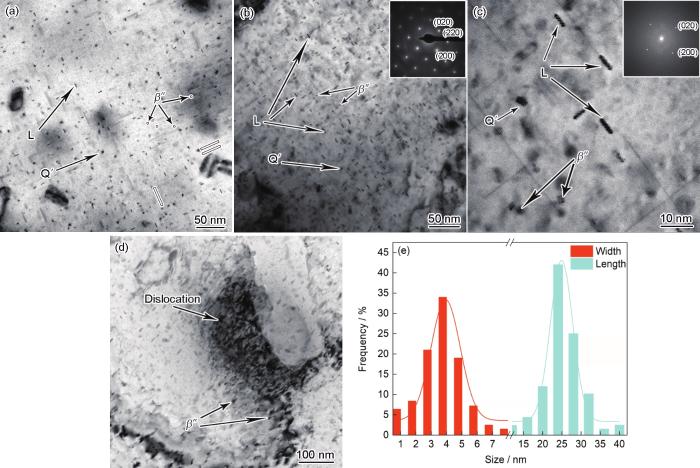

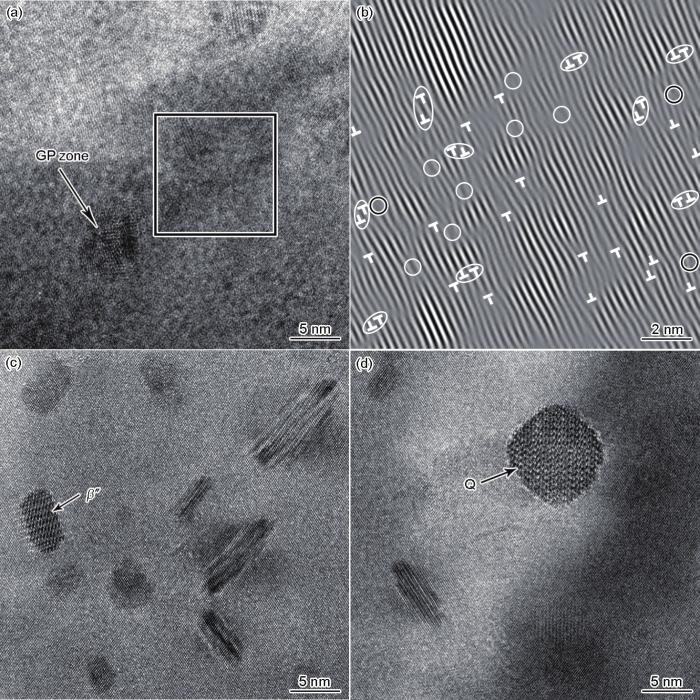

... 图4a 是T6态6061铝合金的TEM明场像.可以看出,T6态合金出现了3种析出相:β'' 相、Q' 相和L相[21 ,22 ] .β'' 相、Q' 相和L相虽然都是在不同取向下的短棒状,但是由于其晶体结构及与Al基体错配度各向异性的不同,其在棒状的横截面上依然有一定的区别[21 ,22 ] .β'' 相的横截面呈圆形,横纵比约为1,Q' 相三维形貌为板条状,因此它的横截面为细长的矩形,横纵比大于3,其惯习面为{510}面,与{100}面有11°的夹角,在TEM中很容易分辨.而L相虽然也呈板条状,横截面为细长的矩形,但其惯习面为{100}面,与Q' 呈11°夹角,因而在TEM中易于分辨.这些析出相都呈针状或者板条状,针状β'' 相总是沿着Al基体的<100>Al 方向析出,具有很好的强化效果,是铝合金峰值时效最主要的强化相.图中圆点看到的实际上是β'' 相的端部,其平均直径约4 nm,平均长度约30 nm.图中一些短棒状析出相是L相,沿<001> α [23 ] .图4b 和c给出了6061铝合金经ECAP变形及80℃、20 min后时效的析出相TEM像及相应的SAED花样和快速Fourier变换(FFT)图.可见,经过ECAP后时效处理的合金中出现了大量不同形态的析出相,包括针状的β'' 相以及板条状的Q' 相和L相.主要析出相β'' 的直径约为4 nm,长度约为26 nm (图4e ),这些针状β'' 相总是沿着Al基体的<100>Al 方向析出.与图4a 中T6态峰时效6061铝合金中相比,经过ECAP后时效处理的合金中的β'' 相尺寸较小,L相数量较少且分布情况与峰时效类似,弥散分布的β ″相与少量的L相分布是合金时效硬化强度高的主要原因.80℃、20 min后时效合金就达到峰值状态,与原始ECAP变形态相比,合金中析出相和晶粒尺寸迅速增大,析出相β'' 相和Q' 相也转化为Q相,合金的强度开始下降.从图4d 还可观察到,在β'' 相周围存在大量的位错,即β'' 相与高密度位错同时存在.β'' 析出相的尺寸和分布及其与位错的交互作用对增强材料的强度和韧性起到了重要的作用[24 ] .即,ECAP引起的更细的析出相和高密度的位错在后时效过程中增强了合金的位错强化和析出强化. ...

... [21 ,22 ].β'' 相的横截面呈圆形,横纵比约为1,Q' 相三维形貌为板条状,因此它的横截面为细长的矩形,横纵比大于3,其惯习面为{510}面,与{100}面有11°的夹角,在TEM中很容易分辨.而L相虽然也呈板条状,横截面为细长的矩形,但其惯习面为{100}面,与Q' 呈11°夹角,因而在TEM中易于分辨.这些析出相都呈针状或者板条状,针状β'' 相总是沿着Al基体的<100>Al 方向析出,具有很好的强化效果,是铝合金峰值时效最主要的强化相.图中圆点看到的实际上是β'' 相的端部,其平均直径约4 nm,平均长度约30 nm.图中一些短棒状析出相是L相,沿<001> α [23 ] .图4b 和c给出了6061铝合金经ECAP变形及80℃、20 min后时效的析出相TEM像及相应的SAED花样和快速Fourier变换(FFT)图.可见,经过ECAP后时效处理的合金中出现了大量不同形态的析出相,包括针状的β'' 相以及板条状的Q' 相和L相.主要析出相β'' 的直径约为4 nm,长度约为26 nm (图4e ),这些针状β'' 相总是沿着Al基体的<100>Al 方向析出.与图4a 中T6态峰时效6061铝合金中相比,经过ECAP后时效处理的合金中的β'' 相尺寸较小,L相数量较少且分布情况与峰时效类似,弥散分布的β ″相与少量的L相分布是合金时效硬化强度高的主要原因.80℃、20 min后时效合金就达到峰值状态,与原始ECAP变形态相比,合金中析出相和晶粒尺寸迅速增大,析出相β'' 相和Q' 相也转化为Q相,合金的强度开始下降.从图4d 还可观察到,在β'' 相周围存在大量的位错,即β'' 相与高密度位错同时存在.β'' 析出相的尺寸和分布及其与位错的交互作用对增强材料的强度和韧性起到了重要的作用[24 ] .即,ECAP引起的更细的析出相和高密度的位错在后时效过程中增强了合金的位错强化和析出强化. ...

