Ti及钛合金具有优良的力学性能、耐腐蚀性能、良好的生物相容性等优点,已被广泛应用于生物医学领域[1~3]。相比于其他传统人体硬组织替代物候选材料,如不锈钢(易发生点腐蚀,释放有毒的合金元素Ni等)、Co-Cr合金(易发生微动腐蚀,释放有毒的合金元素Co、Cr等)、镁合金(力学强度较低,更易被腐蚀)和Au、Ag、Pt、Ta等贵金属(价格昂贵)而言,Ti及钛合金有着更高的比强度、更小的毒性、更好的抗腐蚀能力以及更低的成本[4~8]。同时,相比于不锈钢和Co-Cr合金,钛合金还有着与骨骼更牢固的结合能力,兼具与人体骨骼更接近的Young's模量,有利于减少应力屏蔽等问题(骨和植入体之间Young's模量的不匹配)[9],显示出更具优势的应用前景。随着对Ti及钛合金的研究不断深入开展,研究者对其生物毒性、生物相容性等领域进行了系统研究。结果显示,通过对其表面进行改性处理可以提高钛合金的生物相容性,并降低其生物毒性、提高其抗菌性能。因此,有必要对近些年的相关研究结果进行归纳总结,从而为Ti及钛合金的生物应用提供一定的理论指导。

金属Ti有2种晶体结构,882℃以下的为hcp-α结构,882℃以上的为bcc-β结构。生物医用的纯Ti主要是α结构。根据Ti的2种结构,钛合金也相应地被分为3类:Ti原子以hcp排列的α固溶体合金、以bcc排列的β固溶体合金和同时具有2种排列方式的α + β合金。稳定α固溶体的合金元素主要包括Al、Ga、C、N、O等,其中Al是α固溶体合金的主要元素;稳定β固溶体的合金元素主要包括Nb、Mo、V、Mn、Fe、Ta等。相比于α和α + β合金,β合金往往有着更高的韧性,更接近人体骨骼的Young's模量,因此很适合作为人体植入体的材料,如Ti-15Mo (质量分数,%,下同)、Ti-13Nb-13Zr、Ti-12Mo-Zr-2Fe、Ti-16Nb-9.5Hf等[10~14]。α + β合金的典型代表是Ti-6Al-4V,是研究最为广泛的生物医用材料之一,但是其在人体中会释放对细胞有害的Al3+和V5+,具有一定的生物毒性。在此基础上,研究者开发了一系列不含有毒金属元素的钛合金,而且在疲劳强度、抗腐蚀强度等方面同样优异,如Ti-15Zr-4Nb-4Ta-0.2Pd和Ti-15Zr-4Nb-4Ta-0.2Pd-(0.20~0.05)N。

无论是纯Ti金属,还是不同成分、结构的钛合金,都面临着以下问题:(1) 植入后的炎症反应。即使是与人体骨骼Young's模量更加接近的Ti及钛合金,它们仍具有生物惰性,不利于成骨反应,在植入后与周围骨骼结合方式主要为机械结合,该结合方式会导致植入体与骨骼产生微动,微动带来的摩擦会产生很多碎屑,碎屑的聚集最终会引发炎症[15~18];(2) 植入后力学性能的下降。Ti和钛合金植入体与体液的长时间接触,尤其在微动摩擦后表面结构受到破坏后,容易受到体液中离子的腐蚀,导致合金的力学性能下降,如腐蚀开裂、氧化层变厚[19];(3) 合金的腐蚀效应导致生物毒性。合金中的合金元素也会因为腐蚀反应溶解、释放到人体体液中,对人体产生毒害作用,如Al具有神经毒性,会引发神经问题和脑损伤,V及其化合物具有细胞毒性等[17,20~23];(4) 植入后的细菌感染。Ti及钛合金植入体在植入时,由于本身缺乏抗菌性进而引发术中细菌感染,导致手术失败[24~27]。

为了解决Ti及钛合金表面硬度低、耐磨性差、耐腐蚀能力不足、生物相容性不足以及自身抗菌性差等问题,对Ti及钛合金进行表面改性处理是一种非常有效的解决办法。具体的表面改性处理方案包括以下几点:(1) 通过改变成分、表面处理或者覆盖表面涂层,提高其力学性能、硬度、耐磨性和耐腐蚀性,避免表面结构的破坏引发的后续问题;(2) 赋予Ti及钛合金植入体生物活性,促进植入体周围的人体组织细胞的黏附、增殖,提高植入体的生物相容性;(3) 使Ti及钛合金植入体自身表面具有抑菌/抗菌性能。

1 成分设计和表面改性提升Ti及钛合金力学及耐磨损、耐腐蚀等性能

成分设计为物理改性,代表性方法为合金熔炼。表面改性处理提高Ti及钛合金植入体性能的方法主要分为物理改性和化学改性。物理改性方法包括物理气相沉积、热喷涂、高温热处理、激光处理、3D打印、辉光放电等;化学改性方法包括酸碱反应、水热反应、阳极氧化、化学气相沉积等。一种方法或者多种方法的结合使用可以在改善Ti及钛合金力学及耐磨损、耐腐蚀等性能的同时改善其生物相容性、抑菌性能等,同一种方法在改善Ti及钛合金几种性能上的适用性也不尽相同。

1.1 电弧熔融处理

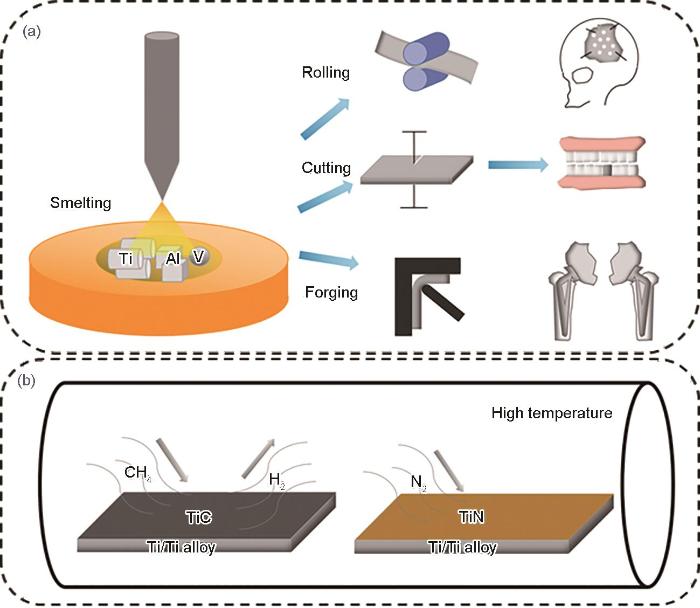

电弧熔融处理(arc treatment)是制备钛合金、调节合金成分(尤其是合金表面成分)的有效方法之一。Ti及钛合金成分的调控可以显著提高其耐腐蚀性能、抗磨损性能、硬度等,而合金整体成分的改变也会有效提高其弹性等。将合金元素按所需比例进行配料并放置在熔炼炉中,在Ar气氛下将几种元素均匀地熔炼以形成合金,并通过热轧、切割、热处理等工艺加工为需要的形状,如图1a所示。不同组成成分的合金性能差异较大,相同组成元素但是比例不同的合金性能也不尽相同。由β相稳定元素Zr和Mo形成的Ti-15Zr-xMo合金具有较高的硬度、较低的Young's模量,与细胞接触时具有可耐受的细胞毒性水平;其中,Ti-15Zr-7.5Mo合金由于ω相析出而具有最高的力学性能,而Ti-15Zr-15Mo合金为生物医学应用提供了最佳的性能组合,具有良好力学性能的同时还促进了成骨细胞的黏附[28]。β型合金Ti-45Nb在低Young's模量(64.3 GPa)、高拉伸强度(527 MPa)和高硬度(233.4 MPa)之间取得了平衡,相比于纯Ti,合金没有额外的副作用,且具有更好的耐腐蚀性[29]。在Ti-27.5Nb合金中熔入Ag元素,降低了合金的硬度,提高了合金的韧性。当Ag含量为0.7% (质量分数)时,在不影响合金本身的细胞黏附和增殖行为的同时提供了优异的抗菌性能[30]。Zhou等[31]制备了Ti-Nb-Zr合金并研究了Zr含量对合金相变、显微组织和力学性能的影响。Zr的添加可以使合金相稳定,Zr含量的增加,细化了合金的显微组织,并提高了强度,而塑性显著降低。其中,Ti-25Nb-2Zr合金具有最低的Young's模量,为62 GPa,其主要归因于应力诱发马氏体相的形成。在Ti-Bi合金中,Bi元素的加入提高了纯Ti的可铸造性,合金的拉伸强度、硬度和耐磨性随Bi含量增加单调递增。相比于纯Ti,Ti-Bi合金分别在唾液、含有0.2%NaF和0.3%C3H6O3的溶液中显示出了更好的耐腐蚀性能,同时合金显示出非溶血性特征,在牙科领域中具有良好应用潜力[32]。对Ti-10Ta-10Nb合金和Ti-6Al-4V合金进行相同的氧化处理,2者的氧化膜均为金红石型TiO2,但是Ti-10Ta-10Nb合金显示出更致密、更薄的氧化层,在提高合金耐蚀性能的同时降低了细胞的毒性[33]。

图1

图1

电弧熔融制备钛合金及其应用示意图、钛合金高温气体热处理示意图

Fig.1

Schematics of the preparation of titanium alloy by arc melting and its application (a) and high temperature gas heat treatment of titanium alloy (b)

电弧熔融处理不仅可以灵活地改变合金成分,精确地调控钛合金成分、比例,设计具有不同功能的钛合金,而且制备的钛合金成分均匀、稳定性好,可以有效改善钛合金的多种性能,适用于大部分钛合金的制备。

1.2 高温气体热处理及高温热处理

高温气体热处理(gas heat treatment),如高温氮化、碳化可以改变Ti及钛合金的表面组织结构,提高表面性能,如图1b所示。Li等[36]对纯Ti和Ti-6Al-4V合金进行了不同温度的高温氮化处理,在700℃下氮化的Ti的抗气蚀性相比未经处理的试样提高了2.65倍,原因在于氮扩散区具有高硬度、无裂纹和良好冶金结合的均匀结构,阻止了微裂纹向内部扩展并延缓了侵蚀;在1000℃下氮化的Ti则具有最低的抗气蚀性,因为该温度下热处理破坏了Ti的微观结构,导致抗气蚀性降低。对于Ti-6Al-4V合金,与纯Ti相反,1000℃下氮化的Ti-6Al-4V合金表现出最高的抗气蚀性。在Ti-6Al-4V合金中,氮扩散区由硬质α-Ti晶粒和软质β-Ti晶粒组成,软质β-Ti晶粒的存在导致选择性气蚀,加速了侵蚀过程。但合金在1000℃下处理后,由于N的固溶诱导了β-Ti向α-Ti的转变,促进了富氮α-Ti晶粒层的形成,抗气蚀性相比原始合金增加了6.72倍。Li等[37]还通过对Ti-6Al-4V合金进行固体渗碳处理在样品表面形成陶瓷涂层,改善了合金的抗气蚀性。涂层结构包含TiC和少量氧化物。空蚀实验结果表明,与未处理的样品相比,处理后的样品抗气蚀性(平均侵蚀率的倒数)由3.44增加至6.68。TiC薄膜的存在也可以提高Ti及其合金的耐磨性,尤其在种植牙的表面和人体关节部分[38]。

高温热处理可以提高合金性能。Li等[39]研究了β型Ti-24Nb-2Zr合金高温时效处理后的超弹性和变形行为,随着时效时间的增加,合金中会形成ω相,适量的ω相能提高β相屈服强度,使更多β相在屈服前发生应力诱发α"马氏体转变,同时抑制α"相的长大和塑性变形,促进α"相卸载后回复成母相,进而提高了合金的超弹性回复能力。

相比于高温热处理,高温气体热处理仅针对钛合金表面进行改性处理,在改变表面性能的同时,还能保持钛合金整体原有的性能,实现钛合金多种性能的结合。

1.3 放电等离子烧结

放电等离子烧结(spark plasma sintering)可以降低烧结材料(通常为金属粉末)的烧结温度,尤其是对于钛合金组分中熔点差别较大的金属元素,可以有效避免低熔点组分材料的挥发,并且能够使粉末快速烧结致密,是一种有前景的粉末冶金烧结技术,如图2a所示。Liu等[40]首先将熔点差别较大的2种金属Ti、Mg通过球磨的方式机械合金化,再通过放电等离子烧结技术形成了不同比例的Ti-Mg合金,合金中含有纳米晶相Mg和Ti的均匀混合物,具有适用于生物医学的新型特性,Mg的加入降低了合金的Young's模量,并且Mg可以在环境溶液中溶解诱导Ca3(PO4)2的形成,提高合金生物活性;但是,合金的耐蚀性能随Mg含量的增加而降低。Karre等[41]分别通过放电等离子烧结技术和常规烧结技术制备了Ti-Nb合金,放电等离子烧结所制备的合金的Young's模量(80 GPa)相比于常规烧结((90 ± 10) GPa)更低,硬度也相对更低,更适用于人体。

