金属结构材料的强化提高屈服强度,应变硬化提高塑性[23],传统强化与应变硬化的微观机制均为林位错塑性[23],即位错的形成、储存、增殖与交互作用。利用晶界强化和形变强化等,得到高强度的纳米及超细晶结构[6,10,11],往往还在晶粒内部储存了高密度位错,这些位错提前消耗了林硬化(forest hardening)、即减弱了随后的塑性变形和应变硬化能力。根据Considère判据,这些高强度微结构在小应变时应变硬化率就赶不上流变应力而无法持续进行均匀变形,因而林硬化能力的不足是其低塑性的原因[10,11],这导致了快速发生应变局部化失稳,即颈缩。本质上,强度与拉伸塑性之间的协同关系是基于林位错塑性的强化与应变硬化的相互竞争和演化,迄今提升应变硬化能力的微结构设计策略包括利用纳米析出[22]、第二相[19]、相变[15]、孪晶[9]以及晶粒细化[20]等,其核心都是增强林位错塑性,即通过形成和存储位错,阻碍位错滑移、促进位错交互作用,然而这些策略对于高强度结构却具有相当的挑战性[6~9]。

旨在提升高强度金属材料的拉伸塑性,近来提出了异构(heterostructure)的应变硬化策略[24~27],其微结构设计的出发点是一个力学概念,即塑性应变梯度[28~30]。异构是有序构筑强度和塑性这2个力学性能具有显著差异的区域(例如晶粒)而形成的微结构[24,27],其中最具代表性的是梯度结构[13,31~35],以晶粒尺寸为梯度变量,跨尺度的晶粒在三维空间形成了从纳米晶到粗晶的梯度分布[13,33]。梯度变量也可以是化学组分[36]或各种微结构和亚结构,例如相组成[37]、孪晶[38]和位错胞[39]等,形成含量、体积分数或密度等的梯度分布。层状结构也是一种极具特色的异构[24],是仅包括纳米结构和粗晶2个尺度晶粒的两级晶粒异构,最近还报道了纳米、亚微米和微米等3种尺度晶粒所构成的三级异构[40]。其实,晶粒内部包含纳米孪晶、纳米析出[41]以及位错胞[42,43]等的微结构时,无论是均匀分布还是梯度分布,只要发生了特征的异质塑性变形,即在拉伸加卸载时形成了力学迟滞环[44,45],就可称为异构。此外,还设计出了不同类型的复合异构,例如晶粒尺寸与晶粒内部纳米孪晶密度的双梯度异构[38],以及晶粒尺寸与纳米析出相密度的双梯度异构[46]。

异构在2个方面不同于传统的均质微结构(homogeneous microstructure),一是晶界的塑性协调变形[26,47~51],二是基于几何必需位错(geometrically necessary dislocations,GNDs)的异质塑性变形[26,27,44]。例如跨尺度异构中,相邻晶粒塑性变形不兼容并在三维空间相互约束,在晶界附近引起了应变梯度[33,52],并形成了协调应变梯度的几何必需位错[27,28,53],因而,应变梯度是异构晶界标志性的塑性响应,几何必需位错则是协调应变梯度的必然结果[28]。研究表明,在拉伸加卸载过程中出现的力学迟滞环[54,55],是几何必需位错较大程度地参与塑性变形并形成背应力的标志性应力应变响应[44]。一般地,位错塑性变形机制应该能够同时解释拉伸加载与卸载过程的力学行为[44],而单一的林位错塑性则无法解释迟滞环的形成及卸载塑性行为。换言之,力学迟滞环是异构区别于传统均质结构的关键力学塑性响应,表明异构同时具有林位错塑性以及几何必需位错的塑性行为。特别地,GNDs引起了异质变形诱导的应力,包括背应力和前应力[42,43,56~58],引起了额外的强化[59]、特别是额外的应变硬化[33],后者往往与林硬化相当、甚至占比更大[24,40],这是异构应变硬化的关键特点,也是异构提升拉伸塑性和韧性的根本原因。

1 异构的微结构特征

1.1 异构及其类型

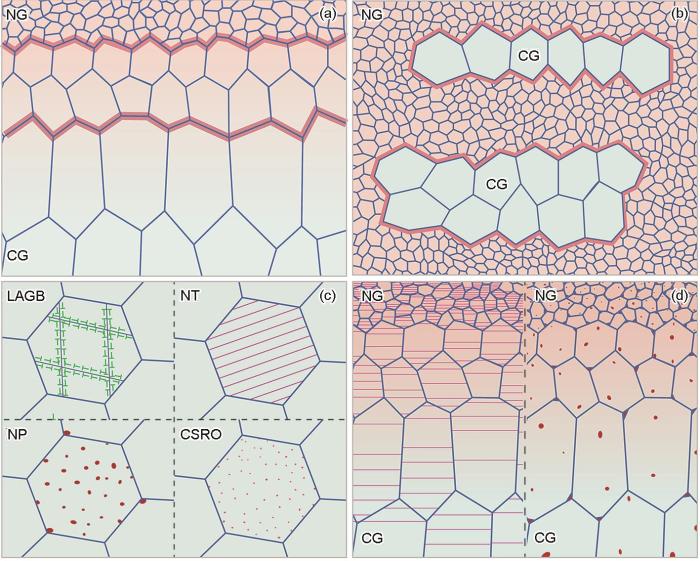

异构可分为3类:一是基元异构,例如跨尺度晶粒的有序构筑以及双相结构等;二是亚基元异构,即基元内部包含了次级的组成物或亚结构,例如纳米孪晶、纳米析出或第二相,甚至小角位错界面等;三是前2种异构组合的复合异构。图1a和b是2种典型的基元异构,根据基元序构(有序构筑)的方式又可称之为梯度结构[13]和层状结构[24],前者的晶粒从纳米晶(NG)到粗晶(CG)在三维空间连续分布,后者则是粗晶聚集为层状并非连续地分布在高强结构的基体上。基元异构有2个典型的微结构特征:一是跨尺度的晶粒;二是长程的异质界面(暗红色线段),异质界面两侧晶粒大的尺寸差异导致不兼容塑性,将产生几何必需位错[28~30]。图1c示意了几种亚基元异构,晶粒内部包含各种“人工的”亚基元组成物,例如小角位错界面[42,43]、纳米孪晶[73,74]及纳米析出[75~77],以及“天然的”亚基元组成物,例如中/高熵合金中纳米尺度的化学短程与中程有序[78~80],后者往往是塑性稳定的有序结构并具有类似纳米析出阻碍位错滑移的作用[78,81]。图1d示意了2种复合异构,即晶粒尺寸和纳米孪晶(左)/纳米析出相密度(右)的双梯度异构。