Improving thermal stability in Cu-containing Al-Mg-Si alloys by precipitate optimization

2

2014

... 图4a 是T6态6061铝合金的TEM明场像.可以看出,T6态合金出现了3种析出相:β'' 相、Q' 相和L相[21 ,22 ] .β'' 相、Q' 相和L相虽然都是在不同取向下的短棒状,但是由于其晶体结构及与Al基体错配度各向异性的不同,其在棒状的横截面上依然有一定的区别[21 ,22 ] .β'' 相的横截面呈圆形,横纵比约为1,Q' 相三维形貌为板条状,因此它的横截面为细长的矩形,横纵比大于3,其惯习面为{510}面,与{100}面有11°的夹角,在TEM中很容易分辨.而L相虽然也呈板条状,横截面为细长的矩形,但其惯习面为{100}面,与Q' 呈11°夹角,因而在TEM中易于分辨.这些析出相都呈针状或者板条状,针状β'' 相总是沿着Al基体的<100>Al 方向析出,具有很好的强化效果,是铝合金峰值时效最主要的强化相.图中圆点看到的实际上是β'' 相的端部,其平均直径约4 nm,平均长度约30 nm.图中一些短棒状析出相是L相,沿<001> α [23 ] .图4b 和c给出了6061铝合金经ECAP变形及80℃、20 min后时效的析出相TEM像及相应的SAED花样和快速Fourier变换(FFT)图.可见,经过ECAP后时效处理的合金中出现了大量不同形态的析出相,包括针状的β'' 相以及板条状的Q' 相和L相.主要析出相β'' 的直径约为4 nm,长度约为26 nm (图4e ),这些针状β'' 相总是沿着Al基体的<100>Al 方向析出.与图4a 中T6态峰时效6061铝合金中相比,经过ECAP后时效处理的合金中的β'' 相尺寸较小,L相数量较少且分布情况与峰时效类似,弥散分布的β ″相与少量的L相分布是合金时效硬化强度高的主要原因.80℃、20 min后时效合金就达到峰值状态,与原始ECAP变形态相比,合金中析出相和晶粒尺寸迅速增大,析出相β'' 相和Q' 相也转化为Q相,合金的强度开始下降.从图4d 还可观察到,在β'' 相周围存在大量的位错,即β'' 相与高密度位错同时存在.β'' 析出相的尺寸和分布及其与位错的交互作用对增强材料的强度和韧性起到了重要的作用[24 ] .即,ECAP引起的更细的析出相和高密度的位错在后时效过程中增强了合金的位错强化和析出强化. ...

... ,22 ].β'' 相的横截面呈圆形,横纵比约为1,Q' 相三维形貌为板条状,因此它的横截面为细长的矩形,横纵比大于3,其惯习面为{510}面,与{100}面有11°的夹角,在TEM中很容易分辨.而L相虽然也呈板条状,横截面为细长的矩形,但其惯习面为{100}面,与Q' 呈11°夹角,因而在TEM中易于分辨.这些析出相都呈针状或者板条状,针状β'' 相总是沿着Al基体的<100>Al 方向析出,具有很好的强化效果,是铝合金峰值时效最主要的强化相.图中圆点看到的实际上是β'' 相的端部,其平均直径约4 nm,平均长度约30 nm.图中一些短棒状析出相是L相,沿<001> α [23 ] .图4b 和c给出了6061铝合金经ECAP变形及80℃、20 min后时效的析出相TEM像及相应的SAED花样和快速Fourier变换(FFT)图.可见,经过ECAP后时效处理的合金中出现了大量不同形态的析出相,包括针状的β'' 相以及板条状的Q' 相和L相.主要析出相β'' 的直径约为4 nm,长度约为26 nm (图4e ),这些针状β'' 相总是沿着Al基体的<100>Al 方向析出.与图4a 中T6态峰时效6061铝合金中相比,经过ECAP后时效处理的合金中的β'' 相尺寸较小,L相数量较少且分布情况与峰时效类似,弥散分布的β ″相与少量的L相分布是合金时效硬化强度高的主要原因.80℃、20 min后时效合金就达到峰值状态,与原始ECAP变形态相比,合金中析出相和晶粒尺寸迅速增大,析出相β'' 相和Q' 相也转化为Q相,合金的强度开始下降.从图4d 还可观察到,在β'' 相周围存在大量的位错,即β'' 相与高密度位错同时存在.β'' 析出相的尺寸和分布及其与位错的交互作用对增强材料的强度和韧性起到了重要的作用[24 ] .即,ECAP引起的更细的析出相和高密度的位错在后时效过程中增强了合金的位错强化和析出强化. ...

The effects of Cu addition on the microstructure and thermal stability of an Al-Mg-Si alloy

1

2007

... 图4a 是T6态6061铝合金的TEM明场像.可以看出,T6态合金出现了3种析出相:β'' 相、Q' 相和L相[21 ,22 ] .β'' 相、Q' 相和L相虽然都是在不同取向下的短棒状,但是由于其晶体结构及与Al基体错配度各向异性的不同,其在棒状的横截面上依然有一定的区别[21 ,22 ] .β'' 相的横截面呈圆形,横纵比约为1,Q' 相三维形貌为板条状,因此它的横截面为细长的矩形,横纵比大于3,其惯习面为{510}面,与{100}面有11°的夹角,在TEM中很容易分辨.而L相虽然也呈板条状,横截面为细长的矩形,但其惯习面为{100}面,与Q' 呈11°夹角,因而在TEM中易于分辨.这些析出相都呈针状或者板条状,针状β'' 相总是沿着Al基体的<100>Al 方向析出,具有很好的强化效果,是铝合金峰值时效最主要的强化相.图中圆点看到的实际上是β'' 相的端部,其平均直径约4 nm,平均长度约30 nm.图中一些短棒状析出相是L相,沿<001> α [23 ] .图4b 和c给出了6061铝合金经ECAP变形及80℃、20 min后时效的析出相TEM像及相应的SAED花样和快速Fourier变换(FFT)图.可见,经过ECAP后时效处理的合金中出现了大量不同形态的析出相,包括针状的β'' 相以及板条状的Q' 相和L相.主要析出相β'' 的直径约为4 nm,长度约为26 nm (图4e ),这些针状β'' 相总是沿着Al基体的<100>Al 方向析出.与图4a 中T6态峰时效6061铝合金中相比,经过ECAP后时效处理的合金中的β'' 相尺寸较小,L相数量较少且分布情况与峰时效类似,弥散分布的β ″相与少量的L相分布是合金时效硬化强度高的主要原因.80℃、20 min后时效合金就达到峰值状态,与原始ECAP变形态相比,合金中析出相和晶粒尺寸迅速增大,析出相β'' 相和Q' 相也转化为Q相,合金的强度开始下降.从图4d 还可观察到,在β'' 相周围存在大量的位错,即β'' 相与高密度位错同时存在.β'' 析出相的尺寸和分布及其与位错的交互作用对增强材料的强度和韧性起到了重要的作用[24 ] .即,ECAP引起的更细的析出相和高密度的位错在后时效过程中增强了合金的位错强化和析出强化. ...

