亚共晶Al-Si合金具有铸造性好,热膨胀系数低,可焊性好等优点,是一种重要的铝合金焊丝材料[1,2]。然而,在常规凝固条件下,亚共晶Al-Si合金的凝固组织常常含有粗大的α-Al晶粒和片状结构的Al-Si共晶组织。因此,合金受力时极易产生应力集中,合金的力学性能较差,尤其是塑性[3,4]。近年来,为了提升合金的力学性能,人们对亚共晶Al-Si合金凝固过程开展了大量的研究工作,考察了化学处理[5~7]、快速凝固[8,9]以及外场[10~12]对组织以及性能的影响。化学处理由于成本低、操作简单并能同时实现对α-Al的细化和共晶Si的变质而被广泛应用,而快速凝固和外场处理要求专业设备且操作复杂,工业应用相对较少。目前,工业上常常用Al-Ti-B中间合金细化α-Al晶粒,用Sr来改变共晶Si的形貌[13~15]。然而大量的生产实践表明,在传统α-Al晶粒细化剂和共晶Si变质剂处理下,亚共晶Al-Si合金的塑性仍难以满足高性能焊丝制备过程中的拉拔成型需求,合金在拉拔成焊丝时经常发生断丝。因此,进一步提高合金的塑性极为必要。

本工作研究了添加α-Al晶粒细化剂Al-Ti-B中间合金和共晶Si变质剂Sr条件下,微合金化元素La对亚共晶Al-Si合金凝固组织与性能的影响。以期为新型稀土铝合金的工业制备提供理论依据和参考。

1 实验方法

以Al-6Si (质量分数,%,下同)预合金,Al-9La、Al-10Sr以及Al-5Ti-B中间合金为实验原料,配置含不同质量分数稀土La的Al-6Si合金。实验过程如下:首先将Al-6Si预合金装入石墨粘土坩埚内,利用电阻炉加热熔化并升温至1023 K,用精炼剂对熔体除气除渣;加入0.02%Sr以及不同量的稀土La,基于前期的研究结果[19],稀土La的添加量(质量分数)分别为0、0.02%、0.06%和0.10%,保温10 min,保温过程进行搅拌,确保形成均一的合金熔体;随后降温至993 K,加入0.3%的Al-5Ti-B中间合金;最后将熔体浇铸到预热至423 K的铁模中,获得直径为20 mm、高为40 mm的圆柱试样。将获得的试样沿径向切开,对切面进行研磨、抛光,制备金相样品。利用2.5% (体积分数)的HBF4水溶液进行阳极覆膜处理,利用Axio Observer Z1光学显微镜(OM)、Quanta 450扫描电子显微镜(SEM)、EPMA-1610电子探针(EPMA)和Tecnai G2 20透射电镜(TEM)观察合金的显微组织。采用SISC IAS V8.0定量金相分析软件统计α-Al的平均晶粒尺寸和共晶Si的孪晶密度。在Ar气保护下利用ZCR-B差热分析仪(DTA)研究合金的凝固行为。过程如下:将约15 mg的试样以5 K/min的升温速率加热到993 K,保温10 min,随后以5 K/min的降温速率冷却至室温。根据GB/T228.1-2010标准加工拉伸试样。室温拉伸实验在Z150试验机上进行,拉伸速率为1 mm/min。

2 实验结果

2.1 凝固组织

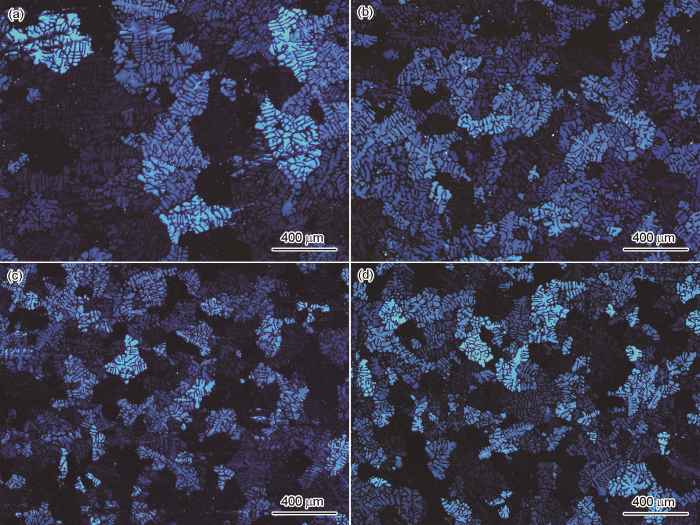

图1

图1

不同La添加量下Al-6Si合金的OM像

Fig.1

OM images of Al-6Si alloys with La additions of 0 (a), 0.02% (b), 0.06% (c), and 0.10% (d)