图1

图1

金属结构材料的异构:基元异构(分别为梯度结构和层状结构)、亚基元异构及复合异构

Fig.1

Heterostructures (HSs) in metallic materials

(a, b) zone HSs. Typical examples are gradient structure (a) and lamellar structure (b) (Thick dull-red lines: hetero-zone boundaries; NG: nano-grain; CG: coarse grain)

(c) sub-zone HSs of four kinds, respectively, with the low-angle grain boundary (LAGB), nano-twin (NT), nano-precipitate (NP), and chemical short-range order (CSRO) inside the grain interior, all independently as the sub-constituent of HSs

(d) composite-like HSs, usually with dual-gradients in both grain size and nano-twin (left)/nano-precipitate (right)

1.2 异构的基元与序构

图2

图2

异构基元及其微观设计

Fig.2

Schematic of characteristic zones in a heterostructure (Upper panel: yield strength (σy), plastic strain (εp), and strain gradient (λ), all as a function of grain size. Thereinto, σy obeys the Hall-Petch relationship, while both εp and λ are of the plasticity-related size effect[28,29]. Shadow area: the maximal strain gradient and strongest strain hardening, usually in the micron range, as the criterion for the HS design[24,26,27]. Lower panel: characteristic HS zones, with a sharply contrasting (σy, εp) combination for the hard/soft zones. HB: hetero-zone boundary. NG here represents nano-grain of high-density dislocation tangles at/inside both the boundaries and interiors)

异构基元在微结构和力学性质上表现出几个特点。首先,基元异构中相邻区域,即2个晶粒之间存在明显、甚至跨尺度的尺寸差异(图1a和b),相应地,2个晶粒具有两极分化的力学性质组合(图2),例如粗晶的低强度大塑性与纳米晶的高强度低塑性[13,24],尤其是明显差异的微观塑性变形和应变硬化能力。其次,基元界面称为异质区界面(hetero-zone boundary,HB)[26],由于异质界面两侧晶粒的微观塑性不兼容[27,48],界面的关键作用是实现相邻晶粒的塑性协调以及应变硬化,特别是针对高强纳米结构的应变硬化、抑制其早期局域化失稳[24,26]。第三,拉伸塑性(

式中,σh与σl分别为高强度与低强度区域的屈服强度。

2 异构的塑性变形

2.1 异构基元的特征力学响应

式中,γ为剪应变,

图3

图3

异构基元的2个特征力学响应:应变梯度和力学迟滞环[27,52,55]

Fig.3

Two characteristic mechanical responses during tensile deformation in heterostructures

(a) distribution of λ. Upon straining, the initial HB extends to the hetero-zone boundary affected region (HBAR)[27,52]

(b) mechanical hysteresis loop during unload-reload cycle[55] (

式中,ρtotal为位错的总密度,ρSSDs和ρGNDs分别为SSDs和GNDs的密度。为此,异构塑性变形时的应变硬化,即流变应力的增量Δσ取决于SSDs和GNDs 2类位错,见

式中,M为Taylor因子,α为材料相关的常数,μ为剪切模量,b为Burgers矢量模。

一般地,ξ越大,表明相邻晶粒的塑性不兼容程度越大,则异质界面的应变梯度就越大,ρGNDs越高,相应地,基于GNDs的异质塑性变形以及基于GNDs的额外应变硬化占比也越大[24,27,40]。进而,只要发生基于GNDs的异质塑性变形,就会在拉伸卸载-再加载过程中形成力学迟滞环[40,55],如图3b[55]所示。异构在加卸载拉伸时,应力-应变曲线上出现的力学迟滞环是其标志性的塑性变形响应[55,61],也是之所以称为异构的根本原因。力学迟滞环的最大宽度被定义为卸载屈服应变[40],一般在0.1%~0.2%,表明即使在外加拉伸应力状态下,仍然发生了局域的压缩塑性变形[40,55],换言之,异构在拉伸变形时发生了应力状态的改变,局域可为多轴应力状态[25,33],同步辐射原位测试证实了拉伸变形时梯度结构纳米层发生了应力状态改变[86]。实验测试和理论研究都证实了异构的2个标志性力学响应,即应变梯度[33,52,87~89]和迟滞环[90~95]。

2.2 异质塑性变形诱导的应力

异构基元在初始塑性变形时,异质界面附近的局域应力会率先激活粗晶内部的位错源[24,53],在滑移面上发射位错,其前端受阻于异质界面,从而形成位错塞积[26,27,58,96],如图4a所示,在层片异构的微米级晶粒中观察到形成的位错塞积,如图4b[24]所示,认为这些位错是几何必需位错,其作用是协调界面塑性。随着位错塞积中位错数量的不断增加,这些位错形成一个力,作用于位错源并抑制其发射位错,此时需要额外增大外加应力才能使位错源继续发射位错,这个由于几何必需位错塞积引起、额外增加的应力被称为背应力(back stress)[42,43,56~58],也称为长程内应力(long-range internal stress)[56],作用于粗晶内部,如图4a所示。同时,位错塞积产生的这个力还作用于异质界面的另一侧,称为前应力(forward stress)[42,43],其作用范围可跨越很多纳米晶粒,这需要实验和理论模拟的进一步研究。把背应力和前应力组合起来,称为异质变形应力(hetero-deformation-induced stress),即HDI-应力[26,27]。针对晶粒内部的小角位错界面、晶界和相界等,已经建立了基于背应力的位错塞积模型[26,42,43]。最近,透射电镜原位拉伸粗晶Cu/纳米晶黄铜的层片异构时,观察到粗晶中位错源启动并不断向异质界面发射位错,形成了位错塞积(图4c中箭头所示),如图4c[53]所示,支持了异构背应力起源的位错塞积机制[53]。利用拉伸加卸载测试可进行背应力的定量测试[97],随后考虑到卸载屈服的影响进行了修正[59],需要指出的是所计算的背应力实际上是HDI-应力[26,27]。

