变形AlSi合金因具有良好的耐磨性能、低热膨胀系数以及高比强度等优异性能,在结构减重的大背景下已部分实现对传统耐磨合金的替代。以AlSi二元合金为基础的多元形变铝合金在航空航天及汽车领域的应用尤其广泛[1~3]。研究[4~6]表明,AlSi基多元合金的耐磨性能随着Si含量的增加以及Al基体强度的提升而提升。然而,利用传统铸造法制备的形变AlSi基合金存在如下缺陷:(1) 棱角锋利的长条状共晶Si相严重割裂了基体并导致形变时过高的应力集中,进而引发形变裂纹,降低合金的塑性[7];(2) Si含量的提升受到凝固速率的限制,通过半连续铸造法增加Si相含量来提高合金耐磨性、降低热膨胀系数的空间已经达到极限[8];(3) Al基体为尺寸粗大的树枝晶,不利于塑性以及基体强度和硬度的提升[9,10];(4) Al基体强化元素,如Cu、Mg等存在明显的宏观和微观偏析,导致性能不均匀[11]。因此,以极速冷却为特征的喷射成形技术[12,13]在制备超高Si含量的形变AlSiCuMg合金方面的研究意义重大。喷射成形技术包括熔体雾化和沉积成坯2个阶段。熔体雾化处理可以消除铸锭宏观偏析,大幅度降低微观偏析,并实现铸锭晶粒的等轴细化以及初生相颗粒的均匀分布。此外,103~104 K/s的冷却速率可在不做变质处理的前提下实现初生Si相的球化和细化。在沉积成坯阶段中,半固态雾化熔体对已凝固基体的冲击破碎作用则进一步细化了组织。目前,喷射成形技术已经可以制备工业规格的大尺寸过共晶AlSiCuMg合金铸锭,Si元素质量分数超过25%。

需要指出的是,与粉末冶金法类似,喷射成形铸锭也存在一定体积分数的喷射孔隙,需要通过热等静压或热挤压的方式予以消除。因此,现阶段喷射成形过共晶AlSiCuMg合金制品的工艺流程包括热挤压和强化热处理2个阶段。众所周知,在铝合金的热加工中,第二相粒子的存在及其分布特征将对合金的热变形行为产生不可忽视的影响,如增加形变抗力[14,15]、导致第二相与基体结合面萌生形变裂纹[16,17]、产生粒子激发形核(PSN)行为[18,19]、加速动态再结晶、降低合金板材的各向异性[20]等。如前所述,喷射成形Al25Si4Cu1Mg (质量分数,%,下同)合金中的Si粒子以及其他可能存在的初生相弥散分布于基体上,这势必对铝合金的动态软化行为以及各向异性等产生重要影响,进而影响合金塑性变形工艺的制定。鉴于此,本工作从晶粒形貌、形变亚结构以及初生粗大相在不同热变形条件下的演变规律方面,系统研究了喷射成形Al25Si4Cu1Mg合金的热变形行为,明确其动态软化机制,以期为该类高Si铝合金的热变形工艺开发提供理论参考。

1 实验方法

实验材料为喷射成形Al25Si4Cu1Mg合金圆柱形铸锭。热压缩实验在Gleeble-3500 热模拟试验机上进行,采用直径10 mm、长15 mm (样品的径向与铸锭的径向一致)的圆柱试样。热压缩时在试样两端面贴石墨片以减少摩擦,减轻侧翻、腰鼓等不均匀变形现象。压缩温度(Td)为623、673和723 K,每种温度下的应变速率(

在Merlin Compact型场发射扫描电镜(SEM)上观察第二相形貌和分布特征。分别利用INCA型能谱仪(EDS)和电子背散射衍射(EBSD)系统进行相成分、晶粒形貌及取向分析。EBSD测试步长为0.3 μm,用Channel 5软件分析晶界角度差以及晶粒取向等组织特征。在XRD-6000型X射线衍射仪(XRD)上对合金进行物相分析,扫描范围为15°~90°,扫描速率为1°/min。在JEM-2100F 型透射电镜(TEM)上观察变形态样品的亚结构。TEM测试的加速电压为200 kV。为避免粗大的初生相粒子脱落,在GATAN PIPSII型离子减薄仪上,采用多阶段逐次降低离子束能量和减薄入射角的方法进行TEM样品的制备。离子束能量控制在3~5 keV,减薄入射角范围为4°~8°,减薄时间为120 min。