图2

图2

放电等离子烧结制备Ti-Mg合金和钛合金激光表面改性示意图

Fig.2

Schematics of the preparation of Ti-Mg alloy by spark plasma sintering (a) and laser surface modification of Ti alloy (b)

放电等离子烧结技术主要应用于成分熔点差别较大的特定合金制备,但是制备的合金无法再次进行热处理、激光处理等高温处理,后续功能化处理困难,适用范围相对受限。

1.4 激光表面改性

激光表面熔敷陶瓷层可以更好地控制陶瓷涂层的结构和厚度,产生致密无裂纹的陶瓷涂层。配合等离子喷涂等工艺可以获得光滑、致密的表面涂层,提高植入体表面强度和耐蚀能力。通过物理气相沉积也可以制备TiN涂层。

激光表面改性的优点在于可以对钛合金进行局部选择性处理,改变局部区域的组织,制备局部涂层,对局部区域改性的可控性高,在加工、应用中更加灵活。

电弧熔融处理是制备各种成分钛合金的主要方法,可以制备大多数不同成分、比例的钛合金,但合金各成分熔点不能相差过大,否则合金成分、比例将失调甚至合金成分缺失;等离子烧结主要用来制备合金成分熔点相差较大的特定合金,弥补了电弧熔融处理方法的不足。钛合金成分是决定其性能的主要因素。高温气体热处理可以在保持钛合金整体性能的同时进一步表面功能化,使得合金具备原本没有的特性;激光表面改性处理既可以通过合金相转变的方式提高表面性能,又可以结合外源物质、改变合金表面成分以制备涂层的方式提高表面性能。相比于高温气体热处理,激光表面改性具有局部选择性,灵活性更高。钛合金成分的调控结合表面改性处理可以最大程度地满足对合金所需的性能要求,可以应用于人体骨骼、牙齿等多个部位,制备性能更加完善的钛合金仍然是主要的研究方向。

2 表面改性处理提高Ti及钛合金表面粗糙度和生物活性

表面处理提高Ti及钛合金的表面粗糙度和添加表面生物活性物质是提高Ti及钛合金植入体生物相容性的主要手段。表面粗糙度是指表面微小的两波峰或者两波谷的距离,距离越大表面越粗糙。Ti及钛合金植入体表面粗糙度在早期成骨细胞黏附、增殖和整合中具有重要作用,合适的粗糙度(分为精细粗糙(1~3 µm)、粗糙(6~10 µm)和宏观粗糙(10~30 µm))可以大大改善植入体的生物相容性,过度的粗糙度则会降低植入体力学性能[48]。添加表面生物活性物质(如沉积活性涂层)可以提高细胞活力,加快细胞在钛合金植入体表面的黏附、增殖,加快骨整合。

2.1 喷砂、酸蚀及其组合使用提高表面粗糙度

图3

图3

喷砂、酸蚀及其组合,3D打印及激光表面纹理化示意图

Fig.3

Schematics of sandblasting, acid etching, and their combination (a), 3D printing (b), and laser surface texturing (c)

喷砂、酸蚀及其组合使用是早期的表面处理方法,具有操作简单、成本低等优点,多用于牙种植体的表面改性。

2.2 3D打印技术提高表面粗糙度

3D打印技术除了能提高钛合金表面粗糙度以外,还可以直接制备合金或非合金的牙齿、骨骼、组织器官、假肢以及手术预演模型等,具有很大的应用前景。

2.3 激光表面纹理化提高表面粗糙度

激光在辅助表面改性的同时,也可以通过自身的高能量状态直接在Ti及钛合金表面产生坑洞,提高表面粗糙度,坑洞的尺寸、深度取决于激光光斑的尺寸、功率等因素,该方法称为激光表面纹理化(laser surface texturing)。如图3c所示,利用激光可以在植入体表面有规律地轰击出一系列的坑洞,产生纹理[59]。激光表面纹理化后可以改变Ti及钛合金植入体表面的粗糙度、湿润性、摩擦系数等,尤其粗糙度的改变可以促进正常细胞的黏附和生长[60]。例如Cunha等[61]通过飞秒激光表面纹理化在Ti表面制备了纳米柱和周期性表面结构,纳米柱增强了Ti表面的亲水性,周期性表面结构则减少了金黄色葡萄球菌在Ti表面的黏附。

激光表面纹理化由于其高度可控性,不仅可以在Ti及钛合金表面产生纹理,还可以在合金表面的功能性涂层上制造纹理,应用更加广泛。

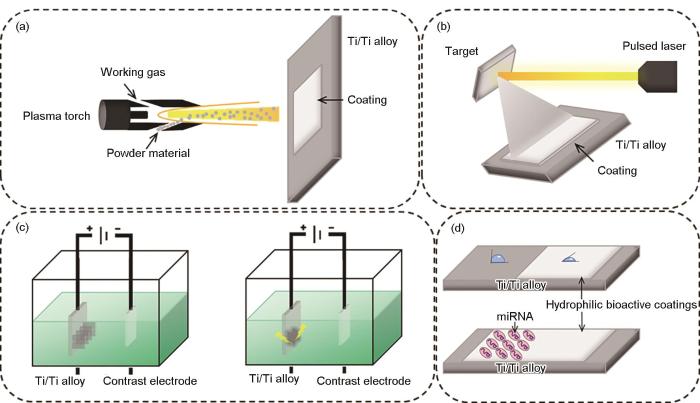

2.4 等离子喷涂提高表面粗糙度及生物活性

等离子喷涂(plasma spray)同样是增加Ti及钛合金植入体表面粗糙度的有效方法,其机理是利用直流电弧等离子枪将所需材料熔化并喷涂在Ti及钛合金基体上,如图4a所示。相比于喷砂,等离子喷涂可制造更小的纳米尺度的表面粗糙结构,大大增加了比表面积,加快了细胞黏附和骨整合[62,63]。在Ti及钛合金表面等离子喷涂人体骨骼的主要无机成分羟基磷灰石,在改善表面粗糙度的同时,还可以显著增加植入体的生物活性,促使植入体与机体组织快速结合,释放诱导成骨离子,加快术后受损组织的恢复。例如,羟基磷灰石涂层/Ti-6Al-4V合金复合材料具有与天然骨骼类似的力学性能,尤其是拉伸强度和韧性[64];Hameed等[65]通过不同参数下的轴向悬浮等离子喷涂和大气等离子喷涂2种方式将羟基磷灰石喷涂在Ti-6Al-4V合金表面,其中轴向悬浮等离子喷涂产物中显示出了最佳的生物活性(黏合强度提高了1.3倍),耐腐蚀性能提高了9.5倍;钛合金表面的羟基磷灰石/TiO2复合涂层呈现出了纳米多孔形貌,与天然骨骼表面形貌类似,极大地促进了植入体与骨骼、细胞组织的结合[66]。

图4

图4

等离子喷涂制备涂层、脉冲激光沉积制备涂层、阳极氧化/等离子体电解氧化/微弧氧化表面改性及基因治疗示意图

Fig.4

Schematics of coatings prepared by plasma spraying (a), coatings prepared by pulsed laser deposition (b), surface modification by anodizing/plasma electrolytic oxidation/micro-arc oxidation (c), and gene therapy (d)

等离子喷涂技术在喷涂生物活性涂层的同时使涂层具有纳米尺度的表面粗糙度,2者的结合可以显著提高Ti及钛合金生物相容性,而且该方法制备的涂层结构致密、黏结强度高、不易氧化,是非常有应用前景的方法。

2.5 脉冲激光沉积提高表面粗糙度及生物活性

脉冲激光沉积(pulsed laser deposition)利用高能激光轰击目标材料,使得目标材料蒸发再沉积到基体材料表面,如图4b所示。通常可以在Ti及钛合金植入体表面制造涂层、薄膜和不同的微观纳米结构,如纳米孔、纳米管、纳米粉末、量子点等,具体的结构取决于脉冲激光沉积的激光功率、气体氛围等工艺参数。对于沉积的涂层和薄膜,一般选取可以改善Ti及钛合金生物惰性的材料,如磷酸钙基材料(如羟基磷灰石)、SiO2、45S5生物陶瓷、部分稳定氧化锆(PSZ)陶瓷等,并且可以在沉积的同时进行掺杂,这些材料具有很好的生物相容性,可以加快植入体和周围人体组织环境的融合,提高植入体力学性能、耐蚀性能[67~73]。而沉积微观纳米结构往往是为了提高表面粗糙度,成为药物载体等。

该方法对靶材的种类没有限制,制备的薄膜或涂层的成分可控、分布均匀,具有较大的兼容性。但是,由于激光输出功率有限,无法制备大面积的薄膜或者涂层,因此适用于Ti及钛合金局部改性或者特定位置改性处理,应用范围受限。改善激光功率,制备大面积薄膜或涂层是该方法未来的主要发展方向。

2.6 电子束物理气相沉积提高表面生物活性

电子束物理气相沉积(physical vapor deposition)是在真空条件下通过电子束将所需的材料源进行气化,变为气态原子或分子状态,或电离为离子状态,然后沉积在目标基体表面形成具有某种特殊功能的薄膜的技术。其原理类似于脉冲激光沉积。在Ti及钛合金表面处理中,常用来沉积生物活性物质如类骨骼成分磷灰石薄膜,以提高合金表面的生物活性,加快合金植入体和周边人体组织的结合速率。Gnanavel等[74]利用电子束物理气相沉积技术在β型钛合金Ti-13Nb-13Zr表面沉积了磷灰石薄膜,相比于没有沉积磷灰石的合金,沉积了磷灰石薄膜的合金具有更好的耐腐蚀性能。值得注意的是,沉积磷灰石薄膜增强了合金的生物活性,利于成骨细胞的黏附、增殖,表现出了良好的细胞活性和生物相容性,并且毒性降到最低。Kaliaraj等[75]在Ti基体上沉积了Y稳定ZrO2涂层,相比于不规则的Ti表面,涂层表面为均匀而致密的颗粒,平均粗糙度由Ti的4.55 nm降为2.99 nm,粗糙度的降低抑制了细菌的黏附,但是也降低了成骨细胞的黏附。45 d生物矿化研究显示,Y稳定ZrO2涂层比纯Ti表现出更多的成核位点,额外形成了磷灰石,同时涂层还增加了对血液蛋白的黏附力。提高涂层表面粗糙度和抗菌性能是改进Y稳定ZrO2涂层的下一步目标。

电子束物理气相沉积制备的薄膜致密均匀,与基体结合紧密,且制备工艺简单、耗材少,对环境友好,适合工业化大规模使用。

2.7 化学转化制备表面涂层提高表面生物活性

与沉积方法制备的涂层不同,化学转化(chemical synthesis)方法是在基底表面通过原位转化的方式生长涂层,涂层与基底之间往往有着更强的结合力,涂层与基底之间的紧密结合避免了植入体在人体中长时间存在可能导致的涂层与基底分离的问题。该方法要在基底上制备可有效提高植入体表面生物活性的材料,如最典型的与天然骨骼成分相似的Ca3(PO4)2、磷灰石[76~78]。Liu等[79]通过化学转化技术在纯Ti和Ti-6Al-4V合金基底上原位转化制备了磷钙锌矿涂层,2种基底上的涂层均由纳米片构成。该方法制备的涂层与基底具有强结合力,使得材料在0.9%NaCl溶液中都具有良好的耐蚀性,尤其在Ti-6Al-4V合金基底上制备的涂层由于其更加致密和均匀的结构表现更佳。在体外成骨细胞MG63细胞培养实验表明,磷钙锌矿涂层具有良好的细胞相容性。Yu等[80]通过化学转化在纯Ti表面制备了壳聚糖、银和羟基磷灰石,再通过旋涂的方法在涂层的表面涂覆了一层溶菌酶,形成了复合涂层。该涂层为多孔分层的纳米结构,有利于细胞的黏附和增殖。涂层组分均具有很低的毒性,其中壳聚糖、银以及溶菌酶的协同作用显示出了12 h内对大肠杆菌和金黄色葡萄球菌高达95.28%和98.02%的抗菌效率。Liu等[81]通过水热合成的化学转化方法在具有低Young's模量的β型钛合金Ti-24Nb-4Zr-7.9Sn表面制备了纳米TiO2涂层,该涂层提高了钛合金表面的粗糙度,增加了表面亲和力,促进了细胞的黏附和增殖。体内实验显示纳米TiO2在皮下和骨内植入具有更好的组织相容性,同时可以增强早期骨整合。Zhang等[82]通过逐层自组装的方法在Ti-24Nb-2Zr合金上制备了多巴胺修饰的透明质酸/壳聚糖生物活性多层涂层,该复合涂层显著降低了接触角并提高了合金的润湿性。体外成骨细胞增殖测试表明,添加涂层后成骨细胞增殖明显高于原始合金,有效提高了生物相容性。

