如何调控层状结构金属材料的微观结构从而进一步优化其力学性能已有诸多研究,大多集中在组元厚度[1,2,19,20]、组元力学性能差异[13,21,22]、组元分布[14,23,24]等方面。组元厚度的改变会明显影响层状结构的力学性能,当组元厚度从微米减小至纳米尺度,层状结构的强度明显提升,强度-塑性匹配更优。例如,Cu/Cu10Zn层厚从250 μm减小到31 μm,强度和塑性同步提升[25];而Cu-Nb的层厚从1.8 μm减小到15 nm,其强度单调增加,同时还保留了一定的断裂伸长率[26]。层厚减小时,变形过程中位错在层内累积产生类似Hall-Petch模式的强化效果或者单根位错在层内受限滑移产生强化,使得层状结构的强度得到提升[27];另一方面界面附近产生的GND可以提高层状结构的加工硬化能力和塑性[25]。增大组元间的硬度或强度、加工硬化差异,可促进存储更高密度GND,更大程度协调变形不兼容性,改善材料力学性能。例如,组元间硬度差异更大的Cu/Cu30Zn[21]相较于Cu/Cu10Zn,能够产生更高的背应力;而相对于组元间强度差异相同的Cu/Cu32Zn,加工硬化差异更大的Cu/Cu4Zn[13]样品中强化效果更加明显。

此外,组元占比(硬/软组元的体积分数)也是影响层状结构金属材料力学性能的重要因素。Liang等[23]研究了不同Cu/Ni组元占比的三明治结构Ni/Cu/Ni的拉伸断裂行为,Cu组元占比为74% (Cu/Ni层厚比为5.62)时材料强度和韧性断裂的匹配最优,这归因于Ni层对Cu层应变局域化的显著约束作用。Wu等[28]将梯度结构无间隙原子钢(IF钢)视为由两表面梯度纳米晶层和芯部粗晶层构成的三明治层状结构,所测得的屈服强度显著高于混合法则,具有显著的额外强化,并且当梯度纳米晶层的体积分数由16%增加到48%时,额外强化逐渐增大,这主要归因于梯度纳米晶层与粗晶层之间的梯度变形行为和相互约束作用。然而,目前层状结构材料多以纳米晶为组元,在变形过程中常发生晶粒长大[29,30]、位错回复[18]等软化行为,难以在实验中澄清组元占比与组元间约束变形行为及额外强化之间的定量关系。

1 实验方法

均匀纳米孪晶(HNT) Cu样品利用直流电解沉积技术制备获得。电解液为Cu2+浓度为80 g/L的高纯CuSO4溶液,pH = 1。电解液温度分别为20和40℃时,制备2种微观结构尺寸的均匀组元纳米孪晶样品[33],分别命名为HNT-

利用Nova NanoSEM 460场发射扫描电镜(SEM)背散射(BSE)模式和Tecnai G2 F20透射电子显微镜(TEM)表征HNT Cu和LNT Cu样品的截面微观结构。对于组元

使用Instron 5848微型拉伸试验机进行室温单轴拉伸测试,应变速率为5 × 10-3 s-1。拉伸试样为平板狗骨头状,标距段尺寸为5 mm × 2 mm× 0.4 mm,每组样品至少测试3次以确保数据的可重复性。采用Qness Q60A+显微Vickers硬度计测试样品截面沿厚度方向的硬度分布,施加载荷为50 g,保载时间10 s,每个厚度处测试5次得到平均硬度。

用基于数字图像相关(DIC)的全场应变技术在拉伸过程中原位观测拉伸试样上表面的应变分布。DIC测试前在试样表面先喷白漆作为背底,后喷黑色墨点作为散斑。采用连续拍摄模式采集样品变形过程中的形貌照片,镜头像素分辨率为2.9 μm/pixel,采集速率为1 frame/s。为保证图像采集的清晰度,原位拉伸时应变速率降低为1 × 10-3 s-1。利用LEXT OLS4000激光共聚焦显微镜(CLSM)表征拉伸试样侧表面变形前后的高度起伏,其高度差分辨率为10 nm。测试前样品经过机械抛光处理以保持表面平整,拉伸变形前后测量同一位置的高度起伏,对各厚度处的高度起伏进行平均。W0为样品初始宽度,根据样品两侧各厚度处拉伸变形前后平均高度差值的净变化(ΔH)计算相对侧向应变(Δεy)[34]:

