多孔材料的强度和密度符合Gibson-Ashby关系,提高强度的同时密度也会增大,很难在低密度下实现高强度需求[4]。为解决这一矛盾,可以通过调整孔型结构和改善孔梁组织组成优化多孔材料的性能。厉雪等[5]研究了Gyroid结构在冲击加载条件下的动态力学响应,发现负梯度结构具有比正梯度结构和均匀结构更低的屈服应力。Luxner等[6]对规则和无序多孔结构进行有限元分析,发现规则结构比无序结构具有更高的强度,但容易发生突然性破坏。Vesenjak等[7]报道了圆形单元结构比矩形单元结构具有更稳定的变形行为和更好的能量吸收能力。Li等[8]的研究表明通过单元结构设计,改变施加于孔梁力的屈曲和弯曲分量匹配,可以有效改善多孔材料的变形行为和强度。Jang等[9]通过降低单元结构尺寸和仿生多级结构设计,制备出强度高达1.75 GPa的超轻陶瓷多孔材料。Zheng等[10]在微米尺度对单元结构进行优化设计,使孔梁仅承受拉-拉或压-压变形,实现了超强超轻多孔材料制备。Bauer等[11]利用增材制造技术,制备出单元结构尺寸达到纳米级的聚合物多孔材料,其“强度/密度”比值与金刚石相当。赵朔等[12]和Yang等[13]利用热处理对Ti-6Al-4V多孔合金组织进行调整,发现通过改变α片层厚度及长度可以有效提高多孔材料的塑性。从已报道的结果来看,目前多孔材料力学性能优化相关研究多集中于孔型结构设计,尚缺乏孔梁组织和性能调整与多孔材料力学性能内在关联的研究。

1 实验方法

通过无坩埚感应熔炼超声气体雾化法(electron inert gas atomized,EIGA)制备Ti55531预合金粉末。采用化学分析方法分析其主要化学成分(质量分数,%)为:Al 4.9,V 4.91,Mo 5.12,Cr 2.90,Zr 0.95,Ti余量。利用Realizer SLM-100型金属铺粉3D打印机制备Ti55531合金多孔材料,激光器所用功率为175 W,激光光斑直径为0.04 mm,扫描间距为0.1 mm,粉层厚度为0.05 mm,扫描速率为1000 mm/s。为考察热处理对孔梁母体材料本征力学性能的影响,随炉打印直径1.75 mm、长度3.5 mm的小棒用于其压缩强度测试。

将制备的Ti55531合金多孔材料和小棒封于真空管内,在马弗炉内分别于750~900℃进行固溶处理,随后在500~600℃进行时效处理,冷却方式均为空冷,样品编号和具体的热处理工艺制度见表1。

表1 Ti55531多孔材料热处理工艺

Table 1

| Specimen | Solution temperature | Solution time | Cooling | Aging temperature | Aging time | Cooling |

|---|---|---|---|---|---|---|

| oC | h | oC | h | |||

| A | - | - | - | 500 | 4 | Air cooling |

| B | 750 | 1 | Air cooling | 500 | 4 | Air cooling |

| C | 800 | 1 | Air cooling | 500 | 4 | Air cooling |

| D | 900 | 1 | Air cooling | 500 | 4 | Air cooling |

| E | 800 | 1 | Air cooling | 600 | 4 | Air cooling |

| F | As-fabricated | - | - | - | - | - |

利用Axiovert 200 Mat型光学显微镜(OM)和Tescan Mira 3型扫描电子显微镜(SEM)对预合金粉末形貌和原始打印态及热处理后多孔材料进行表面形貌和显微组织观察。用于OM和SEM观察的试样采用HF∶HNO3∶C3H6O3 = 1∶10∶30混合溶液进行腐蚀。采用D8 Discover型X射线衍射仪(XRD)对多孔材料相组成进行测定,X射线为Cu靶Kα 射线,X射线衍射角为30°~90°,扫描步长为5°/min,电流为200 mA,电压为40 kV。根据GB/T 6394—2017,采用截线法统计晶粒尺寸。根据GB/T 13305—2008,利用Image Pro Plus软件和jade软件,采用金相法和XRD定量分析法,统计初生α相(αp)和次生α相(αs)含量。采用Instron 5582型电子万能试验机,按照GB/T 7314—2017对Ti55531合金多孔试样和小棒试样进行室温压缩实验,横梁位移速率为0.5 mm/min,每种热处理制度压缩测试样品为2个。