2 实验结果

2.1 喷射态组织

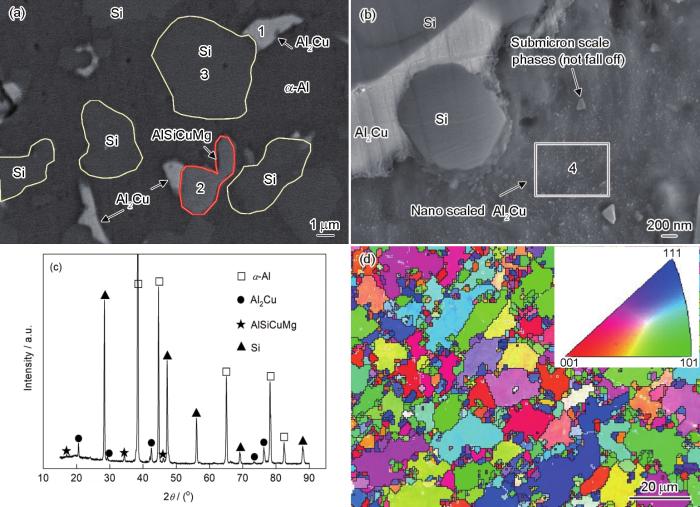

图1为喷射态Al25Si4Cu1Mg合金的SEM、EBSD像以及XRD谱。表1为图1a和b中不同初生相的EDS分析结果。结合物相和成分定量分析可知,喷射态组织包括α-Al基体、初生Si相、AlSiCuMg相以及Al2Cu相。其中,与α-Al基体颜色相近的暗灰色粗大相为初生Si相,其尺寸范围为2~6 μm。与半连续铸锭中的呈长条状的共晶Si相不同,喷射态初生Si相呈块状,且边缘光滑、无尖锐棱角,该组织特征可有效避免局部应力集中,减小形变裂纹的出现几率。与Si粒子伴生的不规则白灰色和亮白色粗大相分别为AlSiCuMg相和Al2Cu相,2者的体积分数和平均尺寸相对较低。3种初生相相邻伴生、呈岛状较为均匀地分布于铝合金基体之上。高倍组织观察发现,在粗大初生相间隙处的α-Al基体中还存在高体积分数的纳米级Al2Cu相(见图1b中方框内的白色析出相)。由EBSD观察可知,α-Al基体的晶粒尺寸范围为10~20 μm,微米级粗大初生相则主要分布于α-Al基体的晶界处(图1d)。大量多尺度脆性初生相的存在将影响位错的滑移,进而改变合金的热变形行为。

图1

图1

喷射态Al25Si4Cu1Mg合金的SEM像、XRD谱及反极图(IPF)

Fig.1

Low (a) and high (b) magnified SEM images, the XRD spectrum (c), and the corresponding inverse pole figure (IPF) (d) of as-sprayed Al25Si4Cu1Mg (mass fraction, %) alloy

表1 喷射态Al25Si4Cu1Mg合金第二相的EDS分析结果

Table 1

| Zone | Composition / (atomic fraction, %) | Phase | |||

|---|---|---|---|---|---|

| Al | Si | Cu | Mg | ||

| 1 | 61.83 | - | 38.17 | - | Crystalline Al2Cu |

| 2 | 17.29 | 32.87 | 12.31 | 37.53 | AlSiCuMg |

| 3 | 1.28 | 98.72 | - | - | Si |

| 4 | 97.03 | - | 2.97 | - | Precipitated Al2Cu |

2.2 真应力-真应变曲线

图2为合金在不同热变形条件下的真应力-真应变曲线。由图可知,喷射成形Al25Si4Cu1Mg合金的真应力随真应变增加而上升或下降的幅度强烈依赖于热压缩温度和应变速率。在相同应变下,真应力随形变温度的升高或者应变速率的降低而下降。固定应变速率和压缩温度,真应力随真应变的增加先快速上升,当达到峰值后出现不同程度的下降,最后趋于稳定。当应变速率低至0.001 s-1时,合金在623 K下的峰值应力快速升至约120 MPa,与应变速率为0.05 s-1时的峰值应力几乎相等,随后急剧下降,稳态流变应力只有62 MPa左右。当应变速率增加至5 s-1时,623 K下的峰值应力约为180 MPa,随后应力持续下降至约130 MPa。