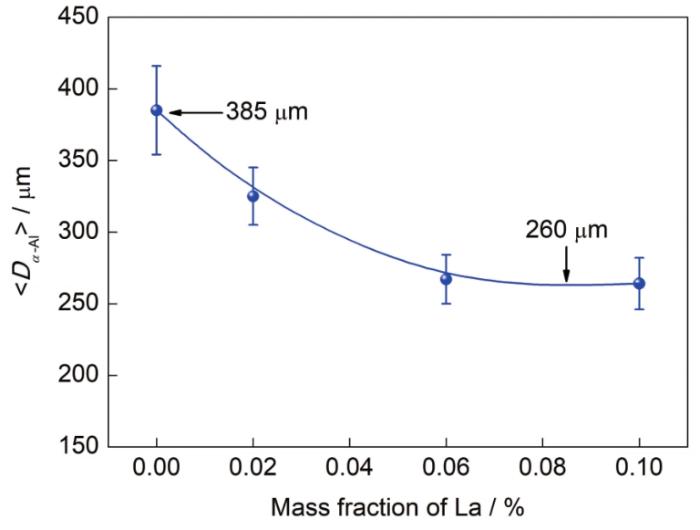

图2

图2

Al-6Si合金平均晶粒尺寸随La添加量的变化

Fig.2

Average grain size (<Dα-Al>) of Al-6Si alloys with different additive amounts of La

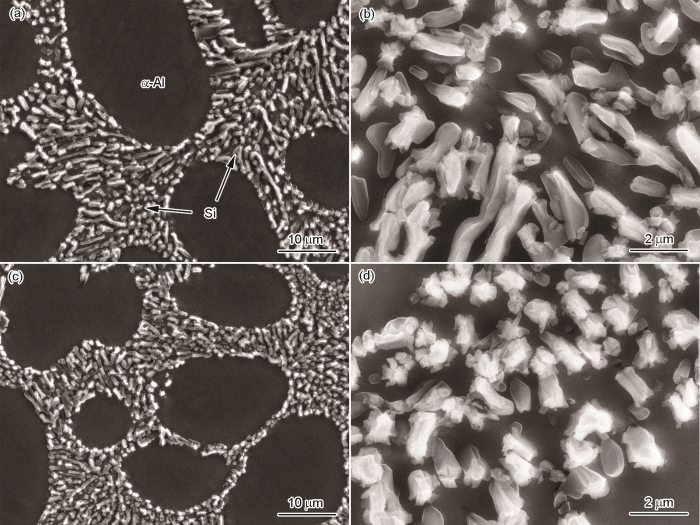

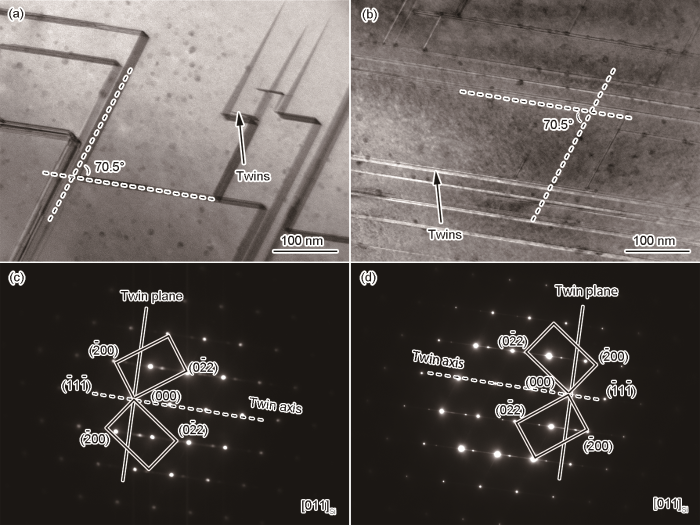

图3为不含La和含有0.06%La的Al-6Si合金显微组织的SEM像。由图3a和c可见,共晶Si均以蠕虫状的形态分布于晶界。与不含La的合金(图3b)相比,含0.06%La合金中的共晶Si尺寸更小,形状更趋于球形(图3d)。表明在Sr变质条件下,微合金元素La可以进一步促进共晶Si的球化。图4给出了不含La和含有0.06%La合金中共晶Si的TEM明场像及其SAED花样。由图4a和b可见,共晶Si内部均含有大量的交错孪晶,经SAED标定(图4c和d),孪晶面均为{111}Si,孪晶方向为<112>Si,两孪晶面之间的夹角为70.5°,但孪晶密度明显不同。定量分析结果表明,含0.06%La合金内共晶Si的孪晶密度((2.1±0.3)×10-2 nm-1)高于不含La合金内共晶Si的孪晶密度((1.2±0.2)×10-2 nm-1)。