图4

Fig.4

Hetero-deformation-induced stress (HDI-stress) in terms of the geometrically necessary dislocation (GND) pile-up

(a) back stress (σback) and forward stress (σforward) exerted on CG and NG, respectively, as a function of distance inside the hetero-zone boundary affected region (HBAR). F-R: Frank-Reed source to form the dislocation pile-up on the slip plane. Blue arrow: indefinite scope of σforward to extend into the nano-grains so far due to the lack of the experimental and theoretical evidences (b, c) dislocation pile-up in heterostructures[24,53]

3 异构的微结构演化

3.1 异质界面影响区

异构基元在塑性变形时,在异质界面两侧的一定范围内,发现侧向压缩应变形成了反常的负应变梯度 [52],这表明初始的异质区界面演化为异质界面影响区(hetero-zone boundary affected region,HBAR)[27,52],如图3[27,52,55]所示。广义地,可以把异质界面附近形成应变梯度的区域称为HBAR,显然,粗晶内所形成的几何必需位错主要集中在这个区域。异构初始变形时,异质界面附近的局域不仅应变大,还处于大应力的复杂应力状态,很容易激活位错源[27,52,53],从而提高了界面附近的位错密度,这是HBAR负应变梯度形成的原因[52]。进一步,推导出了层片异构HBAR的特征宽度

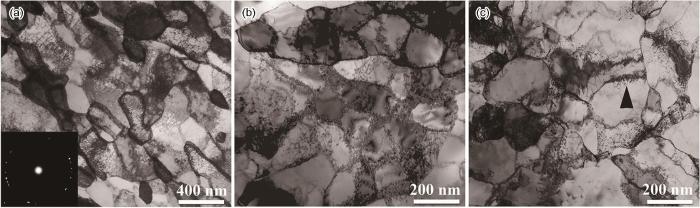

3.2 异构中纳米结构的位错行为演化

纳米结构拉伸变形时应变硬化能力极低[3,6,8,9],纳米结构进行独立的拉伸相比其在异构中进行拉伸,前者的拉伸塑性远小于后者[13,33]。异构塑性变形的核心问题是其高强度结构的位错行为,决定了高强度结构以及异构的塑性变形和应变硬化。异构塑性变形时,纳米结构是与粗晶协调变形,从而表现出不同于其独立变形时的位错行为[25,26]。以梯度异构中的纳米晶粒为例[33,98],其典型特征是高密度位错缠结的晶界,如图5a[33]所示。在梯度结构的塑性变形初期,无论是晶界还是晶粒内部,位错从其高密度缠结中逐渐解开了缠绕,如图5b[33],导致位错湮灭,即位错密度降低。随后,新形成了位错并储存于晶粒内部,出现了新的位错胞和位错亚晶界,如图5c[33]。位错演化过程中,并没有发生界面的迁移、即晶粒长大。因而,纳米晶粒在协调变形时位错先湮灭再储存,即位错密度先降低再升高,纳米结构相应地先应变软化而后硬化,显微硬度表现出与位错密度演化一致的变化规律[99],即随应变的增加先降低再升高。位错演化行为很可能与作用于纳米结构的前应力有关,即前应力促使已有位错沿所在滑移面或进行反向滑移或交滑移,从而导致位错解开纠结和湮灭(disentanglement-and-annihilation)。其实,与背应力的作用类似,前应力也会改变纳米结构的局域应力状态[33]即应变路径,大量实验和理论研究[100,101]表明,应力状态即应变路径的改变会降低位错密度。

图5

图5

位错湮灭/形成以及位错塞积[33]

Fig.5

Dynamic dislocation evolution in response to plastic deformation in heterostructured interstitial-free steel[33]

(a) initially entangled dislocations of high density at/inside both the hetero-boundary and interiors

(b) dis-entanglement of dislocations (c) newly-generated dislocations

因而,前应力对于异构中高强度纳米结构起到了关键作用,即腾出了纳米晶粒内部的空间,使位错的重新储存成为可能,部分恢复了林位错塑性和林硬化能力,还形成了可动位错,从而减缓并抑制了纳米结构发生早期应变局域化的倾向,可进行持续的均匀变形。

4 异构塑性变形与应变硬化

4.1 异构的去应变局域化

异构中高强度晶粒中位错演化行为(图5[33])的直接结果是去应变局域化(strain de-localization),这是典型的塑性变形特征[13,33]。梯度异构同样具有代表性,其纳米结构是一个独立的表层,需满足苛刻的变形要求,即与粗晶进行等塑性应变的拉伸变形。在Cu纳米晶粒的梯度异构中[13],纳米Cu发生了变形诱导的长大,恢复了林位错塑性和林硬化。针对纳米结构很难长大的其他梯度异构以及层片异构等,利用数字图像耦合原位拉伸[52,99]以及同步辐射原位拉伸[86]进行定点观察并测试,发现异构中纳米结构的去应变局域化特征,即形成一条宏观应变带[99]或多重弥散分布的微观应变带[52,87,88]。具体地,低应变硬化的纳米结构率先发生应变局域化,即形成应变带,甚至在应变带形核初期就引起了局部颈缩[99],应变带随后连续扩展,其前端产生了应变梯度并发生了应力状态改变[86],促进了几何必需位错和林位错密度的不断增加[99],同时受到塑性稳定的粗晶所约束,抑制了变形带与局部颈缩的快速扩展和早期失稳,即发生了去应变局域化。应变带扩展过程中,应变带本身承担了占比很大的塑性应变[99];同时,在应变带扩展结束后,纳米结构还部分恢复了林位错塑性和林硬化,异构可以进行均匀变形,这是异构微观塑性变形的普适机理。