Dynamic aging behavior and mechanical properties of an Al-Mg-Si aluminium alloy induced by equal channel angular pressing

1

2016

... 图4a 是T6态6061铝合金的TEM明场像.可以看出,T6态合金出现了3种析出相:β'' 相、Q' 相和L相[21 ,22 ] .β'' 相、Q' 相和L相虽然都是在不同取向下的短棒状,但是由于其晶体结构及与Al基体错配度各向异性的不同,其在棒状的横截面上依然有一定的区别[21 ,22 ] .β'' 相的横截面呈圆形,横纵比约为1,Q' 相三维形貌为板条状,因此它的横截面为细长的矩形,横纵比大于3,其惯习面为{510}面,与{100}面有11°的夹角,在TEM中很容易分辨.而L相虽然也呈板条状,横截面为细长的矩形,但其惯习面为{100}面,与Q' 呈11°夹角,因而在TEM中易于分辨.这些析出相都呈针状或者板条状,针状β'' 相总是沿着Al基体的<100>Al 方向析出,具有很好的强化效果,是铝合金峰值时效最主要的强化相.图中圆点看到的实际上是β'' 相的端部,其平均直径约4 nm,平均长度约30 nm.图中一些短棒状析出相是L相,沿<001> α [23 ] .图4b 和c给出了6061铝合金经ECAP变形及80℃、20 min后时效的析出相TEM像及相应的SAED花样和快速Fourier变换(FFT)图.可见,经过ECAP后时效处理的合金中出现了大量不同形态的析出相,包括针状的β'' 相以及板条状的Q' 相和L相.主要析出相β'' 的直径约为4 nm,长度约为26 nm (图4e ),这些针状β'' 相总是沿着Al基体的<100>Al 方向析出.与图4a 中T6态峰时效6061铝合金中相比,经过ECAP后时效处理的合金中的β'' 相尺寸较小,L相数量较少且分布情况与峰时效类似,弥散分布的β ″相与少量的L相分布是合金时效硬化强度高的主要原因.80℃、20 min后时效合金就达到峰值状态,与原始ECAP变形态相比,合金中析出相和晶粒尺寸迅速增大,析出相β'' 相和Q' 相也转化为Q相,合金的强度开始下降.从图4d 还可观察到,在β'' 相周围存在大量的位错,即β'' 相与高密度位错同时存在.β'' 析出相的尺寸和分布及其与位错的交互作用对增强材料的强度和韧性起到了重要的作用[24 ] .即,ECAP引起的更细的析出相和高密度的位错在后时效过程中增强了合金的位错强化和析出强化. ...

等通道转角挤压Al-Mg-Si铝合金的动态时效特性和力学性能

1

2016

... 图4a 是T6态6061铝合金的TEM明场像.可以看出,T6态合金出现了3种析出相:β'' 相、Q' 相和L相[21 ,22 ] .β'' 相、Q' 相和L相虽然都是在不同取向下的短棒状,但是由于其晶体结构及与Al基体错配度各向异性的不同,其在棒状的横截面上依然有一定的区别[21 ,22 ] .β'' 相的横截面呈圆形,横纵比约为1,Q' 相三维形貌为板条状,因此它的横截面为细长的矩形,横纵比大于3,其惯习面为{510}面,与{100}面有11°的夹角,在TEM中很容易分辨.而L相虽然也呈板条状,横截面为细长的矩形,但其惯习面为{100}面,与Q' 呈11°夹角,因而在TEM中易于分辨.这些析出相都呈针状或者板条状,针状β'' 相总是沿着Al基体的<100>Al 方向析出,具有很好的强化效果,是铝合金峰值时效最主要的强化相.图中圆点看到的实际上是β'' 相的端部,其平均直径约4 nm,平均长度约30 nm.图中一些短棒状析出相是L相,沿<001> α [23 ] .图4b 和c给出了6061铝合金经ECAP变形及80℃、20 min后时效的析出相TEM像及相应的SAED花样和快速Fourier变换(FFT)图.可见,经过ECAP后时效处理的合金中出现了大量不同形态的析出相,包括针状的β'' 相以及板条状的Q' 相和L相.主要析出相β'' 的直径约为4 nm,长度约为26 nm (图4e ),这些针状β'' 相总是沿着Al基体的<100>Al 方向析出.与图4a 中T6态峰时效6061铝合金中相比,经过ECAP后时效处理的合金中的β'' 相尺寸较小,L相数量较少且分布情况与峰时效类似,弥散分布的β ″相与少量的L相分布是合金时效硬化强度高的主要原因.80℃、20 min后时效合金就达到峰值状态,与原始ECAP变形态相比,合金中析出相和晶粒尺寸迅速增大,析出相β'' 相和Q' 相也转化为Q相,合金的强度开始下降.从图4d 还可观察到,在β'' 相周围存在大量的位错,即β'' 相与高密度位错同时存在.β'' 析出相的尺寸和分布及其与位错的交互作用对增强材料的强度和韧性起到了重要的作用[24 ] .即,ECAP引起的更细的析出相和高密度的位错在后时效过程中增强了合金的位错强化和析出强化. ...

Grain boundary structure of Al-Mg alloys processed by high pressure torsion

1

2014

... 图5a 为6061铝合金ECAP后的HRTEM像.可见,ECAP大塑性变形给合金引进大量的位错,同时在图中观察到少量的GP区(Guinier-Preston zone)析出.图5b 为对图5a 中黑色方框处的快速Fourier逆变换(IFFT)图.ECAP后合金中存在极高的位错密度,局部位错密度高达2.75 × 1017 m-2 ,远高于同一样品XRD分析测得的平均位错密度9.19 × 1014 m-2 (表1 ).此外图5b 中的位错大多数以成对的位错偶形式存在,图中还存在间隙型(图5b 中黑色圆圈所示)和空位型(图5b 中白色圆圈所示)位错环.这些都是大塑性变形条件下受到较高的局部应变导致剧烈点阵畸变的表现,位错环和位错偶的引入,增加了储存能,同时为第二相提供了形核核心,促进了第二相的析出[25 ] .图5c 为合金ECAP后80℃、20 min后时效的HRTEM像.低温时效后,合金中的位错密度大大降低,位错缠结和位错环基本消失,并且出现了细小的析出相.从图2b 中可以看出,过高的时效温度会使材料的强度大幅度下降,其主要原因可能是高温对析出相的尺寸分布和结构产生了负面的影响.图5d 给出了ECAP后170℃、180 min后时效的HRTEM像.高温时效后,合金中位错和层错的密度大大降低,并析出了粗大的析出相.通过提高时效温度能够极大地加快回复过程,但是析出活动仅缓慢加快了速度,最终将在基本上恢复的微观结构中形成析出相.这意味着,析出相达到临界尺寸以固定和限制位错运动之前,位错就已经很大程度上消除和重新排列.在进一步时效期间,高度扭曲尚未回复的微观结构处就表现出有利的析出位置,利于析出相的形核,并促进析出相生长. ...