图3

图3

不含La和含0.06%La的Al-6Si合金的显微组织SEM像

Fig.3

Low (a, c) and high (b, d) magnified SEM images of Al-6Si alloys without La (a, b) and with addition of 0.06%La (c, d)

图4

图4

不含La和含0.06%La的Al-6Si合金中共晶Si的TEM明场像及其SAED花样

Fig.4

TEM bright-field images (a, b) of eutectic Si particle and their SAED patterns (c, d) in the zone axis of [011]Si in the Al-6Si alloys without La (a, c) and with addition of 0.06%La (b, d)

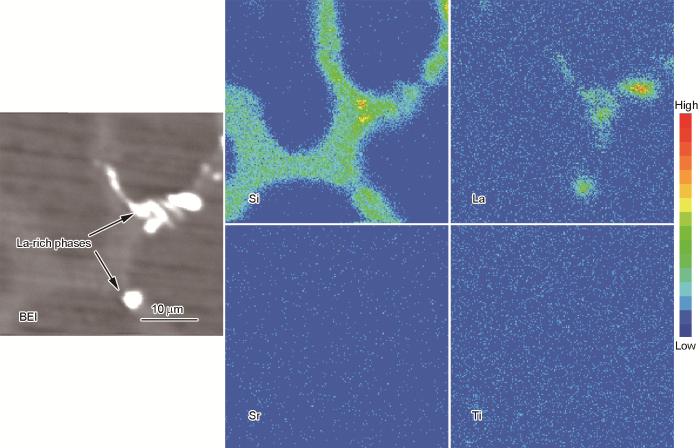

图5

图5

含0.10%La的Al-6Si合金中稀土化合物和共晶Si的BEI像及EPMA元素面分布

Fig.5

Backscattered electron image (BEI) and EPMA mappings of the eutectic Si and La-rich phase particles in the Al-6Si alloy with 0.10%La addition

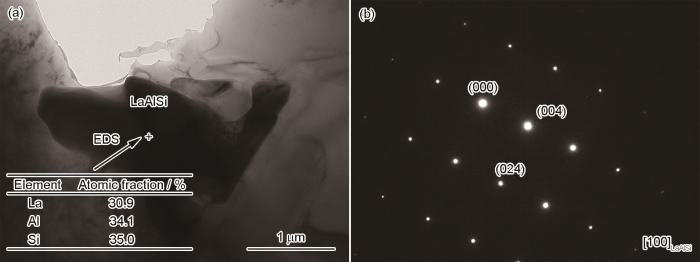

图6

图6

含0.10%La的Al-6Si合金中稀土化合物的TEM明场像、EDS结果及其SAED花样

Fig.6

TEM bright-field image and EDS result (a), and SAED pattern in the zone axis of [100] (b) for the LaAlSi phase in the Al-6Si alloy with 0.10%La addition

2.2 凝固过程

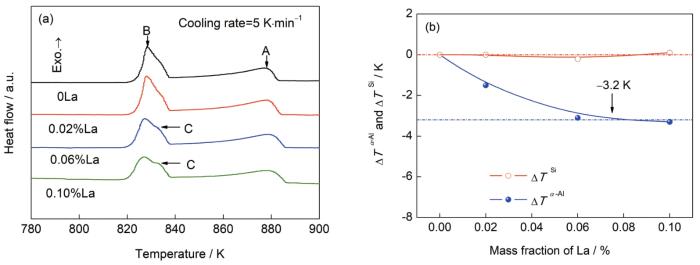

图7a为不同La添加量下Al-6Si合金的DTA冷却曲线。可见,当CLa<0.06%时,合金的冷却曲线在885和837 K附近出现2个放热峰A和B,分别对应于α-Al相的形成和Al-Si共晶反应过程。当CLa≥0.06%时,合金的冷却曲线出现了新的放热峰C,且C峰的强度随着CLa的增大而增大,该峰对应于LaAlSi相的形成。放热峰C与Al-Si共晶反应放热峰B重叠,表明LaAlSi化合物在共晶反应阶段形成。图7b给出了α-Al和共晶Si形核过冷度随稀土添加量的变化曲线。可见,当CLa从0增加到0.06%时,α-Al的形核过冷度(