4.2 异构的应变硬化

式中,σ和

式中,方程右边第二项为纳米结构的初始应变软化,第三项为异构的额外HDI-硬化。

式中,等号右边分别为纳米晶和粗晶的额外应变硬化。

式中,等号右边分别为晶界(GB)、孪晶界(TB)、位错界面(DB)、析出和第二相(particle)的额外应变硬化。基于实验结果,图6示意了异构

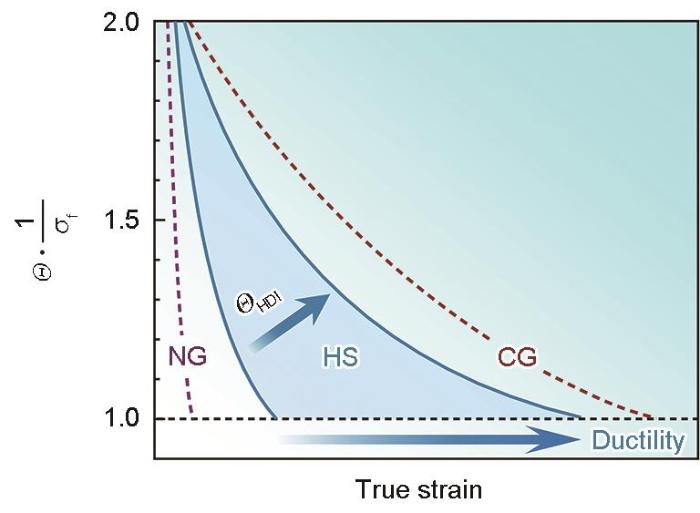

图6

图6

异构的应变硬化率

Fig.6

Normalized strain hardening rate (Θ =

额外HDI-硬化是异构应变硬化的本征特性。首先,前应力引起了纳米结构的额外硬化(但伴随初期的应变软化),不仅抑制其早期塑性失稳,还部分恢复了林位错塑性和林硬化,使其均匀塑性应变。其次,应变梯度具有尺度效应(图2)[96,102,103],在微米尺度最大[96],多见于1~10 μm[96,104],因而,基于几何必需位错的HDI-硬化也是晶粒尺度相关的,粗晶在微米量级时异构的综合硬化效应最为明显[24,103]。第三,异构拉伸变形时,常出现屈服降式(yield-drop-like)的非连续屈服现象[33,55],应变硬化率先快速下降再缓慢升高。利用引入了几何必需位错和背应力的塑性本构模型[105,106],发现屈服降是前应力作用于纳米结构的结果,即纳米结构中位错密度的降低导致了瞬态软化,随后形成新的位错并存储,林硬化和HDI-硬化同时增加。最后,HDI-硬化的作用空间范围以及占比取决于异构中强韧匹配的序构即ξ值,ξ值越大则GNDs密度越高,HDI-硬化能力也越强[24,40]。

5 异构的额外强化

梯度异构中,发现异构的屈服强度大于混合法则计算得到的屈服强度[59],或大于异构中最强组成相的屈服强度[74],表明异构在屈服过程中产生了额外强化。同步辐射原位拉伸结果[86]表明,梯度结构的屈服是从低强度粗晶到高强度纳米晶依次发生,特别地,在已屈服与未屈服的界面观察到一个高密度位错峰,分析表明该位错峰对应已屈服与未屈服区域之间塑性不协调引起的几何必需位错,这是额外强化的位错来源。针对梯度纳米孪晶Cu[74],微观结构观察并结合分子动力学计算模拟,同样发现额外的强化归因于梯度结构之间相互约束而产生的大量几何必需位错的富集束,这些位错富集束在变形初期形成,沿着梯度方向均匀分布在晶粒内部,富集束阻碍位错运动,提高了强度。因而,额外强化是异构非连续屈服导致的本征特性。

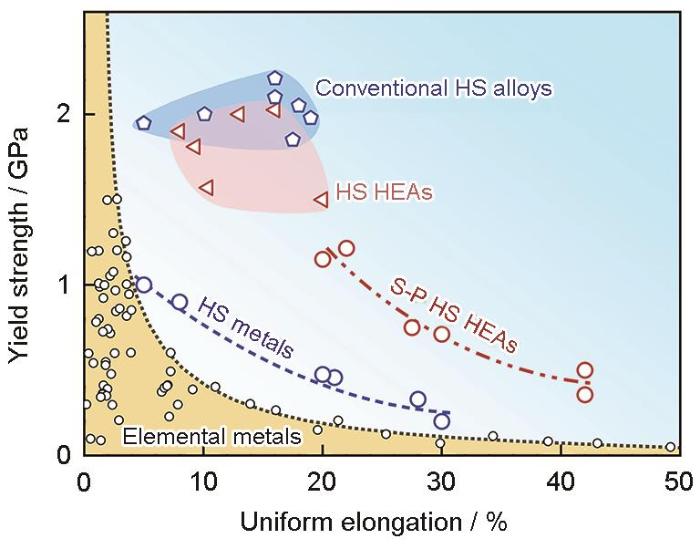

6 异构强度与塑性的协同关系

图7总结了在传统金属材料和中高熵合金中利用异构策略提升强度与塑性匹配的结果。相比均质单相金属(黄色区域),单相的异构金属提高了拉伸均匀塑性(蓝色虚线),即提升了强度与拉伸塑性之间的协同关系,曲线向右上方迁移,这归因于异构的额外应变硬化。同时,单相fcc结构的中/高熵合金异构(红色虚线)则更为显著地提升了强度与拉伸塑性之间的协同关系,这很可能还与其固溶强化[107,108]、点阵畸变[109]、化学短程有序[78~80]和浓度波[110]相关。特别地,在1.5~2 GPa的超高屈服强度范围,无论是传统合金的异构还是中/高熵合金异构,多为依靠纳米析出、马氏体相变和变形孪晶等的各种亚基元复合异构[111~114],获得了理想的均匀拉伸塑性,2者强度与塑性的性能域也基本一致,这表明了超高屈服强度下异构可观的应变硬化潜力。

图7

图7

异构屈服强度与拉伸均匀塑性之间的协同关系

Fig.7

Strength-and-ductility balance in metallic materials (Two areas in blue and pink: ultra-high strength (> 1.5 GPa) alloys all with the nanostructure as the matrix; HEA: high-entropy alloy; S-P: single phase)

7 展望

异构金属材料展现出了一种独特的塑性自协调力学响应,即形成了应变梯度并因此而产生几何必需位错,从而引起了独特的额外应变硬化,不仅抑制了异构中高强度结构的应变局域化,还进一步恢复了其林位错塑性和硬化并实现均匀塑性变形,这是异构提高拉伸塑性和断裂韧性的内在原因。