图2

图2

喷射态Al25Si4Cu1Mg合金在623、673和723 K以及不同应变速率条件下的真应力-真应变曲线

Fig.2

True stress-true strain curves of as-sprayed Al25Si4Cu1Mg alloy deformation at 623 K, 673 K, and 723 K under strain rates of 0.001 s-1 (a), 0.01 s-1 (b), 0.05 s-1 (c), 0.1 s-1 (d), 1 s-1 (e), and 5 s-1 (f)

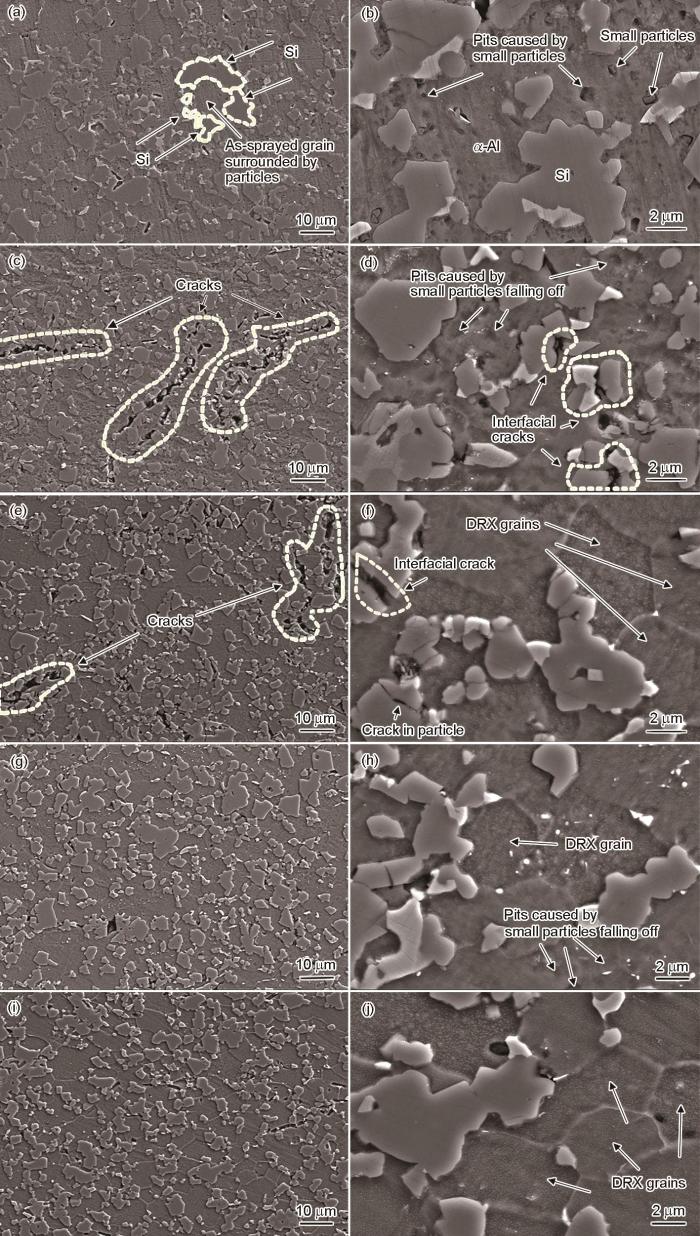

2.3 第二相演变

图3为喷射态与典型热变形条件下Al25Si4Cu1Mg合金试样的SEM像。一般来说,热压缩态组织的晶粒以及第二相会垂直于压缩方向延伸分布。但是喷射成形Al25Si4Cu1Mg合金热压缩态的组织形貌并未表现出方向性,这说明热压缩过程中发生了强烈的晶粒重组行为,完全改变了形变组织形貌。

图3

图3

Al25Si4Cu1Mg合金喷射态和不同热压缩条件下的SEM像

Fig.3

Low (a, c, e, g, i) and high (b, d, f, h, j) magnified SEM images of as-sprayed and as-deformed microstructures under typical conditions of Al25Si4Cu1Mg alloy (Td—deformation temperature,