图7

图7

不同La添加量下Al-6Si合金的DTA冷却曲线及α-Al和共晶Si的形核过冷度随La添加量的变化

Fig.7

Differential thermal analysis (DTA) cooling curves for the Al-6Si alloys with different additive amounts of La (a), and the change of the nucleation undercooling for the α-Al (

2.3 力学性能

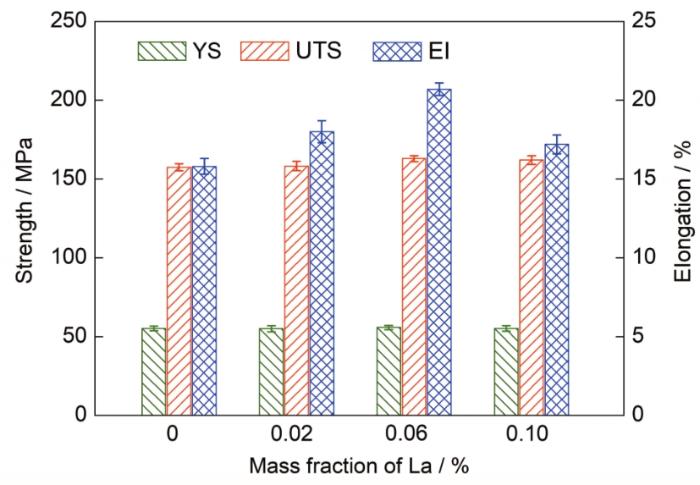

图8给出了不同La添加量下Al-6Si合金的室温拉伸性能数据。可以看出,与不含La的合金相比,含La合金的延伸率(El)显著提高,当CLa≤0.06%时,合金的延伸率随CLa的增大而增大;当CLa继续增加到0.10%时,合金的延伸率反而降低。当La的加入量为0.06%时,合金的延伸率最高,相对于不含La的合金提升了约31%。合金的强度(屈服强度(YS)和抗拉强度(UTS))几乎维持不变,不随稀土La添加量的变化而变化。以上结果表明,在传统Al-Ti-B细化剂和Sr变质剂条件下,添加适量微合金元素La能进一步改善合金的塑性。

图8

图8

不同La添加量下合金的室温拉伸性能

Fig.8

Tensile properties of Al-6Si alloys with different additive amounts of La (YS—yield strength, UTS—ultimate tensile strength, El—elongation)

3 分析讨论

3.1 微合金化元素La对α-Al晶粒的影响

组元之间形成化合物的倾向性可以用混合焓变表示。表1[23]给出了不同组元之间的混合焓变。La-Sr、La-Ti的混合焓变均为正,表明原子之间是排斥的,不易形成化合物。Ti-B的混合焓变低于La-B的混合焓变,说明Ti比La更易与B形成化合物。La-Si混合焓为负且最低,说明La更容易与Si形成化合物,这与实验结果完全吻合(图5和6),即当La的添加量达到0.10%后,La与Si、Al形成了LaAlSi化合物,而未见含Ti、Sr等元素化合物的形成。DTA结果表明LaAlSi化合物在Al-Si共晶反应阶段形成,因此它的形成不会改变α-Al的异质形核条件。计算表明,添加0.10%La对α-Al生长限制因子(Q)的影响仅为Q=

| Element | Al | Si | La | Sr | Ti | B |

|---|---|---|---|---|---|---|

| Al | - | - | - | - | - | - |

| Si | -19 | - | - | - | - | - |

| La | -38 | -73 | - | - | - | - |

| Sr | -18 | -49 | 14 | - | - | - |

| Ti | -30 | -66 | 20 | 53 | - | - |

| B | 0 | -14 | -47 | -18 | -58 | - |

在添加Al-5Ti-B中间合金细化处理条件下,在铝合金熔体凝固过程中,α-Al以TiB2为核心进行异质形核。由经典形核理论可知,决定异质形核的关键因素是形核基体与晶核的润湿角(

式中,

添加微量La并不改变α-Al以TiB2为核心,进行异质形核的本质,但作为表面活性元素,La会改变TiB2与α-Al晶核的

3.2 微合金化元素La对共晶Si的影响

共晶Si的形核过冷度几乎不随稀土添加量的变化而改变(图7b),表明微合金化元素La不会改变共晶Si的形核行为。因此,La主要通过改变Si相的长大行为来影响共晶Si的形貌。研究[26]表明,高密度交错孪晶的形成对共晶Si的形貌改变起着关键作用。Lu和Hellawell[27]基于钢球模型计算得出,诱发交错孪晶的首要条件为变质原子与Si原子的半径比(