2 实验结果

2.1 Ti55531合金粉末与多孔样品表征

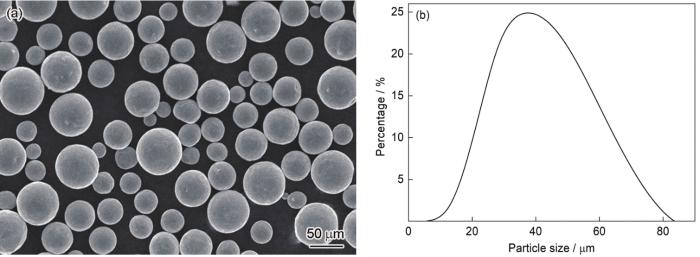

Ti55531合金粉末的形貌及粒度分布如图1所示。由图可见,预合金粉末球形度良好,其粒度尺寸主要分布在10~80 μm之间。

图1

图1

Ti55531合金粉末形貌及粒度分布

Fig.1

SEM image (a) and particle size distribution (b) of the Ti55531 alloy powders

图2

图2

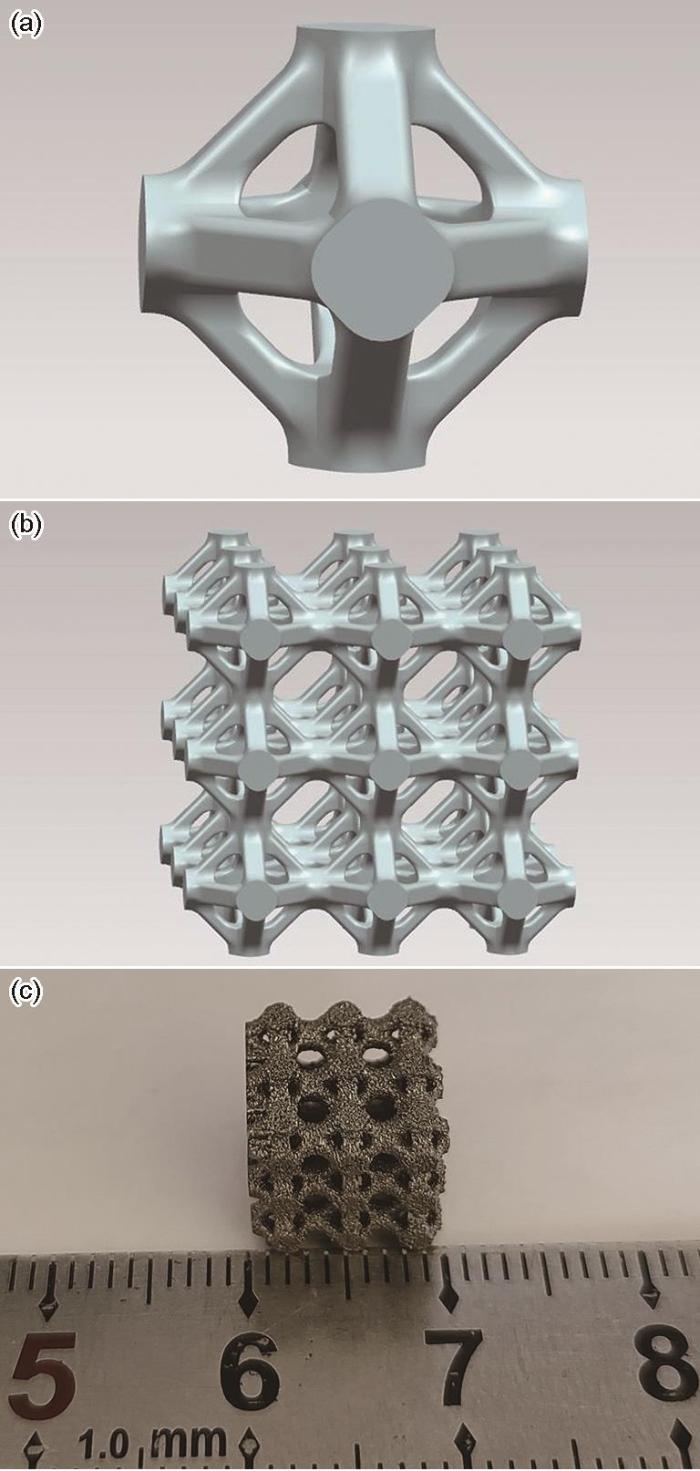

Ti55531合金多孔材料结构模型和选区激光熔化打印样品

Fig.2

Porous structure models (a, b) and selective laster melting (SLM) fabricated specimen (c) of porous Ti55531 alloy