2 实验结果

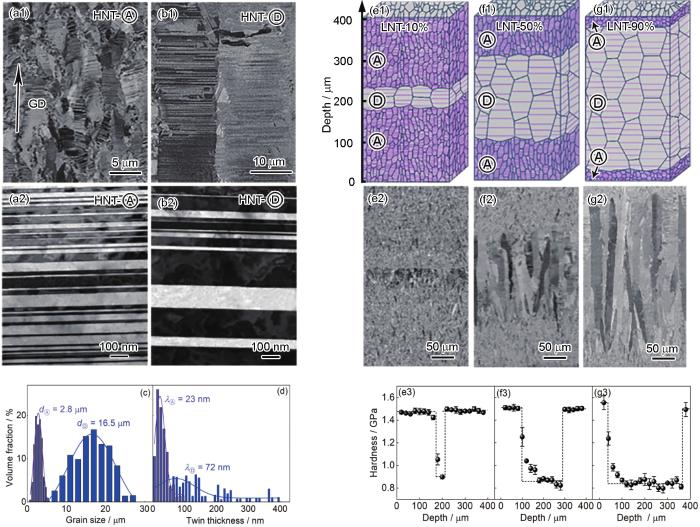

图1

图1

制备态2种均匀组元纳米孪晶(HNT) Cu的微观结构和晶粒尺寸、孪晶片层厚度,及3种不同组元占比层状纳米孪晶(LNT) Cu微观结构和沿深度方向的硬度分布

Fig.1

SEM and TEM images of HNT-

图1e1~g1和e2~g2所示分别为3种制备态LNT Cu样品沿生长方向的截面微观结构示意图和SEM像。所有样品上下表层均为硬组元

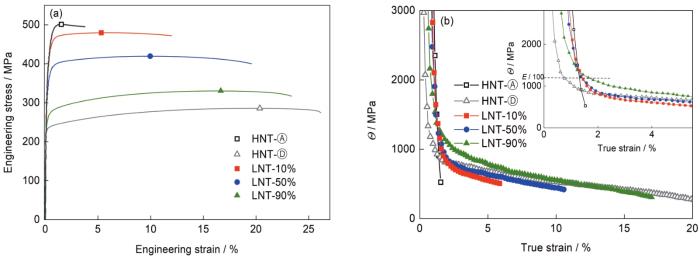

图2

图2

HNT Cu和LNT Cu的拉伸工程应力-应变曲线和加工硬化率-真应变曲线

Fig.2

Engineering stress-strain curves (a) and work hardening rate (Θ) vs true strain curves (b) of LNT Cu and HNT Cu (The endings of elastic-plastic transition are indicated by the intersections of work hardening curves with the dash line at Θ = E / 100 in the inset of Fig.2b, where E is Young's modulus of Cu (120 GPa))