(a, b) as-sprayed state (c, d) Td = 623 K,

由图3a和b可知,喷射态试样的晶粒被初生相包围,近似等轴状。α-Al基体中存在一定体积分数的凹坑,尺寸约为500 nm,这是由于小尺寸初生第二相的剥落所致(图3a和b)。对比图3c、e、g和i可知,高应变速率(5 s-1)诱发了形变裂纹。形变裂纹包括出现在粗大初生相与Al基体界面处的大尺寸裂纹(图3c和e),以及部分粗大相中的内部裂纹(图3d和f)。此外,当形变温度较低(< 723 K)时,Al基体内部依然保留大量尺寸约为500 nm的初生第二相粒子。与喷射态组织(图3b)类似,这些第二相小粒子在制样过程中部分脱落,从而留下凹坑(图3d和h)。当形变温度上升至723 K时(图3f和j),500 nm左右的小尺寸第二相基本消失,因此由粒子脱落所产生的凹坑也基本消失。随着形变温度从623 K上升至723 K,α-Al基体的晶粒轮廓逐渐清晰,表现为包含平直晶界的等轴晶。晶粒尺寸范围从喷射态的10~20 μm (图3b)减小至5~10 μm (图3f和j)。

图4

图4

Al25Si4Cu1Mg合金不同热压缩条件下的TEM像

Fig.4

TEM images of Al25Si4Cu1Mg alloy under different hot compression conditions

(a, b) primary Si particles and deformed grains at Td = 673 K,

(c) interaction between dislocations and nano-Si particles at Td = 623 K and

综上所述,喷射成形AlSiCuMg合金在热变形过程中发生了低温和高应变速率条件下的粗大脆性初生相的破碎、粗大相与α-Al基体界面处的开裂、高温变形条件下纳米细小初生相的回溶以及残余纳米相与位错的交互作用。

2.4 α-Al相的演变

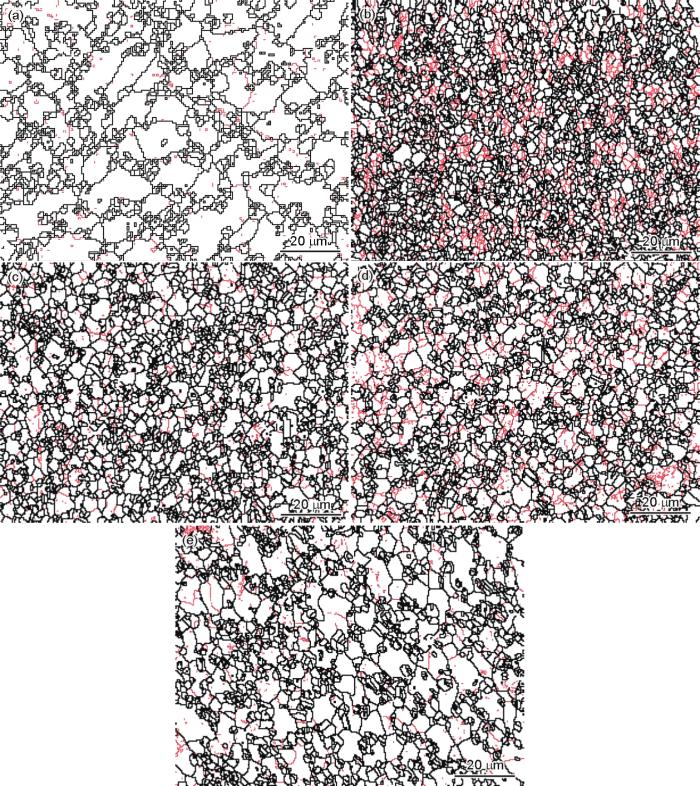

图5为Al25Si4Cu1Mg合金喷射态和不同热变形条件下样品的EBSD像。黑色粗实线表示大于15°的大角度晶界(或第二相粒子的界面),红色细实线表示2°~15°范围内的小角度晶界。与喷射态下粗大的α-Al晶粒(图5a)相比,热压缩态组织得到了明显的细化。等轴细化的晶粒说明喷射成形Al25Si4Cu1Mg合金在本工作的热变形条件下发生了充分的动态再结晶。在Td = 623 K、

图5

图5

Al25Si4Cu1Mg喷射态和不同热压缩条件下的晶粒组织形貌EBSD像

Fig.5

EBSD images of as-sprayed and deformed microstructures under different hot compressed conditions of Al25Si4Cu1Mg alloy (The grain boundaries colored by red indicate the misorientation in the range of 2°-15°. The grain boundaries colored by black indicate the misorientation > 15°)