2.2 热处理对Ti55531合金多孔材料孔梁组织的影响

2.2.1 原始打印态组织

图3

图3

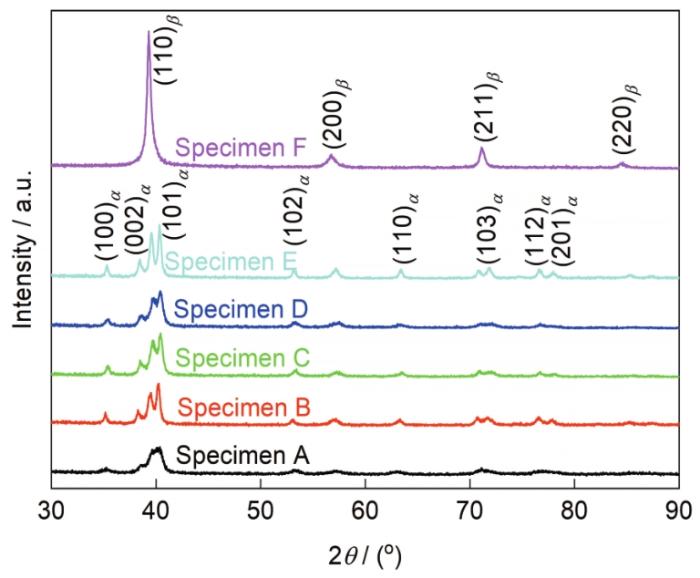

Ti55531多孔材料孔梁原始态和经过不同热处理制度处理后的XRD谱

Fig.3

XRD spectra of the as-fabricated and heat treated porous Ti55531 specimens

图4

图4

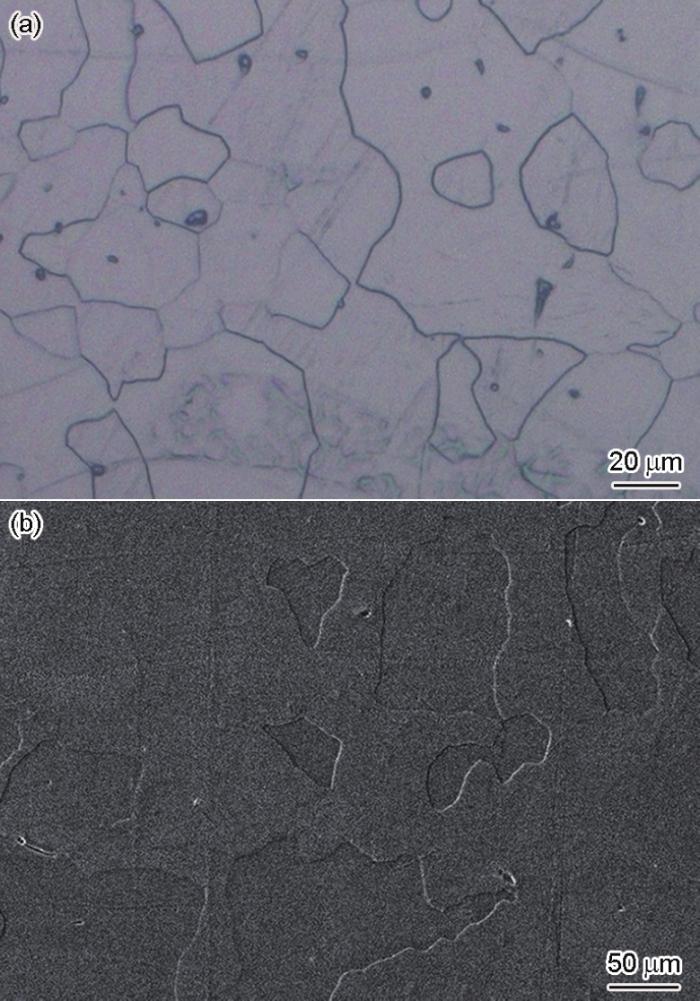

Ti55531多孔材料原始态孔梁横截面显微组织的OM和SEM像

Fig.4

Cross-sectional OM (a) and SEM (b) images of the as-fabricated porous Ti55531 specimen

图5

图5

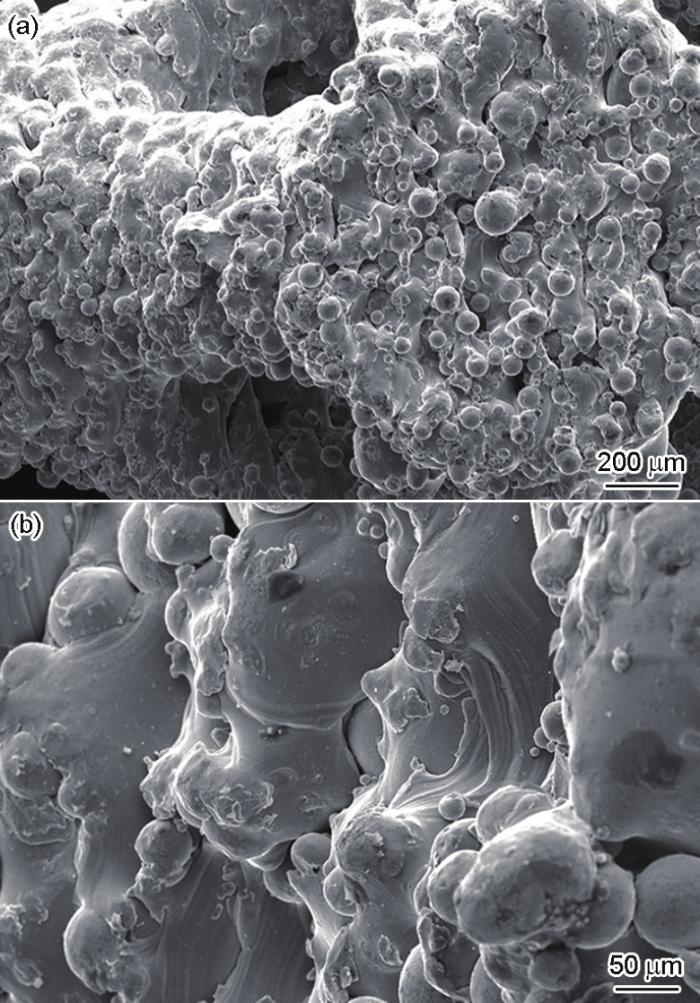

Ti55531多孔材料孔梁表面形貌的SEM像

Fig.5

Low (a) and high (b) magnified surface SEM images of the as-fabricated porous Ti55531 specimen

2.2.2 热处理态组织

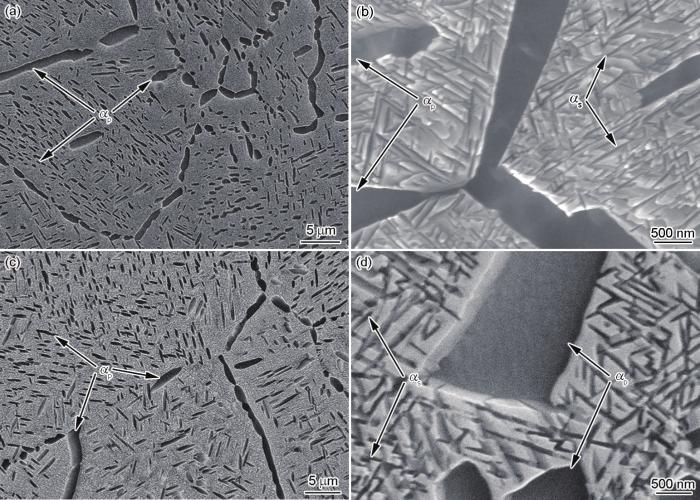

Ti55531合金多孔样品经750~900℃固溶处理和500~600℃时效处理后,孔梁组织主要由α + β相组成(图3),不同固溶温度和时效温度下从β基体中析出的α相形貌和分布会有所不同。