化学转化方法是一种简单有效的表面涂层制备方法,有着低成本、污染小、易于制备、适用性广等优点;缺点为制备的涂层形貌、厚度等较难控制,重复性较差。

2.8 电化学阳极氧化处理改变表面结构

电化学阳极氧化(electrochemical anodizing)方法通过将电能转化为化学能,使阳极和阴极发生化学反应,尤其对于阳极,通过合理调控施加电位、电流强度、氧化时间等条件,可以改变阳极的微观形貌[83,84]。如图4c所示,将Ti及钛合金植入体作为阳极,利用电化学阳极氧化可以在植入体表面制备微米级、纳米级表面形貌以及纳米管、纳米孔等微观结构。微米级表面形貌可以促进成骨细胞分化[85,86],纳米级表面形貌则促进细胞增殖[87],2者结合可以促进成骨细胞的增殖和分化[88];微观结构有利于Ti及钛合金被植入后正常细胞的黏附增殖、结构抑菌、充当药物载体等。Huang等[89]将AgNO3电解质改为Cu(NO3)2电解质,在Ti基底上制备了微/纳米纹理表面,并且生长了TiO2介孔阵列,电解质的改变避免了金属阳离子掺入纳米阵列带来的潜在细胞毒性,提高了细胞相容性,同时在电解质中加入Na3PO4会促使 P的掺入,也可以进一步改善其细胞相容性,而自身的微/纳米纹理表面又促进了细胞的增殖和分化。Hu等[90]通过阳极氧化在Ti表面制备了TiO2纳米管,很好地改善了细胞黏附和骨整合。Lee等[91]通过两步阳极氧化制备的TiO2纳米管阵列,在促进骨整合的同时还可以作为重组人骨形态发生蛋白的载体。Su等[92]证实了TiO2纳米管在机械抑菌方面的积极作用。Kim等[93]对Ti阳极氧化后形成的TiO2纳米管进行了碱处理和热处理,碱处理后的纳米管转变为纳米纤维结构,增加了表面粗糙度以及亲水性;热处理后会促进体液中离子和TiO2纳米管表面Na+交换,加速骨状磷灰石的形成;碱和热处理还有效促进了成骨细胞在植入体表面的扩散。Kang等[94]通过阳极氧化制备了纳米结构TiO2,并在不同浓度的NaCl溶液中进行了二次阳极氧化以将Cl-掺入TiO2中,在具有细胞相容性的同时赋予了材料抗菌性能。Liang等[95]在Ti-4Zr-22Nb-2Sn合金表面通过电化学阳极氧化制备了自支撑纳米管层,显著增加了合金表面粗糙度。

电化学阳极氧化制备表面结构具有可控性高、形貌多样化、反应速率快、成本低等优点,并且可以根据用途(如提高表面粗糙度、充当药物载体等)设计表面结构,应用十分广泛。

2.9 等离子体电解氧化/微弧氧化提高表面粗糙度和生物活性

等离子体电解氧化/微弧氧化(plasma electrolytic oxidation/micro-arc oxidation)来源于阳极氧化技术,区别在于在电极上是否施加了高压,如图4c所示。将目标合金放入特定的电解液中作为电极,并放置对电极,通过调节电参数,使得在电解液中的目标合金表面产生弧光放电,在极短的时间内达到高温高压状态,生长出以基底合金材料的氧化物为主的陶瓷膜层。生长的陶瓷膜层往往具有高硬度、耐腐蚀、耐磨损等优点。Shin等[96]制备纯Ti的氧化层时在电解液中添加了Ag纳米颗粒,Ag纳米颗粒参与了Ti的氧化过程,形成了含有Ag的多孔钛氧化层。其中,含有0.1 g/L Ag纳米颗粒的电解质下形成的氧化层显示了更好的生物活性和抗菌性能。Kaluđerović等[97]在NaOH和Ca(H2PO4)2水溶液中进行等离子体电解氧化制备了3种具有金红石型TiO2表面的新型阳极转化层,同时还存在生物活性陶瓷成分钛酸盐和无定形Ca3(PO4)2,这些表面物质共同促进了骨组织的形成和生长,尤其适用于牙科领域。Wang等[98]在Ti基底喷砂处理的基础上进行了等离子体电解氧化,形成了多孔的、含Ca和P的涂层,这种组合处理方式不仅保留了合金表面微观的多孔结构,Ca和P的存在还促进了羟基磷灰石在涂层上的形成,增强了细胞活力。Hong等[99]在Ti-6Al-4V合金上通过微弧氧化制备了TiO2和羟基磷灰石薄膜,薄膜与基底结合强度高,不受薄膜厚度和形貌影响;且该薄膜具有良好的生物活性和细胞黏附能力,细胞实验显示,成骨细胞MC3T3-E1细胞的附着和增殖受到了薄膜中Ca2+和P5+浓度以及电解质组分的影响。Wang等[100]结合磁控溅射和微弧氧化2种方法在Ti-6Al-4V合金基底上制备了Zn/ZrO2/TiO2涂层,该涂层显示出优异的耐腐蚀性能、细胞相容性和抗菌性能。Matos等[101]对比了微弧放电和辉光放电等离子体2种方法处理纯Ti表面的差别。辉光放电等离子体处理产生硅基光滑薄膜,增加了纯Ti的湿润性,保持了Ti表面的粗糙度;微弧氧化处理产生富含Ca和P的氧化膜,具有火山外观,增加了纯Ti表面粗糙度,并产生锐钛矿和金红石表面TiO2晶体结构,还略微降低了早期生物膜中微生物的数量,对细胞增殖也有一定促进作用。

相比于阳极氧化,等离子体电解氧化/微弧氧化由于电压、电流更大,反应速率更快,制备的产物往往为陶瓷涂层,在兼具生物活性的同时,硬度、耐磨损性能、耐热性能等也得到了提升,通过该方法进行表面改性的Ti及钛合金适用于植入人体易磨损的部位(如关节)等。

2.10 基因治疗提高表面生物活性

微型核糖核酸(microRNAs/miRNAs)可以调节成骨细胞的增殖和分化,因而作为一种新的成骨基因治疗(gene therapy)方法(图4d)。一些miRNAs已被证明在骨细胞调节中具有重要作用。例如,miRNA-335-5p可以促进成骨分化[102];miRNA-26a可以增强骨形成[103];miRNA-29b促进成骨因子基因表达并促进成骨细胞分化[104]。因此,将miRNA与Ti植入体结合是一种可行的策略,可以提高植入体的表面生物活性。与脱氧核糖核酸(DNA)表达相比,miRNA表达没有整合到宿主基因组中的风险,不需要免疫诱导载体,而且其表达是可调节的和快速的。Meng等[105]开发了一种含有miRNA-29b的生物降解涂层来修饰Ti表面,该涂层不仅有利于细胞的黏附和生长,而且还提供了足够的miRNA转录效果和骨诱导潜力,增强了骨表面的骨再生,提高了植入体的生物相容性。Geng等[106]通过水热方法在Ti基底上沉积了Sr取代羟基磷灰石并固定了miRNA-21纳米胶囊,制备了具有良好的超亲水性涂层。体外实验表明这种复合涂层有利于成骨细胞的增殖、分化和矿化。Geng等[107]还通过对Ti表面进行酸处理和原位聚合方法,将miRNA-21纳米胶囊固定在Ti表面,形成涂层。该涂层表现出均匀的miRNA-21分布和可持续的 miRNA-21释放。体外研究表明,miRNA-21可以促进间充质干细胞的血管生成和成骨分化,但也增强了破骨细胞活性。miRNA-21纳米胶囊涂层加速了血管形成、骨重塑和骨成熟,从而显著改善骨-植入体的接触和增强骨-植入体结合强度。Zhang等[108]将多巴胺修饰的海藻酸盐和miRNA固定在Ti表面并形成多层涂层,多层涂层既可以有效原位递送miRNA,又显著增强了细胞增殖,同时也增强了碱性磷酸酶活性,促进了成骨细胞增殖和早期分化。

microRNAs基因治疗不同于其他方法,其作用本质在于提高成骨细胞的细胞活性,而非Ti及钛合金植入体的生物活性。在使用microRNAs基因治疗的同时应结合具有一定表面粗糙度或者良好生物活性的Ti及钛合金植入体,以便更好地发挥基因治疗的作用。

2.11 其他方法改善Ti及钛合金表面生物相容性

其他用于改善Ti及钛合金表面生物相容性方法包括碱热处理(alkali heat treatment)、磁控溅射 (magnetron sputtering)等。Shahriyari等[109]对退火和摩擦硬化后的Ti-6Al-4V合金进行了碱热处理,在表面获得了精细、均匀的纳米网络结构,增加了材料表面的湿润性并改善了其生物相容性,表现为细胞在材料上可以完全扩散、稳定的附着以及具有更高的生物活性。Sun等[110]在碱热处理后得到的多孔Ti表面使用天然交联剂京尼平(genipin)固定了骨形态发生蛋白,该蛋白在基底上具有良好的附着力,并增加了材料亲水性和蛋白质吸附性,且无细胞毒性。多孔的形貌则促进了细胞的黏附、增殖和矿化。Hu等[111]通过对Ti-10Zr-36Cu-14Pd合金进行酸和碱的共同处理,制备了表面多孔结构,该多孔表面可以诱导模拟体液中磷灰石的形成,提高合金生物活性。Chen等[112]采用磁控溅射法在Ti-6Al-4V合金上制备了Ca3(PO4)2和Ti梯度膜。相比于单独的Ca3(PO4)2膜,梯度溅射退火羟基磷灰石/Ti薄膜的拉伸黏合强度约为35 MPa,显著提高。纳米压痕实验结果表明,梯度羟基磷灰石/钛薄膜的Young's模量和显微硬度也呈梯度分布,应变回复明显优于单片羟基磷灰石薄膜。同时,羟基磷灰石/Ti薄膜使得合金表面粗糙度增加,Ca3(PO4)2的存在可以改善表面的生物活性。

仅以提高Ti及钛合金的表面粗糙度为目的的方法往往较为简易、成本低,如喷砂酸蚀、激光表面纹理化等,但是对于具有多功能化的Ti及钛合金,这些方法的处理往往是不够的;在具有一定表面粗糙度的基础上,生物活性涂层的制备可以让Ti及钛合金表面成分类似于人体骨骼成分,2者的协同作用可以显著提高Ti及钛合金的生物相容性,使Ti及钛合金同时具有粗糙度和生物活性的方法有等离子喷涂、脉冲激光沉积、电子束物理气相沉积、化学转化等;等离子体电解氧化/微弧氧化在提高Ti及钛合金表面粗糙度以及生物活性的同时,还可以提升合金表面性能,该方法可以同时满足Ti及钛合金表面改性的多种需求,简化加工处理工艺,具有较大的应用潜力;电化学阳极氧化制备的表面结构可以使Ti及钛合金表面具有多种功能,表面结构既可以提高粗糙度,又可以作为药物、金属离子、基因治疗因子等的载体,使合金兼具生物相容性、抗菌性能,方法简单、成本低,适合广泛应用。在具备生物相容性的表面改性处理的基础上,让Ti及钛合金提升力学性能、抑菌/抗菌性能,是以上这些方法改进的方向。

3 表面处理改性使Ti及钛合金表面具有抑菌/杀菌性能

3.1 超疏水性表面抑菌

Ti及钛合金植入体表面的超疏水性取决于表面微观结构和化学成分[115,116]。超疏水性表面抑菌(superhydrophobic surface antibacterial)主要通过在植入体表面构建超疏水性结构、涂层或者结合超疏水性物质,使得植入体整体呈现出超疏水特性和自清洁特性,这些特性可以有效消除细菌适宜的湿润的生存环境,抑制细菌黏附繁殖,如图5a1所示。同时,超疏水性还可以减少植入体在植入后血液中血小板的黏附和蛋白质的吸附、提高血液相容性和抗凝特性[117]。Tang等[118]在Ti植入体表面制备TiO2纳米管,其具有接触角大于150°的超疏水性,有效防止细菌在植入体表面黏附。在钛合金表面通过高速微铣削构建微槽、阳极氧化制备纳米管阵列、氟烷基硅烷自组装构建涂层改性后,由于物理形态和化学改性的协同作用,尤其是氟烷基硅烷的存在降低了表面自由能,使得植入体整体表面显示出超疏水性[119]。在牙科应用中,疏水表面可以有效防止牙釉质腐蚀,增加牙齿的自清洁能力,保持牙齿健康[120]。

图5

图5

超疏水性抑菌、亲水性抑菌、表面仿生结构抑菌示意图及药物抗菌、正电荷物质抗菌、金属离子抗菌示意图

Fig.5

Schematics of superhydrophobic antibacterial (a1), hydrophilic antibacterial (a2), and surface biomimetic structure antibacterial (a3); drugs antibacterial (b1), positively charged materials antibacterial (b2), and metal ions antibacterial (b3)