(a) as-sprayed (b) Td = 623 K,

(d) Td = 673 K,

值得注意的是,723 K、5 s-1变形样品的亚结构密度低于673 K、0.05 s-1条件变形样品(图5c和d)。这说明喷射成形AlSiCuMg合金的动态再结晶行为对形变温度更加敏感。这首先是因为高温条件下位错的滑移与交滑移更容易进行。其次,从图4中尺寸约为500 nm的小尺寸第二相回溶情况的对比可知,723 K、5 s-1变形样品中细小第二相的回溶程度更高,这进一步减小了位错滑移以及亚晶界迁移的障碍,促进了异号位错的相互抵消和胞状组织的多边形化,进而产生了更高程度的动态再结晶。正是因为形变温度同时影响位错滑移能力和第二相(< 0.5 μm)体积分数,因此喷射成形Al25Si4Cu1Mg合金的形变亚结构随着形变温度的升高而减少。对比图5c和e可知,当变形温度(723 K)相同时,动态再结晶晶粒的尺寸随着应变速率的降低而增大。该现象的出现可以从以下2个方面进行解释:一方面,应变速率的增加提高了位错增殖速率,短时间即可达到再结晶形核所需的临界位错密度条件,进而提高了再结晶形核率,实现了晶粒细化;另一方面,在相同应变量和温度条件下,应变速率的降低使晶界有充足的迁移时间,导致再结晶晶粒长大。

3 分析讨论

铝合金的热变形是位错增殖导致的加工硬化与位错重组、晶界迁移产生的动态软化的竞争过程。高层错能合金因扩展位错窄,位错易束集,因此在热变形时更容易产生动态回复[20]。由于动态回复与动态再结晶的驱动力皆为形变储能,因而随着动态回复行为的加剧,动态再结晶行为被抑制[21]。研究表明,超高强AlZnMgCu合金的热变形行为即以动态回复为主,仅在高变形温度和较低的应变速率条件下,才会在原有大角度晶界处以“亚晶旋转、合并”[20,22]或“应变诱导晶界弓出”机制[23]形成细小的链状再结晶晶粒。由于动态回复行为不涉及大角度晶界的迁移,因此热压缩组织一般呈现扁平状形貌。然而由组织观察可知,喷射成形Al25Si4Cu1Mg合金经热压缩后的晶粒形貌依然表现为等轴状,这说明该合金发生了充分的动态再结晶。

喷射成形Al25Si4Cu1Mg合金的热变形激活能为194.8 kJ/mol[17],而纯Al和7055铝合金的热变形激活能大致为140 kJ/mol[24]。热变形激活能可反应合金热变形的难易程度。对比同样是高合金化但不包含粗大粒子的7055铝合金的应力-应变曲线[24]可知:喷射成形Al25Si4Cu1Mg合金的应变硬化速率更高,且相同热变形条件下的峰值应力水平高于超高强7055铝合金。但是随着应变量的增加,喷射成形Al-Si合金的应力下降幅度更大,甚至在更低的热压缩温度下(如本文中623 K)也表现出明显的动态软化行为。因此,粗大Si相粒子、Al2Cu以及AlSiCuMg第二相的存在是导致喷射成形Al-Si合金表现出不同于其他铝合金热变形行为的关键因素。

再结晶形核需要满足临界位错密度的要求。热压缩致使位错增殖,而粗大初生Si相、Al2Cu和AlSiCuMg相周围的位错密度更高。这一方面是因为脆性相与铝合金基体的应变不相容而产生的高密度“几何必需位错”[25]。另一方面,基体中位错滑移至粗大相前沿而形成位错塞积。当第二相前沿的位错密度积累到临界值时,则出现动态再结晶核心。再结晶核心随着变形的进行而持续长大。与此同时,后续变形继续促使位错增殖。当位错密度再次累积至临界值时,将发生第二轮再结晶。因此,在喷射成形Al25Si4Cu1Mg合金的热变形过程中,位错不断在粗大相与α-Al界面处塞积而引发动态再结晶。需要指出的是,再结晶晶粒的长大依赖于大角度晶界的迁移,而高体积分数的粗大初生相又可以阻碍晶界的迁移。因此,热压缩态Al25Si4Cu1Mg合金的再结晶晶粒尺寸明显低于喷射态。由图4c所示的位错与细小第二相粒子(< 0.5 μm)的交互作用可知,在形变温度较低的情况下,部分初生的纳米Al2Cu相在热变形过程中被保留下来。这些低密度第二相在热变形过程中也可阻碍位错运动,导致一定程度的位错缠结。但是此类Al2Cu相尺寸较小且密度较低,对位错的阻碍作用有限。与位错在粗大Si相前沿的塞积相比,此类位错塞积行为诱发动态再结晶的速率较慢。但是随着变形量的增加,局部位置也可能演变为再结晶核心继而长大成为再结晶晶粒。随着变形的不断进行,在已经再结晶的晶粒内部再次产生位错缠结,最终得到包含一定密度位错或亚结构的再结晶晶粒。

