磁场辅助加工的研究现状及其发展趋势

1

2016

... 主动运用磁、电、热、声等高密度能量场调控材料的力学行为是突破当前先进制造技术指标的重要方法[1,2].其中,利用磁场调控材料力学行为,在磁场辅助加工/成形、刀具磁处理强化、结构损伤修复/延寿等方面表现出良好的应用前景,是一种绿色、环保的制造方法. ...

磁场辅助加工的研究现状及其发展趋势

1

2016

... 主动运用磁、电、热、声等高密度能量场调控材料的力学行为是突破当前先进制造技术指标的重要方法[1,2].其中,利用磁场调控材料力学行为,在磁场辅助加工/成形、刀具磁处理强化、结构损伤修复/延寿等方面表现出良好的应用前景,是一种绿色、环保的制造方法. ...

基于磁场辅助的钛合金超精密切削关键技术研究

1

2020

... 主动运用磁、电、热、声等高密度能量场调控材料的力学行为是突破当前先进制造技术指标的重要方法[1,2].其中,利用磁场调控材料力学行为,在磁场辅助加工/成形、刀具磁处理强化、结构损伤修复/延寿等方面表现出良好的应用前景,是一种绿色、环保的制造方法. ...

基于磁场辅助的钛合金超精密切削关键技术研究

1

2020

... 主动运用磁、电、热、声等高密度能量场调控材料的力学行为是突破当前先进制造技术指标的重要方法[1,2].其中,利用磁场调控材料力学行为,在磁场辅助加工/成形、刀具磁处理强化、结构损伤修复/延寿等方面表现出良好的应用前景,是一种绿色、环保的制造方法. ...

Electrical discharge turning by assistance of external magnetic field, part II: Study of surface integrity

1

2020

... 磁场辅助材料加工能够降低刀具磨损,减小工件材料变形阻力.Azhiri等[3]发现磁场辅助车削AISI D2钢能够改善加工表面完整性,实现表面粗糙度降低、变质层厚度减小、表层微观组织结构优化的优良效果.El Mansori等[4]对比了铁磁性刀具和非铁磁性刀具在干切削铁磁性碳钢过程中磨损量受磁场的影响,证明了磁场辅助切削能够增加刀具的抗磨损性.Dehghani等[5]研究了30CrNiMo8合金钢磁场辅助切削中刀具磨损和切削力的变化,发现磁场导致刀具磨损降低94%,切削力减小100 N,认为磁场促进了切削区域材料的位错运动,增加了材料的变形能力.Muju和Ghosh[6]指出外磁场对变形体的作用增强了位错的迁移率,从而提高了2个摩擦固体中磁导率较高的固体的磨损率,揭示了磁场如何影响两接触体之间的复杂作用机理. ...

Improving surface wearing of tools by magnetization when cutting dry

1

2004

... 磁场辅助材料加工能够降低刀具磨损,减小工件材料变形阻力.Azhiri等[3]发现磁场辅助车削AISI D2钢能够改善加工表面完整性,实现表面粗糙度降低、变质层厚度减小、表层微观组织结构优化的优良效果.El Mansori等[4]对比了铁磁性刀具和非铁磁性刀具在干切削铁磁性碳钢过程中磨损量受磁场的影响,证明了磁场辅助切削能够增加刀具的抗磨损性.Dehghani等[5]研究了30CrNiMo8合金钢磁场辅助切削中刀具磨损和切削力的变化,发现磁场导致刀具磨损降低94%,切削力减小100 N,认为磁场促进了切削区域材料的位错运动,增加了材料的变形能力.Muju和Ghosh[6]指出外磁场对变形体的作用增强了位错的迁移率,从而提高了2个摩擦固体中磁导率较高的固体的磨损率,揭示了磁场如何影响两接触体之间的复杂作用机理. ...

Effects of magnetic assistance on improving tool wear resistance and cutting mechanisms during steel turning

1

2017

... 磁场辅助材料加工能够降低刀具磨损,减小工件材料变形阻力.Azhiri等[3]发现磁场辅助车削AISI D2钢能够改善加工表面完整性,实现表面粗糙度降低、变质层厚度减小、表层微观组织结构优化的优良效果.El Mansori等[4]对比了铁磁性刀具和非铁磁性刀具在干切削铁磁性碳钢过程中磨损量受磁场的影响,证明了磁场辅助切削能够增加刀具的抗磨损性.Dehghani等[5]研究了30CrNiMo8合金钢磁场辅助切削中刀具磨损和切削力的变化,发现磁场导致刀具磨损降低94%,切削力减小100 N,认为磁场促进了切削区域材料的位错运动,增加了材料的变形能力.Muju和Ghosh[6]指出外磁场对变形体的作用增强了位错的迁移率,从而提高了2个摩擦固体中磁导率较高的固体的磨损率,揭示了磁场如何影响两接触体之间的复杂作用机理. ...

Effect of a magnetic field on the diffusive wear of cutting tools

1

1980

... 磁场辅助材料加工能够降低刀具磨损,减小工件材料变形阻力.Azhiri等[3]发现磁场辅助车削AISI D2钢能够改善加工表面完整性,实现表面粗糙度降低、变质层厚度减小、表层微观组织结构优化的优良效果.El Mansori等[4]对比了铁磁性刀具和非铁磁性刀具在干切削铁磁性碳钢过程中磨损量受磁场的影响,证明了磁场辅助切削能够增加刀具的抗磨损性.Dehghani等[5]研究了30CrNiMo8合金钢磁场辅助切削中刀具磨损和切削力的变化,发现磁场导致刀具磨损降低94%,切削力减小100 N,认为磁场促进了切削区域材料的位错运动,增加了材料的变形能力.Muju和Ghosh[6]指出外磁场对变形体的作用增强了位错的迁移率,从而提高了2个摩擦固体中磁导率较高的固体的磨损率,揭示了磁场如何影响两接触体之间的复杂作用机理. ...

Look at magnetic treatment of tools and wear surfaces

1

1990

... 磁处理能够使材料产生强化效果,提升疲劳寿命.Miller[7]和Nikiforov等[8]分别证实了磁处理后刀具寿命提高175%,耐磨性提高1.8~2倍.Çelik等[9]研究了磁处理对AISI 4140钢疲劳寿命的影响,结果表明,在疲劳裂纹萌生阶段,外加磁场使磁畴规则取向和分布导致滑移带的形成推迟,提高了疲劳寿命.Kida等[10]对中碳低合金钢试样疲劳裂纹尖端区域进行磁化,发现磁场变化与塑性变形区有很强的相关性.Fahmy等[11]发现脉冲磁场施加在低碳钢试样上能够增加其疲劳寿命(可能还有疲劳极限),提出疲劳寿命的提高是由于外磁场对磁畴的影响,进而对位错活动的影响,最终导致裂纹萌生的延迟.Shao等[12]发现脉冲磁处理后合金钢的接触疲劳寿命提高了42.11%,认为在脉冲磁场作用下,位错、析出物和磁畴的微观结构变得更加均匀.许擎栋等[13]分析了脉冲磁场处理后位错分布更加均匀的原因是:脉冲磁场引起位错钉扎处的电子能态发生转变,使钉扎处空位或杂质原子易于移动.脉冲磁场处理能够消除材料内有害的残余拉应力[12,14~16],这也有利于结构件疲劳寿命提升. ...

Unit for magnetic hardening of cutting and forming tools

1

1989

... 磁处理能够使材料产生强化效果,提升疲劳寿命.Miller[7]和Nikiforov等[8]分别证实了磁处理后刀具寿命提高175%,耐磨性提高1.8~2倍.Çelik等[9]研究了磁处理对AISI 4140钢疲劳寿命的影响,结果表明,在疲劳裂纹萌生阶段,外加磁场使磁畴规则取向和分布导致滑移带的形成推迟,提高了疲劳寿命.Kida等[10]对中碳低合金钢试样疲劳裂纹尖端区域进行磁化,发现磁场变化与塑性变形区有很强的相关性.Fahmy等[11]发现脉冲磁场施加在低碳钢试样上能够增加其疲劳寿命(可能还有疲劳极限),提出疲劳寿命的提高是由于外磁场对磁畴的影响,进而对位错活动的影响,最终导致裂纹萌生的延迟.Shao等[12]发现脉冲磁处理后合金钢的接触疲劳寿命提高了42.11%,认为在脉冲磁场作用下,位错、析出物和磁畴的微观结构变得更加均匀.许擎栋等[13]分析了脉冲磁场处理后位错分布更加均匀的原因是:脉冲磁场引起位错钉扎处的电子能态发生转变,使钉扎处空位或杂质原子易于移动.脉冲磁场处理能够消除材料内有害的残余拉应力[12,14~16],这也有利于结构件疲劳寿命提升. ...