超疏水性表面在抑制细菌黏附、生长的同时,也会抑制正常细胞的黏附、生长,作为骨骼替代物还需通过增加表面粗糙度、制备生物活性涂层等方式进一步加工后才可以使用,因此主要应用于牙科领域。

3.2 表面亲水性聚合物抑菌

表面亲水性聚合物抑菌(surface hydrophilic polymer antibacterial)与表面超疏水性抑菌都旨在从源头阻断细菌感染,避免了细菌感染后药物治疗带来的负面影响。如抗生素的频繁、过度使用往往会导致细菌耐药性提高,后续抗生素效果变弱。不使用抗生素去抗菌抑菌是新的植入体表面改性思路[121]。钛合金表面涂覆聚合物,例如聚乙二醇及其衍生物,是有效防止细菌黏附的方法,如图5a2所示,其原理是细菌在疏水性表面具有强的黏附力,而在亲水性表面黏附力会大大减弱,而聚合物具有强的亲水性[122~124]。在聚合物上进行功能设计,如添加抗菌阳离子、细胞黏附肽层等,在防止细菌污染的同时可以杀死细菌,并促进细胞黏附和成骨行为,消除聚合物亲水性带来的过度影响[125~127]。

与超疏水性抑菌缺点类似,亲水性表面在抑制细菌黏附时也会减弱细胞的黏附,改善亲水性表面的生物相容性是该方法的主要研究方向。

3.3 表面仿生纳米结构抑菌

表面仿生纳米结构抑菌(surface biomimetic nanostructures antibacterial)的灵感来源于自然界生物某些部位的微观纳米结构,如蝴蝶翅膀上纳米棒簇可以制造多种颜色的结构色,蜻蜓翅膀、蝉翼表面的纳米梳结构可以有效抑菌,如图5a3所示。仿生纳米结构抑菌是一种物理方式抑菌,主要利用独特的表面纳米结构的接触抑菌特性,细菌在接触到植入体表面时很容易被表面纳米结构挤压、撕裂,进而抑制细菌在植入体表面的长时间黏附、增殖[128,129]。在Ti及钛合金植入体表面形成纳米柱(如TiO2纳米柱)、纳米棒(如ZnO纳米棒)、纳米管、纳米锥、纳米刺以及其他纳米结构都可以有效地破坏细菌适宜的生存环境,主要是通过物理的、机械的方式破坏细菌膜和细菌细胞组织,抑制细菌细胞分裂。同样地,在纳米结构中加入抗菌阳离子、促进组织细胞黏附物质和成骨因子,可以在物理结构抑菌的同时释放抗菌阳离子,加快细菌的灭亡,并且不影响甚至促进人体细胞组织的生长[130~133]。

表面仿生纳米结构抑菌的主要优势在于其具有抑菌持续性,在抑菌过程中不会造成自身损耗,相比于通过释放药物、特定的酶等因子抗菌方法的持续时间更久;而且自身的纳米结构也有利于细胞的黏附。该方法可以减缓甚至避免植入体的二次手术风险。

3.4 表面非特异性酶抑菌

表面非特异性酶抑菌(surface non-specific enzyme antibacterial)是通过对钛合金植入体表面涂层添加可以降解、破坏细菌细胞表面组织的酶进而抑制细菌的方法。主要是天然的或人工合成的DNase I酶,其抑菌作用机理是通过水解胞外DNA的磷酸二酯键以破坏其局部结构,而胞外DNA是细菌黏附钛合金植入体的重要物质,胞外DNA可以通过结合细胞外蛋白质、多糖的方式稳定生物膜。DNase I酶降解胞外DNA后,会阻碍细菌与环境中的蛋白质和多糖结合,抑制细菌黏附,防止生物膜的形成[134~136]。DNase I酶的使用不会使细菌产生耐药性,但是酶的作用范围有限,无法抑制游离的细菌,持续时间也相对较短,不超过24 h。解决的可行办法是与抗生素或其他抗菌物质协同抑菌抗菌[137,138]。

表面非特异性酶抑菌对细菌具有针对性,抑制细菌的同时不会对人体细胞产生负面影响;其缺点也较为明显,可持续时间较短,无法抵抗细菌多次感染。

3.5 表面群体感应抑制剂抑菌

在细菌的生长过程中,伴随着细菌群落的不断扩张、细菌密度的不断增加,群落会影响个体细菌的生理功能,而细菌个体会通过分泌化学信号分子来检测和适应菌落的变化,这种细菌与菌落的信息交流系统称为细菌群体感应系统。细菌群体感应系统不仅会使细菌生成抵抗抗生素的生物膜,而且会激发细菌产生毒性因子。群体感应抑制剂(quorum sensing inhibitor)本身不具有杀菌的能力,而是以细菌群体感应系统为靶目标,降解其产生的信号分子并抑制其形成生物膜,减弱细菌群落的耐药性,降低细菌的毒性[139~142]。许多动植物、微生物均可以产生特定的群体感应抑制剂,也可以通过化工合成方式制备所需的群体感应抑制剂。但是,群体感应抑制剂不足以杀死细菌,往往需要与其他功能物质组合使用。例如结合抗生素使用可以提高抗生素的抗菌作用[143],结合聚合物共同负载到Ag纳米粒子上可以在抗菌的同时提高成骨细胞生长能力[144]。

群体感应抑制剂往往作为抗菌的辅助因子,以提高抗菌效果。

3.6 表面药物抗菌

表面药物抗菌比全身给药的抗菌方式更加精准、灵活,但是表面负载的药物数量有限,面对频繁细菌感染时消耗更快且无法进行药物补充,使用寿命随细菌感染次数的增多而缩短,抗菌持续性较差。

3.7 表面正电荷物质抗菌

细菌表面蛋白质的基础单元氨基酸可解离为带负电的羧基和带正电的氨基,而细菌生长环境的pH值通常高于细菌表面氨基酸的等电点(分子表面不带电荷时的pH值),因而细菌总带负电。表面正电荷物质抗菌(surface positive charges antibacterial)正是利用细菌带负电这一特性,在Ti及钛合金表面涂覆带正电荷物质,通过静电相互作用破坏细菌细胞壁的完整性,进而达到杀菌的目的,如图5b2所示。用于合金表面带正电荷的物质主要有生物多糖,如壳聚糖[157~159];聚合阳离子,如聚乙烯亚胺衍生物、ε-聚-l-赖氨酸[123,160,161];阳离子季铵化合物[162~165]等,其中抗菌肽作为新型的抗菌剂,除了与细菌表面产生静电作用外,腺嘌呤核糖核苷酸还会破坏细菌的磷脂双分子层,导致细菌细胞质流出进而死亡[166]。这些物质均可以容易地锚定在合金表面进而发挥作用。

表面正电荷物质由于其被锚定在合金表面,在抗菌过程中损耗较少,因此可持续性更好。该方法已被广泛应用于衣物表面抗菌,在Ti及钛合金植入体表面抗菌方面非常具有潜力。

3.8 表面金属离子抗菌

钛合金植入体表面释放金属离子抗菌(metal ions antibacterial)是直接有力的方法,其作用范围广、效率高,在杀死细菌的同时,不同的金属离子具有提高钛合金植入体的生物相容性、促进骨细胞增殖等多种功能,如图5b3所示。抗菌金属元素有Au、Ag、Cu、Zn、Ga等[167~177]。其中,主流的抗菌金属元素是Ag,在Ti表面上的存在形式有纳米颗粒沉积、嵌入大分子涂层、负载在TiO2纳米管中、多巴胺固定等[178~180]。在进行抗菌行为时,Ti表面的Ag纳米颗粒会源源不断地释放Ag+,在植入体表层附近扩散开来。当接触到细菌时,Ag+会破坏细菌膜的通透性,进入细菌细胞质中引起重要蛋白质如DNA失活,进而达到灭菌的效果[145]。为了提高负载Ag的Ti植入体的生物相容性,可以在负载Ag的同时负载具有促进细胞增殖的功能离子[179]。

金属离子可以杀死多种病毒、细菌,灭菌率高,持续时间长,并且不会产生耐药性,是非常理想的抗菌手段。现已有金属离子抗菌剂应用于临床。需要注意的是,过量的金属离子与人体血液中的物质反应会产生一定的毒性,对金属离子抗菌剂的使用条件应更加严苛。

3.9 外源辅助抗菌

3.9.1 光热抗菌

为了避免Ti及钛合金植入体表面功能药物随时间推移含量减少、功效减弱和失效带来后续的重新修复,可以在植入体表面长久发挥功效的表面处理方法更容易被接受。光热抗菌(photothermal antibacterial)是长久有效的方法。光热抗菌的前提是可以在植入体表面形成长久稳定的光响应涂层,在抗菌治疗中,对植入体部位进行可见光(660 nm)或近红外光(808 nm)照射,可以激发植入体表面光响应涂层的光热效应,产生局部的活性氧(reactive oxygen species,ROS),进而杀死细菌,如图6a所示。可激发光热效应的材料有碳基纳米材料、纳米Au、CuS、MoS2、聚多巴胺等[186~190]。遗憾的是,光热抗菌的效果极其有限,彻底的杀菌往往需要相对高温和长时间的光照,而在该条件下正常的人体组织细胞也会被杀死[191]。因此,光热抗菌仍然不能单独使用,在固有的治疗条件下需要结合协同杀菌物质和利于修复的成分。例如光响应材料MoS2与聚多巴胺-精氨酸-甘氨酸-天冬氨酸结合,在MoS2通过程度相对温和的光热效应杀死细菌的同时,聚多巴胺-精氨酸-甘氨酸-天冬氨酸可以促进间充质干细胞的增殖分化,加快组织的修复[192];由聚多巴胺、氧化石墨烯、Ag纳米粒子和胶原蛋白形成的复合涂层中,在聚多巴胺、氧化石墨烯、Ag纳米粒子协同抗菌的同时,胶原蛋白可以提高植入体的生物相容性[193]。

图6

图6

光热抗菌、光动力抗菌、光声抗菌示意图

Fig.6

Schematics of photothermal antibacterial (a), photodynamic antibacterial (b), and photoacoustic antibacterial (c) (ROS—reactive oxygen species, 1O2—singlet oxygen)

3.9.2 光动力抗菌

3.9.3 光声抗菌

3.9.4 光热光动力结合抗菌

光热抗菌和光动力抗菌均需要调控适当的反应条件和时间,在温和的条件下2者的杀菌效果都会减弱,因此需要结合使用以在尽可能温和的条件下提高抗菌效果,协同抗菌[113,114,198,199]。在追求高效的抗菌效率时,往往还需要加入细胞组织修复剂。Li等[113]在Ti植入体表面同时构建了包含红磷、MoS2的光响应涂层和光敏剂IR780,并加入辅助剂聚多巴胺。2者的结合使用可以杀死细菌,破坏细菌膜,辅助剂聚多巴胺又可以促进正常细胞的黏附和生长。Yuan等[199]制备了介孔聚多巴胺、光敏剂吲哚青绿以及精氨酸-甘氨酸-天冬氨酸修饰的钛复合材料,在近红外光照射下,光敏剂和光响应材料有效杀死细菌,消除细菌膜。而精氨酸-甘氨酸-天冬氨酸的存在也使杀菌后的细胞修复得到保障。

光热抗菌、光动力抗菌以及光声抗菌的主要优势是抗菌的长久持续性,有效避免了抗菌成分失效导致的二次手术,减轻了患者的痛苦。这类型方法的缺点也较为明显,在外源治疗过程中杀死细菌的同时会造成细胞损伤,温和的条件又无法完全杀死细菌,寻找最佳治疗条件以及配合其他方法抗菌是目前主要的解决办法。

抑菌手段旨在消除细菌适宜的生存环境,从根源上让细菌无法在Ti及钛合金表面黏附、生长,如在Ti及钛合金表面构建超疏水性涂层、亲水性聚合物、仿生纳米结构,然而,这些方法在抑制细菌黏附的同时也会在一定程度上抑制细胞的黏附,需要通过改变表面粗糙度、提高表面生物活性以弥补它们的不足;或者针对细菌使用非特异性酶、群体感应抑制剂,破环细菌局部结构,降低其耐药性,抑制细菌进一步生长。抗菌手段则是直接对细菌进行灭活处理,Ti及钛合金植入体表面药物抗菌、金属离子抗菌在效果上虽然显著,但是其抗菌因子均为消耗性物质,无法保持长效;而在植入体表面锚定正电荷物质大大减少了抗菌因子的消耗,具有长久持续性;同样地,通过在Ti及钛合金表面构建可长久存在的光热、光声响应涂层,再由外源信号激活响应涂层进行杀菌的方法有效提高了抗菌的长效性,但是杀菌效果方面还需进一步改善。