与HNT结构相比,LNT结构具有更好的强度-塑性匹配。相比于HNT-

表1 LNT Cu和HNT Cu的室温拉伸性能

Table 1

| Sample | σy / MPa | σuts / MPa | δu / % | |

|---|---|---|---|---|

| LNT-10% | 425 ± 12 | 465 ± 12 | 5.7 ± 0.7 | 2.9 ± 2.9 |

| LNT-50% | 372 ± 13 | 419 ± 2 | 9.9 ± 0.5 | 13.4 ± 4 |

| LNT-90% | 262 ± 9 | 328 ± 3 | 17.0 ± 0.9 | 8.3 ± 3.7 |

| HNT- | 434 ± 9 | 501 ± 14 | 1.6 ± 0.1 | - |

| HNT- | 221 ± 13 | 281 ± 6 | 21.7 ± 1.6 |

从图2b可以看出,HNT-

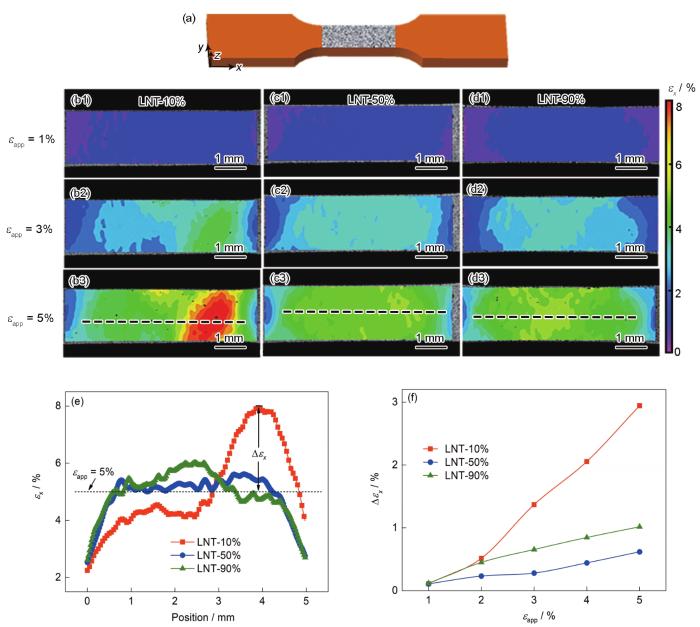

图3

图3

LNT Cu拉伸试样和标距段表面散斑示意图,不同拉伸应变下沿x轴方向的应变(εx )分布,拉伸应变5%时的应变分布曲线和应变局域化程度(Δεx )测量示意图,及Δεx 随拉伸应变的变化趋势

Fig.3

Illustration of tensile specimen and spackle pattern on gauge area (a), strain distributions along x axial (εx ) on the surfaces of LNT-10% (b1-b3),LNT-50% (c1-c3), and LNT-90% (d1-d3) at different applied tensile strains (εapp), εx distribution profiles of three LNT Cu samples at εapp = 5% (e) (measured along the white transverse lines in Figs.3b3-d3), and Δεx of three LNT Cu samples at different εapp (f) (Δεx is the increased value between the maximal εx and εapp, as illustrated in Fig.3e)

梯度塑性变形也是层状结构金属材料的重要塑性变形行为特征。图4a所示为拉伸试样在变形前后侧表面(x-z平面)的高度起伏测量区域。相对于变形前(εapp = 0)侧表面较微弱的高度起伏(图4b1~d1),拉伸变形后(εapp = 6%) 3种LNT Cu样品侧表面均表现出明显的高度起伏(图4b2~d2)。从图4b2可见,LNT-10%样品中间区域(白色虚线所围区域)的高度较低,即侧向收缩量或应变量较大,表明样品侧面也表现出显著的应变局域化,这与图3b3观察的现象一致。与LNT-10%不同,LNT-50%和LNT-90%侧面均无应变局域化现象,而呈现出明显的梯度变形行为(图4c2和d2),芯部软组元的高度低于两侧硬组元,即组元

图4

图4

LNT Cu拉伸变形前后侧表面高度起伏轮廓和分布曲线以及相对侧向应变(Δεy)分布

Fig.4

Illustration of tensile specimen and the observed area (a), CLSM images (b1-d1, b2-d2) and corresponding average height profile (b3-d3) and average relative lateral strain (Δεy) (b4-d4) of LNT-10% (b1-b4), LNT-50% (c1-c4), and LNT-90% (d1-d4) deformed at εapp = 0 and 6%, respectively (The area closed by white dashed lines in Fig.4b2 indicates the strain localization zone. |Δε