Effect of magnetic treatment on fatigue life of AISI 4140 steel

1

2005

... 磁处理能够使材料产生强化效果,提升疲劳寿命.Miller[7]和Nikiforov等[8]分别证实了磁处理后刀具寿命提高175%,耐磨性提高1.8~2倍.Çelik等[9]研究了磁处理对AISI 4140钢疲劳寿命的影响,结果表明,在疲劳裂纹萌生阶段,外加磁场使磁畴规则取向和分布导致滑移带的形成推迟,提高了疲劳寿命.Kida等[10]对中碳低合金钢试样疲劳裂纹尖端区域进行磁化,发现磁场变化与塑性变形区有很强的相关性.Fahmy等[11]发现脉冲磁场施加在低碳钢试样上能够增加其疲劳寿命(可能还有疲劳极限),提出疲劳寿命的提高是由于外磁场对磁畴的影响,进而对位错活动的影响,最终导致裂纹萌生的延迟.Shao等[12]发现脉冲磁处理后合金钢的接触疲劳寿命提高了42.11%,认为在脉冲磁场作用下,位错、析出物和磁畴的微观结构变得更加均匀.许擎栋等[13]分析了脉冲磁场处理后位错分布更加均匀的原因是:脉冲磁场引起位错钉扎处的电子能态发生转变,使钉扎处空位或杂质原子易于移动.脉冲磁场处理能够消除材料内有害的残余拉应力[12,14~16],这也有利于结构件疲劳寿命提升. ...

Changes in magnetic field intensities around fatigue crack tips of medium carbon low alloy steel (S45C, JIS)

1

2013

... 磁处理能够使材料产生强化效果,提升疲劳寿命.Miller[7]和Nikiforov等[8]分别证实了磁处理后刀具寿命提高175%,耐磨性提高1.8~2倍.Çelik等[9]研究了磁处理对AISI 4140钢疲劳寿命的影响,结果表明,在疲劳裂纹萌生阶段,外加磁场使磁畴规则取向和分布导致滑移带的形成推迟,提高了疲劳寿命.Kida等[10]对中碳低合金钢试样疲劳裂纹尖端区域进行磁化,发现磁场变化与塑性变形区有很强的相关性.Fahmy等[11]发现脉冲磁场施加在低碳钢试样上能够增加其疲劳寿命(可能还有疲劳极限),提出疲劳寿命的提高是由于外磁场对磁畴的影响,进而对位错活动的影响,最终导致裂纹萌生的延迟.Shao等[12]发现脉冲磁处理后合金钢的接触疲劳寿命提高了42.11%,认为在脉冲磁场作用下,位错、析出物和磁畴的微观结构变得更加均匀.许擎栋等[13]分析了脉冲磁场处理后位错分布更加均匀的原因是:脉冲磁场引起位错钉扎处的电子能态发生转变,使钉扎处空位或杂质原子易于移动.脉冲磁场处理能够消除材料内有害的残余拉应力[12,14~16],这也有利于结构件疲劳寿命提升. ...

Effects of a pulsed magnetic treatment on the fatigue of low carbon steel

1

1998

... 磁处理能够使材料产生强化效果,提升疲劳寿命.Miller[7]和Nikiforov等[8]分别证实了磁处理后刀具寿命提高175%,耐磨性提高1.8~2倍.Çelik等[9]研究了磁处理对AISI 4140钢疲劳寿命的影响,结果表明,在疲劳裂纹萌生阶段,外加磁场使磁畴规则取向和分布导致滑移带的形成推迟,提高了疲劳寿命.Kida等[10]对中碳低合金钢试样疲劳裂纹尖端区域进行磁化,发现磁场变化与塑性变形区有很强的相关性.Fahmy等[11]发现脉冲磁场施加在低碳钢试样上能够增加其疲劳寿命(可能还有疲劳极限),提出疲劳寿命的提高是由于外磁场对磁畴的影响,进而对位错活动的影响,最终导致裂纹萌生的延迟.Shao等[12]发现脉冲磁处理后合金钢的接触疲劳寿命提高了42.11%,认为在脉冲磁场作用下,位错、析出物和磁畴的微观结构变得更加均匀.许擎栋等[13]分析了脉冲磁场处理后位错分布更加均匀的原因是:脉冲磁场引起位错钉扎处的电子能态发生转变,使钉扎处空位或杂质原子易于移动.脉冲磁场处理能够消除材料内有害的残余拉应力[12,14~16],这也有利于结构件疲劳寿命提升. ...

Improvement in uniformity of alloy steel by pulsed magnetic field treatment

4

2021

... 磁处理能够使材料产生强化效果,提升疲劳寿命.Miller[7]和Nikiforov等[8]分别证实了磁处理后刀具寿命提高175%,耐磨性提高1.8~2倍.Çelik等[9]研究了磁处理对AISI 4140钢疲劳寿命的影响,结果表明,在疲劳裂纹萌生阶段,外加磁场使磁畴规则取向和分布导致滑移带的形成推迟,提高了疲劳寿命.Kida等[10]对中碳低合金钢试样疲劳裂纹尖端区域进行磁化,发现磁场变化与塑性变形区有很强的相关性.Fahmy等[11]发现脉冲磁场施加在低碳钢试样上能够增加其疲劳寿命(可能还有疲劳极限),提出疲劳寿命的提高是由于外磁场对磁畴的影响,进而对位错活动的影响,最终导致裂纹萌生的延迟.Shao等[12]发现脉冲磁处理后合金钢的接触疲劳寿命提高了42.11%,认为在脉冲磁场作用下,位错、析出物和磁畴的微观结构变得更加均匀.许擎栋等[13]分析了脉冲磁场处理后位错分布更加均匀的原因是:脉冲磁场引起位错钉扎处的电子能态发生转变,使钉扎处空位或杂质原子易于移动.脉冲磁场处理能够消除材料内有害的残余拉应力[12,14~16],这也有利于结构件疲劳寿命提升. ...

... [12,14~16],这也有利于结构件疲劳寿命提升. ...

... 磁化处理导致试样纳米压痕尺寸减小,以未磁化处理试样的纳米压痕为固定有效接触面积,提取载荷-位移曲线磁化处理后与未磁化处理的最大载荷差,分别计算磁化处理对珠光体态和回火马氏体态试样诱发的残余应力,计算结果列于表2 (取自5次测试的平均值).磁化处理导致珠光体和回火马氏体态试样表面残余应力分别增加62.2和57.8 MPa,根据图5中残余应力的分布规律,此处增加的应力为压应力.图6 (箱形图) X射线测量表面残余应力结果显示,相比于未磁化处理试样,磁化处理后珠光体和回火马氏体态试样表面残余压应力(不同区域点平均值)分别增加-92.2和-121.4 MPa.进一步证明了磁化处理能够使45CrNiMoVA钢表面残余压应力增加.Shao等[12]在20Cr2Ni4A合金钢脉冲磁场处理实验中得到相似的实验规律. ...

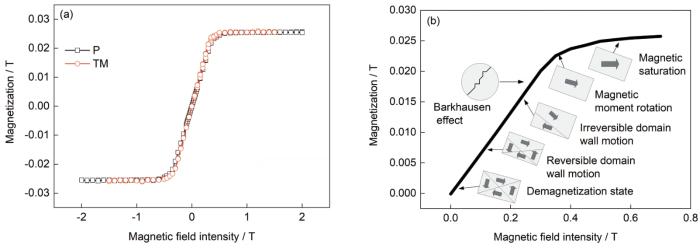

... 铁磁材料的磁化本质是磁畴运动[12,34,35],图9b所示为45CrNiMoVA钢不同磁化阶段的磁畴运动示意图,包含畴壁的位移和磁矩的转动.在磁化初始阶段,磁畴运动以可逆畴壁位移为主,对材料力学性能影响微弱;随着外磁场增大,畴壁位移需要克服材料内应力、杂质、晶界、位错等不均匀分布产生的阻力,形成不可逆畴壁位移;随着外磁场进一步增加,畴壁位移基本结束,磁化强度的增加依赖磁矩的转动,磁矩向外磁场方向转动,直至饱和.巴克豪森效应[34] (Barkhausen effect)认为磁化过程中畴壁的位移是一个不连续的过程,畴壁位移过程中遇到钉扎点,外磁场缓慢增加难以使其移动,而当外磁场达到临界点,畴壁突然移动到平衡位置,产生大量“跳跃”巴克豪森信号,相对应地,磁致应变量发生突变、位错塞积开动. ...

脉冲磁场对TC4钛合金微观结构的影响及其机理探究

1

2019

... 磁处理能够使材料产生强化效果,提升疲劳寿命.Miller[7]和Nikiforov等[8]分别证实了磁处理后刀具寿命提高175%,耐磨性提高1.8~2倍.Çelik等[9]研究了磁处理对AISI 4140钢疲劳寿命的影响,结果表明,在疲劳裂纹萌生阶段,外加磁场使磁畴规则取向和分布导致滑移带的形成推迟,提高了疲劳寿命.Kida等[10]对中碳低合金钢试样疲劳裂纹尖端区域进行磁化,发现磁场变化与塑性变形区有很强的相关性.Fahmy等[11]发现脉冲磁场施加在低碳钢试样上能够增加其疲劳寿命(可能还有疲劳极限),提出疲劳寿命的提高是由于外磁场对磁畴的影响,进而对位错活动的影响,最终导致裂纹萌生的延迟.Shao等[12]发现脉冲磁处理后合金钢的接触疲劳寿命提高了42.11%,认为在脉冲磁场作用下,位错、析出物和磁畴的微观结构变得更加均匀.许擎栋等[13]分析了脉冲磁场处理后位错分布更加均匀的原因是:脉冲磁场引起位错钉扎处的电子能态发生转变,使钉扎处空位或杂质原子易于移动.脉冲磁场处理能够消除材料内有害的残余拉应力[12,14~16],这也有利于结构件疲劳寿命提升. ...