(1) 固溶温度的影响

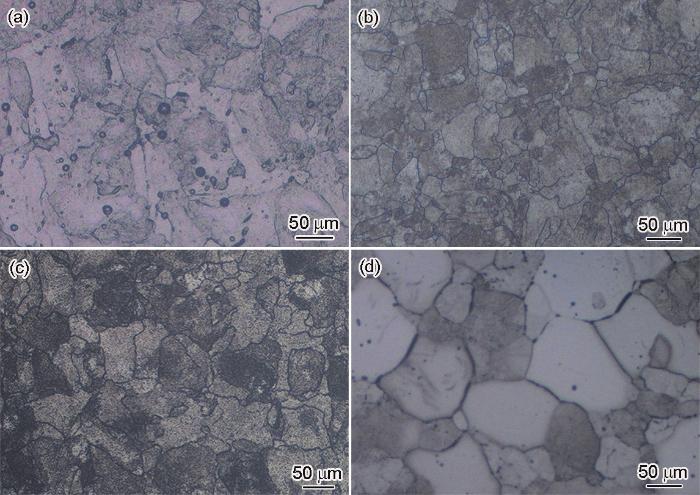

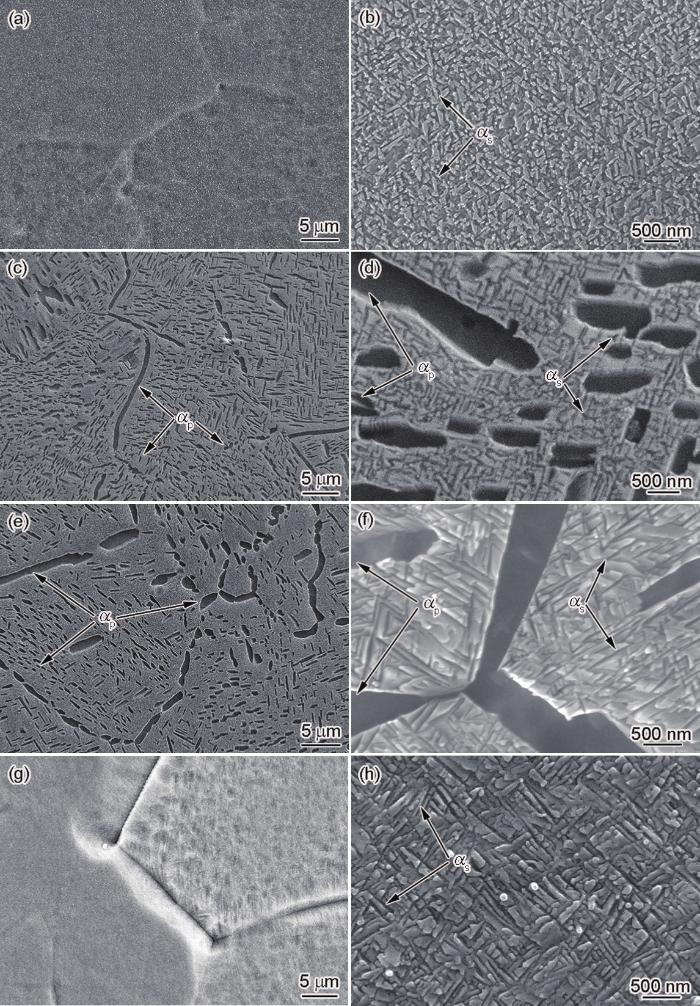

图6和7分别为Ti55531多孔材料经不同固溶温度处理后在500℃时效处理的OM和SEM像。由图6可见,随固溶处理温度升高,晶粒尺寸增加,当固溶温度达到900℃时,晶粒尺寸约为89.8 μm。在Ti55531合金相变点(845 ± 5)℃以上对多孔样品进行固溶处理(900℃)随后时效处理,其孔梁组织主要由针状αs相和β基体构成(图7g和h)。而在相变点以下进行固溶处理随后时效处理,孔梁组织由初生αp相、αs相和β基体组成(图7c~f),αp相形貌为长条状、短棒状或椭球状,尺寸在0.5~2.0 μm之间,主要分布于β晶粒内部和晶界处。αs相形貌为针片状,尺寸在200 nm以下,主要分布于晶粒内部的αp相之间。随着固溶温度的升高,晶界处αp相逐渐碎化,且尺寸有所增加,αp相含量降低,αs相含量增加(表2)。以上结果表明,固溶温度主要影响时效样品中αp相的形貌、分布和数量。对于未经固溶处理直接时效处理样品(图7a和b),组织由αs相与β相组成,与在相变点以上固溶处理并时效处理样品相比,其αs相数量更多,且尺寸更细小。

图6

图6

不同温度固溶1 h随后500℃时效处理4 h后Ti55531多孔材料孔梁组织的OM像

Fig.6

OM images of the porous Ti55531 specimens after solution treated at different temperatures for 1 h followed by aging at 500oC for 4 h

(a) without solution treatment (b) 750oC (c) 800oC (d) 900oC

图7

图7

不同温度固溶处理1 h随后500℃时效处理4 h后Ti55531多孔材料孔梁组织的SEM像

Fig.7

Low (a, c, e, g) and high (b, d, f, h) magnified SEM images of the porous Ti55531 specimens after solution treated at different temperatures for 1 h followed by aging at 500oC for 4 h ( αp—primary α, αs—secondary α )

(a, b) without solution treatment (c, d) 750oC (e, f) 800oC (g, h) 900oC

表2 不同热处理后Ti55531合金多孔材料孔梁中相含量 (%)

Table 2

| Specimen | αp | αs | β |

|---|---|---|---|

| A | - | 97 | 3 |

| B | 25 | 69 | 6 |

| C | 17 | 77 | 6 |

| D | - | 96 | 4 |

| E | 17 | 74 | 9 |

| F | - | - | 100 |

(2) 时效温度的影响

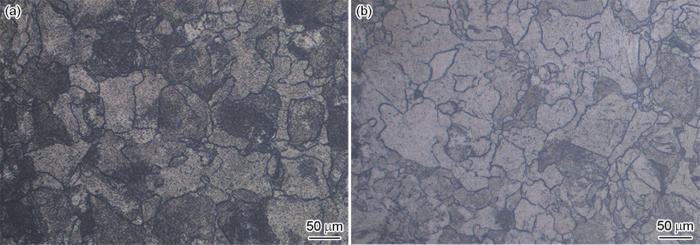

图8

图8

经800℃固溶处理1 h随后在不同温度时效处理4 h后Ti55531多孔材料孔梁组织的OM像

Fig.8

OM images of the porous Ti55531 specimens after solution treated at 800oC for 1 h followed by aging at 500oC (a) and 600oC (b) for 4 h