根据侧表面的高度起伏,能够进一步获得相对侧向应变Δεy的分布。将侧向高度沿拉伸方向(x轴)平均,可得到平均高度沿着样品厚度方向(z轴)的分布(图4b3~d3)。将拉伸变形后(εapp = 6%)的平均高度减去变形前平均高度,则获得高度起伏的净变化ΔH,由此根据

相反,LNT-50%中(图4c4)表层组元

不同组元占比造成的不同程度的抑制应变局域化和梯度塑性变形会导致微观结构演变产生差异,为探究这种差异,在3种LNT Cu样品拉伸断口附近选取变形量相近(截面收缩真应变εT ≈ 35%)的区域进行微观结构观察。从图5可以看出,3种样品严重塑性变形后的微观结构明显不同。LNT-10%中出现贯穿晶粒的剪切变形带(图5a1和a2虚线所围区域),表现出明显的局域剪切变形特征[37]。组元

图5

图5

3种LNT Cu拉伸试样断口附近硬组元

Fig.5

Microstructures of hard component

3 分析讨论

以上实验结果表明,LNT Cu具有良好的强度-塑性匹配,而且组元占比显著影响其力学性能。随着软组元占比增加,LNT Cu的强度降低,塑性却显著升高。对于非均匀结构材料,通常利用混合法则估算其屈服强度

式中,fi 为某组元i占比,

式中,

层状纳米结构的强化行为与其非均匀变形及相互约束行为密切相关[17,39]。这种非均匀变形及相互约束行为来源于两组元不协调的塑性变形,不仅体现在变形初期的弹塑性转变阶段,而且体现在大应变的塑性变形阶段。一般来说,受到外力作用之后,均匀组元软取向的晶粒优先发生塑性变形,而硬取向晶粒塑性变形滞后,由软取向到硬取向晶粒逐渐塑性变形的过程即为弹塑性转变。而LNT Cu在变形初期,除了组元中晶粒间的弹塑性转变之外,还存在软组元

除此之外,组元占比对约束作用的影响在塑性变形阶段还体现在各组元的梯度应变分布上。如图4c4和d4所示,LNT-50%和LNT-90%具有相同的宏观拉伸应变(εapp = 6%),但是其侧向应变分布却不相同。对于LNT-90%,硬组元

综上分析,通过改变软硬组元占比能够调控组元间在弹塑性转变和塑性变形阶段的约束作用程度,进而影响层状纳米结构金属材料的力学性能与变形行为。根据以往研究[2,18,28,39],包括层状结构在内的非均匀结构材料的强化机制一方面来源于组元间存储的GND,其密度与塑性应变梯度成正比,另一方面来源于组元间的约束作用,通过产生多轴的应力状态,促进位错储存。与LNT-90%相比,LNT-50%虽然其塑性应变梯度较小,却具有较大的约束作用和较强的位错储存能力,从而表现出较高程度的额外强化。因此,组元间的约束作用可能是主导组元占比影响LNT Cu额外强化的内在机制。以上结果为高性能层状结构金属材料的发展提供了思路,并对其他含有软硬组元的非均匀结构如梯度结构[42]、双模结构[43]、球壳结构[44]等金属材料的发展具有重要启示作用。

4 结论

(1) LNT Cu的组元占比对其力学性能影响明显。由LNT-10%到LNT-90%,屈服强度从425 MPa下降至262 MPa,均匀延伸率由5.7%增加至17.0%;LNT Cu屈服强度均大于组元混合强度,表现出不同程度的额外强化,当软硬组元占比相当时LNT-50%的额外强化最大,达到13.4%。

(2) LNT Cu组元占比明显影响弹塑性转变阶段和塑性变形阶段两组元间的不协调的塑性变形及相互约束行为。软组元占比较低或较高时,组元间约束作用较小。当软硬组元占比相当时,LNT-50%内的约束作用最强,弹塑性转变区明显变短,塑性变形阶段的应变局域化几乎被完全抑制,组元间侧向应变差减小,变形更加协调。

参考文献

Enhanced hardening in Cu/330 stainless steel multilayers by nanoscale twinning

[J].