脉冲磁场对TC4钛合金微观结构的影响及其机理探究

1

2019

... 磁处理能够使材料产生强化效果,提升疲劳寿命.Miller[7]和Nikiforov等[8]分别证实了磁处理后刀具寿命提高175%,耐磨性提高1.8~2倍.Çelik等[9]研究了磁处理对AISI 4140钢疲劳寿命的影响,结果表明,在疲劳裂纹萌生阶段,外加磁场使磁畴规则取向和分布导致滑移带的形成推迟,提高了疲劳寿命.Kida等[10]对中碳低合金钢试样疲劳裂纹尖端区域进行磁化,发现磁场变化与塑性变形区有很强的相关性.Fahmy等[11]发现脉冲磁场施加在低碳钢试样上能够增加其疲劳寿命(可能还有疲劳极限),提出疲劳寿命的提高是由于外磁场对磁畴的影响,进而对位错活动的影响,最终导致裂纹萌生的延迟.Shao等[12]发现脉冲磁处理后合金钢的接触疲劳寿命提高了42.11%,认为在脉冲磁场作用下,位错、析出物和磁畴的微观结构变得更加均匀.许擎栋等[13]分析了脉冲磁场处理后位错分布更加均匀的原因是:脉冲磁场引起位错钉扎处的电子能态发生转变,使钉扎处空位或杂质原子易于移动.脉冲磁场处理能够消除材料内有害的残余拉应力[12,14~16],这也有利于结构件疲劳寿命提升. ...

脉冲强磁场处理固态铝基复合材料的力学性能和强韧化机制

1

2016

... 磁处理能够使材料产生强化效果,提升疲劳寿命.Miller[7]和Nikiforov等[8]分别证实了磁处理后刀具寿命提高175%,耐磨性提高1.8~2倍.Çelik等[9]研究了磁处理对AISI 4140钢疲劳寿命的影响,结果表明,在疲劳裂纹萌生阶段,外加磁场使磁畴规则取向和分布导致滑移带的形成推迟,提高了疲劳寿命.Kida等[10]对中碳低合金钢试样疲劳裂纹尖端区域进行磁化,发现磁场变化与塑性变形区有很强的相关性.Fahmy等[11]发现脉冲磁场施加在低碳钢试样上能够增加其疲劳寿命(可能还有疲劳极限),提出疲劳寿命的提高是由于外磁场对磁畴的影响,进而对位错活动的影响,最终导致裂纹萌生的延迟.Shao等[12]发现脉冲磁处理后合金钢的接触疲劳寿命提高了42.11%,认为在脉冲磁场作用下,位错、析出物和磁畴的微观结构变得更加均匀.许擎栋等[13]分析了脉冲磁场处理后位错分布更加均匀的原因是:脉冲磁场引起位错钉扎处的电子能态发生转变,使钉扎处空位或杂质原子易于移动.脉冲磁场处理能够消除材料内有害的残余拉应力[12,14~16],这也有利于结构件疲劳寿命提升. ...

脉冲强磁场处理固态铝基复合材料的力学性能和强韧化机制

1

2016

... 磁处理能够使材料产生强化效果,提升疲劳寿命.Miller[7]和Nikiforov等[8]分别证实了磁处理后刀具寿命提高175%,耐磨性提高1.8~2倍.Çelik等[9]研究了磁处理对AISI 4140钢疲劳寿命的影响,结果表明,在疲劳裂纹萌生阶段,外加磁场使磁畴规则取向和分布导致滑移带的形成推迟,提高了疲劳寿命.Kida等[10]对中碳低合金钢试样疲劳裂纹尖端区域进行磁化,发现磁场变化与塑性变形区有很强的相关性.Fahmy等[11]发现脉冲磁场施加在低碳钢试样上能够增加其疲劳寿命(可能还有疲劳极限),提出疲劳寿命的提高是由于外磁场对磁畴的影响,进而对位错活动的影响,最终导致裂纹萌生的延迟.Shao等[12]发现脉冲磁处理后合金钢的接触疲劳寿命提高了42.11%,认为在脉冲磁场作用下,位错、析出物和磁畴的微观结构变得更加均匀.许擎栋等[13]分析了脉冲磁场处理后位错分布更加均匀的原因是:脉冲磁场引起位错钉扎处的电子能态发生转变,使钉扎处空位或杂质原子易于移动.脉冲磁场处理能够消除材料内有害的残余拉应力[12,14~16],这也有利于结构件疲劳寿命提升. ...

磁处理过程中磁致伸缩与残余应力关系的研究

1

2010

... 残余应力的增加表明材料微区不均匀性增加,研究[16,22]认为磁场对位错的作用是导致材料内部均匀性变化的原因.罗丞等[16]认为脉冲磁场对材料内残余应力的影响分为2个阶段,分别是位错开动和位错增殖,位错开动导致残余应力减小,位错增殖导致残余应力增加.缪霞等[22]也认为磁处理会导致位错增殖,引起残余应力变化.另一种观点[15,23]认为脉冲磁场导致磁致伸缩,类似振动时效,引发应力松弛,形成残余应力释放的效果,磁致振动与残余应力存在耦合效应,其微观作用机制仍然是磁场对位错运动的影响.因此,脉冲磁化处理后45CrNiMoVA钢表面残余压应力增加的原因很可能是位错增殖的结果. ...

磁处理过程中磁致伸缩与残余应力关系的研究

1

2010

... 残余应力的增加表明材料微区不均匀性增加,研究[16,22]认为磁场对位错的作用是导致材料内部均匀性变化的原因.罗丞等[16]认为脉冲磁场对材料内残余应力的影响分为2个阶段,分别是位错开动和位错增殖,位错开动导致残余应力减小,位错增殖导致残余应力增加.缪霞等[22]也认为磁处理会导致位错增殖,引起残余应力变化.另一种观点[15,23]认为脉冲磁场导致磁致伸缩,类似振动时效,引发应力松弛,形成残余应力释放的效果,磁致振动与残余应力存在耦合效应,其微观作用机制仍然是磁场对位错运动的影响.因此,脉冲磁化处理后45CrNiMoVA钢表面残余压应力增加的原因很可能是位错增殖的结果. ...

脉冲磁场处理对SKD11模具钢残余拉应力的影响机理分析

3

2016

... 磁处理能够使材料产生强化效果,提升疲劳寿命.Miller[7]和Nikiforov等[8]分别证实了磁处理后刀具寿命提高175%,耐磨性提高1.8~2倍.Çelik等[9]研究了磁处理对AISI 4140钢疲劳寿命的影响,结果表明,在疲劳裂纹萌生阶段,外加磁场使磁畴规则取向和分布导致滑移带的形成推迟,提高了疲劳寿命.Kida等[10]对中碳低合金钢试样疲劳裂纹尖端区域进行磁化,发现磁场变化与塑性变形区有很强的相关性.Fahmy等[11]发现脉冲磁场施加在低碳钢试样上能够增加其疲劳寿命(可能还有疲劳极限),提出疲劳寿命的提高是由于外磁场对磁畴的影响,进而对位错活动的影响,最终导致裂纹萌生的延迟.Shao等[12]发现脉冲磁处理后合金钢的接触疲劳寿命提高了42.11%,认为在脉冲磁场作用下,位错、析出物和磁畴的微观结构变得更加均匀.许擎栋等[13]分析了脉冲磁场处理后位错分布更加均匀的原因是:脉冲磁场引起位错钉扎处的电子能态发生转变,使钉扎处空位或杂质原子易于移动.脉冲磁场处理能够消除材料内有害的残余拉应力[12,14~16],这也有利于结构件疲劳寿命提升. ...

... 残余应力的增加表明材料微区不均匀性增加,研究[16,22]认为磁场对位错的作用是导致材料内部均匀性变化的原因.罗丞等[16]认为脉冲磁场对材料内残余应力的影响分为2个阶段,分别是位错开动和位错增殖,位错开动导致残余应力减小,位错增殖导致残余应力增加.缪霞等[22]也认为磁处理会导致位错增殖,引起残余应力变化.另一种观点[15,23]认为脉冲磁场导致磁致伸缩,类似振动时效,引发应力松弛,形成残余应力释放的效果,磁致振动与残余应力存在耦合效应,其微观作用机制仍然是磁场对位错运动的影响.因此,脉冲磁化处理后45CrNiMoVA钢表面残余压应力增加的原因很可能是位错增殖的结果. ...

... [16]认为脉冲磁场对材料内残余应力的影响分为2个阶段,分别是位错开动和位错增殖,位错开动导致残余应力减小,位错增殖导致残余应力增加.缪霞等[22]也认为磁处理会导致位错增殖,引起残余应力变化.另一种观点[15,23]认为脉冲磁场导致磁致伸缩,类似振动时效,引发应力松弛,形成残余应力释放的效果,磁致振动与残余应力存在耦合效应,其微观作用机制仍然是磁场对位错运动的影响.因此,脉冲磁化处理后45CrNiMoVA钢表面残余压应力增加的原因很可能是位错增殖的结果. ...