高压扭转大塑性变形Al-Mg合金中的晶界结构

1

2014

... 图5a 为6061铝合金ECAP后的HRTEM像.可见,ECAP大塑性变形给合金引进大量的位错,同时在图中观察到少量的GP区(Guinier-Preston zone)析出.图5b 为对图5a 中黑色方框处的快速Fourier逆变换(IFFT)图.ECAP后合金中存在极高的位错密度,局部位错密度高达2.75 × 1017 m-2 ,远高于同一样品XRD分析测得的平均位错密度9.19 × 1014 m-2 (表1 ).此外图5b 中的位错大多数以成对的位错偶形式存在,图中还存在间隙型(图5b 中黑色圆圈所示)和空位型(图5b 中白色圆圈所示)位错环.这些都是大塑性变形条件下受到较高的局部应变导致剧烈点阵畸变的表现,位错环和位错偶的引入,增加了储存能,同时为第二相提供了形核核心,促进了第二相的析出[25 ] .图5c 为合金ECAP后80℃、20 min后时效的HRTEM像.低温时效后,合金中的位错密度大大降低,位错缠结和位错环基本消失,并且出现了细小的析出相.从图2b 中可以看出,过高的时效温度会使材料的强度大幅度下降,其主要原因可能是高温对析出相的尺寸分布和结构产生了负面的影响.图5d 给出了ECAP后170℃、180 min后时效的HRTEM像.高温时效后,合金中位错和层错的密度大大降低,并析出了粗大的析出相.通过提高时效温度能够极大地加快回复过程,但是析出活动仅缓慢加快了速度,最终将在基本上恢复的微观结构中形成析出相.这意味着,析出相达到临界尺寸以固定和限制位错运动之前,位错就已经很大程度上消除和重新排列.在进一步时效期间,高度扭曲尚未回复的微观结构处就表现出有利的析出位置,利于析出相的形核,并促进析出相生长. ...

On the increase of thermal stability of ultrafine grained materials obtained by severe plastic deformation

1

2003

... 依据上述实验结果分析,得到合金不同状态微观结构和时效析出相的演变示意图.如图6a 所示,固溶态时合金中第二相几乎全部融入基体内,且合金中位错密度很低.与固溶态相比(图6a ),ECAP后合金中位错密度迅速增加(见表1 、图5a 和b ),晶粒尺寸明显减小(见表1 和图3a~c ).合金在ECAP过程中同时存在3种时效析出相:(1) 由ECAP动态时效作用[14 ,15 ] 而析出的动态时效相(见图6b 中红色析出相);(2) 动态时效相在ECAP的作用下发生破碎[15 ] 而形成的析出相(见图6b 中蓝色析出相),部分破碎的时效析出相重新融入基体形成新的过饱和固溶体[14 ,15 ,26 ] ;(3) 因时效析出相重新融入基体形成的新的过饱和固溶体在ECAP过程中将再次析出,即产生再析出相(见图6b 中粉红色析出相).图6c 为合金ECAP后高温时效微观结构示意图.与ECAP态相比(图6b ),高温时效态合金中位错密度迅速减少,晶粒尺寸有所长大(见表1 );上述过饱和固溶体在高温时效过程中析出较细小的时效析出相(见图6b 中细小粉红色析出相),同时,ECAP态中存在的时效析出相经高温时效后继续长大形成较粗大的时效析出相(见图6b 中粗大粉红色析出相),即ECAP高温时效后合金中既有粗大时效析出相又有细小时效析出相(图5d ).图6d 为合金ECAP后低温时效微观结构示意图.与ECAP态相比(图6b ),低温时效态合金中位错密度和晶粒尺寸基本不变(见表1 和图3 );在低温时效过程中,上述过饱和固溶体同样会析出较细小的析出相,而原ECAP态可能存在的上述3种时效析出相的尺寸则基本保持不变,即ECAP后低温时效不会引起原ECAP态存在的时效析出相明显长大(见图4b~e 和图5c ),ECAP低温时效后合金中的时效析出相均为较细小的时效析出相(见图6d 中细小粉红色析出相). ...

Improving the strength and ductility of Al-Mg-Si-Cu alloys by a novel thermo-mechanical treatment

8

2014

... 拉伸实验表明,6061铝合金经过ECAP和后时效处理后的力学性能明显高于未处理合金.变形合金所涉及的强化机制包括固溶强化、细晶强化、位错强化和析出强化.假设它们对强度的贡献都是独立的,并且来自不同强化机制的贡献通常被认为是可相加,则本工作纳米结构铝合金的总强度可用下式来估算[27 ,28 ] : ...

... 长期以来,超细晶纳米晶金属材料强韧性的“倒置关系”一直是制约其发展的重要瓶颈,大大限制了其工程应用[7 ,10 ,34 ,35 ] .大多数严重塑性变形超细晶纳米晶材料的低塑性主要是由于晶粒内部存储或容纳位错的能力很低,失去了使位错在晶内塞积和存储的能力,造成了应变(加工)硬化的缺失[36 ] .因此材料在拉伸过程中很容易趋于塑性失稳,造成其均匀延伸率几乎为零.如王贝贝等[35 ] 对6061铝合金进行搅拌摩擦加工,在强制冷却条件下热输入明显降低,析出相的粗化受到一定程度的抑制,屈服强度和抗拉强度分别提高至435和505 MPa,但断裂延伸率仅为2.1%.Nurislamova等[37 ] 对6061铝合金进行高压扭转,屈服强度达660 MPa,但这是以牺牲塑性为代价的,其延伸率仅有5.2%.表3 [10 ,13 ,27 ,34 ~42 ] 总结了国内外6000系铝合金的拉伸性能,并在图7 [10 ,13 ,27 ,34 ~42 ] 中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... ,27 ,34 ~42 ]中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... 国内外超细晶纳米晶6000系时效铝合金的强韧性对比[10 ,13 ,27 ,34 ~42 ] ...

... Comprehensive comparisons of tensile properties of 6000 series Al alloys[10 ,13 ,27 ,34 -42 ] ...

... [

27 ]

6061 HPT at RT 605 705 6.3 [34 ] 6061 Friction stir processing 435 505 2.1 [35 ] AA6060 HPT at RT 475 525 6.0 [36 ] 6061 HPT at RT 660 690 5.5 [37 ] 6061 HPT at RT + post-aging 455 485 15.0 [38 ] 6061 multi directional forging + aging 409 472 8.9 [39 ] 6101 hydrostatic extrusion + aging 345 354 5.5 [40 ] 6061 accumulative roll bonding + aging 450 - 6.5 [41 ] Al-Mg-Si-Cu pre-deformation + aging 435 450 7.1 [42 ] Note: UTS—ultimate tensile strength, E f —elongation to failure, HPT—high-pressure torsion ...

...

Note: UTS—ultimate tensile strength,

E f —elongation to failure, HPT—high-pressure torsion

图7 国内外Al-Mg-Si铝合金屈服强度-延伸率综合对比<sup>[<xref ref-type="bibr" rid="R10">10</xref>,<xref ref-type="bibr" rid="R13">13</xref>,<xref ref-type="bibr" rid="R27">27</xref>,<xref ref-type="bibr" rid="R34">34</xref>~<xref ref-type="bibr" rid="R42">42</xref>]</sup> Comprehensive comparisons of yield strength and uniform elongation of Al-Mg-Si alloys<sup>[<xref ref-type="bibr" rid="R10">10</xref>,<xref ref-type="bibr" rid="R13">13</xref>,<xref ref-type="bibr" rid="R27">27</xref>,<xref ref-type="bibr" rid="R34">34</xref>-<xref ref-type="bibr" rid="R42">42</xref>]</sup> Color online ...

... ,

27 ,

34 -

42 ]

Color online ...

A model for the yield strength of overaged Al-Zn-Mg-Cu alloys

1

2003

... 拉伸实验表明,6061铝合金经过ECAP和后时效处理后的力学性能明显高于未处理合金.变形合金所涉及的强化机制包括固溶强化、细晶强化、位错强化和析出强化.假设它们对强度的贡献都是独立的,并且来自不同强化机制的贡献通常被认为是可相加,则本工作纳米结构铝合金的总强度可用下式来估算[27 ,28 ] : ...