Interface affected zone for optimal strength and ductility in heterogeneous laminate

[J].

Tailoring nanostructured, graded, and particle-reinforced Al laminates by accumulative roll bonding

[J].

Development of multilayer steels for improved combinations of high strength and high ductility

[J].

Role of layered structure in ductility improvement of layered Ti-Al metal composite

[J].

Enhancement of shear stability of a Fe-based amorphous alloy using electrodeposited Ni layers

[J].Tensile and fracture behaviors of sandwich-structured composites consisting of a Fe-based amorphous layer with a constant thickness and ultrafine-grained Ni layers with different thicknesses were investigated. The results indicate that the initiation and the stable propagation of the shear band in the amorphous layer was dominated by the Ni layers due to their strong constraint role. The catastrophic fracture of the amorphous layer was postponed in the sandwich composites through properly increasing the constrained Ni layer thickness, which effectively decreased the shear stress on the shear fracture planes of the amorphous layer, and thus led to stable propagation of the primary SB characterized by the increase in the smooth region size of the shear band.

The deformation of plastically non-homogeneous materials

[J].

Strain gradient plasticity: Theory and experiment

[J].

Mechanism-based strain gradient plasticity—I. Theory

[J].

Gradient plasticity in gradient nano-grained metals

[J].

Geometrically necessary dislocations and strain-gradient plasticity: A few critical issues

[J].

Geometrically necessary dislocation and size-dependent plasticity

[J].

Effect of work hardening discrepancy on strengthening of laminated Cu/CuZn alloys

[J].To clarify the work hardening discrepancy effect on the strengthening of laminated metals, we designed two laminated Cu/Cu4Zn and Cu/Cu32Zn samples with different layer thicknesses. Cu/Cu4Zn has larger work hardening discrepancy between two constituent layers relative to Cu/Cu32Zn, but the yield strengths of two CuZn constituents are comparable. Uniaxial tensile results suggest Cu/Cu4Zn with larger work hardening discrepancy exhibits a significant strengthening at early deformation stage while Cu/Cu32Zn possesses a better ductility. The underlying mechanisms for the strengthening effect are attributed to more geometrically necessary dislocations accumulated at interfaces and severer strain localization due to the larger work hardening discrepancy.

Strain hardening and ductility in a coarse-grain/nanostructure laminate material

[J].

Perspective on hetero-deformation induced (HDI) hardening and back stress

[J].

The role of geometrically necessary dislocations in giving material strengthening

[J].

Gradient and lamellar heterostructures for superior mechanical properties

[J].

Extraordinary strain hardening by gradient structure

[J].Gradient structures have evolved over millions of years through natural selection and optimization in many biological systems such as bones and plant stems, where the structures change gradually from the surface to interior. The advantage of gradient structures is their maximization of physical and mechanical performance while minimizing material cost. Here we report that the gradient structure in engineering materials such as metals renders a unique extra strain hardening, which leads to high ductility. The grain-size gradient under uniaxial tension induces a macroscopic strain gradient and converts the applied uniaxial stress to multiaxial stresses due to the evolution of incompatible deformation along the gradient depth. Thereby the accumulation and interaction of dislocations are promoted, resulting in an extra strain hardening and an obvious strain hardening rate up-turn. Such extraordinary strain hardening, which is inherent to gradient structures and does not exist in homogeneous materials, provides a hitherto unknown strategy to develop strong and ductile materials by architecting heterogeneous nanostructures.

Interface-driven microstructure development and ultra high strength of bulk nanostructured Cu-Nb multilayers fabricated by severe plastic deformation

[J].

Mechanical properties of sputtered Cu/V and Al/Nb multilayer films

[J].

Improved back stress and synergetic strain hardening in coarse-grain/nanostructure laminates

[J].

Work hardening discrepancy designing to strengthening gradient nanotwinned Cu

[J].

Maximizing necking-delayed fracture of sandwich-structured Ni/Cu/Ni composites

[J].