脉冲磁场处理对SKD11模具钢残余拉应力的影响机理分析

3

2016

... 磁处理能够使材料产生强化效果,提升疲劳寿命.Miller[7]和Nikiforov等[8]分别证实了磁处理后刀具寿命提高175%,耐磨性提高1.8~2倍.Çelik等[9]研究了磁处理对AISI 4140钢疲劳寿命的影响,结果表明,在疲劳裂纹萌生阶段,外加磁场使磁畴规则取向和分布导致滑移带的形成推迟,提高了疲劳寿命.Kida等[10]对中碳低合金钢试样疲劳裂纹尖端区域进行磁化,发现磁场变化与塑性变形区有很强的相关性.Fahmy等[11]发现脉冲磁场施加在低碳钢试样上能够增加其疲劳寿命(可能还有疲劳极限),提出疲劳寿命的提高是由于外磁场对磁畴的影响,进而对位错活动的影响,最终导致裂纹萌生的延迟.Shao等[12]发现脉冲磁处理后合金钢的接触疲劳寿命提高了42.11%,认为在脉冲磁场作用下,位错、析出物和磁畴的微观结构变得更加均匀.许擎栋等[13]分析了脉冲磁场处理后位错分布更加均匀的原因是:脉冲磁场引起位错钉扎处的电子能态发生转变,使钉扎处空位或杂质原子易于移动.脉冲磁场处理能够消除材料内有害的残余拉应力[12,14~16],这也有利于结构件疲劳寿命提升. ...

... 残余应力的增加表明材料微区不均匀性增加,研究[16,22]认为磁场对位错的作用是导致材料内部均匀性变化的原因.罗丞等[16]认为脉冲磁场对材料内残余应力的影响分为2个阶段,分别是位错开动和位错增殖,位错开动导致残余应力减小,位错增殖导致残余应力增加.缪霞等[22]也认为磁处理会导致位错增殖,引起残余应力变化.另一种观点[15,23]认为脉冲磁场导致磁致伸缩,类似振动时效,引发应力松弛,形成残余应力释放的效果,磁致振动与残余应力存在耦合效应,其微观作用机制仍然是磁场对位错运动的影响.因此,脉冲磁化处理后45CrNiMoVA钢表面残余压应力增加的原因很可能是位错增殖的结果. ...

... [16]认为脉冲磁场对材料内残余应力的影响分为2个阶段,分别是位错开动和位错增殖,位错开动导致残余应力减小,位错增殖导致残余应力增加.缪霞等[22]也认为磁处理会导致位错增殖,引起残余应力变化.另一种观点[15,23]认为脉冲磁场导致磁致伸缩,类似振动时效,引发应力松弛,形成残余应力释放的效果,磁致振动与残余应力存在耦合效应,其微观作用机制仍然是磁场对位错运动的影响.因此,脉冲磁化处理后45CrNiMoVA钢表面残余压应力增加的原因很可能是位错增殖的结果. ...

45CrNiMoVA钢动态断裂韧度的测定

1

1990

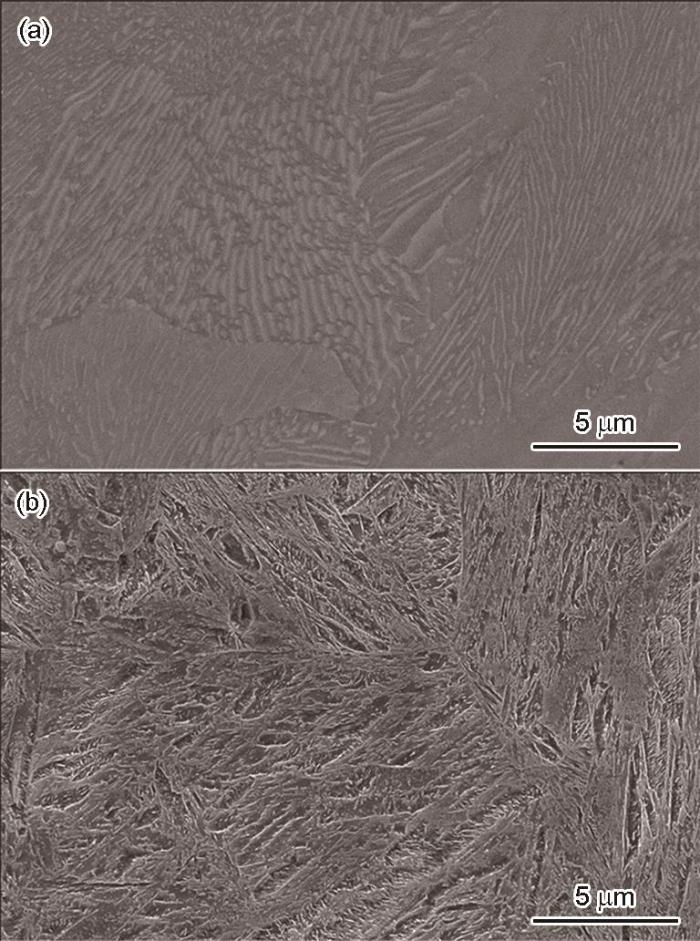

... 试样材料为超高强度钢45CrNiMoVA,测得其元素含量(质量分数,%)为:Ni 1.4,Mo 1.0,Cr 0.9,Si 0.9,C 0.42,Mn 0.6,V 0.2,Fe余量.其中,铁磁性元素Fe和Ni是引起该材料磁场响应的主要元素.低温回火后试样材料的力学性能参数[17]为:抗拉强度() 2120 MPa,屈服强度() 1639 MPa,弹性模量() 175 GPa.为充分分析磁处理对45CrNiMoVA钢力学性能的影响,采用2种不同热处理条件下的45CrNiMoVA钢作为脉冲磁处理试样,一种为退火后、珠光体(P)组织状态,如图1a所示,其形态是铁素体和渗碳体相间排列、形如指纹的片状珠光体;一种为高温淬火+低温回火后、回火马氏体(TM)组织状态,如图1b所示,其形态是呈板条状的马氏体和少量的残余奥氏体. ...

45CrNiMoVA钢动态断裂韧度的测定

1

1990

... 试样材料为超高强度钢45CrNiMoVA,测得其元素含量(质量分数,%)为:Ni 1.4,Mo 1.0,Cr 0.9,Si 0.9,C 0.42,Mn 0.6,V 0.2,Fe余量.其中,铁磁性元素Fe和Ni是引起该材料磁场响应的主要元素.低温回火后试样材料的力学性能参数[17]为:抗拉强度() 2120 MPa,屈服强度() 1639 MPa,弹性模量() 175 GPa.为充分分析磁处理对45CrNiMoVA钢力学性能的影响,采用2种不同热处理条件下的45CrNiMoVA钢作为脉冲磁处理试样,一种为退火后、珠光体(P)组织状态,如图1a所示,其形态是铁素体和渗碳体相间排列、形如指纹的片状珠光体;一种为高温淬火+低温回火后、回火马氏体(TM)组织状态,如图1b所示,其形态是呈板条状的马氏体和少量的残余奥氏体. ...

Measurement of hardness and elastic modulus by instrumented indentation: A dvances in understanding and refinements to methodology

1

2004

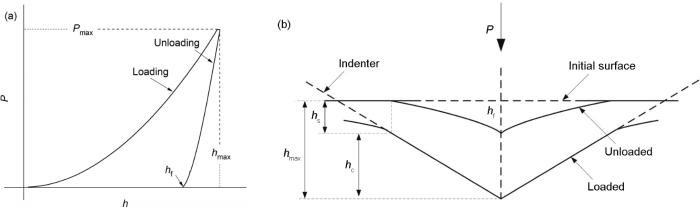

... 采用Nano Indenter XP纳米压痕仪分别对试样进行力学性能测试,Berkovich压头,恒定应变率0.05 s-1加载,峰值保载时间10 s,压入深度2000 nm,每个试样压5个点,取平均值.图3所示为典型的纳米压痕载荷-位移曲线,基于最大载荷()、最大压痕深度()和残留压痕深度(,可分别计算试样材料的硬度和弹性模量,弹性模量主要与卸载曲线起始部分(25%~50%)的斜率有关[18,19].根据Lee和Kwon[20]的纳米压痕残余应力计算模型,可对载荷-位移曲线受残余应力的影响进行分析,参考相关公式(1)~(6): ...

纳米压痕法测量残余应力的研究现状

1

2014

... 采用Nano Indenter XP纳米压痕仪分别对试样进行力学性能测试,Berkovich压头,恒定应变率0.05 s-1加载,峰值保载时间10 s,压入深度2000 nm,每个试样压5个点,取平均值.图3所示为典型的纳米压痕载荷-位移曲线,基于最大载荷()、最大压痕深度()和残留压痕深度(,可分别计算试样材料的硬度和弹性模量,弹性模量主要与卸载曲线起始部分(25%~50%)的斜率有关[18,19].根据Lee和Kwon[20]的纳米压痕残余应力计算模型,可对载荷-位移曲线受残余应力的影响进行分析,参考相关公式(1)~(6): ...