利用传统的工业制备与成型技术可实现异构金属结构材料的制备。例如,利用各种表面变形技术、扭转技术和电沉积技术等制备梯度结构,冷轧结合退火可得到层状异构、多级晶粒异构以及各种复合异构,利用电解沉积技术可制备孪晶片层厚度和晶粒尺寸精准可控的纳米孪晶Cu异构。同时,通过调控热处理退火等工艺可获得不同强度级别的异构,拓展了异构的强度与塑性匹配范围。

异构金属材料所面临的挑战在于高屈服强度的设计策略。可以预期,异构会包括大量的纳米尺度高强度微结构,例如析出、第二相、相变和孪生变形等,具有先天强烈的局域化倾向,为此,需要在实验以及理论计算与模拟方面同时开展基于应变梯度的高密度异质界面的微观异构设计,揭示应变梯度、几何必需位错和应变硬化的內禀相互关联,建立纳米析出、纳米孪晶等纳米组成与额外应变硬化和林硬化的定量关联。同时,需要对异构使役性能(例如疲劳与断裂)以及损伤容限性能的相关研究。

参考文献

Paradox of strength and ductility in metals processed bysevere plastic deformation

[J].

Stabilizing nanostructures in metals using grain and twin boundary architectures

[J].

Strengthening materials by engineering coherent Internal boundaries at the nanoscale

[J].Strengthening materials traditionally involves the controlled creation of internal defects and boundaries so as to obstruct dislocation motion. Such strategies invariably compromise ductility, the ability of the material to deform, stretch, or change shape permanently without breaking. Here, we outline an approach to optimize strength and ductility by identifying three essential structural characteristics for boundaries: coherency with surrounding matrix, thermal and mechanical stability, and smallest feature size finer than 100 nanometers. We assess current understanding of strengthening and propose a methodology for engineering coherent, nanoscale internal boundaries, specifically those involving nanoscale twin boundaries. Additionally, we discuss perspectives on strengthening and preserving ductility, along with potential applications for improving failure tolerance, electrical conductivity, and resistance to electromigration.

Ductility of nanostructured materials

[J].

Review on superior strength and enhanced ductility of metallic nanomaterials

[J].

Instabilities and ductility of nanocrystalline and ultrafine-grained metals

[J].

Nanostructured metals—Retaining ductility

[J].

Significance of stacking fault energy in bulk nanostructured materials: Insights from Cu and its binary alloys as model systems

[J].

Nanostructural metallic materials: Structures and mechanical properties

[J].

An overview of tailoring strain delocalization for strength-ductility synergy

[J].

Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper

[J].Nano-grained (NG) metals are believed to be strong but intrinsically brittle: Free-standing NG metals usually exhibit a tensile uniform elongation of a few percent. When a NG copper film is confined by a coarse-grained (CG) copper substrate with a gradient grain-size transition, tensile plasticity can be achieved in the NG film where strain localization is suppressed. The gradient NG film exhibits a 10 times higher yield strength and a tensile plasticity comparable to that of the CG substrate and can sustain a tensile true strain exceeding 100% without cracking. A mechanically driven grain boundary migration process with a substantial concomitant grain growth dominates plastic deformation of the gradient NG structure. The extraordinary intrinsic plasticity of gradient NG structures offers their potential for use as advanced coatings of bulk materials.

High tensile ductility in a nanostructured metal

[J].

High dislocation density-induced large ductility in deformed and partitioned steels

[J].A wide variety of industrial applications require materials with high strength and ductility. Unfortunately, the strategies for increasing material strength, such as processing to create line defects (dislocations), tend to decrease ductility. We developed a strategy to circumvent this in inexpensive, medium manganese steel. Cold rolling followed by low-temperature tempering developed steel with metastable austenite grains embedded in a highly dislocated martensite matrix. This deformed and partitioned (D and P) process produced dislocation hardening but retained high ductility, both through the glide of intensive mobile dislocations and by allowing us to control martensitic transformation. The D and P strategy should apply to any other alloy with deformation-induced martensitic transformation and provides a pathway for the development of high-strength, high-ductility materials.Copyright © 2017 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Hardening by annealing and softening by deformation in nanostructured metals

[J].We observe that a nanostructured metal can be hardened by annealing and softened when subsequently deformed, which is in contrast to the typical behavior of a metal. Microstructural investigation points to an effect of the structural scale on fundamental mechanisms of dislocation-dislocation and dislocation-interface reactions, such that heat treatment reduces the generation and interaction of dislocations, leading to an increase in strength and a reduction in ductility. A subsequent deformation step may restore the dislocation structure and facilitate the yielding process when the metal is stressed. As a consequence, the strength decreases and the ductility increases. These observations suggest that for materials such as the nanostructured aluminum studied here, deformation should be used as an optimizing procedure instead of annealing.

Ultrahigh strength and high electrical conductivity in copper

[J].Methods used to strengthen metals generally also cause a pronounced decrease in electrical conductivity, so that a tradeoff must be made between conductivity and mechanical strength. We synthesized pure copper samples with a high density of nanoscale growth twins. They showed a tensile strength about 10 times higher than that of conventional coarse-grained copper, while retaining an electrical conductivity comparable to that of pure copper. The ultrahigh strength originates from the effective blockage of dislocation motion by numerous coherent twin boundaries that possess an extremely low electrical resistivity, which is not the case for other types of grain boundaries.

Enhanced strength and ductility of bulk CoCrFeMnNi high entropy alloy having fully recrystallized ultrafine-grained structure

[J].

Nanostructured high-strength molybdenum alloys with unprecedented tensile ductility

[J].The high-temperature stability and mechanical properties of refractory molybdenum alloys are highly desirable for a wide range of critical applications. However, a long-standing problem for these alloys is that they suffer from low ductility and limited formability. Here we report a nanostructuring strategy that achieves Mo alloys with yield strength over 800 MPa and tensile elongation as large as ~ 40% at room temperature. The processing route involves a molecular-level liquid-liquid mixing/doping technique that leads to an optimal microstructure of submicrometre grains with nanometric oxide particles uniformly distributed in the grain interior. Our approach can be readily adapted to large-scale industrial production of ductile Mo alloys that can be extensively processed and shaped at low temperatures. The architecture engineered into such multicomponent alloys offers a general pathway for manufacturing dispersion-strengthened materials with both high strength and ductility.

Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off

[J].

Simultaneously increasing the ductility and strength of nanostructured alloys

[J].

Strain hardening in Fe-16Mn-10Al-0.86C-5Ni high specific strength steel

[J].

Commentary. A brief view of work hardening

[J].

Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility

[J].

Heterogeneous materials: A new class of materials with unprecedented mechanical properties

[J].

Perspective on hetero-deformation induced (HDI) hardening and back stress

[J].

Heterostructured materials: Superior properties from hetero-zone interaction

[J].

The deformation of plastically non-homogeneous materials

[J].

Geometrically necessary dislocation and size-dependent plasticity

[J].

Mechanism-based strain gradient plasticity—I. Theory

[J].

Making strong nanomaterials ductile with gradients

[J].

Make nanostructured metal exceptionally tough by introducing non-localized fracture behaviors

[J].

Extraordinary strain hardening by gradient structure

[J].

Simultaneous improvement of strength and plasticity: Additional work-hardening from gradient microstructure

[J].

Modeling of the plastic deformation of nanostructured materials with grain size gradient

[J].

Mechanical behavior of a compositionally graded 300M steel

[J].

Surface nanocrystallization (SNC) of metallic materials—Presentation of the concept behind a new approach

[J].

Extra strengthening and work hardening in gradient nanotwinned metals

[J].

Gradient cell-structured high-entropy alloy with exceptional strength and ductility

[J].

Dynamically reinforced heterogeneous grain structure prolongs ductility in a medium-entropy alloy with gigapascal yield strength

[J].

Dual heterogeneous structures lead to ultrahigh strength and uniform ductility in a Co-Cr-Ni medium-entropy alloy

[J].Alloys with ultra-high strength and sufficient ductility are highly desired for modern engineering applications but difficult to develop. Here we report that, by a careful controlling alloy composition, thermomechanical process, and microstructural feature, a Co-Cr-Ni-based medium-entropy alloy (MEA) with a dual heterogeneous structure of both matrix and precipitates can be designed to provide an ultra-high tensile strength of 2.2 GPa and uniform elongation of 13% at ambient temperature, properties that are much improved over their counterparts without the heterogeneous structure. Electron microscopy characterizations reveal that the dual heterogeneous structures are composed of a heterogeneous matrix with both coarse grains (10∼30 μm) and ultra-fine grains (0.5∼2 μm), together with heterogeneous L1-structured nanoprecipitates ranging from several to hundreds of nanometers. The heterogeneous L1 nanoprecipitates are fully coherent with the matrix, minimizing the elastic misfit strain of interfaces, relieving the stress concentration during deformation, and playing an active role in enhanced ductility.

Dislocation wall and cell structures and long-range internal stresses in deformed metal crystals

[J].

A numerical study of long range internal stresses associated with subgrain boundaries

[J].

The bauschinger effect in whisker-reinforced metal-matrix composites

[J].

Dislocation behavior in fatigue II. Friction stress and back stress as inferred from an analysis of hysteresis loops

[J].

Designing structures with combined gradients of grain size and precipitation in high entropy alloys for simultaneous improvement of strength and ductility

[J].

Ductility and strain hardening in gradient and lamellar structured materials

[J].

Gradient and lamellar heterostructures for superior mechanical properties

[J].

Towards understanding the structure-property relationships of heterogeneous-structured materials

[J].

Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys

[J].

Gradient nanostructured materials

[J].In this paper, research progresses on gradient nanostructured materials in recent years is briefly reviewed. It includes classification of gradient nanostructures, properties and processing techniques of the gradient nanostructured materials. Perspectives and challenges on scientific understanding and industrial applications of gradient nanostructured materials are addressed.

梯度纳米结构材料

[J].

Interface affected zone for optimal strength and ductility in heterogeneous laminate

[J].

In-situ observation of dislocation dynamics near heterostructured interfaces

[J].There has been a long-standing controversy on how dislocations interact with interfaces. Here we report in-situ observations that in a Cu-brass heterostructured TEM film Frank-Read sources are the primary dislocation sources. They were dynamically formed and deactivated throughout the deformation in grain interior, which has never been reported before. This observation indicates that strain gradient near interfaces cannot be quantitatively related to the density gradient of geometrically necessary dislocations, and it was primarily produced by Frank-Read source gradient instead of dislocation pile-ups. These findings provide new insights on how to design heterostructured interfaces to enhance mechanical properties. [GRAPHICS]

Internal stresses in plasticity, microplasticity and ductile fracture

[J].

Back stress strengthening and strain hardening in gradient structure

[J].

Causes and effects of internal stresses

[A].

On the nature of the long-range back stress in copper

[J].

On the role of strain gradients and long-range internal stresses in the composite model of crystal plasticity

[J].

Synergetic strengthening by gradient structure

[J].

Towards strength-ductility synergy through the design of heterogeneous nanostructures in metals

[J].

Tailoring heterogeneities in high-entropy alloys to promote strength-ductility synergy

[J].Conventional alloys are usually based on a single host metal. Recent high-entropy alloys (HEAs), in contrast, employ multiple principal elements. The strength of HEAs is considerably higher than traditional solid solutions, as the many constituents lead to a rugged energy landscape that increases the resistance to dislocation motion, which can also be retarded by other heterogeneities. The wide variety of nanostructured heterogeneities in HEAs, including those generated on the fly during tensile straining, also offer elevated strain-hardening capability that promotes uniform tensile ductility. Citing recent examples, this review explores the multiple levels of heterogeneities in multi-principal-element alloys that contribute to lattice friction and back stress hardening, as a general strategy towards strength-ductility synergy beyond current benchmark ranges.

Combining gradient structure and TRIP effect to produce austenite stainless steel with high strength and ductility

[J].

Extraordinary fracture toughness in nickel induced by heterogeneous grain structure

[J].

On the exceptional damage-tolerance of gradient metallic materials

[J].

Superior fracture toughness in a high-strength austenitic steel with heterogeneous lamellar microstructure

[J].

Anisotropic toughening of nanotwin bundles in the heterogeneous nanostructured Cu

[J].

Fracture behavior of heterogeneous nanostructured 316L austenitic stainless steel with nanotwin bundles

[J].

Fatigue life improvement through surface nanostructuring of stainless steel by means of surface mechanical attrition treatment

[J].