4 Ti及钛合金表面改性在生物医用领域面临的挑战与未来的展望

Ti及钛合金在生物医用领域的研究,主要分为力学性能提升,生物相容性改善,植入体表面具有抑菌、抗菌性3个方向:(1) 力学性能的提升旨在使Ti及钛合金具有类骨骼性质,如接近骨骼的Young's模量,同时还要具有高的强度、硬度,抗磨损,耐体液腐蚀等性质,以保证植入体在人体中可以长久存在且不会产生有毒物质,诱发炎症。目前研究的多种钛合金可以在多种力学性能中达到最佳平衡状态,即可以同时满足多种力学性能要求,但是无法让每种力学性能都达到最佳。后续研究的目标集中在提升钛合金多种力学性能的最佳平衡状态;(2) 在提升Ti及钛合金力学性能的同时,其生物相容性的改善也是不可或缺的。生物相容性的缺失会导致合金在植入人体后久久无法与人体骨骼、周围组织紧密结合,造成植入体松动、疲劳等问题,给患者带来巨大的痛苦。研究者通过提高钛合金表面粗糙度和制备生物活性物质涂层2种主要途径已有效提高了钛合金的生物相容性。但是,只具有良好的生物相容性的钛合金远远无法满足实际应用需求;(3) 即便Ti及钛合金可以长期稳定存在于人体内且与人体周围组织结合紧密,细菌感染问题仍然无法避免。目前以及未来的发展,仍然需要聚焦于更容易引发炎症、造成生命威胁的细菌感染方面,即植入体表面抑菌、抗菌领域。无论是在Ti及钛合金表面负载抑菌/抗菌因子,还是构建外源响应涂层,在植入人体后都很难保持其持续有效性以及对人体自身细胞组织的长期无害性。

Ti及钛合金某一方面的性能提升很难长期有效地满足实际应用的多种需求。因此,研究者需要在Ti及钛合金力学性能、生物相容性以及具备抗菌性3者之间达到最佳平衡状态。即在兼顾良好的力学性能、良好的生物相容性的同时,术后无需二次手术的、长久有效的抗菌策略是Ti及钛合金在生物医用领域中未来研究的主要方向。

参考文献

Ti based biomaterials, the ultimate choice for orthopaedic implants—A review

[J].

Titanium alloys in total joint replacement—A materials science perspective

[J].Increased use of titanium alloys as biomaterials is occurring due to their lower modulus, superior biocompatibility and enhanced corrosion resistance when compared to more conventional stainless steels and cobalt-based alloys. These attractive properties were a driving force for the early introduction of alpha (cpTi) and alpha + beta (Ti-6A1-4V) alloys as well as for the more recent development of new Ti-alloy compositions and orthopaedic metastable beta titanium alloys. The later possess enhanced biocompatibility, reduced elastic modulus, and superior strain-controlled and notch fatigue resistance. However, the poor shear strength and wear resistance of titanium alloys have nevertheless limited their biomedical use. Although the wear resistance of beta-Ti alloys has shown some improvement when compared to alpha + beta alloys, the ultimate utility of orthopaedic titanium alloys as wear components will require a more complete fundamental understanding of the wear mechanisms involved. This review examines current information on the physical and mechanical characteristics of titanium alloys used in artifical joint replacement prostheses, with a special focus on those issues associated with the long-term prosthetic requirements, e.g., fatigue and wear.

Biomedical applications of titanium and its alloys

[J].

The effect of simulated inflammatory conditions on the surface properties of titanium and stainless steel and their importance as biomaterials

[J].

Chromium genotoxicity: A double-edged sword

[J].

A review of the health hazards posed by cobalt

[J].Cobalt (Co) is an essential element with ubiquitous dietary exposure and possible incremental exposure due to dietary supplements, occupation and medical devices. Adverse health effects, such as cardiomyopathy and vision or hearing impairment, were reported at peak blood Co concentrations typically over 700 µg/L (8-40 weeks), while reversible hypothyroidism and polycythemia were reported in humans at ~300 µg/L and higher (≥2 weeks). Lung cancer risks associated with certain inhalation exposures have not been observed following Co ingestion and Co alloy implants. The mode of action for systemic toxicity relates directly to free Co(II) ion interactions with various receptors, ion channels and biomolecules resulting in generally reversible effects. Certain dose-response anomalies for Co toxicity likely relate to rare disease states known to reduce systemic Co(II)-ion binding to blood proteins. Based on the available information, most people with clearly elevated serum Co, like supplement users and hip implant patients, have >90% of Co as albumin-bound, with considerable excess binding capacity to sequester Co(II) ions. This paper reviews the scientific literature regarding the chemistry, pharmacokinetics and systemic toxicology of Co, and the likely role of free Co(II) ions to explain dose-response relationships. Based on currently available data, it might be useful to monitor implant patients for signs of hypothyroidism and polycythemia starting at blood or serum Co concentrations above 100 µg/L. This concentration is derived by applying an uncertainty factor of 3 to the 300 µg/L point of departure and this should adequately account for the fact that persons in the various studies were exposed for less than one year. A higher uncertainty factor could be warranted but Co has a relatively fast elimination, and many of the populations studied were of children and those with kidney problems. Closer follow-up of patients who also exhibit chronic disease states leading to clinically important hypoalbuminemia and/or severe ischemia modified albumin (IMA) elevations should be considered.

Mechanisms and individuality in chromium toxicity in humans

[J].

Review on titanium and titanium based alloys as biomaterials for orthopaedic applications

[J].

Recent development in beta titanium alloys for biomedical applications

[J].

Biomedical titanium alloys with Young's moduli close to that of cortical bone

[J].Biomedical titanium alloys with Young's moduli close to that of cortical bone, i.e., low Young's modulus titanium alloys, are receiving extensive attentions because of their potential in preventing stress shielding, which usually leads to bone resorption and poor bone remodeling, when implants made of their alloys are used. They are generally β-type titanium alloys composed of non-toxic and allergy-free elements such as Ti-29Nb-13Ta-4.6Zr referred to as TNTZ, which is highly expected to be used as a biomaterial for implants replacing failed hard tissue. Furthermore, to satisfy the demands from both patients and surgeons, i.e., a low Young's modulus of the whole implant and a high Young's modulus of the deformed part of implant, titanium alloys with changeable Young's modulus, which are also β-type titanium alloys, for instance Ti-12Cr, have been developed. In this review article, by focusing on TNTZ and Ti-12Cr, the biological and mechanical properties of the titanium alloys with low Young's modulus and changeable Young's modulus are described. In addition, the titanium alloys with shape memory and superelastic properties were briefly addressed. Surface modifications for tailoring the biological and anti-wear/corrosion performances of the alloys have also been briefly introduced.

Effect of precipitation phase on microstructure and superelasticity of cold-rolled beta titanium alloy during heat treatment

[J].

Microstructure evolution and superelastic behavior in Ti-35Nb-2Ta-3Zr alloy processed by friction stir processing

[J].

Electrochemical behavior of equal channel angular pressed titanium for biomedical application

[C].

Synergistic interactions between corrosion and wear at titanium-based dental implant connections: A scoping review

[J].Two-piece implant systems are mainly used in oral implantology involving an osseointegrated implant connected to an abutment, which supports prosthetic structures. It is well documented that the presence of microgaps, biofilms and oral fluids at the implant-abutment connection can cause mechanical and biological complications. The aim of this review paper was to report the degradation at the implant-abutment connection by wear and corrosion processes taking place in the oral cavity. Most of the retrieved studies evaluated the wear and corrosion (tribocorrosion) of titanium-based materials used for implants and abutments in artificial saliva. Electrochemical and wear tests together with microscopic techniques were applied to validate the tribocorrosion behavior of the surfaces. A few studies inspected the wear on the inner surfaces of the implant connection as a result of fatigue or removal of abutments. The studies reported increased microgaps after fatigue tests. In addition, data suggest that micromovements occurring at the contacting surfaces can increase the wear of the inner surfaces of the connection. Biofilms and/or glycoproteins act as lubricants, although they can also amplify the corrosion of the surfaces. Consequently, loosening of the implant-abutment connection can take place during mastication. In addition, wear and corrosion debris such as ions and micro- and nanoparticles released into the surrounding tissues can stimulate peri-implant inflammation that can lead to pathologic bone resorption.© 2017 John Wiley & Sons A/S. Published by John Wiley & Sons Ltd.

A multicenter retrieval study of the taper interfaces of modular hip prostheses

[J].

Dissemination of metals from a failed patellar component made of titanium-base alloy

[J].

Peripheral neuropathy after hip replacement failure: Is vanadium the culprit?

[J].

In vivo oxide-induced stress corrosion cracking of Ti-6Al-4V in a neck-stem modular taper: Emergent behavior in a new mechanism of in vivo corrosion

[J].

The role of oxidative stress in pro-inflammatory activation of human endothelial cells on Ti6Al4V alloy

[J].Inflammation is an important step in the early phase of tissue regeneration around an implanted metallic orthopaedic device. However, prolonged inflammation, which can be induced by metallic corrosion products, can lead to aseptic loosening and implant failure. Cells in peri-implant tissue as well as metal corrosion can induce reactive oxygen species (ROS) formation, thus contributing to an oxidative microenvironment around an implant. Understanding cellular reactions to implant-induced oxidative stress and inflammatory activation is important to help prevent an adverse response to metallic materials. In an earlier study we have shown that endothelial cells grown on Ti6Al4V alloy are subjected to oxidative stress. Since endothelial cells play a critical role in inflammation, in this study we examined the role of oxidative stress in their response to pro-inflammatory activation. Therefore, we stimulated endothelial cells in contact with Ti6Al4V with tumour necrosis factor-α (TNF-α) and monitored the expression of inflammation-associated molecules, such as E-selectin, intercellular adhesion molecule-1 (ICAM-1) and interleukin-8 (IL-8). The induction of these proteins was lower in endothelial cells on Ti6Al4V compared to control tissue culture conditions. There was, however, a discrepancy in pro-inflammatory activation at protein compared to mRNA level in the cells on Ti6Al4V. To examine the role of oxidative stress in this response we utilized different ROS scavengers and showed that ROS depletion improved cellular response to TNF-α on Ti6Al4V. These results could contribute to developing strategies to improve tissue response to metal implants. © 2013 Elsevier Ltd. All rights reserved.

Biocompatibility of implantable materials: An oxidative stress viewpoint

[J].

Metal concentrations in the serum and hair of patients with titanium alloy spinal implants

[J].

Aluminium and lead: Molecular mechanisms of brain toxicity

[J].The fact that aluminium (Al) and lead (Pb) are both toxic metals to living organisms, including human beings, was discovered a long time ago. Even when Al and Pb can reach and accumulate in almost every organ in the human body, the central nervous system is a particular target of the deleterious effects of both metals. Select human population can be at risk of Al neurotoxicity, and Al is proposed to be involved in the etiology of neurodegenerative diseases. Pb is a widespread environmental hazard, and the neurotoxic effects of Pb are a major public health concern. In spite of the numerous efforts and the accumulating evidence in this area of research, the mechanisms of Al and Pb neurotoxicity are still not completely elucidated. This review will particularly address the involvement of oxidative stress, membrane biophysics alterations, deregulation of cell signaling, and the impairment of neurotransmission as key aspects involved Al and Pb neurotoxicity.

Revision hip arthroplasty: Infection is the most common cause of failure

[J].

Current modes of failure in TKA: Infection, instability, and stiffness predominate

[J].

Review of titanium surface modification techniques and coatings for antibacterial applications

[J].Implanted biomaterials play a key role in the current success of orthopedic and dental procedures. Pure titanium and its alloys are the most commonly used materials for permanent implants in contact with bone. However, implant-related infections remain among the leading reasons for failure. The most critical pathogenic event in the development of infection on biomaterials is biofilm formation, which starts immediately after bacterial adhesion. In the last decade, numerous studies reported the ability of titanium surface modifications and coatings to minimize bacterial adhesion, inhibit biofilm formation and provide effective bacterial killing to protect implanted biomaterials. In the present review, the different strategies to prevent infection onto titanium surfaces are reported: surface modification and coatings by antibiotics, antimicrobial peptides, inorganic antibacterial metal elements and antibacterial polymers. STATEMENT OF SIGNIFICANCE: Implanted biomaterials play a key role in the current success of orthopedic and dental procedures. Pure titanium and its alloys are the most commonly used materials for permanent implants in contact with bone. Microbial infection is one of the main causes of implant failure. Currently, the global infection risk is 2-5% in orthopedic surgery. Numerous solutions exist to render titanium surfaces antibacterial. The LBPS team is an expert on the functionalization of titanium surfaces by using bioactive polymers to improve the biologiocal response. In this review, the different strategies to prevent infection are reported onto titanium and titanium alloy surfaces such as surface modification by antibiotics, antimicrobial peptides, inorganic antibacterial metal elements and antibacterial polymers.Copyright © 2018 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Engineered titanium implants for localized drug delivery: Recent advances and perspectives of titania nanotubes arrays

[J].

Development of Ti-15Zr-Mo alloys for applying as implantable biomedical devices

[J].

Characterization, corrosion behavior, cellular response and in vivo bone tissue compatibility of titanium-niobium alloy with low Young's modulus

[J].