纳米压痕法测量残余应力的研究现状

1

2014

... 采用Nano Indenter XP纳米压痕仪分别对试样进行力学性能测试,Berkovich压头,恒定应变率0.05 s-1加载,峰值保载时间10 s,压入深度2000 nm,每个试样压5个点,取平均值.图3所示为典型的纳米压痕载荷-位移曲线,基于最大载荷()、最大压痕深度()和残留压痕深度(,可分别计算试样材料的硬度和弹性模量,弹性模量主要与卸载曲线起始部分(25%~50%)的斜率有关[18,19].根据Lee和Kwon[20]的纳米压痕残余应力计算模型,可对载荷-位移曲线受残余应力的影响进行分析,参考相关公式(1)~(6): ...

Residual stresses in DLC/Si and Au/Si systems: application of a stress-relaxation model to the nanoindentation technique

1

2002

... 采用Nano Indenter XP纳米压痕仪分别对试样进行力学性能测试,Berkovich压头,恒定应变率0.05 s-1加载,峰值保载时间10 s,压入深度2000 nm,每个试样压5个点,取平均值.图3所示为典型的纳米压痕载荷-位移曲线,基于最大载荷()、最大压痕深度()和残留压痕深度(,可分别计算试样材料的硬度和弹性模量,弹性模量主要与卸载曲线起始部分(25%~50%)的斜率有关[18,19].根据Lee和Kwon[20]的纳米压痕残余应力计算模型,可对载荷-位移曲线受残余应力的影响进行分析,参考相关公式(1)~(6): ...

A new method for estimating residual stresses by instrumented sharp indentation

1

1998

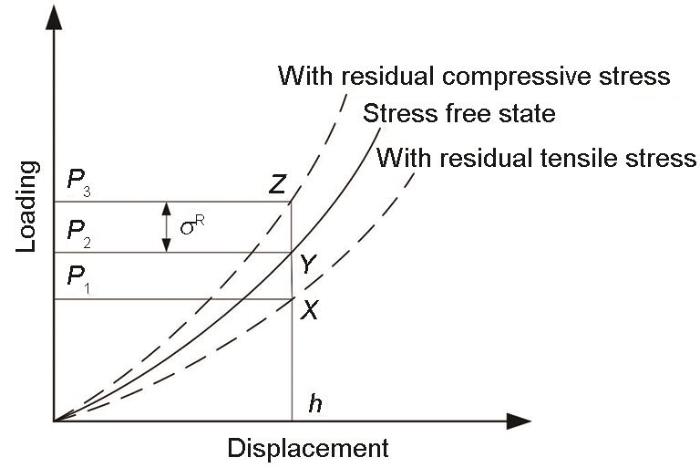

... 纳米压痕载荷-位移曲线可以反映材料的残余应力状况.45CrNiMoVA钢在不同组织状态下的纳米压痕载荷-位移曲线如图4所示,相比于未磁化处理的试样,磁化处理后试样的载荷-位移曲线发生向上的偏移,载荷最大值Pmax增加.根据Suresh和Giannakopoulos[21]对压痕过程中残余应力的分析,材料残余应力对载荷-位移曲线的影响可以用图5表示,在固定压入深度为h的条件下,材料压入区域残余拉应力的释放会导致载荷-位移曲线从X到Y的变化,接触力从P1到P2增大;而如果材料压入区域带有残余压应力,则会出现载荷-位移曲线从Z到Y的变化,接触力从P3到P2减小.基于X射线表面残余应力测量结果(图6),珠光体态和回火马氏体态试样磁化处理前表面分别为残余压应力,得出磁化处理后珠光体态和回火马氏体态试样的载荷-位移曲线分别向上偏移的原因是磁化处理导致45CrNiMoVA钢试样表面残余压应力变大. ...

磁处理对GCr15轴承环冷轧-淬火残余应力影响规律

2

2014

... 残余应力的增加表明材料微区不均匀性增加,研究[16,22]认为磁场对位错的作用是导致材料内部均匀性变化的原因.罗丞等[16]认为脉冲磁场对材料内残余应力的影响分为2个阶段,分别是位错开动和位错增殖,位错开动导致残余应力减小,位错增殖导致残余应力增加.缪霞等[22]也认为磁处理会导致位错增殖,引起残余应力变化.另一种观点[15,23]认为脉冲磁场导致磁致伸缩,类似振动时效,引发应力松弛,形成残余应力释放的效果,磁致振动与残余应力存在耦合效应,其微观作用机制仍然是磁场对位错运动的影响.因此,脉冲磁化处理后45CrNiMoVA钢表面残余压应力增加的原因很可能是位错增殖的结果. ...

... [22]也认为磁处理会导致位错增殖,引起残余应力变化.另一种观点[15,23]认为脉冲磁场导致磁致伸缩,类似振动时效,引发应力松弛,形成残余应力释放的效果,磁致振动与残余应力存在耦合效应,其微观作用机制仍然是磁场对位错运动的影响.因此,脉冲磁化处理后45CrNiMoVA钢表面残余压应力增加的原因很可能是位错增殖的结果. ...

磁处理对GCr15轴承环冷轧-淬火残余应力影响规律

2

2014

... 残余应力的增加表明材料微区不均匀性增加,研究[16,22]认为磁场对位错的作用是导致材料内部均匀性变化的原因.罗丞等[16]认为脉冲磁场对材料内残余应力的影响分为2个阶段,分别是位错开动和位错增殖,位错开动导致残余应力减小,位错增殖导致残余应力增加.缪霞等[22]也认为磁处理会导致位错增殖,引起残余应力变化.另一种观点[15,23]认为脉冲磁场导致磁致伸缩,类似振动时效,引发应力松弛,形成残余应力释放的效果,磁致振动与残余应力存在耦合效应,其微观作用机制仍然是磁场对位错运动的影响.因此,脉冲磁化处理后45CrNiMoVA钢表面残余压应力增加的原因很可能是位错增殖的结果. ...

... [22]也认为磁处理会导致位错增殖,引起残余应力变化.另一种观点[15,23]认为脉冲磁场导致磁致伸缩,类似振动时效,引发应力松弛,形成残余应力释放的效果,磁致振动与残余应力存在耦合效应,其微观作用机制仍然是磁场对位错运动的影响.因此,脉冲磁化处理后45CrNiMoVA钢表面残余压应力增加的原因很可能是位错增殖的结果. ...

钢铁材料中残余应力与磁致振动的相互作用关系

1

2008

... 残余应力的增加表明材料微区不均匀性增加,研究[16,22]认为磁场对位错的作用是导致材料内部均匀性变化的原因.罗丞等[16]认为脉冲磁场对材料内残余应力的影响分为2个阶段,分别是位错开动和位错增殖,位错开动导致残余应力减小,位错增殖导致残余应力增加.缪霞等[22]也认为磁处理会导致位错增殖,引起残余应力变化.另一种观点[15,23]认为脉冲磁场导致磁致伸缩,类似振动时效,引发应力松弛,形成残余应力释放的效果,磁致振动与残余应力存在耦合效应,其微观作用机制仍然是磁场对位错运动的影响.因此,脉冲磁化处理后45CrNiMoVA钢表面残余压应力增加的原因很可能是位错增殖的结果. ...

钢铁材料中残余应力与磁致振动的相互作用关系

1

2008

... 残余应力的增加表明材料微区不均匀性增加,研究[16,22]认为磁场对位错的作用是导致材料内部均匀性变化的原因.罗丞等[16]认为脉冲磁场对材料内残余应力的影响分为2个阶段,分别是位错开动和位错增殖,位错开动导致残余应力减小,位错增殖导致残余应力增加.缪霞等[22]也认为磁处理会导致位错增殖,引起残余应力变化.另一种观点[15,23]认为脉冲磁场导致磁致伸缩,类似振动时效,引发应力松弛,形成残余应力释放的效果,磁致振动与残余应力存在耦合效应,其微观作用机制仍然是磁场对位错运动的影响.因此,脉冲磁化处理后45CrNiMoVA钢表面残余压应力增加的原因很可能是位错增殖的结果. ...

F6-21Ni-4Mn合金强脉冲磁场诱发马氏体相变的研究

2

1990

... 磁化处理导致材料硬度增加,目前主要有3种解释:一是磁诱导马氏体相变理论[24],在马氏体相变临界温度附近,磁场能够提供额外的相变驱动力,促使马氏体相变提前发生,马氏体相的增加导致硬度增加.磁场引起的马氏体相变温度改变()可用式(7)[25]表示: ...