Grain size dependence of the strength of metals: The Hall-Petch effect does not scale as the inverse square root of grain size

2

2014

... 式中,σ 0.2 是总屈服强度;M 是Taylor因子,通常为3;σ o 是摩擦应力;σ ss 是固溶强化对强度的贡献;σ gs 是细晶强化对强度的贡献;σρ 是位错强化对强度的贡献;σ prec 是6061铝合金ECAP和后时效所产生的析出强化对强度的贡献.考虑到其他强化机制会增加铝合金中的摩擦应力,因此ECAP合金的摩擦应力取为纯Al的摩擦应力(约10 MPa)[29 ] .合金的固溶强化与晶格参数有关.本工作中,晶格参数的波动范围在0.017%~0.208%之间,可以忽略固溶强化. ...

... 如图1 和表1 所示,尺寸较小的晶粒表明更多的晶界或亚晶界而有助于强化,σ gs 可用Hall-Petch公式描述[29 ] : ...

Microstructure of ultrafine-grained fcc metals produced by severe plastic deformation

1

2006

... 其中,σ 1 为纯Al的屈服应力(20 MPa),K 为一个正的屈服常数,d 为平均晶粒尺寸(参见表1 D XRD ).K 通常与晶界位错堆积的应力强度有关,一般取值为K = 0.06~0.09 MPa·m1/2 ,与纯纳米晶Al的估计值一致[30 ] .本工作ECAP铝合金中的K 值取为0.040 MPa·m1/2 ,与高纯Al[31 ] 相同. ...

Recovery of deformation substructure and coarsening of particles on annealing severely plastically deformed Al-Mg-Si alloy and analysis of strengthening mechanisms

1

2006

... 其中,σ 1 为纯Al的屈服应力(20 MPa),K 为一个正的屈服常数,d 为平均晶粒尺寸(参见表1 D XRD ).K 通常与晶界位错堆积的应力强度有关,一般取值为K = 0.06~0.09 MPa·m1/2 ,与纯纳米晶Al的估计值一致[30 ] .本工作ECAP铝合金中的K 值取为0.040 MPa·m1/2 ,与高纯Al[31 ] 相同. ...

Mechanical behaviour of dilute Al-Mg alloy processed by equal channel angular pressing

1

2003

... 如表2 所示,在后时效过程中位错密度会显着降低,可见位错强化仍然是合金最重要的强化机制之一.σρ 通常由Tayler公式计算[32 ] : ...

Influence of predeformation and ageing of an Al-Zn-Mg alloy—II. Modeling of precipitation kinetics and yield stress

2

1999

... ECAP样品中大量析出相分散阻碍位错运动而产生的强化效应称为析出强化,强度的增加主要取决于析出相的特征参数,分为2种强化机制:切过机制和绕过机制.若析出相尺寸小于位错可切过该析出相的等效过渡尺寸r e = 2βb / k (其中β 接近0.5,取k = 0.07)[33 ] ,则符合切过机制;若析出相尺寸大于r e ,可选用位错绕过析出相的Orowan强化机制.通过图4 e的统计结果可以算出析出相的等效圆半径为6 nm,r e = 4.08 nm.即本工作ECAP铝合金中的析出相尺寸(6 nm)大于其等效过渡尺寸(4.08 nm),因此,σ prec 可由Orowan强化机制计算[33 ] : ...

... [33 ]: ...

Effect of the grain refinement via severe plastic deformation on strength properties and deformation behavior of an Al6061 alloy at room and cryogenic temperatures

8

2011

... 长期以来,超细晶纳米晶金属材料强韧性的“倒置关系”一直是制约其发展的重要瓶颈,大大限制了其工程应用[7 ,10 ,34 ,35 ] .大多数严重塑性变形超细晶纳米晶材料的低塑性主要是由于晶粒内部存储或容纳位错的能力很低,失去了使位错在晶内塞积和存储的能力,造成了应变(加工)硬化的缺失[36 ] .因此材料在拉伸过程中很容易趋于塑性失稳,造成其均匀延伸率几乎为零.如王贝贝等[35 ] 对6061铝合金进行搅拌摩擦加工,在强制冷却条件下热输入明显降低,析出相的粗化受到一定程度的抑制,屈服强度和抗拉强度分别提高至435和505 MPa,但断裂延伸率仅为2.1%.Nurislamova等[37 ] 对6061铝合金进行高压扭转,屈服强度达660 MPa,但这是以牺牲塑性为代价的,其延伸率仅有5.2%.表3 [10 ,13 ,27 ,34 ~42 ] 总结了国内外6000系铝合金的拉伸性能,并在图7 [10 ,13 ,27 ,34 ~42 ] 中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... ,34 ~42 ]总结了国内外6000系铝合金的拉伸性能,并在图7 [10 ,13 ,27 ,34 ~42 ] 中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... ,34 ~42 ]中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... 国内外超细晶纳米晶6000系时效铝合金的强韧性对比[10 ,13 ,27 ,34 ~42 ] ...

... Comprehensive comparisons of tensile properties of 6000 series Al alloys[10 ,13 ,27 ,34 -42 ] ...

... [

34 ]

6061 Friction stir processing 435 505 2.1 [35 ] AA6060 HPT at RT 475 525 6.0 [36 ] 6061 HPT at RT 660 690 5.5 [37 ] 6061 HPT at RT + post-aging 455 485 15.0 [38 ] 6061 multi directional forging + aging 409 472 8.9 [39 ] 6101 hydrostatic extrusion + aging 345 354 5.5 [40 ] 6061 accumulative roll bonding + aging 450 - 6.5 [41 ] Al-Mg-Si-Cu pre-deformation + aging 435 450 7.1 [42 ] Note: UTS—ultimate tensile strength, E f —elongation to failure, HPT—high-pressure torsion ...

...

Note: UTS—ultimate tensile strength,

E f —elongation to failure, HPT—high-pressure torsion

图7 国内外Al-Mg-Si铝合金屈服强度-延伸率综合对比<sup>[<xref ref-type="bibr" rid="R10">10</xref>,<xref ref-type="bibr" rid="R13">13</xref>,<xref ref-type="bibr" rid="R27">27</xref>,<xref ref-type="bibr" rid="R34">34</xref>~<xref ref-type="bibr" rid="R42">42</xref>]</sup> Comprehensive comparisons of yield strength and uniform elongation of Al-Mg-Si alloys<sup>[<xref ref-type="bibr" rid="R10">10</xref>,<xref ref-type="bibr" rid="R13">13</xref>,<xref ref-type="bibr" rid="R27">27</xref>,<xref ref-type="bibr" rid="R34">34</xref>-<xref ref-type="bibr" rid="R42">42</xref>]</sup> Color online ...

... ,

34 -

42 ]

Color online ...