图9

图9

经800℃固溶处理1 h随后在不同温度时效处理4 h后Ti55531多孔材料孔梁组织的SEM像

Fig.9

Low (a, c) and high (b, d) magnified SEM images of the porous Ti55531 specimens after solution treated at 800oC for 1 h followed by aging at 500oC (a, b) and 600oC (c, d) for 4 h

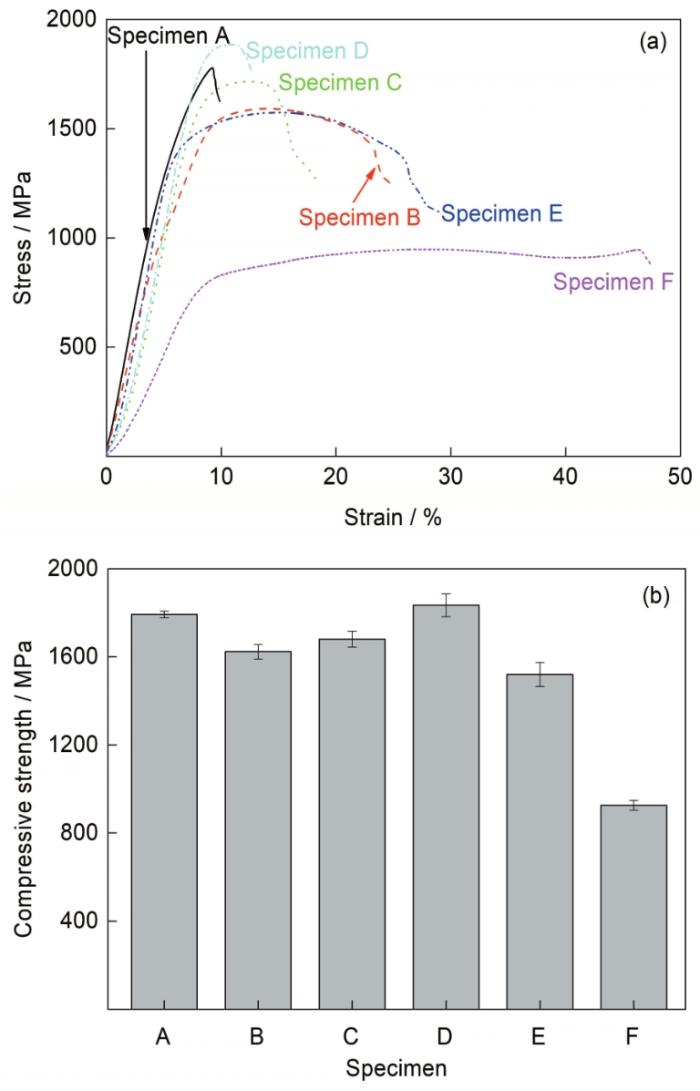

2.3 热处理对Ti55531合金多孔材料孔梁母材力学性能影响

为考察热处理对Ti55531合金多孔材料孔梁母材本征力学性能的影响,随炉打印了尺寸为直径1.75 mm、长3.5 mm的小棒,并对其进行了压缩性能测试(图10)。结果表明,与原始打印态相比,热处理后由于αp相和αs相的析出,孔梁母材强度升高,但塑性下降。当样品经不同温度固溶处理随后同一温度时效处理时,随着固溶温度的升高,孔梁母材的强度增加,塑性降低;样品在同一温度(800℃)固溶处理随后在不同温度时效处理时,随着时效温度的升高,孔梁母材的强度降低,塑性增加。如果样品不经固溶直接进行时效处理,样品强度较高,但塑性低于固溶处理样品。与传统锻态Ti55531合金相比,固溶时效处理后SLM制备合金的强度更高[16]。

图10

图10

热处理后Ti55531多孔材料孔梁母材压缩应力-应变曲线和压缩强度

Fig.10

Compressive stress-strain curves (a) and compressive strength (b) of the porous Ti55531 parent materials after different heat treatments