... 式中,为外加磁场,为母相和马氏体相磁化强度差,为母相和马氏体相的熵差.孙恩喜等[24]的研究中得到强脉冲磁场诱发马氏体相变时,.马利平等[26]对高速钢脉冲磁处理过程中的磁热效应进行了检测,脉冲磁处理过程中试样表面温度仅升高5℃.因此,在常温、静态下对45CrNiMoVA钢进行脉冲磁处理,不足以引起其相变发生.根据2种组织状态下45CrNiMoVA钢受磁化处理后硬度变化差别不大的结果,也可以说明2种试样内部没有发生相变.二是位错运动理论[27~29],脉冲磁场作用下,材料晶格畸变发生,位错密度增加引起硬度增加,这一解释获得较多实验的证实.Veligatla[27]讨论了形状记忆合金中磁畴与孪晶界之间的相互作用,磁畴界能够阻碍孪晶界迁移,形成孪晶高密度区域,导致材料硬化.Ma等[28]研究了脉冲磁场处理后高速钢的硬度变化,认为位错密度增加是导致硬度变大的主要原因.位错在磁场中受磁场强度作用力(σ)可以通过式(8)进行计算[29]. ...

F6-21Ni-4Mn合金强脉冲磁场诱发马氏体相变的研究

2

1990

... 磁化处理导致材料硬度增加,目前主要有3种解释:一是磁诱导马氏体相变理论[24],在马氏体相变临界温度附近,磁场能够提供额外的相变驱动力,促使马氏体相变提前发生,马氏体相的增加导致硬度增加.磁场引起的马氏体相变温度改变()可用式(7)[25]表示: ...

... 式中,为外加磁场,为母相和马氏体相磁化强度差,为母相和马氏体相的熵差.孙恩喜等[24]的研究中得到强脉冲磁场诱发马氏体相变时,.马利平等[26]对高速钢脉冲磁处理过程中的磁热效应进行了检测,脉冲磁处理过程中试样表面温度仅升高5℃.因此,在常温、静态下对45CrNiMoVA钢进行脉冲磁处理,不足以引起其相变发生.根据2种组织状态下45CrNiMoVA钢受磁化处理后硬度变化差别不大的结果,也可以说明2种试样内部没有发生相变.二是位错运动理论[27~29],脉冲磁场作用下,材料晶格畸变发生,位错密度增加引起硬度增加,这一解释获得较多实验的证实.Veligatla[27]讨论了形状记忆合金中磁畴与孪晶界之间的相互作用,磁畴界能够阻碍孪晶界迁移,形成孪晶高密度区域,导致材料硬化.Ma等[28]研究了脉冲磁场处理后高速钢的硬度变化,认为位错密度增加是导致硬度变大的主要原因.位错在磁场中受磁场强度作用力(σ)可以通过式(8)进行计算[29]. ...

Effects of a strong magnetic field on the phase stability of plain carbon steels

1

2000

... 磁化处理导致材料硬度增加,目前主要有3种解释:一是磁诱导马氏体相变理论[24],在马氏体相变临界温度附近,磁场能够提供额外的相变驱动力,促使马氏体相变提前发生,马氏体相的增加导致硬度增加.磁场引起的马氏体相变温度改变()可用式(7)[25]表示: ...

脉冲磁化处理对M42高速钢刀具组织和力学性能的影响

3

2015

... 式中,为外加磁场,为母相和马氏体相磁化强度差,为母相和马氏体相的熵差.孙恩喜等[24]的研究中得到强脉冲磁场诱发马氏体相变时,.马利平等[26]对高速钢脉冲磁处理过程中的磁热效应进行了检测,脉冲磁处理过程中试样表面温度仅升高5℃.因此,在常温、静态下对45CrNiMoVA钢进行脉冲磁处理,不足以引起其相变发生.根据2种组织状态下45CrNiMoVA钢受磁化处理后硬度变化差别不大的结果,也可以说明2种试样内部没有发生相变.二是位错运动理论[27~29],脉冲磁场作用下,材料晶格畸变发生,位错密度增加引起硬度增加,这一解释获得较多实验的证实.Veligatla[27]讨论了形状记忆合金中磁畴与孪晶界之间的相互作用,磁畴界能够阻碍孪晶界迁移,形成孪晶高密度区域,导致材料硬化.Ma等[28]研究了脉冲磁场处理后高速钢的硬度变化,认为位错密度增加是导致硬度变大的主要原因.位错在磁场中受磁场强度作用力(σ)可以通过式(8)进行计算[29]. ...

... 式中,为位错单位长度,为单位长度位错受到的磁场作用力,是晶面间距,是真空磁导率,是饱和磁化强度,是外磁场强度,是磁化矢量与外磁场方向夹角.然而,对于多晶材料,磁矩取向混乱,晶界、夹杂都可能产生影响,难以进行相关的解析计算.三是外部磁场促进碳化物沉淀析出[26],导致硬度增加.Wu等[30]发现高能磁场处理高铬钢,导致碳化物析出密度增加2倍,马利平等[26]在高速钢脉冲磁处理中也发现碳化物析出增多.碳化物析出颗粒能够阻碍位错运动,形成位错环,这就是Orowan强化机制,是提高材料强韧性的重要方法.基于以上分析,45CrNiMoVA钢受脉冲磁场处理后硬度增加的主要原因推断为磁场对位错、碳化物的作用引起. ...

... [26]在高速钢脉冲磁处理中也发现碳化物析出增多.碳化物析出颗粒能够阻碍位错运动,形成位错环,这就是Orowan强化机制,是提高材料强韧性的重要方法.基于以上分析,45CrNiMoVA钢受脉冲磁场处理后硬度增加的主要原因推断为磁场对位错、碳化物的作用引起. ...

脉冲磁化处理对M42高速钢刀具组织和力学性能的影响

3

2015

... 式中,为外加磁场,为母相和马氏体相磁化强度差,为母相和马氏体相的熵差.孙恩喜等[24]的研究中得到强脉冲磁场诱发马氏体相变时,.马利平等[26]对高速钢脉冲磁处理过程中的磁热效应进行了检测,脉冲磁处理过程中试样表面温度仅升高5℃.因此,在常温、静态下对45CrNiMoVA钢进行脉冲磁处理,不足以引起其相变发生.根据2种组织状态下45CrNiMoVA钢受磁化处理后硬度变化差别不大的结果,也可以说明2种试样内部没有发生相变.二是位错运动理论[27~29],脉冲磁场作用下,材料晶格畸变发生,位错密度增加引起硬度增加,这一解释获得较多实验的证实.Veligatla[27]讨论了形状记忆合金中磁畴与孪晶界之间的相互作用,磁畴界能够阻碍孪晶界迁移,形成孪晶高密度区域,导致材料硬化.Ma等[28]研究了脉冲磁场处理后高速钢的硬度变化,认为位错密度增加是导致硬度变大的主要原因.位错在磁场中受磁场强度作用力(σ)可以通过式(8)进行计算[29]. ...

... 式中,为位错单位长度,为单位长度位错受到的磁场作用力,是晶面间距,是真空磁导率,是饱和磁化强度,是外磁场强度,是磁化矢量与外磁场方向夹角.然而,对于多晶材料,磁矩取向混乱,晶界、夹杂都可能产生影响,难以进行相关的解析计算.三是外部磁场促进碳化物沉淀析出[26],导致硬度增加.Wu等[30]发现高能磁场处理高铬钢,导致碳化物析出密度增加2倍,马利平等[26]在高速钢脉冲磁处理中也发现碳化物析出增多.碳化物析出颗粒能够阻碍位错运动,形成位错环,这就是Orowan强化机制,是提高材料强韧性的重要方法.基于以上分析,45CrNiMoVA钢受脉冲磁场处理后硬度增加的主要原因推断为磁场对位错、碳化物的作用引起. ...

... [26]在高速钢脉冲磁处理中也发现碳化物析出增多.碳化物析出颗粒能够阻碍位错运动,形成位错环,这就是Orowan强化机制,是提高材料强韧性的重要方法.基于以上分析,45CrNiMoVA钢受脉冲磁场处理后硬度增加的主要原因推断为磁场对位错、碳化物的作用引起. ...

Magnetic domain-twin boundary interactions in Ni-Mn-Ga

2

2020

... 式中,为外加磁场,为母相和马氏体相磁化强度差,为母相和马氏体相的熵差.孙恩喜等[24]的研究中得到强脉冲磁场诱发马氏体相变时,.马利平等[26]对高速钢脉冲磁处理过程中的磁热效应进行了检测,脉冲磁处理过程中试样表面温度仅升高5℃.因此,在常温、静态下对45CrNiMoVA钢进行脉冲磁处理,不足以引起其相变发生.根据2种组织状态下45CrNiMoVA钢受磁化处理后硬度变化差别不大的结果,也可以说明2种试样内部没有发生相变.二是位错运动理论[27~29],脉冲磁场作用下,材料晶格畸变发生,位错密度增加引起硬度增加,这一解释获得较多实验的证实.Veligatla[27]讨论了形状记忆合金中磁畴与孪晶界之间的相互作用,磁畴界能够阻碍孪晶界迁移,形成孪晶高密度区域,导致材料硬化.Ma等[28]研究了脉冲磁场处理后高速钢的硬度变化,认为位错密度增加是导致硬度变大的主要原因.位错在磁场中受磁场强度作用力(σ)可以通过式(8)进行计算[29]. ...

... [27]讨论了形状记忆合金中磁畴与孪晶界之间的相互作用,磁畴界能够阻碍孪晶界迁移,形成孪晶高密度区域,导致材料硬化.Ma等[28]研究了脉冲磁场处理后高速钢的硬度变化,认为位错密度增加是导致硬度变大的主要原因.位错在磁场中受磁场强度作用力(σ)可以通过式(8)进行计算[29]. ...