Prepration and mechanical properties of ultrafine-grained 6061 Al-alloy by friction stir process

3

2021

... 长期以来,超细晶纳米晶金属材料强韧性的“倒置关系”一直是制约其发展的重要瓶颈,大大限制了其工程应用[7 ,10 ,34 ,35 ] .大多数严重塑性变形超细晶纳米晶材料的低塑性主要是由于晶粒内部存储或容纳位错的能力很低,失去了使位错在晶内塞积和存储的能力,造成了应变(加工)硬化的缺失[36 ] .因此材料在拉伸过程中很容易趋于塑性失稳,造成其均匀延伸率几乎为零.如王贝贝等[35 ] 对6061铝合金进行搅拌摩擦加工,在强制冷却条件下热输入明显降低,析出相的粗化受到一定程度的抑制,屈服强度和抗拉强度分别提高至435和505 MPa,但断裂延伸率仅为2.1%.Nurislamova等[37 ] 对6061铝合金进行高压扭转,屈服强度达660 MPa,但这是以牺牲塑性为代价的,其延伸率仅有5.2%.表3 [10 ,13 ,27 ,34 ~42 ] 总结了国内外6000系铝合金的拉伸性能,并在图7 [10 ,13 ,27 ,34 ~42 ] 中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... [35 ]对6061铝合金进行搅拌摩擦加工,在强制冷却条件下热输入明显降低,析出相的粗化受到一定程度的抑制,屈服强度和抗拉强度分别提高至435和505 MPa,但断裂延伸率仅为2.1%.Nurislamova等[37 ] 对6061铝合金进行高压扭转,屈服强度达660 MPa,但这是以牺牲塑性为代价的,其延伸率仅有5.2%.表3 [10 ,13 ,27 ,34 ~42 ] 总结了国内外6000系铝合金的拉伸性能,并在图7 [10 ,13 ,27 ,34 ~42 ] 中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... Comprehensive comparisons of tensile properties of 6000 series Al alloys

[10 ,13 ,27 ,34 -42 ] Table 3 State/treatment σ 0.2 / MPaUTS / MPa E f / %Ref. 6061 ECAP at RT + post-aging 483 514 15.1 This work Al-Mg-Si-Cu rolling+aging 452 487 10.0 [10 ] 6061 ECAP at RT + post-aging 411 450 17.8 [13 ] 6061 under-aging + coldrolling + re-aging 542 560 8.5 [27 ] 6061 HPT at RT 605 705 6.3 [34 ] 6061 Friction stir processing 435 505 2.1 [35 ] AA6060 HPT at RT 475 525 6.0 [36 ] 6061 HPT at RT 660 690 5.5 [37 ] 6061 HPT at RT + post-aging 455 485 15.0 [38 ] 6061 multi directional forging + aging 409 472 8.9 [39 ] 6101 hydrostatic extrusion + aging 345 354 5.5 [40 ] 6061 accumulative roll bonding + aging 450 - 6.5 [41 ] Al-Mg-Si-Cu pre-deformation + aging 435 450 7.1 [42 ]

Note: UTS—ultimate tensile strength, E f —elongation to failure, HPT—high-pressure torsion ...

超细晶6061铝合金的搅拌摩擦制备和性能

3

2021

... 长期以来,超细晶纳米晶金属材料强韧性的“倒置关系”一直是制约其发展的重要瓶颈,大大限制了其工程应用[7 ,10 ,34 ,35 ] .大多数严重塑性变形超细晶纳米晶材料的低塑性主要是由于晶粒内部存储或容纳位错的能力很低,失去了使位错在晶内塞积和存储的能力,造成了应变(加工)硬化的缺失[36 ] .因此材料在拉伸过程中很容易趋于塑性失稳,造成其均匀延伸率几乎为零.如王贝贝等[35 ] 对6061铝合金进行搅拌摩擦加工,在强制冷却条件下热输入明显降低,析出相的粗化受到一定程度的抑制,屈服强度和抗拉强度分别提高至435和505 MPa,但断裂延伸率仅为2.1%.Nurislamova等[37 ] 对6061铝合金进行高压扭转,屈服强度达660 MPa,但这是以牺牲塑性为代价的,其延伸率仅有5.2%.表3 [10 ,13 ,27 ,34 ~42 ] 总结了国内外6000系铝合金的拉伸性能,并在图7 [10 ,13 ,27 ,34 ~42 ] 中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... [35 ]对6061铝合金进行搅拌摩擦加工,在强制冷却条件下热输入明显降低,析出相的粗化受到一定程度的抑制,屈服强度和抗拉强度分别提高至435和505 MPa,但断裂延伸率仅为2.1%.Nurislamova等[37 ] 对6061铝合金进行高压扭转,屈服强度达660 MPa,但这是以牺牲塑性为代价的,其延伸率仅有5.2%.表3 [10 ,13 ,27 ,34 ~42 ] 总结了国内外6000系铝合金的拉伸性能,并在图7 [10 ,13 ,27 ,34 ~42 ] 中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... Comprehensive comparisons of tensile properties of 6000 series Al alloys

[10 ,13 ,27 ,34 -42 ] Table 3 State/treatment σ 0.2 / MPaUTS / MPa E f / %Ref. 6061 ECAP at RT + post-aging 483 514 15.1 This work Al-Mg-Si-Cu rolling+aging 452 487 10.0 [10 ] 6061 ECAP at RT + post-aging 411 450 17.8 [13 ] 6061 under-aging + coldrolling + re-aging 542 560 8.5 [27 ] 6061 HPT at RT 605 705 6.3 [34 ] 6061 Friction stir processing 435 505 2.1 [35 ] AA6060 HPT at RT 475 525 6.0 [36 ] 6061 HPT at RT 660 690 5.5 [37 ] 6061 HPT at RT + post-aging 455 485 15.0 [38 ] 6061 multi directional forging + aging 409 472 8.9 [39 ] 6101 hydrostatic extrusion + aging 345 354 5.5 [40 ] 6061 accumulative roll bonding + aging 450 - 6.5 [41 ] Al-Mg-Si-Cu pre-deformation + aging 435 450 7.1 [42 ]

Note: UTS—ultimate tensile strength, E f —elongation to failure, HPT—high-pressure torsion ...

Strength, grain refinement and solute nanostructures of an Al-Mg-Si alloy (AA6060) processed by high-pressure torsion

2

2014

... 长期以来,超细晶纳米晶金属材料强韧性的“倒置关系”一直是制约其发展的重要瓶颈,大大限制了其工程应用[7 ,10 ,34 ,35 ] .大多数严重塑性变形超细晶纳米晶材料的低塑性主要是由于晶粒内部存储或容纳位错的能力很低,失去了使位错在晶内塞积和存储的能力,造成了应变(加工)硬化的缺失[36 ] .因此材料在拉伸过程中很容易趋于塑性失稳,造成其均匀延伸率几乎为零.如王贝贝等[35 ] 对6061铝合金进行搅拌摩擦加工,在强制冷却条件下热输入明显降低,析出相的粗化受到一定程度的抑制,屈服强度和抗拉强度分别提高至435和505 MPa,但断裂延伸率仅为2.1%.Nurislamova等[37 ] 对6061铝合金进行高压扭转,屈服强度达660 MPa,但这是以牺牲塑性为代价的,其延伸率仅有5.2%.表3 [10 ,13 ,27 ,34 ~42 ] 总结了国内外6000系铝合金的拉伸性能,并在图7 [10 ,13 ,27 ,34 ~42 ] 中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... Comprehensive comparisons of tensile properties of 6000 series Al alloys

[10 ,13 ,27 ,34 -42 ] Table 3 State/treatment σ 0.2 / MPaUTS / MPa E f / %Ref. 6061 ECAP at RT + post-aging 483 514 15.1 This work Al-Mg-Si-Cu rolling+aging 452 487 10.0 [10 ] 6061 ECAP at RT + post-aging 411 450 17.8 [13 ] 6061 under-aging + coldrolling + re-aging 542 560 8.5 [27 ] 6061 HPT at RT 605 705 6.3 [34 ] 6061 Friction stir processing 435 505 2.1 [35 ] AA6060 HPT at RT 475 525 6.0 [36 ] 6061 HPT at RT 660 690 5.5 [37 ] 6061 HPT at RT + post-aging 455 485 15.0 [38 ] 6061 multi directional forging + aging 409 472 8.9 [39 ] 6101 hydrostatic extrusion + aging 345 354 5.5 [40 ] 6061 accumulative roll bonding + aging 450 - 6.5 [41 ] Al-Mg-Si-Cu pre-deformation + aging 435 450 7.1 [42 ]

Note: UTS—ultimate tensile strength, E f —elongation to failure, HPT—high-pressure torsion ...