Effect of amorphous layer thickness on the tensile behavior of bulk-sized amorphous Ni-P/crystalline Ni laminates

[J].

Mechanical properties of copper/bronze laminates: Role of interfaces

[J].

Tensile behavior and flow stress anisotropy of accumulative roll bonded Cu-Nb nanolaminates

[J].

Length-scale-dependent deformation mechanisms in incoherent metallic multilayered composites

[J].

Synergetic strengthening by gradient structure

[J].

Mechanical properties of nanocrystalline materials

[J].

Strain incompatibility and its influence on grain coarsening during cyclic deformation of ARB copper

[J].

Extra strengthening and work hardening in gradient nanotwinned metals

[J].\n Materials with structural gradients often have unique combinations of properties. Gradient-structured materials are found in nature and can be engineered. Cheng\n et al.\n made a structural gradient by introducing gradients of crystallographic twins into copper. This strategy creates bundles of dislocations in the crystal interiors, which makes the metal stronger than any of the individual components. This method offers promise for developing high-performance metals.\n

Dependence of dislocation structure on orientation and slip systems in highly oriented nanotwinned Cu

[J].

Effect of electrolyte temperature on microstructures of direct-current electrodeposited nanotwinned Cu

[J].Nanotwinned (NT) metals are promising structural materials due to their excellent combination of strength and ductility. These superior properties are strongly dependent on the microstructures i.e. the twin length (grain size), the twin thickness and the twin orientation. Understanding the synthesis process and growth mechanism of NT metals is essential for their structure design. In this work, the effect of electrolyte temperature on the microstructures of highly oriented NT Cu samples, including twin thickness and twin length (grain size), are systematically studied. The NT Cu samples were prepared by means of the direct-current electrodeposition at 293, 298, 303, 308 and 313 K, respectively, while other deposition parameters such as current density, concentration of additive and pH value were kept constant. With decreasing the temperature from 313 K to 293 K, the average grain size decreases from 27.6 μm to 2.8 μm and the average twin thickness decreases from 111 nm to 28 nm, which results in an increment of hardness from 0.7 GPa to 1.5 GPa. This is because with decreasing the temperature, the overpotential of cathode for depositing metal elevates, leading to the nucleation rate of both the grain and twin enhanced.

电解液温度对直流电解沉积纳米孪晶Cu微观结构的影响

[J].

The effect of gradient order on mechanical behaviors of gradient nanotwinned Cu

[J].

Epitaxial growth and electrode impedance of copper electrodeposits

[J].

Tensile behavior of columnar grained Cu with preferentially oriented nanoscale twins

[J].

Detwinning behavior induced by local shear strain in nanotwinned Cu

[J].

纳米孪晶Cu中局部剪切应变诱导的退孪生行为

[J].

Deformation of sandwich sheet materials in uniaxial tension

[J].

Heterostructured materials: Superior properties from hetero-zone interaction

[J].

Effect of variation in Poisson's ratio on plastic tensile instability

[J].Using the concept of the tensile-instability mechanism which determines the ultimate strength of most of the ductile materials under uniaxial or biaxial tension conditions, two new analyses are carried out. In these are considered an effect previously neglected: Variation of Poisson’s ratio (based on total strain) with strain in the plastic range. One analysis treats a uniaxial tensile specimen, and the predicted results are generally in better agreement with experimental values for seven alloys of aerospace structural importance than the results of classical theory, in which Poisson’s ratio is assumed to remain constant at a value of 1/2 in the plastic range. The other considers a thin-walled spherical shell subject to internal pressure, and the predicted result is again closer to the experimental value than that predicted by classical theory.

Role of internal stresses in co-deformed two-phase materials

[J].

Effect of volume fraction of gradient nanograined layer on high-cycle fatigue behavior of Cu

[J].

Effect of thermal annealing on mechanical properties of a nanostructured copper prepared by means of dynamic plastic deformation

[J].

Improvement of mechanical properties in SUS304L steel through the control of bimodal microstructure characteristics

[J].