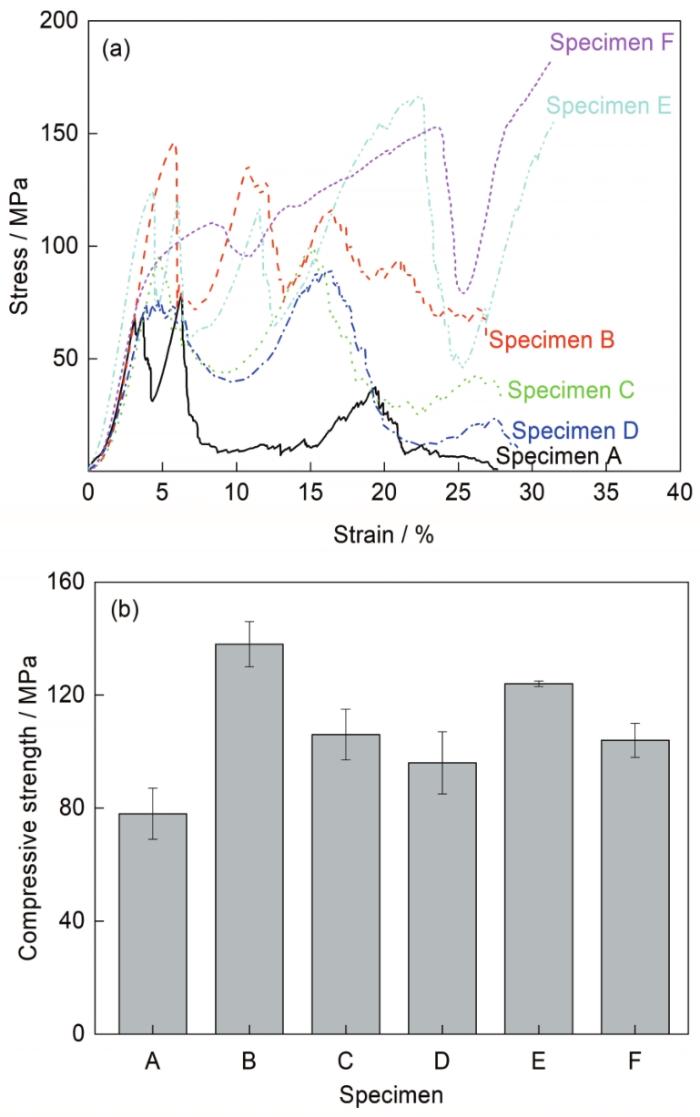

2.4 热处理对Ti55531合金多孔材料力学性能的影响

图11为原始打印态Ti55531合金多孔材料的压缩应力-应变曲线和抗压强度。由图11a可见,对于原始打印态多孔样品,其应力-应变曲线呈现出韧性金属多孔材料变形行为。而热处理后,多孔材料应力-应变曲线呈现出脆性金属多孔材料的变形特征,当应力达到最高值后,出现了比较大的波动。图11b表明,热处理可以提高多孔材料的强度,但其变化趋势与孔梁母材本征强度变化显著不同。当样品经不同温度固溶处理随后时效处理时,随着固溶温度的升高,多孔材料的强度降低;样品在同一温度固溶处理随后在不同温度时效处理时,随着时效温度的升高,多孔材料的强度升高。如果样品不经固溶处理直接进行时效处理时,样品强度最低。与具有相同孔隙特征的纯Ti、Ti-6Al-4V、Ti2448合金等多孔材料相比,Ti55531合金多孔材料具有更高的强度,但其塑性较差[3,17]。

图11

图11

热处理后Ti55531多孔材料压缩应力-应变曲线和压缩强度

Fig.11

Compressive stress-strain curves (a) and compressive strength (b) of the porous Ti55531 specimens after different heat treatments

3 分析讨论

3.1 热处理对Ti55531合金多孔材料孔梁母材力学性能影响机制

金属材料的力学性能与其显微组织密切相关。对于钛合金来说,时效处理导致的强度提高主要与热处理过程中形成的αs相含量及形貌有关,而αp相的含量、形貌及分布主要影响材料的塑性[18~20]。在本工作中,对Ti55531合金在相变点以上固溶处理随后时效处理,样品中析出相全部为αs相。αs相为钛合金中的强化相[18,19],因此造成该合金强度显著提高。由于αs相大都从β晶内析出,晶界的强度与晶内差别过大,造成材料过早地在晶界处失效,导致材料塑性降低[20]。对于未经固溶处理直接时效处理的样品,其析出相也全为αs相,但相较于900℃固溶后时效样品,由于SLM成形过程中的快速凝固特性,使合金组织中存在高密度位错和较大的残余内应力[21,22],造成了其时效过程中优先形核质点更多[23],促进了αs相形核,使得αs相含量更高,且αs相的尺寸更加细小,其晶内的强度与晶界处差别更大,造成其塑性更低。

对Ti55531合金在相变点以下固溶处理时,在其β晶界和晶内有αp相生成。晶界处不连续的αp相能够强化晶界,降低晶界和晶内的强度差,避免材料从晶界过早开裂的倾向,晶内的αp相能够协调与αs相的变形,因此αp相的析出有利于提高材料的塑性。随着固溶温度的提高,α相形核驱动力降低,热力学稳定性减弱,导致保留到室温的αp相减少[24,25],因此Ti55531合金塑性降低。而晶粒内部αp相减少为随后时效过程αs相的析出提供了更多的析出空间,导致αs相析出数量增加,材料强度提高。当Ti55531合金在同一温度固溶处理后再经不同温度时效处理时,由于固溶温度相同,αp相的形貌及含量相同,其力学性能的变化主要与αs相形貌和含量有关。随着时效温度的升高,为αs相的生长提供了更大的驱动力,同时降低了αs相的成核速率[26],使得αs相的尺寸有所增加,根据Hall-Patch关系,材料强度降低。而αs相尺寸增加,在塑性变形过程中会激活更多的滑移系,使得材料的塑性有所提高[27,28]。