An investigation on the mechanical property changing mechanism of high speed steel by pulsed magnetic treatment

1

2014

... 式中,为外加磁场,为母相和马氏体相磁化强度差,为母相和马氏体相的熵差.孙恩喜等[24]的研究中得到强脉冲磁场诱发马氏体相变时,.马利平等[26]对高速钢脉冲磁处理过程中的磁热效应进行了检测,脉冲磁处理过程中试样表面温度仅升高5℃.因此,在常温、静态下对45CrNiMoVA钢进行脉冲磁处理,不足以引起其相变发生.根据2种组织状态下45CrNiMoVA钢受磁化处理后硬度变化差别不大的结果,也可以说明2种试样内部没有发生相变.二是位错运动理论[27~29],脉冲磁场作用下,材料晶格畸变发生,位错密度增加引起硬度增加,这一解释获得较多实验的证实.Veligatla[27]讨论了形状记忆合金中磁畴与孪晶界之间的相互作用,磁畴界能够阻碍孪晶界迁移,形成孪晶高密度区域,导致材料硬化.Ma等[28]研究了脉冲磁场处理后高速钢的硬度变化,认为位错密度增加是导致硬度变大的主要原因.位错在磁场中受磁场强度作用力(σ)可以通过式(8)进行计算[29]. ...

Magnetic field effects on twin dislocations

2

1999

... 式中,为外加磁场,为母相和马氏体相磁化强度差,为母相和马氏体相的熵差.孙恩喜等[24]的研究中得到强脉冲磁场诱发马氏体相变时,.马利平等[26]对高速钢脉冲磁处理过程中的磁热效应进行了检测,脉冲磁处理过程中试样表面温度仅升高5℃.因此,在常温、静态下对45CrNiMoVA钢进行脉冲磁处理,不足以引起其相变发生.根据2种组织状态下45CrNiMoVA钢受磁化处理后硬度变化差别不大的结果,也可以说明2种试样内部没有发生相变.二是位错运动理论[27~29],脉冲磁场作用下,材料晶格畸变发生,位错密度增加引起硬度增加,这一解释获得较多实验的证实.Veligatla[27]讨论了形状记忆合金中磁畴与孪晶界之间的相互作用,磁畴界能够阻碍孪晶界迁移,形成孪晶高密度区域,导致材料硬化.Ma等[28]研究了脉冲磁场处理后高速钢的硬度变化,认为位错密度增加是导致硬度变大的主要原因.位错在磁场中受磁场强度作用力(σ)可以通过式(8)进行计算[29]. ...

... [29]. ...

Influence of high magnetic field on carbides and the dislocation density during tempering of high Chromium-containing steel

1

2019

... 式中,为位错单位长度,为单位长度位错受到的磁场作用力,是晶面间距,是真空磁导率,是饱和磁化强度,是外磁场强度,是磁化矢量与外磁场方向夹角.然而,对于多晶材料,磁矩取向混乱,晶界、夹杂都可能产生影响,难以进行相关的解析计算.三是外部磁场促进碳化物沉淀析出[26],导致硬度增加.Wu等[30]发现高能磁场处理高铬钢,导致碳化物析出密度增加2倍,马利平等[26]在高速钢脉冲磁处理中也发现碳化物析出增多.碳化物析出颗粒能够阻碍位错运动,形成位错环,这就是Orowan强化机制,是提高材料强韧性的重要方法.基于以上分析,45CrNiMoVA钢受脉冲磁场处理后硬度增加的主要原因推断为磁场对位错、碳化物的作用引起. ...

Magnetic field sensitive functional elastomers with tuneable elastic modulus

2

2006

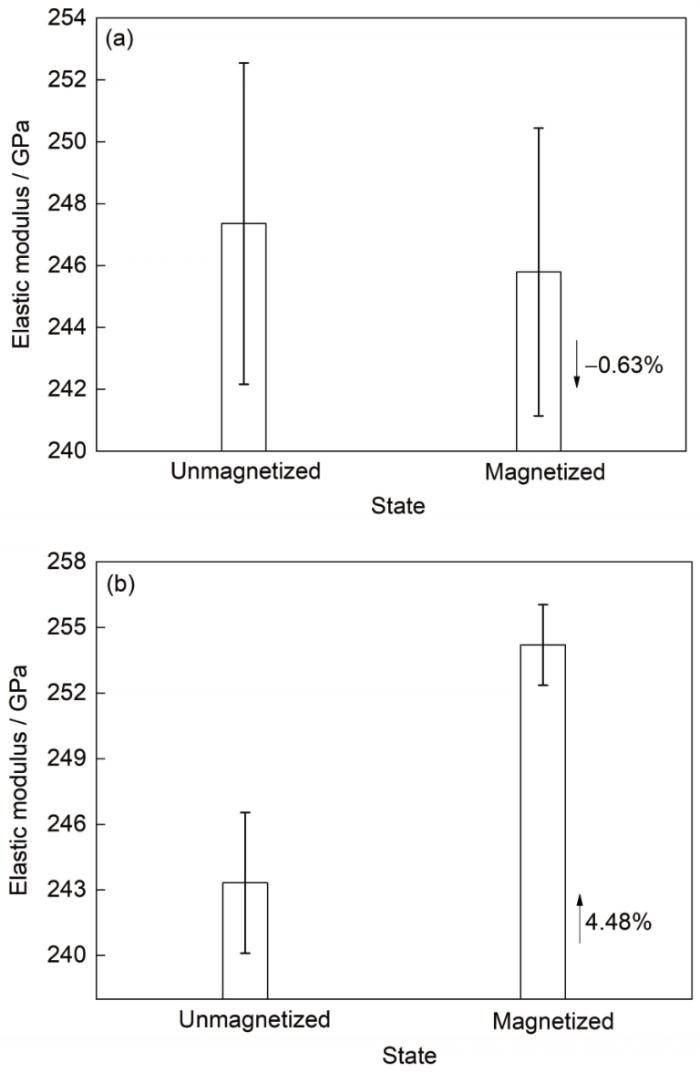

... 已有研究[31~33]表明,磁致伸缩效应可能是弹性模量变化的主要原因.Varga等[31]研究了特殊磁弹性体材料,发现外加磁场可以提高磁弹性体的弹性模量,磁致应变引起的应变能密度变化是弹性模量变化的主要原因,这种材料特性在弹性体轴承和减振器方面有重要的应用潜力.Zheng等[32]在过共晶合金退火过程中施加高能静磁场,发现弹性模量大幅增加,但这是磁热力耦合的作用过程,很难解释为磁场诱发弹性模量增加.弹性模量受外部磁场的影响变化反映出材料的磁致伸缩性能,磁场中材料的弹性变形来自2部分[33]:纯弹性应变和磁畴运动引入的磁弹性应变,在磁化状态下,材料弹性模量发生如下变化: ...

... [31]研究了特殊磁弹性体材料,发现外加磁场可以提高磁弹性体的弹性模量,磁致应变引起的应变能密度变化是弹性模量变化的主要原因,这种材料特性在弹性体轴承和减振器方面有重要的应用潜力.Zheng等[32]在过共晶合金退火过程中施加高能静磁场,发现弹性模量大幅增加,但这是磁热力耦合的作用过程,很难解释为磁场诱发弹性模量增加.弹性模量受外部磁场的影响变化反映出材料的磁致伸缩性能,磁场中材料的弹性变形来自2部分[33]:纯弹性应变和磁畴运动引入的磁弹性应变,在磁化状态下,材料弹性模量发生如下变化: ...

Diffusion-controlled mechanical property-enhancement of Al-20wt.%Si ribbon annealed under high static magnetic fields, from the microscale to the atomic scale

1

2020

... 已有研究[31~33]表明,磁致伸缩效应可能是弹性模量变化的主要原因.Varga等[31]研究了特殊磁弹性体材料,发现外加磁场可以提高磁弹性体的弹性模量,磁致应变引起的应变能密度变化是弹性模量变化的主要原因,这种材料特性在弹性体轴承和减振器方面有重要的应用潜力.Zheng等[32]在过共晶合金退火过程中施加高能静磁场,发现弹性模量大幅增加,但这是磁热力耦合的作用过程,很难解释为磁场诱发弹性模量增加.弹性模量受外部磁场的影响变化反映出材料的磁致伸缩性能,磁场中材料的弹性变形来自2部分[33]:纯弹性应变和磁畴运动引入的磁弹性应变,在磁化状态下,材料弹性模量发生如下变化: ...

Stress and magnetic field-dependent Young's modulus in single crystal iron-gallium alloys

2

2010

... 已有研究[31~33]表明,磁致伸缩效应可能是弹性模量变化的主要原因.Varga等[31]研究了特殊磁弹性体材料,发现外加磁场可以提高磁弹性体的弹性模量,磁致应变引起的应变能密度变化是弹性模量变化的主要原因,这种材料特性在弹性体轴承和减振器方面有重要的应用潜力.Zheng等[32]在过共晶合金退火过程中施加高能静磁场,发现弹性模量大幅增加,但这是磁热力耦合的作用过程,很难解释为磁场诱发弹性模量增加.弹性模量受外部磁场的影响变化反映出材料的磁致伸缩性能,磁场中材料的弹性变形来自2部分[33]:纯弹性应变和磁畴运动引入的磁弹性应变,在磁化状态下,材料弹性模量发生如下变化: ...