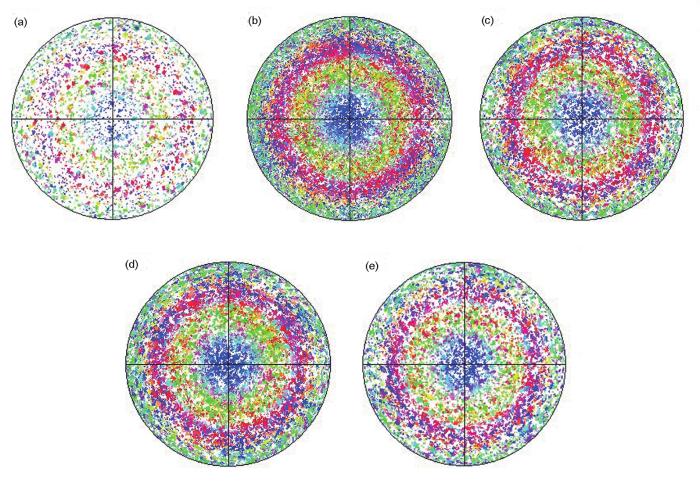

图6为Al25Si4Cu1Mg合金喷射组织和形变组织的{111}极图。结果表明,喷射组织和4种典型热变形组织都表现出随机取向。喷射成形过程不同于传统水冷结晶器内熔体的整体顺次凝固。喷射态组织来自于微米级雾化熔滴的二次冶金结合。熔滴取向差异导致喷射组织呈现随机取向。需要强调的是,形变铝合金常见的再结晶织构是Cube以及R-cube型。由前述实验分析可知,喷射成形Al25Si4Cu1Mg合金在热变形后发生了几乎完全的动态再结晶行为。假设没有高密度第二相粒子参与再结晶形核,那么喷射成形Al25Si4Cu1Mg合金的再结晶组织同样会存在Cube以及R-cube型织构取向,而不会表现出如图6b~e所示的随机取向分布特征。研究[26~29]表明,PSN机制恰恰能弱化再结晶织构,导致具有随机取向再结晶晶粒的形成。因此,喷射成形Al25Si4Cu1Mg合金的动态再结晶就是典型的PSN机制。这与高体积分数粗大初生相对动态再结晶行为的促进相一致。

图6

图6

Al25Si4Cu1Mg合金喷射态和不同条件热压缩组织对应的{111}极图

Fig.6

{111} pole figures of as-sprayed and hot deformed Al25Si4Cu1Mg alloy microstructure (extrude direction-normal direction section) under different deformation conditions

(a) as-sprayed state (b) Td = 623 K,

(d) Td = 673 K,

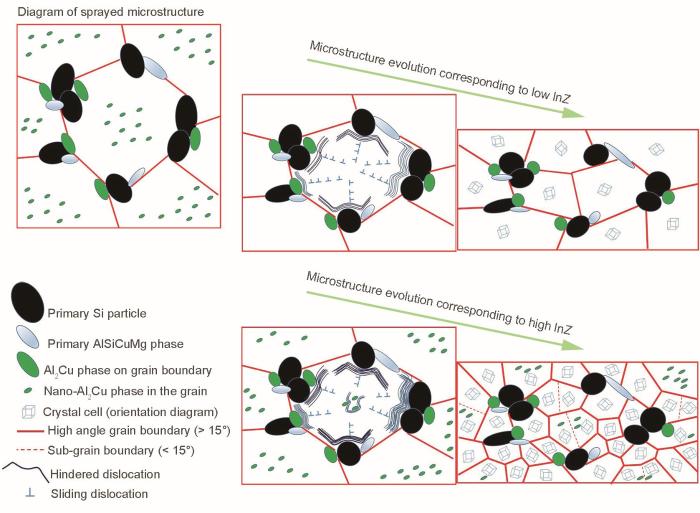

图7为喷射成形Al25Si4Cu1Mg合金在热变形过程中的组织演变示意图。由图可见,在喷射成形Al25Si4Cu1Mg合金的热变形过程中,位错一方面在粗大不可回溶和不可变形的Si、AlSiCuMg和Al2Cu相前沿产生塞积;另一方面,在低温变形条件下,残留的细小第二相也可导致一定的位错缠结(结合图4c)。位错增殖速率随应变速率的提高和变形温度的下降而增加,提高了位错塞积速率和动态再结晶形核率。因此,在本工作的实验参数范围内,Td = 623 K、