A promising of alloying modified beta-type titanium-niobium implant for biomedical applications: Microstructural characteristics, in vitro biocompatibility and antibacterial performance

[J].

Influence of Zr content on phase transformation, microstructure and mechanical properties of Ti75 - x Nb25Zr x (x = 0-6) alloys

[J].

Microstructure, mechanical properties, castability and in vitro biocompatibility of Ti-Bi alloys developed for dental applications

[J].In this study, the microstructure, mechanical properties, castability, electrochemical behaviors, cytotoxicity and hemocompatibility of Ti-Bi alloys with pure Ti as control were systematically investigated to assess their potential applications in the dental field. The experimental results showed that, except for the Ti-20Bi alloy, the microstructure of all other Ti-Bi alloys exhibit single α-Ti phase, while Ti-20Bi alloy is consisted of mainly α-Ti phase and a small amount of BiTi2 and BiTi3 phases. The tensile strength, hardness and wear resistance of Ti-Bi alloys were demonstrated to be improved monotonically with the increase of Bi content. The castability test showed that Ti-2Bi alloy increased the castability of pure Ti by 11.7%. The studied Ti-Bi alloys showed better corrosion resistance than pure Ti in both AS (artificial saliva) and ASFL (AS containing 0.2% NaF and 0.3% lactic acid) solutions. The concentrations of both Ti ion and Bi ion released from Ti-Bi alloys are extremely low in AS, ASF (AS containing 0.2% NaF) and ASL (AS containing 0.3% lactic acid) solutions. However, in ASFL solution, a large number of Ti and Bi ions are released. In addition, Ti-Bi alloys produced no significant deleterious effect to L929 cells and MG63 cells, similar to pure Ti, indicating a good in vitro biocompatibility. Besides, both L929 and MG63 cells perform excellent cell adhesion ability on Ti-Bi alloys. The hemolysis test exhibited that Ti-Bi alloys have an ultra-low hemolysis percentage below 1% and are considered nonhemolytic. To sum up, the Ti-2Bi alloy exhibits the optimal comprehensive performance and has great potential for dental applications. Copyright © 2015 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Oxidation behavior and corrosion resistance of Ti-10Ta-10Nb alloy

[J].

Osteoblast cellular activity on low elastic modulus Ti-24Nb-4Zr-8Sn alloy

[J].Low modulus β-titanium alloys with non-toxic alloying elements are envisaged to provide good biocompatibility and alleviate the undesired stress shielding effect. The objective of this study is to fundamentally elucidate the biological response of novel high strength-low elastic modulus Ti2448 alloy through the study of bioactivity and osteoblast cell functions.Characterization techniques such as SEM, EDX, XRD, and fluorescence microscopy were utilized to analyze the microstructure, morphology, chemical composition, and cell adhesion. The cellular activity was explored in terms of cell-to-cell communication involving proliferation, spreading, synthesis of extracellular and intracellular proteins, differentiation, and mineralization.The formation of fine apatite-like crystals on the surface during immersion test in simulated body fluid confirmed the bioactivity of the surface, which provided the favorable osteogenic microenvironment for cell-material interaction. The proliferation and differentiation of pre-osteoblasts and their ability to form a well mineralized bone-like extracellular matrix (ECM) by secreting bone markers (ALP, calcium, etc.) over the surface point toward the determining role of unique surface chemistry and surface properties of the Ti-24Nb-4Zr-8Sn (Ti2448) alloy in modulating osteoblasts functions.These results demonstrated that the low modulus (∼49GPa) Ti2448 alloy with non-toxic alloying elements can be used as a potential dental or orthopedic load-bearing implant material.Copyright © 2016 The Academy of Dental Materials. Published by Elsevier Ltd. All rights reserved.

Introduction of antibacterial function into biomedical TiNi shape memory alloy by the addition of element Ag

[J].A new kind of biomedical shape memory TiNiAg alloy with antibacterial function was successfully developed in the present study by the introduction of pure Ag precipitates into the TiNi matrix phase. The microstructure, mechanical property, corrosion resistance, ion release behavior in simulated body fluid, cytotoxicity and antibacterial properties were systematically investigated. The typical microstructural feature of TiNiAg alloy at room temperature was tiny pure Ag particles (at submicrometer or micrometer scales with irregular shape) randomly distributed in the TiNi matrix phase. The presence of Ag precipitates was found to result in a slightly higher tensile strength and larger elongation of TiNiAg alloy in comparison with that of TiNi binary alloy. Furthermore, a maximum shape recovery strain of ∼6.4% was obtained with a total prestrain of 7% in the TiNiAg alloy. In electrochemical and immersion tests, TiNiAg alloy presented good corrosion resistance in simulated body fluid, comparable with that of CP Ti and TiNi alloy. The cytotoxicity evaluation revealed that TiNiAg alloy extract induced slight toxicity to cells, but the viability of experimental cells was similar to or higher than that of TiNi alloy extract. In vitro bacterial adhesion study indicated a significantly reduced number of bacteria (S. aureus, S. epidermidis and P. gingivalis) on the TiNiAg alloy plate surface when compared with that on TiNi alloy plate surface, and the corresponding antibacterial mechanism for the TiNiAg alloy is discussed.Copyright © 2011 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

Effect of gas nitriding treatment on cavitation erosion behavior of commercially pure Ti and Ti-6Al-4V alloy

[J].

Microstructure and cavitation erosion properties of ceramic coatings fabricated on Ti-6Al-4V alloy by pack carburizing

[J].

Deposition of TiC film on titanium for abrasion resistant implant material by ion-enhanced triode plasma CVD

[J].

Improvements in the superelasticity and change in deformation mode of β-type TiNb24Zr2 alloys caused by aging treatments

[J].

Powder metallurgical low-modulus Ti-Mg alloys for biomedical applications

[J].

Comparative study on Ti-Nb binary alloys fabricated through spark plasma sintering and conventional P/M routes for biomedical application

[J].

Manufacture by selective laser melting and mechanical behavior of commercially pure titanium

[J].

Selective laser melting of weak-textured commercially pure titanium with high strength and ductility: A study from laser power perspective

[J].

Corrosion properties of tin prepared by laser gas alloying of Ti and Ti6Al4V

[J].

Wear resistance of a laser surface alloyed Ti-6Al-4V alloy

[J].

Excimer laser surface treatment of Ti-6Al-4V alloy for corrosion resistance enhancement

[J].

Therapeutic approaches to the treatment of neuroinflammatory diseases

[J].

Dual effects of acid etching on cell responses and mechanical properties of porous titanium with controllable open-porous structure

[J].

Biological properties of acid etched titanium implants: Effect of sandblasting on bone anchorage

[J].

The effect of sandblasting treatment on endurance properties of titanium alloy hip prostheses

[J].Sandblasting is a procedure of increasing surface roughness. This treatment is common in the orthopedic field. An increased roughness may affect the endurance limit of the material. This study investigates the effect on the endurance limit of the Ti6Al4V due to two different sandblasting treatments: fine sandblasting and coarse sandblasting. Twenty hip stems, 10 finely sandblasted and 10 coarsely sandblasted, were tested under sinusoidal fluctuating bending. The staircase method was used to estimate the endurance limit of the material. The results show an important reduction in the endurance properties up to 40% for the coarsely sandblasted specimens. The failures of the sandblasted specimens were not due to material defects. Rather, the decreased endurance strength of the sandblasted stems was caused by surface defects, which act as crack initiators. By modulating the roughness with an appropriate sandblasting treatment, it is possible to limit the reduction in the endurance limit of the alloy.

Etched implants: A comparative surface analysis of four implant systems

[J].

Effects of titanium surface topography on bone integration: A systematic review

[J].

Early endosseous integration enhanced by dual acid etching of titanium: A torque removal study in the rabbit

[J].

Antibacterial and bioactive nanostructured titanium surfaces for bone integration

[J].

Innovative surface modification procedures to achieve micro/nano-graded Ti-based biomedical alloys and implants

[J].

Early bone response to machined, sandblasting acid etching (SLA) and novel surface-functionalization (SLAffinity) titanium implants: Characterization, biomechanical analysis and histological evaluation in pigs

[J].

Effects of transition metal ion dopants (Ag, Cu and Fe) on the structural, mechanical and antibacterial properties of bioactive glass

[J].

3D printing technologies in metallic implants: A thematic review on the techniques and procedures

[J].

Review paper: Surface modification for bioimplants: The role of laser surface engineering

[J].Often hard implants undergo detachment from the host tissue due to inadequate biocompatibility and poor osteointegration. Changing surface chemistry and physical topography of the surface influences biocompatibility. At present, the understanding of biocompatibility of both virgin and modified surfaces of bioimplant materials is limited and a great deal of research is being dedicated to this aspect. In view of this, the current review casts new light on research related to the surface modification of biomaterials, especially materials for prosthetic applications. A brief overview of the major surface modification techniques has been presented, followed by an in-depth discussion on laser surface modifications that have been explored so far along with those that hold tremendous potential for bioimplant applications.

Novel laser surface texturing for improved primary stability of titanium implants

[J].Recently, the production of well-defined patterned surfaces with random or regular micro and nano-features has brought new opportunities for research and development in the field of tissue engineering and regenerative medicine. Among advanced micro and nano processing technologies, laser surface texturing (LST) stands out due to its simplicity, flexibility, precision, reproducibility and relatively low cost. This work studies the development of patterned surfaces controlled by of LST into biomedical grade V titanium, Ti-6Al-4V-alloy. We present different cross-hatched micropatterns followed by the characterisation of surface morphology and topography. Structural integrity of the produced patterns is evaluated by friction tests against bone, mimicking the insertion of an implant. Wettability is studied as it is crucial for protein adsorption and cell adhesion. The results show that the surface topography obtained using different patterning plans influences the wetting behaviour and the coefficient of friction against bone.Copyright © 2019 Elsevier Ltd. All rights reserved.

Femtosecond laser surface texturing of titanium as a method to reduce the adhesion of Staphylococcus aureus and biofilm formation

[J].

In vivo behavior and mechanical stability of surface-modified titanium implants by plasma spray coating and chemical treatments

[J].

Investigation of in vitro behavior of plasma sprayed Ti, TiO2 and HA coatings on peek

[J].

Plasma spraying of functionally graded hydroxyapatite/Ti-6Al-4V coatings

[J].

Axial suspension plasma spraying: An ultimate technique to tailor Ti6Al4V surface with hap for orthopaedic applications

[J].

Plasma spray deposition of HA-TiO2 on β-phase Ti-35Nb-7Ta-5Zr alloy for hip stem: Characterization of bio-mechanical properties, wettability, and wear resistance

[J].

In vivo assessment of synthetic and biological-derived calcium phosphate-based coatings fabricated by pulsed laser deposition: A review

[J].

Laser deposition of bioactive coatings by in situ synthesis of pseudowollastonite on Ti6Al4V alloy

[J].

Magnesium and fluoride doped hydroxyapatite coatings grown by pulsed laser deposition for promoting titanium implant cytocompatibility

[J].

Corrosion resistance of pulsed laser-treated Ti-6Al-4V implant in simulated biofluids

[J].

In vitro and in vivo osteogenic activity of titanium implants coated by pulsed laser deposition with a thin film of fluoridated hydroxyapatite

[J].

Mechanical properties of pulsed laser-deposited hydroxyapatite thin film implanted at high energy with N+ and Ar+ ions. Part I: nanoindentation with spherical tipped indenter

[J].

Laser ablation and deposition of bioglass® 45S5 thin films

[J].

Electrochemical behavior of biomedical titanium alloys coated with diamond carbon in Hanks' solution

[J].

Bio-inspired YSZ coated titanium by EB-PVD for biomedical applications

[J].

Calcium phosphate coatings for bio-implant applications: Materials, performance factors, and methodologies

[J].

Calcium phosphate composite layers for surface-mediated gene transfer

[J].

Significance of calcium phosphate coatings for the enhancement of new bone osteogenesis—A review

[J].A systematic analysis of results available from in vitro, in vivo and clinical trials on the effects of biocompatible calcium phosphate (CaP) coatings is presented. An overview of the most frequently used methods to prepare CaP-based coatings was conducted. Dense, homogeneous, highly adherent and biocompatible CaP or hybrid organic/inorganic CaP coatings with tailored properties can be deposited. It has been demonstrated that CaP coatings have a significant effect on the bone regeneration process. In vitro experiments using different cells (e.g. SaOS-2, human mesenchymal stem cells and osteoblast-like cells) have revealed that CaP coatings enhance cellular adhesion, proliferation and differentiation to promote bone regeneration. However, in vivo, the exact mechanism of osteogenesis in response to CaP coatings is unclear; indeed, there are conflicting reports of the effectiveness of CaP coatings, with results ranging from highly effective to no significant or even negative effects. This review therefore highlights progress in CaP coatings for orthopaedic implants and discusses the future research and use of these devices. Currently, an exciting area of research is in bioactive hybrid composite CaP-based coatings containing both inorganic (CaP coating) and organic (collagen, bone morphogenetic proteins, arginylglycylaspartic acid etc.) components with the aim of promoting tissue ingrowth and vascularization. Further investigations are necessary to reveal the relative influences of implant design, surgical procedure, and coating characteristics (thickness, structure, topography, porosity, wettability etc.) on the long-term clinical effects of hybrid CaP coatings. In addition to commercially available plasma spraying, other effective routes for the fabrication of hybrid CaP coatings for clinical use still need to be determined and current progress is discussed. Copyright © 2013 Acta Materialia Inc. Published by Elsevier Ltd. All rights reserved.