... [33]:纯弹性应变和磁畴运动引入的磁弹性应变,在磁化状态下,材料弹性模量发生如下变化: ...

基于磁畴动态行为特征的应力表征研究

2

2019

... 铁磁材料的磁化本质是磁畴运动[12,34,35],图9b所示为45CrNiMoVA钢不同磁化阶段的磁畴运动示意图,包含畴壁的位移和磁矩的转动.在磁化初始阶段,磁畴运动以可逆畴壁位移为主,对材料力学性能影响微弱;随着外磁场增大,畴壁位移需要克服材料内应力、杂质、晶界、位错等不均匀分布产生的阻力,形成不可逆畴壁位移;随着外磁场进一步增加,畴壁位移基本结束,磁化强度的增加依赖磁矩的转动,磁矩向外磁场方向转动,直至饱和.巴克豪森效应[34] (Barkhausen effect)认为磁化过程中畴壁的位移是一个不连续的过程,畴壁位移过程中遇到钉扎点,外磁场缓慢增加难以使其移动,而当外磁场达到临界点,畴壁突然移动到平衡位置,产生大量“跳跃”巴克豪森信号,相对应地,磁致应变量发生突变、位错塞积开动. ...

... [34] (Barkhausen effect)认为磁化过程中畴壁的位移是一个不连续的过程,畴壁位移过程中遇到钉扎点,外磁场缓慢增加难以使其移动,而当外磁场达到临界点,畴壁突然移动到平衡位置,产生大量“跳跃”巴克豪森信号,相对应地,磁致应变量发生突变、位错塞积开动. ...

基于磁畴动态行为特征的应力表征研究

2

2019

... 铁磁材料的磁化本质是磁畴运动[12,34,35],图9b所示为45CrNiMoVA钢不同磁化阶段的磁畴运动示意图,包含畴壁的位移和磁矩的转动.在磁化初始阶段,磁畴运动以可逆畴壁位移为主,对材料力学性能影响微弱;随着外磁场增大,畴壁位移需要克服材料内应力、杂质、晶界、位错等不均匀分布产生的阻力,形成不可逆畴壁位移;随着外磁场进一步增加,畴壁位移基本结束,磁化强度的增加依赖磁矩的转动,磁矩向外磁场方向转动,直至饱和.巴克豪森效应[34] (Barkhausen effect)认为磁化过程中畴壁的位移是一个不连续的过程,畴壁位移过程中遇到钉扎点,外磁场缓慢增加难以使其移动,而当外磁场达到临界点,畴壁突然移动到平衡位置,产生大量“跳跃”巴克豪森信号,相对应地,磁致应变量发生突变、位错塞积开动. ...

... [34] (Barkhausen effect)认为磁化过程中畴壁的位移是一个不连续的过程,畴壁位移过程中遇到钉扎点,外磁场缓慢增加难以使其移动,而当外磁场达到临界点,畴壁突然移动到平衡位置,产生大量“跳跃”巴克豪森信号,相对应地,磁致应变量发生突变、位错塞积开动. ...

2

2

... 铁磁材料的磁化本质是磁畴运动[12,34,35],图9b所示为45CrNiMoVA钢不同磁化阶段的磁畴运动示意图,包含畴壁的位移和磁矩的转动.在磁化初始阶段,磁畴运动以可逆畴壁位移为主,对材料力学性能影响微弱;随着外磁场增大,畴壁位移需要克服材料内应力、杂质、晶界、位错等不均匀分布产生的阻力,形成不可逆畴壁位移;随着外磁场进一步增加,畴壁位移基本结束,磁化强度的增加依赖磁矩的转动,磁矩向外磁场方向转动,直至饱和.巴克豪森效应[34] (Barkhausen effect)认为磁化过程中畴壁的位移是一个不连续的过程,畴壁位移过程中遇到钉扎点,外磁场缓慢增加难以使其移动,而当外磁场达到临界点,畴壁突然移动到平衡位置,产生大量“跳跃”巴克豪森信号,相对应地,磁致应变量发生突变、位错塞积开动. ...

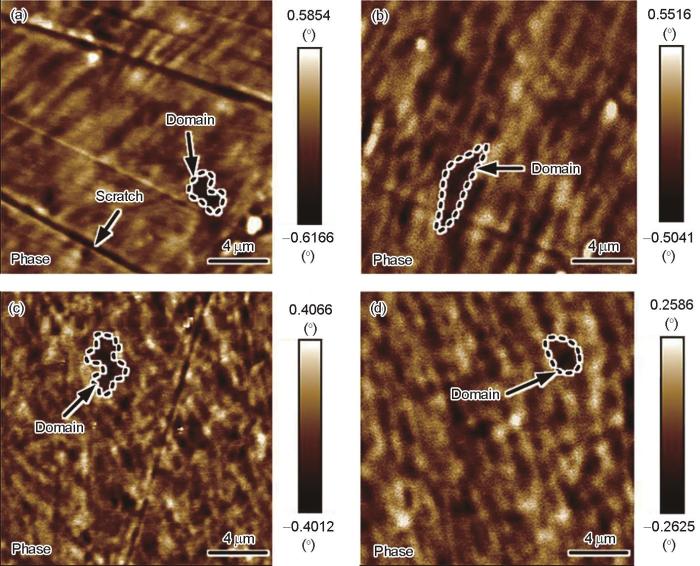

... 图10所示为MFM测得的45CrNiMoVA钢试样脉冲磁处理前后表面磁畴结构形貌,图中亮暗程度反映了磁力探针受磁场力作用下的相位变化(单位为“毫度”),局部亮暗均匀区域即代表一个磁畴单元.受材料组织晶粒不均匀的影响,45CrNiMoVA钢的磁畴结构型式杂乱.相对珠光体态组织,回火马氏体态组织更为细碎,导致其磁畴呈“碎畴”形态分布.相比于未磁化处理试样(图10a和c),脉冲磁化处理后(图10b和d)整个图像亮暗分布更为均匀,过渡区更为平滑,表明脉冲磁化处理导致表面磁畴分布更加均匀,这是在脉冲磁场作用下,磁畴克服材料内部阻碍后运动,重新排布的结果.在初始试样内部存在残余压应力的条件下,当外界磁场强度大于位错增殖所需的临界场强,磁畴的这种不可逆运动就会引起微区应力、应变,促进位错增殖、积聚,使位错密度提高,宏观表现为残余压应力和硬度的增大.弹性模量的变化可能与材料在磁化过程中总能量密度改变有关,根据铁磁学理论[35],当材料未受外应力和外磁场作用时,总能量密度()为: ...

2

2

... 铁磁材料的磁化本质是磁畴运动[12,34,35],图9b所示为45CrNiMoVA钢不同磁化阶段的磁畴运动示意图,包含畴壁的位移和磁矩的转动.在磁化初始阶段,磁畴运动以可逆畴壁位移为主,对材料力学性能影响微弱;随着外磁场增大,畴壁位移需要克服材料内应力、杂质、晶界、位错等不均匀分布产生的阻力,形成不可逆畴壁位移;随着外磁场进一步增加,畴壁位移基本结束,磁化强度的增加依赖磁矩的转动,磁矩向外磁场方向转动,直至饱和.巴克豪森效应[34] (Barkhausen effect)认为磁化过程中畴壁的位移是一个不连续的过程,畴壁位移过程中遇到钉扎点,外磁场缓慢增加难以使其移动,而当外磁场达到临界点,畴壁突然移动到平衡位置,产生大量“跳跃”巴克豪森信号,相对应地,磁致应变量发生突变、位错塞积开动. ...

... 图10所示为MFM测得的45CrNiMoVA钢试样脉冲磁处理前后表面磁畴结构形貌,图中亮暗程度反映了磁力探针受磁场力作用下的相位变化(单位为“毫度”),局部亮暗均匀区域即代表一个磁畴单元.受材料组织晶粒不均匀的影响,45CrNiMoVA钢的磁畴结构型式杂乱.相对珠光体态组织,回火马氏体态组织更为细碎,导致其磁畴呈“碎畴”形态分布.相比于未磁化处理试样(图10a和c),脉冲磁化处理后(图10b和d)整个图像亮暗分布更为均匀,过渡区更为平滑,表明脉冲磁化处理导致表面磁畴分布更加均匀,这是在脉冲磁场作用下,磁畴克服材料内部阻碍后运动,重新排布的结果.在初始试样内部存在残余压应力的条件下,当外界磁场强度大于位错增殖所需的临界场强,磁畴的这种不可逆运动就会引起微区应力、应变,促进位错增殖、积聚,使位错密度提高,宏观表现为残余压应力和硬度的增大.弹性模量的变化可能与材料在磁化过程中总能量密度改变有关,根据铁磁学理论[35],当材料未受外应力和外磁场作用时,总能量密度()为: ...