Improved fatigue resistance of gradient nanograined Cu

[J].Cyclic stresses generally lead to fatigue damage and failure with important implications for material and component design, safety, performance and lifetime costs in major structural applications. Here we present unique results for copper to demonstrate that a thin superficial layer of graded surface nanostructure over a coarse-grained core suppresses strain localization and surface roughening, thereby imparting unprecedented resistance to both low-cycle and high-cycle fatigue without compromising ductility. Progressive homogenization of the surface-graded copper is shown to be superior in fatigue properties compared to that of any of its homogeneous counterparts with micro-, submicro- or nanograined structures. Since the findings here for enhancing resistance to fatigue are broadly applicable to a wide spectrum of engineering metals and alloys, the present results offer unique pathways to mitigate fatigue damage using a broad variety of processing routes, geometric design considerations, and structural parameters in many practical applications. (C) 2018 Acta Materialia Inc. Published by Elsevier Ltd.

Low-cycle and extremely-low-cycle fatigue behaviors of high-Mn austenitic TRIP/TWIP alloys: Property evaluation, damage mechanisms and life prediction

[J].

Enhanced thermal stability of nanograined metals below a critical grain size

[J].

Lowering coefficient of friction in Cu alloys with stable gradient nanostructures

[J].

Strengthening an austenitic Fe-Mn steel using nanotwinned austenitic grains

[J].

Unraveling the origin of extra strengthening in gradient nanotwinned metals

[J].

The work-hardening of copper-silica

[J].

The determination of the elastic field of an ellipsoidal inclusion, and related problems

[J].

The work-hardening of copper-silica: IV. The Bauschinger effect and plastic relaxation

[J].

Direct observation of chemical short-range order in a medium-entropy alloy

[J].

Chemical medium-range order in a medium-entropy alloy

[J].High-/medium-entropy alloys (H/MEA) have the inherent local chemical order. Yet, as a structural link between the incipient short-range order and mature long-range counterpart, the chemical medium-range order (CMRO) is conjectural and remains open questions as to if, and what kind of, CMRO would be produced and if CMRO is mechanically stable during plastic deformation. Here, we show compelling evidences for CMRO in an AlCrCoNi MEA. Specifically, the electron diffraction under both [[Formula: see text]] and [[Formula: see text]] zone axis show the definite spots for CMRO of lattice periodicity. CMRO entities are seen directly of medium-ranged in sizes by using dark-field imaging, along with the tendency towards like-pair avoidance and unlike-pair preference based on atomic-resolution EDS mapping. These findings substantiate CMRO with a realistic structural picture in view of crystal periodicity and chemical species occupation, shedding light on understanding the microstructural link at an extended length scale beyond the short-range order.© 2022. The Author(s).

Enhanced strength and ductility in a high-entropy alloy via ordered oxygen complexes

[J].

Strengthening in multi-principal element alloys with local-chemical-order roughened dislocation pathways

[J].

A micromechanical model for heterogeneous nanograined metals with shape effect of inclusions and geometrically necessary dislocation pileups at the domain boundary

[J].

Enhanced ductility of surface nano-crystallized materials by modulating grain size gradient

[J].

Geometrically necessary boundaries, incidental dislocation boundaries and geometrically necessary dislocations

[J].

A multiscale model for the ductile fracture of crystalline materials

[J].

Plastic accommodation during tensile deformation of gradient structure

[J].

Extra strengthening in a coarse/ultrafine grained laminate: Role of gradient interfaces

[J].

Dense dispersed shear bands in gradient-structured Ni

[J].

Mechanical property comparisons between CrCoNi medium-entropy alloy and 316 stainless steels

[J].We systematically compared the mechanical properties of CrCoNi, a recently emerged prototypical medium-entropy alloy (MEA) with face-centered-cubic (FCC) structure, with hallmark FCC alloys, in particular, the well-known austenitic 316L and 316LN stainless steels, which are also concentrated single-phase FCC solid solutions and arguably next-of-kin to the MEAs. The tensile and impact properties, across the temperatures range from 373 K to 4.2 K, as well as fracture toughness at 298 K and 77 K, were documented. From room temperature to cryogenic temperature, all three alloys exhibited similarly good mechanical properties; CrCoNi increased its tensile uniform elongation and fracture toughness, which was different from the decreasing trend of the 316L and 316LN. On the other hand, the stainless steels showed higher fracture toughness than CrCoNi at all temperatures. To explain the differences in macroscopic mechanical properties of the three alloys, microstructural hardening mechanisms were surveyed. CrCoNi MEA relied on abundant mechanical twinning on the nanoscale, while martensitic transformation was dominant in 316L at low temperatures. The deformation mechanisms in the plastic zone ahead of the propagating crack in impact and fracture toughness tests were also analyzed and compared for the three alloys.

Enhanced strength-ductility synergy in ultrafine-grained eutectic high-entropy alloys by inheriting microstructural lamellae

[J].Realizing improved strength-ductility synergy in eutectic alloys acting as in situ composite materials remains a challenge in conventional eutectic systems, which is why eutectic high-entropy alloys (EHEAs), a newly-emerging multi-principal-element eutectic category, may offer wider in situ composite possibilities. Here, we use an AlCoCrFeNi EHEA to engineer an ultrafine-grained duplex microstructure that deliberately inherits its composite lamellar nature by tailored thermo-mechanical processing to achieve property combinations which are not accessible to previously-reported reinforcement methodologies. The as-prepared samples exhibit hierarchically-structural heterogeneity due to phase decomposition, and the improved mechanical response during deformation is attributed to both a two-hierarchical constraint effect and a self-generated microcrack-arresting mechanism. This work provides a pathway for strengthening eutectic alloys and widens the design toolbox for high-performance materials based upon EHEAs.

Aged metastable high-entropy alloys with heterogeneous lamella structure for superior strength-ductility synergy

[J].