图7

图7

不同变形条件下喷射成形Al25Si4Cu1Mg合金的热变形组织演变示意图

Fig.7

Schematics of hot deformation microstructure evolution of spray formed Al25Si4Cu1Mg alloy under different deformation conditions (Z—Zener-Hollomon parameter)

4 结论

(1) 喷射成形Al25Si4Cu1Mg合金铸锭组织包含近似球状的初生Si相,以及与其伴生的初生Al2Cu相和AlSiCuMg相。α-Al基体晶粒尺寸范围为10~20 μm,粗大初生相分布于α-Al基体晶粒的晶界处。

(2) 喷射成形Al25Si4Cu1Mg合金的热压缩流变应力随变形温度的升高以及应变速率的降低而下降。在623~723 K的温度范围内,合金都表现出显著的动态再结晶特征。在应变速率为5 s-1时,因为位错增殖速率过快而导致初生相前沿产生严重的应力集中,进而诱发形变裂纹。

(3) 热压缩后近似等轴状的晶粒形貌、极低的位错亚结构密度以及随机取向的再结晶晶粒充分说明:高体积分数的硬质初生相颗粒促使PSN机制的产生,进而使Al25Si4Cu1Mg合金在较宽的形变温度范围内都可以发生几乎完全的动态再结晶。

参考文献

Effect of particle shape and size distribution on the dissolution behavior of Al2Cu particles during homogenization in aluminum casting alloy Al-Si-Cu-Mg

[J].

Textural evaluation of Al-Si-Cu alloy processed by route BC-ECAP

[J].

Influence of Cu addition on the heat treatment response of A356

[J].Strength and high-temperature performance are important properties in Al-Si-Mg alloys for power-train applications such as combustion engine cylinder head components in automotive industry. Addition of Copper (Cu) to Al-Si-Mg alloys is a common practice to obtain high strength as well as high temperature stability. However, Cu addition alters precipitation kinetics and precipitate types during artificial ageing, and consequently properties of final cast products. In this study, the effects of Cu on tensile properties in connection with precipitation and precipitate types, as observed through aging curves and TEM analysis, were investigated in Al-Si-Mg alloys having three different Cu contents in order to optimize Cu contents and heat treatment parameters. Higher solutionizing temperature enabled a significant increased Cu content in solid solution without any incipient melting of Cu-rich phases. A refinement of the precipitate microstructures was observed in the Cu-containing alloys, accompanied with a phase-change of the hardening needle precipitates. different precipitation kinetics and double aging peaks were observed during artificial aging in higher Cu containing alloys, which were correlated to higher strength than in the Cu-free alloy in underaged and peak aged conditions. Optimized Cu contents and heat treatment parameters were found with respect to a combination of strength and elongation.

Effect of Si content on microstructure and mechanical properties of Al-Si-Mg alloys

[J].

Effect of minor addition of vanadium on mechanical properties and microstructures of as-extruded near eutectic Al-Si-Mg alloy

[J].

Hardening response and precipitation behavior of Al-7%Si-0.3%Mg alloy in a pre-aging process

[J].

Effects of conform continuous extrusion and heat treatment on the microstructure and mechanical properties of Al-13Si-7.5Cu-1Mg alloy

[J].

Breaking through the strength-ductility trade-off dilemma in an Al-Si-based casting alloy

[J].Al-Si-based casting alloys have a great potential in various industrial applications. Common strengthening strategies on these alloys are accompanied inevitably by sacrifice of ductility, known as strength-ductility trade-off dilemma. Here, we report a simple route by combining rapid solidification (RS) with a post-solidification heat treatment (PHT), i.e. a RS + PHT route, to break through this dilemma using a commercial Al-Si-based casting alloy (A356 alloy) as an example. It is shown that yield strength and elongation to failure of the RS + PHT processed alloy are elevated simultaneously by increasing the cooling rate upon RS, which are not influenced by subsequent T6 heat treatment. Breaking through the dilemma is attributed to the hierarchical microstructure formed by the RS + PHT route, i.e. highly dispersed nanoscale Si particles in Al dendrites and nanoscale Al particles decorated in eutectic Si. Simplicity of the RS + PHT route makes it being suitable for industrial scaling production. The strategy of engineering microstructures offers a general pathway in tailoring mechanical properties of other Al-Si-based alloys. Moreover, the remarkably enhanced ductility of A356 alloy not only permits strengthening further the material by work hardening but also enables possibly conventional solid-state forming of the material, thus extending the applications of such an alloy.