Nanostructure and related mechanical properties of an Al-Mg-Si alloy processed by severe plastic deformation

2

2008

... 长期以来,超细晶纳米晶金属材料强韧性的“倒置关系”一直是制约其发展的重要瓶颈,大大限制了其工程应用[7 ,10 ,34 ,35 ] .大多数严重塑性变形超细晶纳米晶材料的低塑性主要是由于晶粒内部存储或容纳位错的能力很低,失去了使位错在晶内塞积和存储的能力,造成了应变(加工)硬化的缺失[36 ] .因此材料在拉伸过程中很容易趋于塑性失稳,造成其均匀延伸率几乎为零.如王贝贝等[35 ] 对6061铝合金进行搅拌摩擦加工,在强制冷却条件下热输入明显降低,析出相的粗化受到一定程度的抑制,屈服强度和抗拉强度分别提高至435和505 MPa,但断裂延伸率仅为2.1%.Nurislamova等[37 ] 对6061铝合金进行高压扭转,屈服强度达660 MPa,但这是以牺牲塑性为代价的,其延伸率仅有5.2%.表3 [10 ,13 ,27 ,34 ~42 ] 总结了国内外6000系铝合金的拉伸性能,并在图7 [10 ,13 ,27 ,34 ~42 ] 中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... Comprehensive comparisons of tensile properties of 6000 series Al alloys

[10 ,13 ,27 ,34 -42 ] Table 3 State/treatment σ 0.2 / MPaUTS / MPa E f / %Ref. 6061 ECAP at RT + post-aging 483 514 15.1 This work Al-Mg-Si-Cu rolling+aging 452 487 10.0 [10 ] 6061 ECAP at RT + post-aging 411 450 17.8 [13 ] 6061 under-aging + coldrolling + re-aging 542 560 8.5 [27 ] 6061 HPT at RT 605 705 6.3 [34 ] 6061 Friction stir processing 435 505 2.1 [35 ] AA6060 HPT at RT 475 525 6.0 [36 ] 6061 HPT at RT 660 690 5.5 [37 ] 6061 HPT at RT + post-aging 455 485 15.0 [38 ] 6061 multi directional forging + aging 409 472 8.9 [39 ] 6101 hydrostatic extrusion + aging 345 354 5.5 [40 ] 6061 accumulative roll bonding + aging 450 - 6.5 [41 ] Al-Mg-Si-Cu pre-deformation + aging 435 450 7.1 [42 ]

Note: UTS—ultimate tensile strength, E f —elongation to failure, HPT—high-pressure torsion ...

Aging behavior of Al 6061 alloy processed by high-pressure torsion and subsequent aging

1

2015

... Comprehensive comparisons of tensile properties of 6000 series Al alloys

[10 ,13 ,27 ,34 -42 ] Table 3 State/treatment σ 0.2 / MPaUTS / MPa E f / %Ref. 6061 ECAP at RT + post-aging 483 514 15.1 This work Al-Mg-Si-Cu rolling+aging 452 487 10.0 [10 ] 6061 ECAP at RT + post-aging 411 450 17.8 [13 ] 6061 under-aging + coldrolling + re-aging 542 560 8.5 [27 ] 6061 HPT at RT 605 705 6.3 [34 ] 6061 Friction stir processing 435 505 2.1 [35 ] AA6060 HPT at RT 475 525 6.0 [36 ] 6061 HPT at RT 660 690 5.5 [37 ] 6061 HPT at RT + post-aging 455 485 15.0 [38 ] 6061 multi directional forging + aging 409 472 8.9 [39 ] 6101 hydrostatic extrusion + aging 345 354 5.5 [40 ] 6061 accumulative roll bonding + aging 450 - 6.5 [41 ] Al-Mg-Si-Cu pre-deformation + aging 435 450 7.1 [42 ]

Note: UTS—ultimate tensile strength, E f —elongation to failure, HPT—high-pressure torsion ...

Effect of ageing on tensile behavior of ultrafine grained Al 6061 alloy

1

2015

... Comprehensive comparisons of tensile properties of 6000 series Al alloys

[10 ,13 ,27 ,34 -42 ] Table 3 State/treatment σ 0.2 / MPaUTS / MPa E f / %Ref. 6061 ECAP at RT + post-aging 483 514 15.1 This work Al-Mg-Si-Cu rolling+aging 452 487 10.0 [10 ] 6061 ECAP at RT + post-aging 411 450 17.8 [13 ] 6061 under-aging + coldrolling + re-aging 542 560 8.5 [27 ] 6061 HPT at RT 605 705 6.3 [34 ] 6061 Friction stir processing 435 505 2.1 [35 ] AA6060 HPT at RT 475 525 6.0 [36 ] 6061 HPT at RT 660 690 5.5 [37 ] 6061 HPT at RT + post-aging 455 485 15.0 [38 ] 6061 multi directional forging + aging 409 472 8.9 [39 ] 6101 hydrostatic extrusion + aging 345 354 5.5 [40 ] 6061 accumulative roll bonding + aging 450 - 6.5 [41 ] Al-Mg-Si-Cu pre-deformation + aging 435 450 7.1 [42 ]

Note: UTS—ultimate tensile strength, E f —elongation to failure, HPT—high-pressure torsion ...

Enhanced strength and electrical conductivity of ultrafine-grained Al-Mg-Si alloy processed by hydrostatic extrusion

1

2018

... Comprehensive comparisons of tensile properties of 6000 series Al alloys

[10 ,13 ,27 ,34 -42 ] Table 3 State/treatment σ 0.2 / MPaUTS / MPa E f / %Ref. 6061 ECAP at RT + post-aging 483 514 15.1 This work Al-Mg-Si-Cu rolling+aging 452 487 10.0 [10 ] 6061 ECAP at RT + post-aging 411 450 17.8 [13 ] 6061 under-aging + coldrolling + re-aging 542 560 8.5 [27 ] 6061 HPT at RT 605 705 6.3 [34 ] 6061 Friction stir processing 435 505 2.1 [35 ] AA6060 HPT at RT 475 525 6.0 [36 ] 6061 HPT at RT 660 690 5.5 [37 ] 6061 HPT at RT + post-aging 455 485 15.0 [38 ] 6061 multi directional forging + aging 409 472 8.9 [39 ] 6101 hydrostatic extrusion + aging 345 354 5.5 [40 ] 6061 accumulative roll bonding + aging 450 - 6.5 [41 ] Al-Mg-Si-Cu pre-deformation + aging 435 450 7.1 [42 ]

Note: UTS—ultimate tensile strength, E f —elongation to failure, HPT—high-pressure torsion ...