Excellent strength-ductility synergy properties of gradient nano-grained structural CrCoNi medium-entropy alloy

[J].Tailoring heterogeneities could bring out excellent strength-ductility synergy properties. A gradient nano-grained (GNG) structure, i.e. grain size range from nanometer (∼50 nm) at topest surface layer to micrometer (∼1.3 μm) at center layer, was successfully introduced into CrCoNi medium-entropy alloy (MEA) by means of high energy shot peening in this work. Experimental results demonstrated that this GNG CrCoNi MEA shows excellent strength and ductility combination properties, exhibiting high yield strength and ultimate tensile strength of ∼1215 MPa and ∼1524 MPa, respectively, while remaining a good ductility of ∼23.0%. The extraordinary hetero-deformation induced (HDI) hardening origins from heterogeneous structure, i. e. GNG structure, which contributes to the majority strength enhancement. Dynamical reinforced heterogeneous structure during tension process results in the enhanced HDI hardening effect, which facilitates excellent ductility and strain hardening capacity at high-level strength. Our work provide not only a feasible and effective way to strengthen the CrCoNi MEA, and other low stacking faults energy (SFE) materials, but also an useful insight to understanding HDI hardening in heterogeneous structure.

Achieving ultra-high strength and ductility in equiatomic CrCoNi with partially recrystallized microstructures

[J].Despite having otherwise outstanding mechanical properties, many single-phase medium and high entropy alloys are limited by modest yield strengths. Although grain refinement offers one opportunity for additional strengthening, it requires significant and undesirable compromises to ductility. This work therefore explores an alternative, simple processing route to achieve strength by cold-rolling and annealing an equiatomic CrCoNi alloy to produce heterogeneous, partially recrystallized microstructures. Tensile tests reveal that our approach dramatically increases the yield strength (to similar to 1100 MPa) while retaining good ductility (total elongation similar to 23%) in the single-phase CrCoNi alloy. Scanning and transmission electron microscopy indicate that the strengthening is due to the non-recrystallized grains retaining their deformation-induced twins and very high dislocation densities. Load-unload-reload tests and grain-scale digital image correlation are also used to study the accumulation of plastic deformation in our highly heterogeneous microstructures. (C) 2018 Acta Materialia Inc. Published by Elsevier Ltd.

Hierarchical features infused heterogeneous grain structure for extraordinary strength-ductility synergy

[J].

Strain partitioning enables excellent tensile ductility in precipitated heterogeneous high-entropy alloys with gigapascal yield strength

[J].

Bauschinger effect in thin metal films

[J].

On the origin of the tensile flow stress in the stainless steel AISI 316L at 300 K: Back stress and effective stress

[J].

Indentation size effects in crystalline materials: A law for strain gradient plasticity

[J].

Ductility by shear band delocalization in the nano-layer of gradient structure

[J].

Influences of cell walls and grain boundaries on transient responses of an IF steel to changes in strain path

[J].

Size effect measurement and characterization in nanoindentation test

[J].

A trans-scale linkage model and application to analyses of nanocrystalline Al-alloy material

[A].

A trans-scale linkage model and application to analyses of nanocrystalline Al-alloy material

[A].

Revealing the deformation mechanisms of Cu-Al alloys with high strength and good ductility

[J].

On strain hardening mechanism in gradient nanostructures

[J].

Revealing extra strengthening and strain hardening in heterogeneous two-phase nanostructures

[J].

Interstitial atoms enable joint twinning and transformation induced plasticity in strong and ductile high-entropy alloys

[J].High-entropy alloys (HEAs) consisting of multiple principle elements provide an avenue for realizing exceptional mechanical, physical and chemical properties. We report a novel strategy for designing a new class of HEAs incorporating the additional interstitial element carbon. This results in joint activation of twinning-and transformation-induced plasticity (TWIP and TRIP) by tuning the matrix phase's instability in a metastable TRIP-assisted dual-phase HEA. Besides TWIP and TRIP, such alloys benefit from massive substitutional and interstitial solid solution strengthening as well as from the composite effect associated with its dual-phase structure. Nanosize particle formation and grain size reduction are also utilized. The new interstitial TWIP-TRIP-HEA thus unifies all metallic strengthening mechanisms in one material, leading to twice the tensile strength compared to a single-phase HEA with similar composition, yet, at identical ductility.

Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system

[J].

Novel atomic-scale mechanism of incipient plasticity in a chemically complex CrCoNi medium-entropy alloy associated with inhomogeneity in local chemical environment

[J].

Tuning element distribution, structure and properties by composition in high-entropy alloys

[J].

Making ultrastrong steel tough by grain-boundary delamination

[J].Developing ultrahigh-strength steels that are ductile, fracture resistant, and cost effective would be attractive for a variety of structural applications. We show that improved fracture resistance in a steel with an ultrahigh yield strength of nearly 2 gigapascals can be achieved by activating delamination toughening coupled with transformation-induced plasticity. Delamination toughening associated with intensive but controlled cracking at manganese-enriched prior-austenite grain boundaries normal to the primary fracture surface dramatically improves the overall fracture resistance. As a result, fracture under plane-strain conditions is automatically transformed into a series of fracture processes in "parallel" plane-stress conditions through the thickness. The present "high-strength induced multidelamination" strategy offers a different pathway to develop engineering materials with ultrahigh strength and superior toughness at economical materials cost.Copyright © 2020 The Authors, some rights reserved; exclusive licensee American Association for the Advancement of Science. No claim to original U.S. Government Works.

Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation

[J].

Plastic deformation mechanisms in a severely deformed Fe-Ni-Al-C alloy with superior tensile properties

[J].Nanostructured metals have high strength while they usually exhibit limited uniform elongation. While, a yield strength of approximately 2.1 GPa and a uniform elongation of about 26% were achieved in a severely deformed Fe-24.8%Ni-6.0%Al-0.38%C alloy in the present work. The plastic deformation mechanisms for the coarse-grained (CG) sample and the cold-rolled (CR) samples of this alloy were investigated by a series of mechanical tests and microstructure characterizations before and after tensile tests. No obvious phase transformation was observed during the tensile deformation for the CG sample, and the plastic deformation was found to be mainly accommodated by deformation twins and dislocation behaviors. While significant phase transformation occurs for the CR samples due to the facts that the deformed grains by CR are insufficient to sustain the tensile deformation themselves and the flow stress for the CR samples is high enough to activate the martensite transformation. The amount of phase transformation increases with increasing thickness reduction of CR, resulting in excellent tensile ductility in the severely deformed alloy. The back stress hardening was found to play a more important role in the CR samples than in the CG sample due to the dynamically reinforced heterogeneous microstructure by phase transformation.