In-situ preparation of scholzite conversion coatings on titanium and Ti-6Al-4V for biomedical applications

[J].

Synergistic antibacterial activity of multi components in lysozyme/chitosan/silver/hydroxyapatite hybrid coating

[J].

Cytocompatibility and early osseointegration of nano TiO2-modified Ti-24Nb-4Zr-7.9Sn surfaces

[J].

Fabrication of dopamine-modified hyaluronic acid/chitosan multilayers on titanium alloy by layer-by-layer self-assembly for promoting osteoblast growth

[J].

Anodization of titanium alloys for orthopedic applications

[J].

A review of the application of anodization for the fabrication of nanotubes on metal implant surfaces

[J].

Mechanisms regulating increased production of osteoprotegerin by osteoblasts cultured on microstructured titanium surfaces

[J].Osteoblasts grown on microstructured Ti surfaces enhance osteointegration by producing local factors that regulate bone formation as well as bone remodeling, including the RANK ligand decoy receptor osteoprotegerin (OPG). The objective of this study was to explore the mechanism by which surface microstructure and surface energy mediate their stimulatory effects on OPG expression. Titanium disks were manufactured to present different surface morphologies: a smooth pretreatment surface (PT, Ra<0.2microm), microstructured sandblasted/acid etched surface (SLA, Ra=3-4microm), and a microstructured Ti plasma-sprayed surface (TPS, Ra=4microm). Human osteoblast-like MG63 cells were cultured on these substrates and the regulation of OPG production by TGF-beta1, PKC, and alpha2beta1 integrin signaling determined. Osteoblasts produced increased amounts of OPG as well as active and latent TGF-beta1 and had increased PKC activity when grown on SLA and TPS. Exogenous TGF-beta1 increased OPG production in a dose-dependent manner on all surfaces, and this was prevented by adding blocking antibody to the TGF-beta type II receptor or by reducing TGF-beta1 binding to the receptor by adding exogenous soluble type II receptor. The PKC inhibitor chelerythrine inhibited the production of OPG in a dose-dependent manner, but only in cultures on SLA and TPS. shRNA knockdown of alpha2 or a double knockdown of alpha2beta1 also reduced OPG, as well as production of TGF-beta1. These results indicate that substrate-dependent OPG production is regulated by TGF-beta1, PKC, and alpha2beta1 and suggest a mechanism by which alpha2beta1 signaling increases PKC, resulting in TGF-beta1 production and TGF-beta1 then acts on its receptor to increase transcription of OPG.

Microrough titanium surface affects biologic response in MG63 osteoblast-like cells

[J].

The effect of anatase TiO2 nanotube layers on MC3T3-E1 preosteoblast adhesion, proliferation, and differentiation

[J].

The influence of hierarchical hybrid micro/nano-textured titanium surface with titania nanotubes on osteoblast functions

[J].

One-step fabrication of cytocompatible micro/nano-textured surface with TiO2 mesoporous arrays on titanium by high current anodization

[J].

Enhanced interfacial adhesion and osseointegration of anodic TiO2 nanotube arrays on ultra-fine-grained titanium and underlying mechanisms

[J].

Improved osseointegration of dental titanium implants by TiO2 nanotube arrays with recombinant human bone morphogenetic protein-2: A pilot in vivo study

[J].

Effects of titanium nanotubes on the osseointegration, cell differentiation, mineralisation and antibacterial properties of orthopaedic implant surfaces

[J].

Effect of alkali and heat treatments for bioactivity of TiO2 nanotubes

[J].

Antibacterial effect and cytocompatibility of nano-structured TiO2 film containing Cl

[J].

Self-organized nanotubular layer on Ti-4Zr-22Nb-2Sn alloys formed in organic electrolytes

[J].

Effects of concentration of Ag nanoparticles on surface structure and in vitro biological responses of oxide layer on pure titanium via plasma electrolytic oxidation

[J].

First titanium dental implants with white surfaces: Preparation and in vitro tests

[J].To evaluate first white titanium surfaces developed for improvement of existing clinically used titanium-based implants Ticer.The anodic plasma-electrochemical oxidation in aqueous solutions of sodium hydroxide and calcium dihydrogen phospate was used to prepare three novel anodic conversion layers with white titanium oxide surfaces. The surfaces have been characterized by the means of scanning electron microscopy, surface microanalysis and X-ray diffraction. In vitro studies were conducted on primary human osteoblast cells using novel surfaces (M1-M3) as well as commercially pure titanium (Ti cp), Ticer and SS (subtracted surface). An indirect toxicity test using MTT and SRB assays has been carried out. Furthermore, immunohistochemical analysis of cell proliferation, morphology, and expression of non-collagenous bone matrix proteins (sialoprotein, BSP, and osteocalcin, OC) were performed.The basic morphology of the surfaces shows clusters in a size of 100 μm of knob-like structures. The coatings are composed of rutile and monoclinic sodium titanates. Novel white surfaces (M1-M3) induced proliferation rates, morphological changes and influenced the expression of OC and BSP similarly to Ticer. On the other hand, Ti cp and SS exhibited different in vitro behavior.The novel surfaces expressed similar in vitro behavior as Ticer, successfully used in clinical practice. Furthermore, due to their white color they are also promising from the esthetic point of view. The results described herein open the door toward a new generation of white titanium dental implants.Copyright © 2014 Academy of Dental Materials. Published by Elsevier Ltd. All rights reserved.

Preparation and properties of plasma electrolytic oxidation coating on sandblasted pure titanium by a combination treatment

[J].

Study on bioactivity and bonding strength between Ti alloy substrate and TiO2 film by micro-arc oxidation

[J].

Antimicrobial property, cytocompatibility and corrosion resistance of Zn-doped ZrO2/TiO2 coatings on Ti6Al4V implants

[J].

Three-species biofilm model onto plasma-treated titanium implant surface

[J].

Effects of miR-335-5p in modulating osteogenic differentiation by specifically downregulating Wnt antagonist DKK1

[J].Dickkopf-related protein 1 (DKK1) is essential to maintain skeletal homeostasis as an inhibitor of Wnt signaling and osteogenic differentiation. The purpose of this study was to investigate the molecular mechanisms underlying the developmental stage-specific regulation of the DKK1 protein level. We performed a series of studies including luciferase reporter assays, micro-RNA microarray, site-specific mutations, and gain- and loss-of-function analyses. We found that the DKK1 protein level was regulated via DKK1 3' UTR by miRNA control, which was restricted to osteoblast-lineage cells. As a result of decreased DKK1 protein level by miR-335-5p, Wnt signaling was enhanced, as indicated by elevated GSK-3β phosphorylation and increased β-catenin transcriptional activity. The effects of miR-335-5p were reversed by anti-miR-335-5p treatment, which downregulated endogenous miR-335-5p. In vivo studies showed high expression levels of miR-335-5p in osteoblasts and hypertrophic chondrocytes of mouse embryos, indicating a pivotal role of miR-335-5p in regulating bone development. In conclusion, miR-335-5p activates Wnt signaling and promotes osteogenic differentiation by downregulating DKK1. This cell- and development-specific regulation is essential and mandatory for the initiation and progression of osteogenic differentiation. miR-335-5p proves to be a potential and useful targeting molecule for promoting bone formation and regeneration.Copyright © 2011 American Society for Bone and Mineral Research.

The promotion of bone regeneration through positive regulation of angiogenic-osteogenic coupling using microRNA-26a

[J].

Erratum to ‘Peptide-mediated intracellular delivery of miRNA-29b for osteogenic stem cell differentiation' [Biomaterials 34 (2013) 4347-4359]

[J].

Surface functionalization of titanium alloy with miR-29b nanocapsules to enhance bone regeneration

[J].

The synergistic effect of strontium-substituted hydroxyapatite and microRNA-21 on improving bone remodeling and osseointegration

[J].

Mir-21 promotes osseointegration and mineralization through enhancing both osteogenic and osteoclastic expression

[J].

Multilayer modification on titanium surface for in situ delivery of MicroRNAs

[J].

Effect of friction hardening pre-treatment on increasing cytocompatibility of alkali heat-treated Ti-6Al-4V alloy

[J].

Enhancing the biological response of titanium surface through the immobilization of bone morphogenetic protein-2 using the natural cross-linker genipin

[J].

Preparation of hydroxyapatite layer on Ti-based bulk metallic glasses by acid and alkali pre-treatment

[J].

Interfacial characteristic of graded hydroxyapatite and titanium thin film by magnetron sputtering

[J].

Highly effective and noninvasive near-infrared eradication of a Staphylococcus aureus biofilm on implants by a photoresponsive coating within 20 min

[J].

Rapid biofilm eradication on bone implants using red phosphorus and near-infrared light

[J].

Creating micro textured surfaces for the improvement of surface wettability through ultrasonic vibration assisted turning

[J].

Facile fabrication of a superhydrophobic titanium surface with mechanical durability by chemical etching

[J].

Preparation of polypropylene superhydrophobic surface and its blood compatibility

[J].

Effect of superhydrophobic surface of titanium on Staphylococcus aureus adhesion

[J].

Preparation of superhydrophobic surface on titanium alloy via micro-milling, anodic oxidation and fluorination

[J].

Hydrophobic coatings for prevention of dental enamel erosion

[J].

Reducing bacterial infections and biofilm formation using nanoparticles and nanostructured antibacterial surfaces

[J].

Covalent attachment of poly(ethylene glycol) to surfaces, critical for reducing bacterial adhesion

[J].

Staphylococcus aureus adhesion to titanium oxide surfaces coated with non-functionalized and peptide-functionalized poly(l-lysine)-grafted-poly(ethylene glycol) copolymers

[J].Implanted biomaterials are coated immediately with host plasma constituents, including extracellular matrix (ECM); this reaction may be undesirable in some cases. Poly(L-lysine)-grafted-poly(ethylene glycol) (PLL-g-PEG) has been shown to spontaneously adsorb from aqueous solution onto metal oxide surfaces, effectively reducing the degree of non-specific adsorption of blood and ECM proteins, and decreasing the adhesion of fibroblastic and osteoblastic cells to the coated surfaces. Cell adhesion through specific peptide-integrin receptors could be restored on surfaces coated with PLL-g-PEG functionalized with peptides of the RGD (Arg-Asp-Gly) type. To date, no study has examined the effect of surface modifications by PLL-g-PEG-based polymers on bacterial adhesion. The ability of Staphylococcus aureus to adhere to the ECM and plasma proteins deposited on biomaterials is a significant factor in the pathogenesis of medical-device-related infections. This study describes methods for visualizing and quantifying the adhesion of S. aureus to smooth and rough (chemically etched) titanium surfaces without and with monomolecular coatings of PLL-g-PEG, PLL-g-PEG/PEG-RGD and PLL-g-PEG/PEG-RDG. The different surfaces were exposed to S. aureus cultures for 1-24h and bacteria surface density was evaluated using scanning electron microscopy and fluorescence microscopy. Coating titanium surfaces with any of the three types of copolymers significantly decreased the adhesion of S. aureus to the surfaces by 89-93% for PLL-g-PEG, and 69% for PLL-g-PEG/PEG-RGD. Therefore, surfaces coated with PLL-g-PEG/PEG-RGD have the ability to attach cells such as fibroblasts and osteoblasts while showing reduced S. aureus adhesion, resulting in a selective biointeraction pattern that may be useful for applications in the area of osteosynthesis, orthopaedic and dental implantology.

The effect of incorporating RGD adhesive peptide in polyethylene glycol diacrylate hydrogel on osteogenesis of bone marrow stromal cells

[J].Advances in tissue engineering require biofunctional scaffolds that can not only provide cells with structural support, but also interact with cells in a biological manner. To achieve this goal, a frequently used cell adhesion peptide Arg-Gly-Asp (RGD) was covalently incorporated into poly(ethylene glycol) diacrylate (PEODA) hydrogel and its dosage effect (0.025, 1.25 and 2.5 mm) on osteogenesis of marrow stromal cells in a three-dimensional environment was examined. Expression of bone-related markers, osteocalcin (OCN) and Alkaline phosphatase (ALP), increased significantly as the RGD concentration increased. Compared with no RGD, 2.5 mm RGD group showed a 1344% increase in ALP production and a 277% increase in OCN accumulation in the medium. RGD helped MSCs maintain cbfa-1 expression when shifted from a two-dimensional environment to a three-dimensional environment. Soluble RGD was found to completely block the mineralization of marrow stromal cells, as manifested by quantitative calcium assay, phosphorus elemental analysis and Von Kossa staining. In conclusion, we have demonstrated that RGD-conjugated PEODA hydrogel promotes the osteogenesis of MSCs in a dosage-dependent manner, with 2.5 mm being optimal concentration.