The effect of Mg on the structure and properties of Type 319 aluminum casting alloys

[J].

Effect of micro-alloying element la on solidification microstructure and mechanical properties of hypoeutectic Al-Si alloys

[J].

微合金化元素La对亚共晶Al-Si合金凝固组织与力学性能的影响

[J].利用DTA、OM、SEM、TEM、EPMA以及拉伸实验等方法研究了在添加α-Al晶粒细化剂Al-Ti-B中间合金和共晶Si变质剂Sr条件下,微合金化元素La对亚共晶Al-Si合金凝固组织与力学性能的影响。结果表明:添加微量稀土La能进一步细化α-Al,变质共晶Si,显著提高合金的塑性。分析表明:微量La能降低α-Al晶核与TiB<sub>2</sub>的润湿角,减小α-Al的形核过冷度,促进α-Al的进一步细化;La能诱发交错孪晶的形成,增大共晶Si的孪晶密度,改变Si相的长大行为,进一步改变共晶Si的形貌。当La的添加量达到0.10%时,LaAlSi金属间化合物在凝固过程的共晶反应阶段形成,该化合物的形成将降低合金的塑性。

Effect of thermal exposure on microstructure and mechanical properties of Al-Si-Cu-Ni-Mg alloy produced by different casting technologies

[J].

Evolution behavior of primary phase during pre-heat treatment before deformation for spray formed 7055 aluminum alloy

[J].

喷射成形7055铝合金初生相在形变前预热处理中的演变行为

[J].

The strengthening mechanism of FSWed spray formed 7055 aluminum alloy under water mist cooling condition

[J].

Dynamic precipitation of Mg2Si induced by temperature and strain during hot extrusion and its impact on microstructure and mechanical properties of near eutectic Al-Si-Mg-V alloy

[J].

Effect of Si content on dynamic recrystallization of Al-Si-Mg alloys during hot extrusion

[J].

Effect of hot extrusion on mechanical properties and microstructure of near eutectic Al-12.0%Si-0.2%Mg alloy

[J].

Constitutive equation and thermal processing map of spray formed AlSi25Cu4Mg wear resistant alloy

[J].

喷射成形AlSi25Cu4Mg耐磨合金的本构方程及热加工图

[J].

Hot deformation behavior and microstructure evolution of annealed Al-7.9Zn-2.7Mg-2.0Cu (wt.%) alloy

[J].

Effects of initial microstructure on hot deformation behavior of Al-7.9Zn-2.7Mg-2.0Cu (wt%) alloy

[J].

Microstructure and mechanical properties of Al-7.9Zn-2.7Mg-2.0Cu (wt%) alloy strip fabricated by twin roll casting and hot rolling

[J].

Effect of grain size on hot deformation behavior of a new high strength aluminum alloy

[J].

晶粒尺寸对新型高强铝合金热变形行为的影响

[J].

Constitutive equation and hot deformation behavior of homogenized Al-7.68Zn-2.12Mg-1.98Cu-0.12Zr alloy during compression at elevated temperature

[J].

The transition from discontinuous to continuous recrystallization in some aluminium alloys: I-The deformed state

[J].

Effect of grain size inhomogeneity of ingot on dynamic softening behavior and processing map of Al-8Zn-2Mg-2Cu alloy

[J].

Quantifying geometrically necessary dislocation density during hot deformation in AA6082 Al alloy

[J].

The double-edge effect of second-phase particles on the recrystallization behaviour and associated mechanical properties of metallic materials

[J].

Effect of texture evolution on mechanical properties of near eutectic Al-Si-Mg alloy with minor addition of Zr/V during hot extrusion

[J].

Particle-stimulated nucleation and recrystallization texture initiated by coarsened Al2CuLi phase in Al-Cu-Li alloy

[J].