3.2 热处理对Ti55531合金多孔材料力学性能影响机制

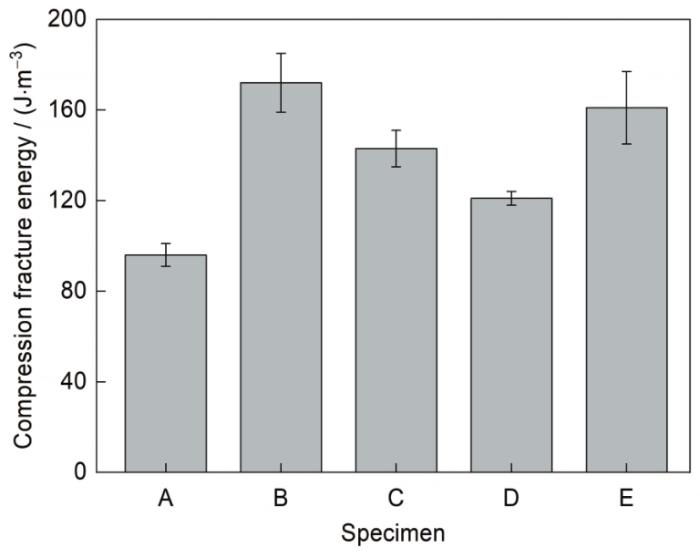

上述实验结果表明,热处理后Ti55531合金多孔材料强度呈现出与其孔梁母材强度完全不同的变化趋势。在增材制备过程中,由于多孔材料孔梁表面存在未熔融和半熔融黏附粉末颗粒,使其表面非常粗糙,形成凹凸不平的表面,这是增材制造多孔材料的一个特点[29,30]。在压缩变形过程中,容易在孔梁表面凹坑处形成应力集中,促进裂纹的形成,造成孔梁还未达到孔梁母材本征强度的最大值就过早失效,降低了多孔材料结构的强度,因此热处理后孔梁母材强度最高时其对应的多孔材料强度并未达到最高值,2者呈现出不同的变化趋势。材料抵抗裂纹形成与扩展的能力主要与材料韧性有关[31,32]。为使材料具有较高的抵抗裂纹生成的能力,要求材料具有较高的韧性。韧性一般可以定性地表示为材料在断裂前吸收能量和进行塑性变形的能力,其大小与其强度和塑性的匹配密切相关。为表征材料强度、塑性与韧性的关系,温茂萍等[33]提出断裂能的概念,断裂能是指试样在拉伸或压缩过程中,在裂纹出现前单位体积所吸收的能量,其计算公式为[33]:

图12

图12

不同热处理后Ti55531合金多孔材料孔梁母材压缩断裂能

Fig.12

Compression fracture energies of the parent materials of porous Ti55531 specimens after different heat treatments

4 结论

(1) SLM制备的Ti55531合金多孔材料,在750~900℃之间进行固溶处理后在500~600℃之间进行时效处理。固溶时效处理后,孔梁组织由α相和β相组成。

(2) 随着固溶温度升高,孔梁组织中αp相含量减少,αs相含量增加,孔梁母材的抗压强度升高,塑性降低,使得压缩断裂能降低,韧性变差。随着时效温度的升高,孔梁组织中αp相形貌、尺寸和含量无明显变化,αs相的含量减少,尺寸增加,孔梁母材抗压强度降低,塑性增加,使得压缩断裂能增加,韧性变好。

(3) 钛合金多孔材料抗压强度与其孔梁母材韧性密切相关。通过热处理调节材料强度和塑性匹配,提高其韧性,能够有效改善多孔材料的压缩强度。

参考文献

Research status of biomedical porous Ti and its alloy in china

[J].

医用多孔Ti及钛合金的国内研究现状

[J].

Fatigue behavior of Ti-6Al-4V cellular structures fabricated by additive manufacturing technique

[J].Porous titanium and its alloys have been considered as promising replacement for dense implants, as they possess low elastic modulus comparable to that of compact human bones and are capable of providing space for in-growth of bony tissues to achieve a better fixation. Recently, the additive manufacturing (AM) method has been successfully applied to the fabrication of Ti-6Al-4V cellular meshes and foams. Comparing to traditional fabrication methods, the AM method offers advantages of accurate control of complex cell shapes and internal pore architectures, thus attracting extensive attention. Considering the long-term safety in the human body, the metallic cellular structures should possess high fatigue strength. In this paper, the recent progress on the fatigue properties of Ti-6Al-4V cellular structures fabricated by the AM technique is reviewed. The various design factors including cell shapes, surface properties, post treatments and graded porosity distribution affecting the fatigue properties of additive manufactured Ti-6Al-4V cellular structures were introduced and future development trends were also discussed.

Enhanced fatigue characteristics of a topology-optimized porous titanium structure produced by selective laser melting

[J].

Dynamic behavior of 3D printed graded gyroid structures under impact loading

[J].

3D打印梯度Gyroid结构的动态冲击响应

[J].

A finite element study on the effects of disorder in cellular structures

[J].The susceptibility to deformation localization of simple cubic arrangements of struts, which are a simple approximation of the micro-architecture in cancellous bone, is analyzed. The coherence between structural disorder and the tendency towards deformation localization is investigated and its relevance from a biological point of view is discussed. A systematic study on the spatial deformation distribution of regular and disordered open cell structures is carried out. To this end, finite element models are employed which account for elastic-plastic bulk material and large strain theory, and a methodology for the estimation of the degree of deformation localization is introduced.

Cell shape effect evaluation of polyamide cellular structures

[J].

Influence of cell shape on mechanical properties of Ti-6Al-4V meshes fabricated by electron beam melting method

[J].Ti-6Al-4V reticulated meshes with different elements (cubic, G7 and rhombic dodecahedron) in Materialise software were fabricated by additive manufacturing using the electron beam melting (EBM) method, and the effects of cell shape on the mechanical properties of these samples were studied. The results showed that these cellular structures with porosities of 88-58% had compressive strength and elastic modulus in the range 10-300MPa and 0.5-15GPa, respectively. The compressive strength and deformation behavior of these meshes were determined by the coupling of the buckling and bending deformation of struts. Meshes that were dominated by buckling deformation showed relatively high collapse strength and were prone to exhibit brittle characteristics in their stress-strain curves. For meshes dominated by bending deformation, the elastic deformation corresponded well to the Gibson-Ashby model. By enhancing the effect of bending deformation, the stress-strain curve characteristics can change from brittle to ductile (the smooth plateau area). Therefore, Ti-6Al-4V cellular solids with high strength, low modulus and desirable deformation behavior could be fabricated through the cell shape design using the EBM technique. Copyright © 2014 Acta Materialia Inc. All rights reserved.

Fabrication and deformation of three-dimensional hollow ceramic nanostructures

[J].Creating lightweight, mechanically robust materials has long been an engineering pursuit. Many siliceous skeleton species--such as diatoms, sea sponges and radiolarians--have remarkably high strengths when compared with man-made materials of the same composition, yet are able to remain lightweight and porous. It has been suggested that these properties arise from the hierarchical arrangement of different structural elements at their relevant length scales. Here, we report the fabrication of hollow ceramic scaffolds that mimic the length scales and hierarchy of biological materials. The constituent solids attain tensile strengths of 1.75 GPa without failure even after multiple deformation cycles, as revealed by in situ nanomechanical experiments and finite-element analysis. We discuss the high strength and lack of failure in terms of stress concentrators at surface imperfections and of local stresses within the microstructural landscape. Our findings suggest that the hierarchical design principles offered by hard biological organisms can be applied to create damage-tolerant lightweight engineering materials.