Antibacterial and antifouling catheter coatings using surface grafted PEG-b-cationic polycarbonate diblock copolymers

[J].Intravascular catheter-associated infections (CAIs), which are normally induced by microbial adhesion and subsequent biofilm formation, are a major cause of morbidity and mortality. Therefore, strategies to prevent CAIs are in great demand. In this study, a series of diblock copolymers of PEG and cationic polycarbonate with various compositions were synthesized by metal-free organocatalytic ring-opening polymerization, and coated onto silicone rubber (a commonly used catheter material) at different concentrations via a reactive polydopamine coating. Static contact angle and X-ray photoelectron spectroscopy measurements proved the successful coating, and quartz crystal microbalance results showed that the coating thickness increased as polymer concentration increased. Methicillin-susceptible Staphylococcus aureus (MSSA) and methicillin-resistant S. aureus (MRSA) isolates - leading causes of intravascular CAIs - were employed to evaluate the antibacterial and antifouling activities of the polymer coatings. Polymer coatings with a hydrophobic component effectively killed planktonic MSSA and MRSA in solution and prevented their fouling on silicone rubber surface. Live/dead cell staining experiments revealed that polymer coatings with the optimal polymer composition possessed significantly higher antifouling activity than PEG coating. In addition, scanning electron microscopic studies showed that the polymer coating inhibited S. aureus biofilm formation over a period of 7 days. Furthermore, the polymer coating caused no significant hemolysis, and there was no blood protein adsorption or platelet adhesion observed. Therefore, PEG-b-cationic polycarbonates with optimal compositions are effective antifouling and antibacterial coatings for the prevention of intravascular CAIs.Copyright © 2012 Elsevier Ltd. All rights reserved.

Brush-like polycarbonates containing dopamine, cations, and PEG providing a broad-spectrum, antibacterial, and antifouling surface via one-step coating

[J].

An adaptive biointerface from self-assembled functional peptides for tissue engineering

[J].

Bactericidal activity of black silicon

[J].Black silicon is a synthetic nanomaterial that contains high aspect ratio nanoprotrusions on its surface, produced through a simple reactive-ion etching technique for use in photovoltaic applications. Surfaces with high aspect-ratio nanofeatures are also common in the natural world, for example, the wings of the dragonfly Diplacodes bipunctata. Here we show that the nanoprotrusions on the surfaces of both black silicon and D. bipunctata wings form hierarchical structures through the formation of clusters of adjacent nanoprotrusions. These structures generate a mechanical bactericidal effect, independent of chemical composition. Both surfaces are highly bactericidal against all tested Gram-negative and Gram-positive bacteria, and endospores, and exhibit estimated average killing rates of up to similar to 450,000 cells min(-1) cm(-2). This represents the first reported physical bactericidal activity of black silicon or indeed for any hydrophilic surface. This biomimetic analogue represents an excellent prospect for the development of a new generation of mechano-responsive, antibacterial nanomaterials.

The nature of inherent bactericidal activity: Insights from the nanotopology of three species of dragonfly

[J].While insect wings are widely recognised as multi-functional, recent work showed that this extends to extensive bactericidal activity brought about by cell deformation and lysis on the wing nanotopology. We now quantitatively show that subtle changes to this topography result in substantial changes in bactericidal activity that are able to span an order of magnitude. Notably, the chemical composition of the lipid nanopillars was seen by XPS and synchrotron FTIR microspectroscopy to be similar across these activity differences. Modelling the interaction between bacterial cells and the wing surface lipids of 3 species of dragonflies, that inhabit similar environments, but with distinctly different behavioural repertoires, provided the relationship between surface structure and antibacterial functionality. In doing so, these principal behavioural patterns correlated with the demands for antimicrobial efficiency dictated by differences in their foraging strategies. This work now reveals a new feature in the design elegance of natural multi-functional surfaces as well providing insights into the bactericidal mechanism underlying inherently antimicrobial materials, while suggesting that nanotopology is related to the evolutionary development of a species through the demands of its behavioural repertoire. The underlying relationship between the processes of wetting, adhesion and capillarity of the lipid nanopillars and bactericidal efficiency suggests new prospects for purely mechano-responsive antibacterial surfaces.

Balancing bacteria-osteoblast competition through selective physical puncture and biofunctionalization of ZnO/polydopamine/arginine-glycine-aspartic acid-cysteine nanorods

[J].

Unusual air filters with ultrahigh efficiency and antibacterial functionality enabled by ZnO nanorods

[J].

Impact of RGD nanopatterns grafted onto titanium on osteoblastic cell adhesion

[J].This work reports on the synthesis of titanium bone implants functionalized with nanoparticles (NPs) containing Arg-Gly-Asp-Cys peptide (RGDC) and shows the adhesion behavior of cells seeded on these materials. RGDC peptides were first conjugated to a norbornenyl-poly(ethylene oxide) macromonomer (Nb-PEO). Then, functional NPs with a size of ∼300 nm and constituted of polynorbornene core surrounded by poly(ethylene oxide) shell were prepared by ring-opening metathesis polymerization in dispersed medium. The grafting density of these NPs on the titanium surface is up to 2 NPs·μm(-2) (80 pmol of RGDC per cm(-2) of NP surface). Cell adhesion was evaluated using preosteoblast cells (MC3T3-E1). Results of cells cultured for 24 h showed that materials grafted with NPs functionalized with RGDC peptides enhance specific cell adhesion and can create filopodia-like structures among NP sites by stressing the cells.

Advantages of RGD peptides for directing cell association with biomaterials

[J].Despite many years of in vitro research confirming the effectiveness of RGD in promoting cell attachment to a wide variety of biomaterials, animal studies evaluating tissue responses to implanted RGD-functionalized substrates have yielded more variable results. The goals of this report are to present some of the reasons why cell culture studies may not always reliably predict in vivo responses, and more importantly, to highlight potential applications that may benefit from the use of RGD peptides.Copyright © 2011 Elsevier Ltd. All rights reserved.

A functional DNase I coating to prevent adhesion of bacteria and the formation of biofilm

[J].

Implant infections: Adhesion, biofilm formation and immune evasion

[J].Medical device-associated infections account for a large proportion of hospital-acquired infections. A variety of opportunistic pathogens can cause implant infections, depending on the type of the implant and on the anatomical site of implantation. The success of these versatile pathogens depends on rapid adhesion to virtually all biomaterial surfaces and survival in the hostile host environment. Biofilm formation on implant surfaces shelters the bacteria and encourages persistence of infection. Furthermore, implant-infecting bacteria can elude innate and adaptive host defences as well as biocides and antibiotic chemotherapies. In this Review, we explore the fundamental pathogenic mechanisms underlying implant infections, highlighting orthopaedic implants and Staphylococcus aureus as a prime example, and discuss innovative targets for preventive and therapeutic strategies.

A multinuclear metal complex based dnase-mimetic artificial enzyme: Matrix cleavage for combating bacterial biofilms

[J].

A series of MOF/Ce-based nanozymes with dual enzyme-like activity disrupting biofilms and hindering recolonization of bacteria

[J].

Quorum sensing in bacteria

[J].Quorum sensing is the regulation of gene expression in response to fluctuations in cell-population density. Quorum sensing bacteria produce and release chemical signal molecules called autoinducers that increase in concentration as a function of cell density. The detection of a minimal threshold stimulatory concentration of an autoinducer leads to an alteration in gene expression. Gram-positive and Gram-negative bacteria use quorum sensing communication circuits to regulate a diverse array of physiological activities. These processes include symbiosis, virulence, competence, conjugation, antibiotic production, motility, sporulation, and biofilm formation. In general, Gram-negative bacteria use acylated homoserine lactones as autoinducers, and Gram-positive bacteria use processed oligo-peptides to communicate. Recent advances in the field indicate that cell-cell communication via autoinducers occurs both within and between bacterial species. Furthermore, there is mounting data suggesting that bacterial autoinducers elicit specific responses from host organisms. Although the nature of the chemical signals, the signal relay mechanisms, and the target genes controlled by bacterial quorum sensing systems differ, in every case the ability to communicate with one another allows bacteria to coordinate the gene expression, and therefore the behavior, of the entire community. Presumably, this process bestows upon bacteria some of the qualities of higher organisms. The evolution of quorum sensing systems in bacteria could, therefore, have been one of the early steps in the development of multicellularity.

Quorum sensing: Cell-to-cell communication in bacteria

[J].

Quorum sensing between Pseudomonas aeruginosa biofilms accelerates cell growth

[J].This manuscript describes the fabrication of arrays of spatially confined chambers embossed in a layer of poly(ethylene glycol) diacrylate (PEGDA) and their application to studying quorum sensing between communities of Pseudomonas aeruginosa. We hypothesized that biofilms may produce stable chemical signaling gradients in close proximity to surfaces, which influence the growth and development of nearby microcolonies into biofilms. To test this hypothesis, we embossed a layer of PEGDA with 1.5-mm wide chambers in which P. aeruginosa biofilms grew, secreted homoserine lactones (HSLs, small molecule regulators of quorum sensing), and formed spatial and temporal gradients of these compounds. In static growth conditions (i.e., no flow), nascent biofilms secreted N-(3-oxododecanoyl) HSL that formed a gradient in the hydrogel and was detected by P. aeruginosa cells that were ≤8 mm away. Diffusing HSLs increased the growth rate of cells in communities that were <3 mm away from the biofilm, where the concentration of HSL was >1 μM, and had little effect on communities farther away. The HSL gradient had no observable influence on biofilm structure. Surprisingly, 0.1-10 μM of N-(3-oxododecanoyl) HSL had no effect on cell growth in liquid culture. The results suggest that the secretion of HSLs from a biofilm enhances the growth of neighboring cells in contact with surfaces into communities and may influence their composition, organization, and diversity.

Combating biofilm associated infection in vivo: Integration of quorum sensing inhibition and photodynamic treatment based on multidrug delivered hollow carbon nitride sphere

[J].

Hamamelitannin analogues that modulate quorum sensing as potentiators of antibiotics against Staphylococcus aureus

[J].The modulation of bacterial communication to potentiate the effect of existing antimicrobial drugs is a promising alternative to the development of novel antibiotics. In the present study, we synthesized 58 analogues of hamamelitannin (HAM), a quorum sensing inhibitor and antimicrobial potentiator. These efforts resulted in the identification of an analogue that increases the susceptibility of Staphylococcus aureus towards antibiotics in vitro, in Caenorhabditis elegans, and in a mouse mammary gland infection model, without showing cytotoxicity.© 2016 WILEY-VCH Verlag GmbH & Co. KGaA, Weinheim.

Enzyme multilayer coatings inhibit Pseudomonas aeruginosa biofilm formation on urinary catheters

[J].

Antibacterial surface design of biomedical titanium materials for orthopedic applications

[J].

Staphylococcus epidermidis saeR is an effector of anaerobic growth and a mediator of acute inflammation

[J].The saeRS two-component regulatory system regulates transcription of multiple virulence factors in Staphylococcus aureus. In the present study, we demonstrated that the saePQRS region in Staphylococcus epidermidis is transcriptionally regulated in a temporal manner and is arranged in a manner similar to that previously described for S. aureus. Studies using a mouse foreign body infection model demonstrated that the virulence of strain 1457 and the virulence of a mutant, strain 1457 saeR, were statistically equivalent. However, histological analyses suggested that the polymorphonuclear neutrophil response at 2 days postinfection was significantly greater in 1457-infected mice than in 1457 saeR-infected mice, demonstrating that SaeR influences the early, acute phases of infection. Microarray analysis demonstrated that a saeR mutation affected the transcription of 65 genes (37 genes were upregulated and 28 genes were downregulated); in particular, 8 genes that facilitate growth under anaerobic conditions were downregulated in 1457 saeR. Analysis of growth under anaerobic conditions demonstrated that 1457 saeR had a decreased growth rate compared to 1457. Further metabolic experiments demonstrated that 1457 saeR had a reduced capacity to utilize nitrate as a terminal electron acceptor and exhibited increased production of lactic acid in comparison to 1457. These data suggest that in S. epidermidis SaeR functions to regulate the transition between aerobic growth and anaerobic growth. In addition, when grown anaerobically, 1457 saeR appeared to compensate for the redox imbalance created by the lack of electron transport-mediated oxidation of NADH to NAD+ by increasing lactate dehydrogenase activity and the subsequent oxidation of NADH.

Bacteria-targeting nanoparticles with microenvironment-responsive antibiotic release to eliminate intracellular Staphylococcus aureus and associated infection

[J].

Essential Staphylococcus aureus toxin export system