组元占比对层状纳米孪晶Cu力学行为的影响

Effect of Component Proportion on Mechanical Behaviors of Laminated Nanotwinned Cu

组元占比对层状纳米孪晶Cu力学行为的影响 |

| 万涛, 程钊, 卢磊 |

|

Effect of Component Proportion on Mechanical Behaviors of Laminated Nanotwinned Cu |

| WAN Tao, CHENG Zhao, LU Lei |

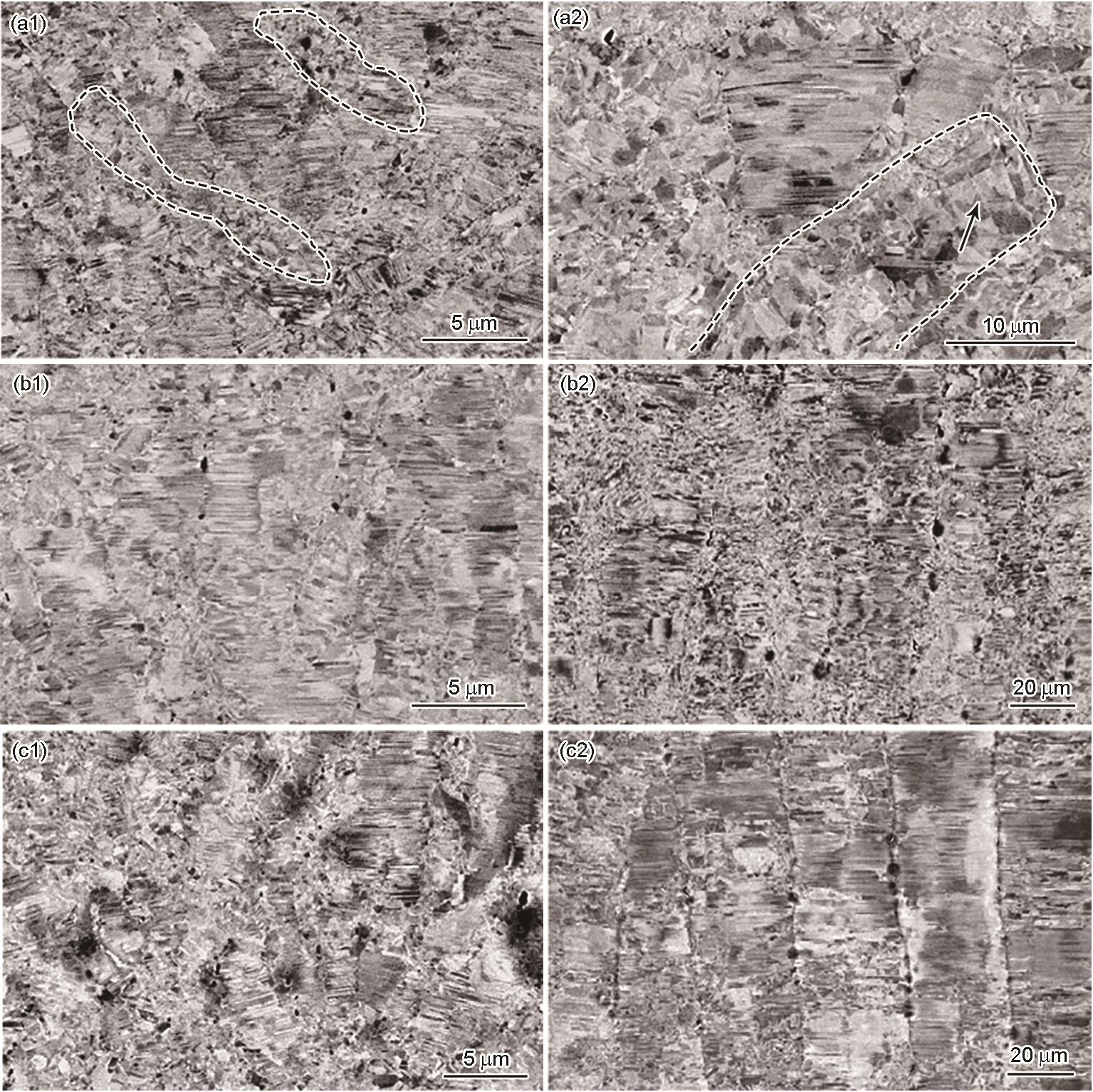

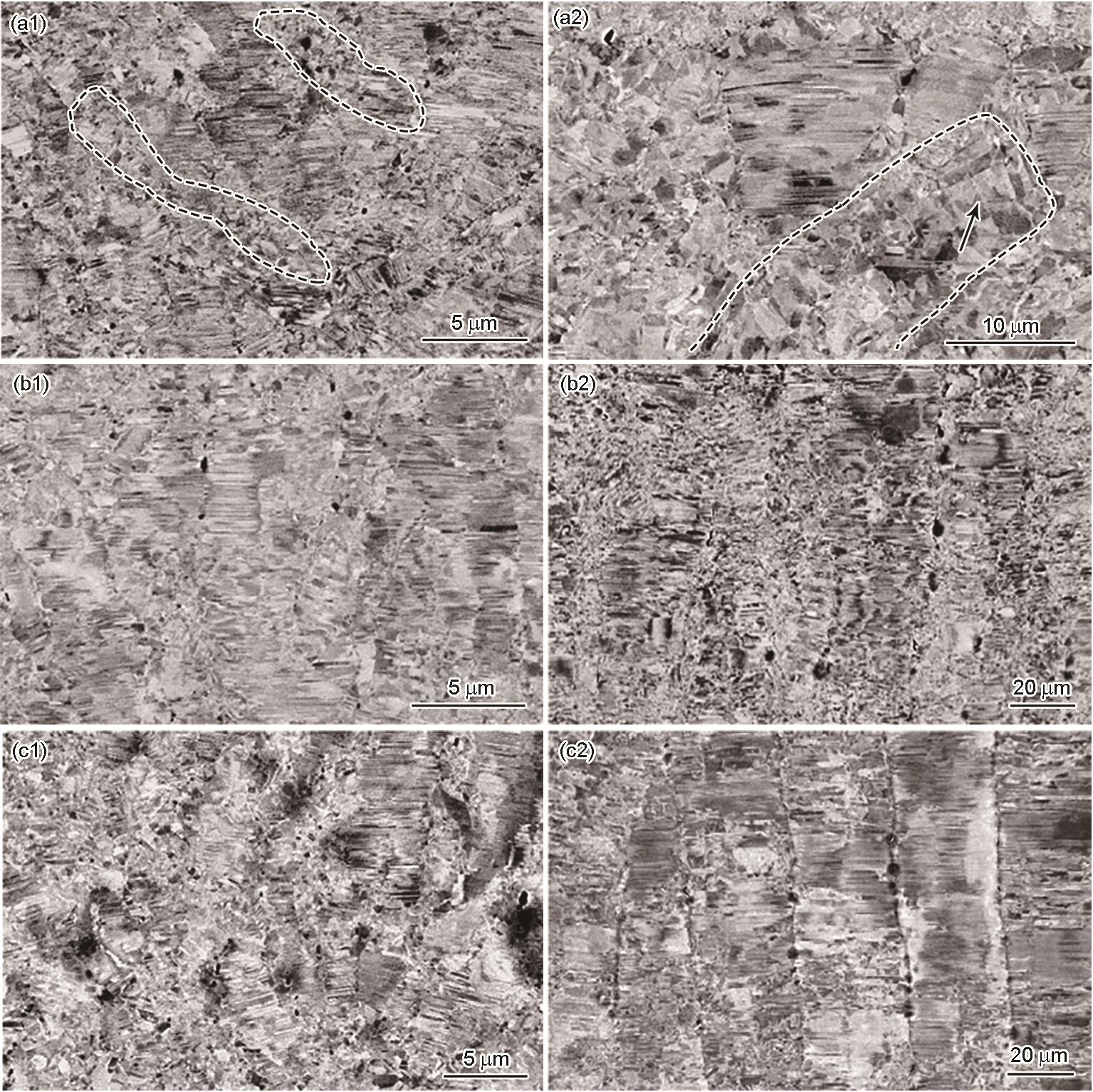

| 图5 3种LNT Cu拉伸试样断口附近硬组元 |

| Fig.5 Microstructures of hard component |

|