Effects of ARB and ageing processes on mechanical properties and microstructure of 6061 aluminum alloy

1

2011

... Comprehensive comparisons of tensile properties of 6000 series Al alloys

[10 ,13 ,27 ,34 -42 ] Table 3 State/treatment σ 0.2 / MPaUTS / MPa E f / %Ref. 6061 ECAP at RT + post-aging 483 514 15.1 This work Al-Mg-Si-Cu rolling+aging 452 487 10.0 [10 ] 6061 ECAP at RT + post-aging 411 450 17.8 [13 ] 6061 under-aging + coldrolling + re-aging 542 560 8.5 [27 ] 6061 HPT at RT 605 705 6.3 [34 ] 6061 Friction stir processing 435 505 2.1 [35 ] AA6060 HPT at RT 475 525 6.0 [36 ] 6061 HPT at RT 660 690 5.5 [37 ] 6061 HPT at RT + post-aging 455 485 15.0 [38 ] 6061 multi directional forging + aging 409 472 8.9 [39 ] 6101 hydrostatic extrusion + aging 345 354 5.5 [40 ] 6061 accumulative roll bonding + aging 450 - 6.5 [41 ] Al-Mg-Si-Cu pre-deformation + aging 435 450 7.1 [42 ]

Note: UTS—ultimate tensile strength, E f —elongation to failure, HPT—high-pressure torsion ...

Effect of pre-deformation on age- hardening and microstructure in Al-Mg-Si-Cu alloy

8

2015

... 长期以来,超细晶纳米晶金属材料强韧性的“倒置关系”一直是制约其发展的重要瓶颈,大大限制了其工程应用[7 ,10 ,34 ,35 ] .大多数严重塑性变形超细晶纳米晶材料的低塑性主要是由于晶粒内部存储或容纳位错的能力很低,失去了使位错在晶内塞积和存储的能力,造成了应变(加工)硬化的缺失[36 ] .因此材料在拉伸过程中很容易趋于塑性失稳,造成其均匀延伸率几乎为零.如王贝贝等[35 ] 对6061铝合金进行搅拌摩擦加工,在强制冷却条件下热输入明显降低,析出相的粗化受到一定程度的抑制,屈服强度和抗拉强度分别提高至435和505 MPa,但断裂延伸率仅为2.1%.Nurislamova等[37 ] 对6061铝合金进行高压扭转,屈服强度达660 MPa,但这是以牺牲塑性为代价的,其延伸率仅有5.2%.表3 [10 ,13 ,27 ,34 ~42 ] 总结了国内外6000系铝合金的拉伸性能,并在图7 [10 ,13 ,27 ,34 ~42 ] 中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... ~42 ]中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... [42 ]对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... 国内外超细晶纳米晶6000系时效铝合金的强韧性对比[10 ,13 ,27 ,34 ~42 ] ...

... Comprehensive comparisons of tensile properties of 6000 series Al alloys[10 ,13 ,27 ,34 -42 ] ...

... [

42 ]

Note: UTS—ultimate tensile strength, E f —elongation to failure, HPT—high-pressure torsion ...

...

Note: UTS—ultimate tensile strength,

E f —elongation to failure, HPT—high-pressure torsion

图7 国内外Al-Mg-Si铝合金屈服强度-延伸率综合对比<sup>[<xref ref-type="bibr" rid="R10">10</xref>,<xref ref-type="bibr" rid="R13">13</xref>,<xref ref-type="bibr" rid="R27">27</xref>,<xref ref-type="bibr" rid="R34">34</xref>~<xref ref-type="bibr" rid="R42">42</xref>]</sup> Comprehensive comparisons of yield strength and uniform elongation of Al-Mg-Si alloys<sup>[<xref ref-type="bibr" rid="R10">10</xref>,<xref ref-type="bibr" rid="R13">13</xref>,<xref ref-type="bibr" rid="R27">27</xref>,<xref ref-type="bibr" rid="R34">34</xref>-<xref ref-type="bibr" rid="R42">42</xref>]</sup> Color online ...

预变形对Al-Mg-Si-Cu合金时效硬化和显微结构的影响

8

2015

... 长期以来,超细晶纳米晶金属材料强韧性的“倒置关系”一直是制约其发展的重要瓶颈,大大限制了其工程应用[7 ,10 ,34 ,35 ] .大多数严重塑性变形超细晶纳米晶材料的低塑性主要是由于晶粒内部存储或容纳位错的能力很低,失去了使位错在晶内塞积和存储的能力,造成了应变(加工)硬化的缺失[36 ] .因此材料在拉伸过程中很容易趋于塑性失稳,造成其均匀延伸率几乎为零.如王贝贝等[35 ] 对6061铝合金进行搅拌摩擦加工,在强制冷却条件下热输入明显降低,析出相的粗化受到一定程度的抑制,屈服强度和抗拉强度分别提高至435和505 MPa,但断裂延伸率仅为2.1%.Nurislamova等[37 ] 对6061铝合金进行高压扭转,屈服强度达660 MPa,但这是以牺牲塑性为代价的,其延伸率仅有5.2%.表3 [10 ,13 ,27 ,34 ~42 ] 总结了国内外6000系铝合金的拉伸性能,并在图7 [10 ,13 ,27 ,34 ~42 ] 中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... ~42 ]中绘制出不同条件下获得的屈服强度和延伸率.研究发现,大多数合金遵循强度和塑性之间的制衡原则,分布在蓝色区域.如顾媛等[42 ] 对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... [42 ]对Al-Mg-Si-Cu合金预先冷轧变形后,在120、150和180℃下进行后时效处理,材料强度明显提高,最高抗拉强度达到450 MPa,延伸率为7.1%.而本工作结果摆脱了强度-塑性制衡区域,实现了高强度和塑韧性的完美结合,其中80℃峰值后时效的性能为强韧性的最佳组合,抗拉强度、屈服强度和延伸率分别为514 MPa、483 MPa和15.1%.因此,通过改变变形量和优化时效工艺,有助于制备高强度和高韧性兼备的6000系时效铝合金. ...

... 国内外超细晶纳米晶6000系时效铝合金的强韧性对比[10 ,13 ,27 ,34 ~42 ] ...

... Comprehensive comparisons of tensile properties of 6000 series Al alloys[10 ,13 ,27 ,34 -42 ] ...

... [

42 ]

Note: UTS—ultimate tensile strength, E f —elongation to failure, HPT—high-pressure torsion ...

...

Note: UTS—ultimate tensile strength,

E f —elongation to failure, HPT—high-pressure torsion

图7 国内外Al-Mg-Si铝合金屈服强度-延伸率综合对比<sup>[<xref ref-type="bibr" rid="R10">10</xref>,<xref ref-type="bibr" rid="R13">13</xref>,<xref ref-type="bibr" rid="R27">27</xref>,<xref ref-type="bibr" rid="R34">34</xref>~<xref ref-type="bibr" rid="R42">42</xref>]</sup> Comprehensive comparisons of yield strength and uniform elongation of Al-Mg-Si alloys<sup>[<xref ref-type="bibr" rid="R10">10</xref>,<xref ref-type="bibr" rid="R13">13</xref>,<xref ref-type="bibr" rid="R27">27</xref>,<xref ref-type="bibr" rid="R34">34</xref>-<xref ref-type="bibr" rid="R42">42</xref>]</sup> Color online ...