Ultralight, ultrastiff mechanical metamaterials

[J].The mechanical properties of ordinary materials degrade substantially with reduced density because their structural elements bend under applied load. We report a class of microarchitected materials that maintain a nearly constant stiffness per unit mass density, even at ultralow density. This performance derives from a network of nearly isotropic microscale unit cells with high structural connectivity and nanoscale features, whose structural members are designed to carry loads in tension or compression. Production of these microlattices, with polymers, metals, or ceramics as constituent materials, is made possible by projection microstereolithography (an additive micromanufacturing technique) combined with nanoscale coating and postprocessing. We found that these materials exhibit ultrastiff properties across more than three orders of magnitude in density, regardless of the constituent material. Copyright © 2014, American Association for the Advancement of Science.

Approaching theoretical strength in glassy carbon nanolattices

[J].The strength of lightweight mechanical metamaterials, which aim to exploit material-strengthening size effects by their microscale lattice structure, has been limited by the resolution of three-dimensional lithography technologies and their restriction to mainly polymer resins. Here, we demonstrate that pyrolysis of polymeric microlattices can overcome these limitations and create ultra-strong glassy carbon nanolattices with single struts shorter than 1 mu m and diameters as small as 200 nm. They represent the smallest lattice structures yet produced-achieved by an 80% shrinkage of the polymer during pyrolysis-and exhibit material strengths of up to 3 GPa, corresponding approximately to the theoretical strength of glassy carbon. The strength-to-density ratios of the nanolattices are six times higher than those of reported microlattices. With a honeycomb topology, effective strengths of 1.2 GPa at 0.6 g cm(3) are achieved. Diamond is the only bulk material with a notably higher strength-to-density ratio.

Influence of annealing treatment on microstructure and mechanical properties of graded structure Ti-6Al-4V alloys

[J].

退火处理对梯度多孔Ti-6Al-4V合金组织和力学性能的影响

[J].

Additive manufacturing of Ti-6Al-4V lattice structures with high structural integrity under large compressive deformation

[J].

Influence of heat treatment process on microstructure and tensile property of Ti55531 titanium alloy

[J].

热处理工艺对Ti55531钛合金显微组织与拉伸性能的影响

[J].

Thermomechanical processing of Ti-5Al-5Mo-5V-3Cr

[J].

Effects of heat treatment processes on microstructure and tensile properties of Ti55531 alloy

[J].

热处理工艺对Ti55531合金组织和拉伸性能的影响

[J].

Compressive and fatigue behavior of beta-type titanium porous structures fabricated by electron beam melting

[J].

Alloying and heat treatment of structural (α + β) titanium alloys of high and superhigh strength

[J].

Aging response of coarse-and fine-grained β titanium alloys

[J].

The effect of post-processing heat treatment on the microstructure, residual stress and mechanical properties of selective laser melted 316L stainless steel

[J].

Origin of dislocation structures in an additively manufactured austenitic stainless steel 316L

[J].

Aging-hardening behavior and phase transition kinetics of a novel β-Ti alloy

[J].

新型β钛合金的时效机制和相变动力学研究

[J].

The relationship of heat treatment-microstructures-mechanical properties of the TC18 titanium alloy

[J].

TC18钛合金的组织和性能与热处理制度的关系

[J].

Influence of heat treatment on microstructure and mechanical properties of a high-strength Zr-Ti alloy

[J].Due to the high stress, relative low density and excellent resistance of radiation, Zr-based alloys have become promising structural materials used in the space environment. The relationship between microstructure and mechanical properties is the key issue for designing Zr-based alloy in different alloy systems and has attracted extensive research interests. The microstructures could be adjusted by different processes of heat treatment and thus realizing the optimization of mechanical properties. In this work, the initial microstructure and mechanical properties of a high strength Zr47Ti45Al5V3 (mass fraction, %) alloy was investigated. The XRD results reveal that the initial Zr-based alloy is consisted of α (hcp) and β (bcc) phases. Transmission electron microscopy result shows that the lathy α phase homogenously distributed within the β phase matrix. Mechanical tests of this alloy show very high strength but limited plasticity. The tensile strength is 1648 MPa. However, the tensile elongation is only 0.8%. DSC trace indicates that the transition temperature of α phase to β phase is located between 560~750 ℃ that provides the possibility to adjust the microstructures through different processes of heat treatment. In order to optimize the mechanical properties, several different processes of heat treatment were conducted on this Zr-based alloy, and the relative volume fraction of α and β phase is successfully adjusted. According to the mechanical tests, the plasticity becomes larger as the amount of β phase increases with a slight decrease in strength. When the volume fraction of β phase is about 60%, the alloy exhibits the optimal mechanical performance with a tensile strength of 1398 MPa and an elongation of 3.1%.

热处理对一种高强Zr-Ti合金组织和力学性能的影响

[J].

Effect of aging heat treatment on microstructure and tensile properties of a new β high strength titanium alloy

[J].

Property optimization through microstructural control in titanium and aluminum alloys

[J].

Room temperature deformation and mechanisms of slip transmission in oriented single-colony crystals of an α/β titanium alloy

[J].

Analysis on powder adhesion problems in selective laser melting forming process

[J].

激光选区熔化成型过程的粉末粘附问题分析

[J].

Sidewall precision analysis of metal part formed by selective laser melting

[A].

激光选区熔化增材制造零件侧壁成型精度分析

[A].

A generalized Paris' law for fatigue crack growth

[J].

Investigation on fracture toughness and crack growth mechanism of high-strength steels

[D].

高强钢断裂韧性与裂纹扩展机制研究

[D].