3.3 微合金化元素La对合金力学性能的影响

对铸态Al-Si合金而言,晶粒尺寸决定了合金的强度,共晶Si的形貌和尺寸以及金属间化合物的尺寸和体积分数决定了合金的塑性[29,30]。晶粒细化对屈服强度的贡献(Δσ)可以用Hall-Petch公式Δσ=

4 结论

(1) 在传统Al-Ti-B晶粒细化剂和Sr变质剂条件下,添加适量的微合金化元素La即能作为表面活性剂降低TiB2与α-Al的润湿角,提高TiB2的异质形核能力,促进α-Al的进一步细化;又能诱发Si形成交错孪晶,增大Si的孪晶密度,改变Si相的长大行为,促进共晶Si的进一步细化与球化,从而导致亚共晶Al-Si合金塑性的有效提高。

(2) 在亚共晶Al-Si合金中,La的最佳添加量约为0.06%。当La的添加量达到0.10%时,LaAlSi金属间化合物会在凝固过程的共晶反应阶段形成,导致合金塑性的降低。

参考文献

Microstructure and property of welding joint weld with micro-Alloying 4043 welding wire

[J].

微合金化4043铝合金焊丝焊接接头的组织与性能

[J].

Modification of eutectic silicon in Al-Si alloys

[J].

A review on grain refinement of aluminum alloys: Progresses, challenges and prospects

[J].

The effect of the flake to fiber transition in silicon morphology on the tensile properties of Al-Si eutectic alloys

[J].

Grain refinement of hypoeutectic Al-Si alloys with B

[J].

The role of strontium in modifying aluminium-silicon alloys

[J].

Formation of equiaxed crystal structures in directionally solidified Al-Si alloys using Nb-based heterogeneous nuclei

[J].

Microstructure and mechanical properties of Al-Si-Mg ribbons

[J].

Breaking through the strength-ductility trade-off dilemma in an Al-Si-based casting alloy

[J].

Microstructure evolution of A356 alloy under compound field

[J].

Structural evolution of Al-8%Si hypoeutectic alloy by ultrasonic processing

[J].

Research on the morphology and fractaldimension of primary phase in semisolid A356-La aluminum alloy by electro-magnetic stirring

[J].

电磁场作用下半固态A356-La铝合金初生相形貌及分形维数的研究

[J].

Effects of combined additions of Sr and AlTiB grain refiners in hypoeutectic Al-Si foundry alloys

[J].A

The influence of Al-10Sr or/ and Al-5Ti-1B on microstructure and mechanical properties of Al-12Si-4Cu-2Ni-0.8 Mg alloys

[J].

Influence of process parameters and Sr addition on the microstructure and casting defects of LPDC A356 alloy for engine blocks

[J].

Simultaneous improvement in corrosion resistance and hardness of a model 2xxx series Al-Cu alloy with the microstructural variation caused by Sc and Zr additions

[J].

Modification of eutectic Si in Al-Si alloys with Eu addition

[J].

Effect of trace La addition on the microstructures and mechanical properties of A356 (Al-7Si-0.35Mg) aluminum alloys

[J].

Effect mechanisms of micro-alloying element La on microstructure and mechanical properties of hypoeutectic Al-Si alloys

[J].

Effects of La intermetallics on the structure and tensile properties of thin section gravity die-cast A357 Al alloy

[J].

Thermodynamic modelling of growth-restriction effects in aluminium alloys

[J].

Grain refinement of Al alloys: Mechanisms determining as-cast grain size in directional solidification

[J].

Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element

[J].

Phase equilibria and thermodynamic limits for partitionless crystallization in the Al-La binary system

[J].

Effect of Zr addition on the grain refinement mechanism of Mg-Gd-Er alloys

[J].

Zr对Mg-Gd-Er合金晶粒细化机理的影响

[J].

Eutectic modification by ternary compound cluster formation in Al-Si alloys

[J].

The mechanism of silicon modification in aluminum-silicon alloys: Impurity induced twinning

[J].

Effects of Sr content on the microstructure and mechanical properties of cast Al-12Si-4Cu-2Ni-0.8Mg alloys

[J].

Modification of eutectic Si and the microstructure in an Al-7Si alloy with barium addition

[J].

Effect of grain refiner on the tensile and impact properties of Al-Si-Mg cast alloys

[J].

Mechanical properties and fracture of in-situ Al3Ti particulate reinforced A356 composites

[J].